Tungsten manganese calcium/mesoporous tungsten trioxide compound for preparing photo-anode and preparation method thereof

A tungsten trioxide, calcium oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve a wide range of light absorption, wide light response range, high light Effects on catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

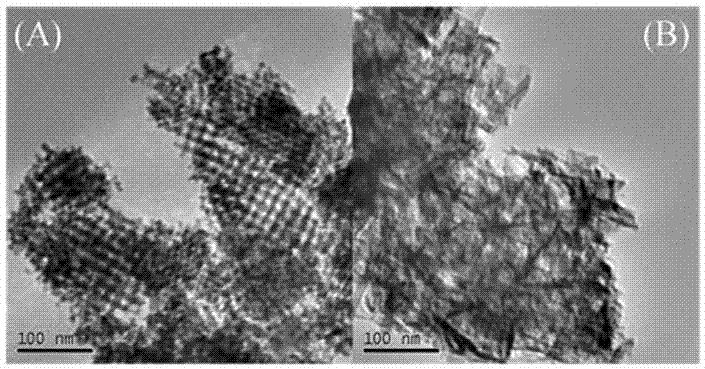

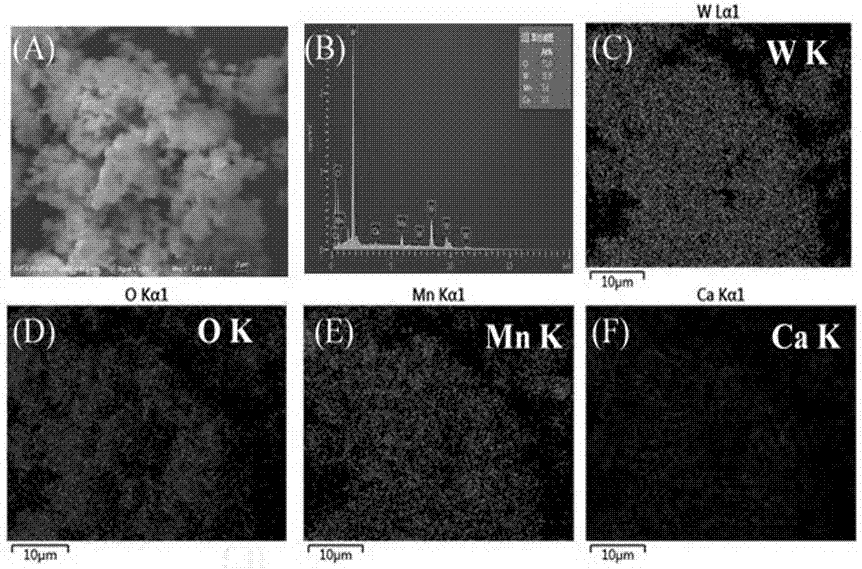

[0038] 12g of phosphotungstic acid, 8g of KIT-6 and 200 mL of absolute ethanol were mixed, stirred magnetically for 2 h, and centrifuged. The solid was washed several times with deionized water and dried at 60°C for 10 h. Calcined at 550 °C for 5 h and cooled to room temperature naturally. Disperse the obtained pale yellow solid into 200 mL hydrofluoric acid (2mol / L) and stir for 6 hours, then centrifuge. The solid was washed several times with deionized water and dried in vacuum to obtain mesoporous tungsten trioxide.

[0039] Dissolve 1.2g of calcium acetate monohydrate and 3.98g of manganese acetate tetrahydrate in 30mL of deionized water, and slowly add 30mL of KOH (8.6 mol / L) aqueous solution under magnetic stirring to obtain a brown suspension. Add 100 mL KMnO dropwise to the suspension 4 Aqueous solution (0.06 mol / L), magnetically stirred at room temperature for 8 hours, centrifuged, the solid was washed several times with deionized water, dried in vacuum, and then ca...

Embodiment 2

[0044] Add 1.9g of mesoporous tungsten trioxide and 0.10g of layered manganese-calcium oxide into a 50 mL ball mill jar, and grind on a star ball mill at 500 rpm for 4 hours, and the rest of the steps are the same as in Example 1. A porous tungsten trioxide photocatalytic material with island-like tungsten-manganese-calcium complexes on the surface was prepared, in which the mass fraction of manganese-calcium oxide was 5 wt.%. The photoanode preparation, photocatalytic reactor and photocatalytic reaction conditions are also the same as those in Example 1. After 2 hours of light reaction, when the applied voltage was 0.9V vs. RHE, the yields of hydrogen and oxygen were 1.1 and 0.4 µmol, respectively; when the applied voltage was 1.0 V vs. RHE, the yields of hydrogen and oxygen were 2.0 and 0.9 µmol, respectively; When V vs. RHE, the production of hydrogen and oxygen are 2.5 and 1.1 μmol, respectively; when the applied voltage is 1.2V vs. RHE, the production of hydrogen and oxyg...

Embodiment 3

[0046] After mixing 1.2g of phosphotungstic acid, 2.4g of KIT-6 and 30mL of absolute ethanol, stir magnetically for 2 hours, and centrifuge. The solid is washed several times with deionized water and dried at 60°C for 10 hours. Calcined at 400 °C for 5 h and cooled to room temperature naturally. The obtained pale yellow solid was dispersed into 20 mL of hydrofluoric acid (2mol / L), stirred for 6 hours, and centrifuged. The solid was washed several times with deionized water and dried in vacuum to obtain mesoporous tungsten trioxide. Add 1.86 g of mesoporous tungsten trioxide obtained by this method and 0.14 g of layered manganese-calcium oxide prepared by the method in Example 1 into a 50 mL ball mill jar, and grind for 4 hours on a star ball mill at 500 rpm. One method prepares a porous tungsten trioxide photocatalytic material with an island-shaped tungsten-manganese-calcium compound on the surface, and the mass fraction of manganese-calcium oxide is 7wt.%. The photoanode p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com