Battery device and packaging, dismounting and recovering method of same

A technology of a battery device and a packaging method, which is applied in the disposal/recycling of fuel cells, fuel cell-type half-cells, primary cell-type half-cells, and fuel cells, etc., can solve the difficulty of packaging and recycling, and the increase of labor and mechanical costs. , the difficulty of packaging and disassembly recycling, etc., to solve the difficulty of packaging and disassembly recycling, simplify packaging and disassembly steps, and save time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific examples, and various modifications and changes can be made to the details in this specification based on different viewpoints and applications without departing from the spirit of the present invention.

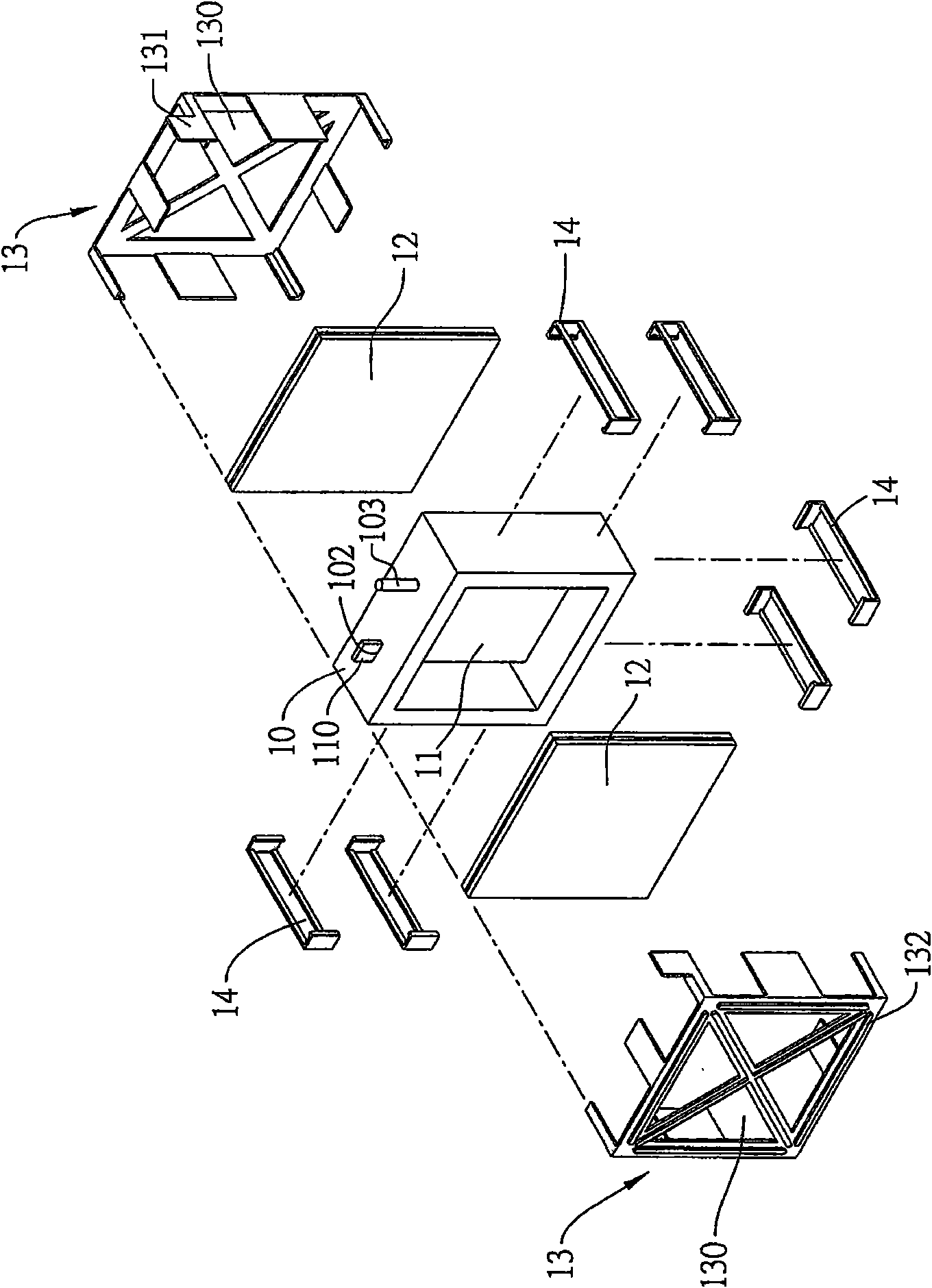

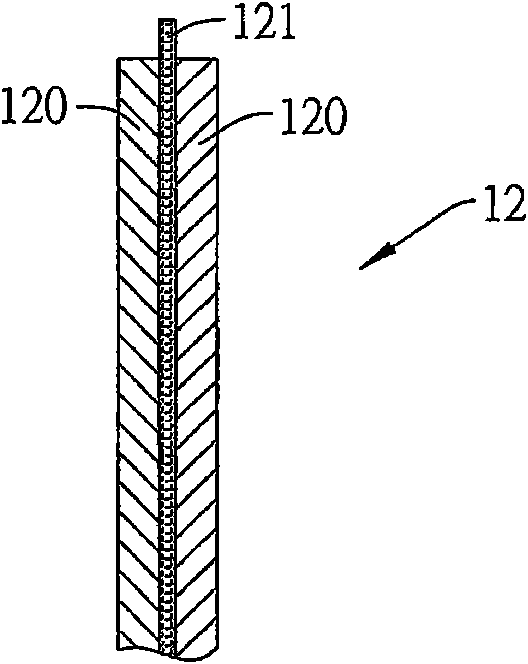

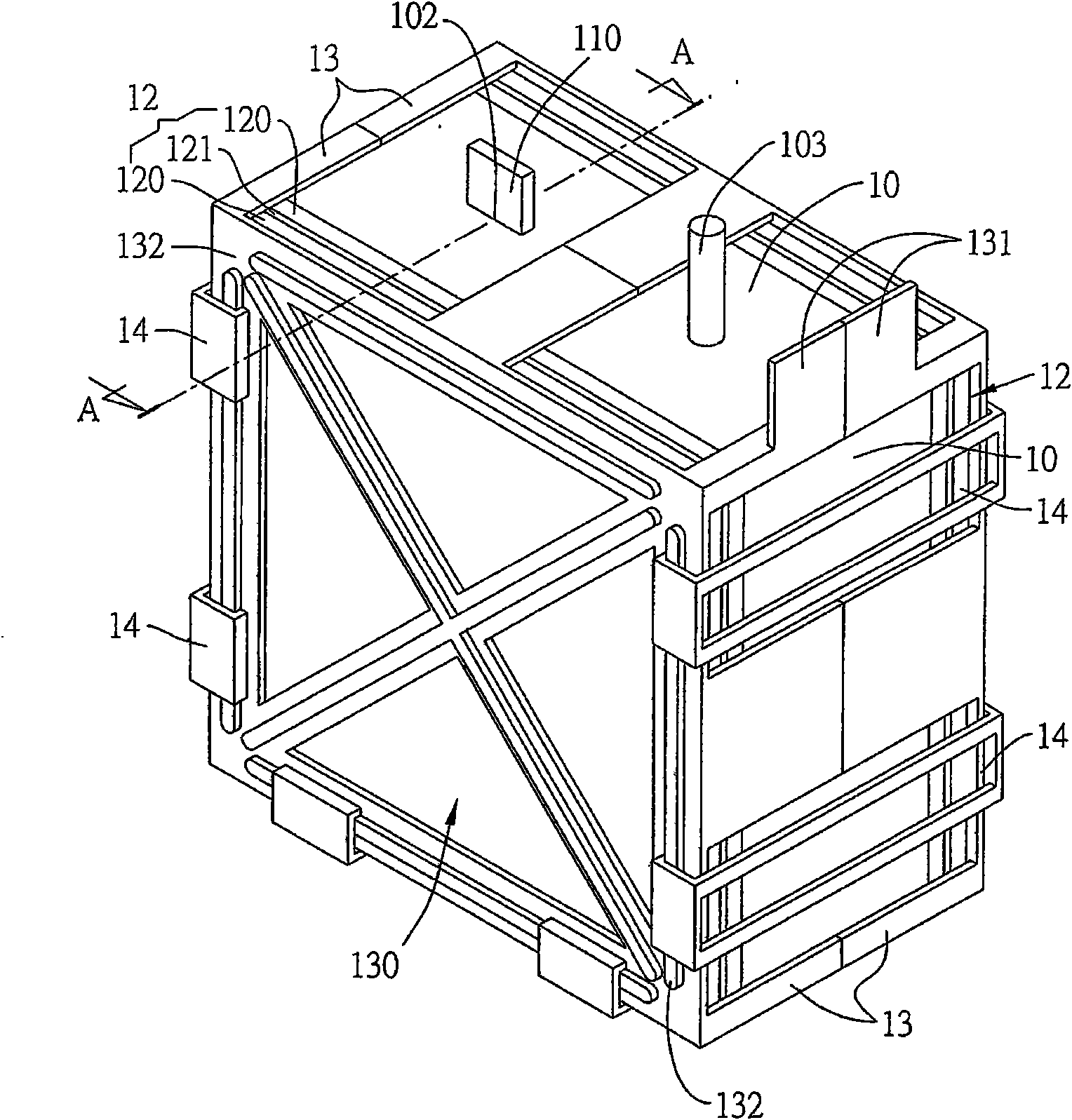

[0054] see Figure 1A , which is a three-dimensional exploded schematic view of the battery device 1 of the present invention. As shown in the figure, the battery device 1 includes: a reaction tank frame 10, an anode conductive component 11, two cathode conductive components 12, a metal fixing piece 13, and a buckle piece 14.

[0055] The reaction tank frame 10 is made of materials such as plastics, artificial rubber, natural rubber or ethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com