Exhaust gas recycling device of fuel cell

A tail gas recovery and fuel cell technology, which is applied in the disposal/recycling of fuel cells, fuel cells, battery recycling, etc., can solve the problems of no longer having drying capacity, high operating temperature of fuel cells, and heat consumption, etc., so as to improve energy utilization Efficiency, improvement of energy utilization rate, effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

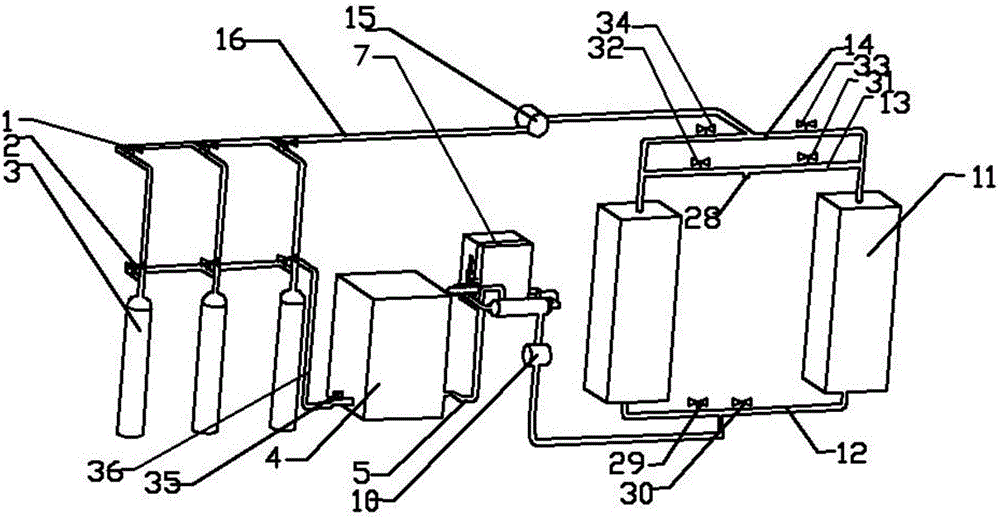

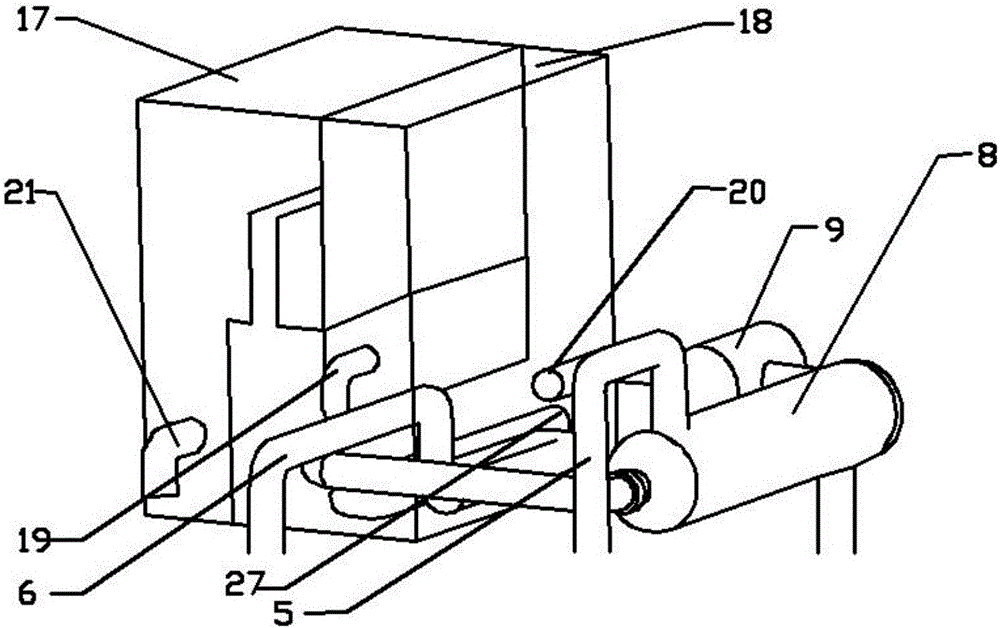

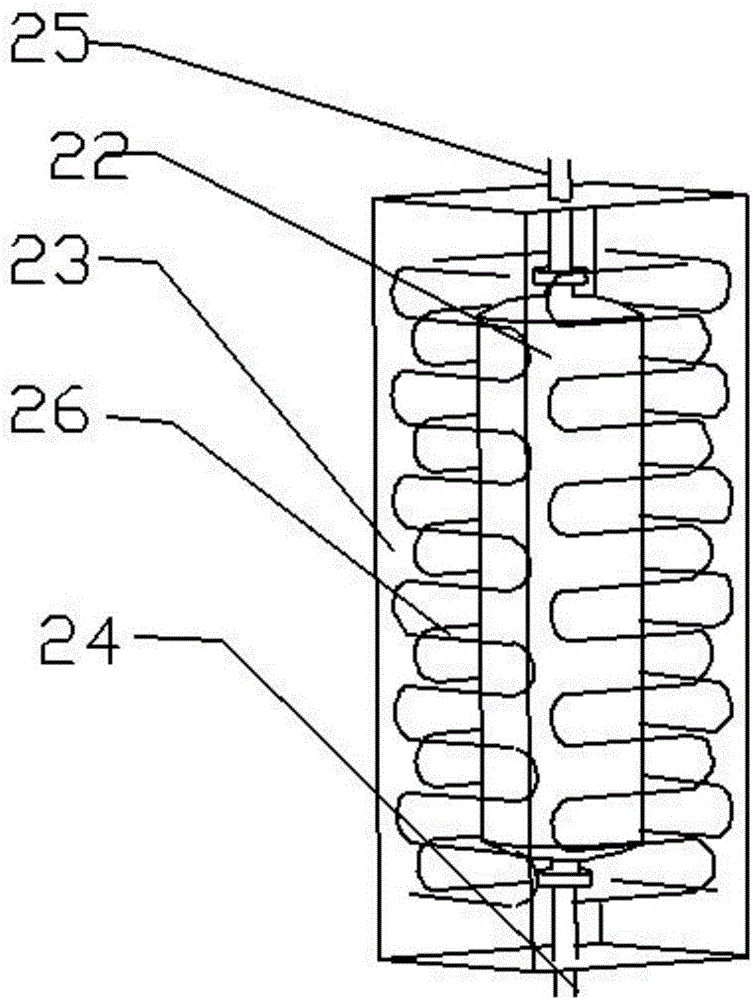

[0033] as attached figure 1 The shown fuel cell tail gas recovery and utilization device includes a three-stage hydrogen storage tank 3, an electric stack 4, a heat conversion device 7, a circulation pump 9, a heat exchanger 8, a gas-water separator 10, a compressor 15, and a drying tower 11 , wherein the heat conversion device 7 is a water heater.

[0034] The hydrogen storage tank 3 is connected to the negative end of the battery cell stack 4 through a hydrogen pipeline 36 to feed hydrogen, the positive electrode of the cell stack 4 is provided with an air inlet 35 to feed in air, and the hydrogen tail gas pipeline 5 of the cell stack 4 is connected to the heat exchanger 8. On the one hand, the temperature of the hydrogen tail gas is reduced, and on the other hand, the heat in the hydrogen tail gas is recovered for the generation of hot water. The outlet of the heat exchanger 8 is connected to the gas-water separator 10 to remove the liquid water in the hydrogen tail gas, an...

Embodiment 2

[0039] like Figure 4 The shown schematic diagram of a fuel cell tail gas recycling device includes a three-stage hydrogen storage tank 3, an electric stack 4, a heat exchanger 8, a circulation pump 9, a heat conversion device 7, a gas-water separator 10, and a drying tower 11 . Compressor 15, wherein the heat conversion device is a thermal steam generator.

[0040] The hydrogen storage tank 3 is connected to the negative end of the battery cell stack 4 through a hydrogen pipeline 36 to feed hydrogen, the positive electrode of the cell stack 4 is provided with an air inlet 35 to feed in air, and the hydrogen tail gas pipeline 5 of the cell stack 4 is connected to the heat exchanger 8. On the one hand, the temperature of the hydrogen tail gas is reduced, and on the other hand, the heat in the tail gas is recovered for the generation of hot water. The outlet of the heat exchanger 8 is connected to the gas-water separator 10 to remove the liquid water in the hydrogen gas, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com