Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

196results about "Fuel cells disposal/recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manclaw-Harrison fuel cell

The Manclaw-Harrison Fuel Cell is a new Environmentally SAFE Fuel Cell (Lead Free, Acid Free, Mercury Free and has No Heavy Metals), and as such, it sets the definition of a new Class of Fuel Cell device because it has been verified to be a Non-Faraday device, making it the first such device discovered in the past 160+ years. See the “Preamble” for a more technical explanation.

Owner:MANCLAW RONALD R +1

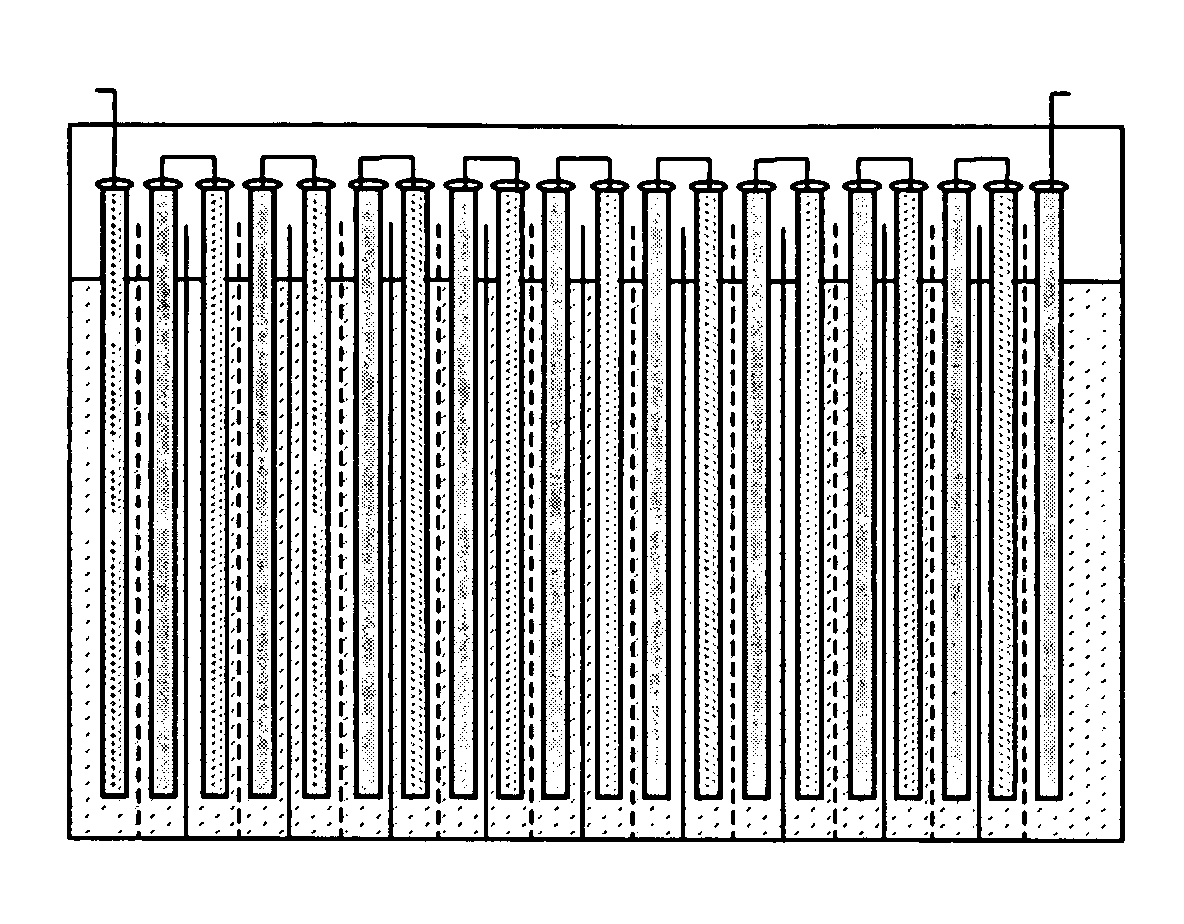

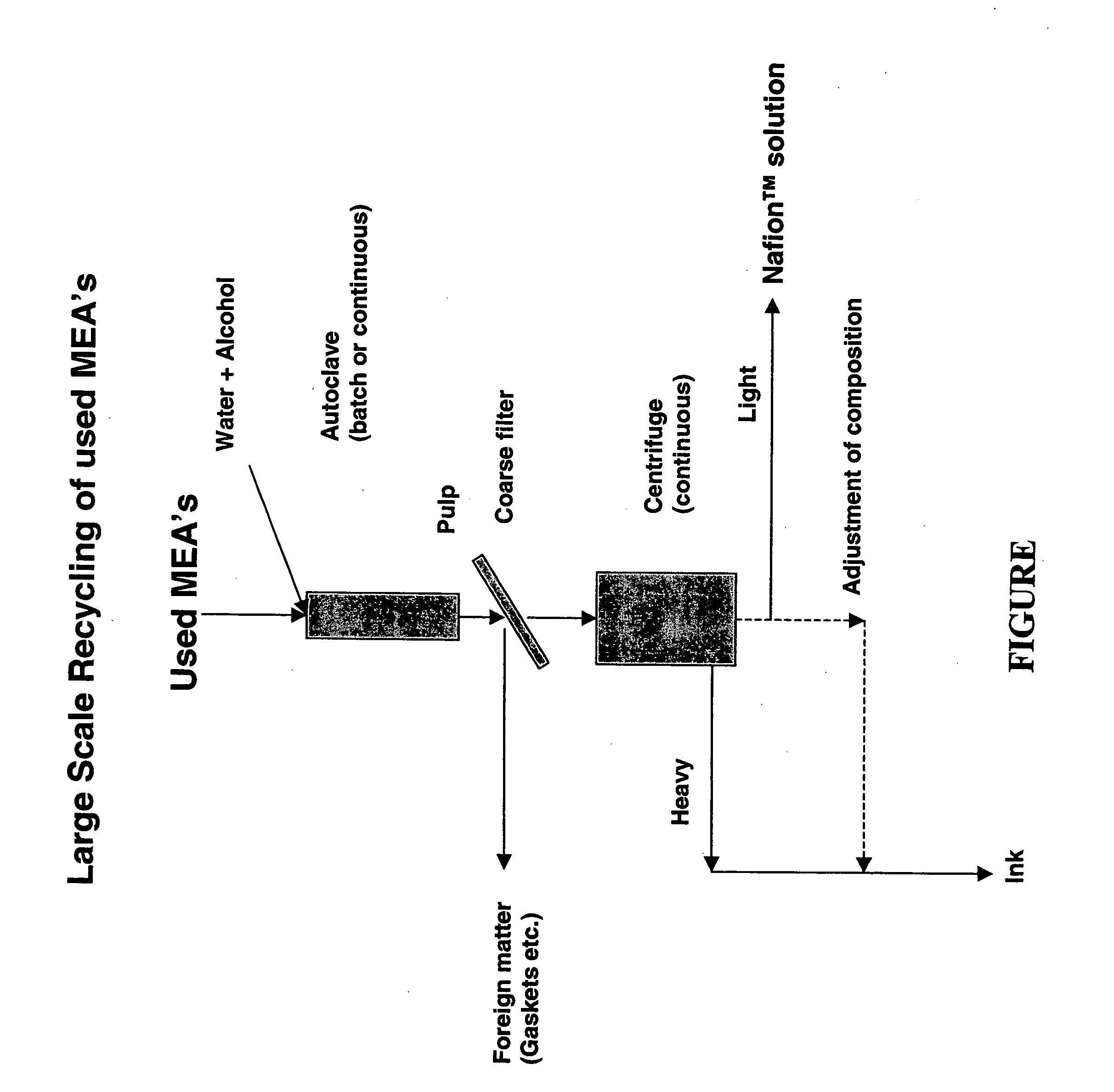

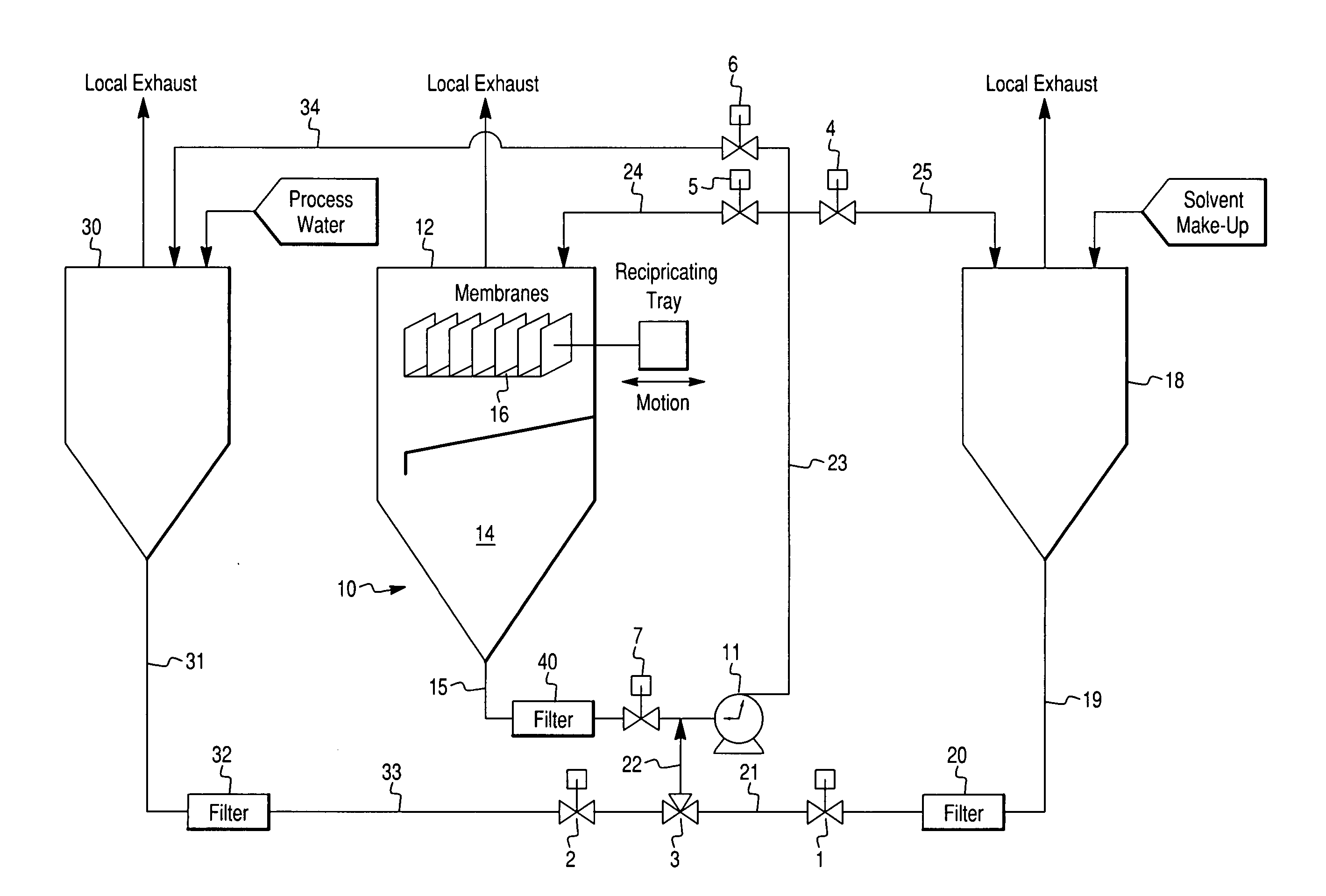

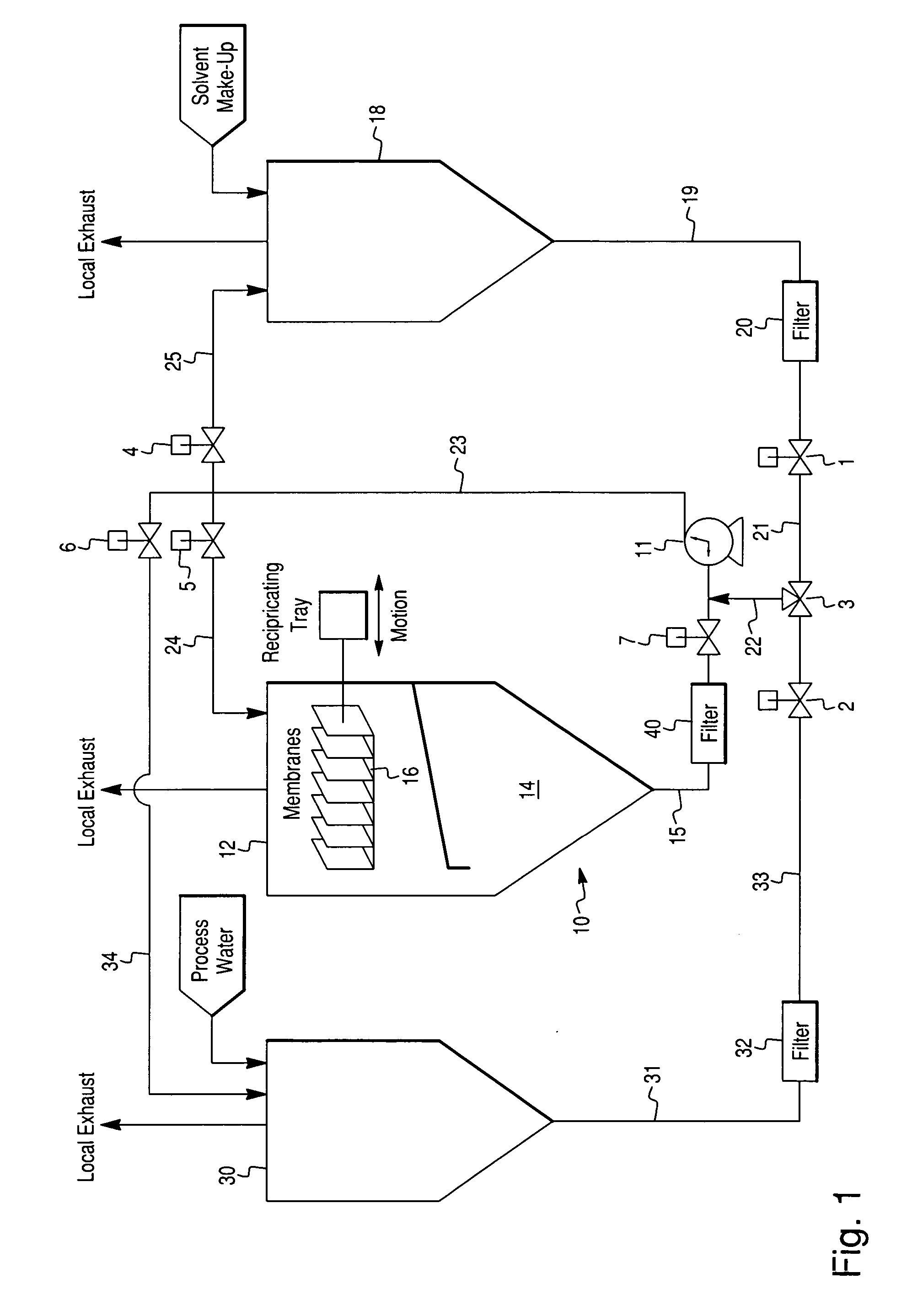

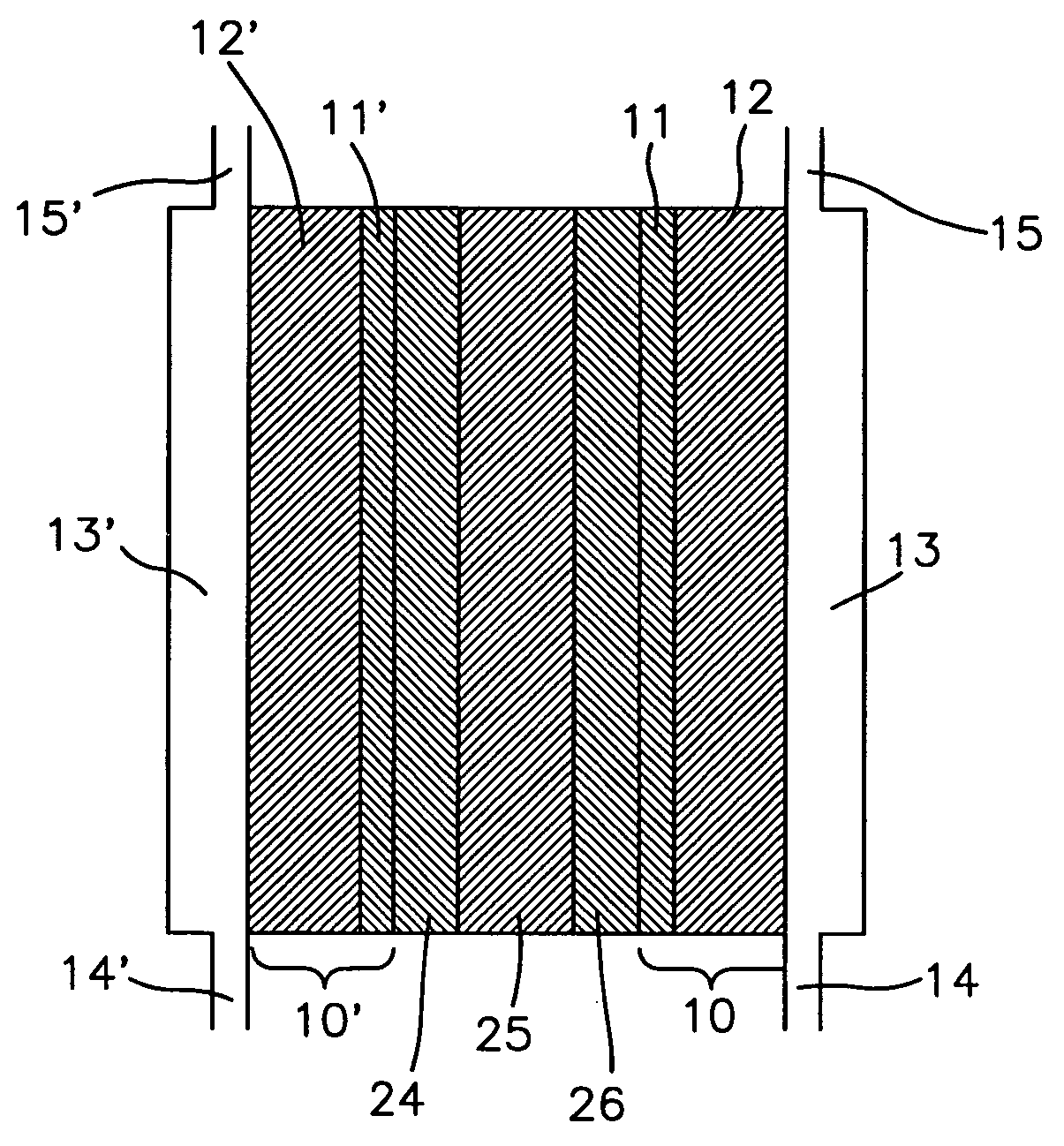

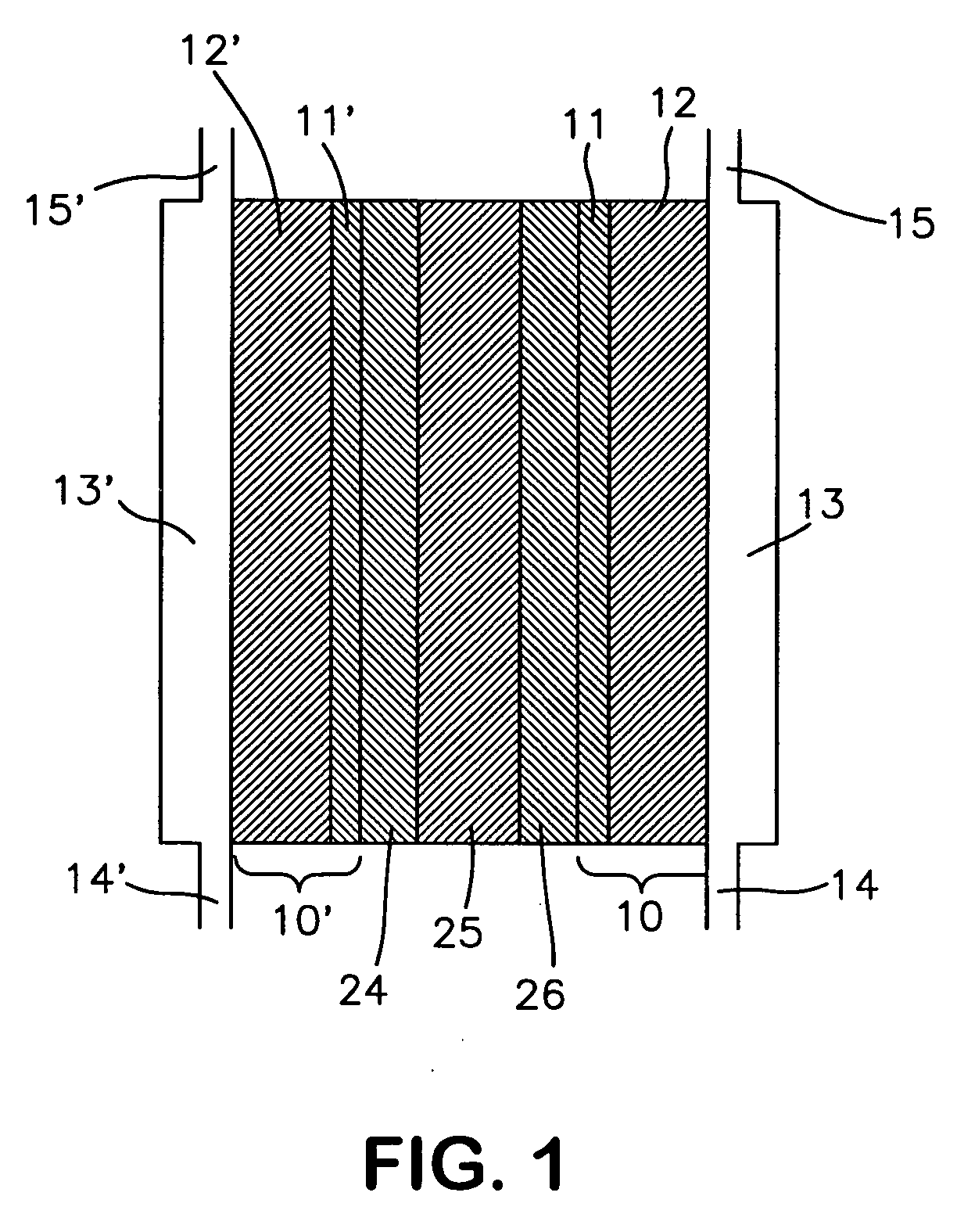

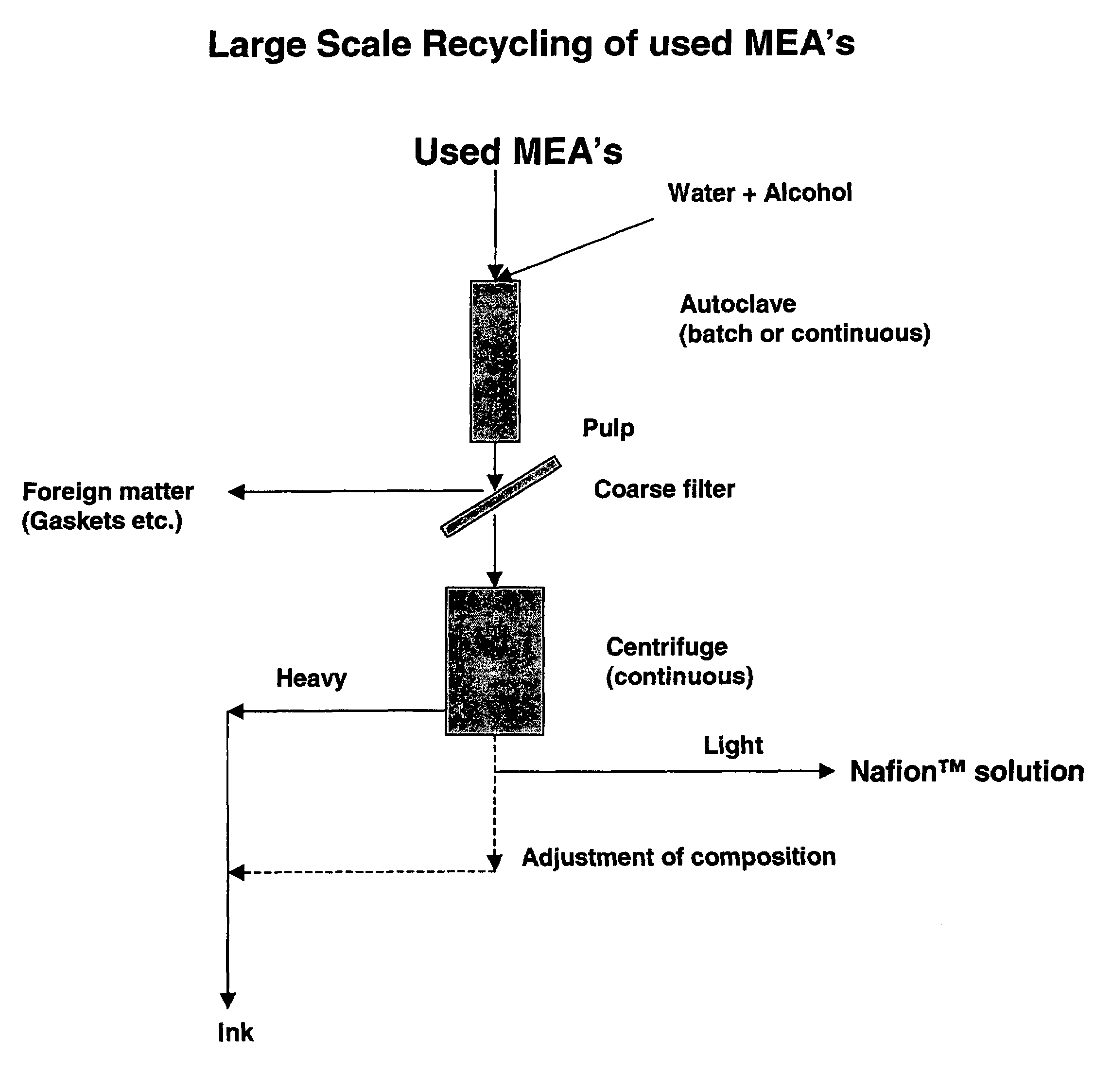

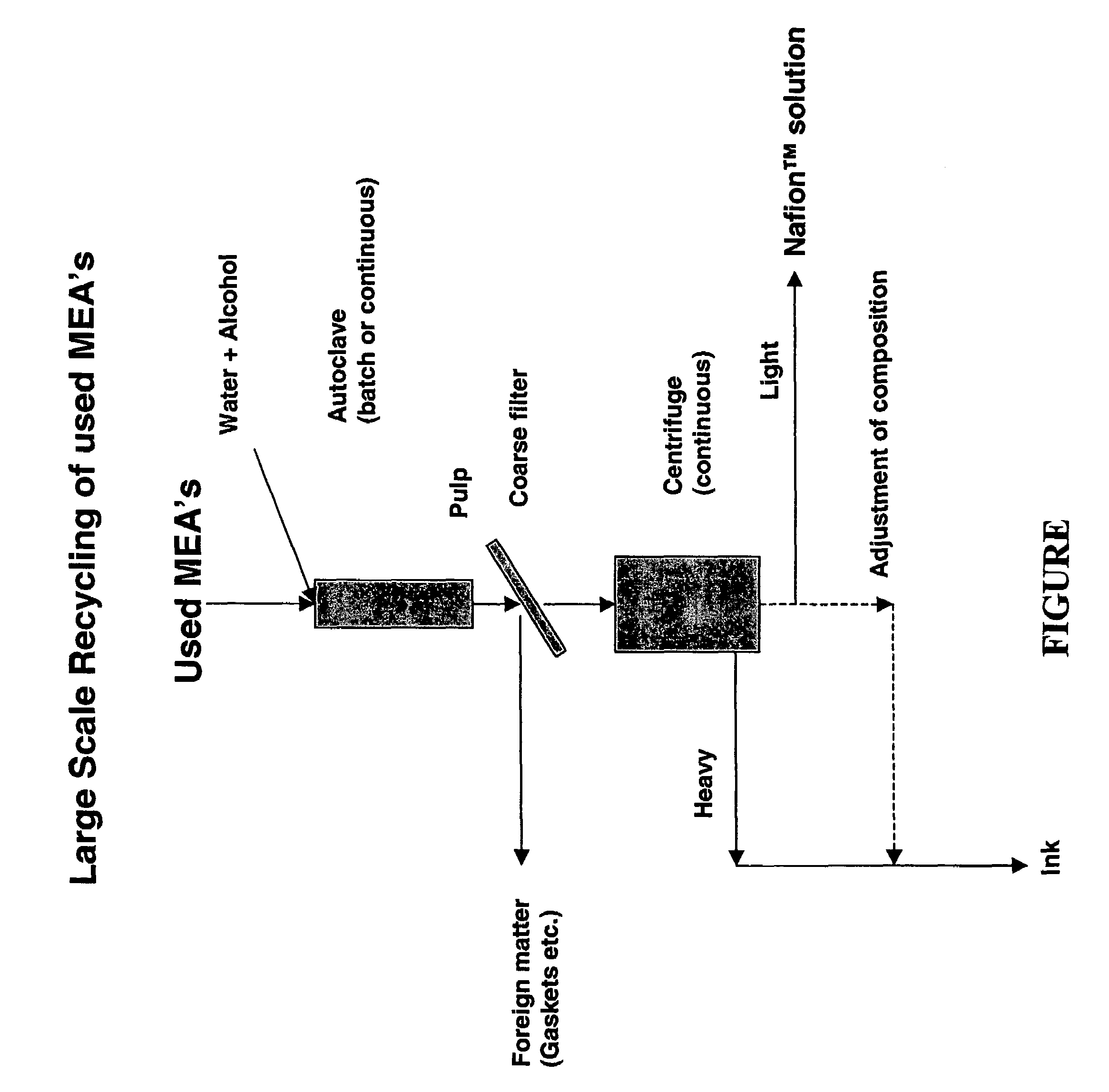

Recycling of used perfluorosulfonic acid membranes

InactiveUS20050211630A1Guaranteed long-term availabilityIncrease consumptionTransuranic element compoundsActive material electrodesSolventMembrane configuration

Owner:ION POWER

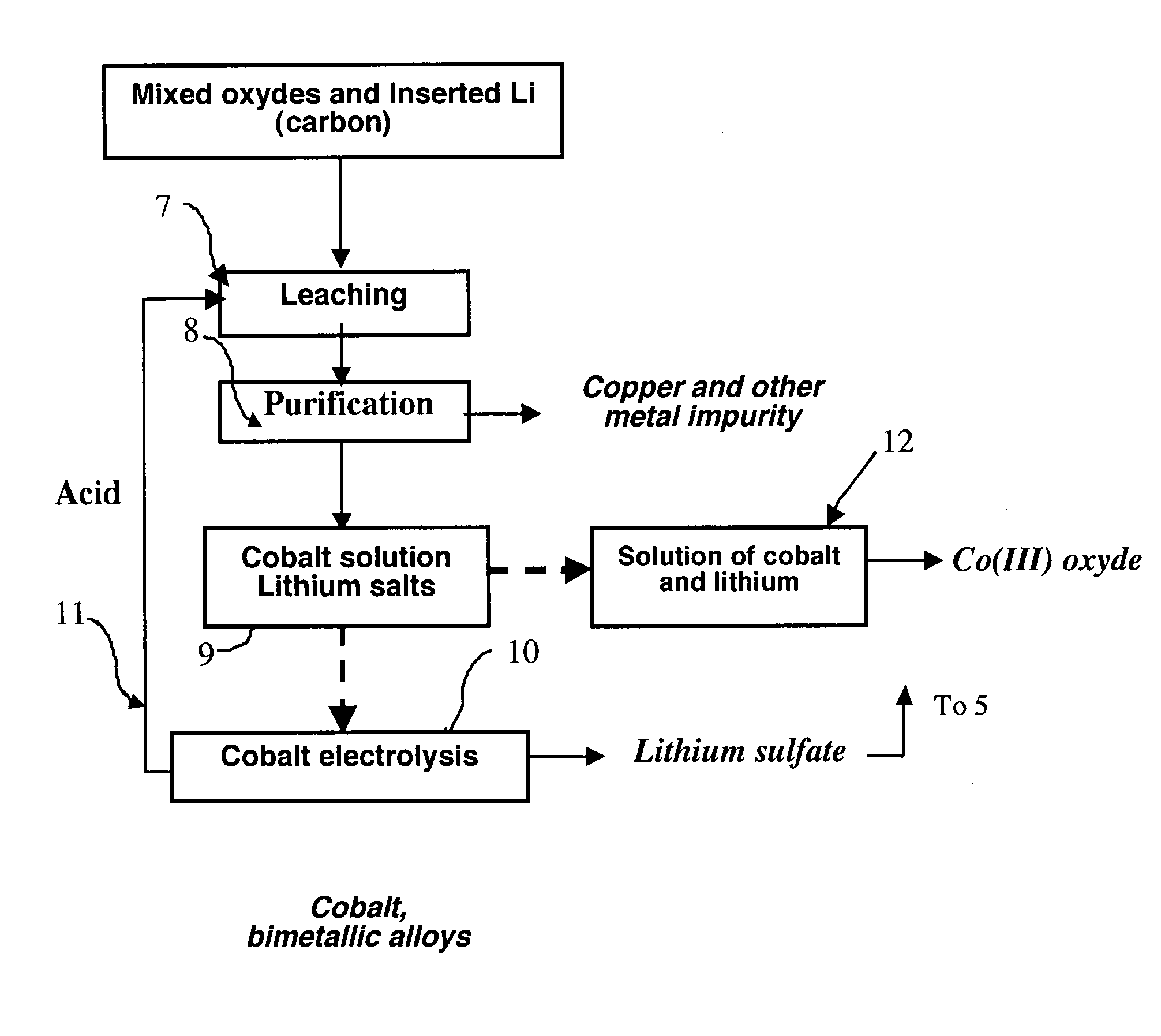

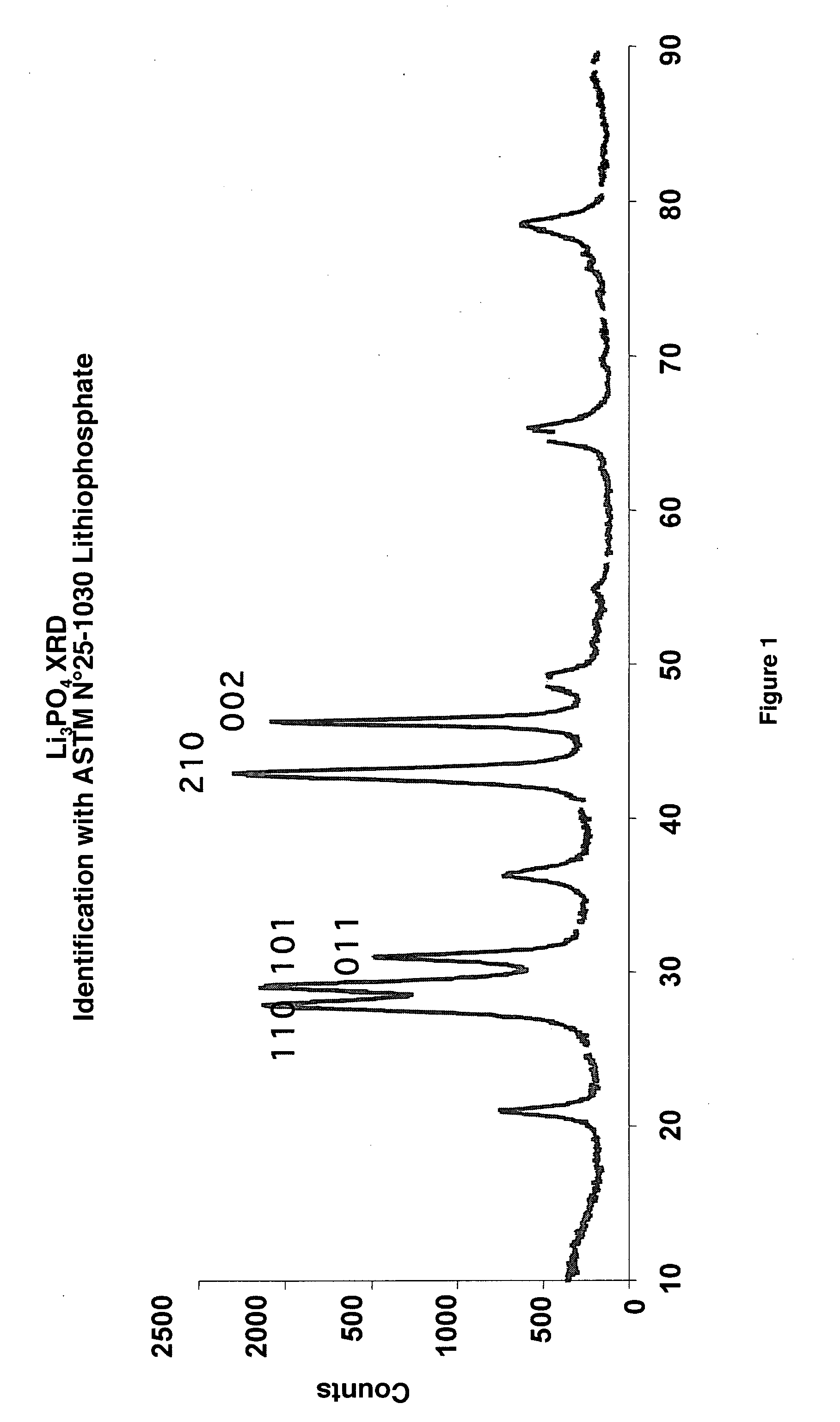

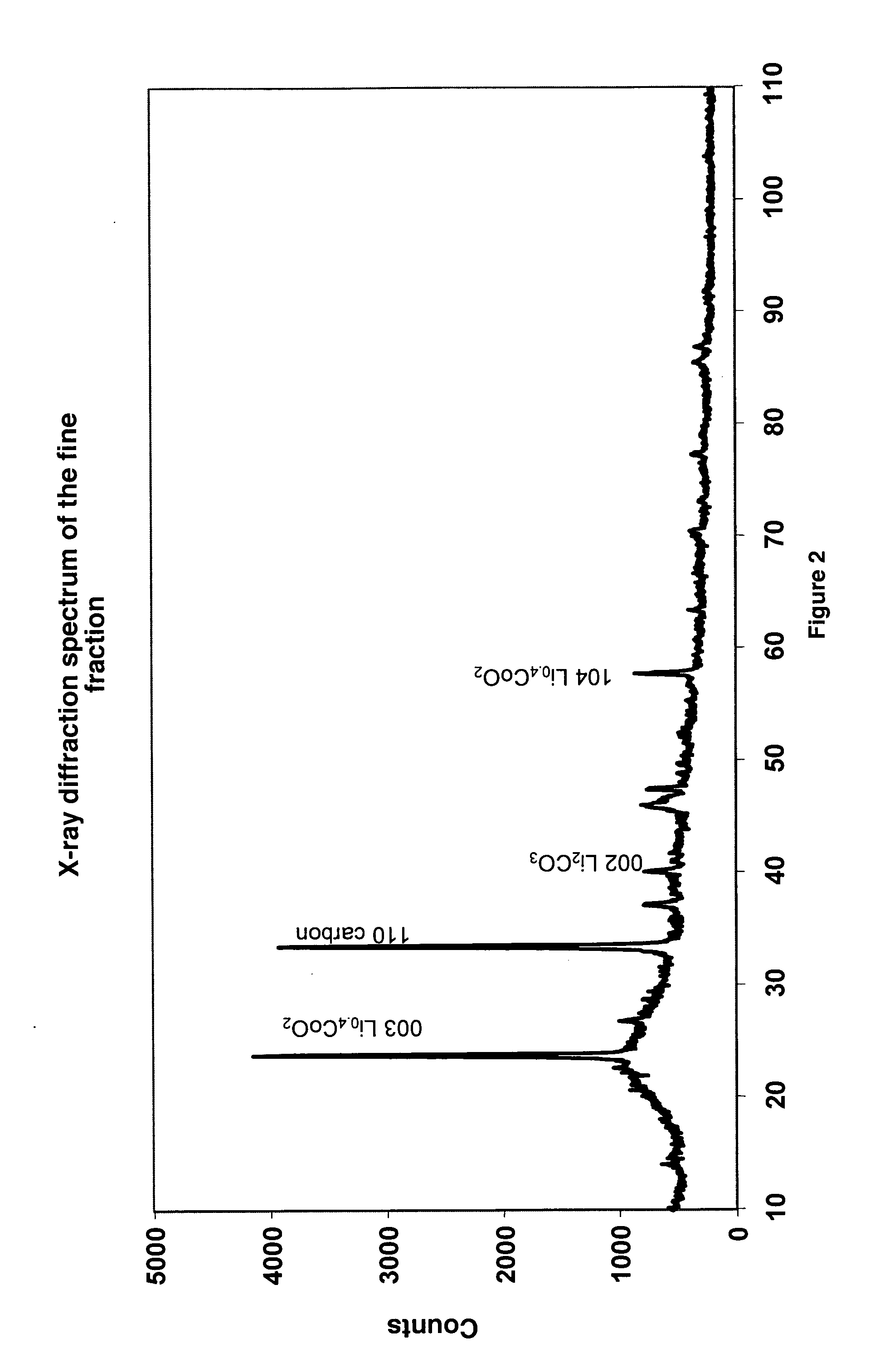

Method for the mixed recycling of lithium-based anode batteries and cells

InactiveUS20070196725A1Fuel cells disposal/recyclingPrimary cell maintainance/servicingMetallic lithiumRoom temperature

The invention relates to a method for treating all types of lithium anode cells and batteries by means of a hydrometallurgical process at room temperature. The treatment method enables cells and batteries comprising a metallic lithium-based anode or an anode containing lithium incorporated in an anodic insertion compound to be treated under safe conditions, thus enabling the metallic casings, electrode contacts, cathode metal oxides and lithium salts to be separated and recovered.

Owner:RECUPYL

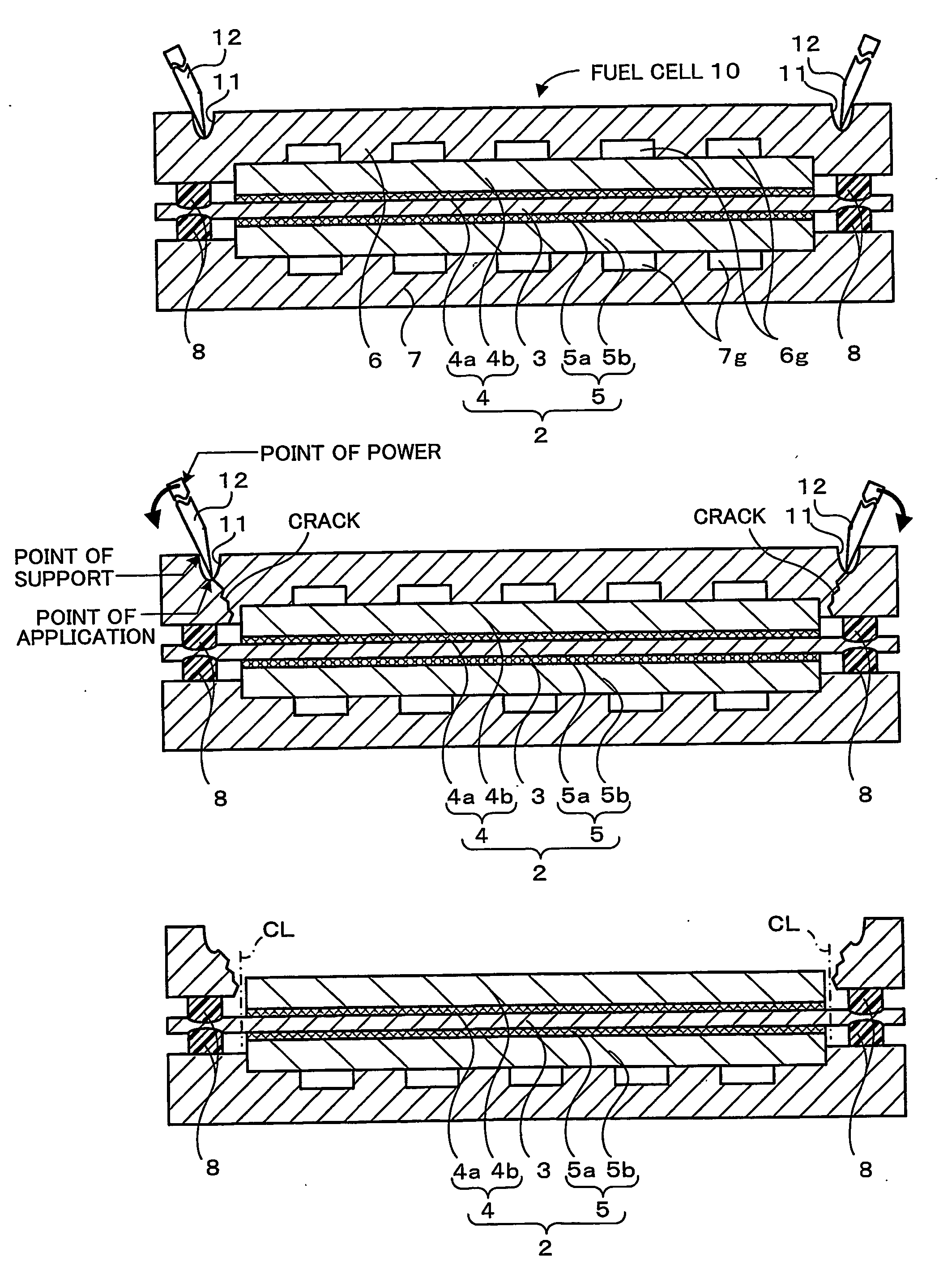

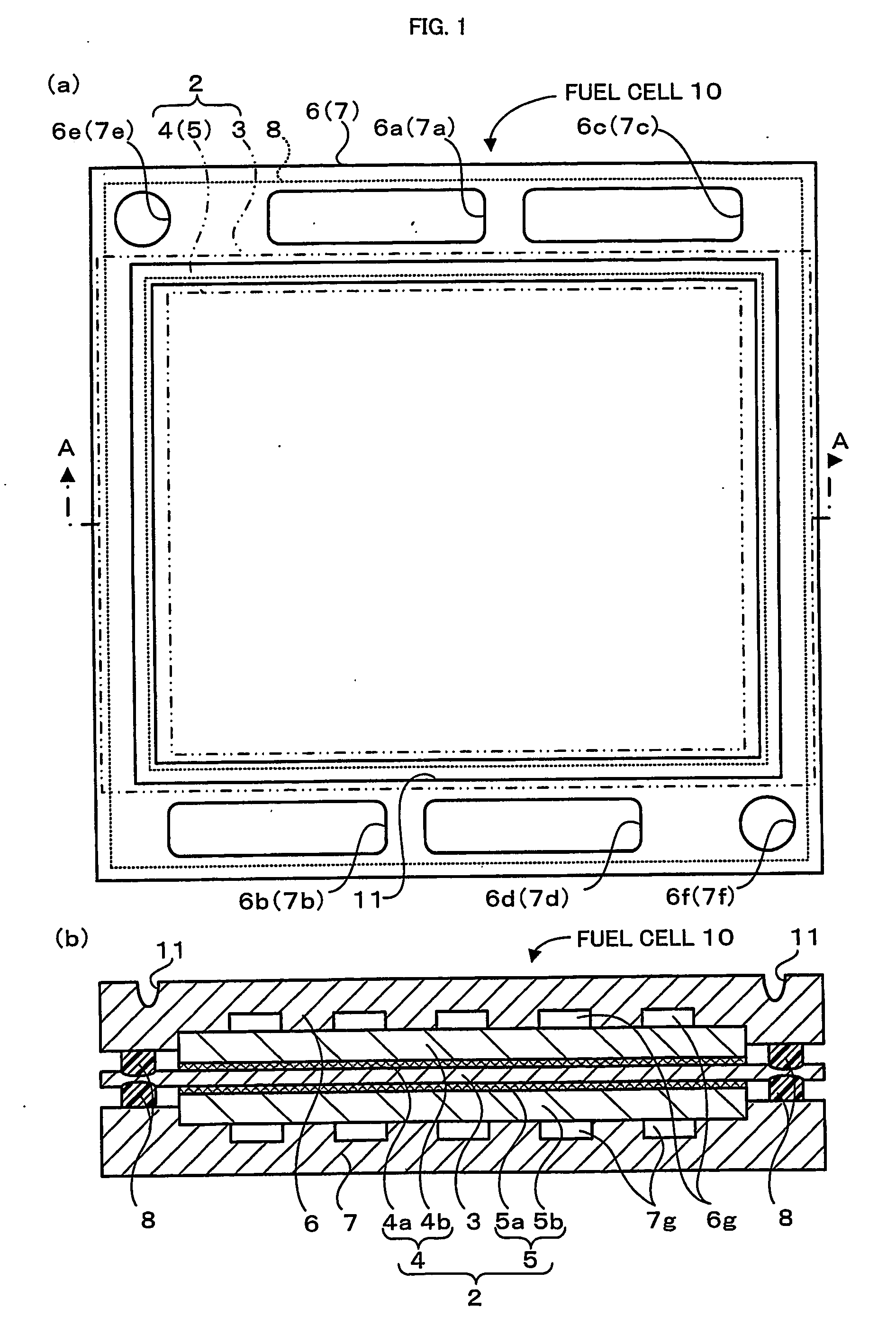

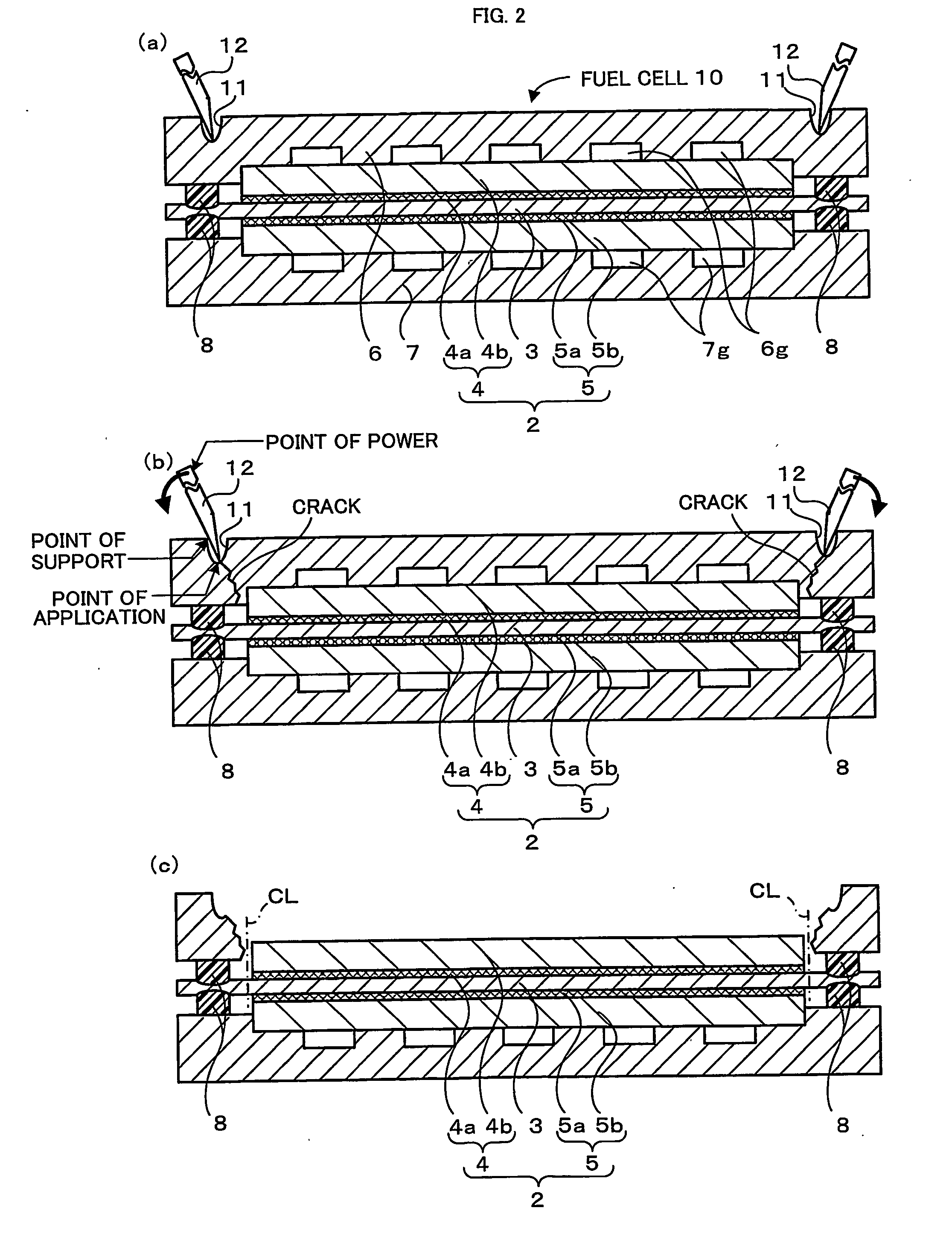

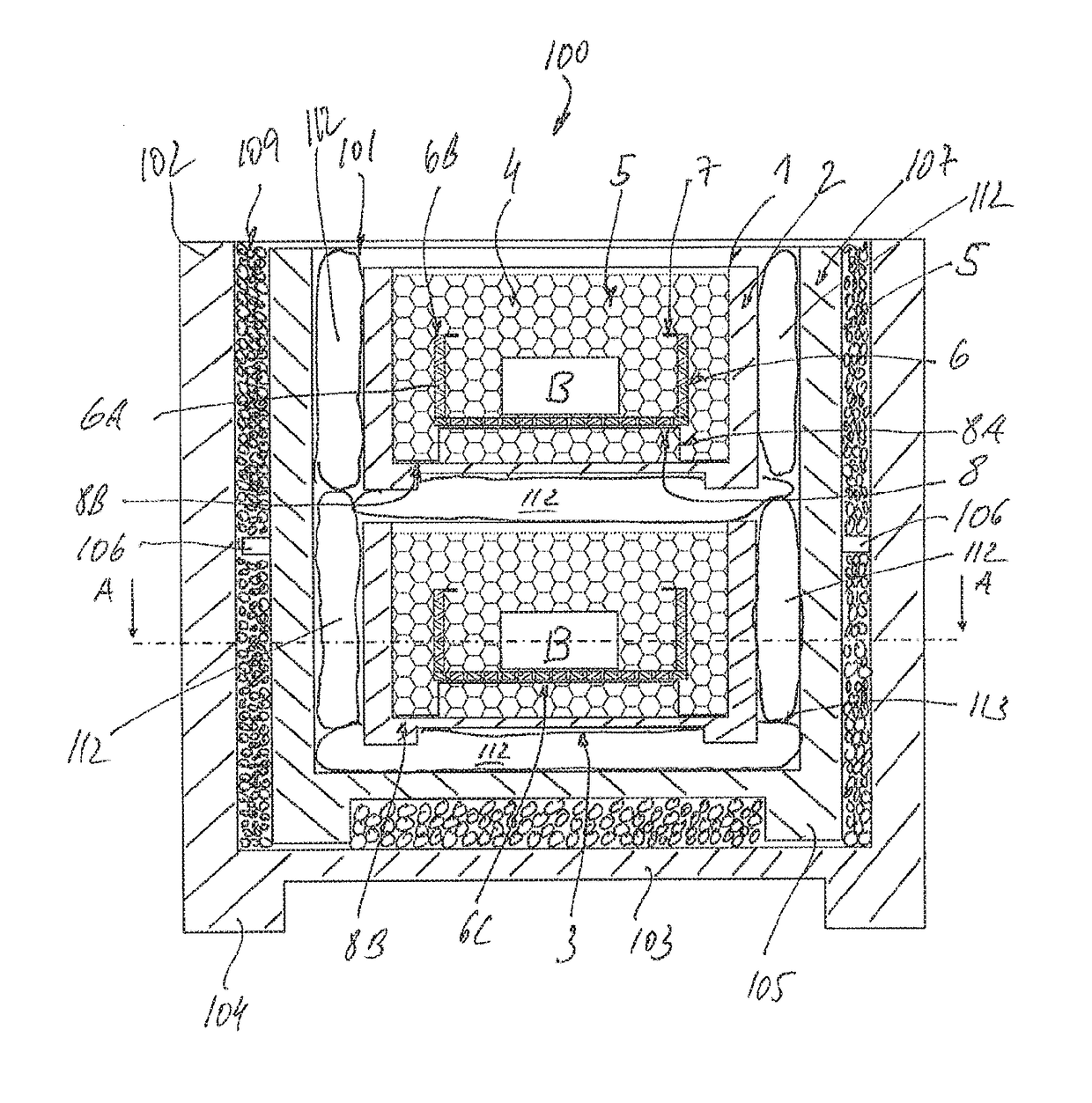

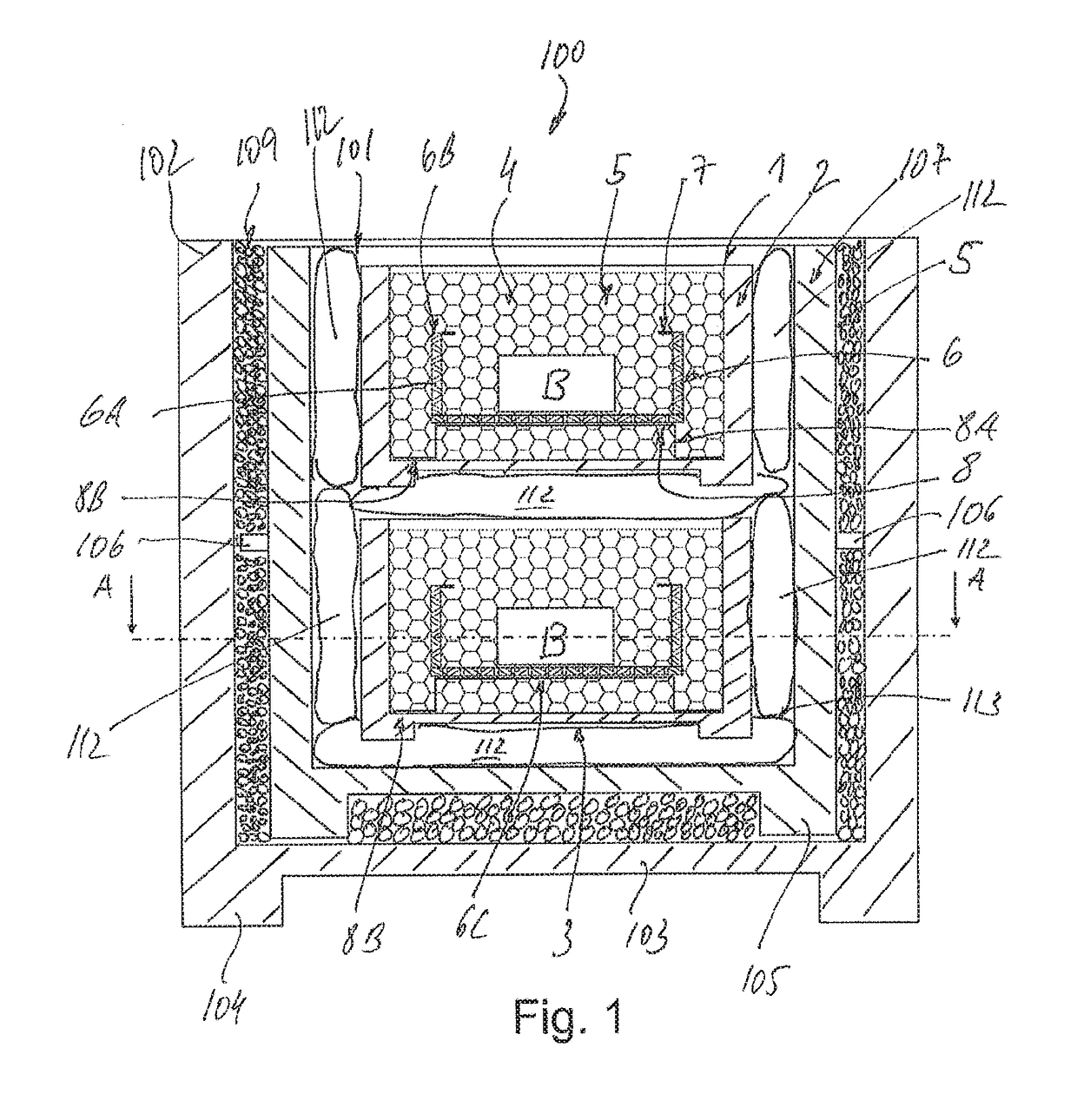

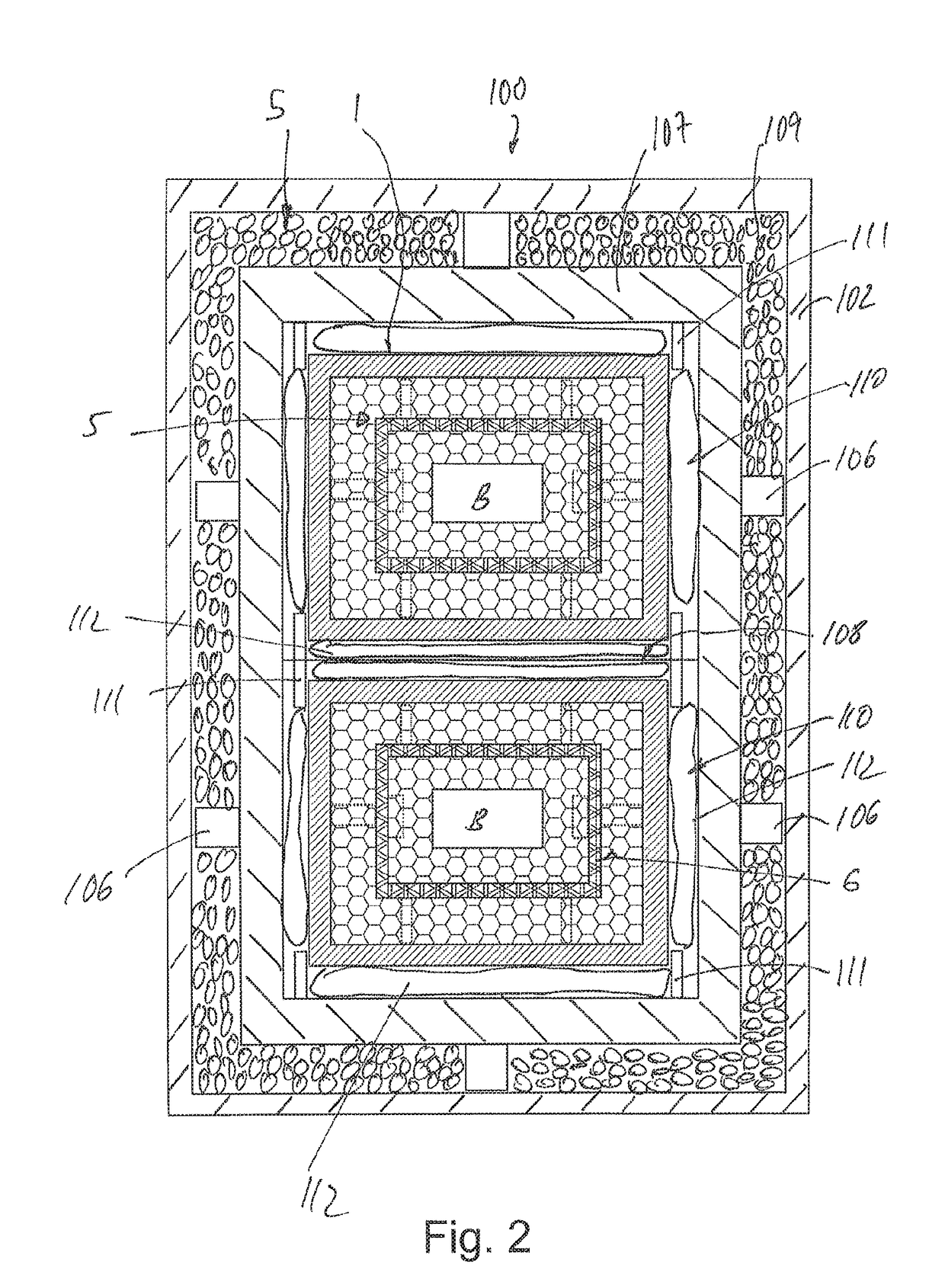

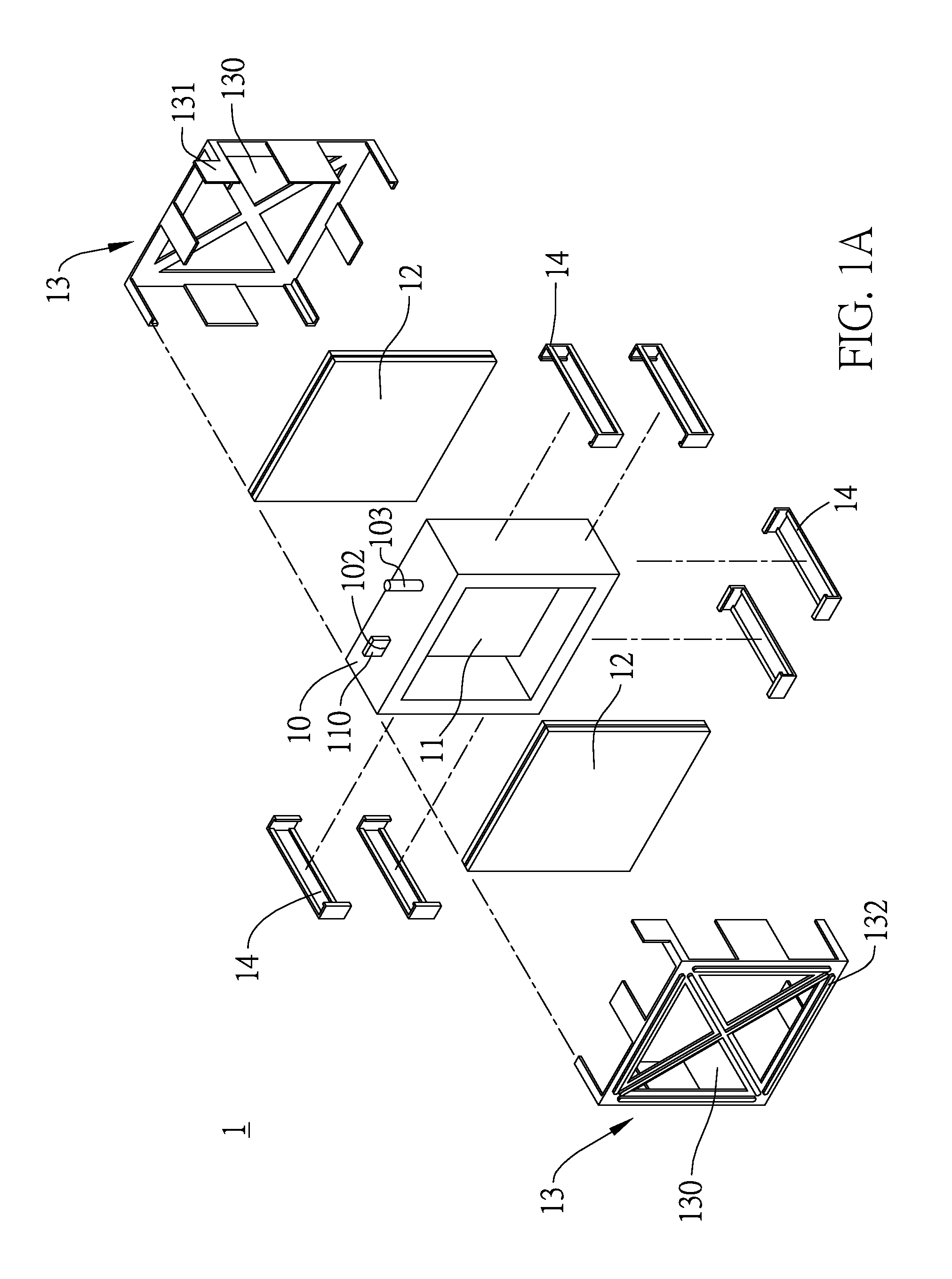

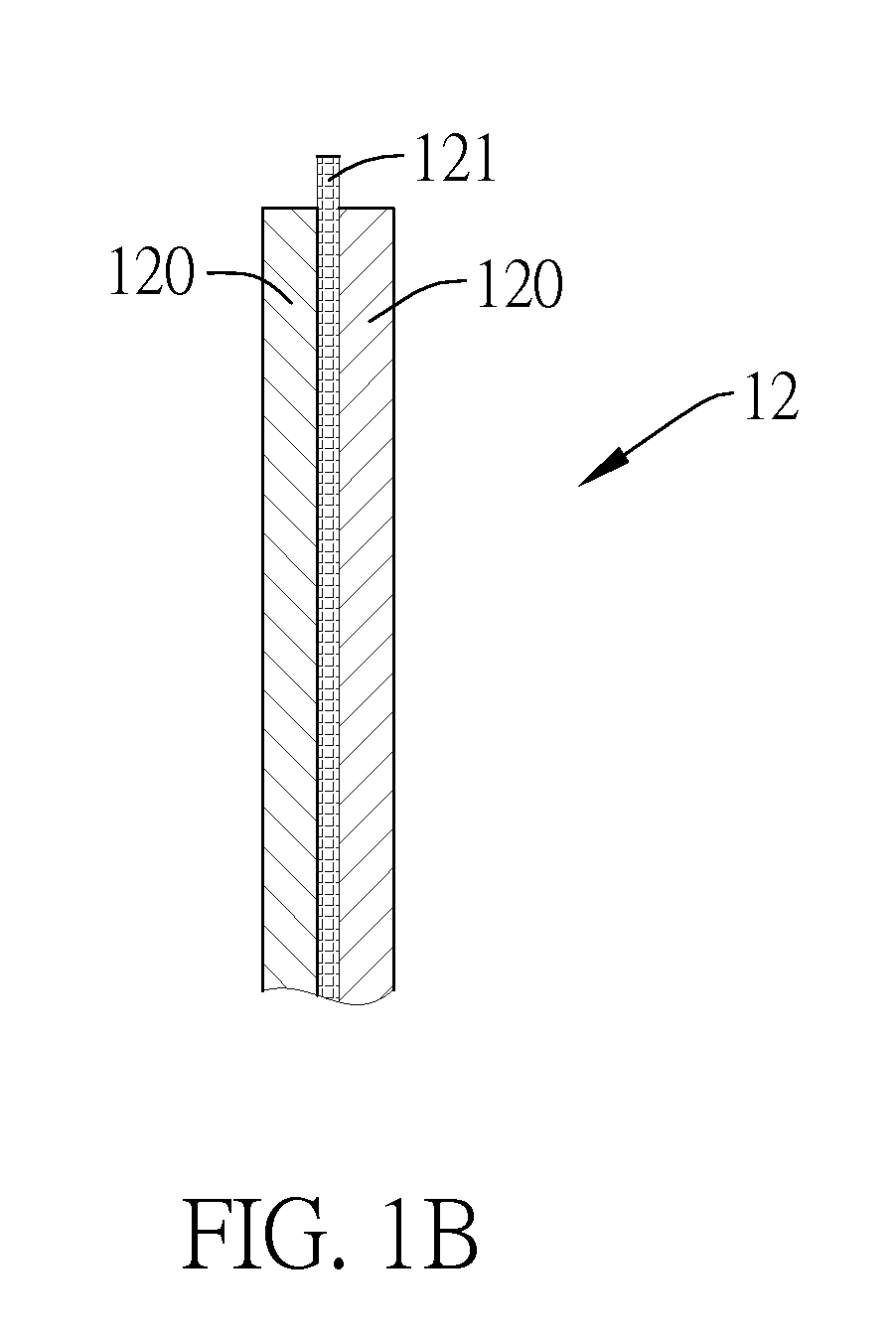

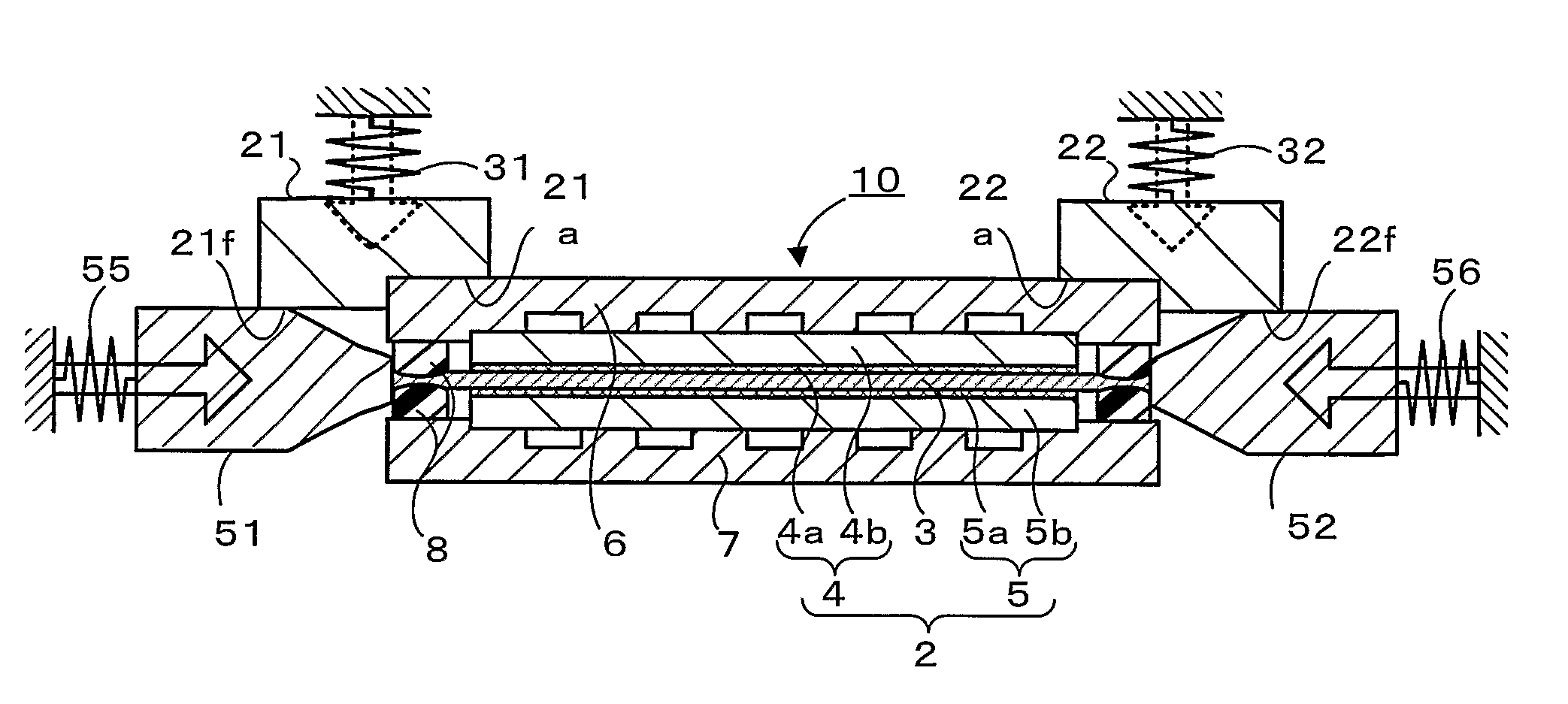

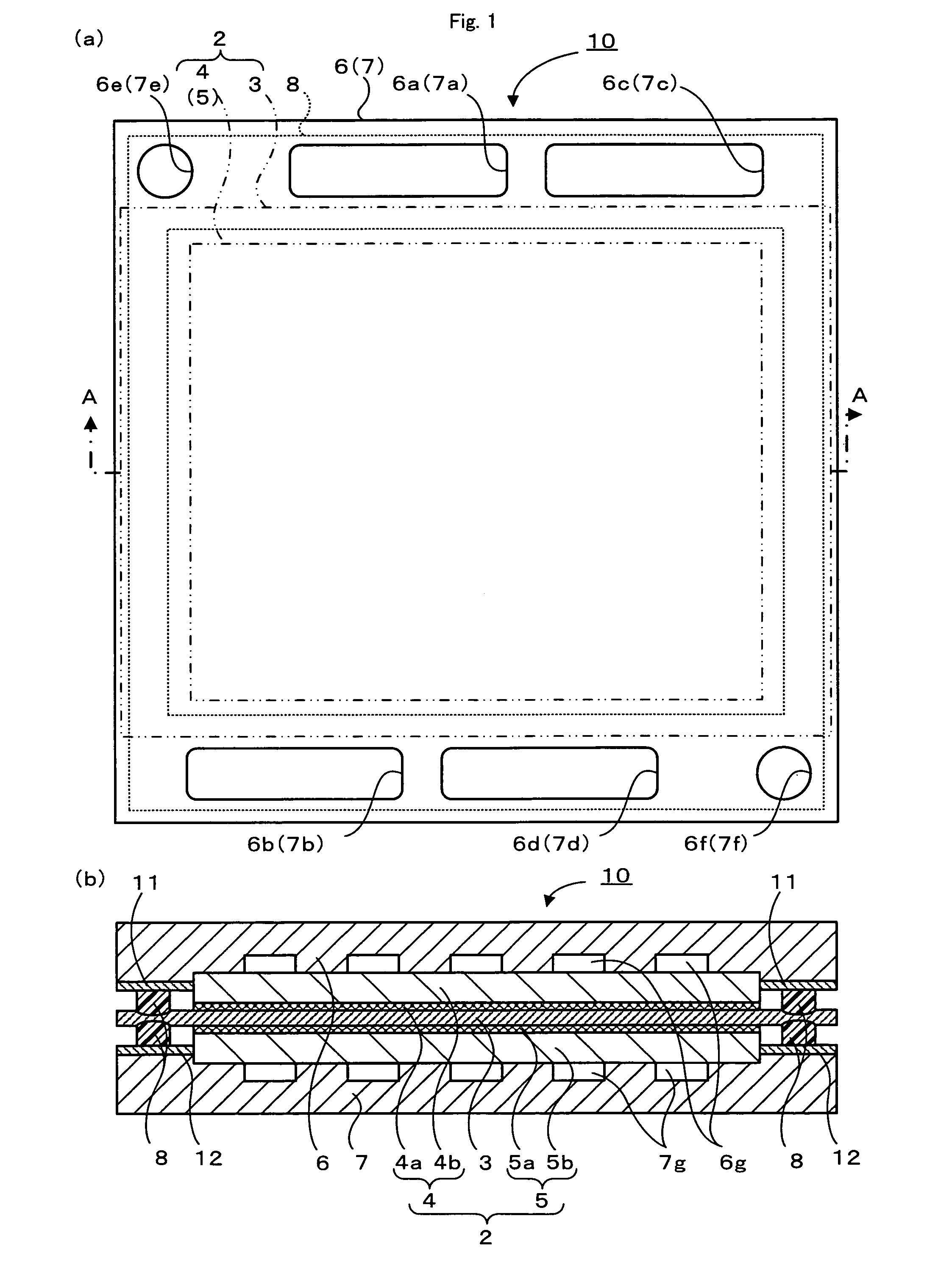

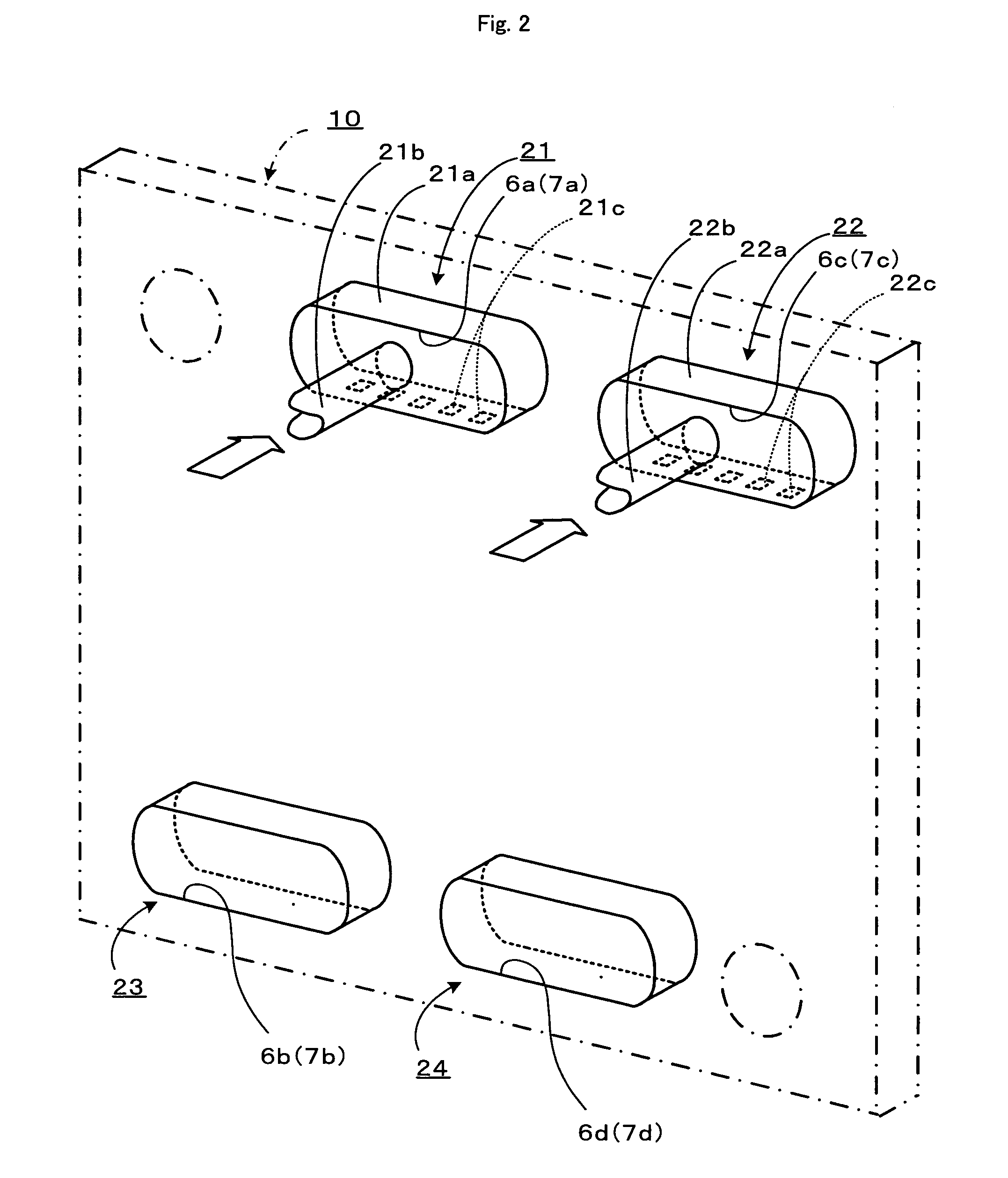

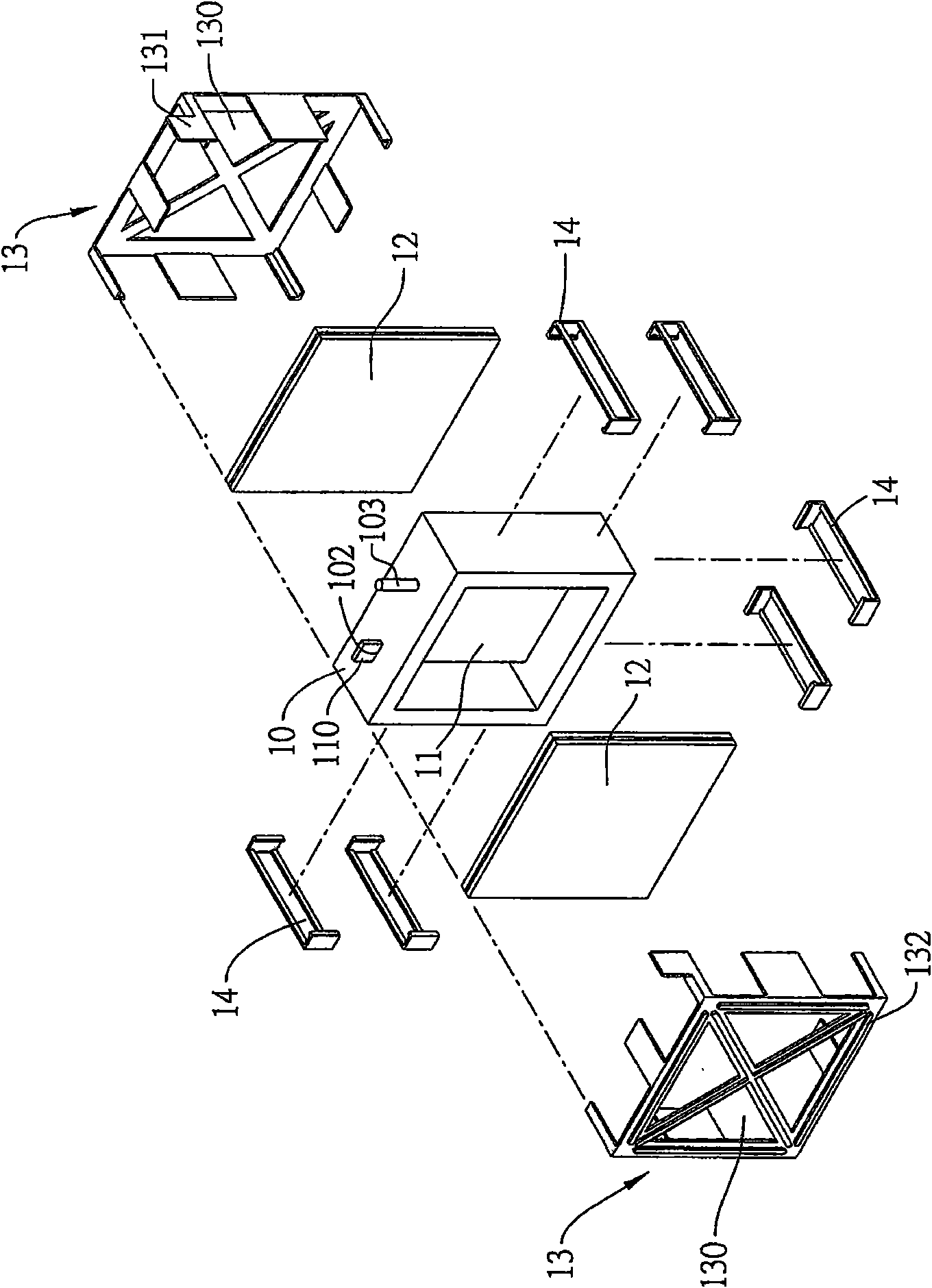

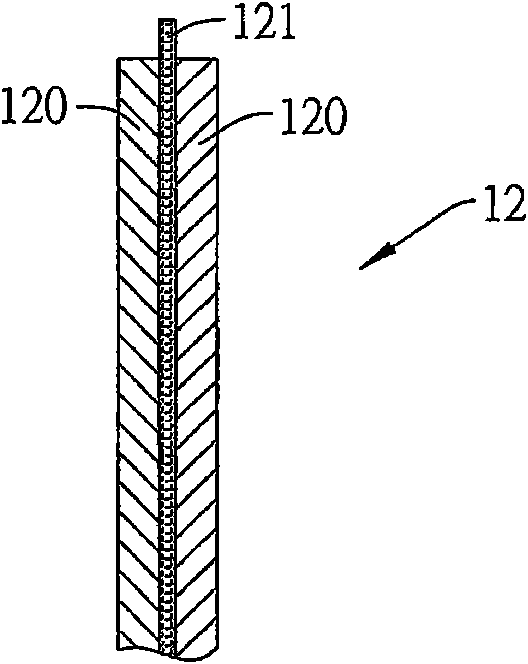

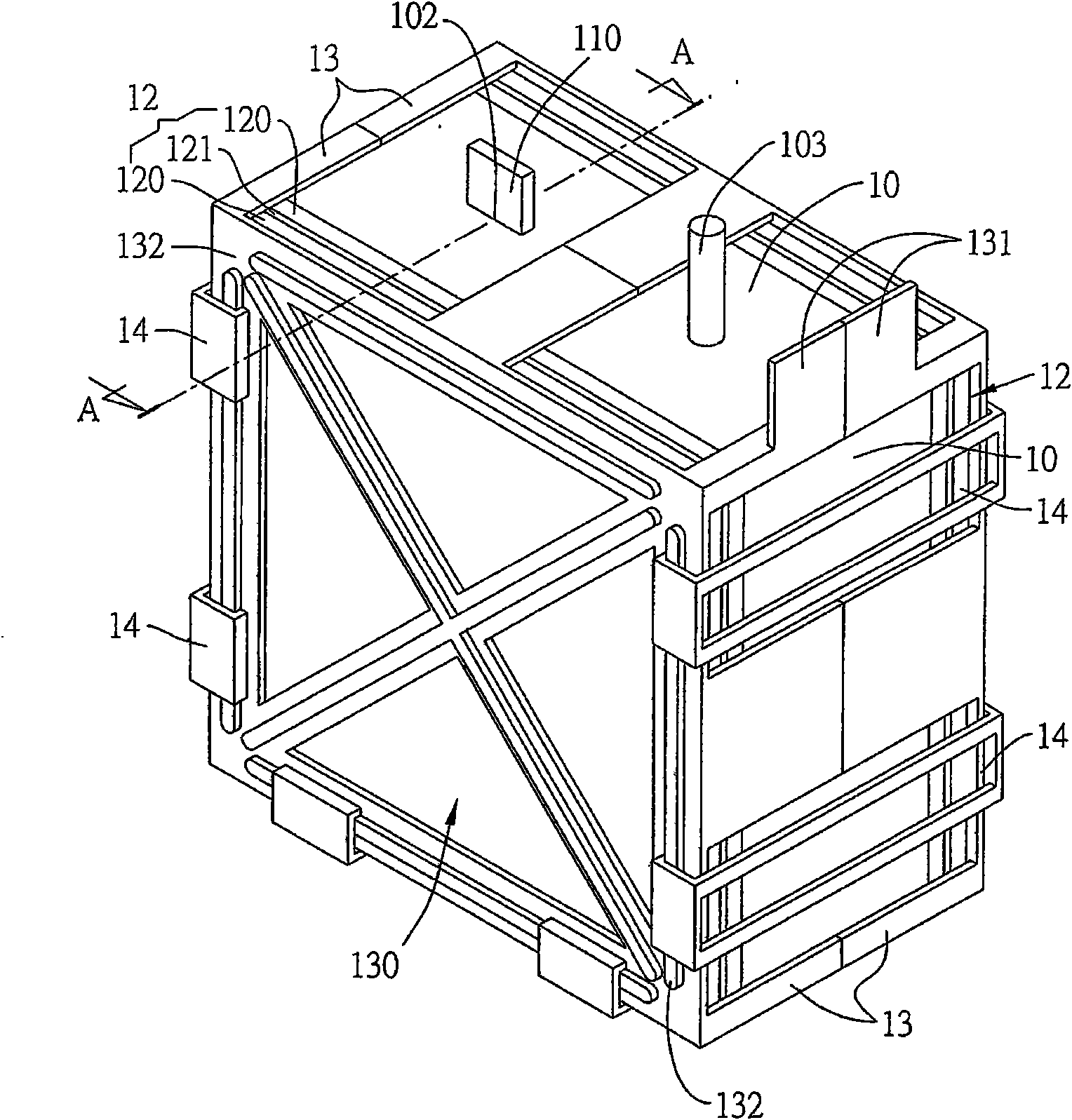

Fuel cell, disassembly method thereof, and separators used therein

ActiveUS20070134536A1Precise positioningFuel cells groupingFuel cells disposal/recyclingFuel cellsEngineering

A disassembly procedure of a fuel cell 10 first provides a cracking tool 12 having a sloped edge and places the sloped edge of the cracking tool 12 on a bottom of a recess 11. The disassembly procedure subsequently sets the bottom of the recess 11 where the sloped edge of the cracking tool 12 is placed, as a point of application, an opening edge of the recess 11 where a flat side of the cracking tool 12 is placed, as a point of support, and a base end of the cracking tool 12 where a force is applied, as a point of power, and applies an external force to the point of application by the principle of leverage. A crack starts from the point of application in a separator 6. The crack goes from the point of application toward a position outside electrodes 4 and 5 of an MEA (membrane electrode assembly) 2 but inside sealing members 8. The procedure then removes the broken separator 6 to expose the MEA 2 outside and cuts off an electrolyte membrane 3 along a cut line CL outside the electrodes 4 and 5 but inside the sealing members 8.

Owner:TOYOTA JIDOSHA KK

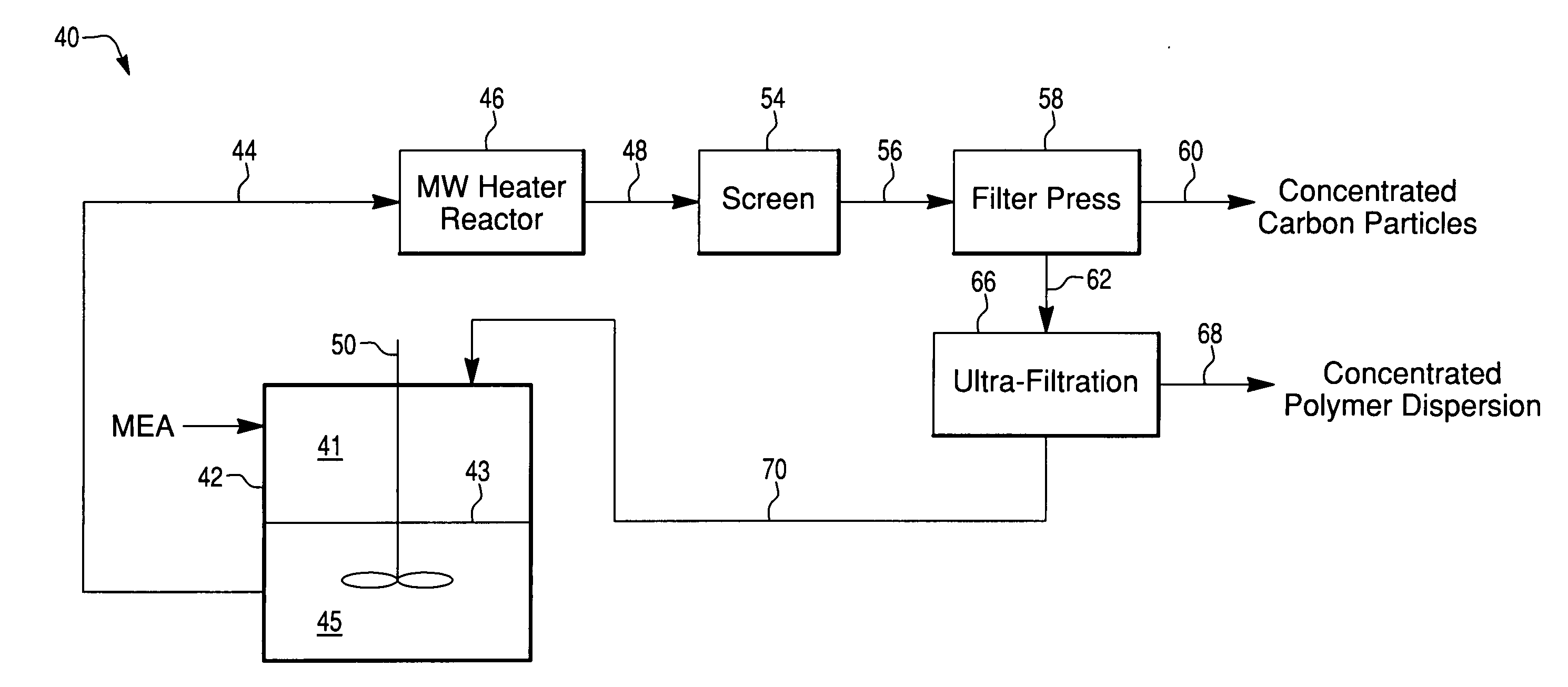

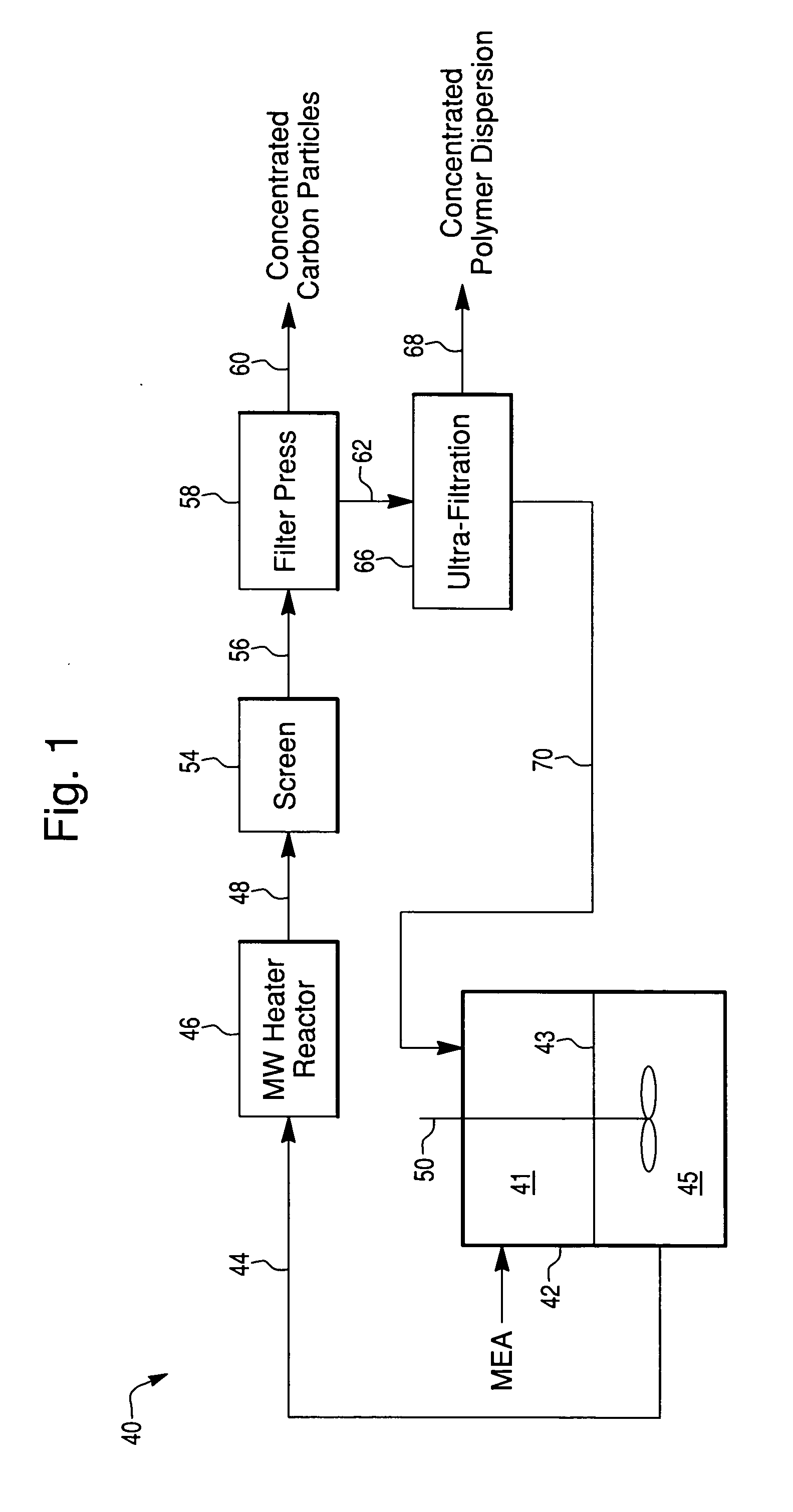

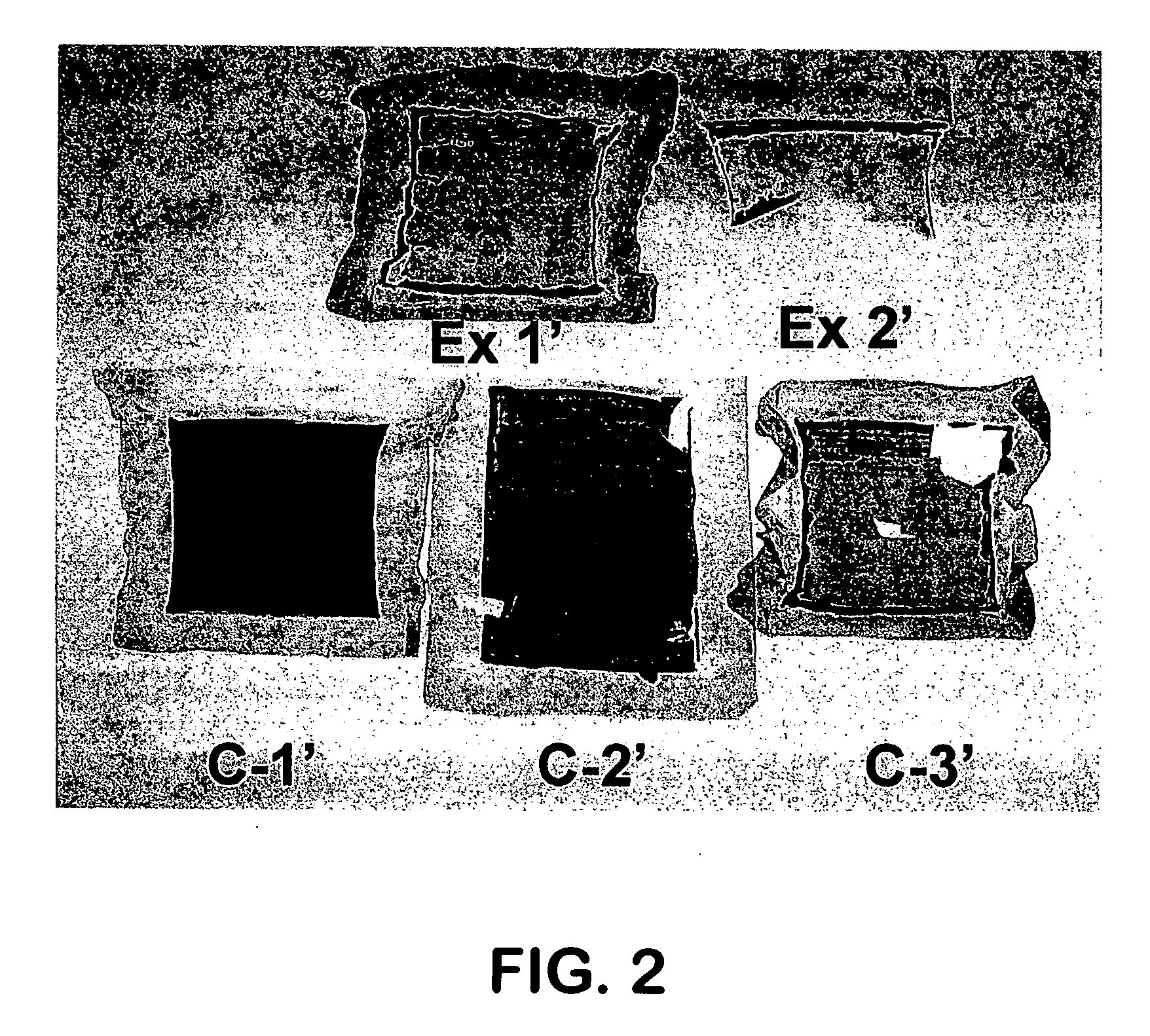

Process for recycling components of a PEM fuel cell membrane electrode assembly

InactiveUS20070292745A1Fuel cells disposal/recyclingPrimary cell maintainance/servicingFuel cellsAlcohol

The membrane electrode assembly (MEA) of a PEM fuel cell can be recycled by contacting the MEA with a lower alkyl alcohol solvent which separates the membrane from the anode and cathode layers of the assembly. The resulting solution containing both the polymer membrane and supported noble metal catalysts can be heated under mild conditions to disperse the polymer membrane as particles and the supported noble metal catalysts and polymer membrane particles separated by known filtration means.

Owner:BASF CORP

Process for recycling components of a PEM fuel cell membrane electrode assembly

InactiveUS20060237034A1Achieve recoveryPromote recoveryFuel cells disposal/recyclingCell electrodesFuel cellsAlcohol

Owner:ENGELHARD CORP

Device and method for transporting galvanic cells

InactiveUS20170155103A1Easy to operateInhibition releaseFuel cells disposal/recyclingBattery isolationFire protectionGalvanic cell

An apparatus and method for transporting used, damaged, or defective galvanic cells while impeding and combating safety-critical states of the galvanic cells, in particular lithium-ion-based cells and / or lithium-ion polymer cells, includes an outer container, which defines a space, an inner container being arranged in the space. The inner container has spacers in order to maintain a distance from the bottom and inner faces of the outer container, an accommodating container for accommodating at least on galvanic cell being arranged in the inner container, free intermediate spaces being filled with a fire protection agent composed of inert, non-conductive, non-flammable, absorbent hollow glass granular material.

Owner:GENIUS PATENTVERWERTUNG

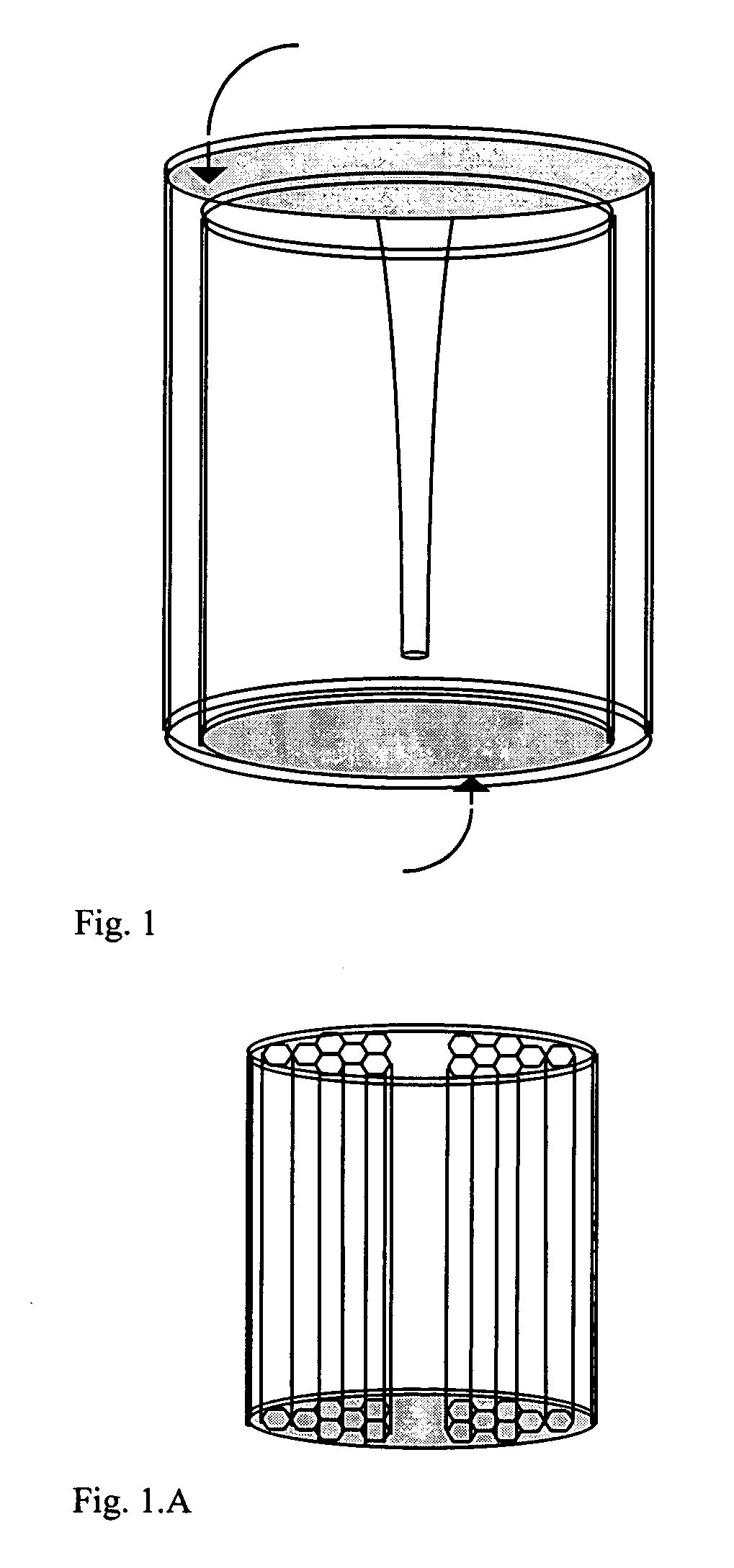

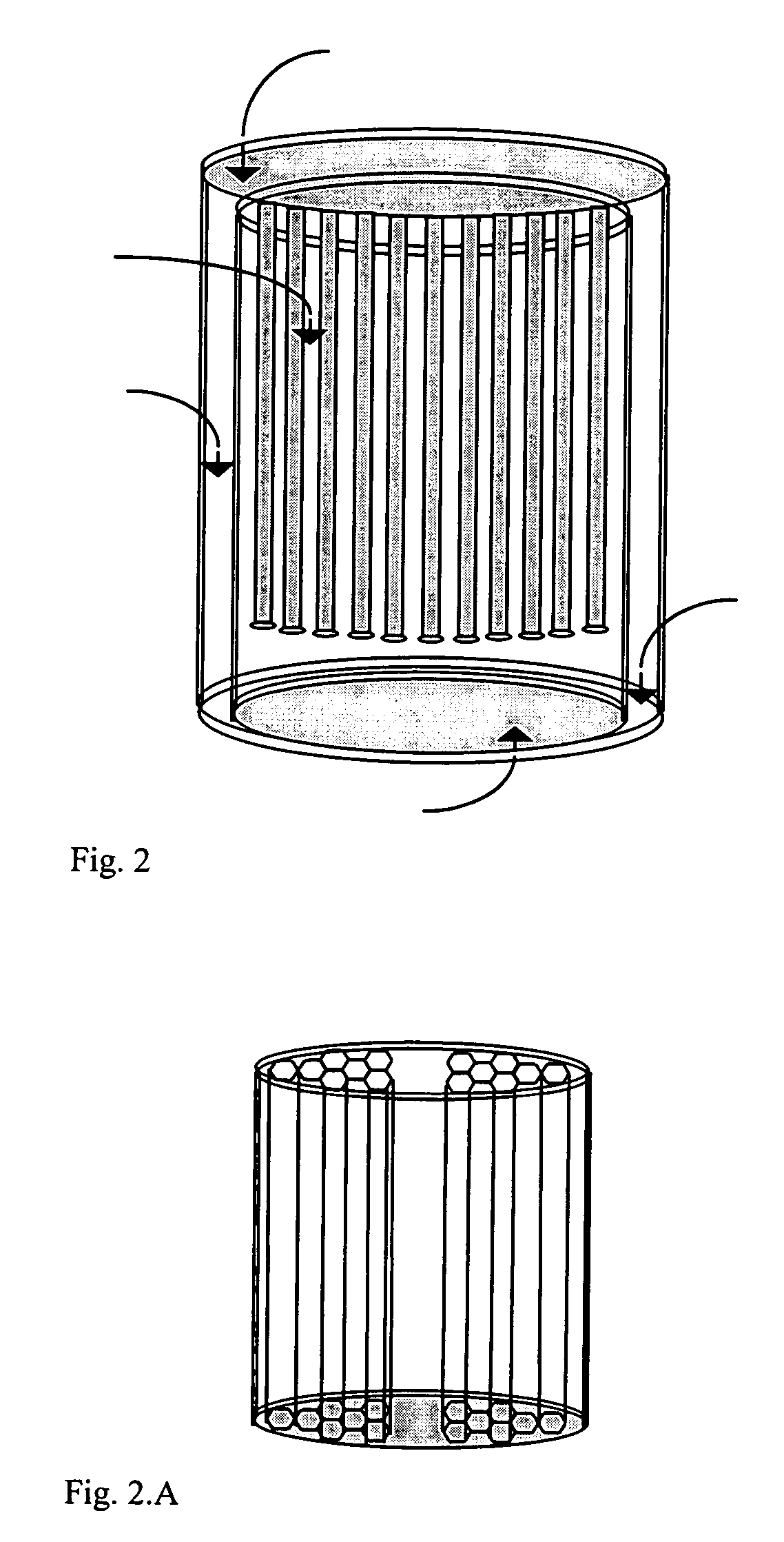

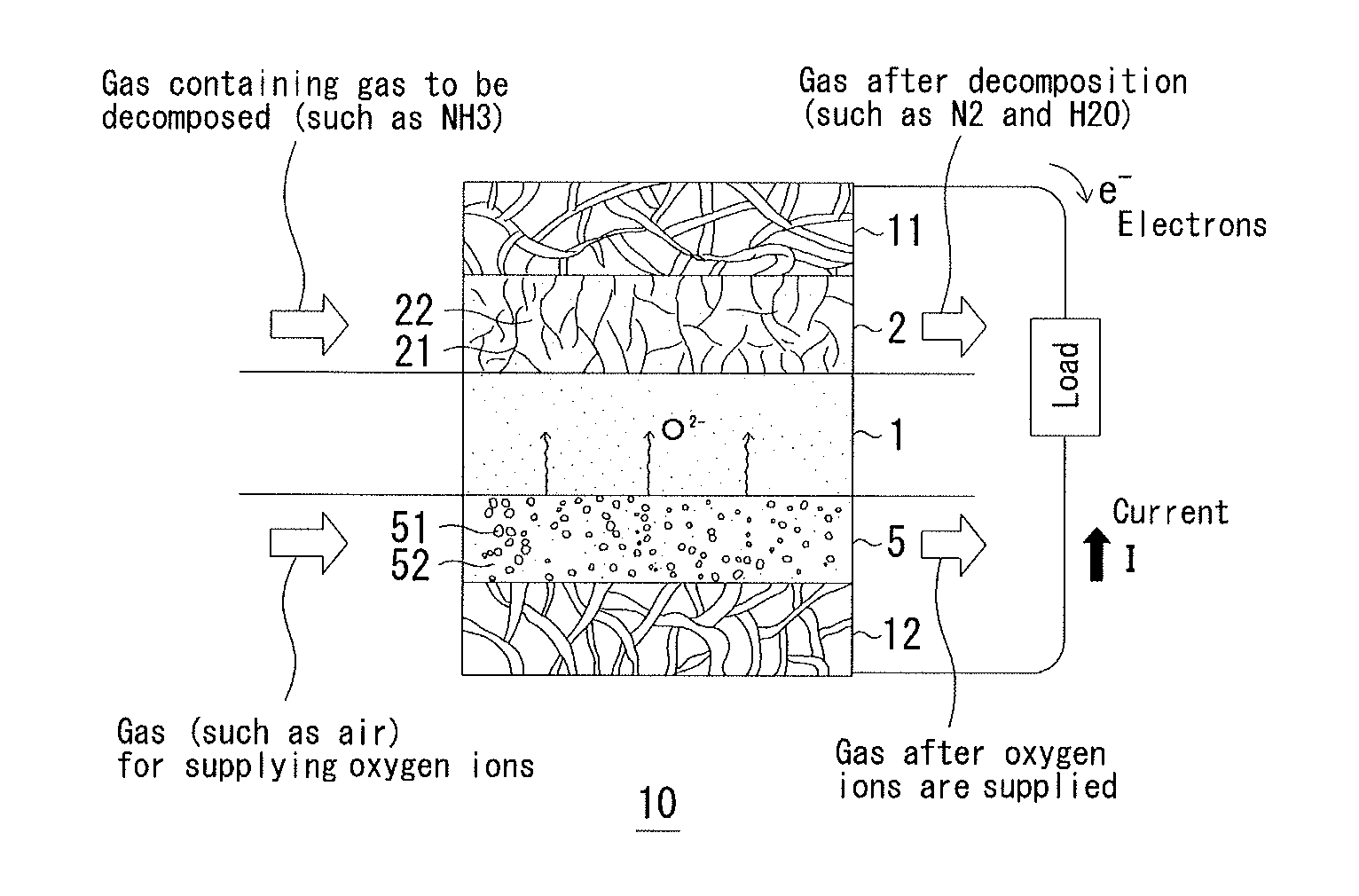

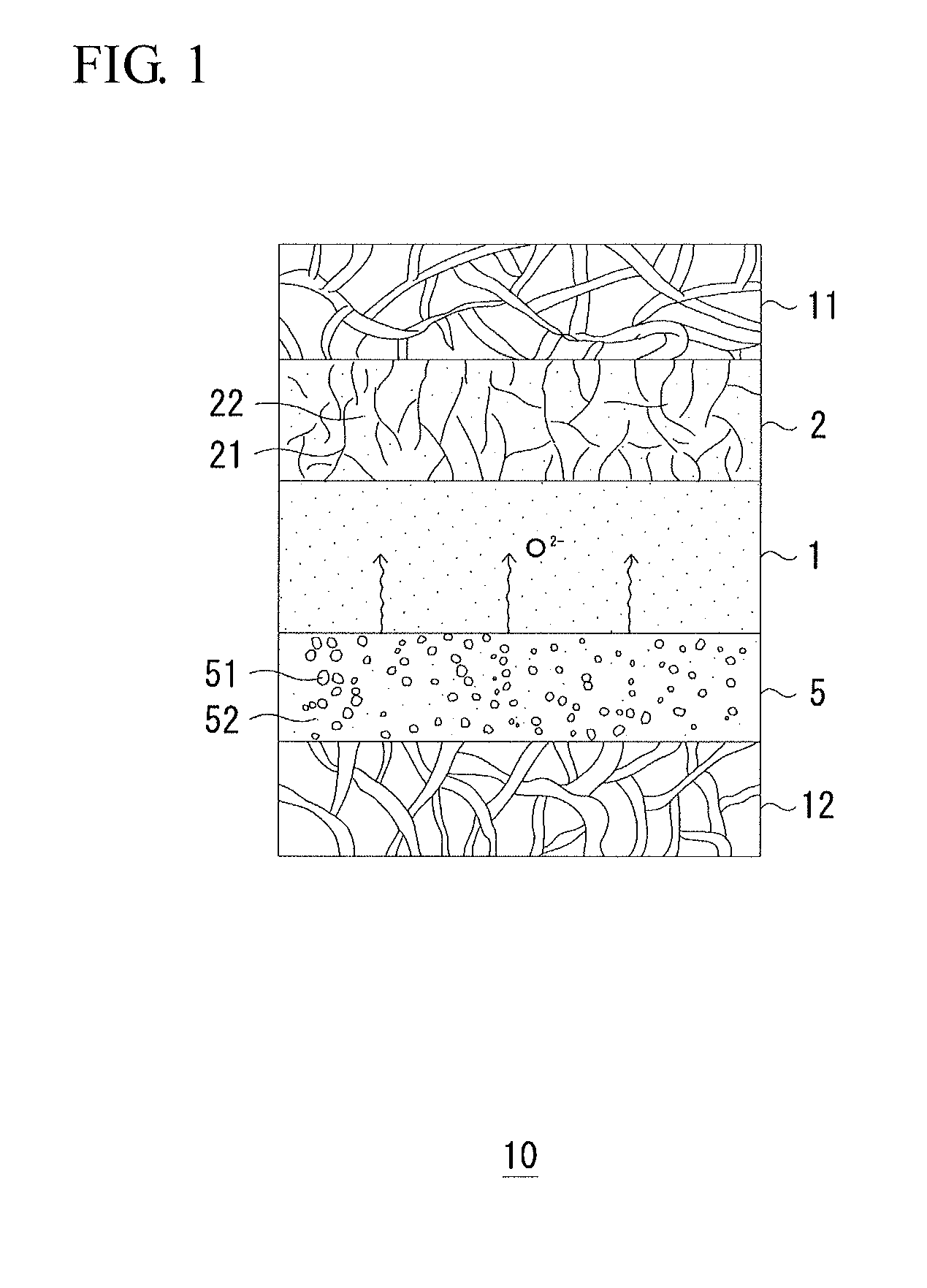

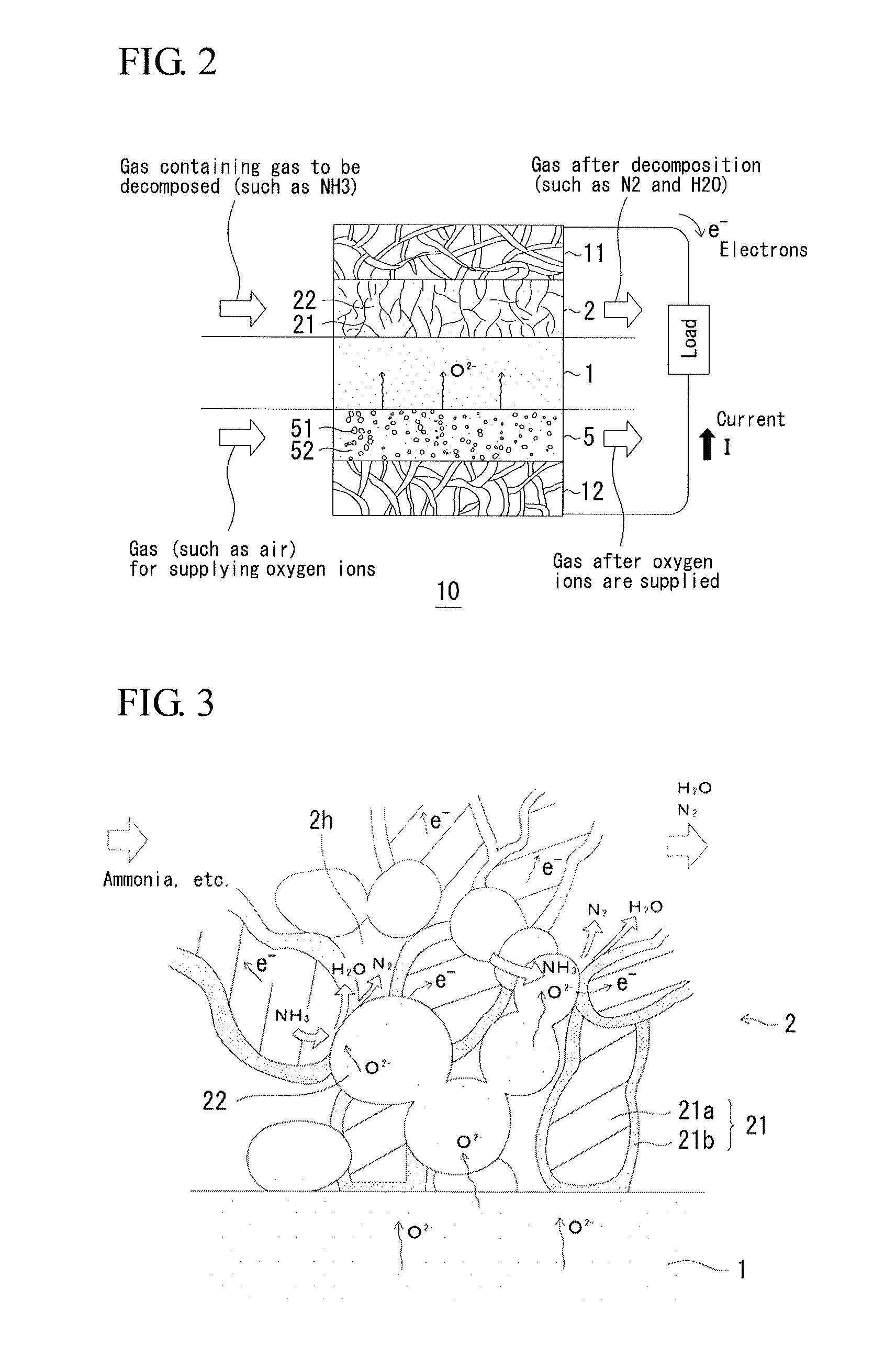

Electrochemical reactor, method for manufacturing the electrochemical reactor, gas decomposing element, ammonia decomposing element, and power generator

InactiveUS20110177407A1Small sizeImprove throughputCellsGas treatmentElectrochemical responseSurface oxidation

[Object] To provide an electrochemical reactor that is small in size but high in throughput capacity, does not generate NOx or carbon dioxide, can be operated at a low running cost, is easy to handle during assembling, and has a simple structure and high durability, a method for manufacturing the reactor, a gas decomposing element, an ammonia decomposing element, and a power generator.[Solution] An electrochemical reactor 10 includes a porous anode 2, a porous cathode 5 that is paired with the anode, and an ion conductive material 1 having an ion conductivity and being interposed between the anode and the cathode. The anode 2 includes surface-oxidized metal particle chains 21.

Owner:SUMITOMO ELECTRIC IND LTD

Method for reducing degradation in a fuel cell

InactiveUS20060183006A1Reduce solubilityFuel cells disposal/recyclingFinal product manufacturePolymer electrolytesFuel cells

The invention is a method of reducing catalyst dissolution in the cathode of a membrane electrode assembly fuel cell, said method comprising the steps of: (a) preparing a membrane electrode assembly comprising an anode, a cathode and a polymer electrolyte membrane interposed between said anode and said cathode; (b) assembling a fuel cell using said membrane electrode assembly; (c) applying a fluid comprising an oxidant to said cathode of said membrane electrode assembly; (d) applying a fluid comprising a fuel to said anode of said membrane electrode assembly; and (e) supplying a sufficient quantity of reducing agent to said cathode to maintain the average open-circuit voltage of said cathode at less than about 0.98 V.

Owner:WL GORE & ASSOC INC

Recovery method for fuel cell membrane electrode key material

The invention provides a recovery method of key materials of membrane electrode assembly for fuel cells. The recovery method adopts concentrated sulfuric acid, concentrated nitric acid, or mixed acid of the concentrated sulfuric acid and the concentrated nitric acid in any proportion to treat waste membrane electrode assemblies, and is characterized in that acting force between proton exchange resin molecular chains in proton exchange membranes and catalyst layers is reduced by acid treatment, thereby separating the proton exchange resin molecular chains to scatter in acid to form a solution, catalyst noble metals can be sufficiently isolated by carbon carriers of oxidization supported catalysts, and additionally, gas diffusion layer materials (carbon paper or carbon fabric) can be isolated. The recovery method includes steps of (1) after cleaning, drying and shredding, immersing used membrane electrode assembly in the acid for further stirring and heating, (2) using NaOH solution to neutralize excess acid after reaction, and (3) isolating proton exchange resin solution, noble metal catalyst or gas diffusion layer materials. The recovery method has the advantages of simple operation, high recovery rate, low cost and the like.

Owner:WUHAN UNIV OF TECH

Method for recycling failed vanadium electrolyte

ActiveCN106450371ASimple processEasy to operateFuel cells disposal/recyclingBattery recyclingSulfate radicalsPhysical chemistry

The invention provides a method for recycling failed vanadium electrolyte. The method includes steps of confirming vanadium ion concentration C1, averaged valence state M1 of vanadium ion and sulfate radical concentration Cs1 in the failed vanadium electrolyte; according to the volume ratio of the failed vanadium electrolyte, determining the quantity n1 of the vanadyl sulfate or vanadium sulphate as required; according to the vanadium ion concentration C2 and sulfate radical concentration Cs2 required by the regenerated vanadium electrolyte, confirming the volume V2 of the regenerated vanadium electrolyte and the quantity n2 of the vitriolic material as required; and then adding water and adjusting the volume of the obtained solution to V2, and thereby obtaining the regenerated vanadium electrolyte. Through recycling the recycled vanadium electrolyte, the electrolyte is regenerated; the recycle rate is up to 10%; moreover, the method is simple in process and easy to operate.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

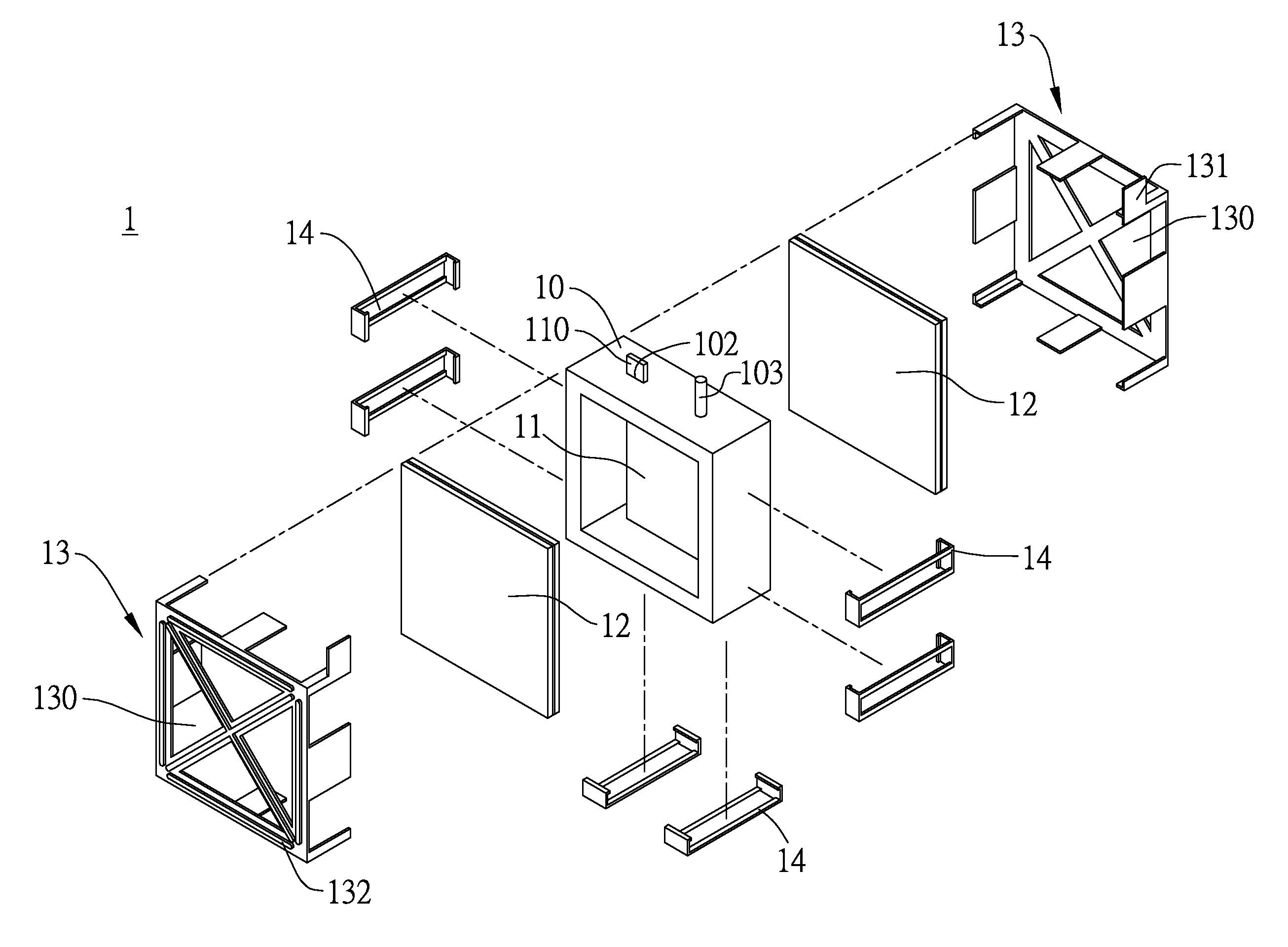

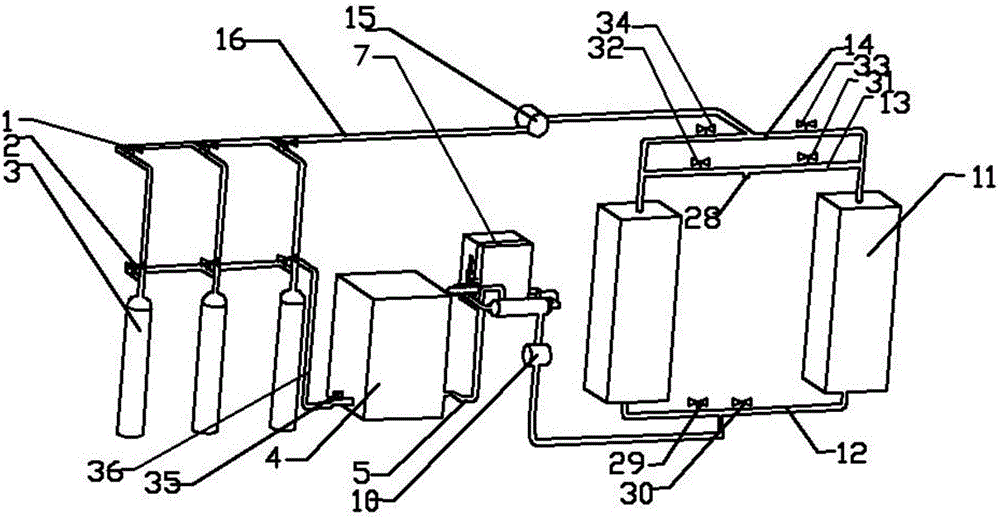

Battery device and method of packaging, disassembling, and recycling thereof

InactiveUS20100310967A1Improve stabilitySimple structureFuel cells disposal/recyclingPrimary cellsRecovery methodEngineering

The invention provides a battery device and a method for packaging, disassembling, and recycling the battery device, wherein the anode conductive element is disposed in a reaction trough frame with a bump thereof protruding from the frame; two sets of the cathode conductive elements cover on a first opening and a second opening of the reaction trough frame, respectively, so as to form a reaction region for accommodating electrolyte therein; and a metallic fastener is disposed on surfaces of the cathode conductive elements and the reaction trough frame and fastened with a buckling member. The invention provides a simple structure that can be packaged rapidly, disassembled and recycled to thereby overcome the drawbacks of conventional batteries.

Owner:ADVANCED POWER & ENERGY SOURCES HK

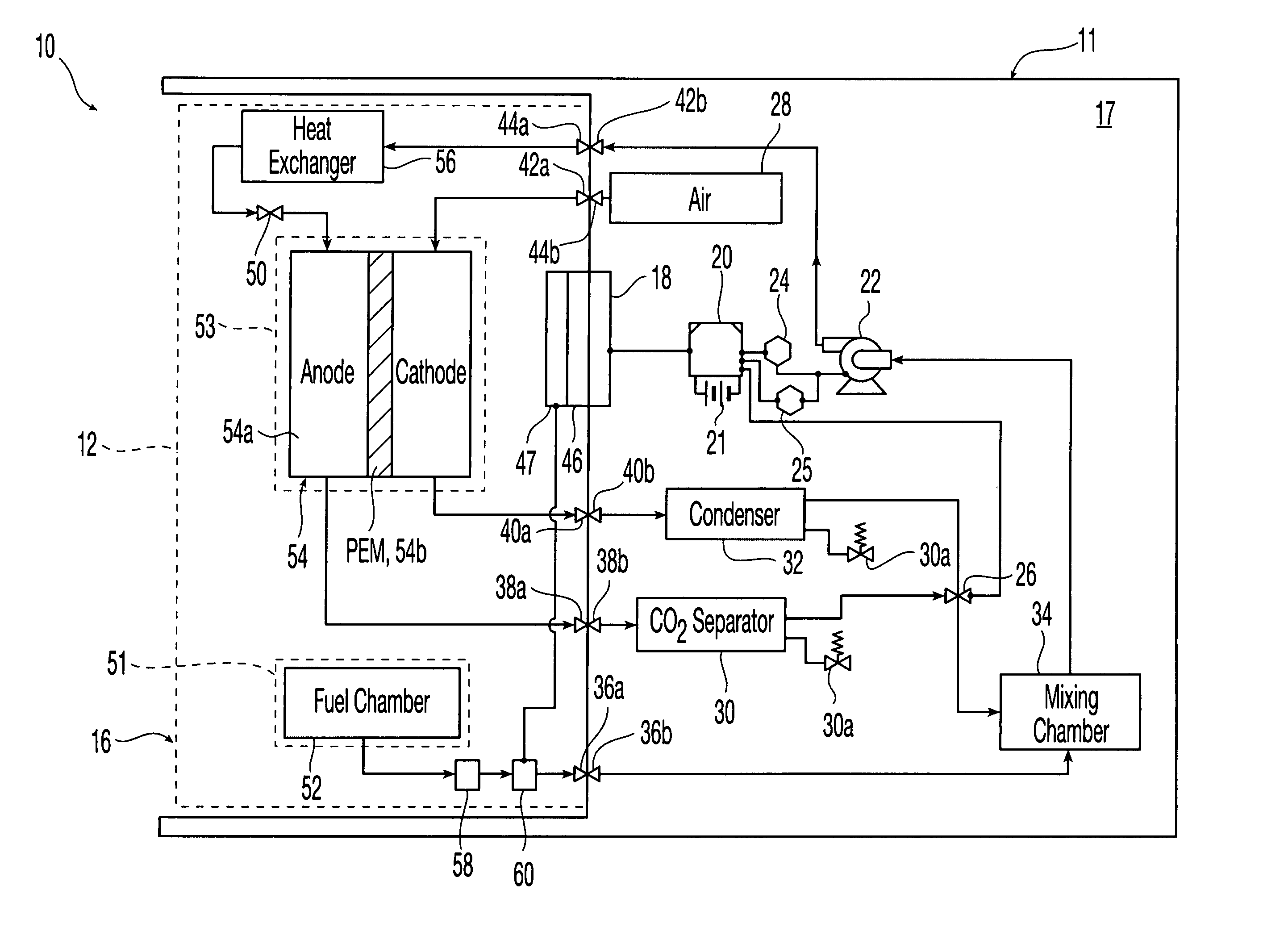

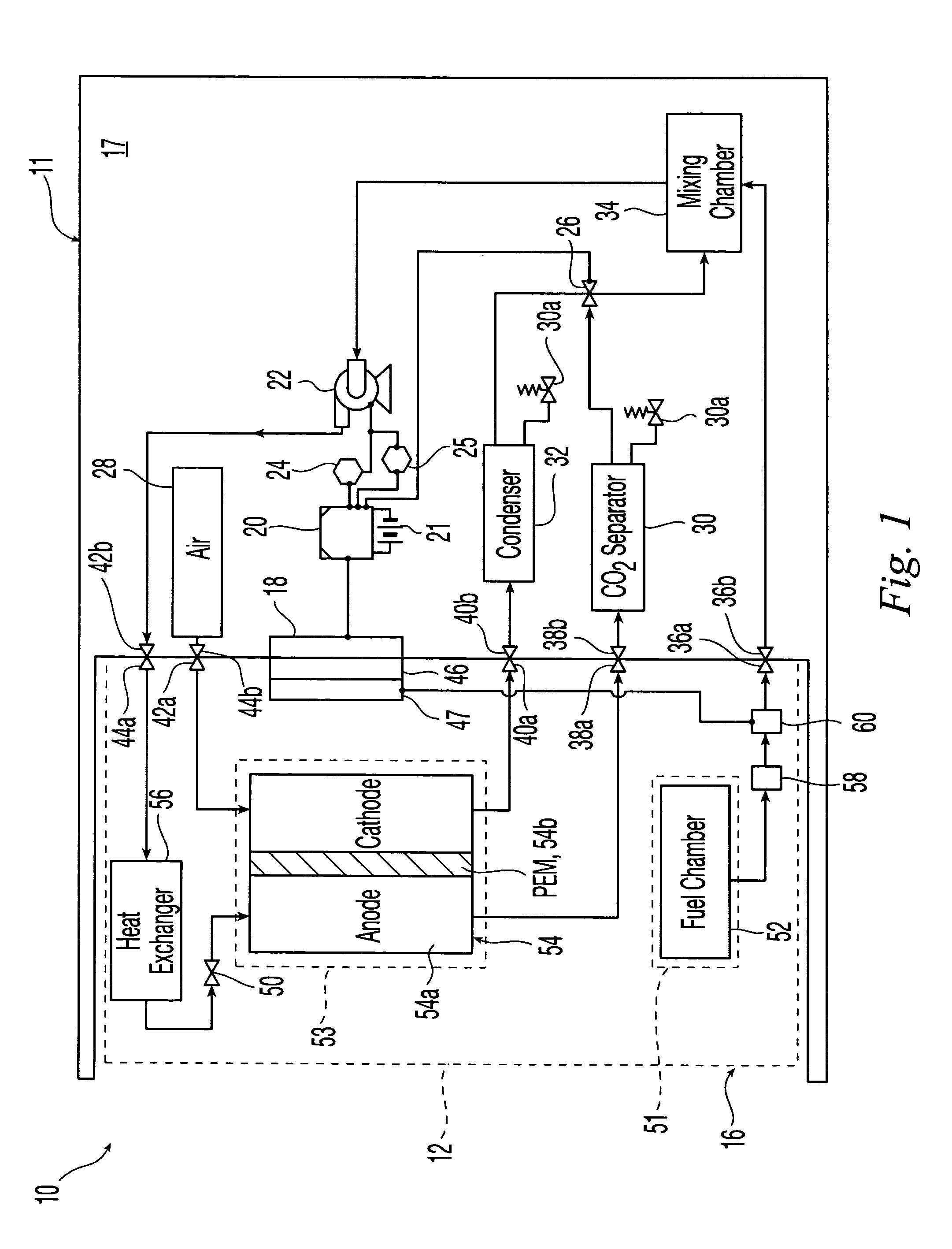

Cartridge with fuel supply and membrane electrode assembly stack

The present invention is directed to a fuel cell system with various features for optimal operations of an electronic device. The fuel cell system includes a fuel cartridge with a fuel reservoir containing fuel and a membrane electrode assembly (MEA) or a stack. The fuel cartridge is selectively operatively associated with the electronic device to power the device. In one embodiment, the fuel cartridge may be received within a chamber in the electronic device. In another embodiment, the fuel cartridge may be operatively associated with the electronic device while external thereto.

Owner:INTELLIGENT ENERGY LTD

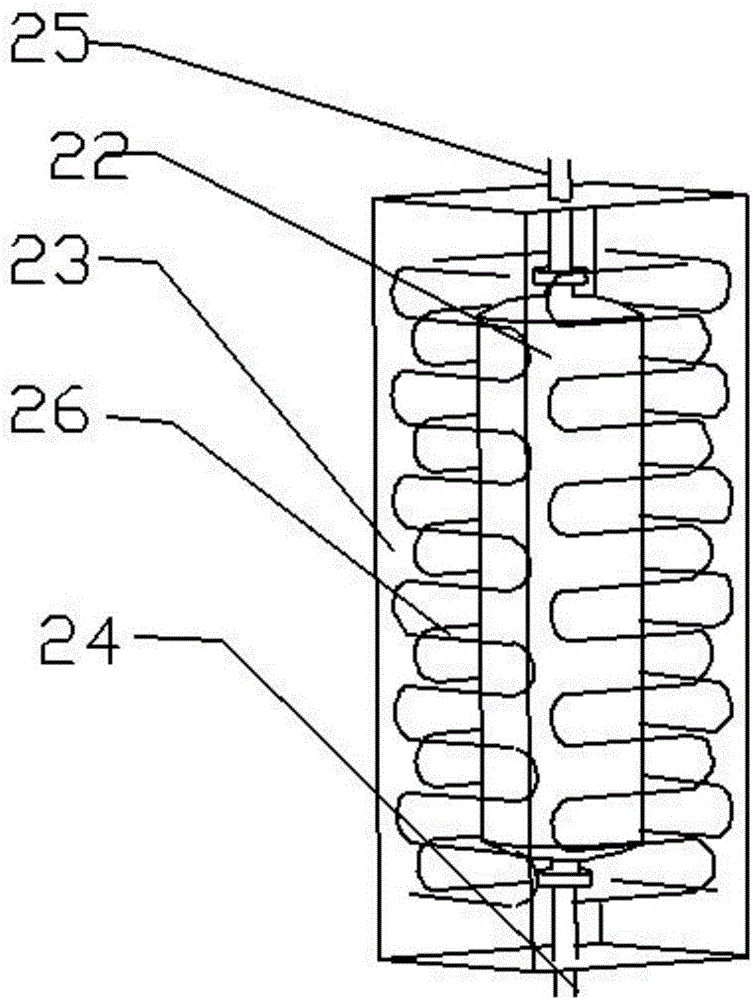

Exhaust gas recycling device of fuel cell

InactiveCN106229528AAchieve re-useIncrease profitFuel cells disposal/recyclingWater heatersElectrochemical responseFuel cells

The invention discloses an exhaust gas recycling device of a fuel cell, and belongs to the field of fuel cells. The exhaust gas recycling device comprises a hydrogen storage tank, a galvanic pile, a heat exchanger, a heat conversion device, a gas-water separator, a drying tower and a compressor, wherein hydrogen in the hydrogen storage tank is introduced into the galvanic pile for electrochemical reaction to generate electric energy, and the remaining hydrogen exhaust gas enters the heat exchanger for heat recovery, sequentially passes through the gas-water separator, the drying tower and the compressor and finally enters the hydrogen storage tank; air is introduced into the galvanic pile for electrochemical reaction to generate electric energy, and the remaining air exhaust gas enters the heat conversion device and provides the heat conversion device with heat; and a high-temperature medium generated by the heat conversion device enters the drying tower to provide heat for absorbent regeneration and returns to the heat conversion device again after heat supply. By the exhaust gas recycling device of the fuel cell disclosed by the invention, the residual fuel and heat in the exhaust gas of the fuel cell are fully recycled, so that improvement of the fuel utilization rate of the fuel cell is facilitated; energy is saved; the power generation efficiency is improved; and the cost is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

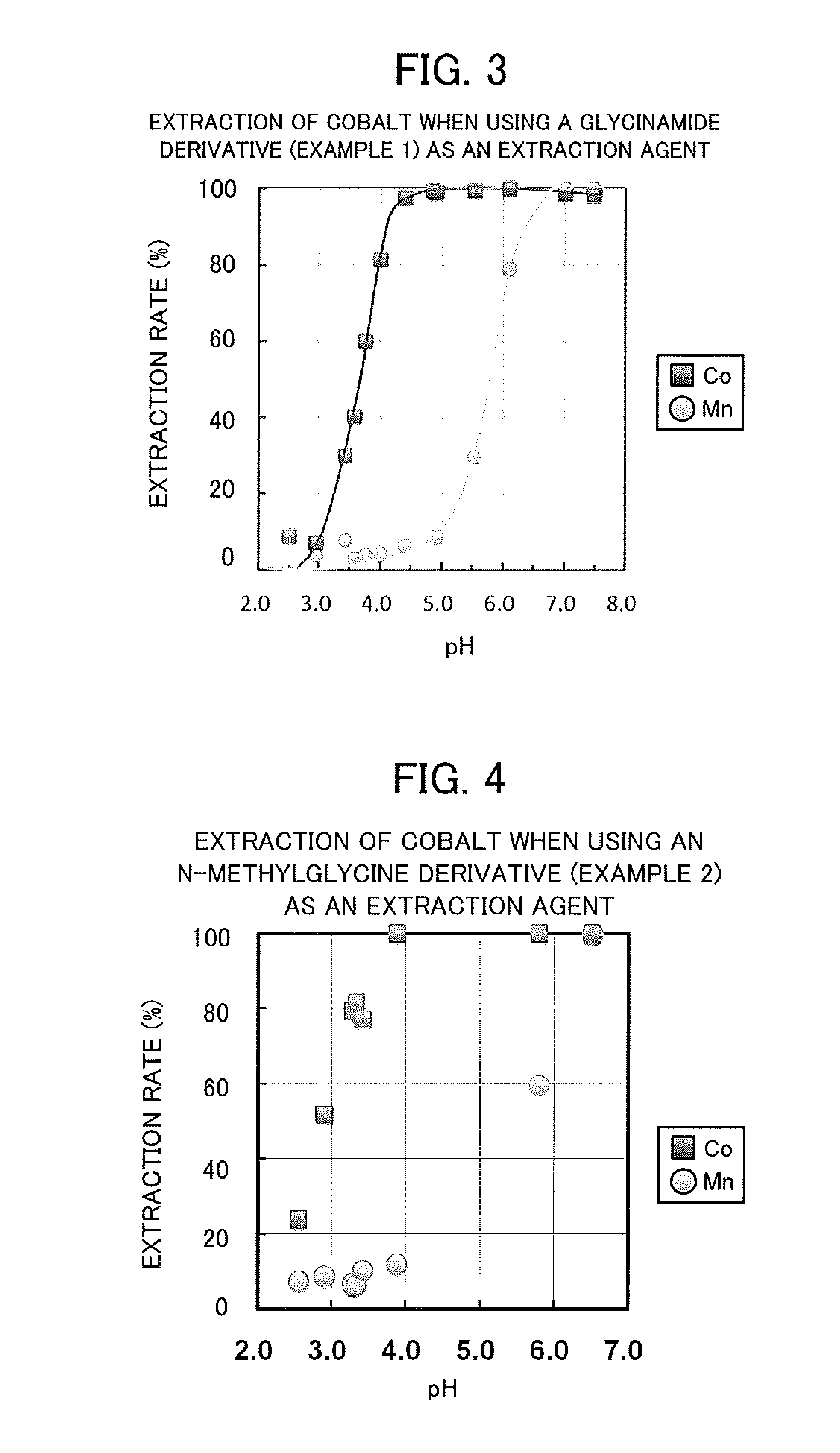

Valuable metal extraction agent and valuable metal extraction method using said extraction agent

The objective of the present invention is to selectively extract light rare earth metals, and by extension, europium, from an acidic solution containing a plurality of types of rare earth metal. This valuable metal extraction agent is represented by the general formula. In the formula: R1 and R2 each indicate the same or different alkyl group; R3 indicates a hydrogen atom or an alkyl group; and R4 indicates a hydrogen atom or any given group other than an amino group bonded to the α carbon as an amino acid. Preferably, the general formula has a glycine unit, a histidine unit, a lysine unit, an aspartic acid unit, or an N-methylglycine unit. Preferably, when extracting europium using the extraction agent, the pH is adjusted into the range of 2.0-3.0 inclusive, and when selectively extracting light rare earth metals, the pH is adjusted to 1.7-2.7 inclusive.

Owner:KYUSHU UNIV +1

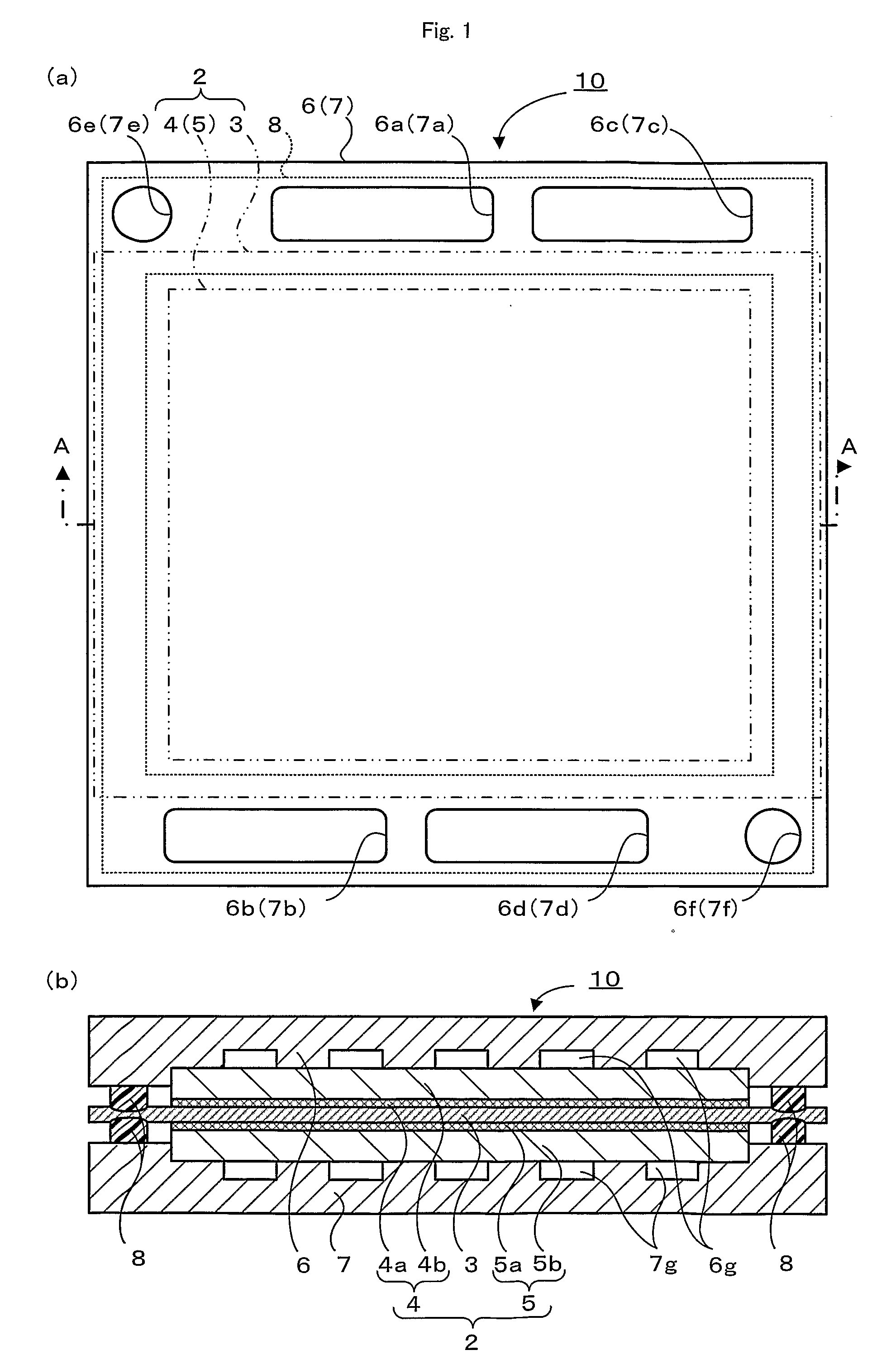

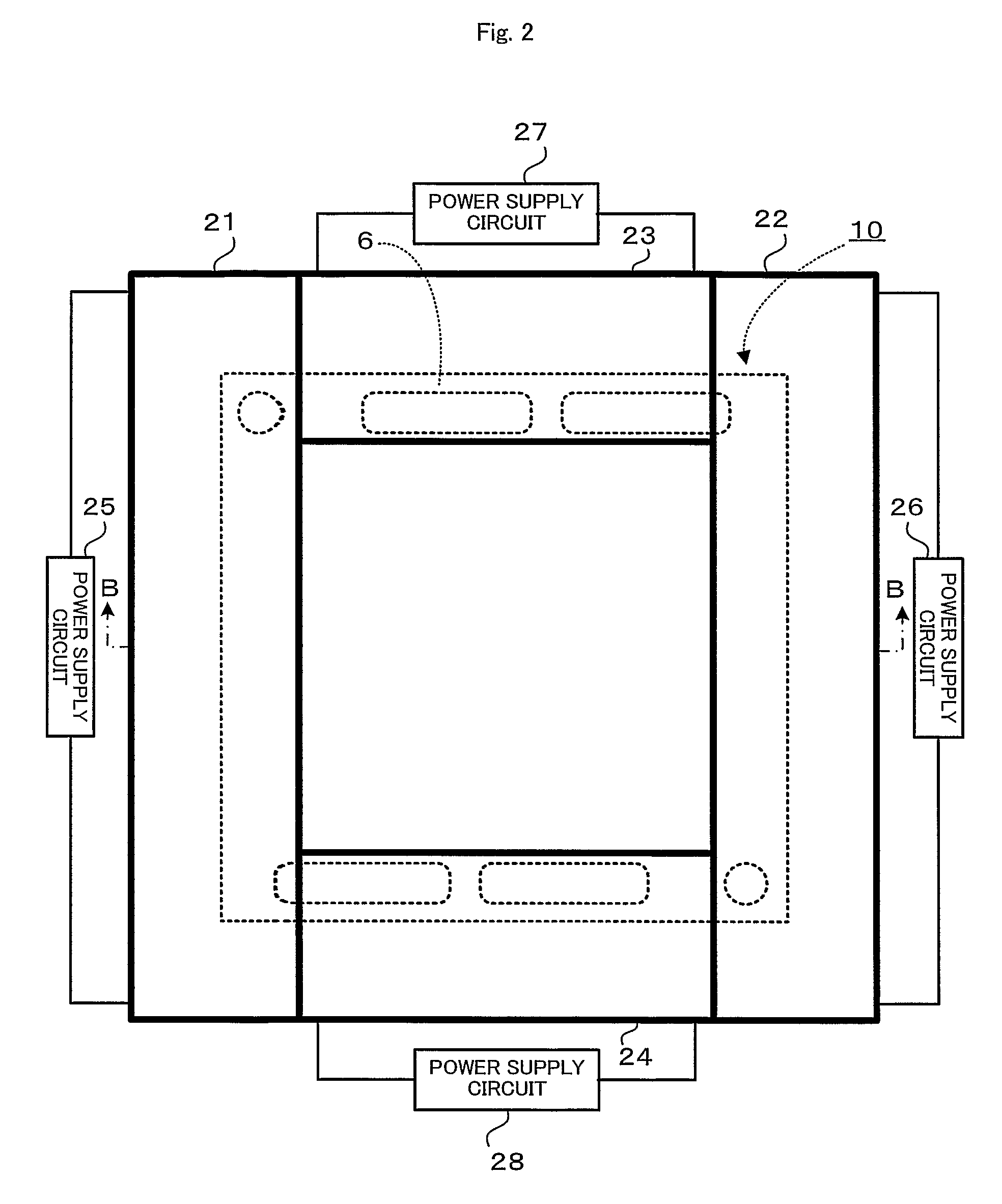

Fuel cell disassembly method

ActiveUS20070151088A1Easy to separateSimple structurePrimary cell maintainance/servicingFuel cells groupingFuel cellsElectrical and Electronics engineering

Respective heaters 21 through 24 receive power supply and start heating. The heaters 21 through 24 keep heating sealing layers 8 to or over a softening temperature at which the sealing layers 8 are softened or molten. After the sealing layers 8 are softened or molten to weaken the adhesive force between a pair of separators 6 and 7, the heaters 21 through 24 are detached from a fuel cell 10. The worker then completely separates the pair of separators 6 and 7 from each other with some tool or by hand and removes an MEA 2 from the fuel cell 10.

Owner:TOYOTA JIDOSHA KK

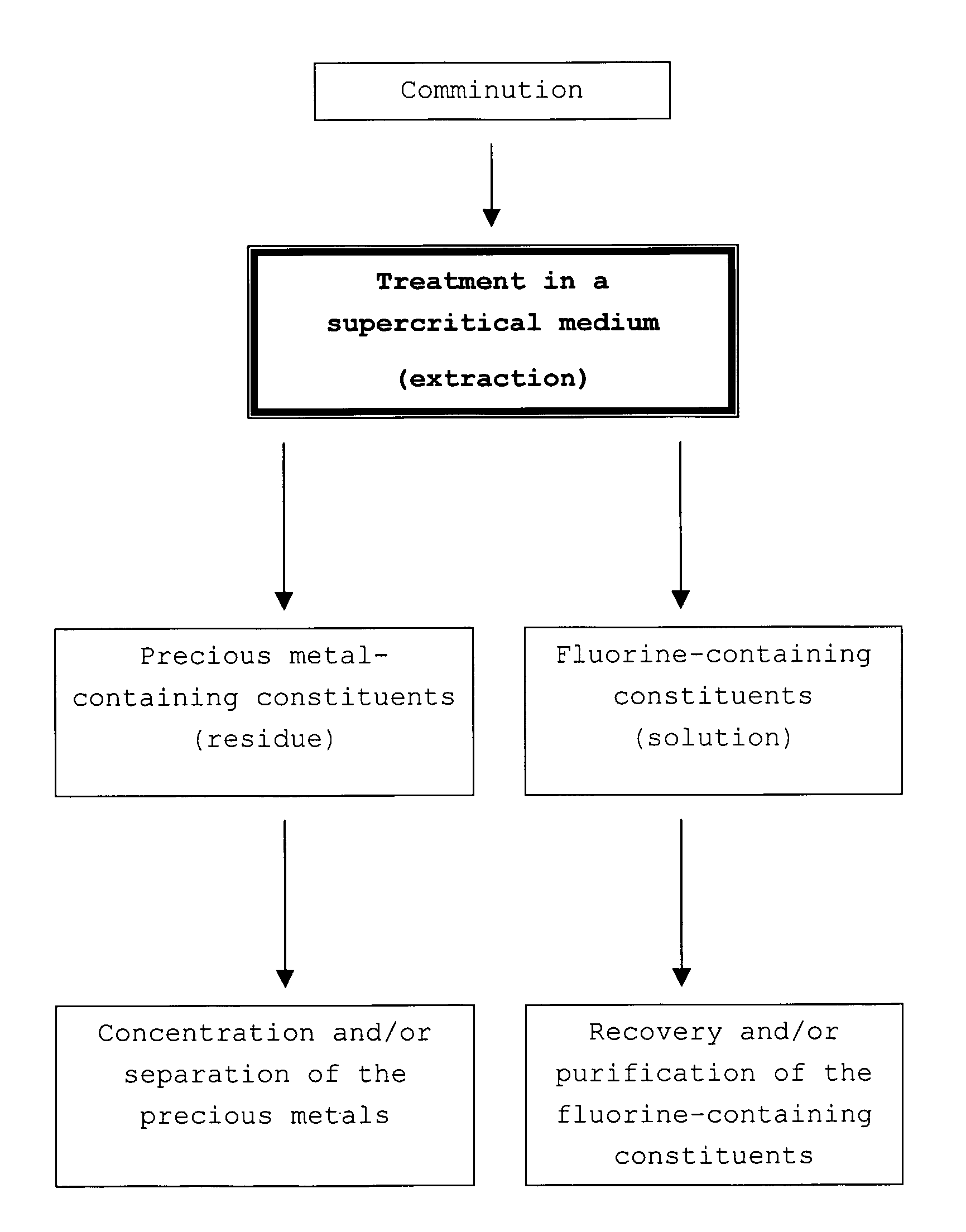

Process for recycling fuel cell components containing precious metals

InactiveUS7713502B2Overcome disadvantagesFuel cells disposal/recyclingRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsHydrogen fluorideElectrolysis

The invention relates to a process for recycling fuel cell components containing fluorine-containing and precious metal-containing constituents: in this process, the fluorine-containing constituents are separated off from the precious metal-containing constituents by treatment with a medium present in the supercritical state. Preference is given to using water as supercritical medium. After the fluorine-containing constituents have been separated off, the precious metal-containing residues can be recovered in a recycling process without harmful fluorine or hydrogen fluoride emissions. The fluorine-containing constituents can likewise be recovered. The process is used in the recovery of precious metals and / or fluorine-containing constituents from membrane fuel cells, electrolysis cells, batteries, sensors and other electrochemical devices.

Owner:UMICORE AG & CO KG

Process for recovery of ruthenium from a ruthenium-containing supported catalyst material

InactiveUS20080287282A1High purityHigh purity gradeCell electrodesFinal product manufactureHydrogen halideRuthenium Compounds

Process to recover ruthenium in the form of ruthenium halide, particularly ruthenium chloride, from a ruthenium-containing supported catalyst material comprising:a) chemically decomposing the ruthenium-containing supported catalyst material;b) producing a raw ruthenium salt solution;c) purifying the raw ruthenium salt solution and optionally stripping gaseous ruthenium tetroxide from the raw ruthenium salt solution; andd) treating the purified ruthenium compound obtained in c), particularly the ruthenium tetroxide, with hydrogen halide or hydrohalic acid to obtain ruthenium halide, particularly with hydrogen chloride or hydrochloric acid to obtain ruthenium chloride.

Owner:BAYER MATERIALSCIENCE AG

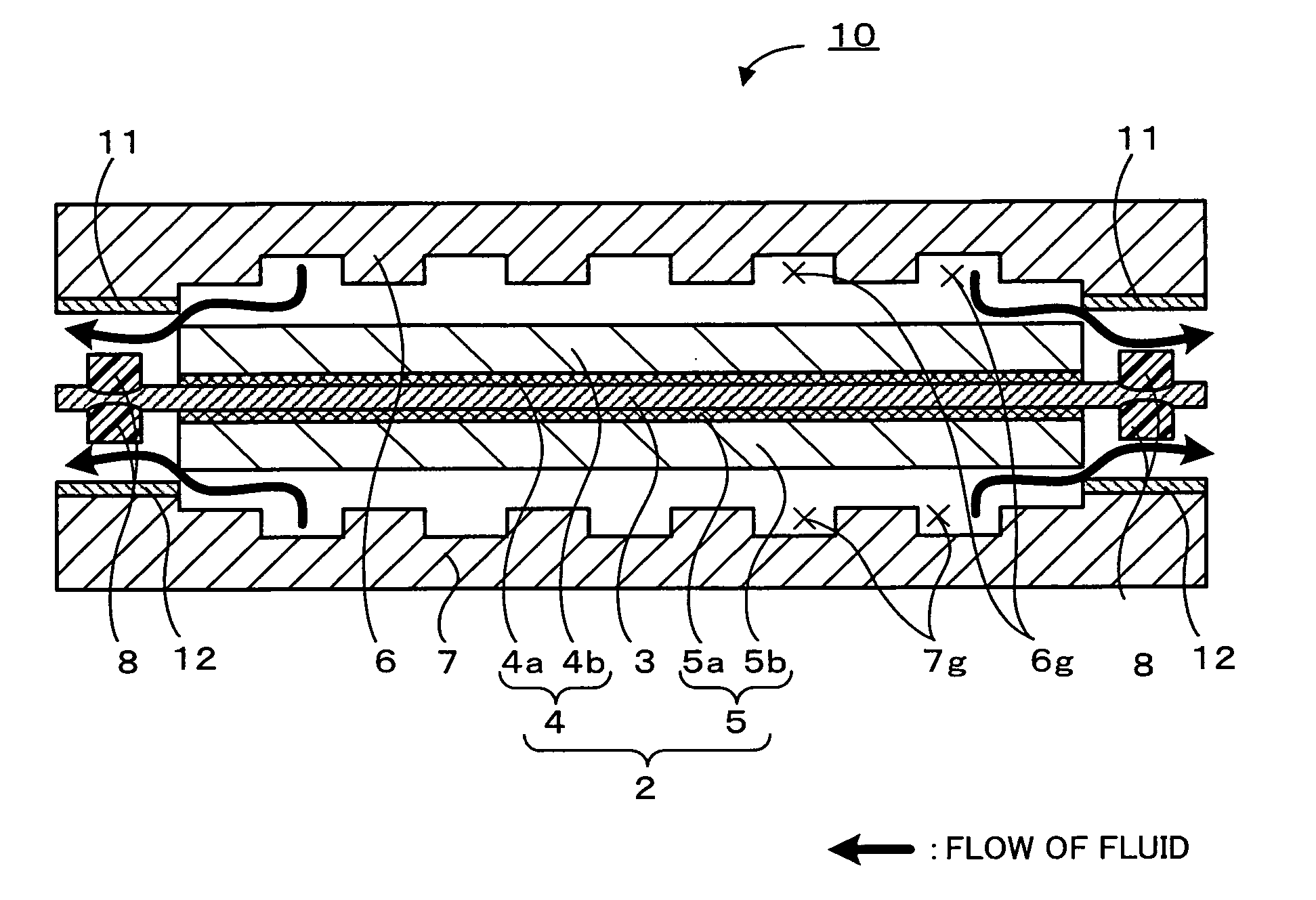

Fuel cell disassembly method and fuel cell

InactiveUS20070082250A1Easy to disassembleEasy to disengagePrimary cell maintainance/servicingFuel cells groupingInternal pressureFuel cells

A process of disassembling a fuel cell 10 supplies a fluid to both a fuel gas conduit 6g and an oxidizing gas conduit 7g. Since outlets of the respective gas conduits 6g and 7g are shielded, the internal pressure or in-passage pressure of the respective gas conduits 6g and 7g gradually rises and eventually exceeds a specific in-passage pressure level for power generation of the fuel cell 10. The high in-passage pressure expands a gas diffusion electrode 4b of a membrane electrode assembly (MEA) 2 and a separator 6, which define the fuel gas conduit 6g, in opposite directions to make a clearance between the gas diffusion electrode 4b and the separator 6. Similarly the high in-passage pressure expands a gas diffusion electrode 5b of the MEA 2 and a separator 7, which define the oxidizing gas conduit 7g, in opposite directions to make a clearance between the gas diffusion electrode 5b and the separator 7. The supplied fluid then flows out through these clearances into seals between the separators 6 and 7 and the MEA 2. These flows raise the in-passage pressure and release the seals.

Owner:TOYOTA JIDOSHA KK

Recycling method of vanadium flow battery electrolyte

ActiveCN106532079ANo side effectsLow priceFuel cells disposal/recyclingBattery recyclingElectricityPre treatment

The invention relates to a recycling method of a vanadium flow battery electrolyte. According to the method, the electrolyte of the flow battery of which the capacity fades after charge and discharge use is taken as a raw material, a reducing agent or an oxidizing agent is added to the raw material after pretreatment, the concentration of vanadium ions in the electrolyte is adjusted and the electrolyte can be repeatedly recycled. A waste electrolyte is pretreated, a proper reducing agent or oxidizing agent is added to the waste electrolyte and the concentration of the vanadium ions in the electrolyte is adjusted, so that the problem of recycling of the waste electrolyte is finally solved and efficient utilization of the electrolyte is achieved. The recycling method is simple in process, simple and convenient to operate, simple and available in raw material, low in cost and significant in effect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

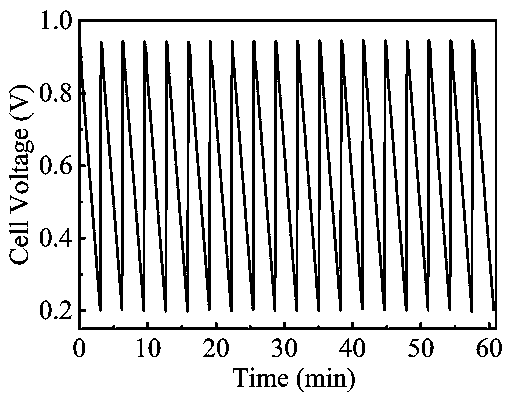

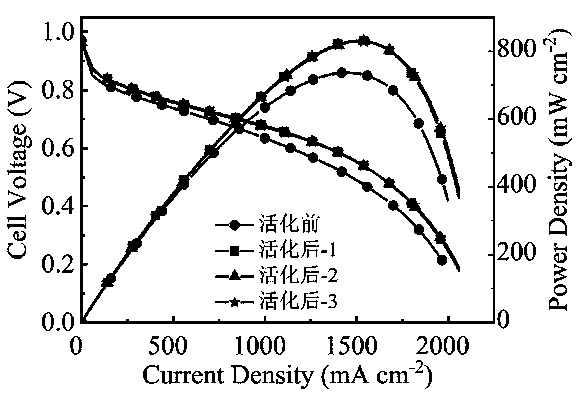

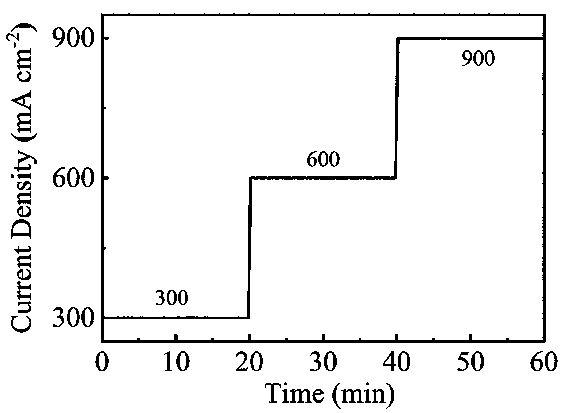

Rapid activation method for film electrode of proton exchange film fuel cell and application thereof

ActiveCN110783589AQuick buildImprove activation efficiencyFuel cells disposal/recyclingBattery recyclingChemical physicsFuel cells

The invention relates to a rapid activation method for a film electrode of a proton exchange film fuel cell and an application of the rapid activation method, and aims to enable the film electrode toreach an optimal state in a shorter time. The rapid activation method is continuous high-frequency variable-voltage forced activation in which voltage is linearly reduced at a constant rate. Comparedwith a constant-current activation mode in the prior art, an activation mode provided is simple and feasible, the activation time can be obviously shortened, and the activation mode has important significance for improving activation efficiency of the fuel cell, saving energy and reducing emission.

Owner:BEIJING UNIV OF CHEM TECH

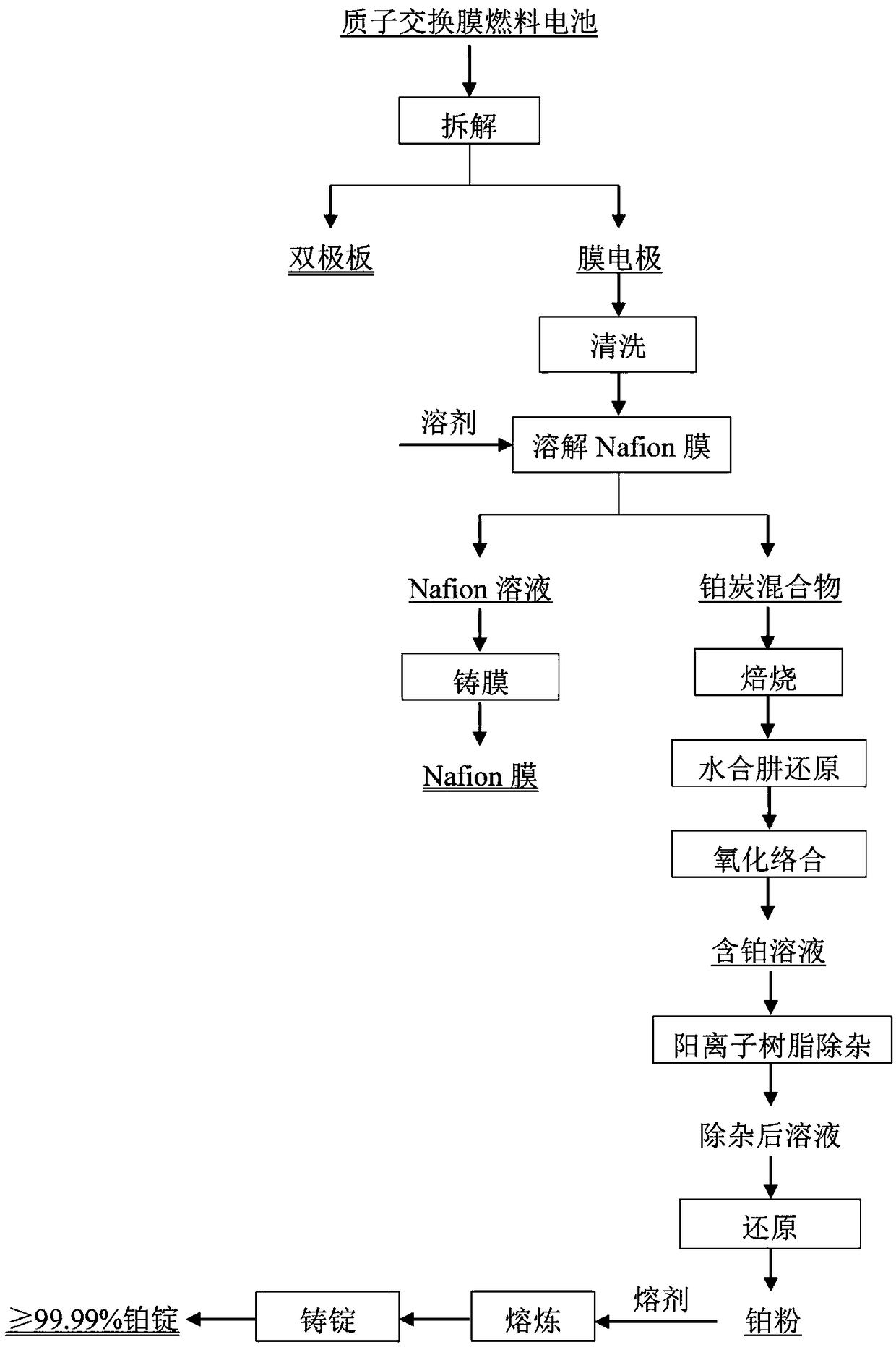

A method for recovering proton exchange membrane fuel cell

InactiveCN109088080AAchieve recyclingEfficient recyclingFuel cells disposal/recyclingBattery recyclingRecovery methodDissolution

The invention relates to a recovery method of a proton exchange membrane fuel cell, belonging to the field of resource recycling. The method comprises disassembly of a proton exchange membrane fuel cell, dissolution of a perfluorosulfonic acid (Nafion) membrane and regeneration of a cast membrane, oxidative complexation and purification of platinum, finally obtaining a bipolar plate, regeneratingthe Nafion membrane and the platinum ingot. The invention adopts organic solvent to dissolve and recover high-value Nafion membrane, avoids fluoride pollution caused by traditional direct incineration, and has remarkable economic benefit; Platinum ingots with purity over 99.99% are obtained by cationic resin adsorption and pyrometallurgical refining. The process is short and no pollutant is discharged, so it is suitable for industrial application.

Owner:UNIV OF SCI & TECH BEIJING

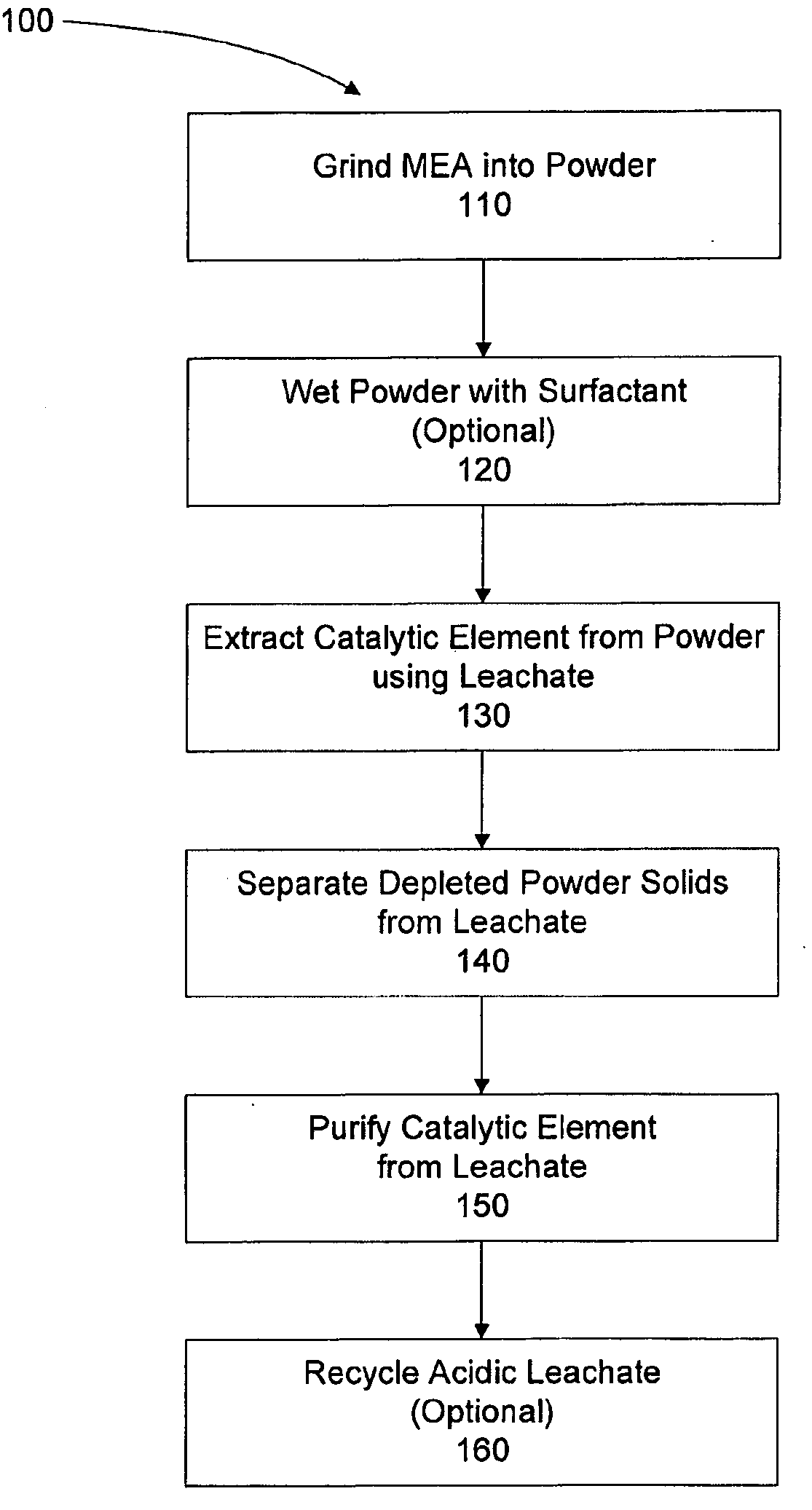

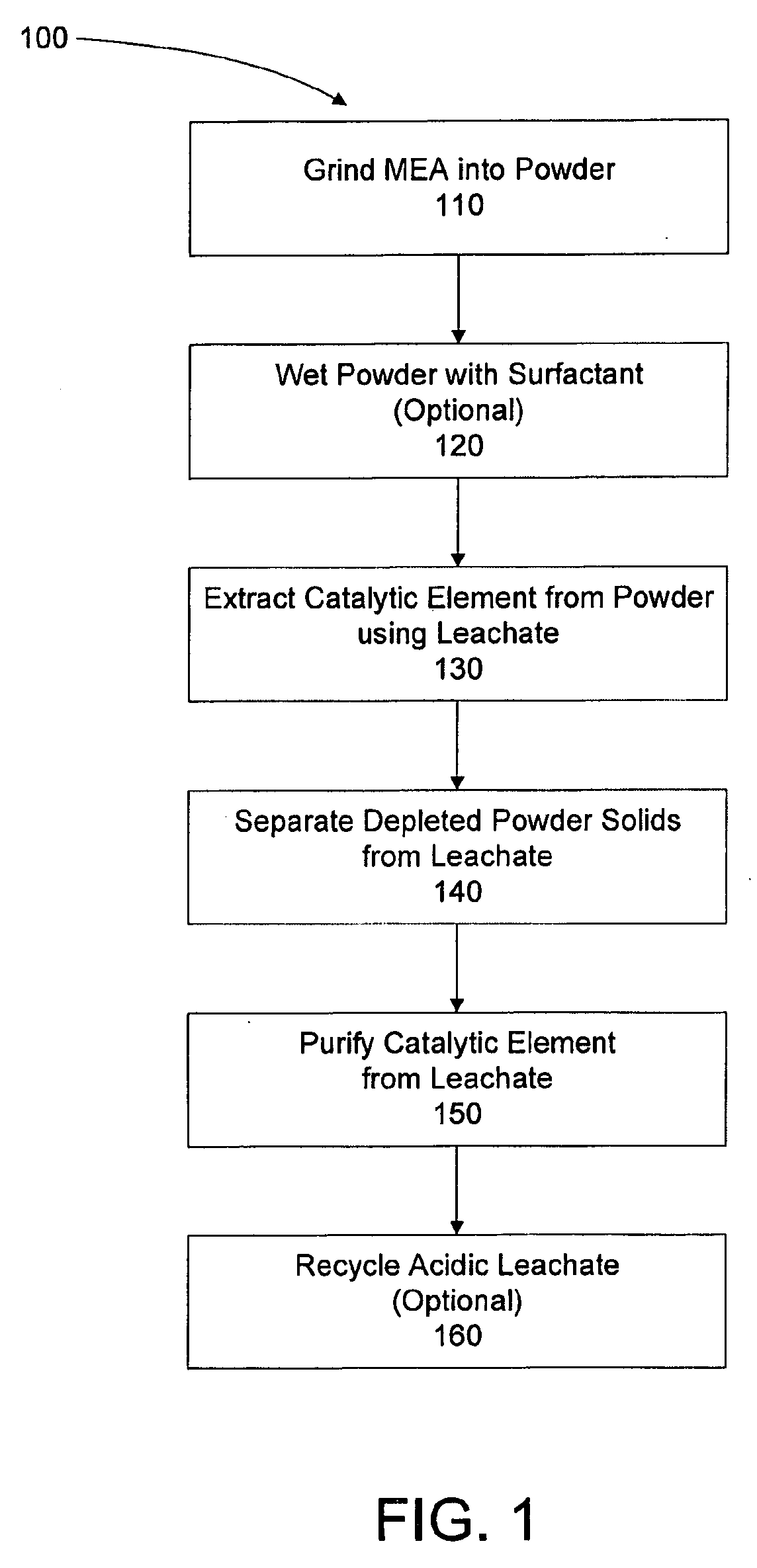

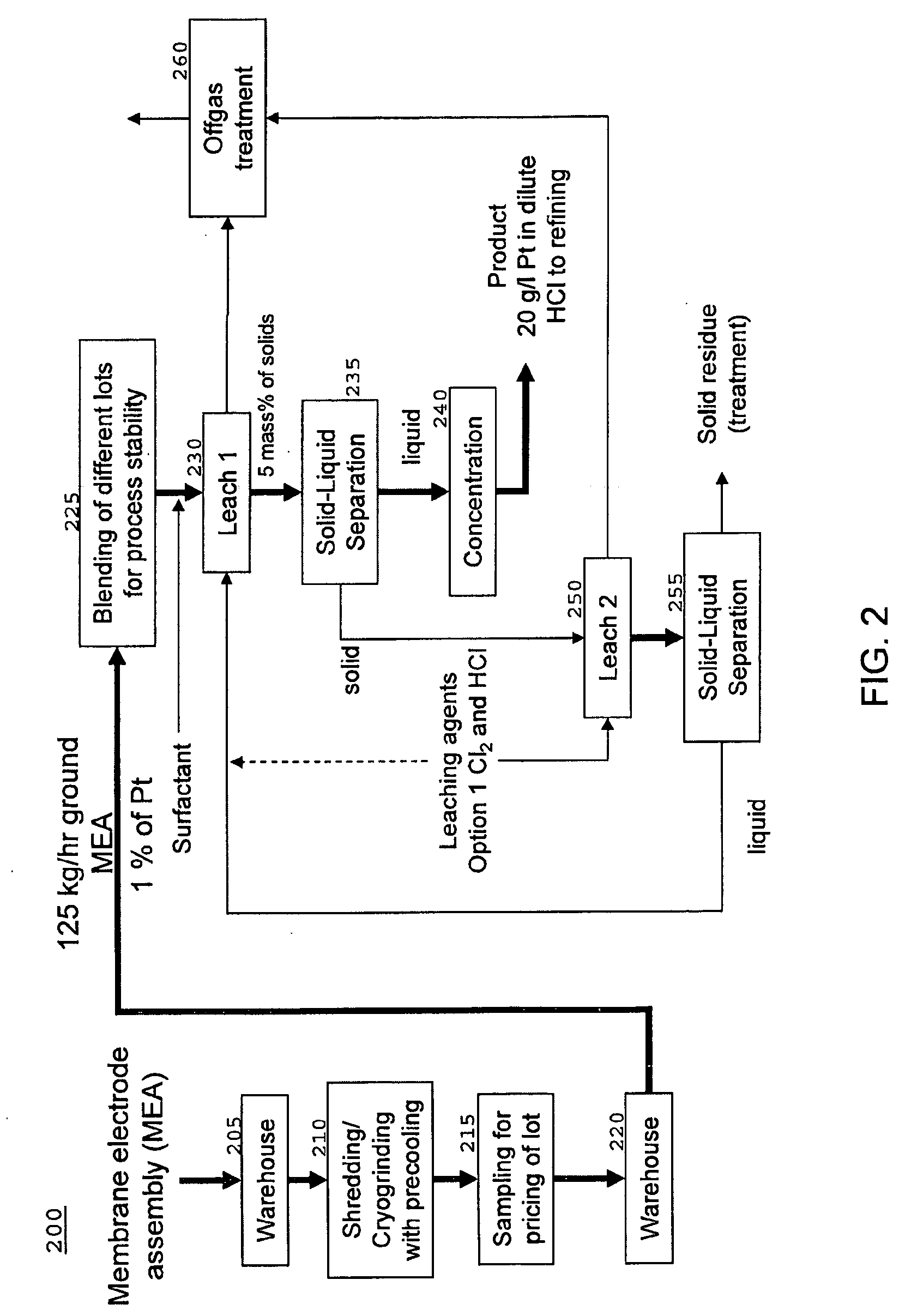

Efficient process for previous metal recovery from fuel cell membrane electrode assemblies

A method is provided for recovering a catalytic element from a fuel cell membrane electrode assembly. The method includes grinding the membrane electrode assembly into a powder, extracting the catalytic element by forming a slurry comprising the powder and an acid leachate adapted to dissolve the catalytic element into a soluble salt, and separating the slurry into a depleted powder and a supernatant containing the catalytic element salt. The depleted powder is washed to remove any catalytic element salt retained within pores in the depleted powder and the catalytic element is purified from the salt.

Owner:BASF CORP

Method for recycling membrane electrode of proton exchange membrane fuel cell

The invention relates to a method for recycling a membrane electrode of a proton exchange membrane fuel cell. The membrane electrode comprises a cathode catalysis layer, an anode catalysis layer and a proton exchange membrane. The method comprises the following steps: putting a to-be-recycled membrane electrode into alcohol-water mixed liquid, and carrying out ultrasonic treatment or wet-process ball milling until the cathode catalysis layer and the anode catalysis layer are completely separated from the proton exchange membrane; taking out the processed membrane electrode, and cleaning, so as to obtain a recycled to-be-used electrolyte membrane; and carrying out solid-liquid separation on black slurry, and carrying out high-temperature processing on solid matters, so as to obtain a catalyst containing precious metals. Compared with the prior art, the method has the advantage that the cost of the proton exchange membrane fuel cell is lowered. The method has the outstanding characteristics that the catalysis layers and the membrane in an MEA of the proton exchange membrane fuel cell are separated by virtue of a mild method and are respectively recycled; and the recycled catalyst can be repeatedly used or can be further purified, so as to obtain the precious metals, and the recycled electrolyte membrane can be repeatedly used or can be further dissolved, so as to obtain an electrolyte membrane emulsion or a re-cast membrane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

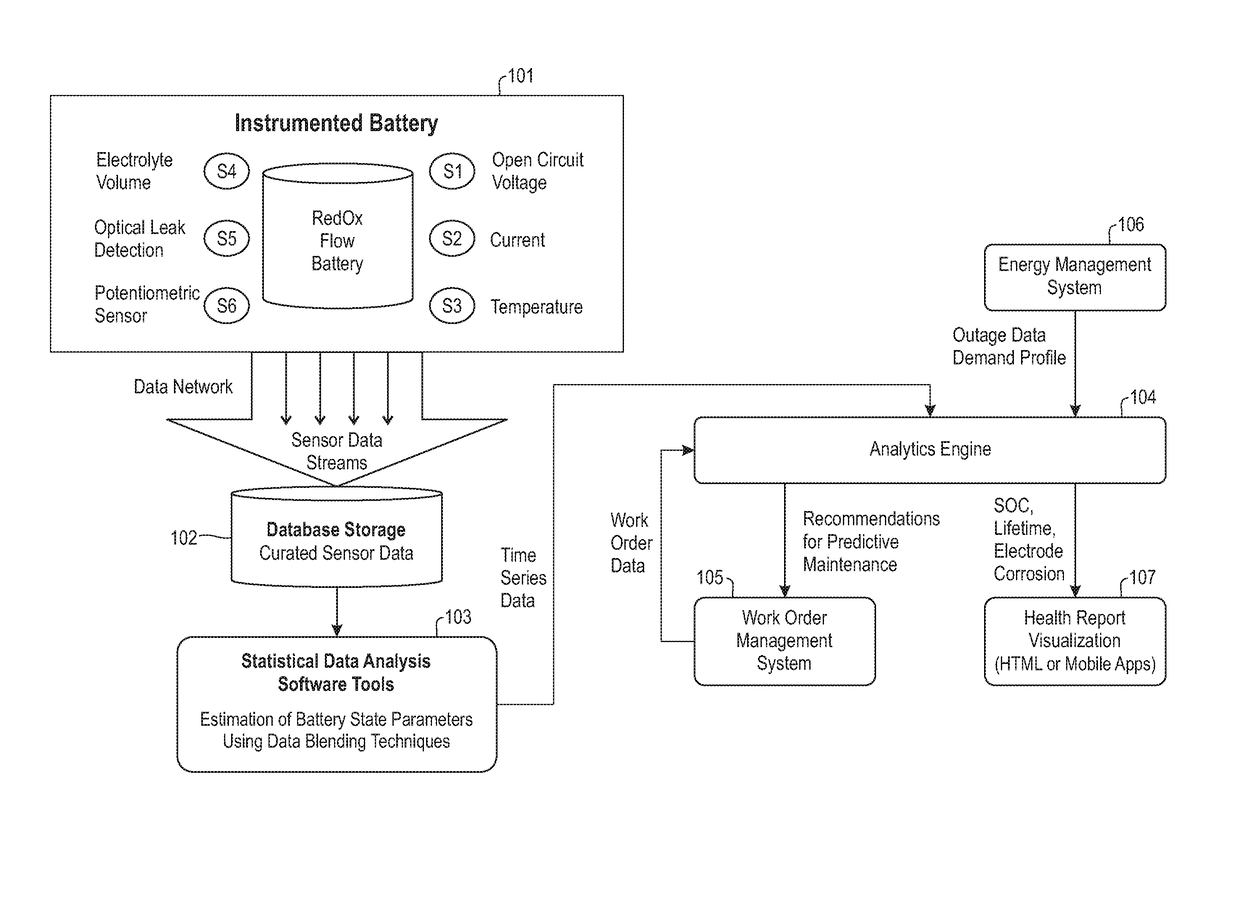

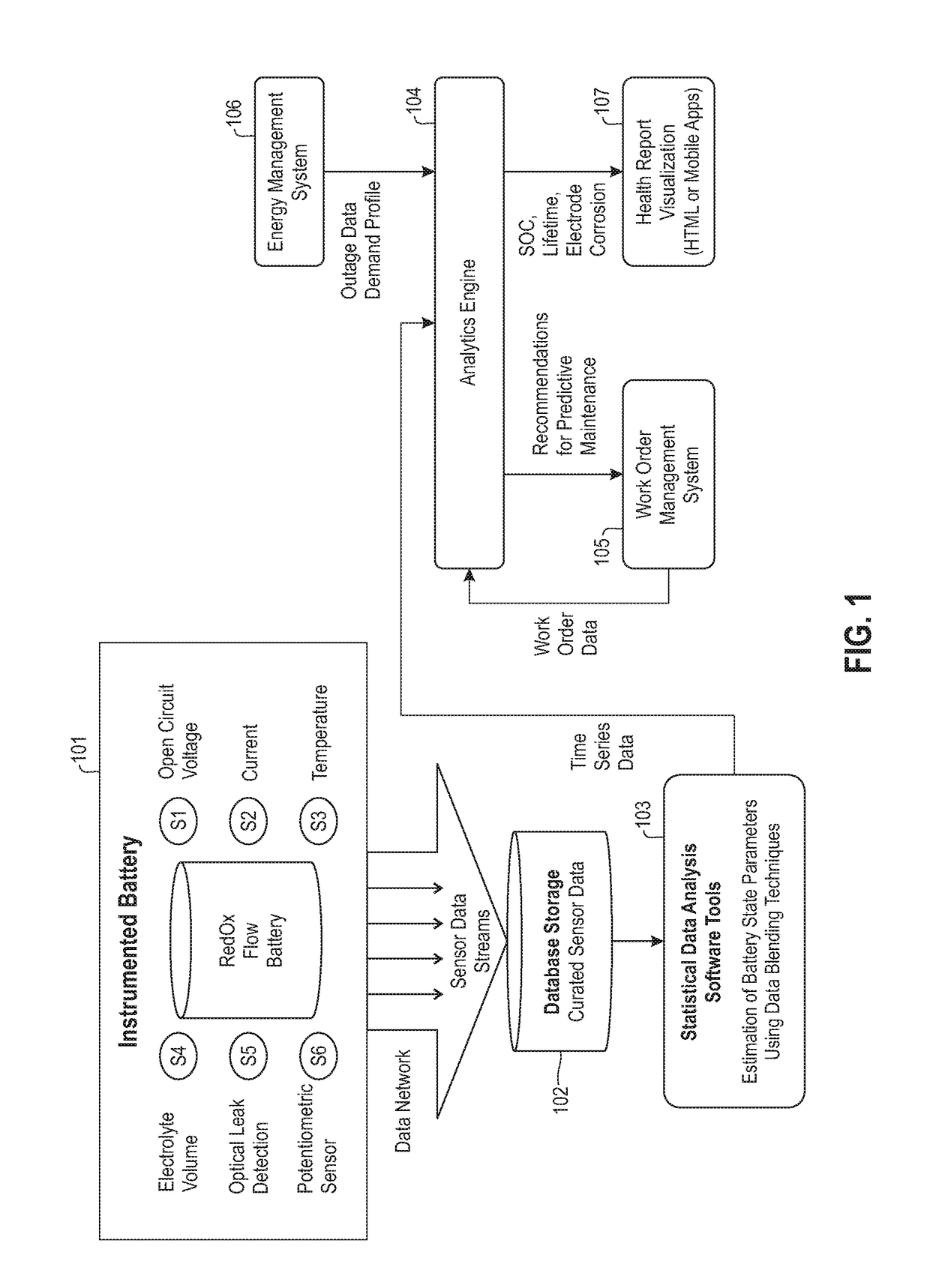

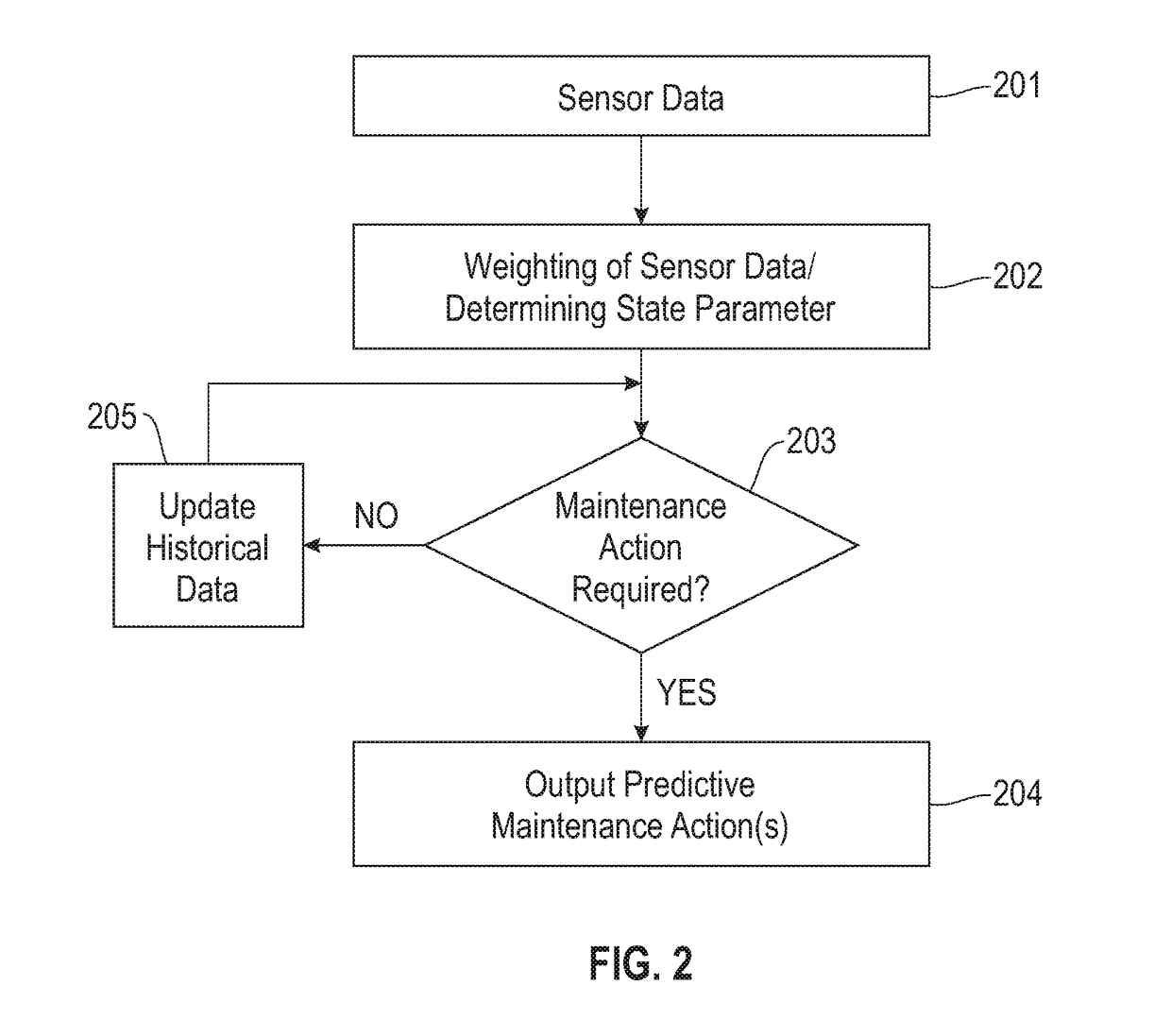

System and method for condition monitoring of redox flow batteries using data analytics

One embodiment provides a method for predicting maintenance of a redox flow battery, the method including: receiving, from a plurality of sensors, data regarding characteristics of the redox flow battery; weighting, using a processor, each of the characteristics to form an estimated state parameter for the redox flow battery; and determining, using the processor, a maintenance action for the redox flow battery using the estimated state parameter. Other aspects are described and claimed.

Owner:IBM CORP

Method for recycling vanadium electrolytic solution

ActiveCN106340657AAchieve recyclingExtended operating cycleFuel cells disposal/recyclingRegenerative fuel cellsSulfate radicalsElectrolyte

The invention provides a method for recycling vanadium electrolytic solution. The method comprises the steps of determining the concentration of all-vanadium ion in the high valence vanadium positive electrolytic solution C1 and V<5+> concentration c11; adding V205, wherein the quantity of V205 substance n1 is determined by C1, V1, concentration of vanadium ion of target electrolyte solution C2 and volume V2; adding reductant to conduct reduction reaction; measuring the concentration of sulfate radical in the solution after reduction reaction CS1 and volume V1-2; adding vitriol, wherein the quantity of vitriol substance n2 is determined by CS1, V1-2, V2 and concentration of sulfate radical needed by target electrolyte solution; adding water into the solution after vitriol is added to obtain the target electrolyte solution with the volume V2. According to the method for recycling vanadium electrolytic solution, waste electrolyte solution can be recycled and treated in batches, recycling of the electrolytic solution is achieved, moreover, the method is simple to operate. The vanadium electrolytic solution can be treated nearby, and is beneficial to prolonging operational cycle of the vanadium battery.

Owner:SICHUAN PAN YAN TECH

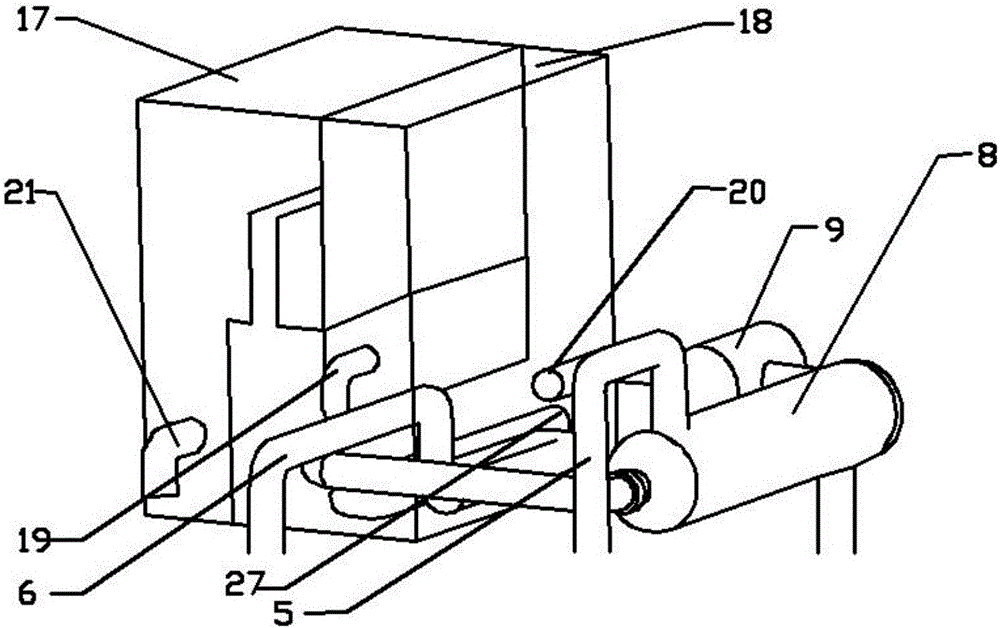

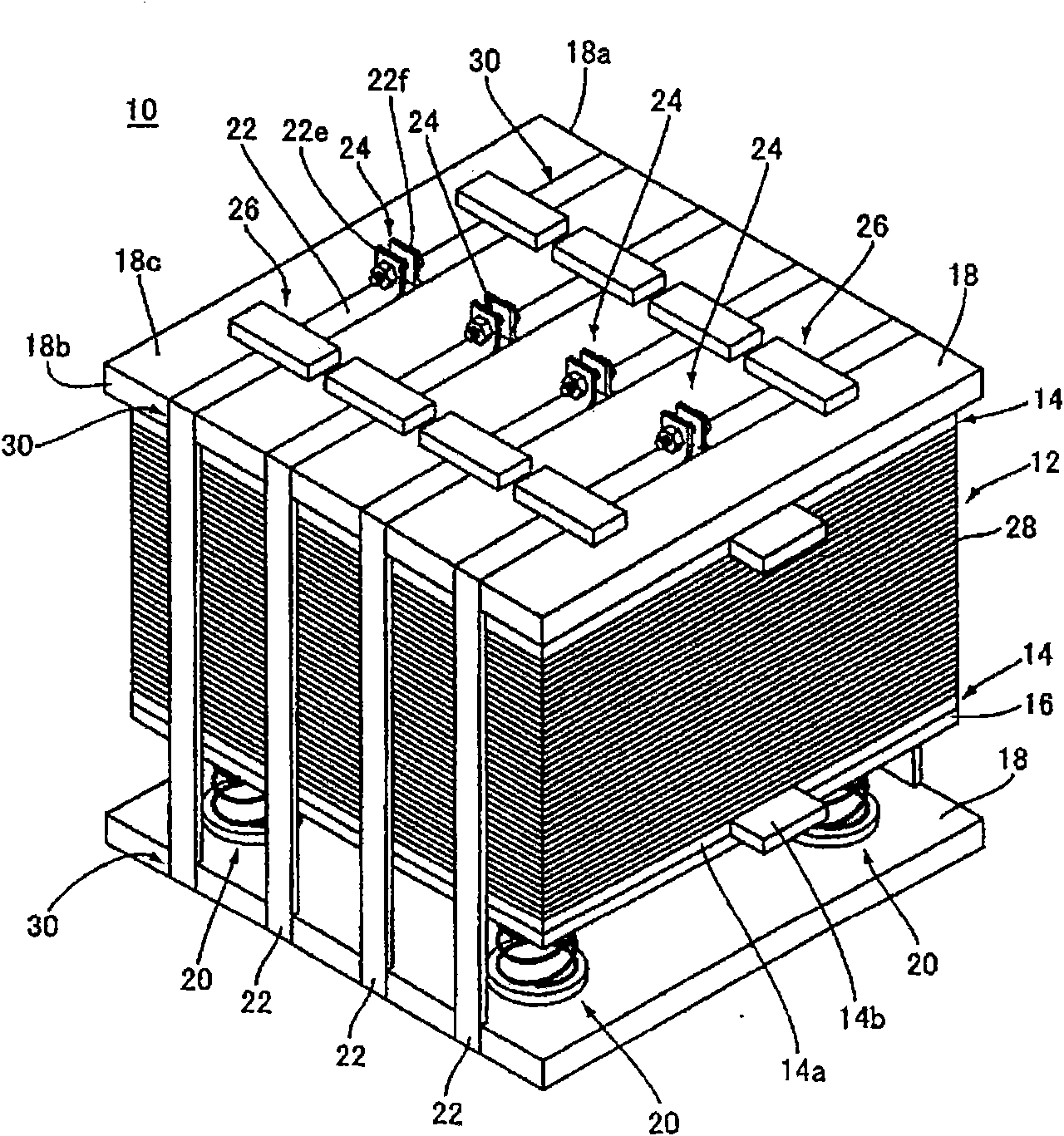

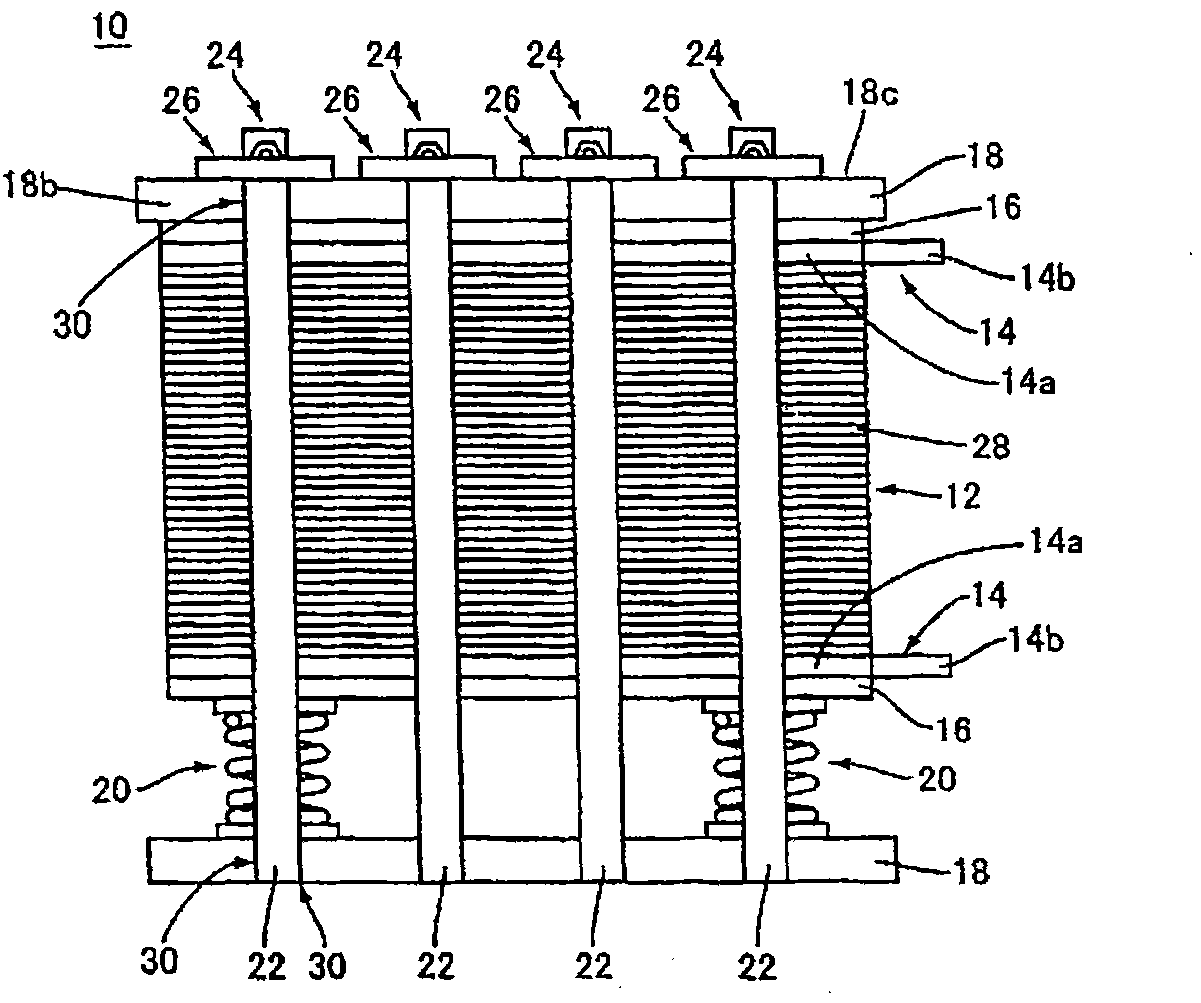

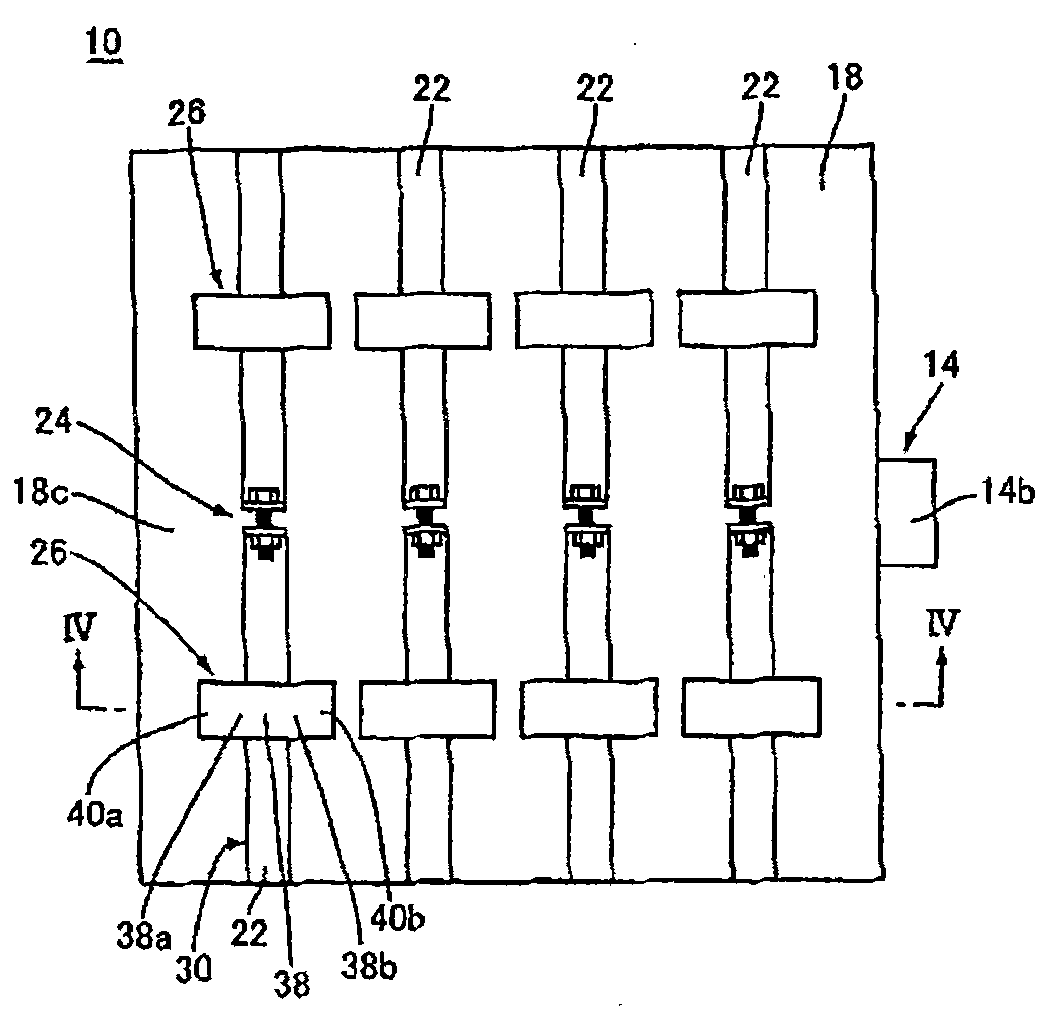

Fuel cell and method for diassembling the same

InactiveCN102037597AImprove securityReactant parameters controlFuel cells groupingFuel cellsEngineering

The invention relates to a fuel cell and a method for diassembling the same. The fuel cell (10) comprises: two end plates (18) arranged on either side of a cell stack (12) in the direction of lamination thereof; a fastening band (22) for fastening the cell stack (12) and the end plates (18) in the direction of lamination; a connecting portion (24) for connecting one end portion (22e) of the fastening band (22) with the other end portion (22f) thereof; and a displacement restricting portion (26) provided in at least one of the two end plates (18) for restricting the displacement of the fastening band (22) in the direction away from a surface (18c) of the end plates (18).

Owner:PANASONIC CORP

Battery device and packaging, dismounting and recovering method of same

InactiveCN101944623AEasy to packFast packFuel and primary cellsFuel cells disposal/recyclingRecovery methodBiochemical engineering

The invention relates to a battery device and a packaging, dismounting and recovering method of same. The method comprises the following steps of: firstly, arranging an anode conducting assembly in a reaction tank frame, and protruding an anode conducting bump out of the reaction tank frame; subsequently, respectively covering a first opening and a second opening of the reaction tank frame by using two groups of cathode conducting assemblies to form a reaction area capable of accommodating electrolyte; subsequently, laying a metal fixing part on the surfaces of the cathode conducting assemblies and the reaction tank frame; and finally, fastening the metal fixing part by using a fastener. Thus, the battery device provided by the invention for a user has the characteristics of simple structure, rapid packaging, dismountability and recyclability through special structural design, and thus, the problems of difficult packaging and dismounting, difficult recovering and the like caused by complex structure of the traditional battery device are solved.

Owner:OPEN MINDER GROUP

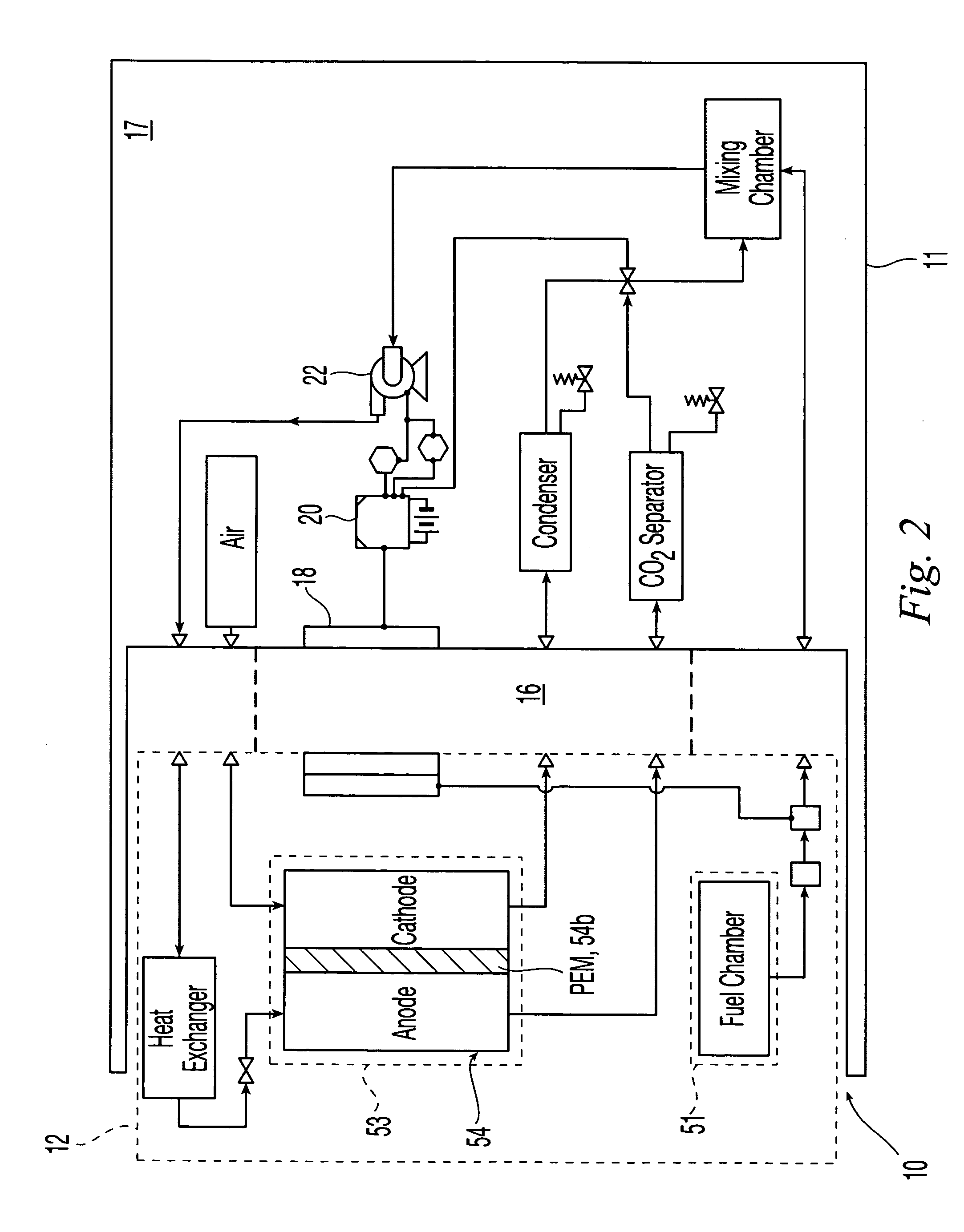

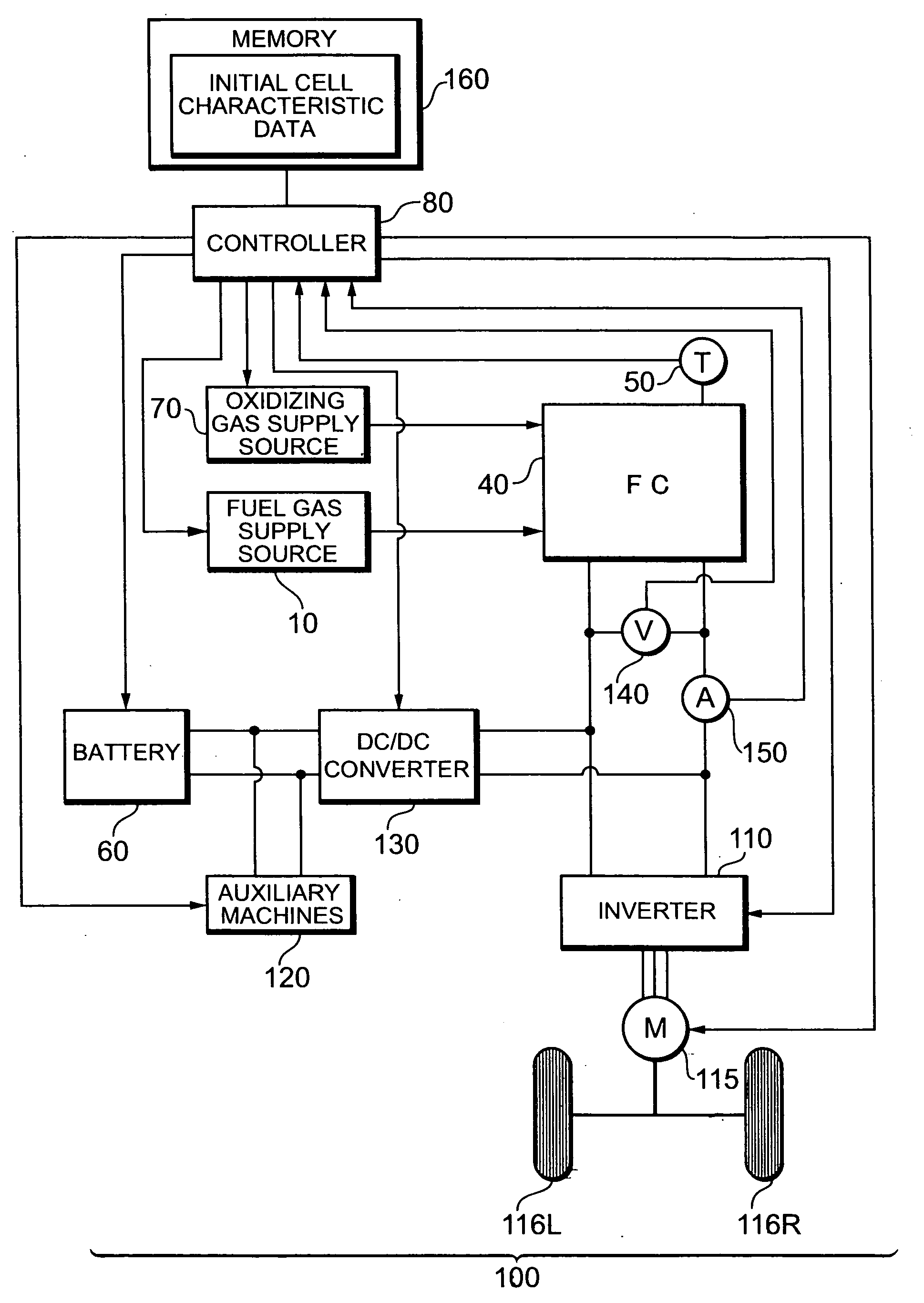

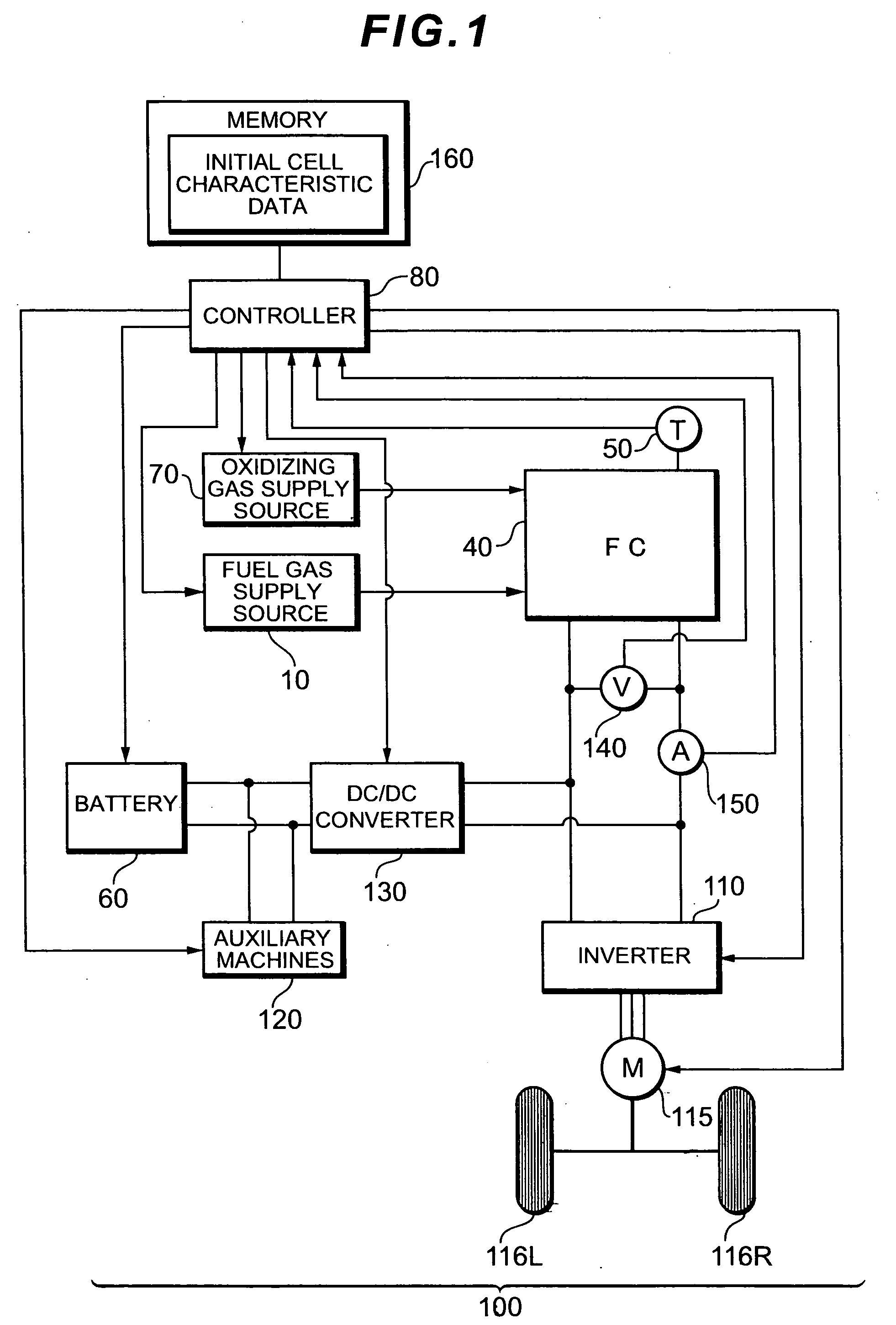

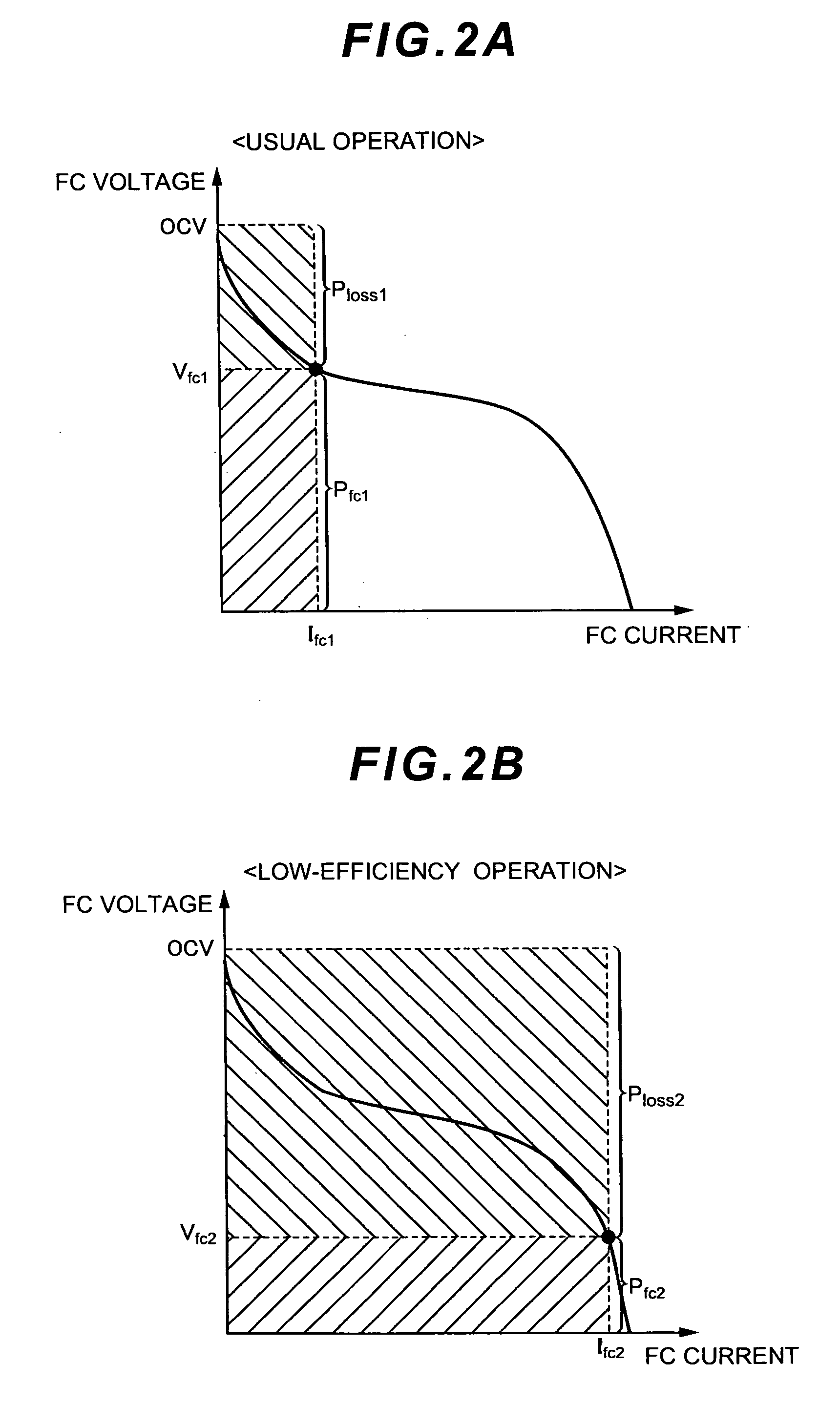

Fuel Cell System

ActiveUS20090130509A1Reduce functionRecoverable catalyst deteriorationFuel cells disposal/recyclingFuel cell auxillariesFuel cellsOperation point

There is disclosed a fuel cell system in which a poisoned electrode catalyst can be recovered while meeting a demand for an output power. When a controller detects that an electrode catalyst is positioned, the controller derives a target operation point adequate for recovering a function of the poisoned electrode catalyst to realize shift of an operation point so that the output power is kept constant. Specifically, an FC voltage is controlled using a DC / DC converter, and an amount of an oxidizing gas to be fed from an oxidizing gas supply source is adjusted, thereby controlling an FC current.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com