Automobile washing nozzle assembly capable of automatically adjusting spraying direction of nozzle

A technology of spraying direction and automatic adjustment, applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, can solve the problems of inability to meet the requirements of use, affecting user satisfaction, high or low, etc., to achieve better spray performance and shorter Development cycle, improving the effect of scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

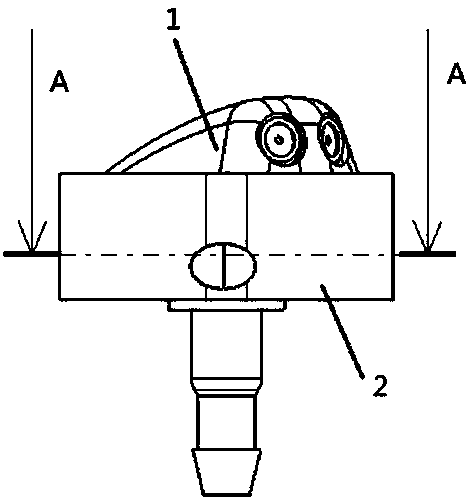

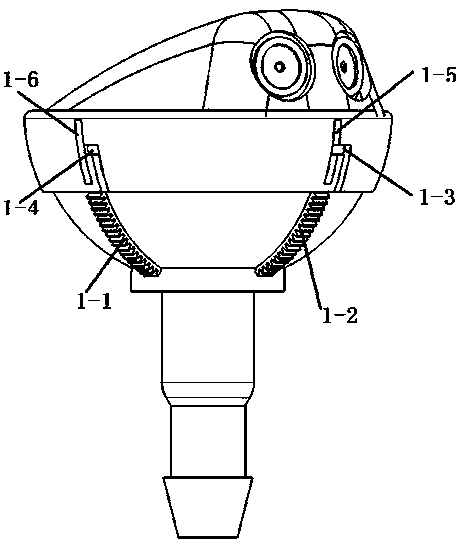

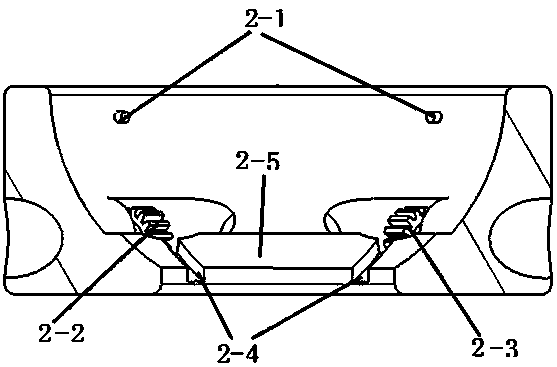

[0019] Depend on Figure 1-5 As shown, 1 in the figure is the nozzle body, and 2 is the nozzle regulator. The nozzle body 1 is wrapped inside the nozzle controller 2. The wrapped part is a spherical structure and is fixed on the exterior cover plate; The peripheral spherical structure between the nozzle body 1 and the nozzle controller 2 is provided with a clamping structure and a rotating shaft guide rail structure; the clamping structure between the nozzle body and the nozzle controller is a nozzle clamping groove symmetrically distributed along the spherical structure 1-4 and nozzle card slot 1-5; the structure of the rotating shaft guide rail between the nozzle body and the nozzle controller is the rotating shaft guiding rail 1-5, the rotating shaft guiding rail 1-6 symmetrically distributed along the spherical structure, and the nozzle adjuster The nozzle rotating shaft 2-1 on the 2 snaps into the rotating shaft guide rail 1-5 and the rotating shaft guide rail 1-6. The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com