Anode used for aluminum electrolysis

An aluminum electrolysis and anode technology, which is applied in the field of new structure anodes, can solve the problems of increased energy consumption of electrolytic aluminum and difficulty in discharging carbon dioxide gas, and achieves the effects of reducing electrolysis energy consumption, reducing the bottom coverage area, and reducing voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

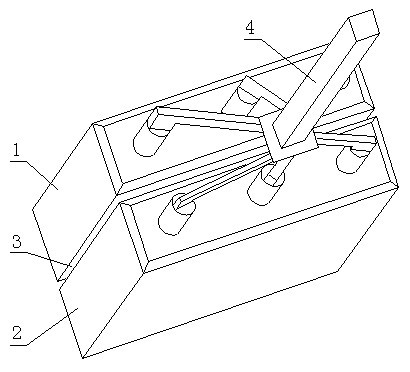

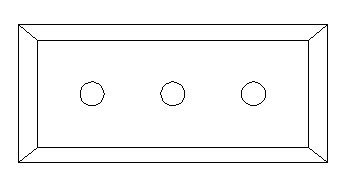

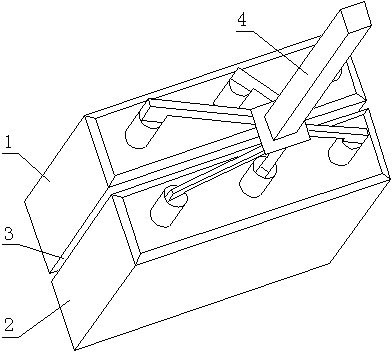

[0016] Embodiment 1: as figure 1 and figure 2 As shown, an anode for aluminum electrolysis includes a first carbon block 1 and a second carbon block 2, the first carbon block 1 and the second carbon block 2 are placed in parallel, and the first carbon block 1 and the second A channel 3 for exhaust is reserved between the carbon blocks 2, and the first carbon block 1 and the second carbon block 2 are all connected to the power supply through steel claws 4; the widths of the first carbon block 1 and the second carbon block 2 are both The width of the channel 3 between the first carbon block 1 and the second carbon block 2 is 20 mm.

Embodiment 2

[0017] Embodiment 2: another anode for aluminum electrolysis is based on embodiment 1, the width of the first carbon block 1 and the second carbon block 2 are all set to 430 mm, the first carbon block 1 and the The width of the channel 3 between the second carbon blocks 2 is set to 40 mm. Here, the width of the first carbon block 1 and the second carbon block 2 and the width of the channel 3 are all adopted with a larger value, because the amount of air bubbles produced by using a wider carbon block is larger, so the corresponding larger value is adopted. The wide channel 3 can increase the discharge flow rate of air bubbles, so as to achieve the purpose of accelerating exhaust.

Embodiment 3

[0018] Embodiment 3: another anode for aluminum electrolysis is based on embodiment 1, the width of the first carbon block 1 and the second carbon block 2 are all set to 360 mm, the first carbon block 1 and the The width of the channel 3 between the second carbon blocks 2 is set to 10 mm. In this embodiment, the configuration with a smaller size is adopted, because after reducing the width of the first carbon block and the second carbon block, the flow distance of the gas at the bottom of the anode is shortened, and it can be quickly discharged from both sides of the carbon block. Therefore, the width of the middle channel 3 can be correspondingly reduced.

[0019] Here, simulation calculations were carried out for the anode according to the invention using a carbon block with a width of 400 mm. In this case, the thickness of the bubble layer at the bottom of the anode is 1.389~1.414 cm, and 1.4 cm is taken as the average value here. Therefore, when the thickness of the bubbl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com