A method for recovering proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in the field of resource recycling, can solve the problem that high-value materials cannot be effectively reused, and achieve the effects of avoiding fluoride and sulfide pollution, short process, and no pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

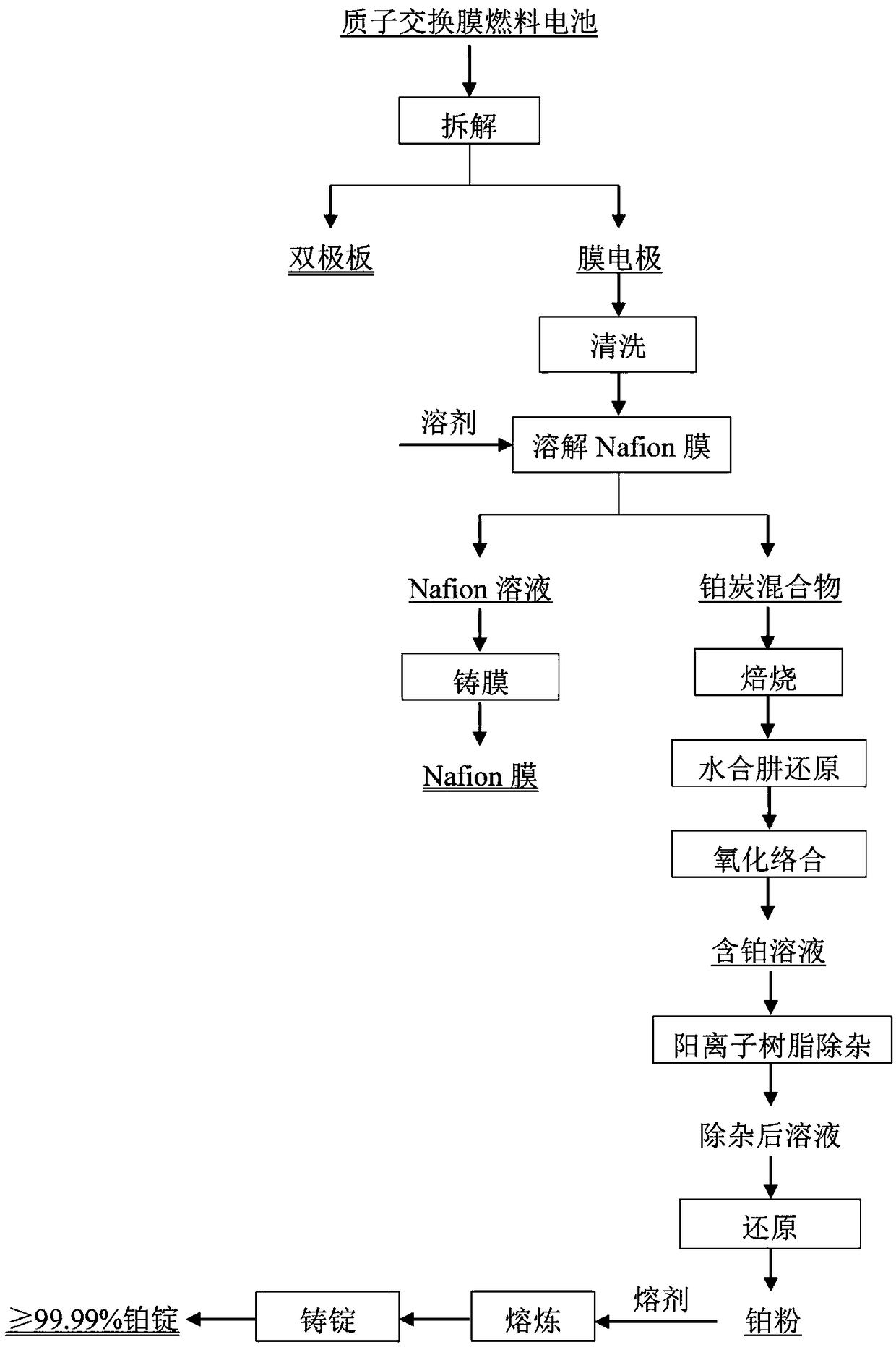

Method used

Image

Examples

Embodiment 1

[0032] First, the proton exchange membrane fuel cell was disassembled to obtain bipolar plates and membrane electrodes, and the membrane electrodes were placed in an aqueous solution with a hydrogen peroxide concentration of 10.0% at 100°C for 30 minutes and washed repeatedly with deionized water for 3 times; then the washed membrane The electrode was reacted with 0.1mol / L sulfuric acid at 90°C for 30min, then washed twice with deionized water and dried. The dried membrane electrode was reacted with ethanol aqueous solution in a hydrothermal reaction kettle at 160° C. for 4 hours, and filtered to obtain Nafion solution and platinum carbon filter residue. Evaporate the Nafion solution to dryness to obtain Nafion resin, add dimethyl sulfoxide (DMSO) to dissolve it, perform vacuum defoaming, and cast a film to obtain a Nafion regeneration film. The platinum charcoal filter residue was roasted at 800°C to remove organic matter and carbon, then the roasted product was reduced with ...

Embodiment 2

[0034]First, the proton exchange membrane fuel cell was disassembled to obtain bipolar plates and membrane electrodes, and the membrane electrodes were placed in an aqueous solution with a hydrogen peroxide concentration of 9.0% at 95°C for 40 minutes, and washed twice with deionized water; then the washed membrane The electrode was reacted with 0.2mol / L sulfuric acid at 86°C for 35min, then washed three times with deionized water and dried. The dried membrane electrode was reacted with isopropanol aqueous solution in a hydrothermal reaction kettle at 165° C. for 3.8 hours, and filtered to obtain Nafion solution and platinum carbon filter residue. Evaporate the Nafion solution to dryness to obtain Nafion resin, add dimethyl sulfoxide (DMSO) to dissolve it, perform vacuum defoaming, and cast a film to obtain a Nafion regeneration film. The platinum charcoal filter residue was roasted at 800°C to remove organic matter and carbon, then the roasted product was reduced with hydrazi...

Embodiment 3

[0036] First, the proton exchange membrane fuel cell was disassembled to obtain bipolar plates and membrane electrodes, and the membrane electrodes were placed in an aqueous solution with a hydrogen peroxide concentration of 8.0% at 90°C for 50 minutes, and washed repeatedly with deionized water for 3 times; then the washed membrane The electrode was reacted with 0.4mol / L sulfuric acid at 84°C for 40min, then washed three times with deionized water and dried. The dried membrane electrode was reacted with isopropanol aqueous solution in a hydrothermal reaction kettle at 170° C. for 3.5 hours, and filtered to obtain Nafion solution and platinum carbon filter residue. Evaporate the Nafion solution to dryness to obtain Nafion resin, add dimethyl sulfoxide (DMSO) to dissolve it, perform vacuum defoaming, and cast a film to obtain a Nafion regeneration film. The platinum charcoal filter residue was roasted at 800°C to remove organic matter and carbon, then the roasted product was re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com