Efficient ultrasonic nondestructive detection method

A technology of non-destructive testing and testing methods, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc., can solve the problems of low detection efficiency and unstable detection results, and achieve The effect of avoiding detection errors, optimizing equipment inspection work, and saving internal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

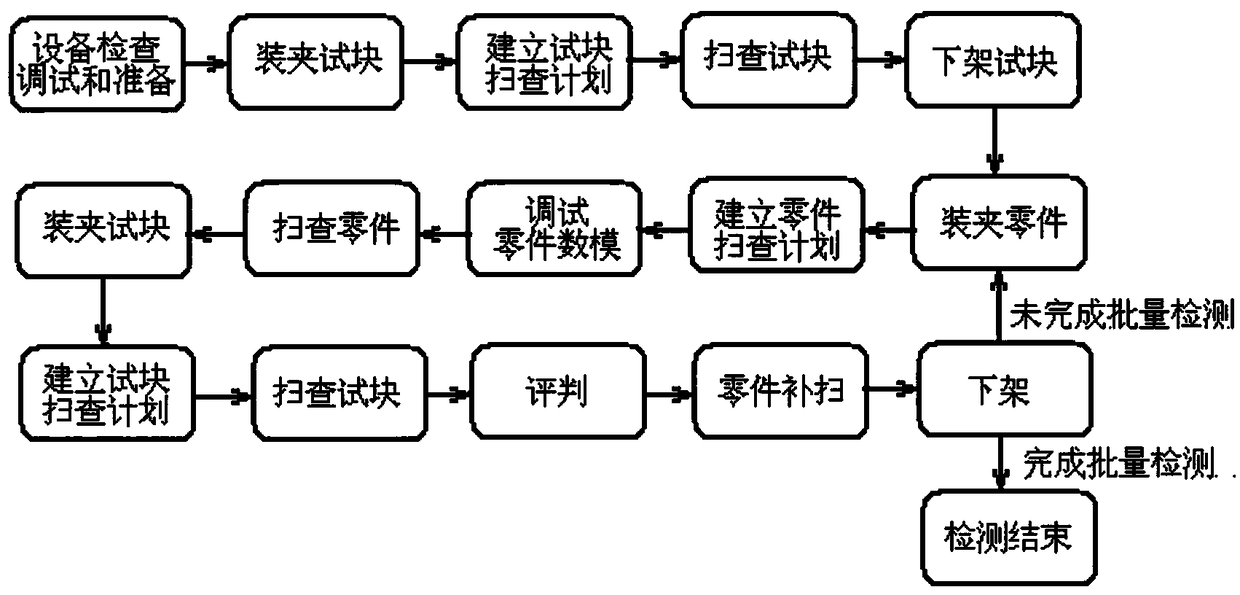

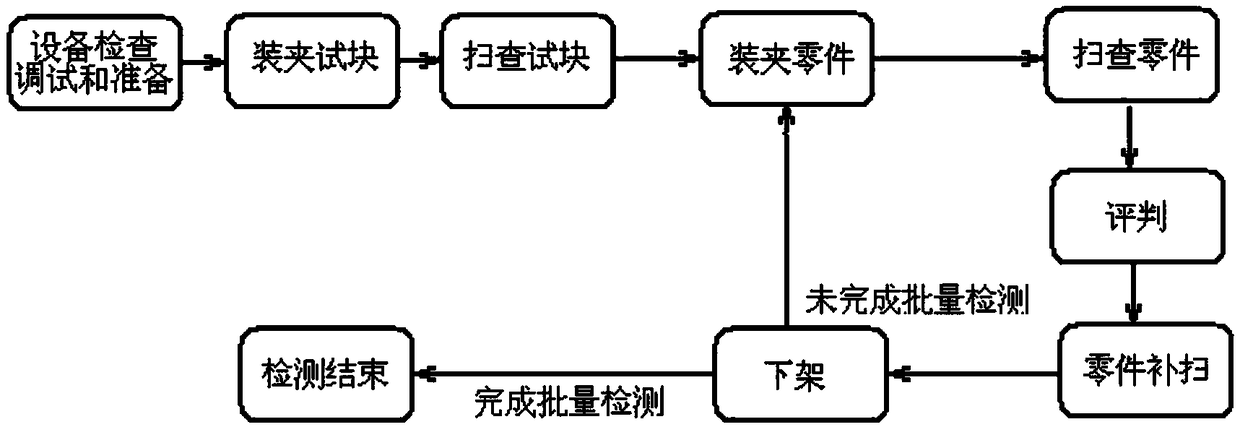

Method used

Image

Examples

Embodiment 1

[0043] An efficient detection method for ultrasonic non-destructive testing. The detection method includes the steps of setting detection parameters, setting detection digital and analog, and setting clamping methods. In addition, the detection method sets the corresponding detection parameters, detection data, and The setting information of at least one setting step in the mold setting and clamping mode setting steps is preset and solidified, and the preset solidified setting information is stored in the database; when performing the corresponding setting steps, according to the configuration of the inspected part, The setting information of the corresponding configuration is called from the database to complete the corresponding setting steps. in,

[0044] Preset and solidify the setting information in the detection parameter setting step corresponding to the inspected part, including the following steps:

[0045] S101: Determine the detection parameter setting information ...

Embodiment 2

[0058] This embodiment provides an efficient detection method for ultrasonic nondestructive testing. Compared with Embodiment 1, the detection digital and analog settings are preset and solidified, and are further preferably replaced with the following setting steps:

[0059] S202a: Copy the production model of the inspected part in an external computer to obtain the initial information of the inspection digital model corresponding to the inspected part;

[0060] S202b: Import the initial digital-analog detection information into the ultrasonic testing equipment, and complete the debugging of the initial digital-analog detection information when the first inspected piece is detected;

[0061] S202c: Lock and store the debugged detection digital and analog information and the corresponding configuration of the inspected part into the database;

[0062] The technical features of the processing methods in the remaining steps remain unchanged, so that an optimized high-efficiency ...

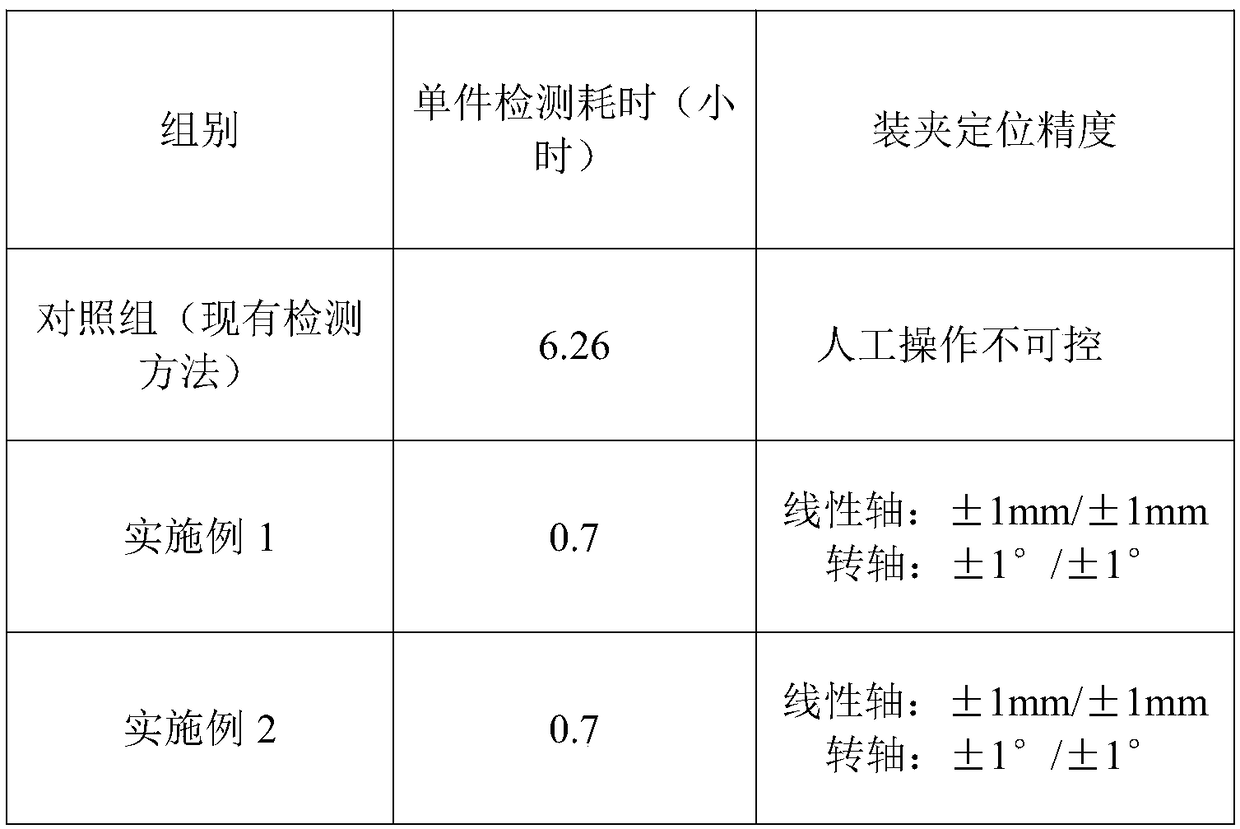

Embodiment 3

[0065] This embodiment provides a high-efficiency detection method for ultrasonic nondestructive testing. Compared with Embodiment 2, only one or two of the three steps of setting the detection parameters, setting the detection digital and analog, and setting the clamping method are set. The setting information in is pre-cured, and the setting information of the remaining setting steps is set using the existing manual adjustment method. According to whether the corresponding setting steps are preset and solidified, specifically include the embodiments shown in Table 1:

[0066] Table 1

[0067] group

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com