Method for electrolysis reuse of alkaline etching waste liquid

An etching waste liquid and alkaline technology, which is applied in the field of alkaline etching waste liquid electrolysis and reuse, can solve the problems of increasing the electrolytic voltage, increasing the resistance of the electrolytic cell, wasting raw materials, etc., achieving a small peak current effect and reducing the generation speed. , the effect of improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Use an electrolytic cell composed of an electrolytic cell, an electrolytic power supply, an electrolytic anode and an electrolytic cathode, and separate the electrolytic cell into an anode area and a cathode area by superimposing a ceramic filter plate and a filter cloth;

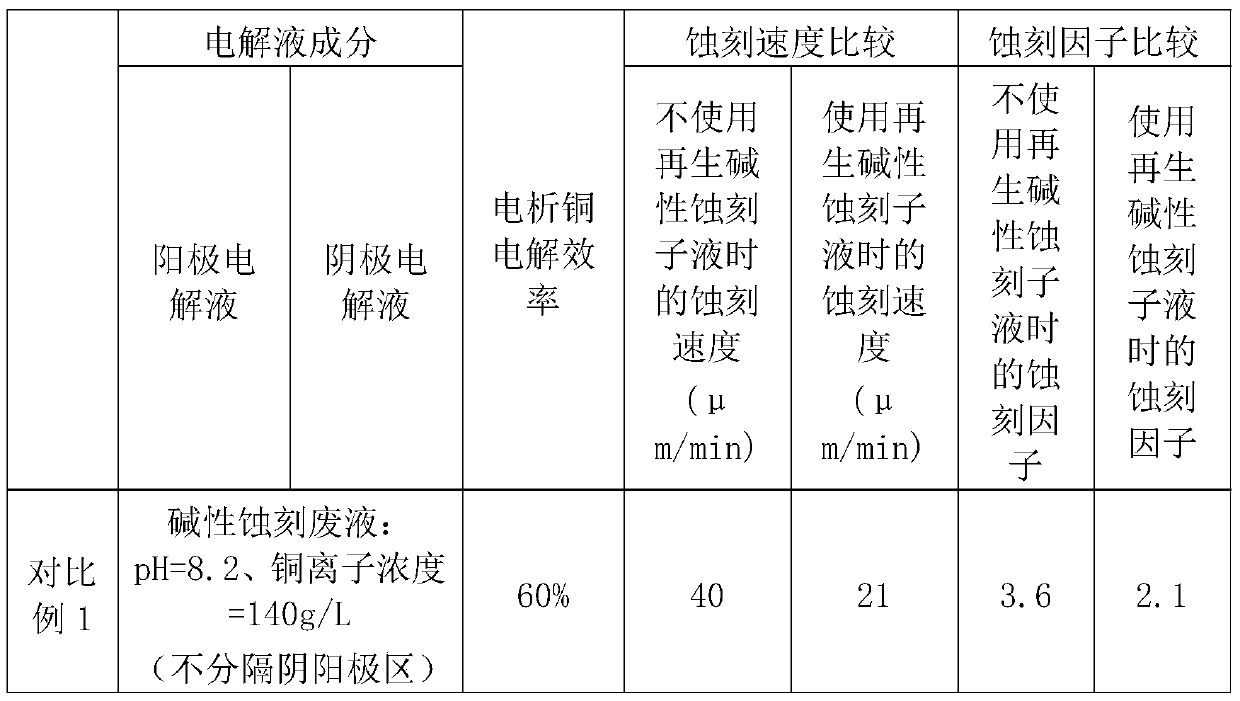

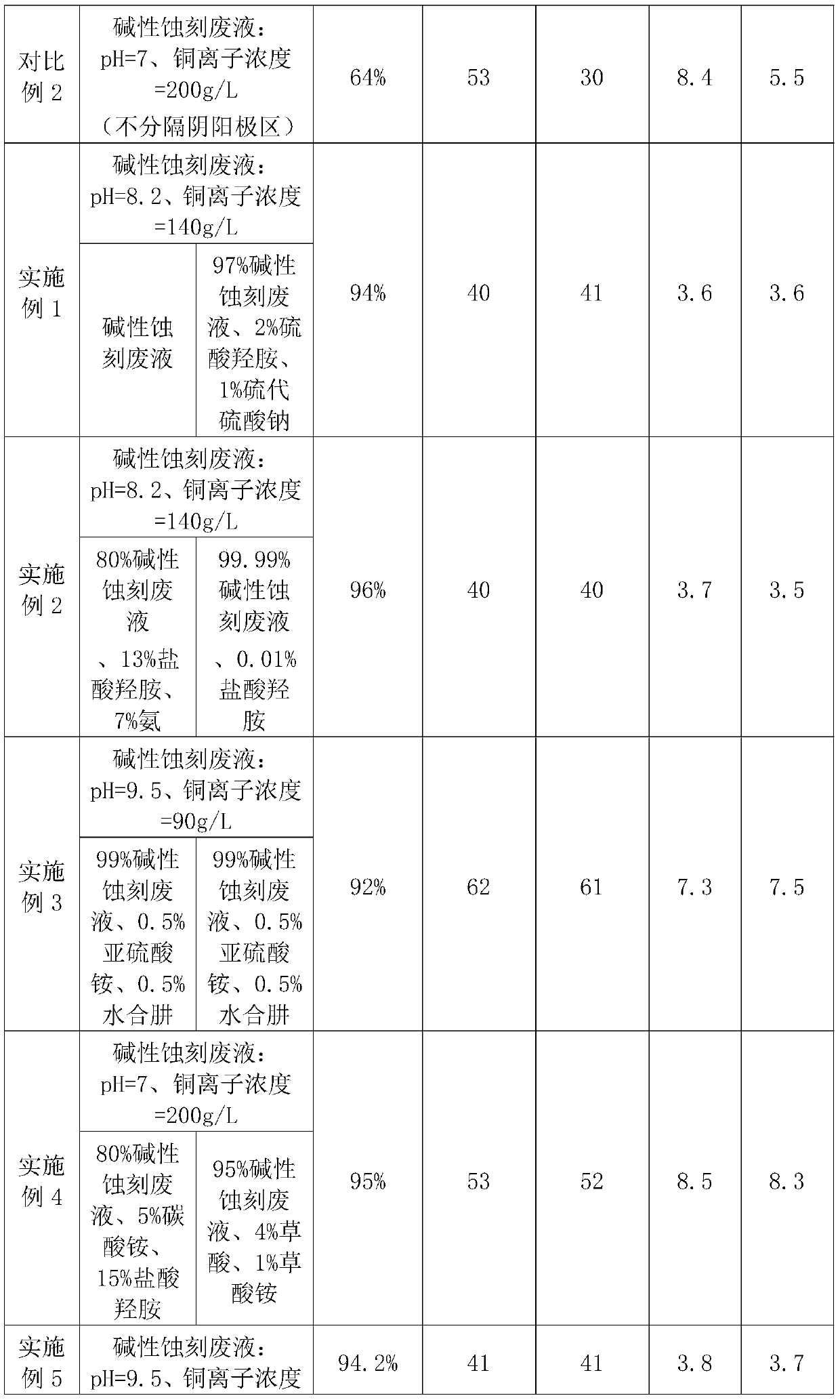

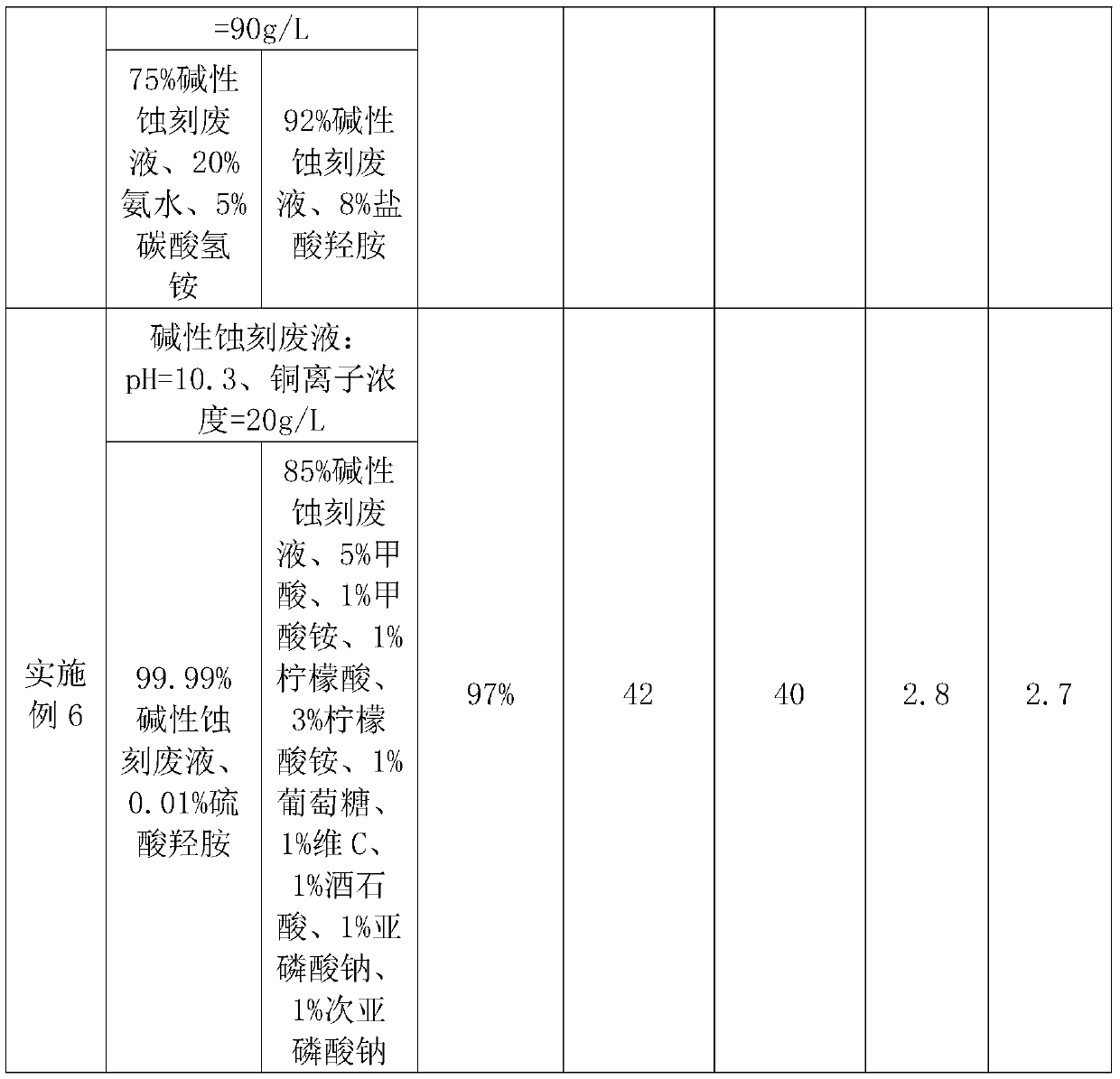

[0058] Prepare the anolyte and catholyte according to the composition and ratio of the following table-1, and add the anolyte and catholyte to the anode area and the cathode area respectively;

[0059] (2) Start the electrolysis power supply to carry out the electrolysis operation, and deposit metallic copper on the electrolysis cathode;

[0060] (3) After 2 hours of electrolysis, mix the anolyte and catholyte, add 5% water by weight, and then use liquid ammonia to adjust the pH to 11 to form a regenerated alkaline etching sub-liquid, which is recycled for use in Etching production line.

Embodiment 2

[0062] (1) Use an electrolytic cell consisting of a sealed electrolytic cell, an electrolytic power supply, an electrolytic anode and an electrolytic cathode, and use a PE filter plate to separate the electrolytic cell into an anode area and a cathode area;

[0063]Prepare the anolyte and catholyte according to the composition and ratio of the following table-1, and add the anolyte and catholyte to the anode area and the cathode area respectively;

[0064] (2) Start the electrolysis power supply to carry out the electrolysis operation, and at the same time, the gas generated in the electrolytic cell is pumped out, and metal copper is deposited on the electrolysis cathode, and is manually transferred to the anode area and the cathode area every half an hour. Supplementary volume of anolyte and catholyte with a volume of 5% of the preset liquid level;

[0065] (3) After 2 hours of electrolysis, the anolyte and catholyte were mixed for solid-liquid separation, and then adjusted t...

Embodiment 3

[0067] (1) Use an electrolytic cell consisting of a sealed electrolytic cell, an electrolytic power supply, an electrolytic anode and an electrolytic cathode, and use an anion membrane to separate the electrolytic cell into an anode area and a cathode area;

[0068] Prepare the anolyte and catholyte according to the composition and ratio of the following table-1, and add the anolyte and catholyte to the anode area and the cathode area respectively;

[0069] (2) Start the electrolysis power supply to carry out the electrolysis operation, and at the same time, the gas generated in the electrolytic cell is pumped out, and metallic copper is precipitated on the electrolysis cathode, and is automatically detected according to the real-time pH value of the anolyte in the anode area The input and control machine replenishes alkaline etching waste liquid to the anode area, and the automatic detection input and control machine adds reducing agent to the anode area according to the real-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com