Porous catalyst used for photo-electrolysis water oxygen evolution reaction and preparation method of porous catalyst

A porous catalyst, photoelectrolysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrolysis processes, etc., can solve problems such as long-term stable use, metal electrodes are easily corroded, equipment damage, etc. Practical value and pioneering, content-rich, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

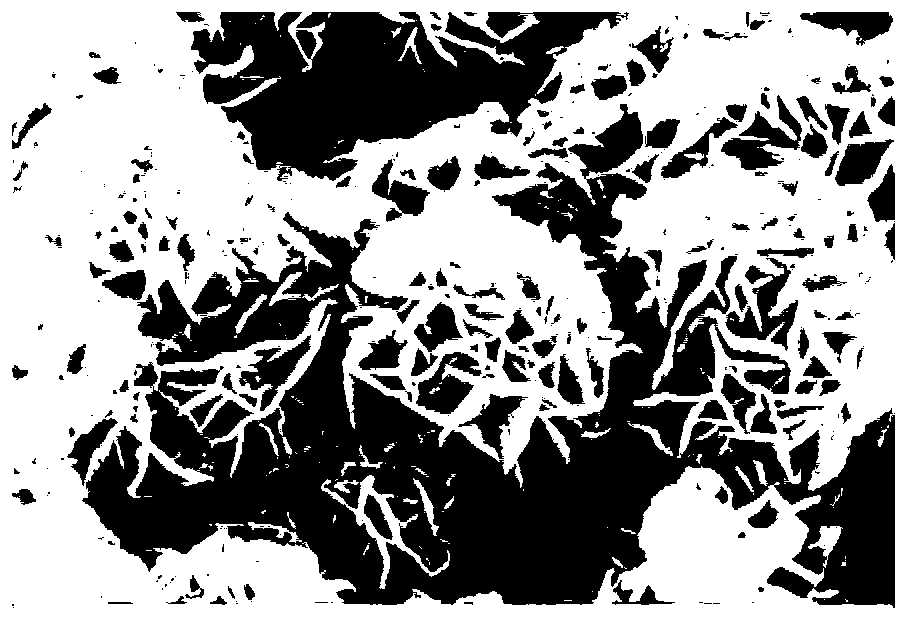

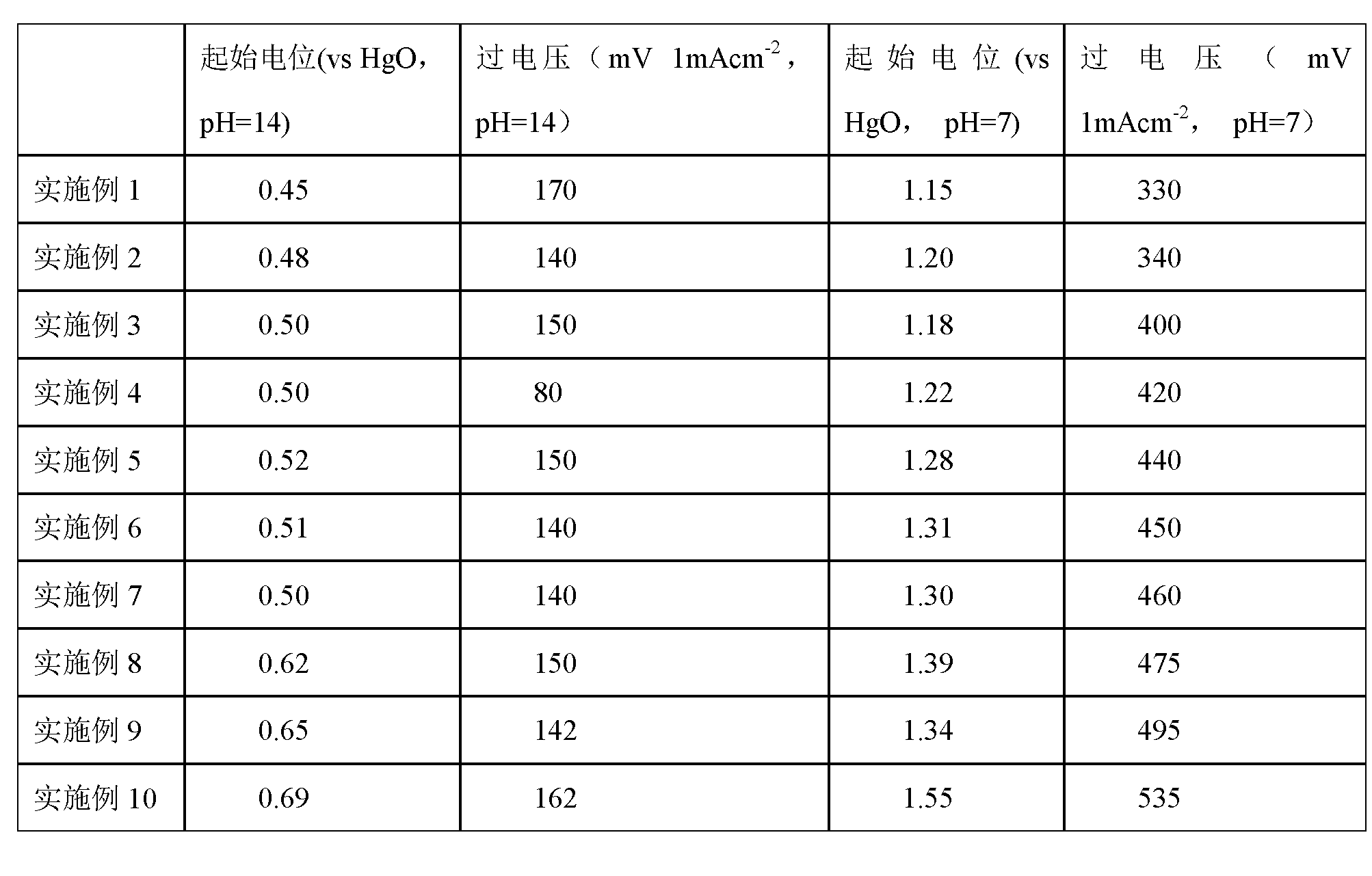

[0025] This example presents a porous catalyst for photoelectrolysis of water oxygen evolution reaction, which has amorphous characteristics and its chemical formula is KCoPO 4 , with several crystal water molecules.

[0026] Preparation method: Prepare 50mL of cobalt nitrate solution with a concentration of about 0.1mol / L, and add 5mL of commercially available 25%-28% ammonia water at a drop rate of 10mL·s -1 Add dropwise evenly, and after the suspension is continuously stirred for 10 minutes, the -1 Add 25 mL of 0.2 mol / L potassium dihydrogen phosphate solution, and continue stirring for 10 min. The blue-green precipitated product was washed by centrifugation with deionized water and alcohol in sequence until the supernatant was clear, and then dried and ground in a thermostat at 70°C. A porous catalyst for the oxygen evolution reaction of photoelectrolyzed water is obtained.

[0027] 10mg of oxygen evolution catalyst and commercially available 1mL 5wt% Nafion solution we...

Embodiment 2

[0029] This example presents a porous catalyst for photoelectrolysis of water oxygen evolution reaction, which has amorphous characteristics and its chemical formula is KCoPO 4 , with several crystal water molecules.

[0030] Prepare 50mL of cobalt nitrate solution with a concentration of about 0.8mol / L, add 5mL of commercially available 25%-28% ammonia water at a drop rate of 10mL·s-1 Add dropwise evenly, and after the suspension is continuously stirred for 10 minutes, the -1 Add 25 mL of 0.2 mol / L potassium dihydrogen phosphate solution and continue stirring for 10 min. The blue-green precipitated product was washed by centrifugation with deionized water and alcohol in sequence until the supernatant was clear, and then dried and ground in a thermostat at 70°C. 10mg of oxygen evolution catalyst and commercially available 5wt% Nafion solution were sonicated for 30 minutes, evenly dropped on the FTO glass, dried in an oven at 70 degrees, and annealed at 120 degrees for 30 minu...

Embodiment 3

[0032] This example presents a porous catalyst for photoelectrolysis of water oxygen evolution reaction, which has amorphous characteristics and its chemical formula is KCoPO 4 , with several crystal water molecules.

[0033] Prepare 50mL of cobalt nitrate solution with a concentration of about 0.1mol / L, add 15mL of commercially available 25%-28% ammonia water at a drop rate of 10mL·s -1 Add dropwise evenly, and after the suspension is continuously stirred for 10 minutes, the -1 Add 25 mL of 0.2 mol / L potassium dihydrogen phosphate solution, and continue stirring for 20 min. The blue-green precipitated product was washed by centrifugation with deionized water and alcohol in sequence until the supernatant was clear, and then dried and ground in a thermostat at 70°C. 10mg of oxygen evolution catalyst and commercially available 5wt% Nafion solution were sonicated for 30 minutes, evenly dropped on the FTO glass, dried in an oven at 70 degrees, and annealed at 120 degrees for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com