Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce local concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

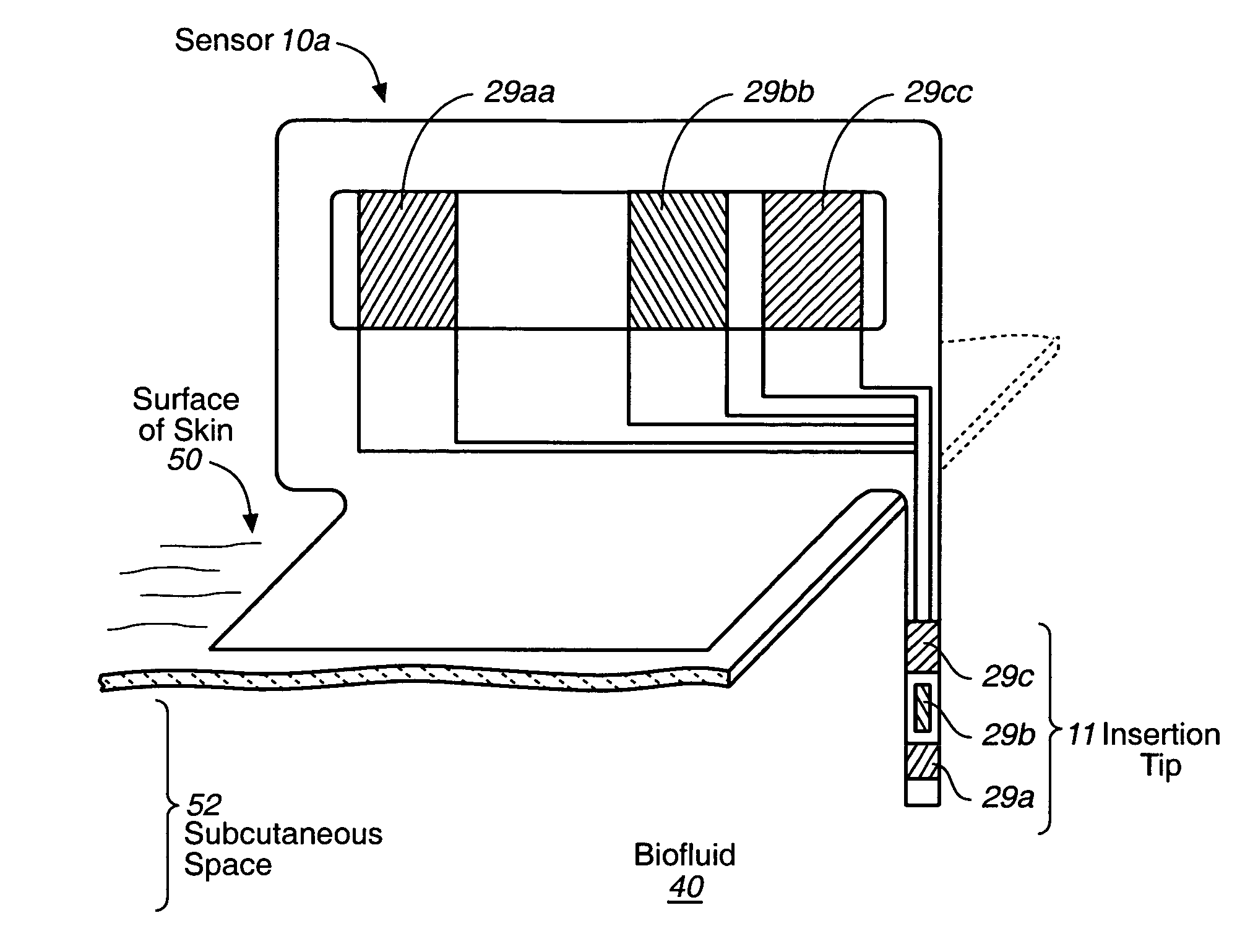

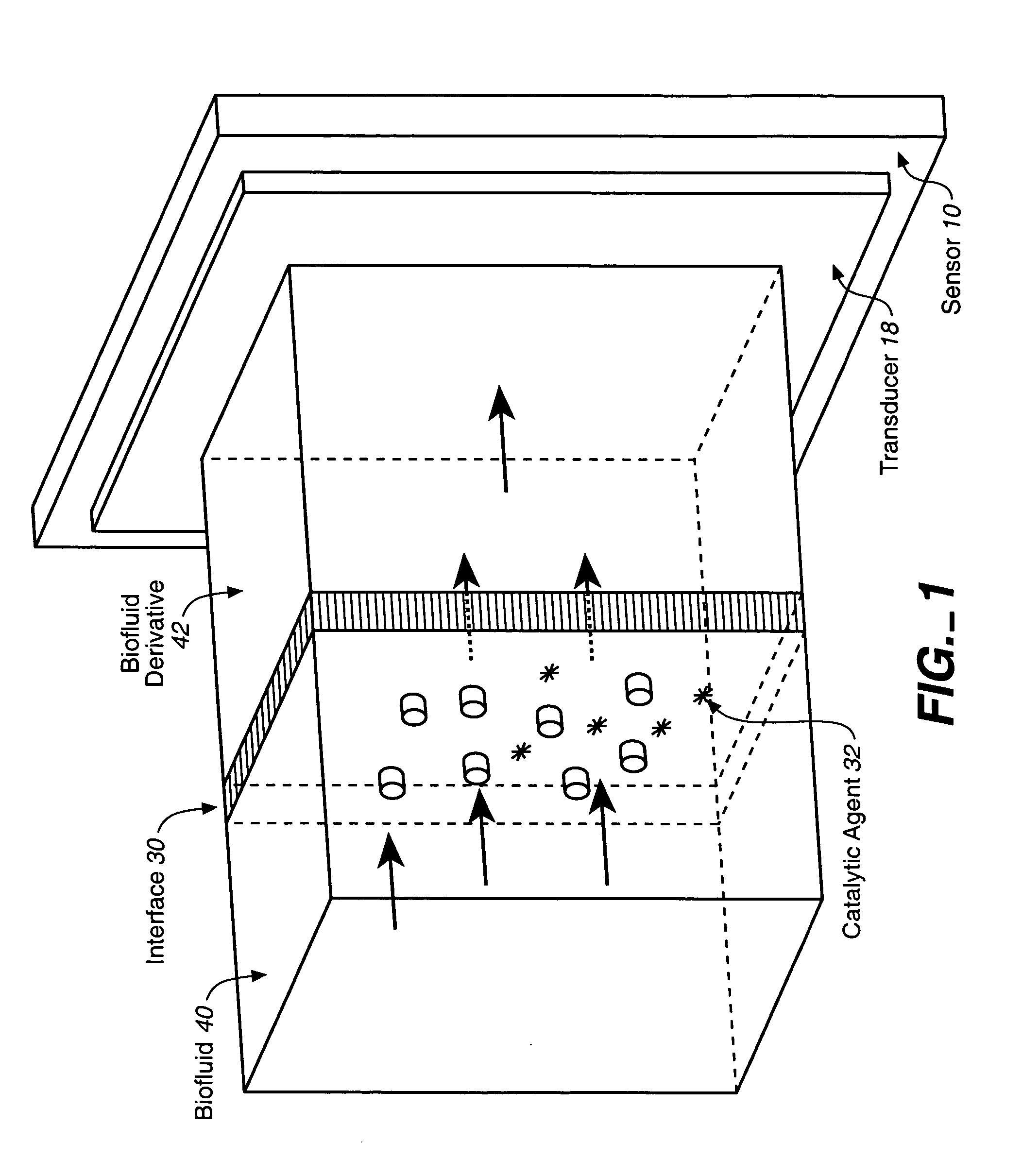

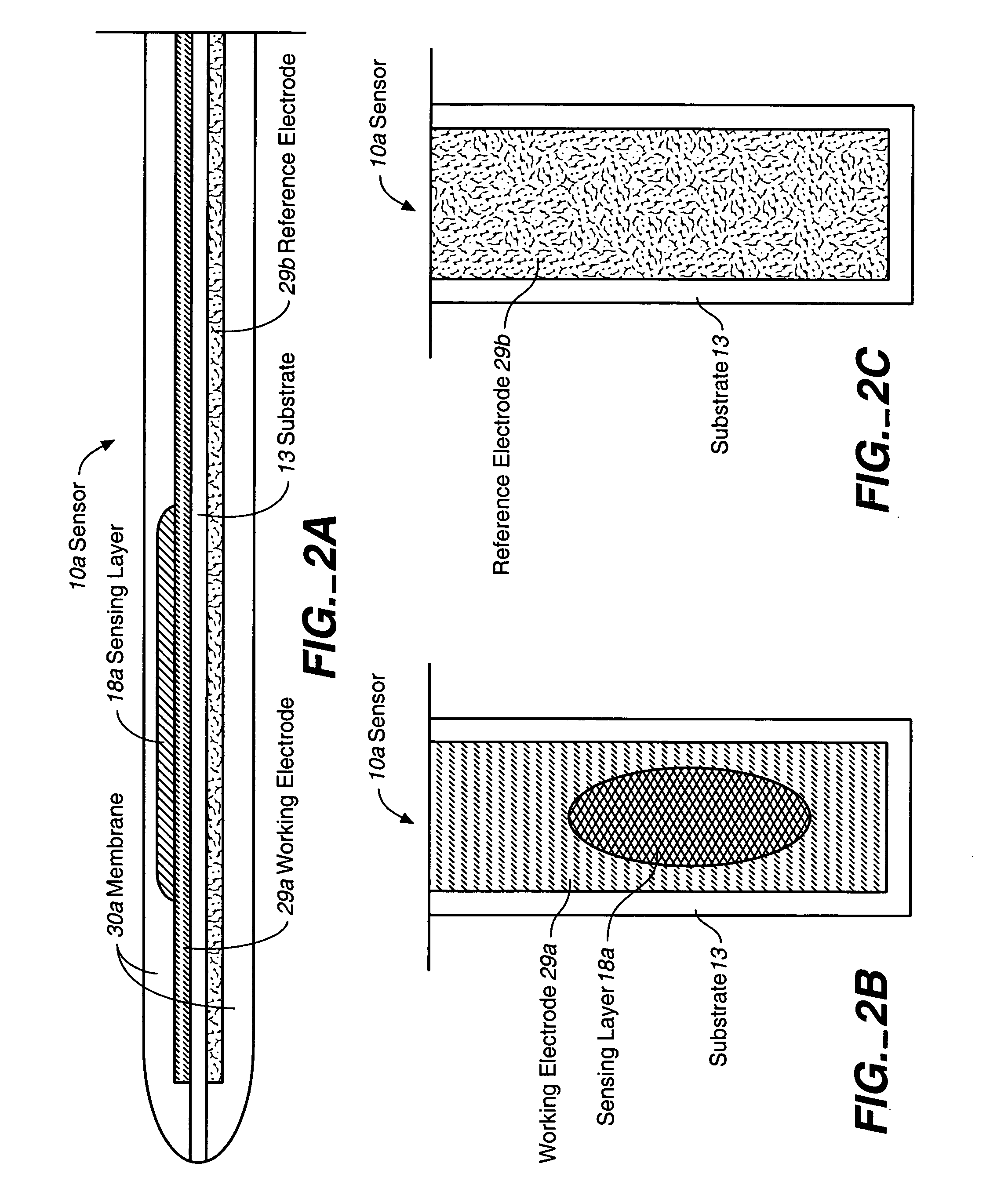

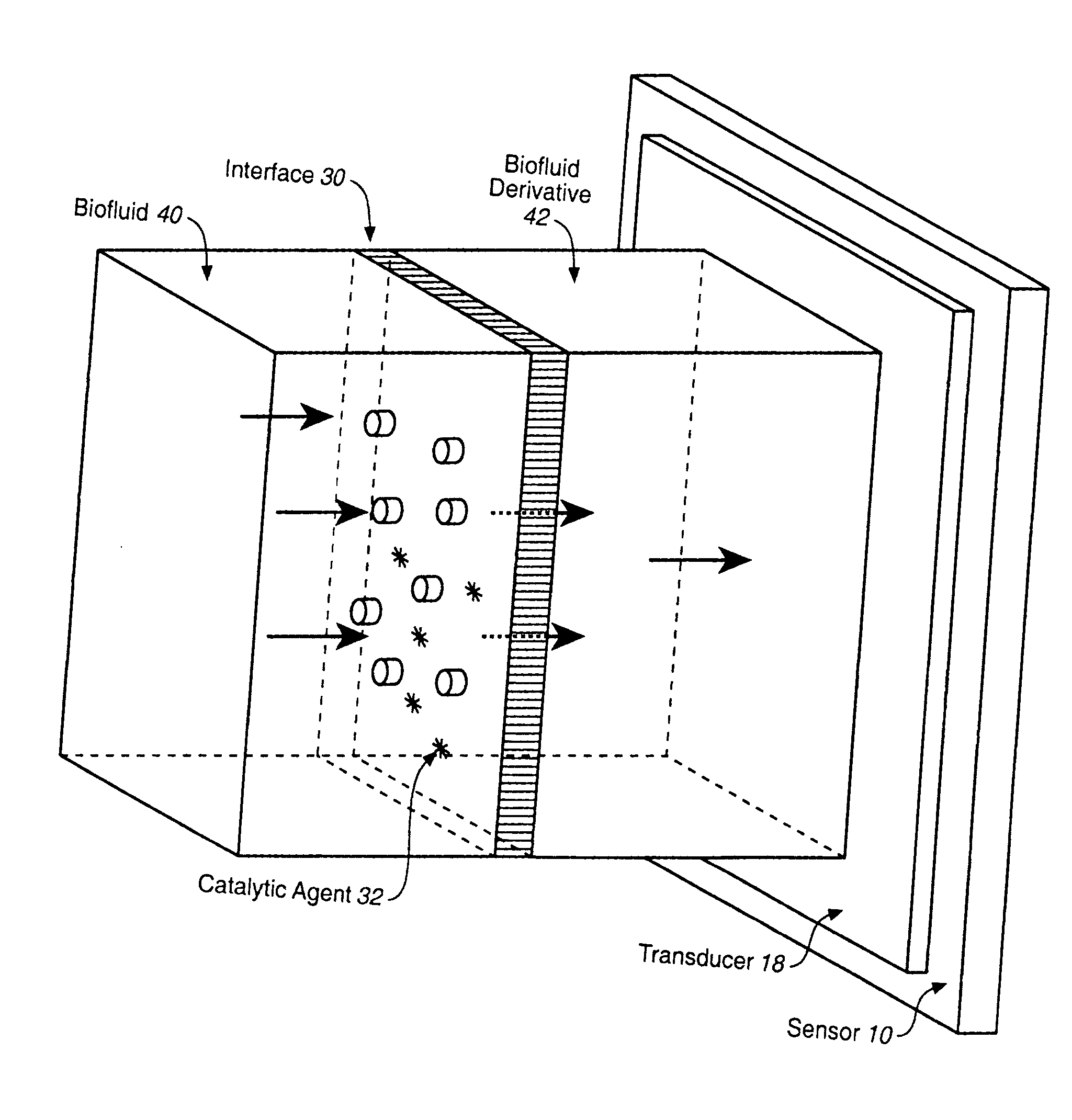

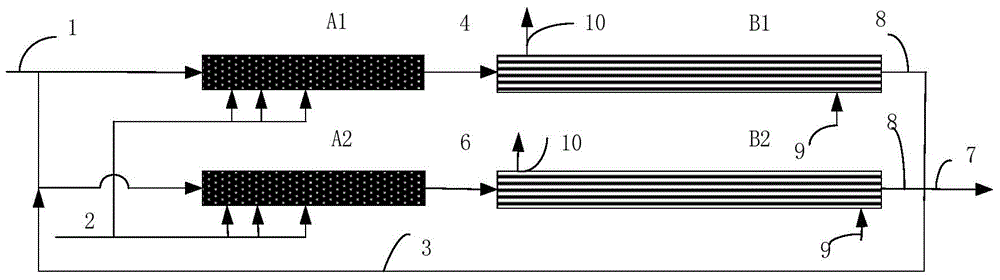

Analyte sensor, and associated system and method employing a catalytic agent

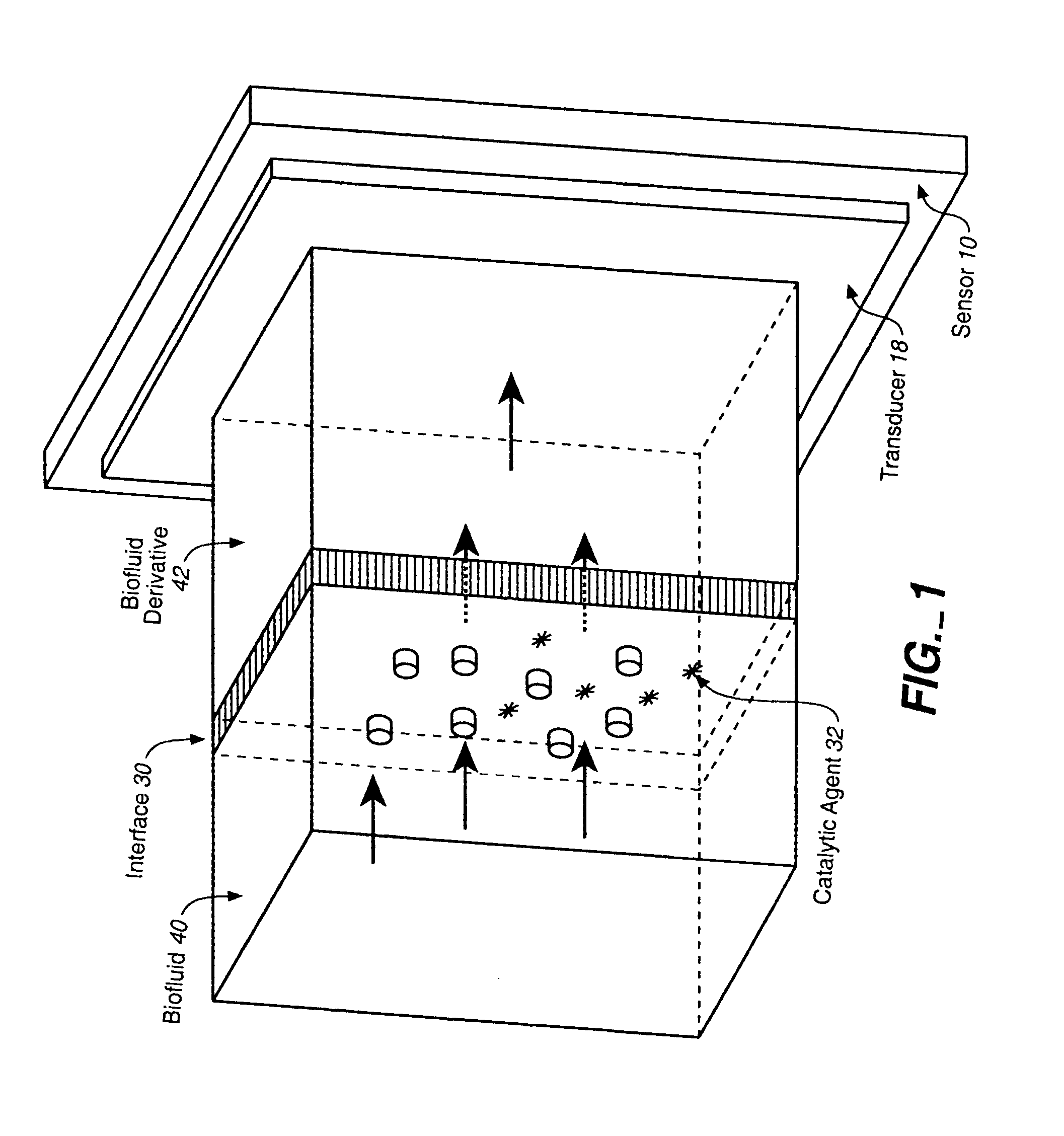

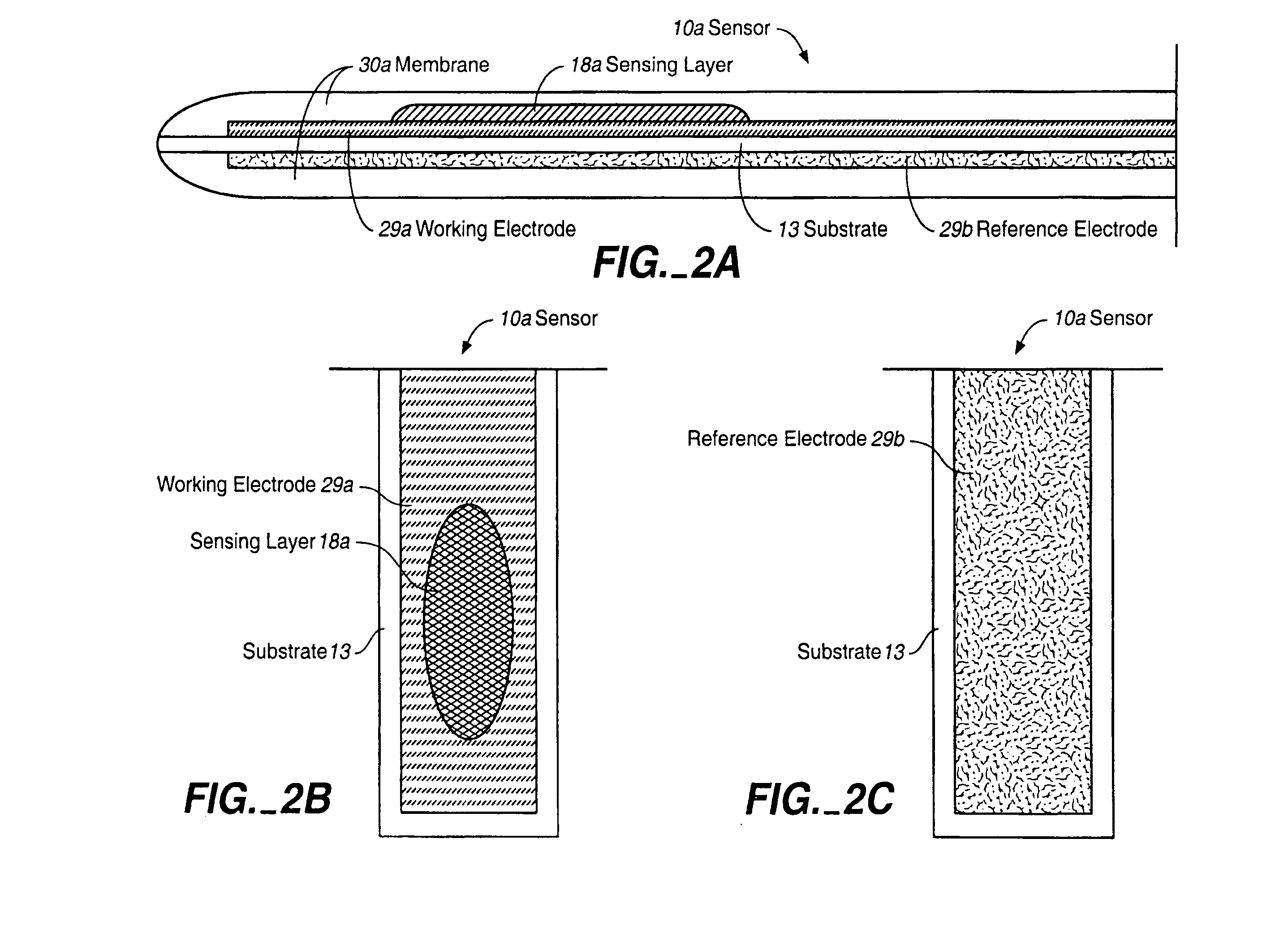

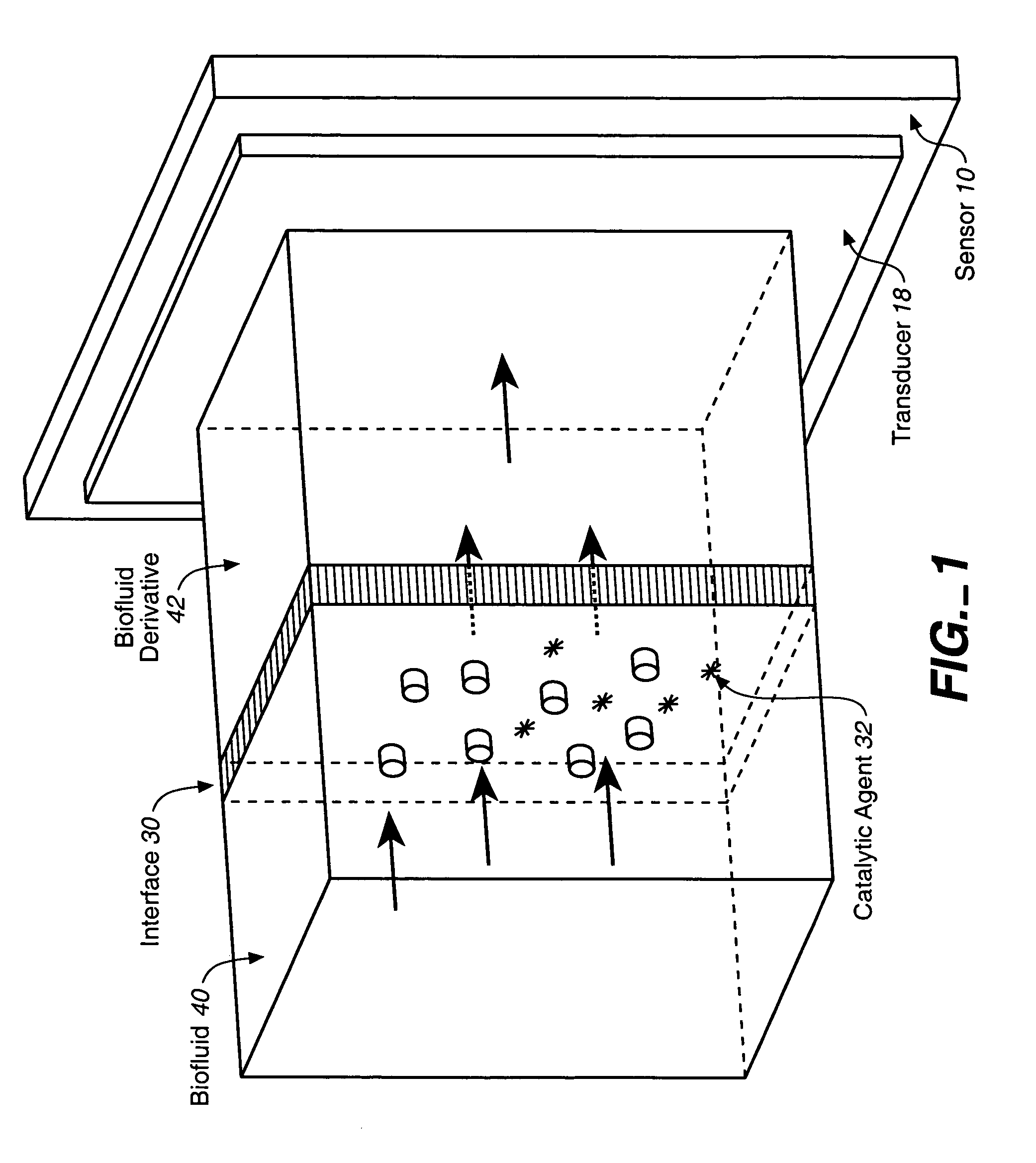

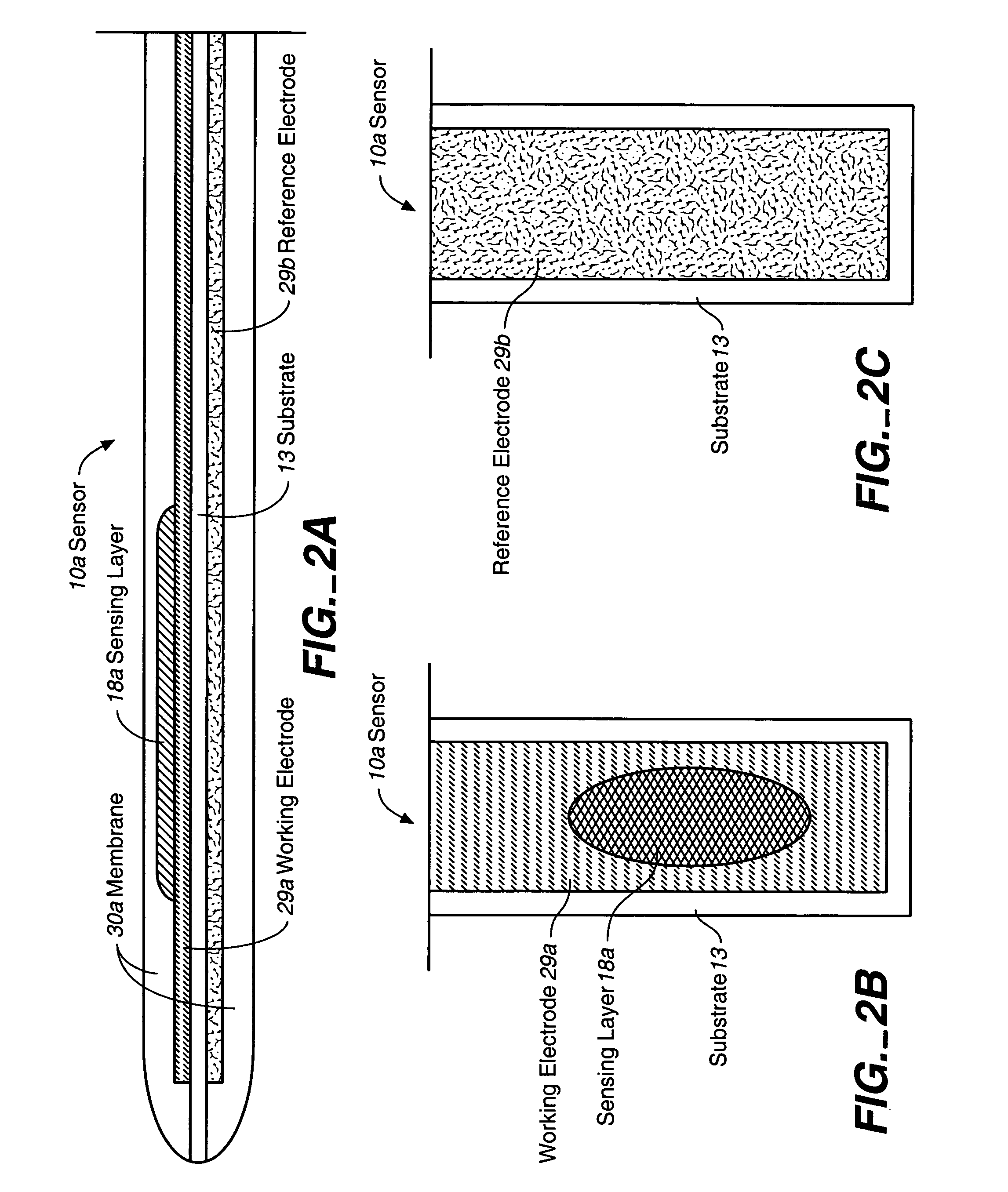

ActiveUS20050215871A1Good biocompatibilityExtend effective lifeImmobilised enzymesBioreactor/fermenter combinationsAnalyteTransducer

An analyte sensor for use in connection with a biofluid is described. The analyte sensor may comprise any suitable interface between the biofluid and a derivative of the biofluid and any suitable transducer of information concerning an analyte. At least one catalytic agent is provided in a locale or vicinity of the interface. The catalytic agent, such as a proteinaceous agent or a non-proteinaceous, organic-metal agent, is sufficient to catalyze the degradation of reactive oxygen and / or nitrogen species that may be present in the vicinity of the interface. An analyte-sensing kit and a method of sensing an analyte are also described.

Owner:ABBOTT DIABETES CARE INC

Analyte Sensor, and Associated System and Method Employing a Catalytic Agent

InactiveUS20070191701A1Good biocompatibilityExtend effective lifeImmobilised enzymesBioreactor/fermenter combinationsAnalyteTransducer

An analyte sensor for use in connection with a biofluid is described. The analyte sensor may comprise any suitable interface between the biofluid and a derivative of the biofluid and any suitable transducer of information concerning an analyte. At least one catalytic agent is provided in a locale or vicinity of the interface. The catalytic agent, such as a proteinaceous agent or a non-proteinaceous, organic-metal agent, is sufficient to catalyze the degradation of reactive oxygen and / or nitrogen species that may be present in the vicinity of the interface. An analyte-sensing kit and a method of sensing an analyte are also described.

Owner:ABBOTT DIABETES CARE INC

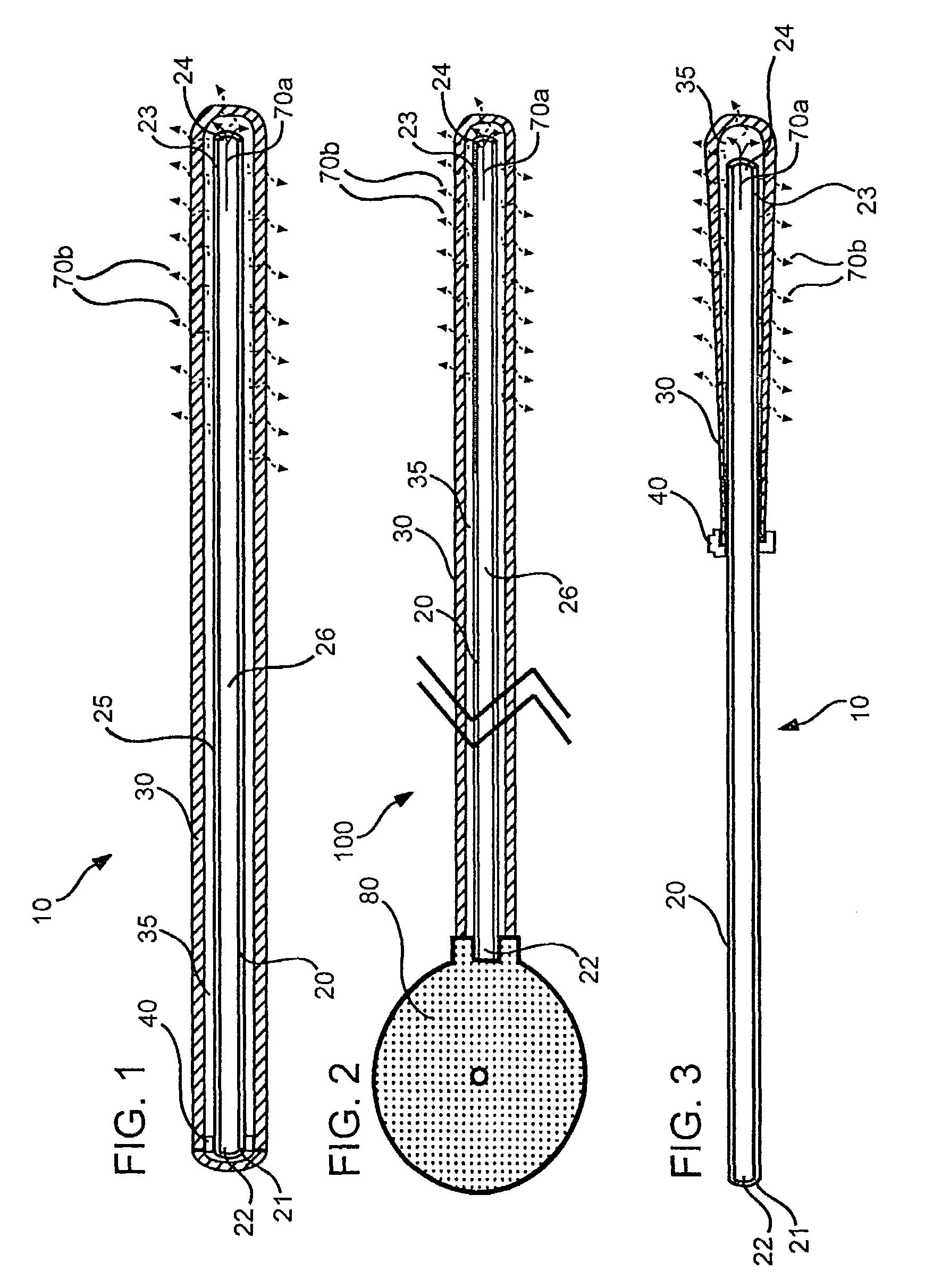

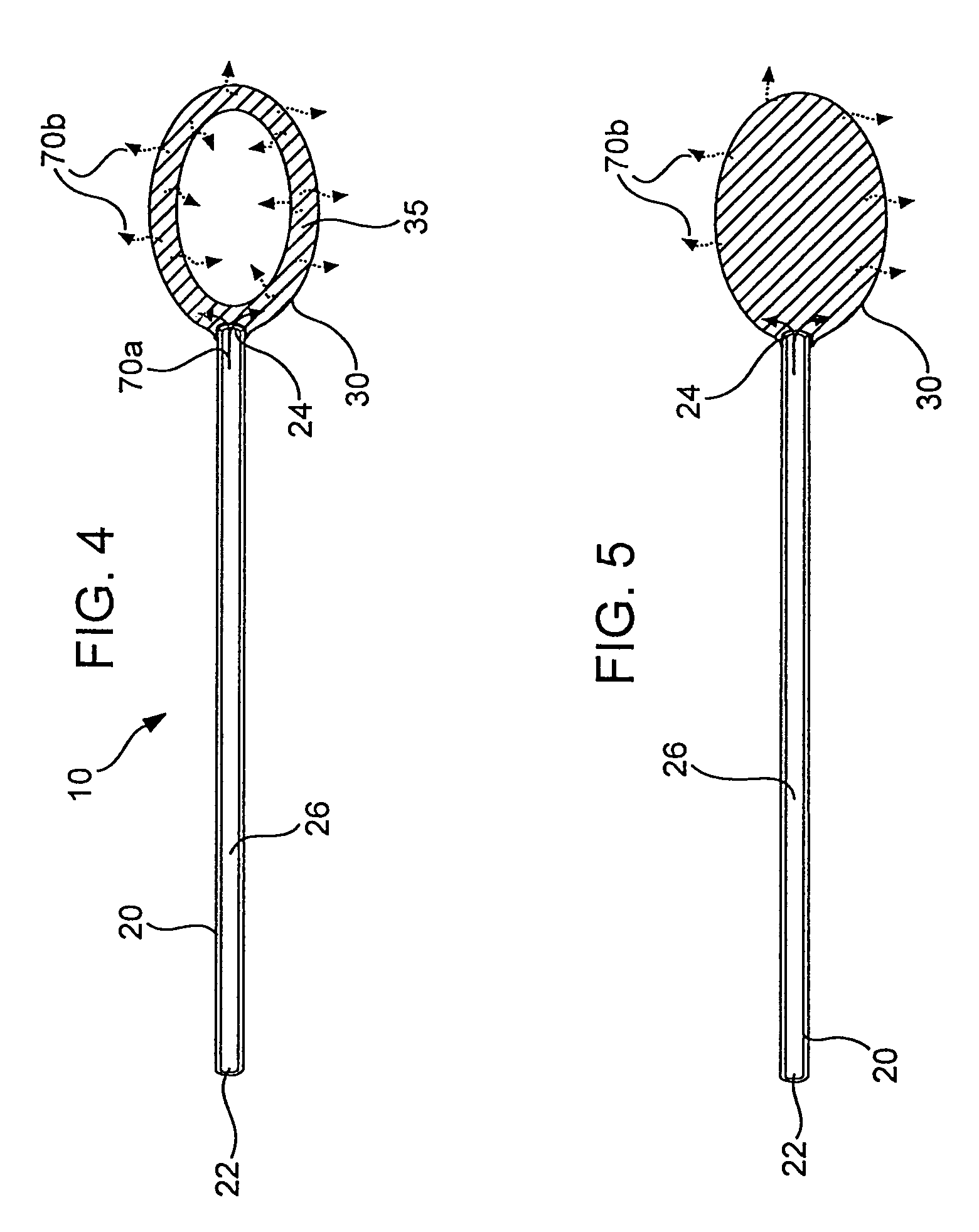

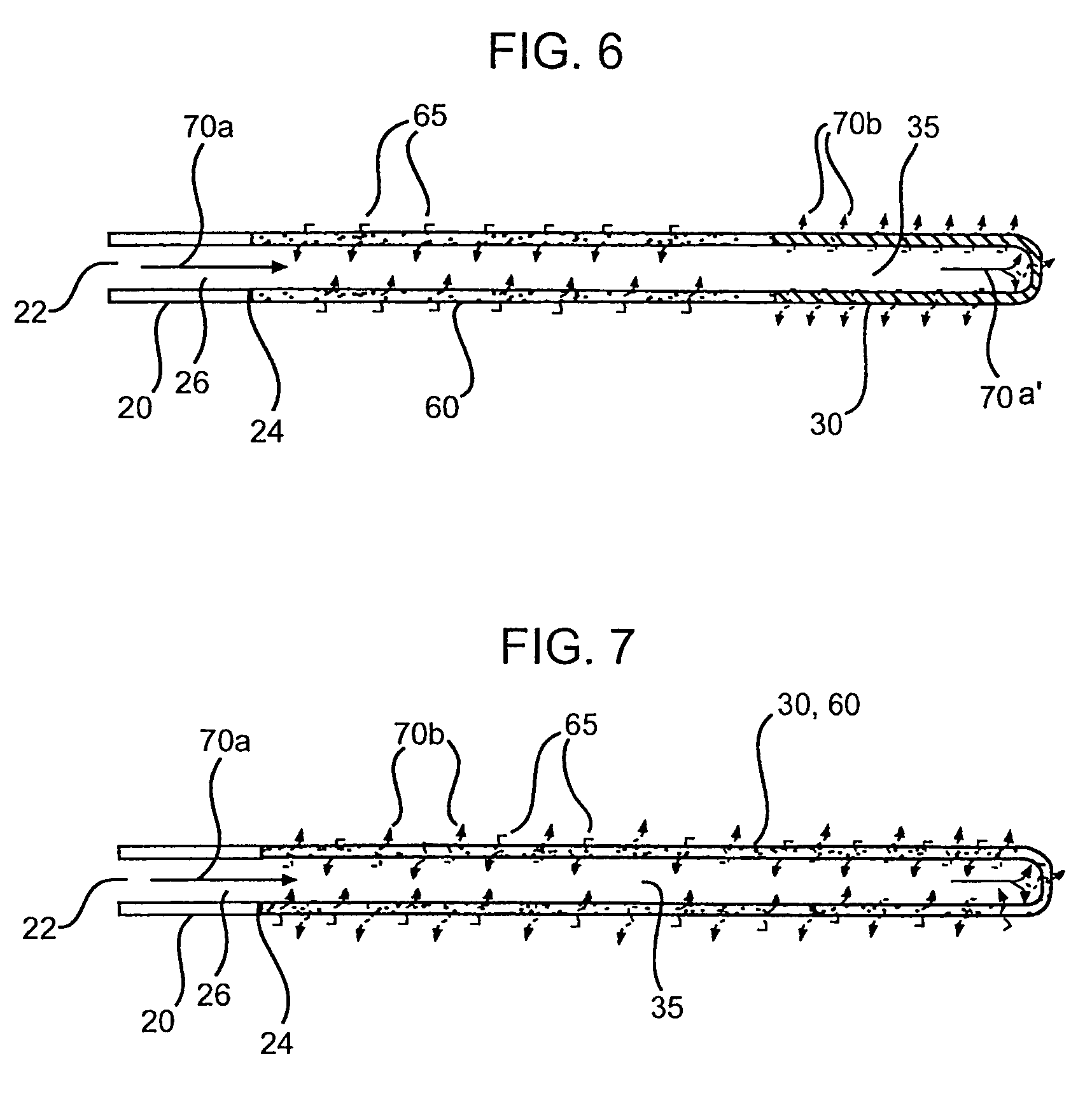

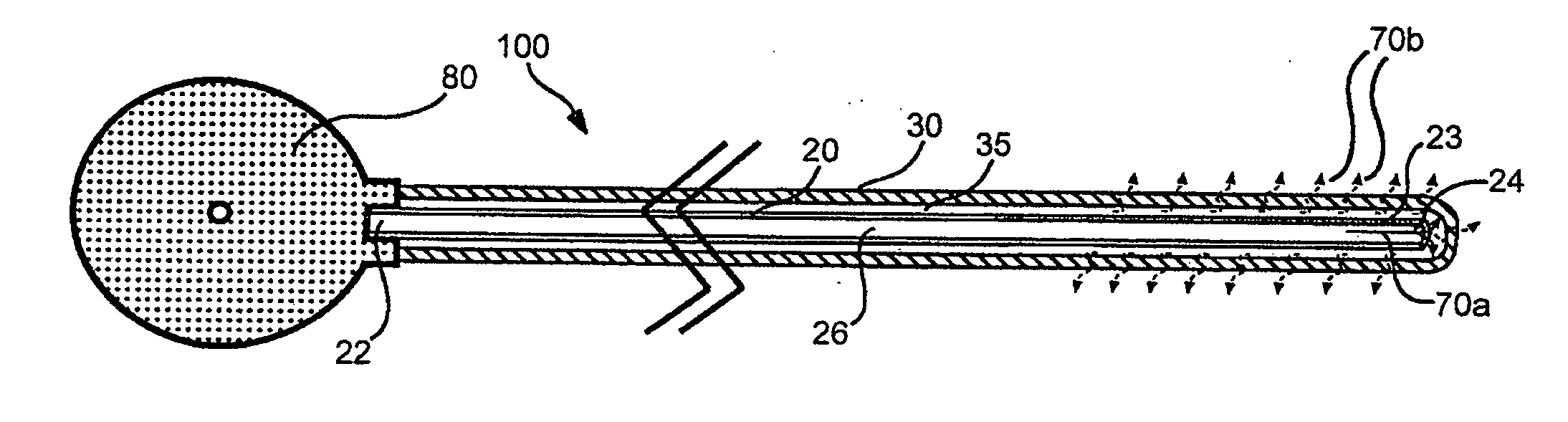

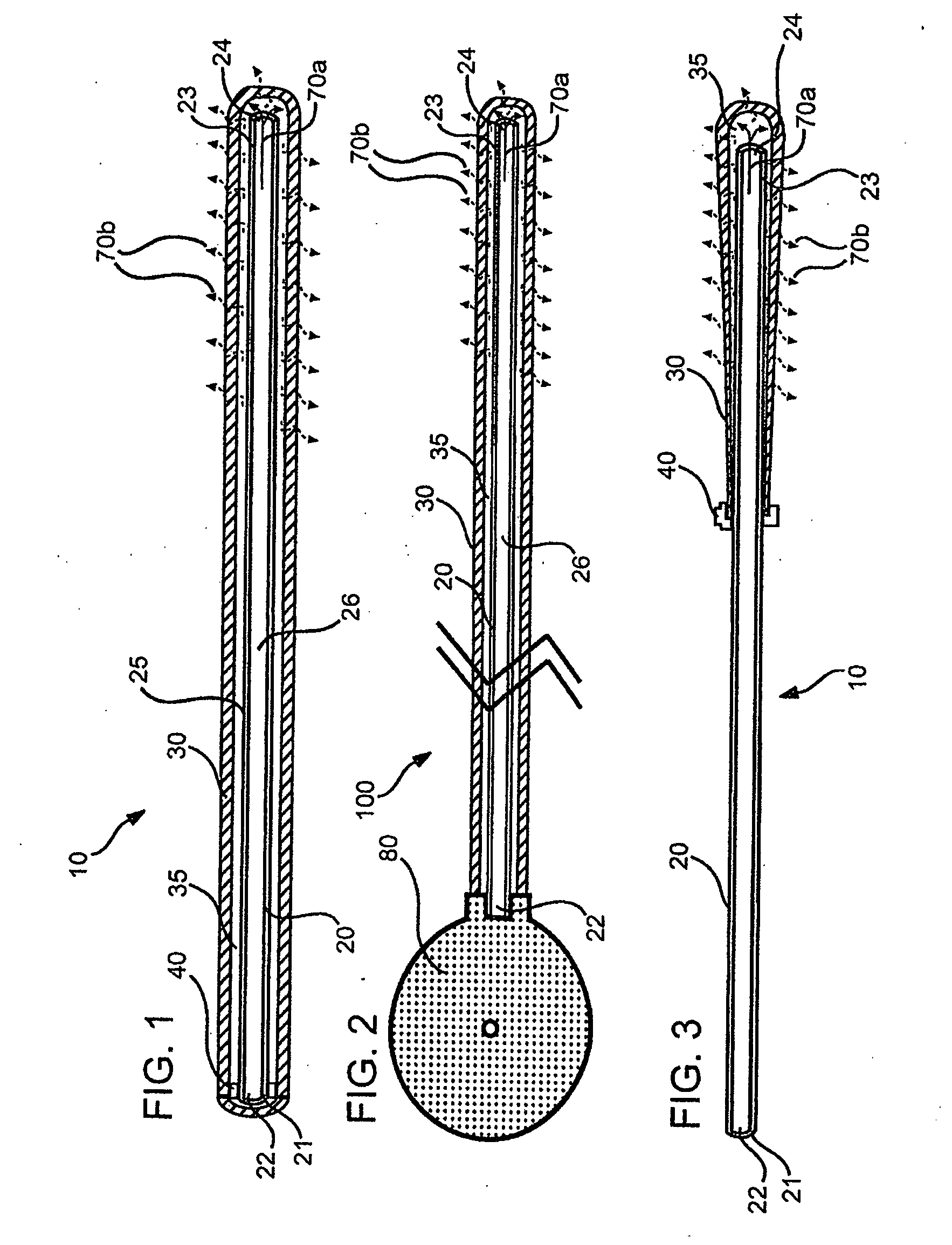

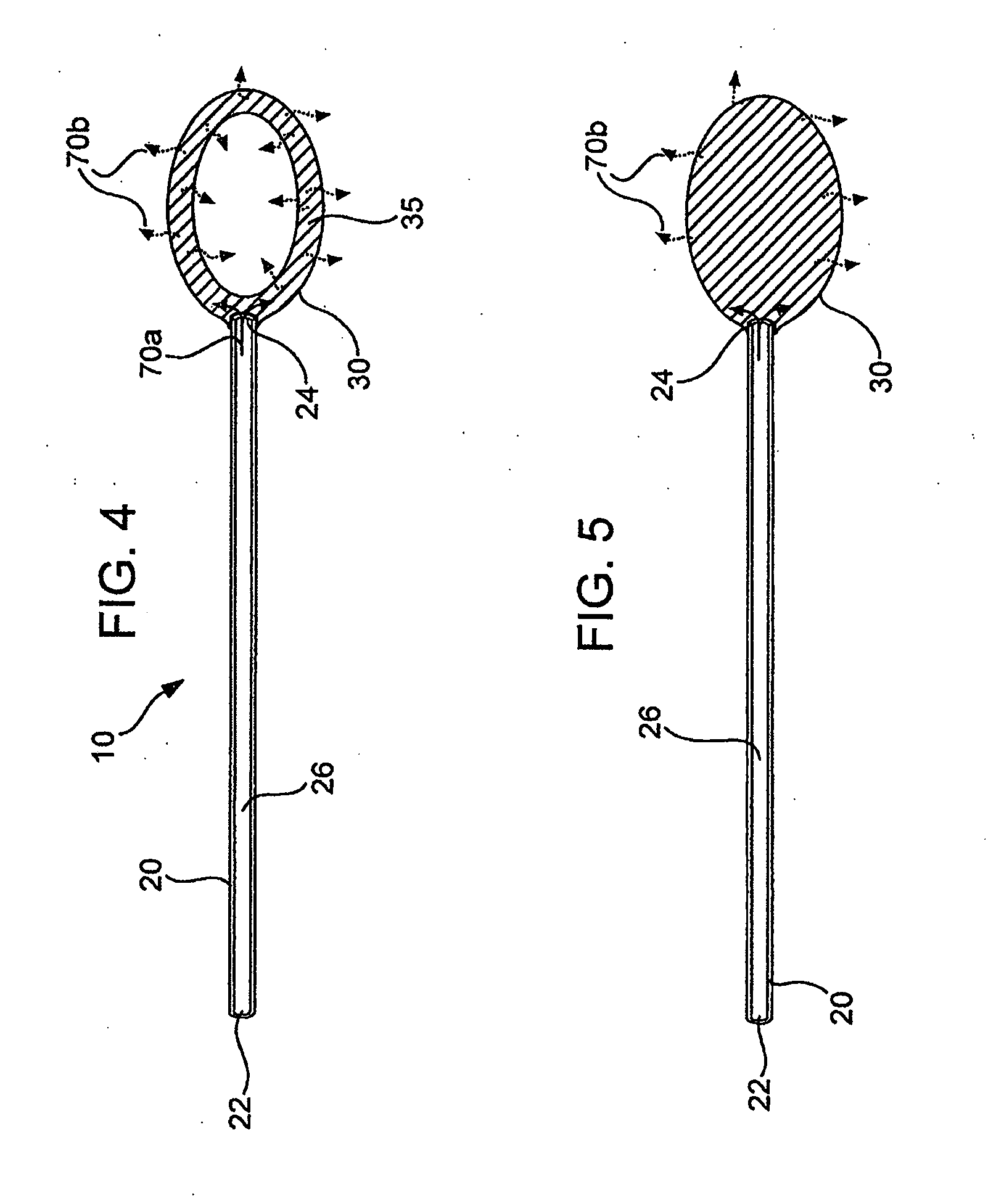

Local concentration management system

InactiveUS7438701B2Reduce deliveryEasy to handleBalloon catheterSurgeryMedicineCentralized management

The invention provides a local concentration management system (LCMS) for delivery of highly concentrated therapeutic agent formulations. The LCMS comprises a device comprising an elongate body defining a lumen between its proximal and distal ends, and a diffuser element, a dilutor element, or both. The diffuser element, which is selectively permeable to the agent, is operatively associated with the elongate body so that agent flows through the elongate body, and into and through the diffuser element to exit the system. The dilutor element can be operatively associated with the system to be in fluid communication with the elongate body lumen, a diffusion space defined by a diffuser element inner wall, or both. The dilutor element is selectively water permeable, but substantially impermeable to agent, to provide for dilution of the agent during transit through the system. The LCMS system is designed to disperse and / or dilute the drug delivery stream.

Owner:DURECT CORP

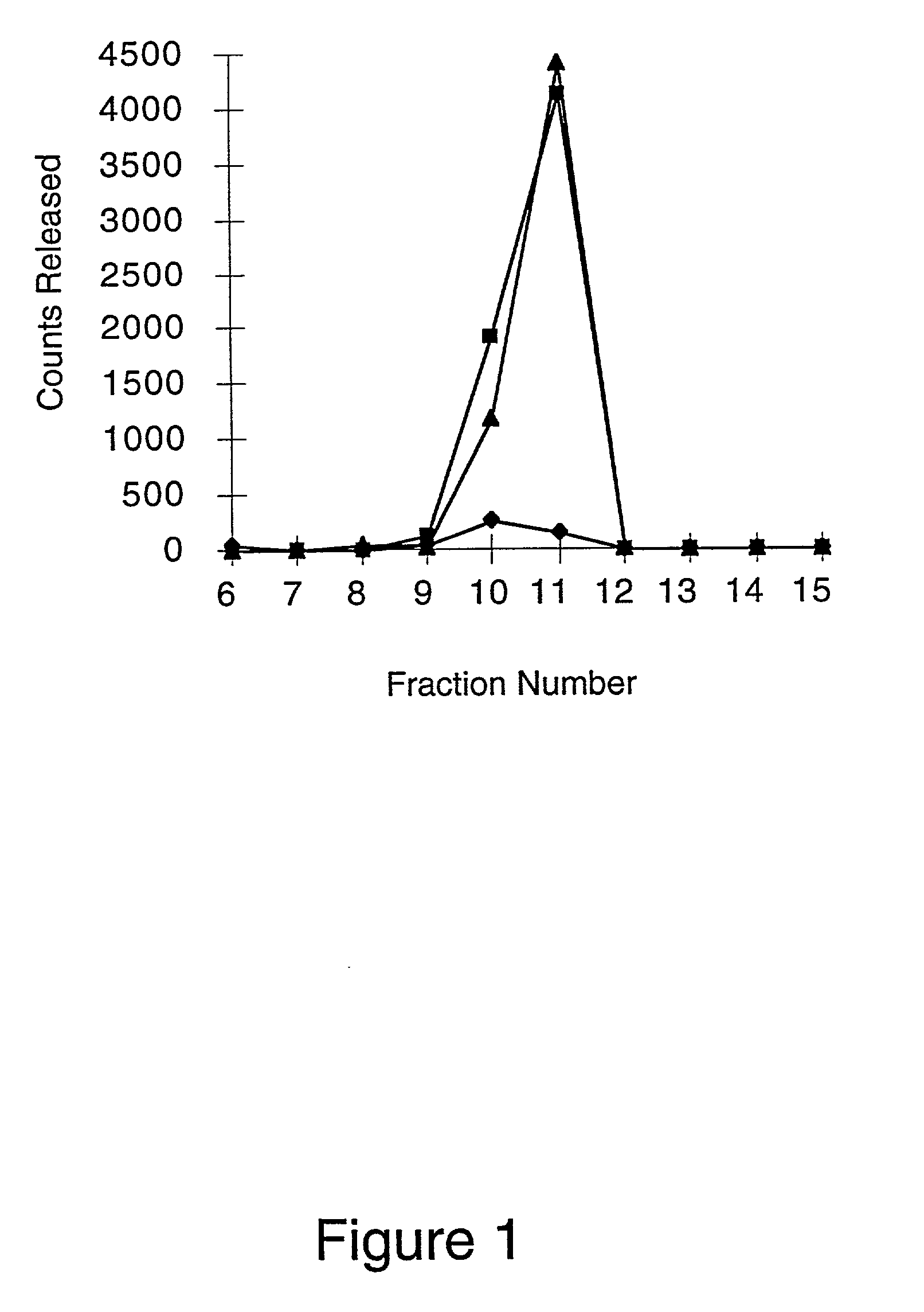

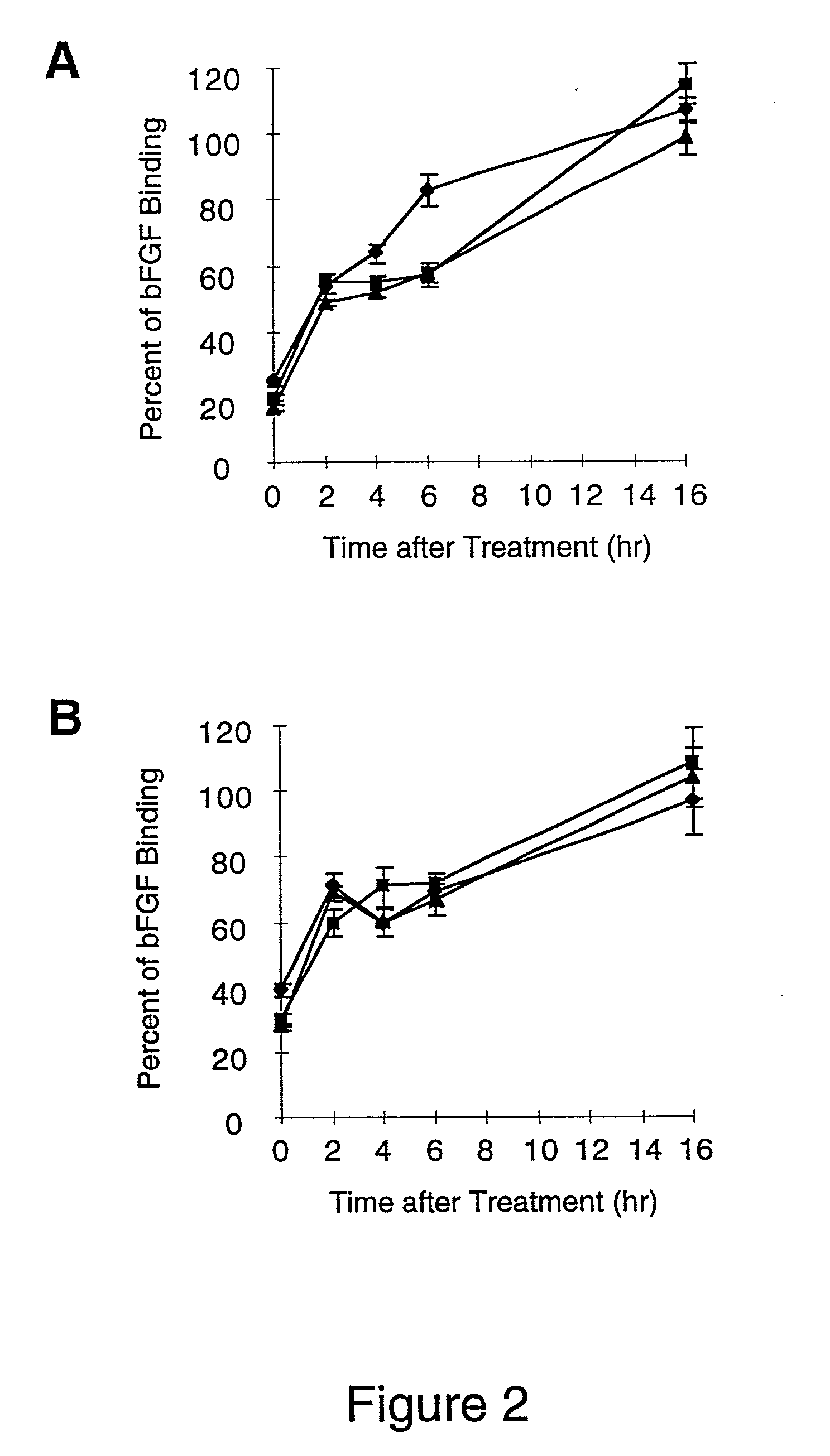

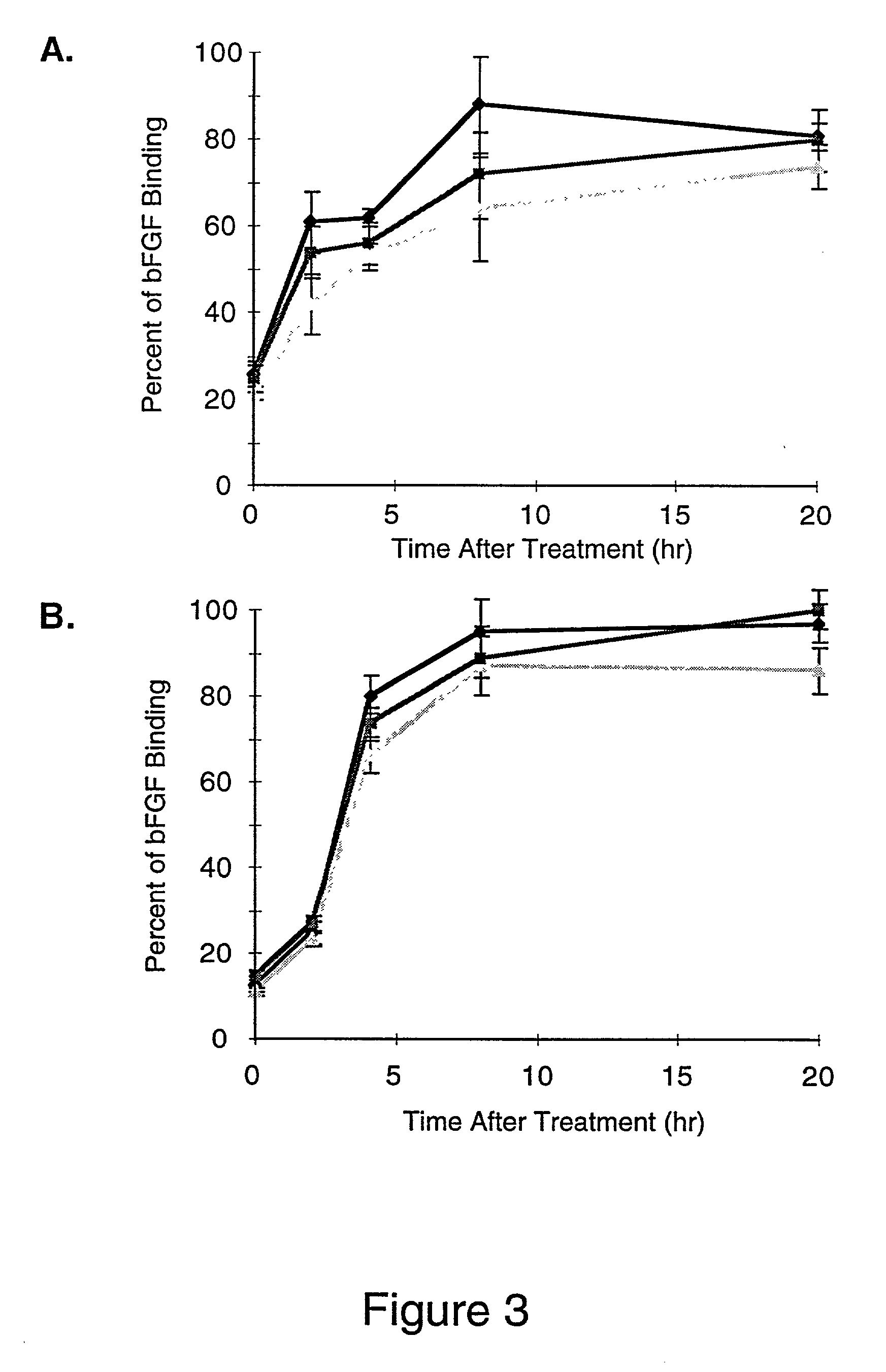

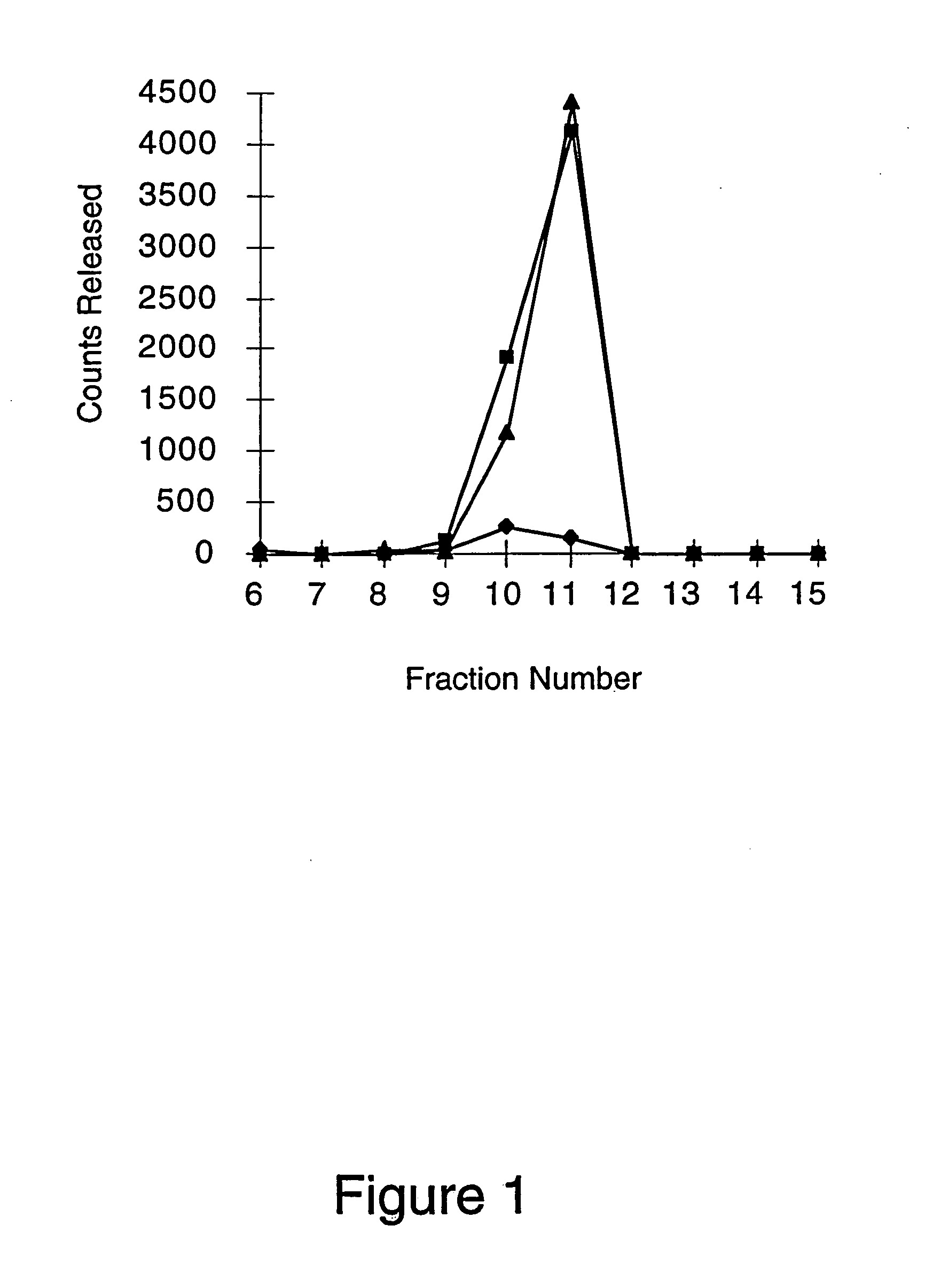

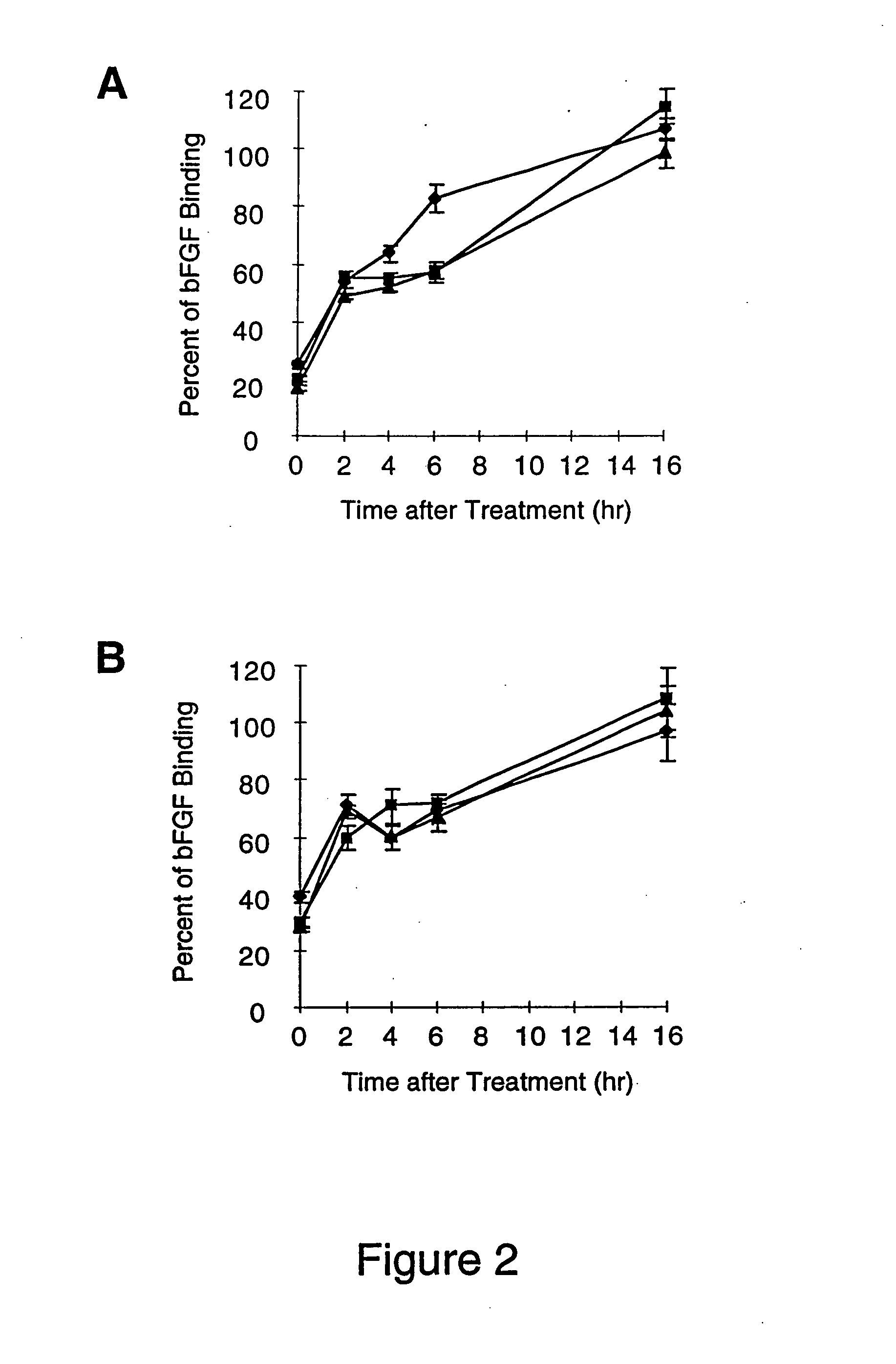

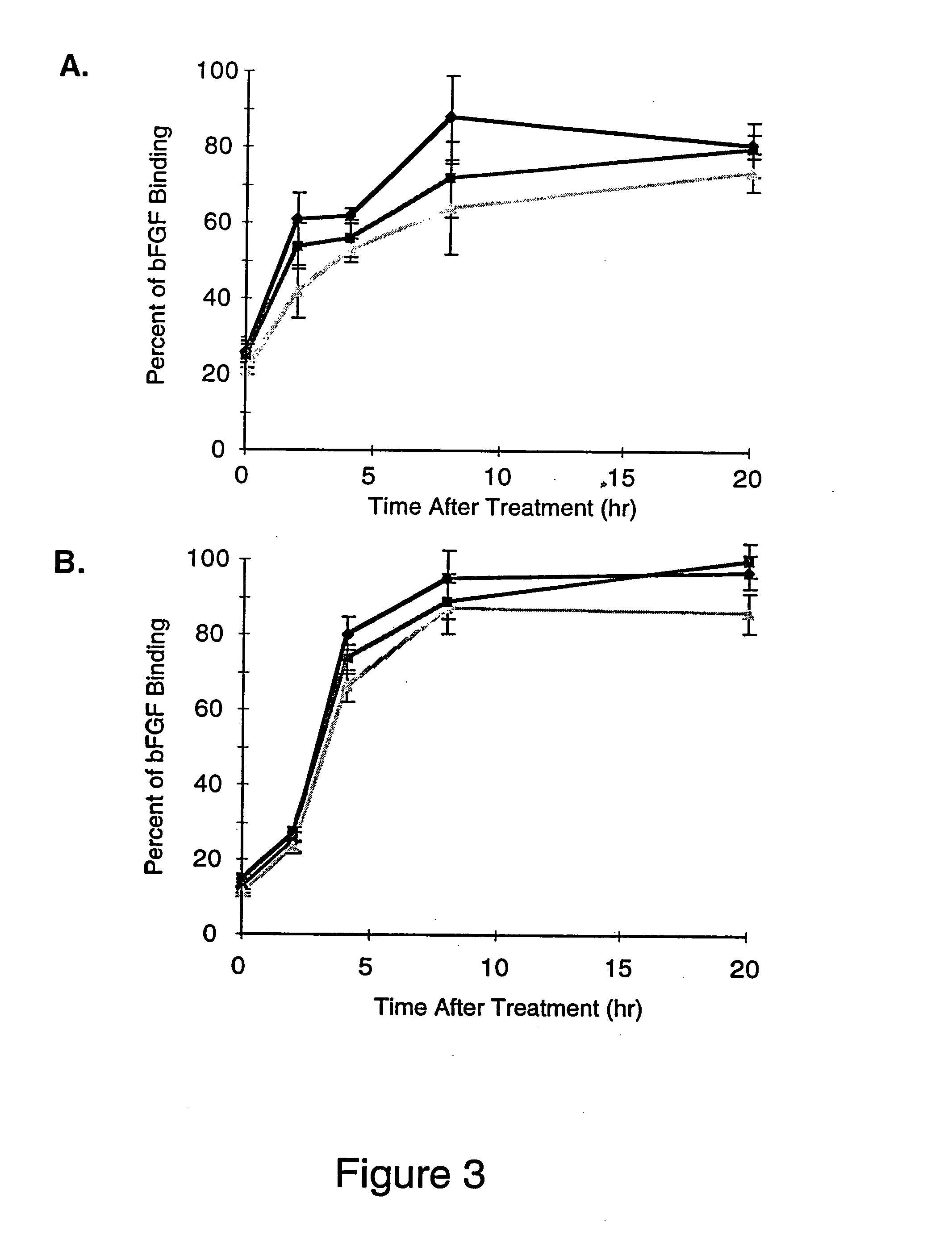

Use of heparinase to decrease inflammatory responses

InactiveUS20010006635A1Inhibiting leukocyte rollingInhibiting chemokine gradient formationOrganic active ingredientsPowder deliveryWhite blood cellDigestion

Heparinase enzymes can be used as a medical treatment to reduce localized inflammatory responses. Treatment of activated endothelium with heparinase inhibits leukocyte rolling, adhesion and extravasation. Most of the heparin and heparan sulfate on endothelial cell surfaces and in basement membranes is degraded by exposure to heparinase. In addition, immobilized chemokines, which are attached to heparin / heparan sulfate on activated endothelium are solubilized by heparinase digestion. Heparinase can be infused into the vascular system to inhibit accumulation of leukocytes in inflamed tissue and decrease damage resulting from localized inflammations. Targeting of heparinase to activated endothelium can be accomplished through localized administration and / or use of genetically engineered heparinase containing endothelium ligand-binding domains.

Owner:BIOMARIN PHARMA INC +1

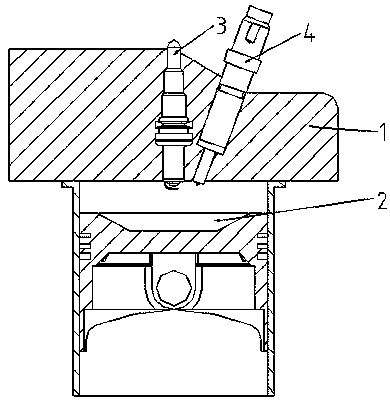

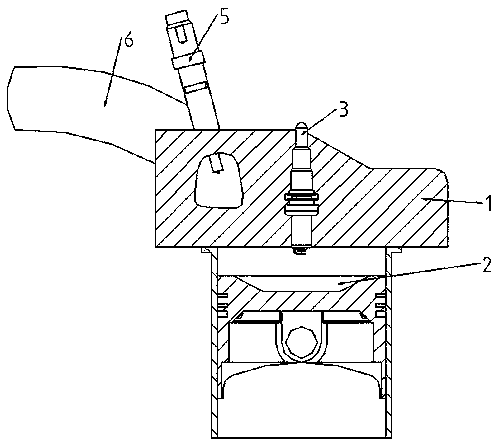

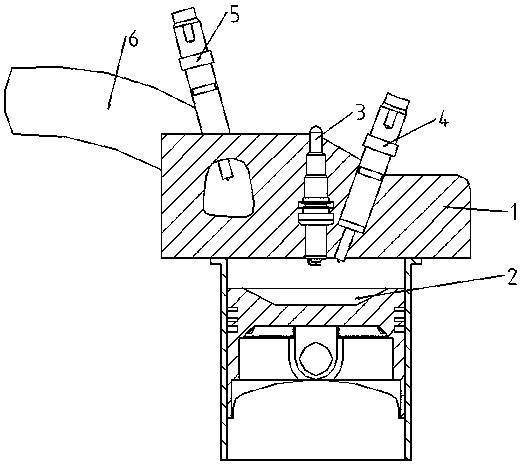

Sparking plug ignition-type premixing compression ignition system of internal combustion engine

ActiveCN107781026AReduce the effective compression ratioReduce the temperatureMechanical controlElectrical controlSpontaneous combustionExternal combustion engine

The invention discloses a sparking plug ignition-type premixing compression ignition system of an internal combustion engine, and belongs to the technical field of combustion of internal combustion engines. According to the premixing compression ignition system, a high-energy sparking plug is adopted for igniting diesel oil or igniting mixtures of the diesel oil and other fuels, wherein the dieseloil or the mixtures serve as the fuels for premixing and are jetted out in a gas feeding process or a compression process to generate premixing gas in a combustion chamber. By adopting an effective compression ratio under which the premixing gas cannot be ignited, the premixing gas in a cylinder cannot burn spontaneously; by using the high-energy sparking plug for ignition close to a compressionupper limit point, the mixed gas nearby the sparking plug is ignited to make the temperature and the pressure in the cylinder quickly rise, the other remaining premixing gas in the cylinder satisfiesthe conditions for spontaneous combustion, large-scale multi-point spontaneous combustion happens, and fast combustion of the premixing gas is achieved. By adopting a high expansion ratio, the heat efficiency is further improved.

Owner:DALIAN UNIV OF TECH

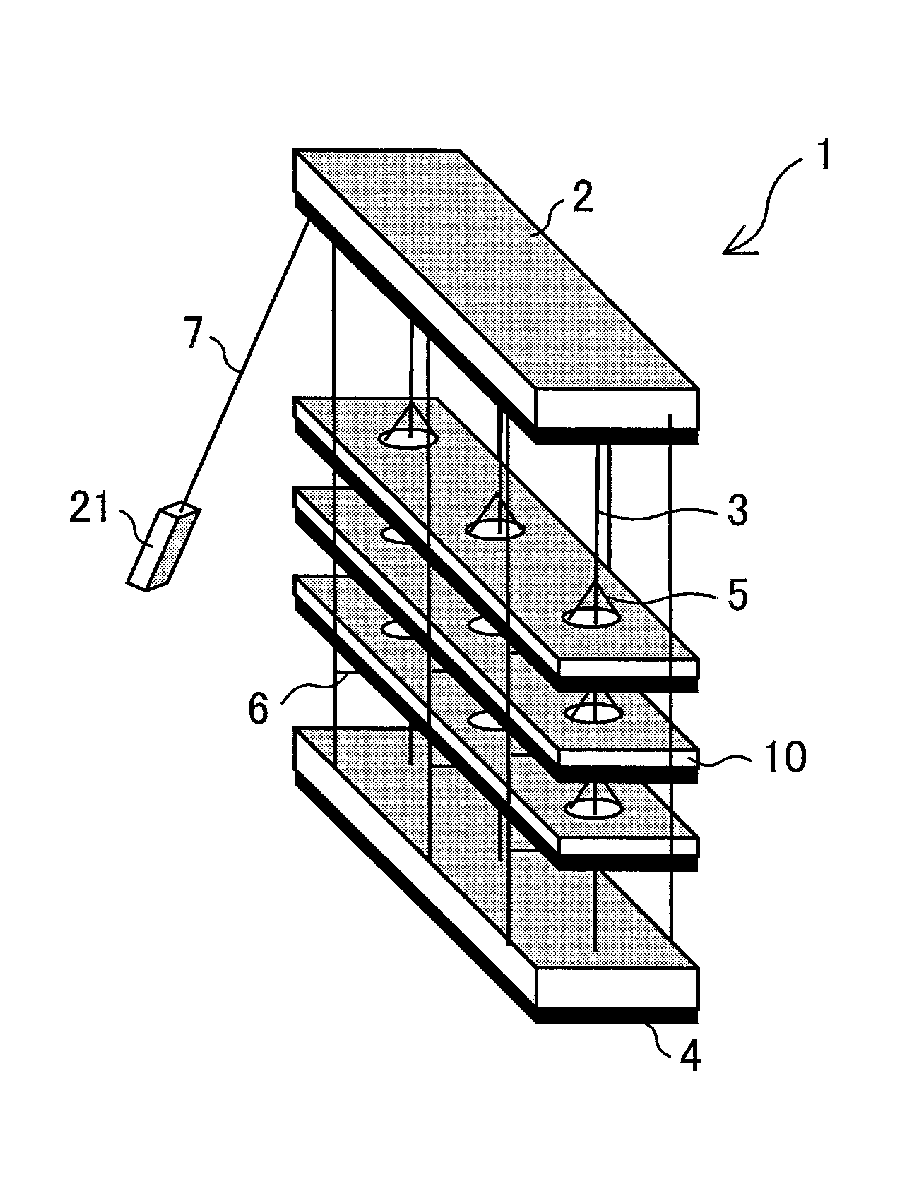

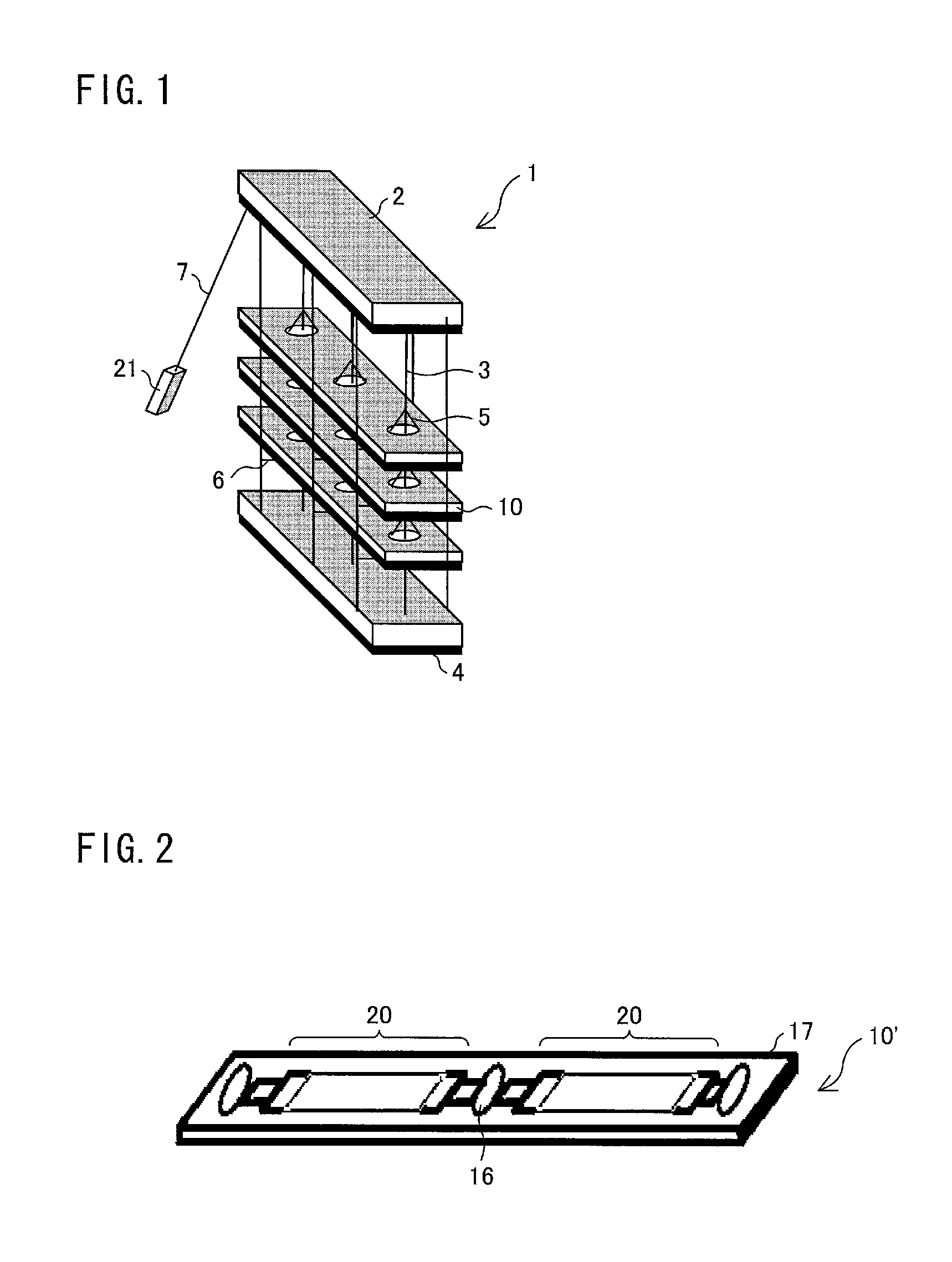

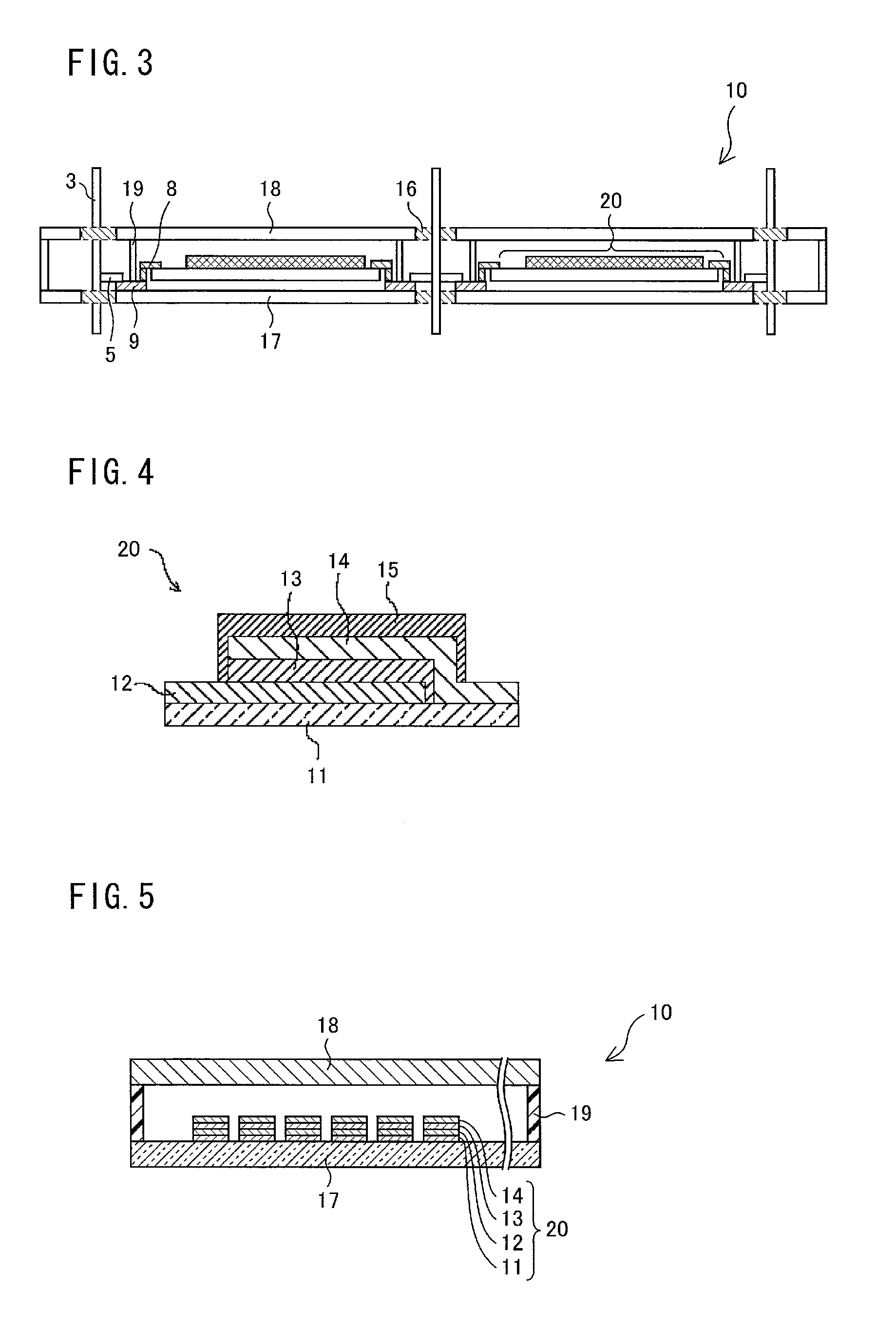

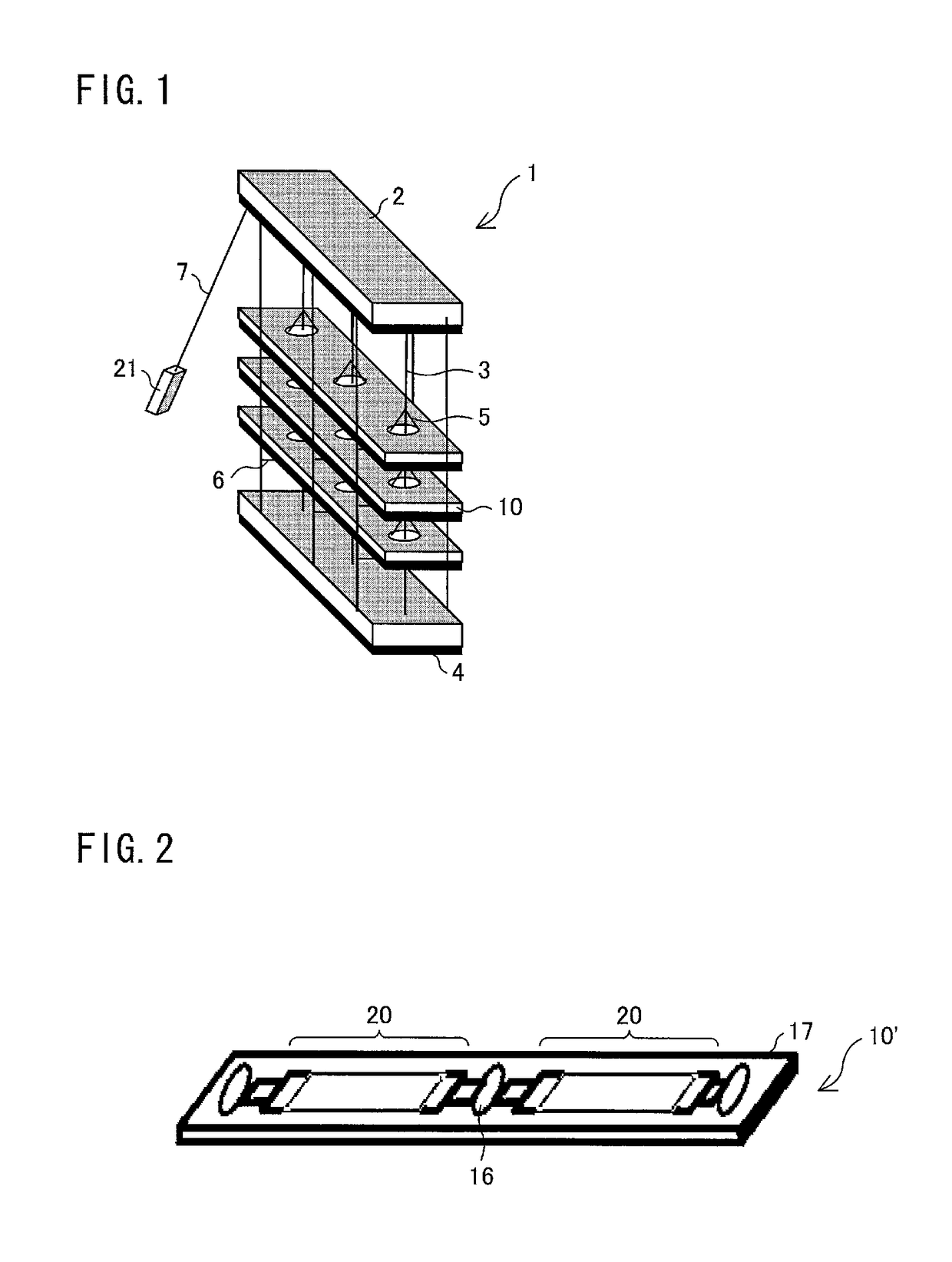

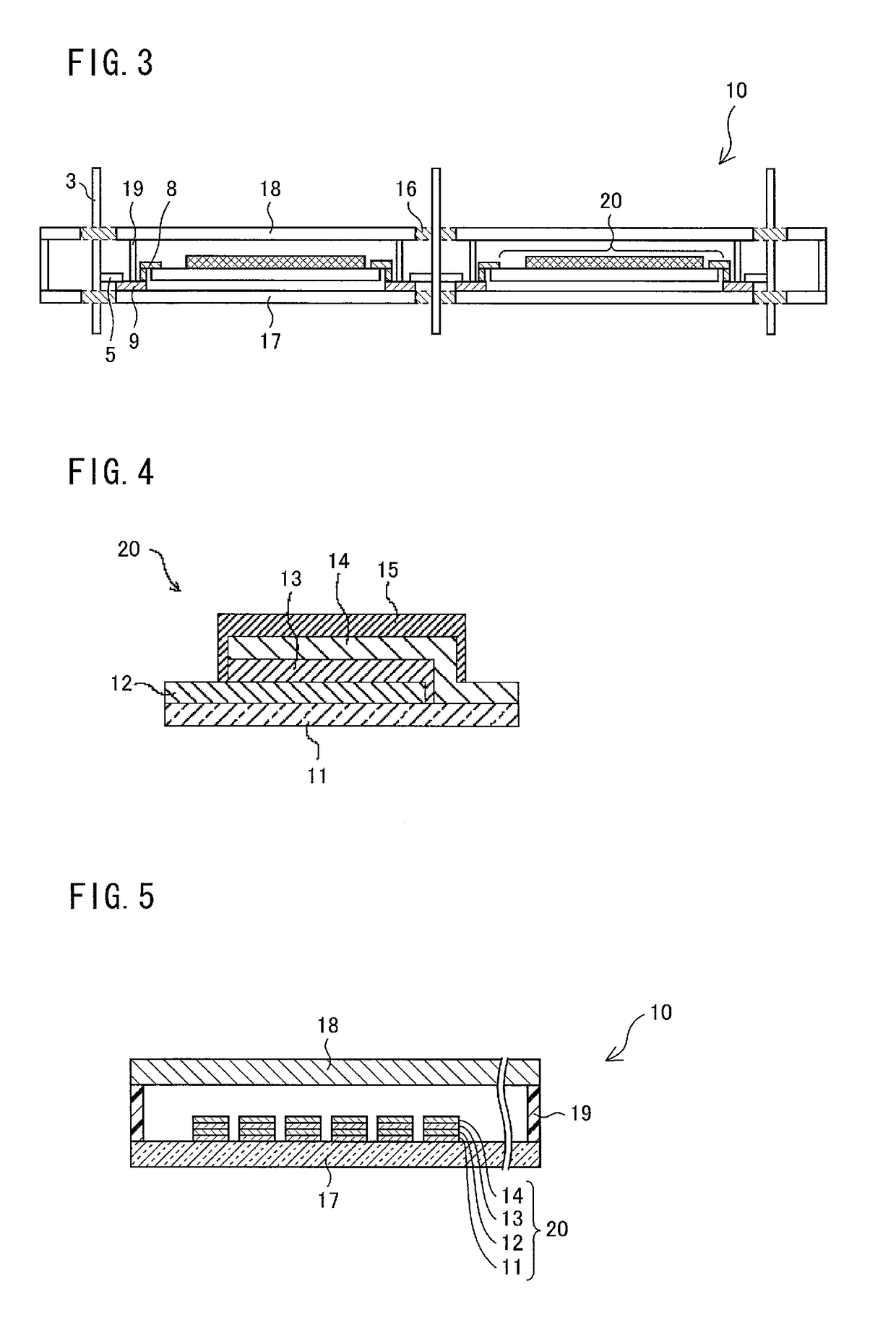

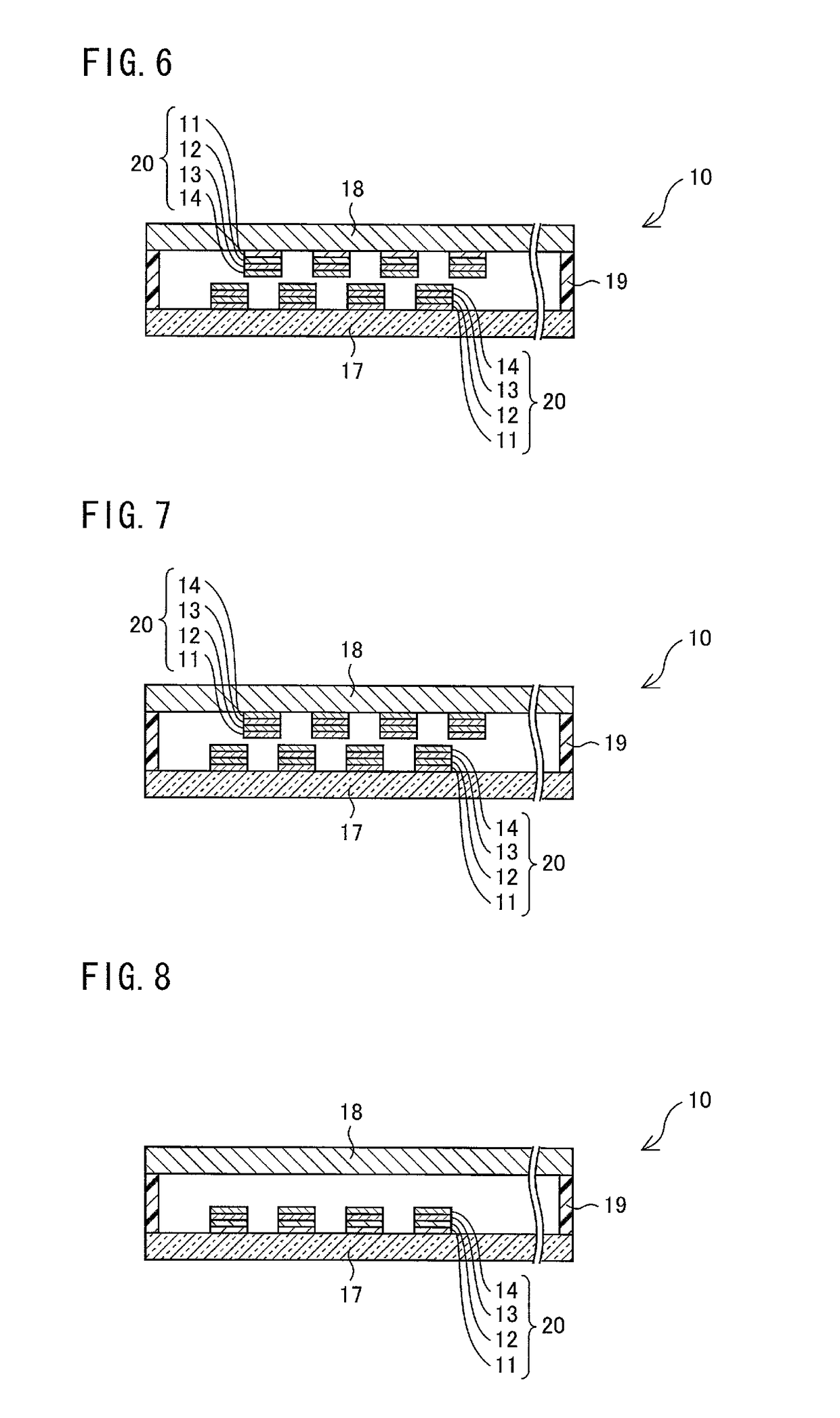

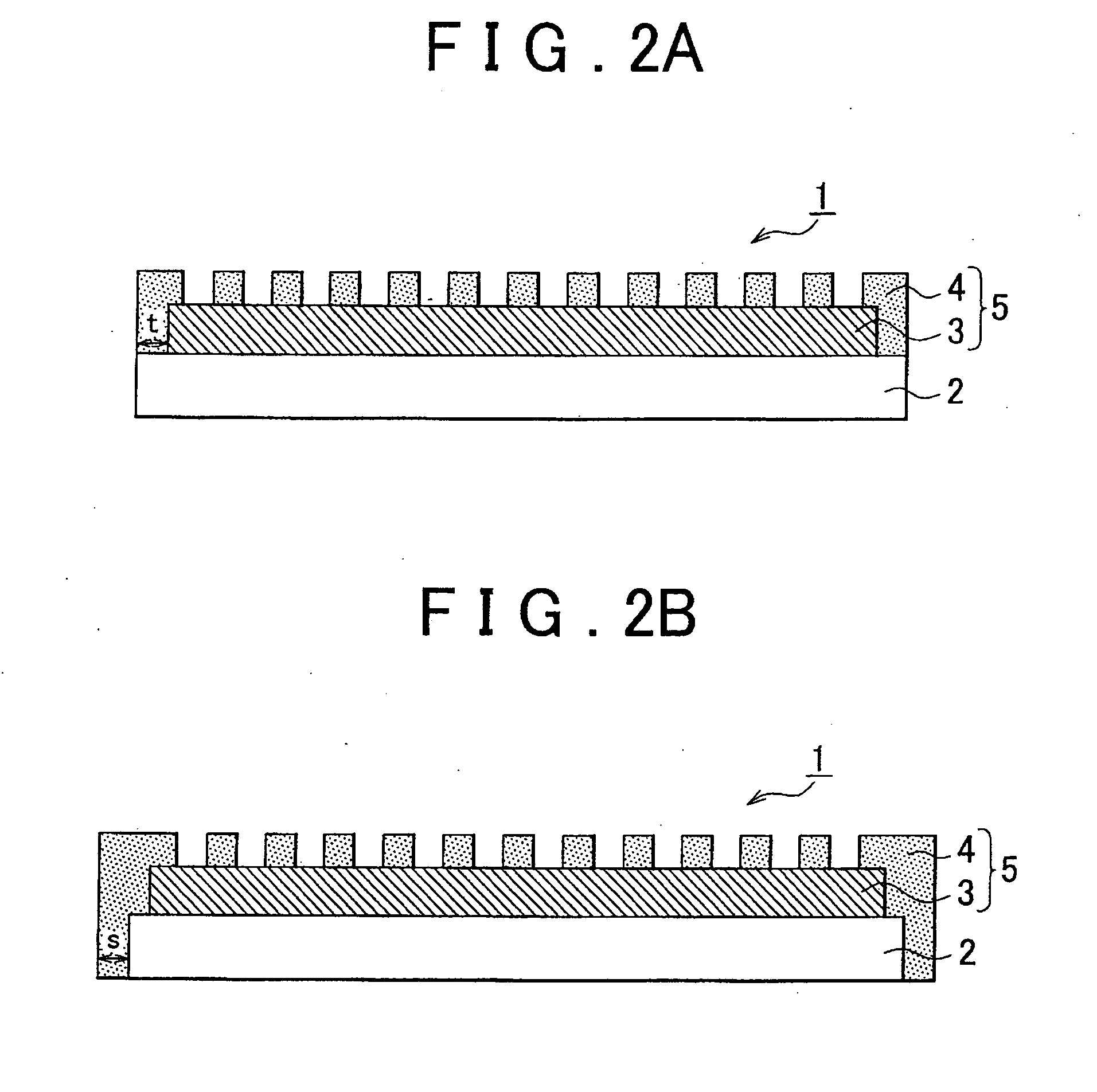

Integrated illumination apparatus and method of manufacturing same

ActiveUS20120313512A1Reduce local concentrationPrevents the wire from getting deterioratedPlanar light sourcesDischarge tube luminescnet screensStress concentrationEngineering

A plurality of illumination panels (10) are hung by up-and-down cords (3). The up-and-down cords (3) have a function of hanging the illumination panels (10) and a function of supplying electric power to the illumination panels (10). Pulling a rod (7), which is a take-up tool causes the up-and-down cords (3) to be taken up and, at the same time, the bottom rail (4) and the illumination panels (10) are also raised. At this time, the up-and-down cords (3) are taken up into the head box (2). As such, when the bottom rail (4) is raised, the up-and-down cords (3) are taken up without bending. This makes it possible to distribute stress that may otherwise be concentrated locally on the up-and-down cords (3). As a result, the up-and-down cords (3) can be prevented from getting broken due to deterioration caused by concentration of stress on the up-and-down cords (3), which concentration is caused by bending etc. of the up-and-down cords (3).

Owner:SHARP KK

Use of heparinase to decrease inflammatory responses

InactiveUS20050191288A1Reduce local concentrationInhibiting chemokine activationOrganic active ingredientsPowder deliveryWhite blood cellDigestion

Heparinase enzymes can be used as a medical treatment to reduce localized inflammatory responses. Treatment of activated endothelium with heparinase inhibits leukocyte rolling, adhesion and extravasation. Most of the heparin and heparan sulfate on endothelial cell surfaces and in basement membranes is degraded by exposure to heparinase. In addition, immobilized chemokines, which are attached to heparin / heparan sulfate on activated endothelium are solubilized by heparinase digestion. Heparinase can be infused into the vascular system to inhibit accumulation of leukocytes in inflamed tissue and decrease damage resulting from localized inflammations. Targeting of heparinase to activated endothelium can be accomplished through localized administration and / or use of genetically engineered heparinase containing endothelium ligand-binding domains.

Owner:BIOMARIN PHARMA INC

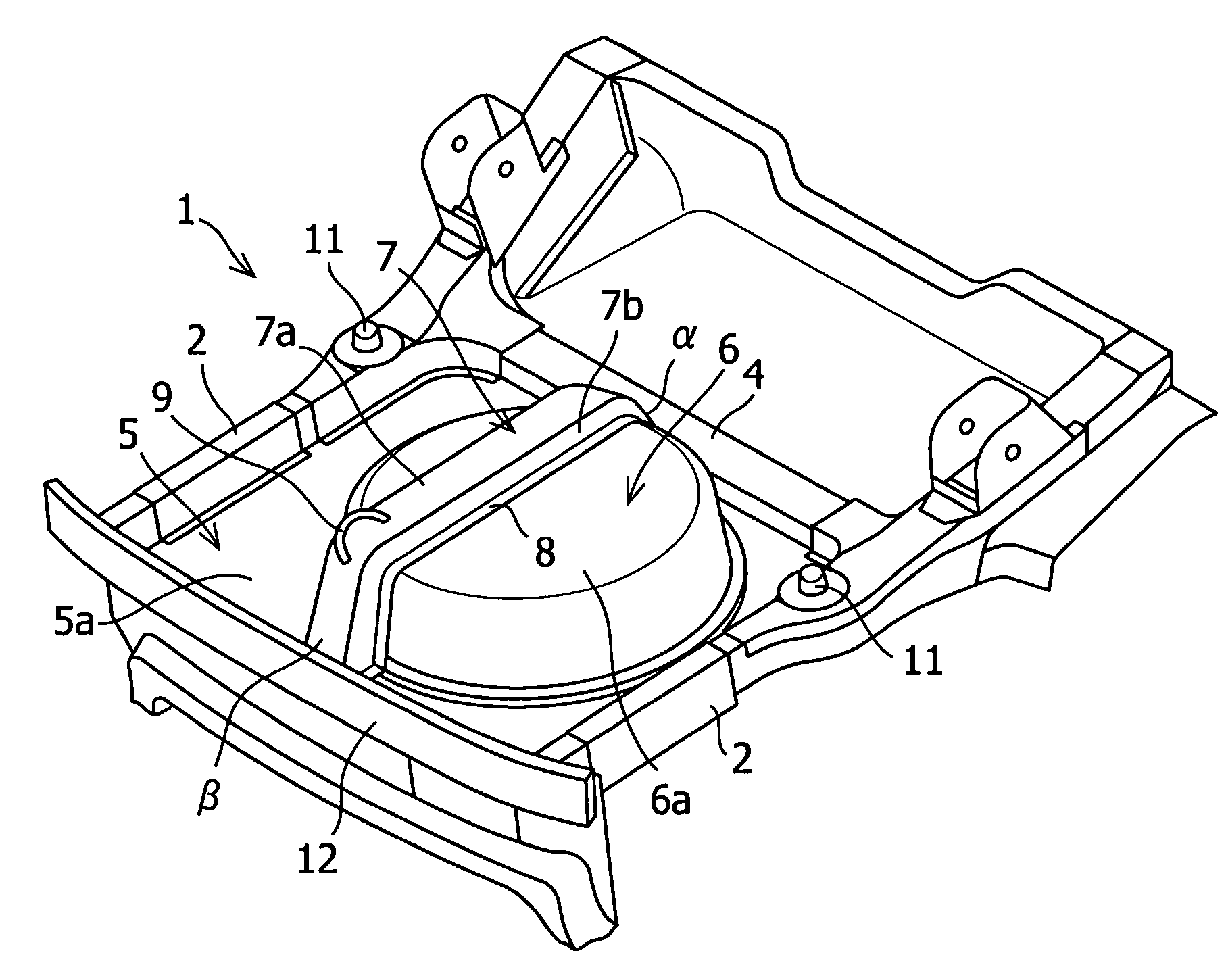

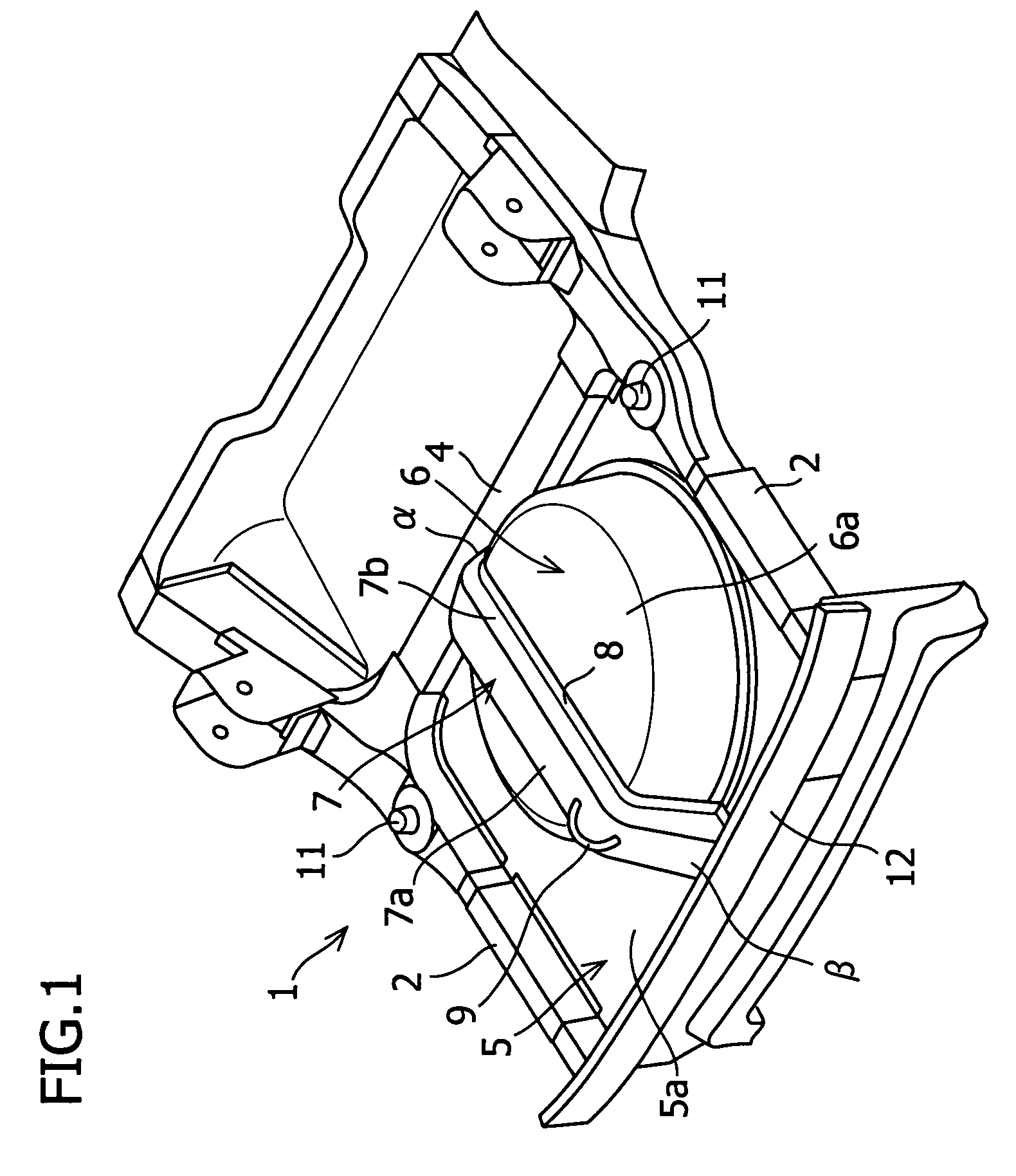

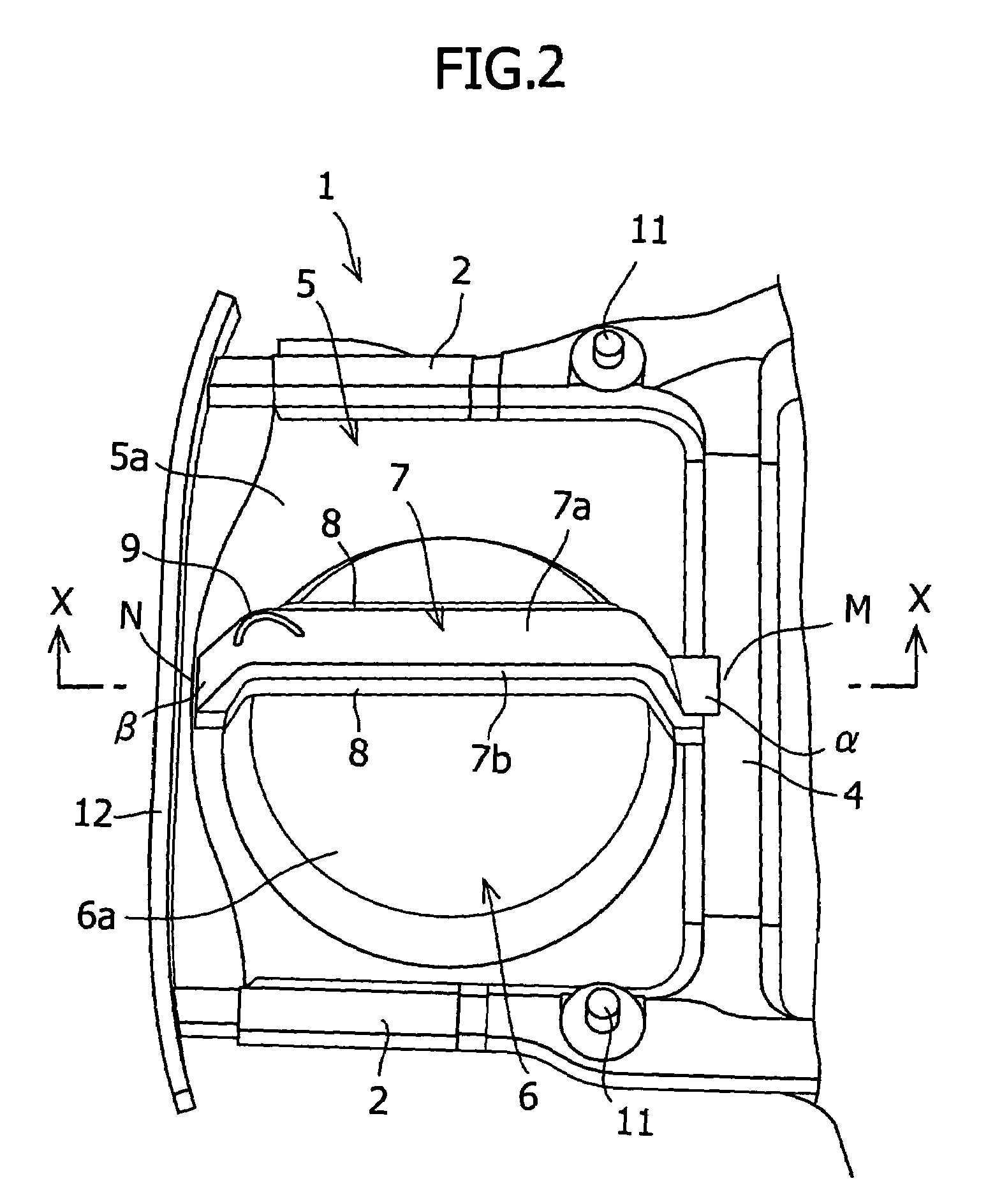

Vehicle body rear structure of automobile

InactiveUS7380856B2Reduce load concentrationStrengthVehicle seatsSuperstructure subunitsBelt safetySpare tire

There is provided a vehicle body rear structure of an automobile, which can deal with all of a load from a towing hook, a load from a jack-up point, a load from the rear of vehicle body, and a load from a seat belt anchor, though having a simple construction that does not bring about an increase in the number of parts and an increase in weight of vehicle body. A load distributing member 7 extending along the body longitudinal direction is assembled to a spare tire house 6 so as to trail over a lower surface 6a of the spare tire house 6; and a front end portion α of the load distributing member 7 is joined to a cross member 4, and a rear end portion β thereof is joined to the back panel 3 (located on the rear side of the cross member 4).

Owner:SUZUKI MOTOR CORP

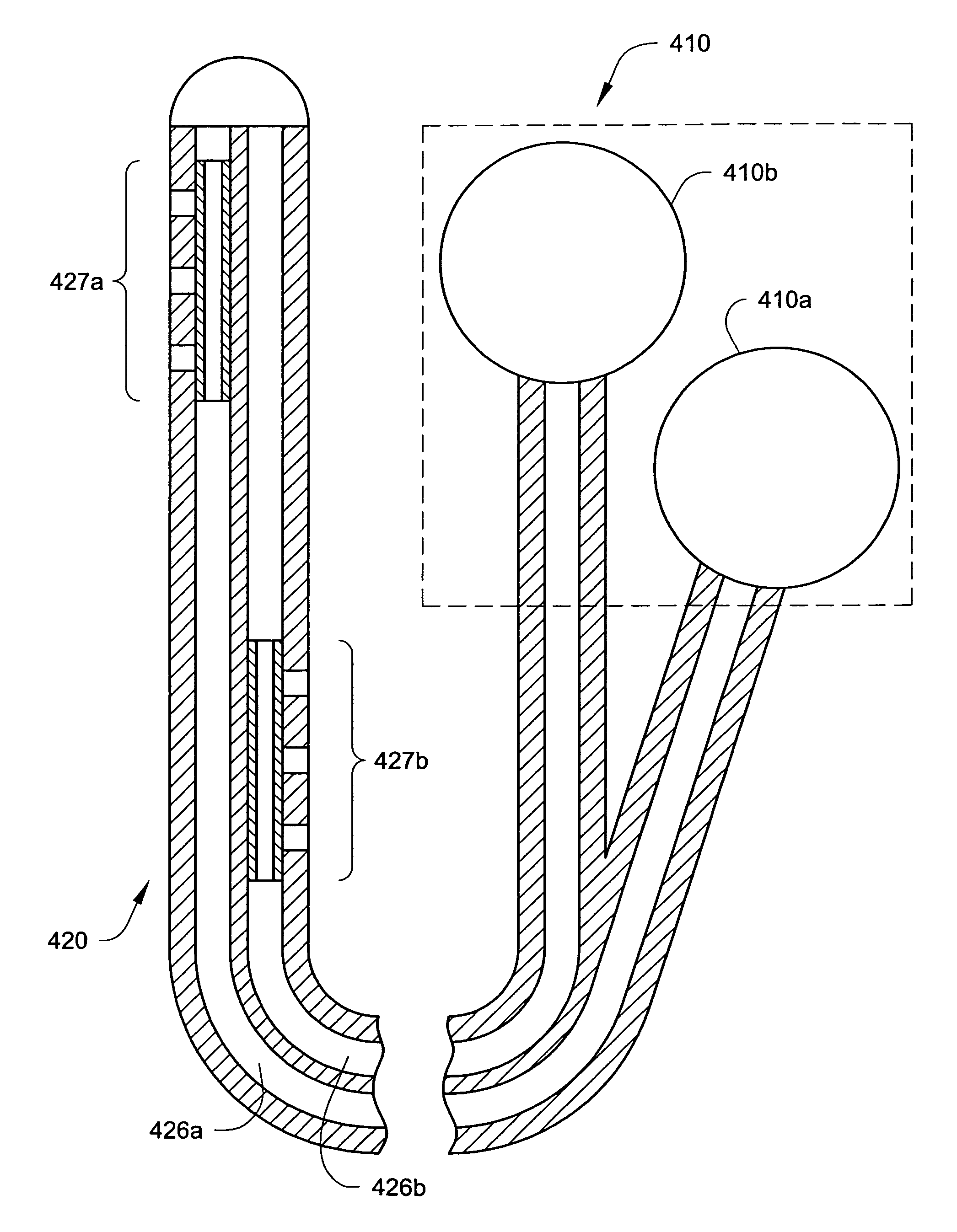

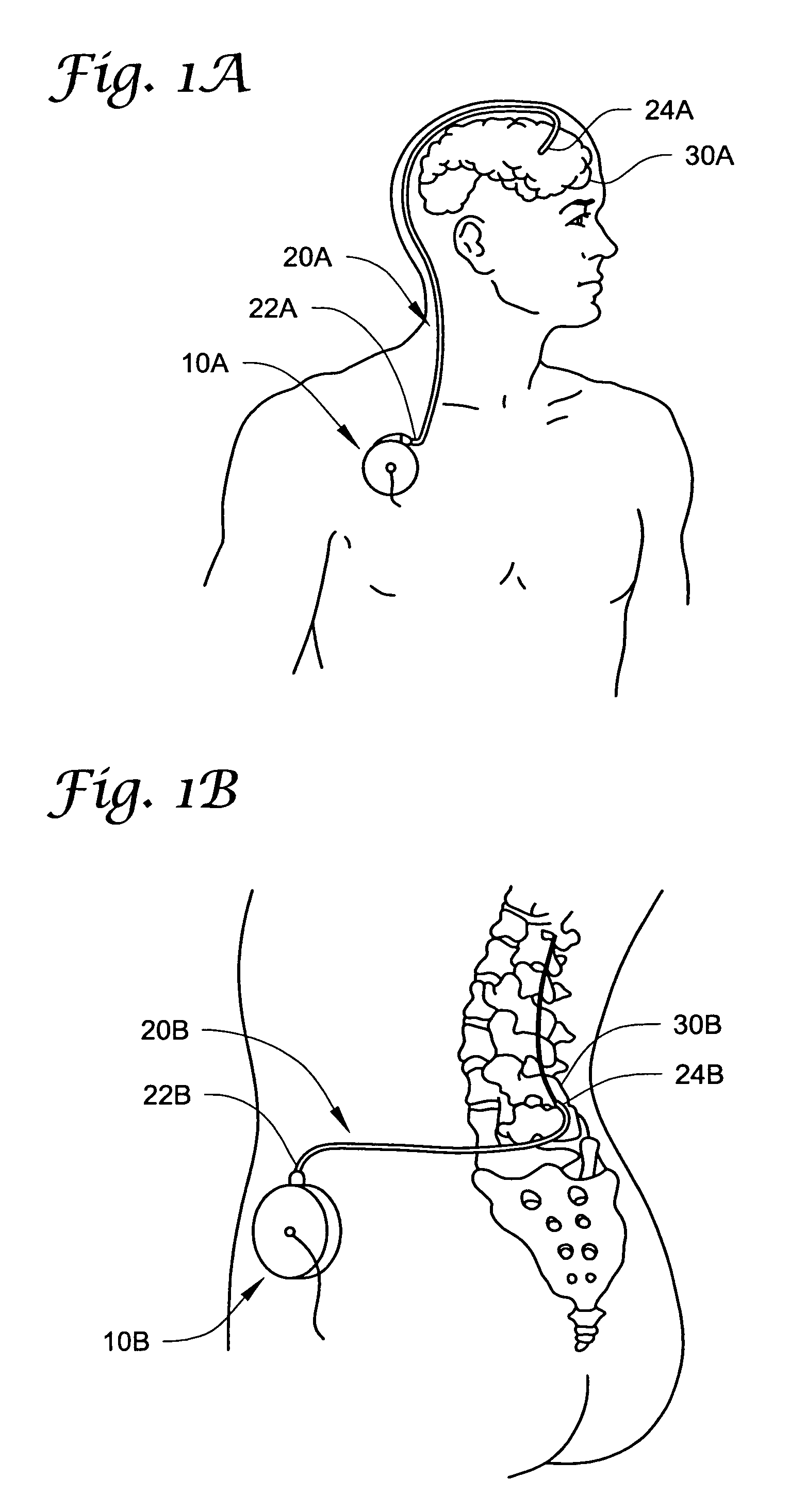

Reduction of inflammatory mass with spinal catheters

ActiveUS8137334B2Improve efficacyReduce the amount requiredPharmaceutical delivery mechanismMedical devicesSpinal columnDisease

Devices, systems and methods for delivering one or more drugs to one or more internal body locations (such as the cerebrospinal fluid) are disclosed. In various aspects, the systems and methods may involve catheters having infusion sections with permeable membranes that develop significant back pressure to enhance uniform delivery of the drug over an infusion section; catheters that have two or more infusion sections spaced apart along the length of the same catheter, catheters that include two or more infusion sections serviced by independent lumens (such that, e.g., different drug solutions can be delivered to the different infusion sections); implantable drug delivery systems with pumps and multiple reservoirs from which drugs can be delivered; systems that are capable of delivering drug solutions with selected densities; etc. Methods for treating diseases, including pain and spasticity are also discussed, as well as methods for screening patients and optimizing therapies. In addition, methods for delivering a drug to a brain through a spinal canal are described.

Owner:MEDTRONIC INC

Integrated illumination apparatus and method of manufacturing same

ActiveUS8471464B2Reduce local concentrationPrevents the wire from getting deterioratedPlanar light sourcesDoor/window protective devicesStress concentrationEngineering

One or more illumination panels (10) are hung by up-and-down cords (3). The up-and-down cords (3) have a function of hanging the illumination panels (10) and a function of supplying electric power to the illumination panels (10). Pulling a rod (7), which is a take-up tool causes the up-and-down cords (3) to be taken up and, at the same time, the bottom rail (4) and the illumination panels (10) are also raised. At this time, the up-and-down cords (3) are taken up into the head box (2). As such, when the bottom rail (4) is raised, the up-and-down cords (3) are taken up without bending. This makes it possible to distribute stress that may otherwise be concentrated locally on the up-and-down cords (3). As a result, the up-and-down cords (3) can be prevented from getting broken due to deterioration caused by concentration of stress on the up-and-down cords (3), which concentration is caused by bending etc. of the up-and-down cords (3).

Owner:SHARP KK

Method for preparing highly-dispersed magnesium hydroxide by magnesium salt

InactiveCN105060319AReduce local concentrationAvoid formingMagnesium hydroxidePigment treatment with non-polymer organic compoundsInorganic saltsMagnesium salt

The invention relates to the chemical field of inorganic salt and discloses a method for preparing highly-dispersed magnesium hydroxide by magnesium salt. By adopting a synchronous feeding method and inorganic magnesium salt and inorganic alkaline liquor as raw materials, the pH value is controlled to obtain a magnesium hydroxide mixed liquid; and the magnesium hydroxide liquid is aged, suction-filtered, washed and dried to prepare magnesium hydroxide powder. By using water as a substrate and synchronously adding the inorganic magnesium salt and inorganic alkaline liquor, the local concentration of the reactant can be effectively reduced so as to prevent magnesium hydroxide from forming a colloid. The obtained magnesium hydroxide powder is small in grain size and uniform in size and is highly dispersed. The method disclosed by the invention is simple in synthetic process, mild in reaction condition and convenient for industrial production.

Owner:韦海棉

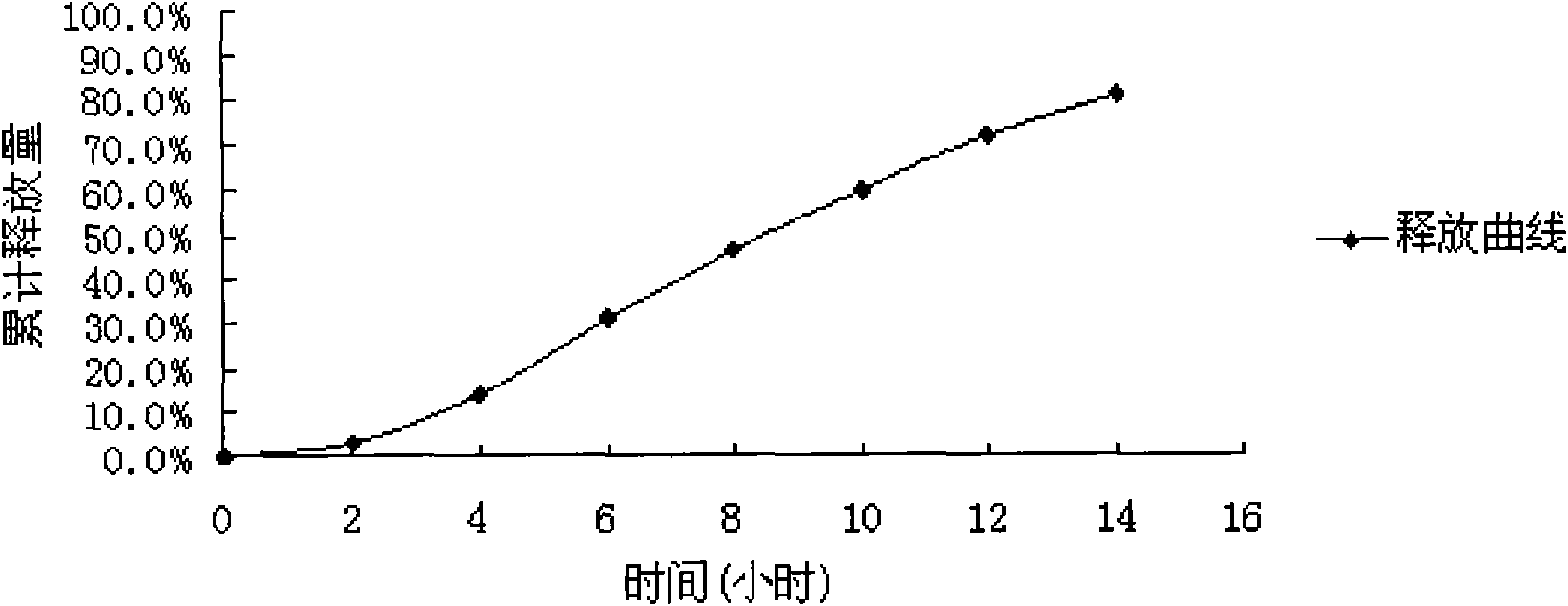

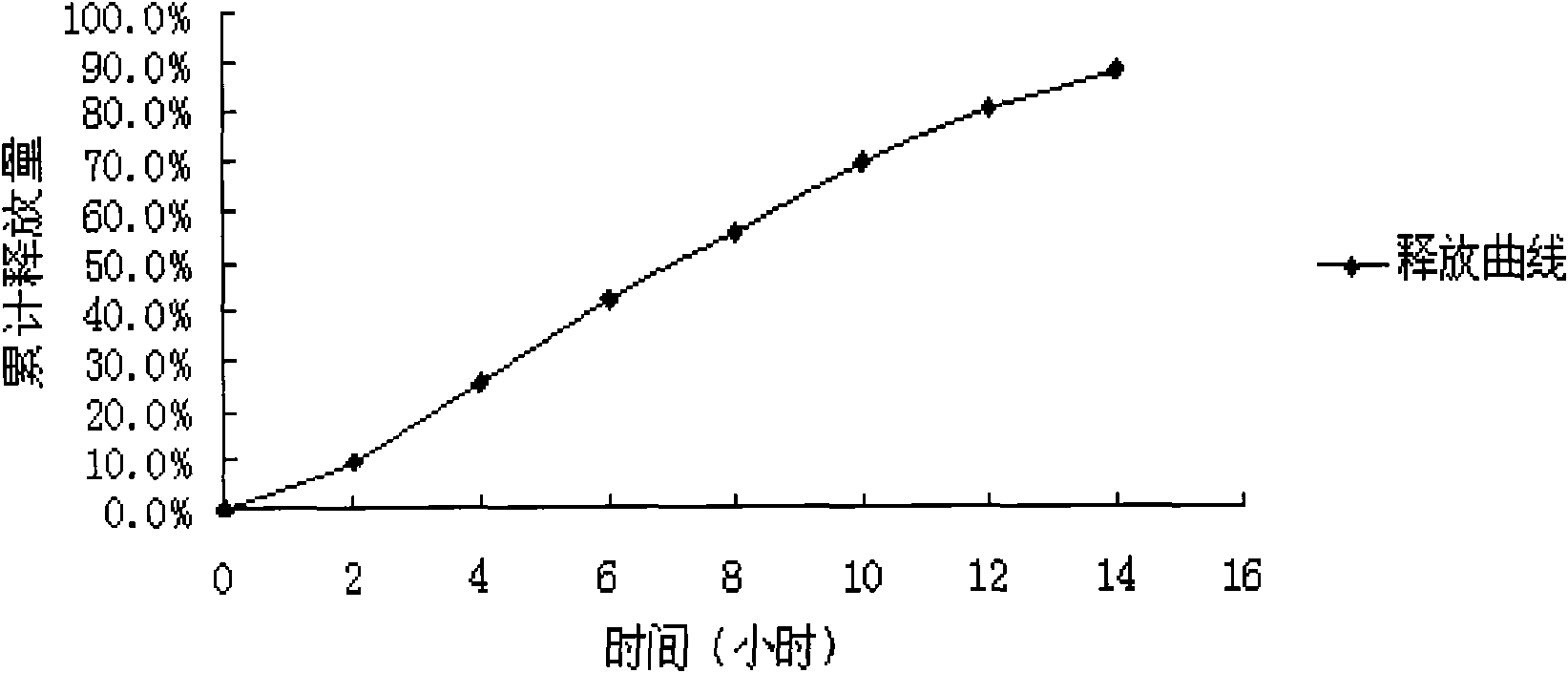

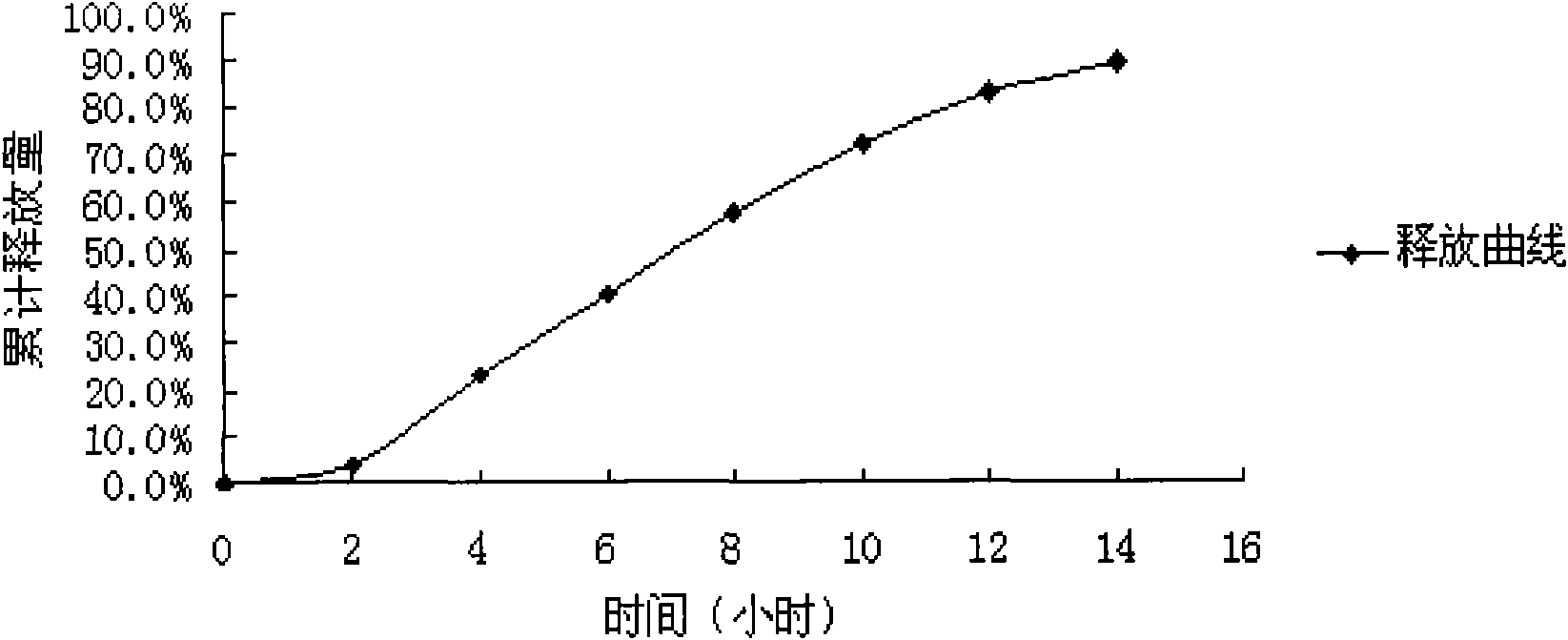

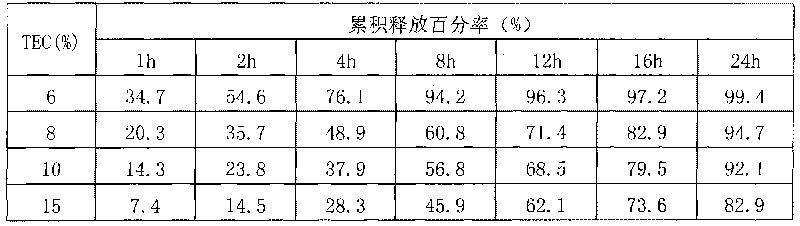

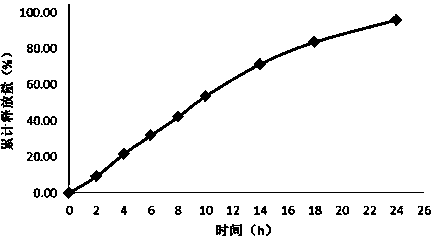

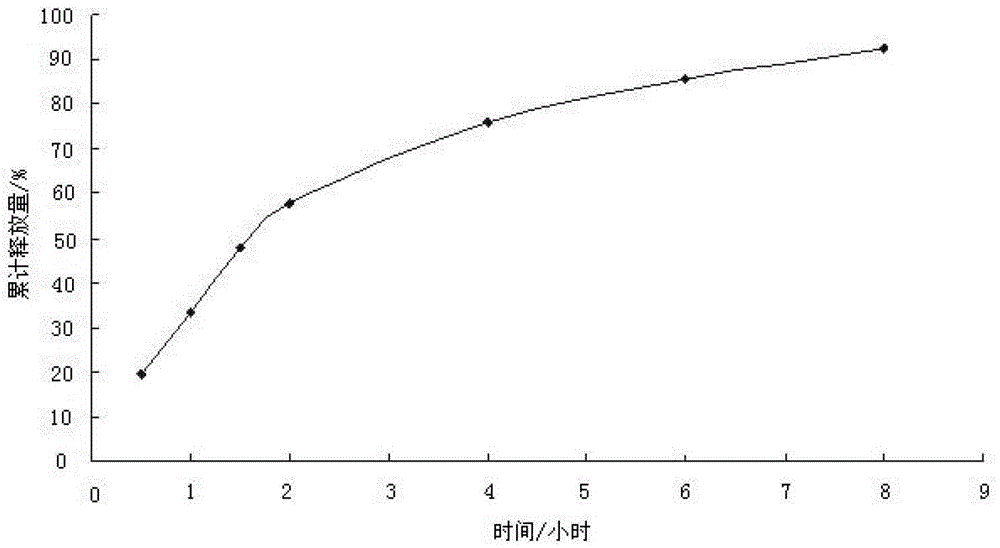

Aceclofenac bi-layer osmotic pump controlled release tablets and preparation method thereof

InactiveCN101618027AShort half-lifeImprove complianceOrganic active ingredientsAntipyreticAnkylosing spondylitisAceclofenac

The invention provides an aceclofenac bi-layer osmotic pump controlled release tablet and a preparation method thereof, belongs to the technical field of medicinal preparation. The osmotic pump preparation comprises a tablet core containing aceclofenac and a semipermeable coating membrane which is coated outside the tablet core and provided with orifices, the tablet core comprises a drug layer containing aceclofenac and a boosting layer; wherein, the drug layer comprises the following components: 200mg of aceclofenac, 100mg-300mg of suspension, 10mg-50mg of osmotic stress active substance and0.5 mg-2mg of lubricant; the boosting layer comprises 50mg-150mg of sweller and 5mg-30mg of osmotic stress active substance; the semipermeable coating membrane comprises the following components: 10g-20g of semipermeable high polymer material dissolved in 500ml of acetone and 2g-5g of water soluble pore former dissolved in 20ml of distilled water and the weight of the coating membrane is 5%-10% of the tablet core weight; laser or a power drill is used to drill the orifices on the drug-containing side of the coating tablet. The invention is characterized of less dosing frequency, convenient taking way, long lasting and stable curative effect and can be used to cure pains and inflammations caused by osteoarthritis, rheumatoid arthritis, ankylosing spondylitis and the like.

Owner:SHENYANG PHARMA UNIVERSITY

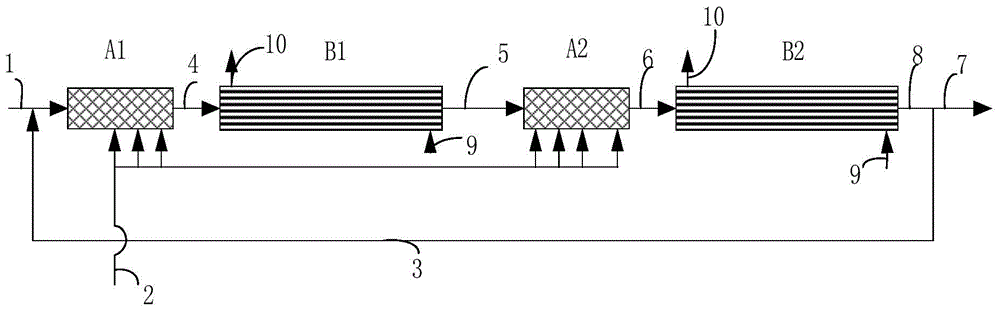

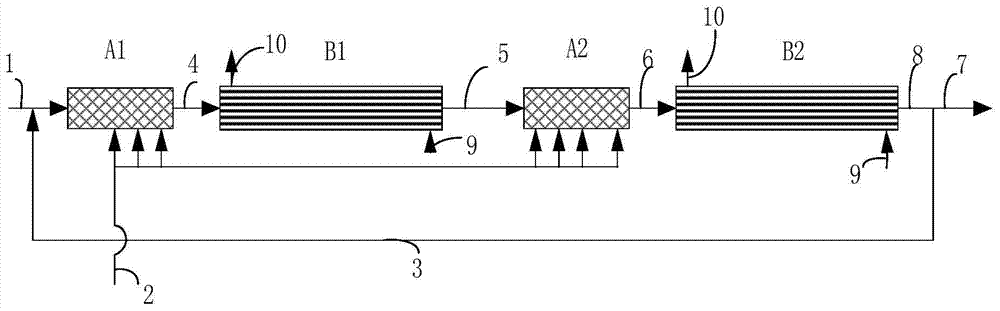

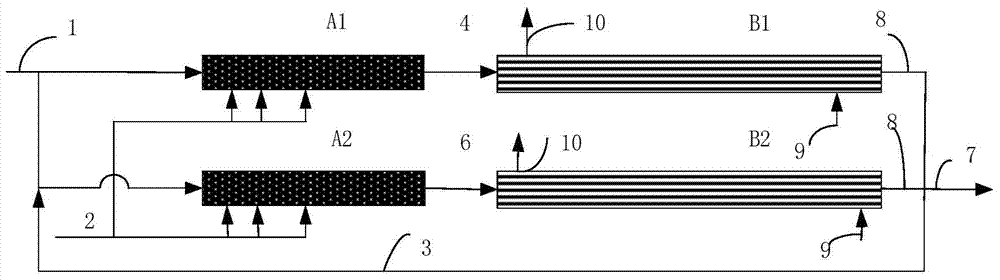

Static tube type alkylation reaction device and alkylation reaction method for liquid acid catalysis

ActiveCN105018134AAvoids disadvantages that impair sealing performanceImprove sealingLiquid hydrocarbon mixtures productionAlkyl transferEmulsion

The invention provides a static tube type alkylation reaction device and an alkylation reaction method for liquid acid catalysis by adopting the same. The reaction device comprises n+1 groups of reactors, wherein n is more than or equal to 1, each group of the reactor comprises a mixed reaction section A and a mixed reaction section B connected in series with the mixed reaction section A, and the mixed reaction section B has a heat exchange function; the mixed reaction section A of the first group of the reactors is marked as A1 which is provided with a fresh liquid acid feed pipeline; the mixed reaction section B of the (n+1)th group of the reactors is marked as Bn+1 which is provided with an alkylation reaction product outlet pipeline for discharging acidolysis hydrocarbon emulsion; part of the acidolysis hydrocarbon emulsion is circulated by a circulating pump; the mixed reaction section A of each group of the reactors is connected with a feed pipeline of an alkylation reaction raw material containing olefin, and the mixed reaction section A is provided with m (m is more than or equal to 1) feed openings for adding the alkylation reaction raw material containing olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Analyte sensor, and associated system and method employing a catalytic agent

ActiveUS8165651B2Good biocompatibilityExtend effective lifeImmobilised enzymesBioreactor/fermenter combinationsAnalyteNitrogen

Owner:ABBOTT DIABETES CARE INC

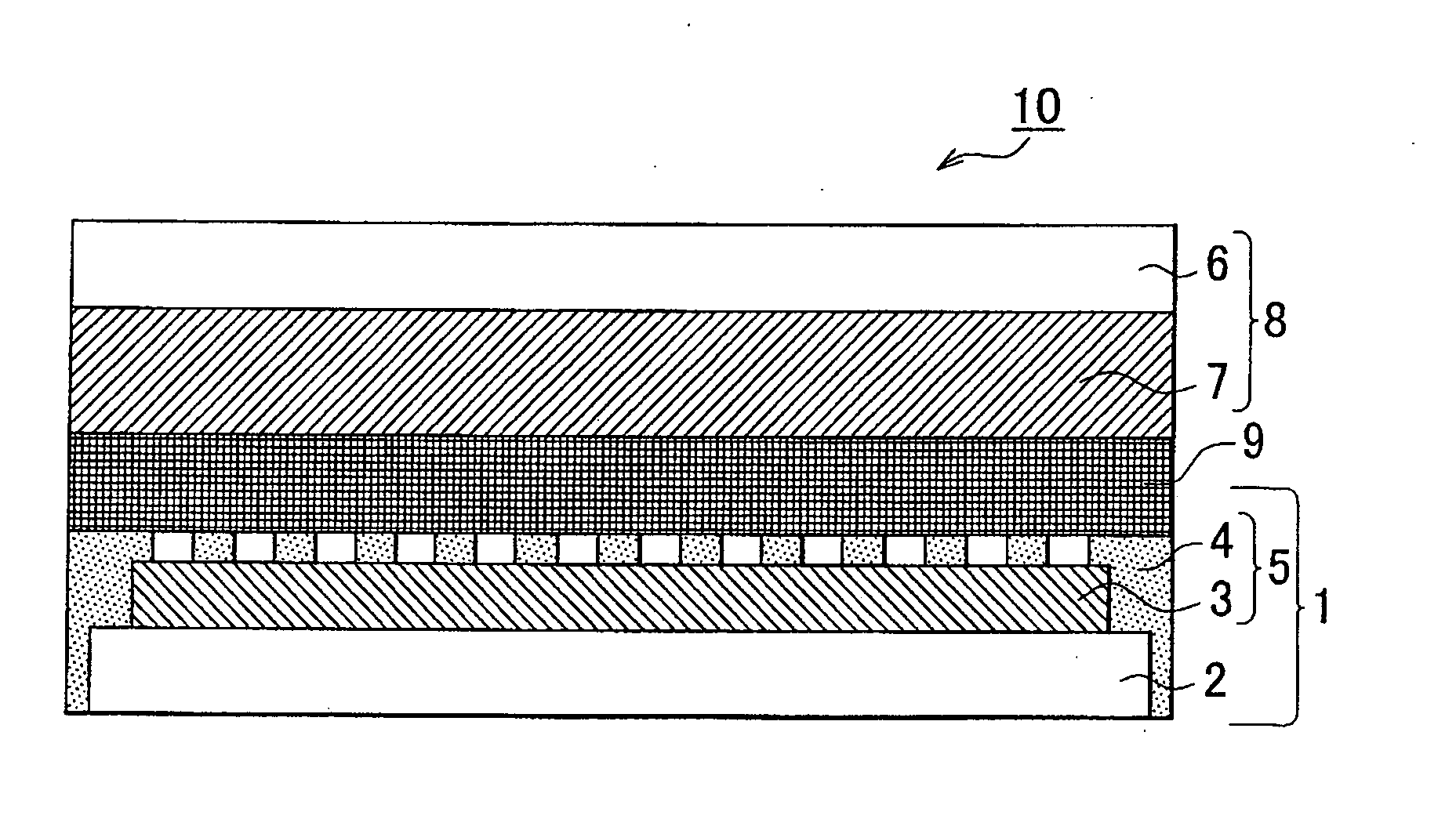

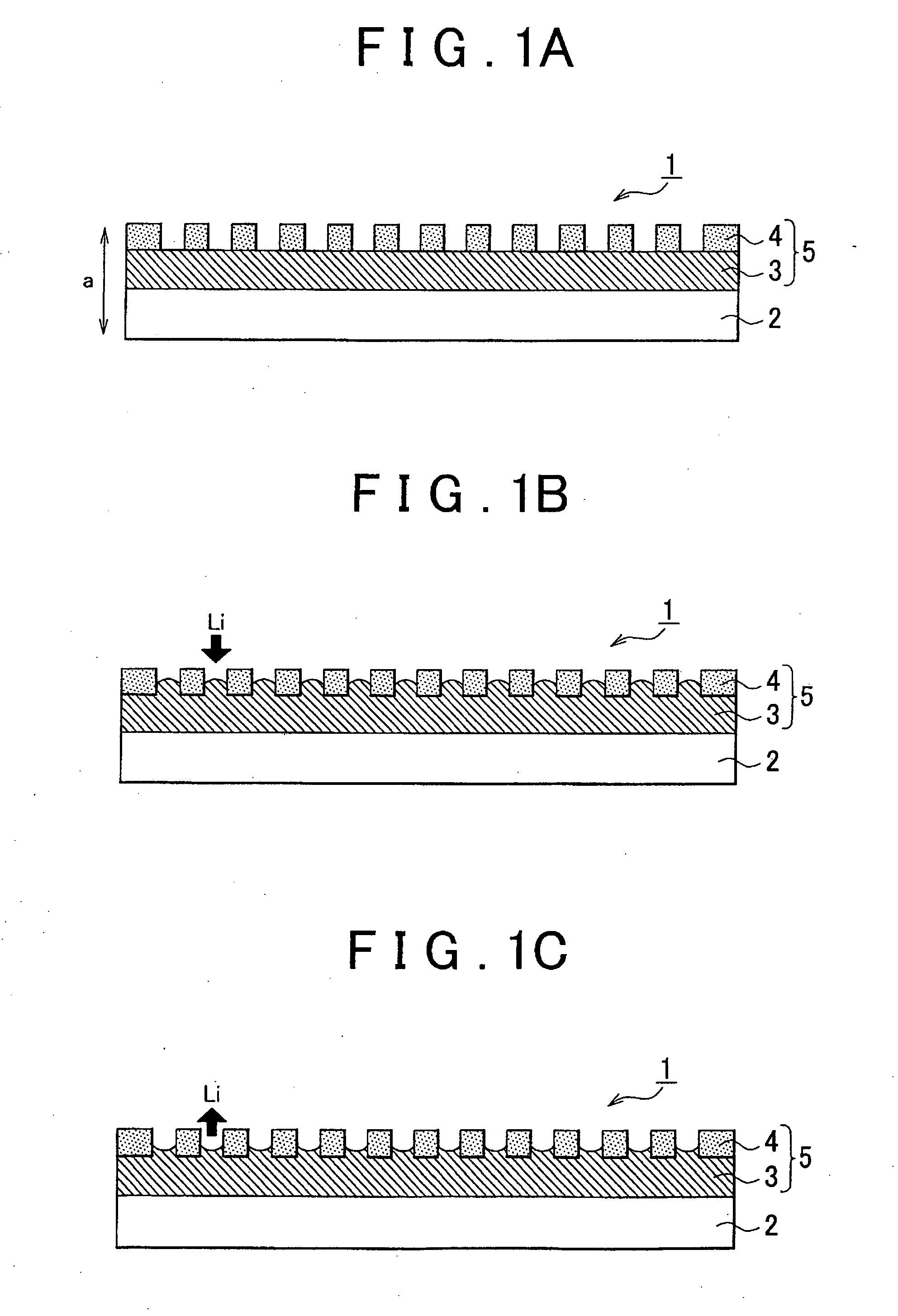

Negative electrode element for lithium-ion secondary battery, lithium-ion secondary battery and method of manufacturing the same

InactiveUS20110003199A1Suppress peelingSuppress slipElectrode manufacturing processesFinal product manufactureLithiumElectrical battery

A negative electrode element for a lithium-ion secondary battery includes: a negative electrode current collector; and a negative electrode layer that includes an alloying active material layer formed on the negative electrode current collector and a resin layer formed on a surface of the alloying active material layer so as to have an opening that exposes part of the alloying active material layer to a surface of the negative electrode layer. The surface of the alloying active material layer, exposed to the opening, and a surface of the resin layer form a step so that the surface of the resin layer is farther from a surface of the negative electrode current collector than the exposed surface of the alloying active material layer.

Owner:TOYOTA JIDOSHA KK +1

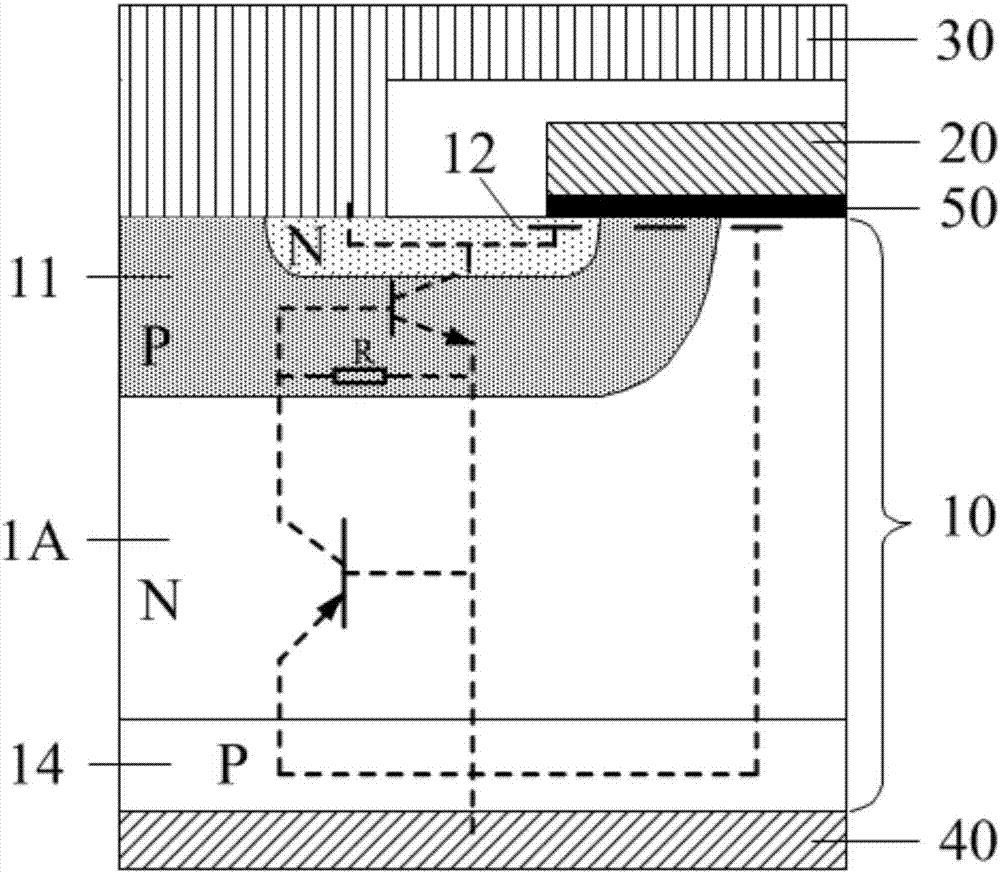

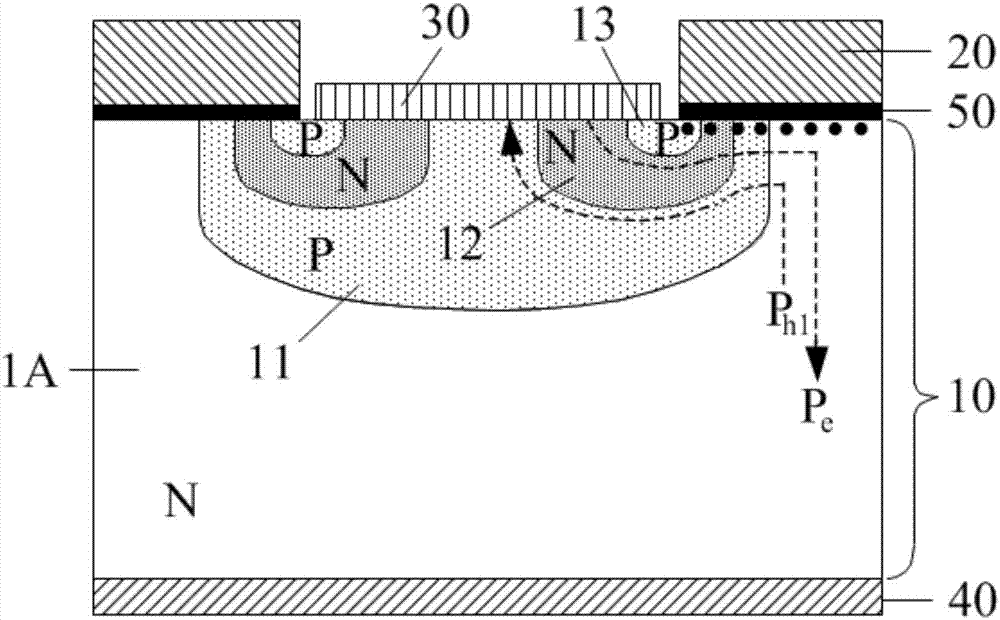

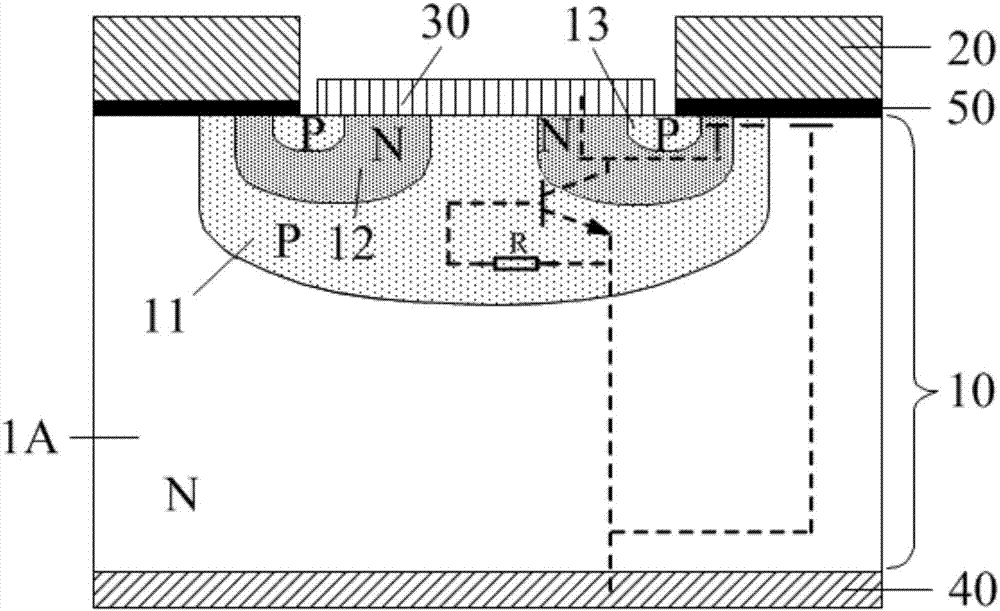

Power semiconductor device and manufacturing method thereof

PendingCN107452790AReduce local concentrationLower the barrierSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor devicePhysical chemistry

The present invention discloses a power semiconductor device and a manufacturing method thereof. The power semiconductor device comprises: a first conductive-type substrate; a first doping layer arranged in the substrate and having a second conductive type being opposite to the first conductive type; a second doping layer arranged in the first doping layer and having the first conductive type; a third doping layer arranged in the second doping layer and having the second conductive type; a control electrode arranged on the first surface of the substrate through an isolation layer, wherein the isolation layer is in contact with the surfaces of the first doping layer, the second doping layer and the third doping layer; a first electrode arranged on the first surface of the substrate, wherein the first electrode is in contact with the surfaces of the first doping layer, the second doping layer and the third doping layer; and a second electrode arranged on the second surface of the substrate. When the control electrode is connected with negative electricity, the third doping layer forms the extraction path of holes of an n-type doping layer so as to reduce the local concentration of carriers and reduce the barrier between the first doping layer and the original doping type layer of the substrate.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

Mini-pill type nicergoline capsule and preparation method thereof

InactiveCN104622850AImprove solubilityWidely distributedSenses disorderNervous disorderSide effectBiomedical engineering

The invention discloses a mini-pill type nicergoline capsule and a preparation method thereof. The mini-pill type nicergoline capsule is a sustained-release preparation and is prepared from a capsule shell and a nicergoline mini-pill accommodated in the capsule shell, wherein the nicergoline mini-pill sequentially comprises an empty pill core, a main drug layer and a pigmented layer from inside to outside; the main drug layer accounts for 15-60 percent of the empty pill core, and the pigmented layer accounts for 0.5-1 percent of the total weight of the empty pill core and the main drug layer. The mini-pill type nicergoline capsule has the advantages of small stimulation to intestines and stomach, high utilization rate, high stability, less toxic or side effects and capability of fully releasing effective components in time.

Owner:ZHEJIANG CHANGDIAN PHARMA +1

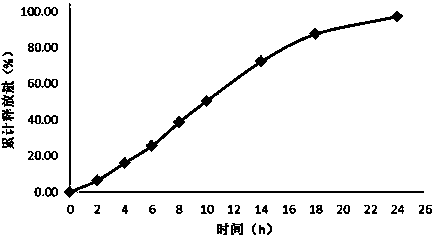

Dexketoprofen coating sustained-release micro-encapsulated capsule

ActiveCN101756939AReduce the frequency of takingSmall fluctuations in blood concentrationOrganic active ingredientsAntipyreticUse medicationTherapeutic effect

The invention provides a dexketoprofen coating sustained-release micro-encapsulated capsule and a preparation method thereof, which belong to the technical filed of chemico-pharmaceutical preparations. The coating sustained-release micro-encapsulated capsule consists of coating sustained-release particles and a capsule shell. The coating sustained-release particles are made of core particles containing dexketoprofen basic remedy through a coating technique. The invention can reduce the stimulation of the dexketoprofen on gastrointestinal tract and taking times, consequently, the medication compliance of patients is improved, the fluctuation of dexketoprofen blood concentration is reduced, bioavailability and treatment effect are improved and adverse reactions are reduced.

Owner:NEW FOUNDER HLDG DEV LLC +2

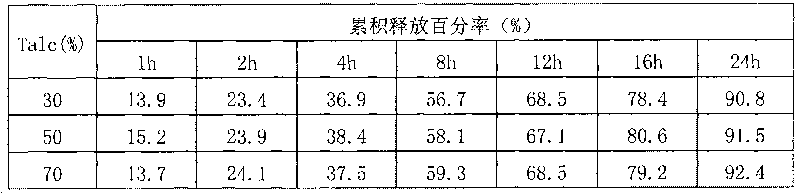

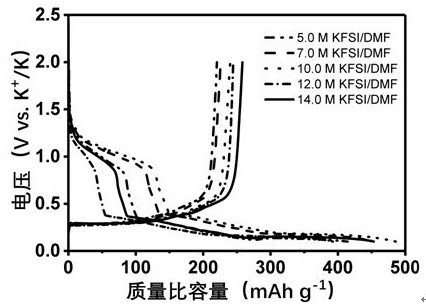

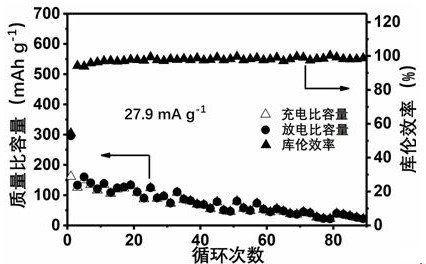

Potassium ion battery amide electrolyte with high stability and application thereof

ActiveCN114069050AWide variety of sourcesSimple preparation processSecondary cells servicing/maintenanceElectrolytic agentPhysical chemistry

The invention relates to a potassium ion battery amide electrolyte with high stability. The electrolyte comprises an amide solvent, an electrolyte and an additive, the concentration of the electrolyte is 5-14 mol L <-1 >, and the content of the additive accounts for 0-16% of the total volume of the electrolyte. The potassium ion battery amide electrolyte with high stability is used in a potassium ion battery; the electrolyte provided by the invention can buffer the volume fluctuation of graphite in the charging and discharging process, and effectively inhibit the side reaction of the electrolyte and the graphite so as to improve the electrochemical stability of the graphite; and after the additive HFE is added into the SEI film, the content of KF can be further increased to stabilize the interface between the electrode and the electrolyte, the local concentration of the electrolyte can be reduced, and the diffusion rate of ions in the battery is improved.

Owner:HEBEI UNIV OF TECH

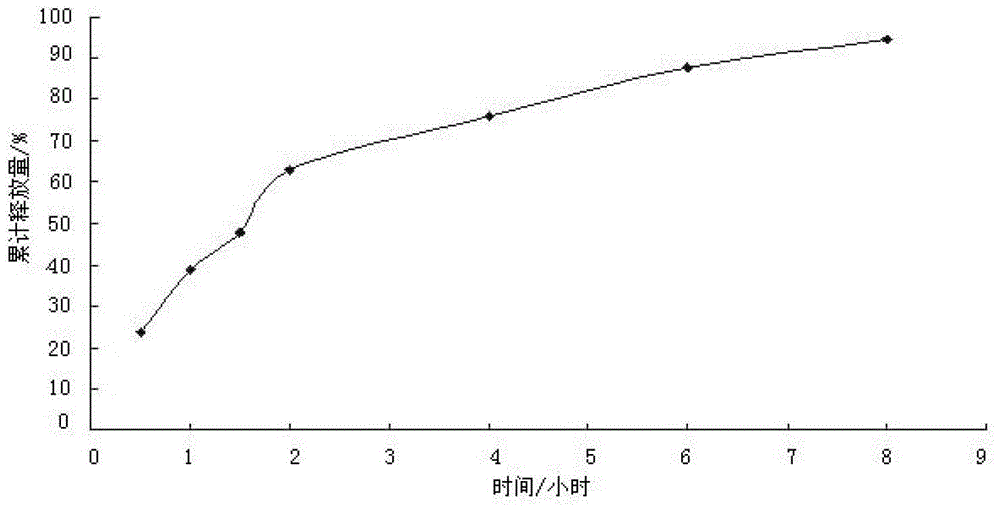

Flurbiprofen double-layer osmotic pump controlled-release tablet and preparation method thereof

ActiveCN103816131AShort half-lifeImprove complianceOrganic active ingredientsAntipyreticPatient complianceTherapeutic effect

The invention belongs to the technical field of pharmaceutic preparations, and discloses a flurbiprofen double-layer osmotic pump controlled-release tablet and a preparation method thereof. The flurbiprofen double-layer osmotic pump controlled-release tablet comprises flurbiprofen and a pharmaceutically acceptable polymer, and consists of a tablet core and a controlled-release coat coating the tablet core and having medicine-releasing holes, wherein a medicine layer comprises 200mg of flurbiprofen, 10-90mg of osmotic active substance, 100-300mg of suspension and 3-10mg of lubricant; a boosting layer comprises 100-200mg of sweller and 10-50mg of osmotic active substance; a semipermeable coat comprises 10-20g of semipermeable high molecular material, 0.5-3g of water-soluble pore-foaming agent and a proper amount of an organic solvent; the weight of the coat is 6-12% that of the tablet core; 1-2 medicine-releasing holes are drilled in one side of the medicine layer of the coated tablet by using laser or a mechanical drill. The flurbiprofen double-layer osmotic pump controlled-release tablet can effectively adjust constant-speed medicine release to obtain steady blood concentration, thereby reducing the medicine taking times and improving patient compliance, and has the characteristics of few medicine taking times, convenience in taking, lasting effect and stable therapeutic effect.

Owner:SHENYANG PHARMA UNIVERSITY

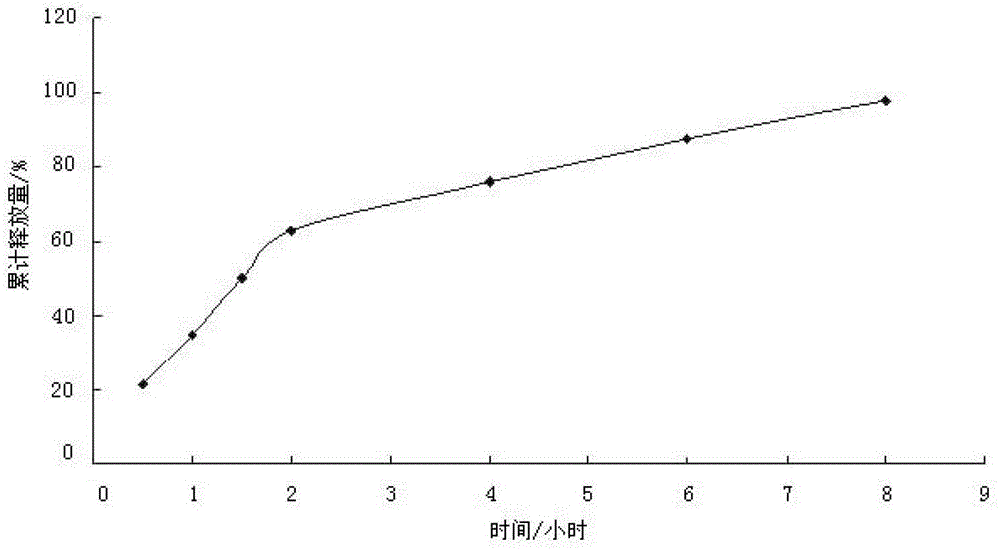

Dexketoprofen tromethamine sustained release particles and preparation method and sustained release medicinal preparation thereof

ActiveCN102743341BReduce or even eliminate irritationIncreased surface distribution areaOrganic active ingredientsAntipyreticDexketoprofen tromethaminePlasticizer

The invention discloses dexketoprofen tromethamine sustained release particles which are prepared by coating the dexketoprofen tromethamine sustained release particles with coating liquid, wherein the mass ratio of the dexketoprofen tromethamine sustained release particles to the coating liquid is 1-10:1, the dexketoprofen tromethamine sustained release particles are prepared from the following raw materials by weight: 10-50% of dexketoprofen tromethamine, 15-60% of diluent, 0-10% of stabilizer and 20-40% of adhesive, and the coating liquid is prepared from the following raw materials by weight: 2-20% of coating material, 0-5% of porogen, 0-5% of plasticizer and 70-97% of solvent. In addition, the invention also discloses a preparation method and sustained release medicinal preparation of the dexketoprofen tromethamine sustained release particles. After being taken, the dexketoprofen tromethamine sustained release particles can widely spread in gastrointestinal tract, and medicines are released slowly and continuously, so that irritation of the medicines to gastrointestinal tract can be reduced, even eliminated.

Owner:西安远大德天药业股份有限公司

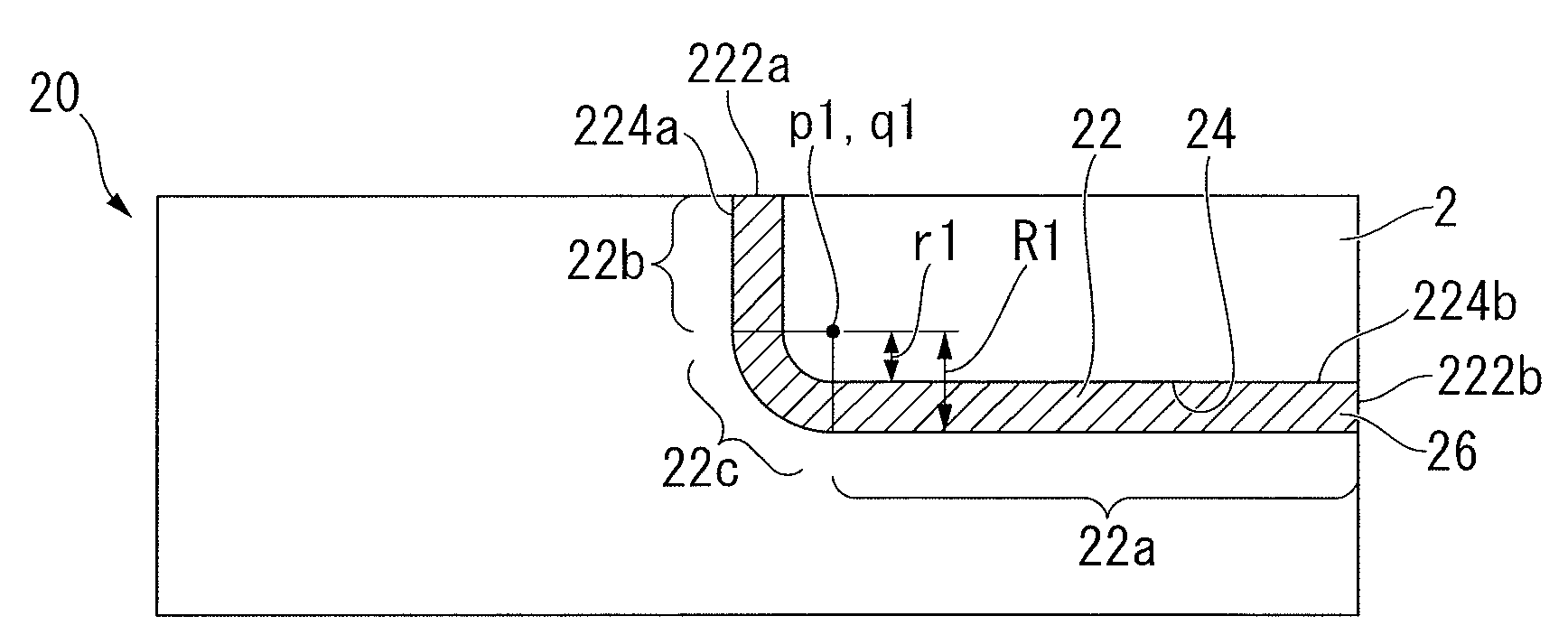

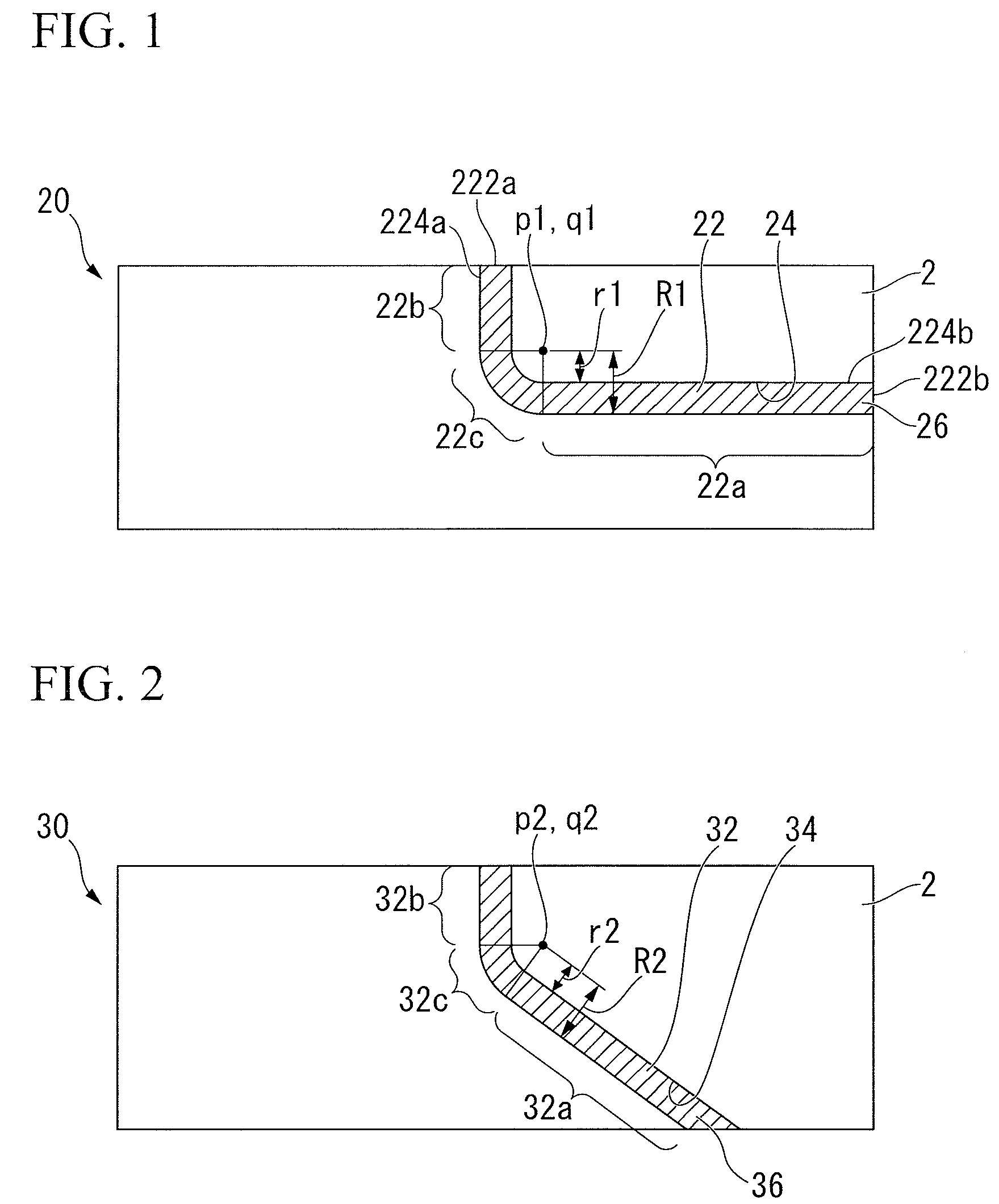

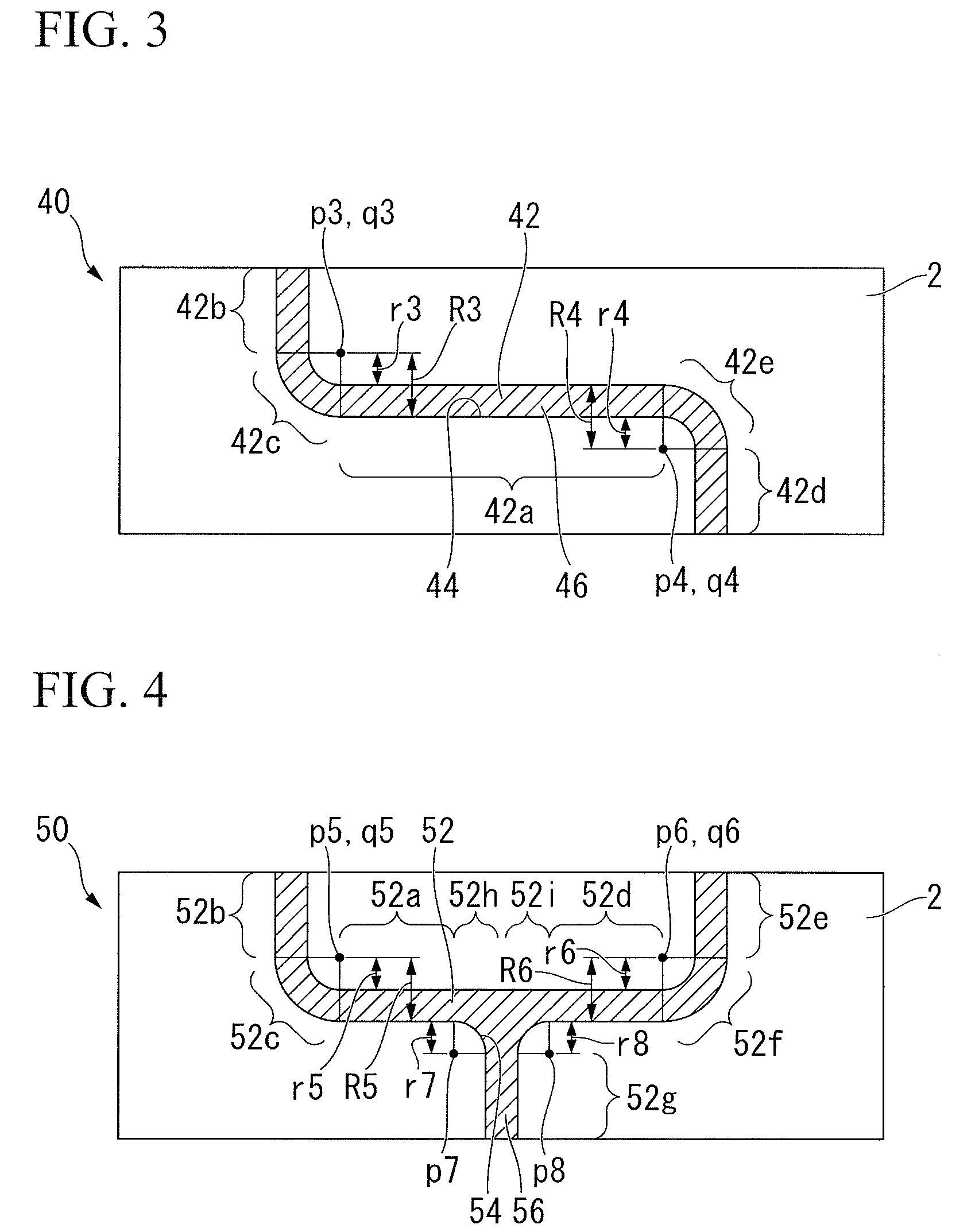

Through wiring substrate and manufacturing method thereof

InactiveUS8785791B2Reduce transmission lossReduce conductivityRadiation applicationsSemiconductor/solid-state device detailsMechanical engineeringElectrically conductive

A through wiring substrate includes a substrate having a first face and a second face; and a through-wire formed by filling, or forming a film of, an electrically-conductive substance into a through-hole, which penetrates between the first face and the second face. The through-hole has a bend part comprising an inner peripheral part that is curved in a recessed shape and an outer peripheral part that is curved in a protruding shape, in a longitudinal cross-section of the through-hole, and at least the inner peripheral part is formed in a circular arc shape in the longitudinal cross-section.

Owner:FUJIKURA LTD

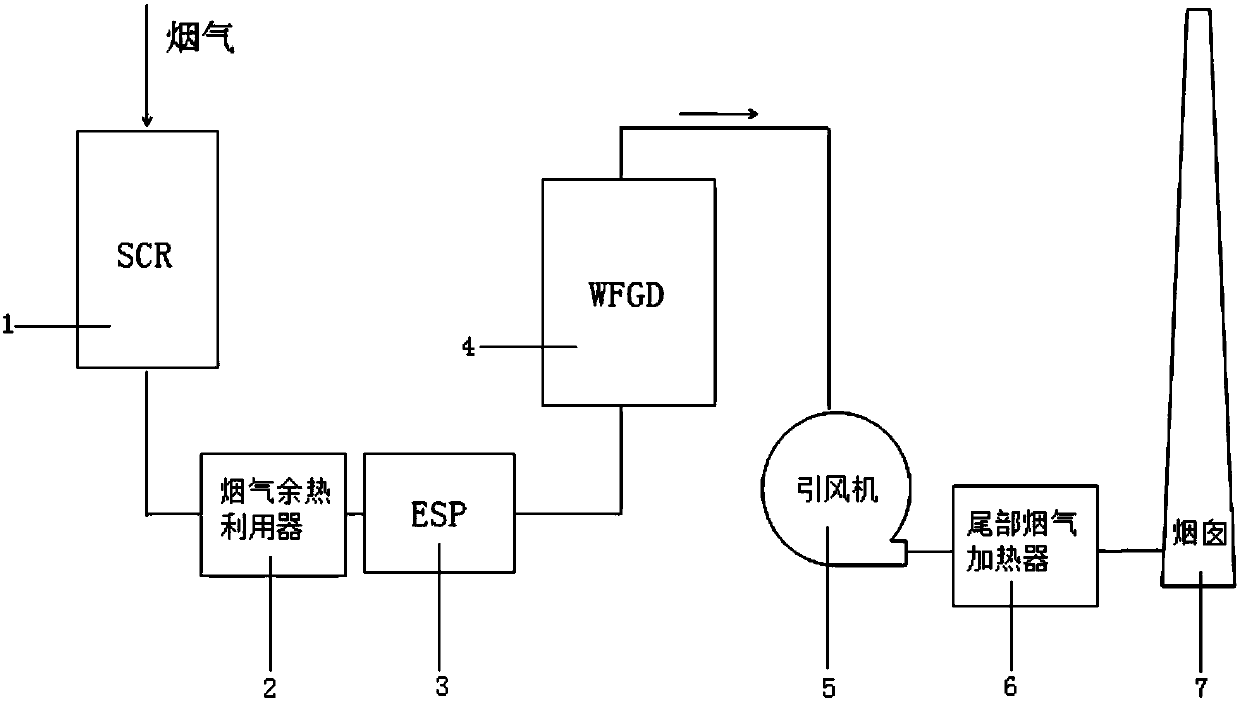

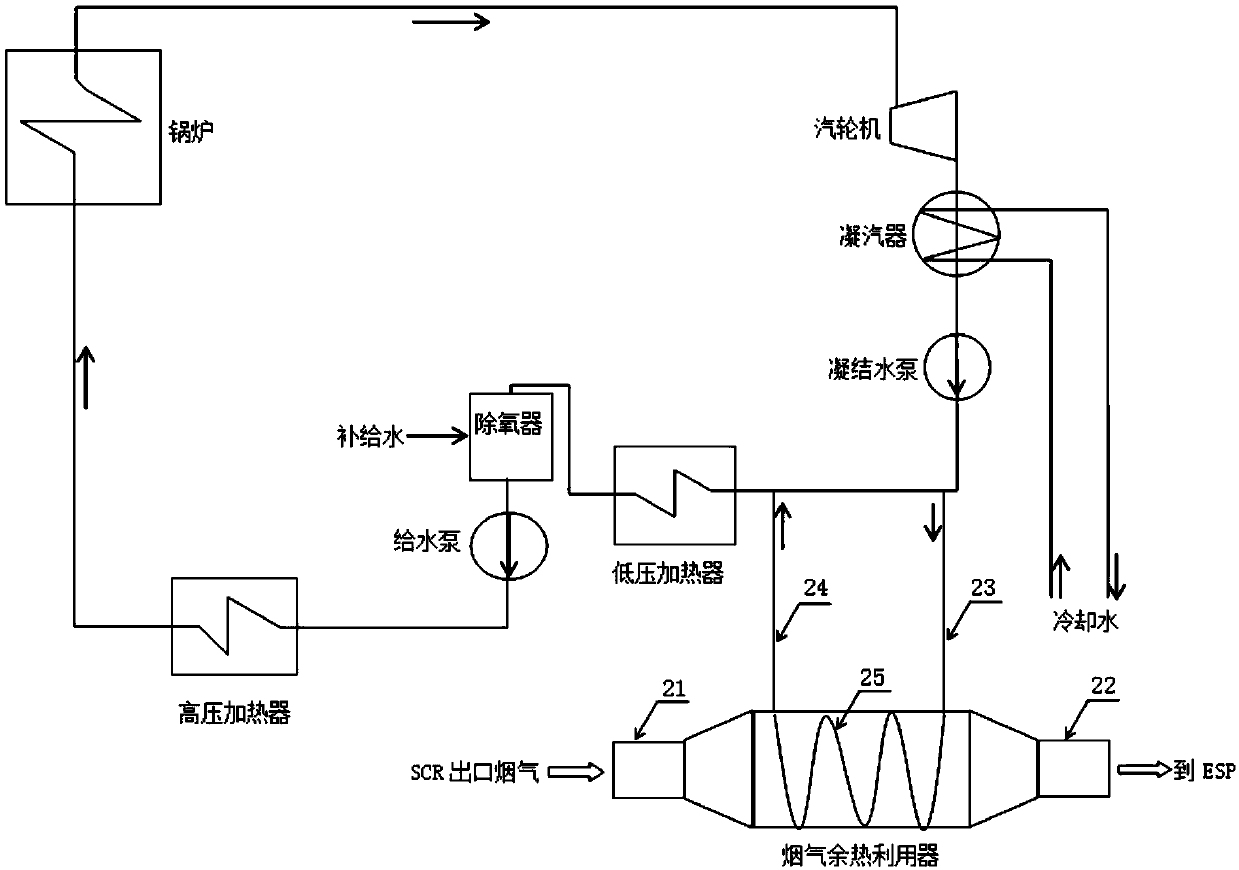

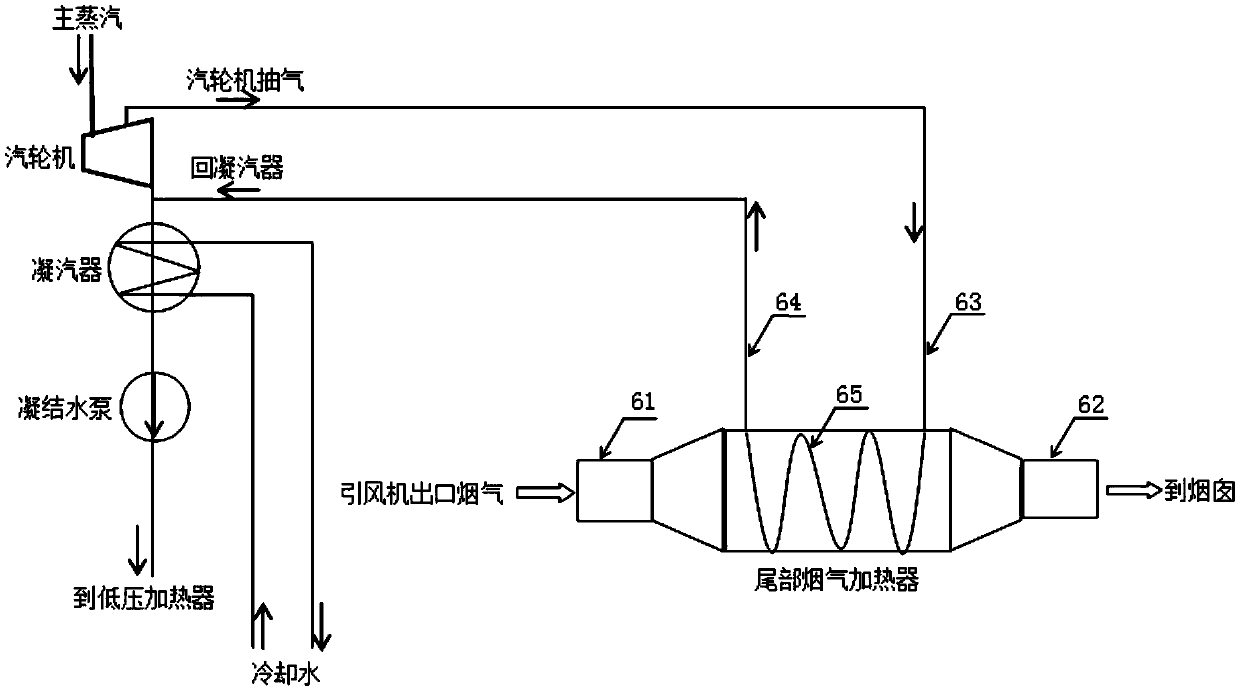

Condensation and reheating integration type smoke plume white-eliminating system

PendingCN108679638AReduce the temperatureReduce salt contentEmission preventionCombustion technology mitigationAtmospheric airSmoke plume

The invention relates to a condensation and reheating integration type smoke plume white-eliminating system. The system comprises a denitration device, a flue gas waste heat utilization device, an electrostatic precipitator, a wet desulphurization device, an induced draft fan, a tail flue gas heater and a chimney which are connected in series in order, wherein the flue gas waste heat utilization device is used for recovering flue gas waste heat, and the tail flue gas heater is used for raising flue gas temperature. Compared with the prior art, the system utilizes the flue gas waste heat to heat condensed water, recovers the flue gas waste heat, and reduces the salt content; the tail flue gas heater utilizes a steam turbine to extract air so as to heat flue gas and raise the flue gas temperature; at the moment, the salt content of the steam of flue gas is not high, the steam temperature is raised, and the density declines; and thus, the flue gas is beneficially diffused to higher heightafter being discharged into the atmosphere, the local concentration of the flue gas discharged into the atmosphere is reduced, and the impact of flue gas containing smoke on the environment is reduced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

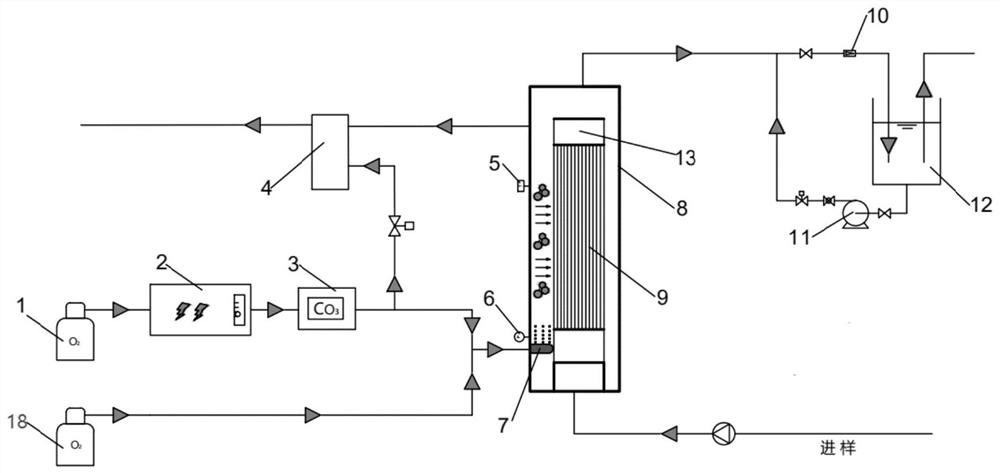

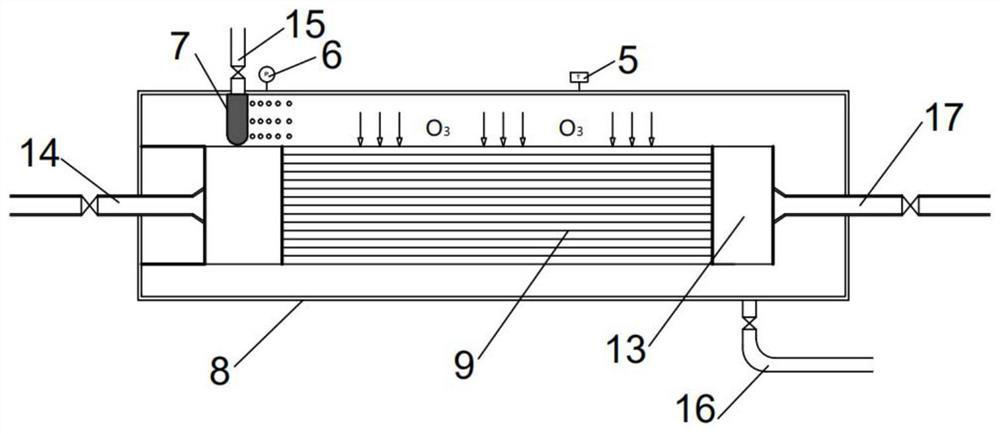

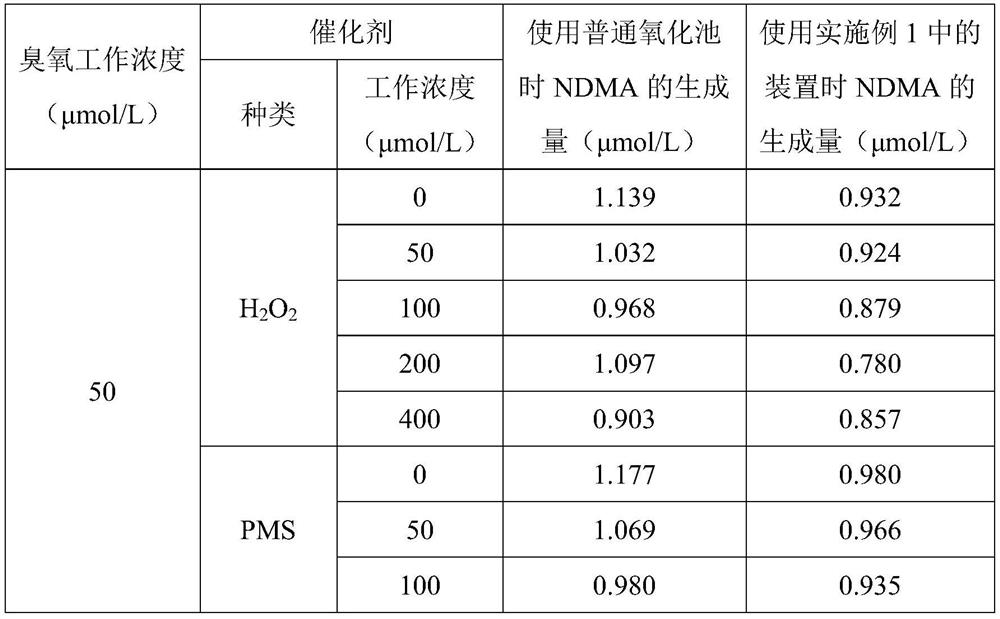

Drinking water ozone oxidation device and process with low NDMA generation

ActiveCN113716677AReduce local concentrationDecrease the apparent reaction rateWater treatment compoundsWater contaminantsPtru catalystPotable water

The invention belongs to the technical field of drinking water disinfection, and particularly relates to a drinking water ozone oxidation device and process with low NDMA generation. The device comprises a first oxygen generator, an ozone generator, a gas concentration analyzer, an ozone distribution disc, a polytetrafluoroethylene hollow fiber membrane and a glass reactor. The process comprises the following two steps: premixing an ozone catalyst and a water body; introducing ozone into the organic glass reactor; and enabling the premixed water body to flow through the polytetrafluoroethylene hollow fiber. The drinking water is subjected to ozone pre-oxidation by adding the ozone catalyst to strengthen a .OH oxidation path and limit a direct oxidation path of ozone molecules at the same time, the generation amount of NDMA in the ozone oxidation process is effectively reduced, and meanwhile, the method has the advantages of being low in production cost, convenient to maintain, capable of being recycled for multiple times, easy and convenient to operate, free of secondary pollution and the like.

Owner:GUANGDONG UNIV OF TECH

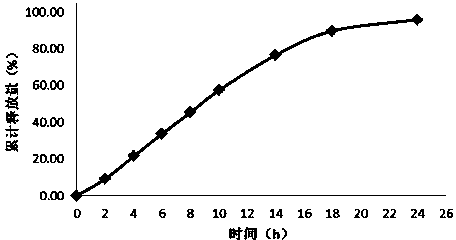

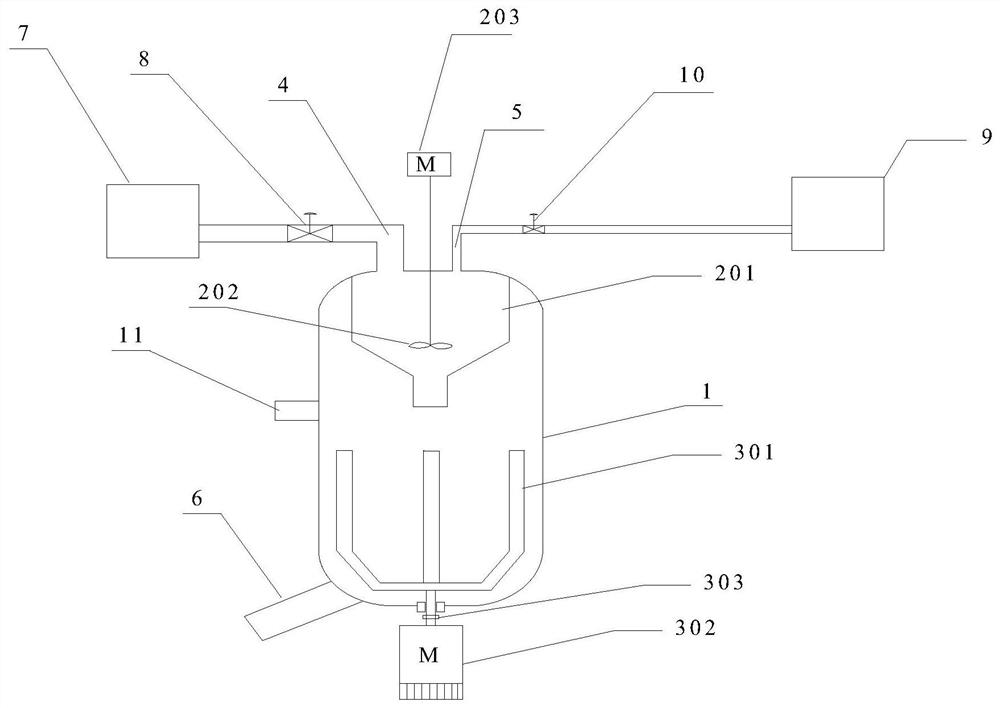

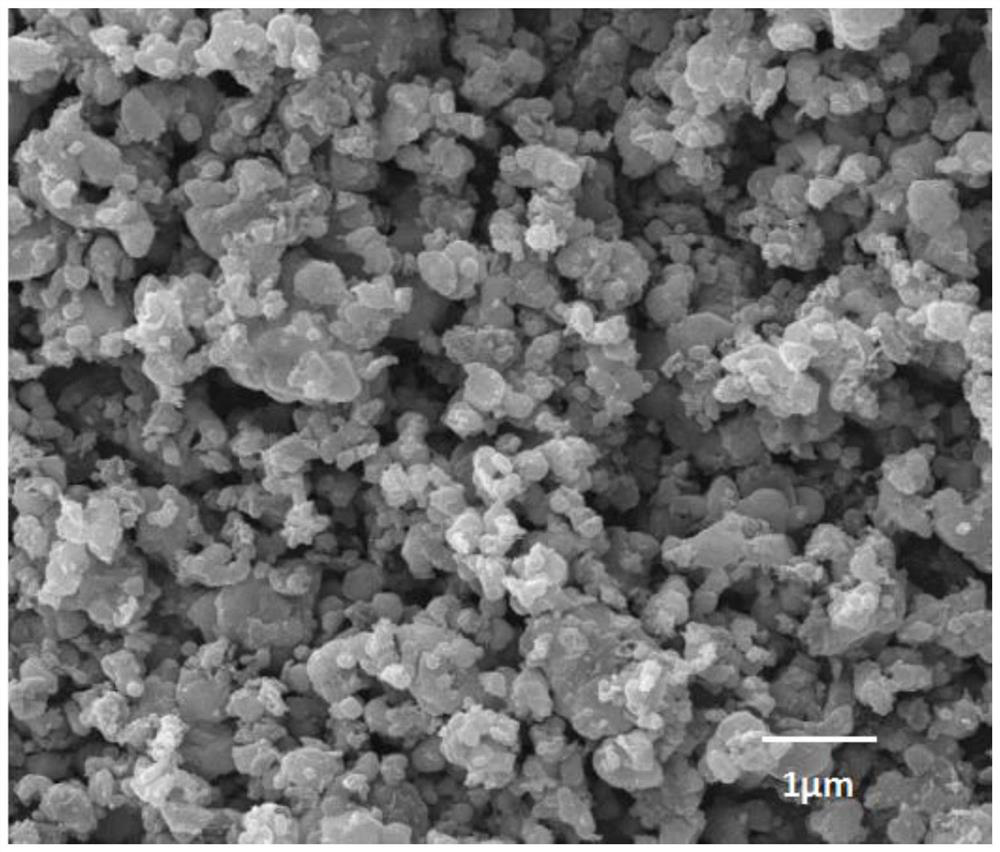

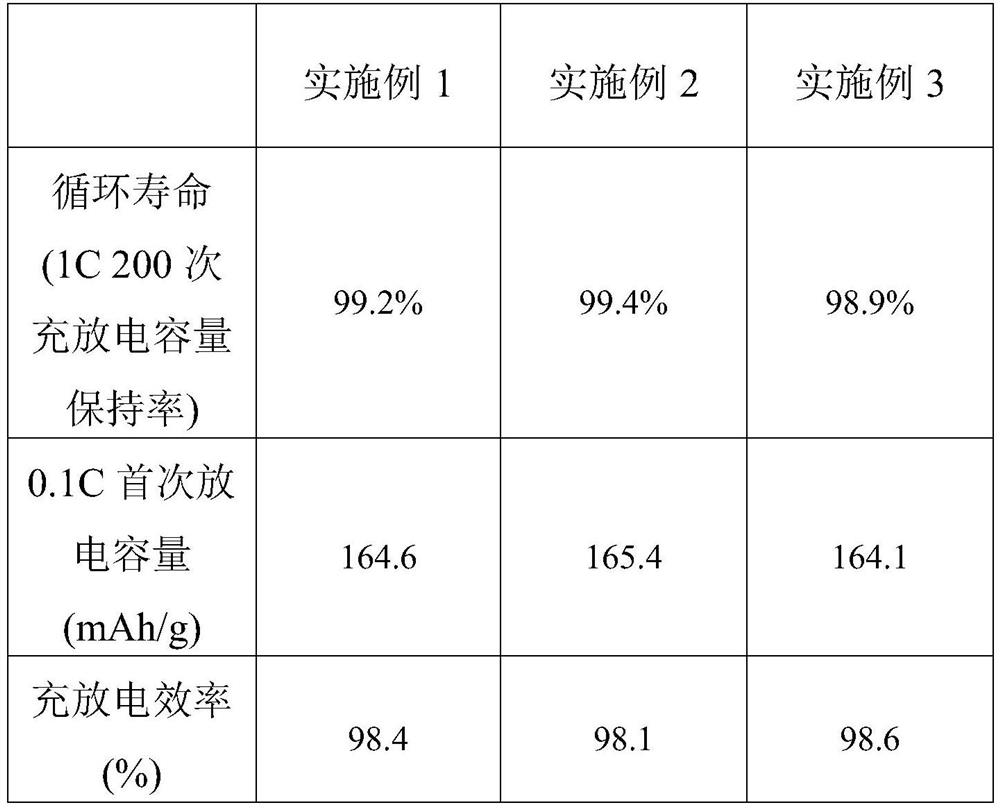

Preparation method of lithium manganese iron phosphate

PendingCN114014292AImprove conductivityUniform responseCell electrodesPhosphorus compoundsCarbon coatingDischarge efficiency

The invention discloses a preparation method of lithium manganese iron phosphate, wherein through a premixing unit and a stirring unit in a reaction kettle, the reaction is more uniform when an iron salt and a phosphate are mixed, the local concentration is reduced, a uniform iron phosphate precursor is prepared, and then the lithium manganese iron phosphate with uniform morphology is prepared by combining a wet method and a solid phase method. The conductivity of the lithium manganese iron phosphate is improved through carbon coating, and the cycle life, the first discharge capacity and the charge-discharge efficiency of the lithium manganese iron phosphate positive electrode material are improved.

Owner:湖南安尔信新材料有限责任公司

A static tubular alkylation reaction device and liquid acid-catalyzed alkylation reaction method

ActiveCN105018134BAvoids disadvantages that impair sealing performanceImprove sealingLiquid hydrocarbon mixtures productionAlkyl transferEmulsion

The invention provides a static tube type alkylation reaction device and an alkylation reaction method for liquid acid catalysis by adopting the same. The reaction device comprises n+1 groups of reactors, wherein n is more than or equal to 1, each group of the reactor comprises a mixed reaction section A and a mixed reaction section B connected in series with the mixed reaction section A, and the mixed reaction section B has a heat exchange function; the mixed reaction section A of the first group of the reactors is marked as A1 which is provided with a fresh liquid acid feed pipeline; the mixed reaction section B of the (n+1)th group of the reactors is marked as Bn+1 which is provided with an alkylation reaction product outlet pipeline for discharging acidolysis hydrocarbon emulsion; part of the acidolysis hydrocarbon emulsion is circulated by a circulating pump; the mixed reaction section A of each group of the reactors is connected with a feed pipeline of an alkylation reaction raw material containing olefin, and the mixed reaction section A is provided with m (m is more than or equal to 1) feed openings for adding the alkylation reaction raw material containing olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

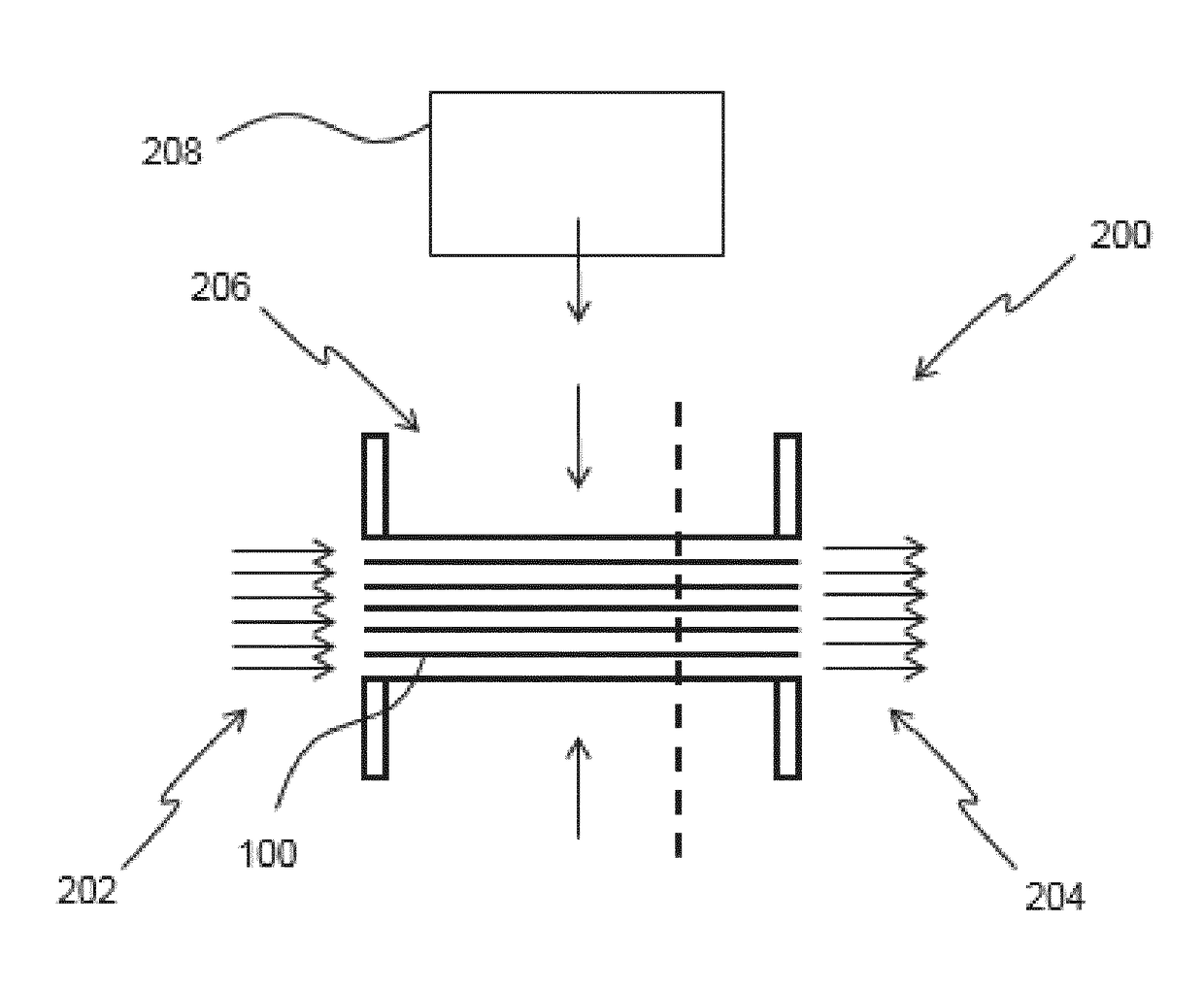

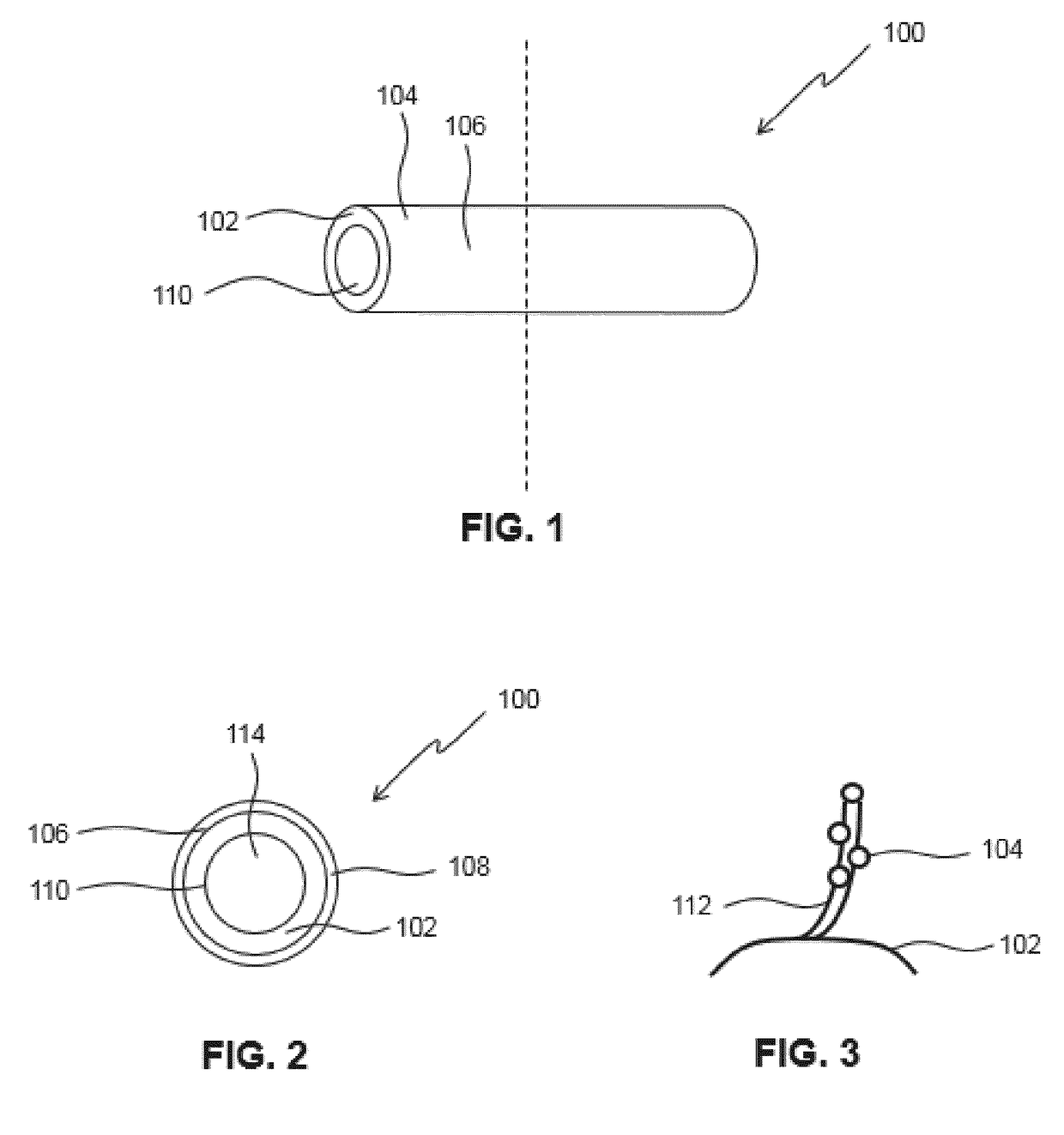

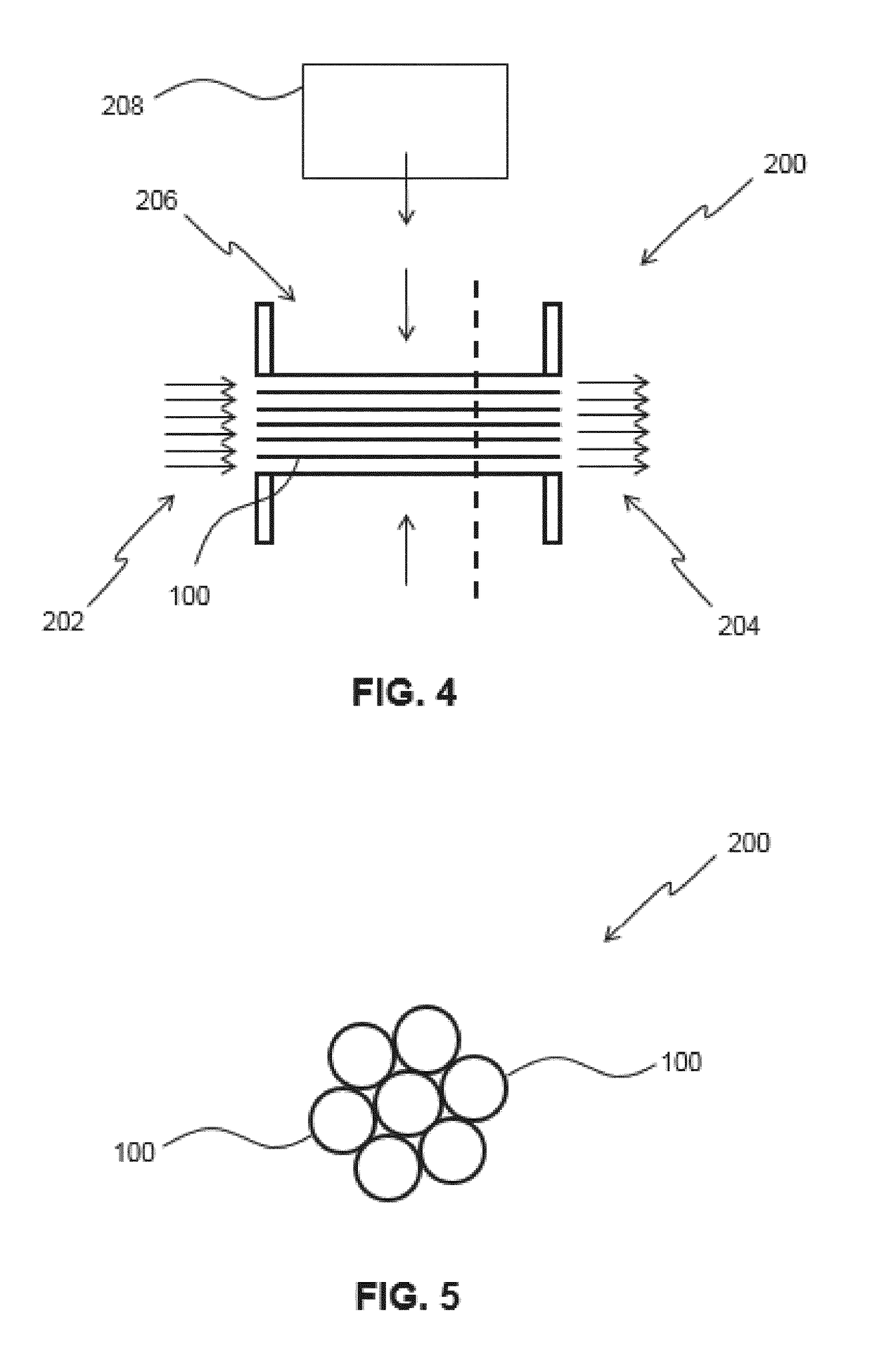

Water purification catalyst, water purifier, beverage maker and method

InactiveUS20180050323A1Not availableIncrease effectiveness and efficiencyWater treatment parameter controlWater/sewage treatment by irradiationNoble metalNitrite

There is provided a water purification catalyst element (100). The catalyst element (100) comprises a porous support (102) having a first surface (106) and a second surface (110). The first or the second surface (106, 110) delimit a conduit (114) through the catalyst element (100). A material (104) comprising a noble metal is supported on the porous support (102). At least the first surface (106) is coated with a coating material (108) permeable to hydrogen gas and impermeable to water, and at least the second surface (110) is water-permeable. This catalyst element (100) can selectively convert nitrites and / or nitrates to N2 gas and can be used to provide a cost efficient and / or maintenance free water purification setup. There is also provided a water purifier (200) comprising the catalyst element (100), a beverage maker (300) comprising the water purifier (200), a method (1800) of water purification and a method (1900) of making the catalyst element (100).

Owner:KONINKLJIJKE PHILIPS NV +1

Local concentration management system

InactiveUS20070167932A1Reduce deliveryEasy to handleBalloon catheterPharmaceutical delivery mechanismSystems designMedicine

The invention provides a local concentration management system (LCMS) for delivery of highly concentrated therapeutic agent formulations. The LCMS comprises a device comprising an elongate body defining a lumen between its proximal and distal ends, and a diffuser element, a dilutor element, or both. The diffuser element, which is selectively permeable to the agent, is operatively associated with the elongate body so that agent flows through the elongate body, and into and through the diffuser element to exit the system. The dilutor element can be operatively associated with the system to be in fluid communication with the elongate body lumen, a diffusion space defined by a diffuser element inner wall, or both. The dilutor element is selectively water permeable, but substantially impermeable to agent, to provide for dilution of the agent during transit through the system. The LCMS system is designed to disperse and / or dilute the drug delivery stream.

Owner:DURECT CORP

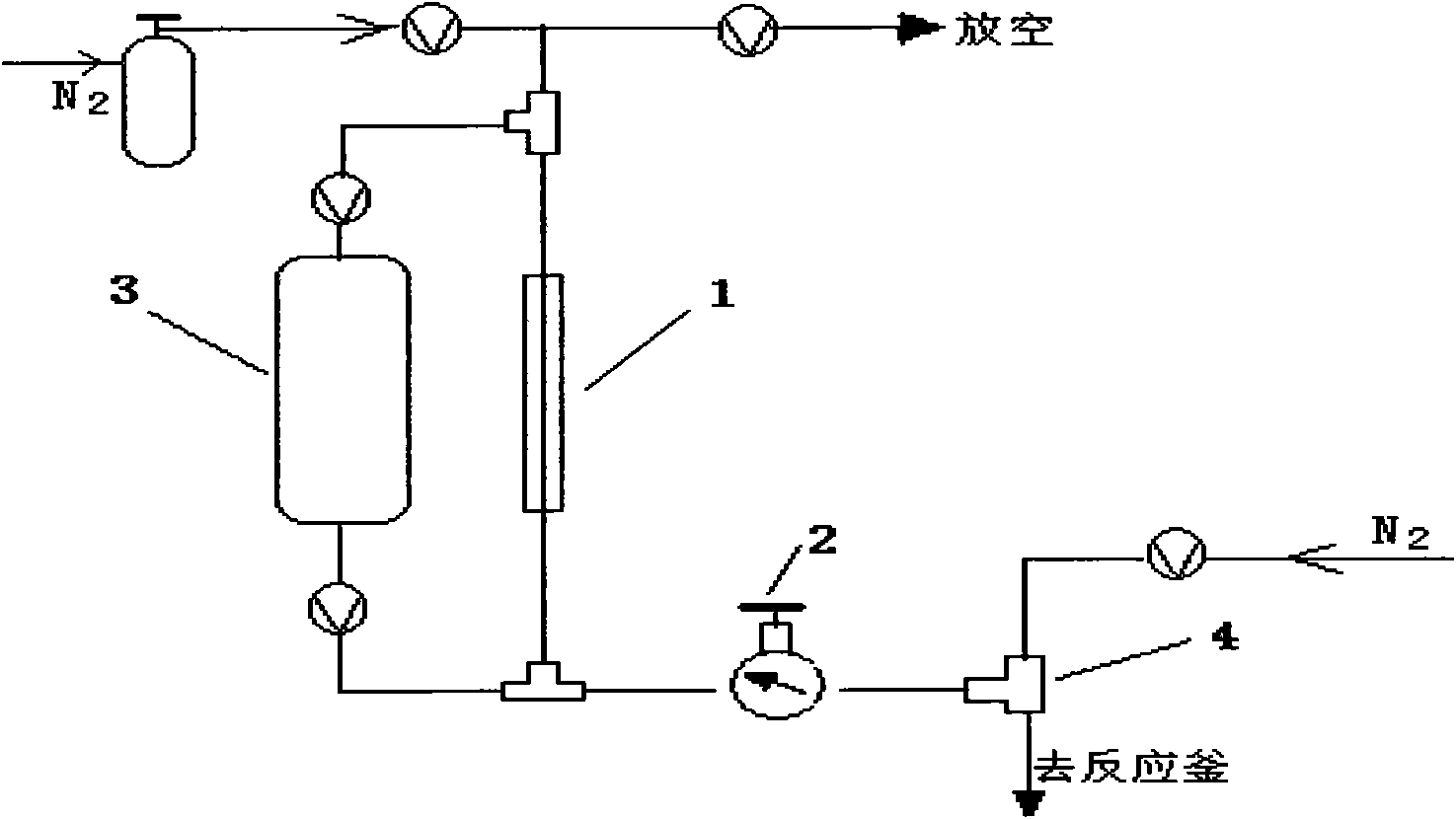

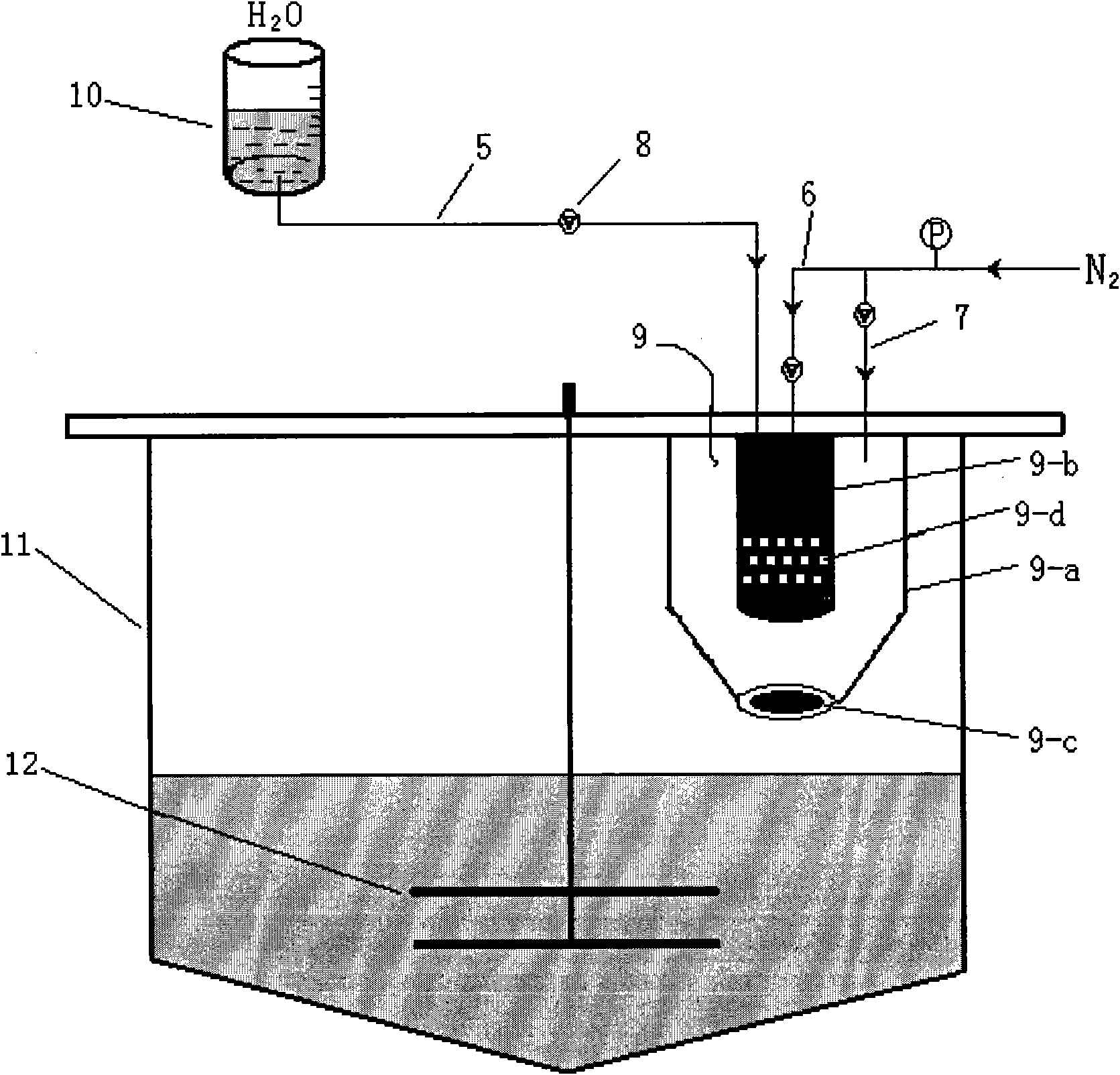

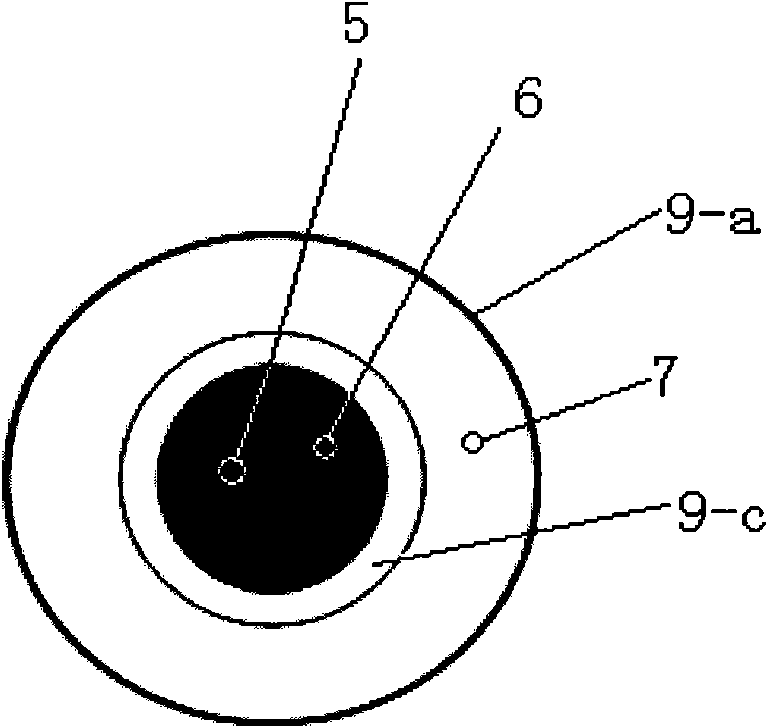

Atomization synthesizer and application thereof in synthesis of alkylaluminoxane

ActiveCN102190677BReduce processingAvoid security issuesGroup 3/13 element organic compoundsChemical/physical/physico-chemical stationary reactorsRound tableWater storage tank

The invention discloses an atomization synthesizer which comprises a reaction kettle (11) with a stirring device (12), a high-position visible water storage tank (10), a liquid flowmeter (8), an atomizer (9), a water inlet pipe (5), a central gas inlet pipe (6) and a peripheral gas inlet pipe (7), wherein the atomizer (9) is mainly composed of a central barrel (9-b), an outer barrel (9-a) and an annular nozzle (9-c); the outer barrel (9-a) is in an cylindrical / inverted V-shaped round table composite structure, and the length-to-diameter ratio is 8-10 on the basis of the diameter of the cylindrical part; the central barrel (9-b) and outer barrel (9-a) are coaxial and concentric, the central barrel (9-b) and the cylindrical part of the outer barrel (9-a) are of the same height, the bottom end of the central barrel (9-b) is closed, and the length-to-diameter ratio of the central barrel (9-b) is 8-10; the side wall on the middle and lower parts of the central barrel (9-b) is uniformly distributed with pinholes (9-d), wherein the density of the pinholes is 1-2 / mm<2>, and the sizes of the pinholes are 0.4-0.6mm; the bottom end of the outer barrel (9-a) is provided with the annular nozzle (9-c) which has the same diameter as the central barrel, and the clearances of the pinholes in the annular nozzle are 0.5-0.8mm; the water inlet pipe (5) and central gas inlet pipe (6) are inserted into the central barrel (9-b); and the peripheral gas inlet pipe (7) is connected between the outer barrel (9-a) and the central barrel (9-b). The atomization synthesizer has the advantages of controllable pressure, favorable water atomization effect and low cost, is safe and easy for operation, can be well applied to direct hydrosynthesis reaction of alkylaluminoxane, and greatly increases the yield of alkylaluminoxane as compared with the indirect hydrosynthesis technique.

Owner:PETROCHINA CO LTD

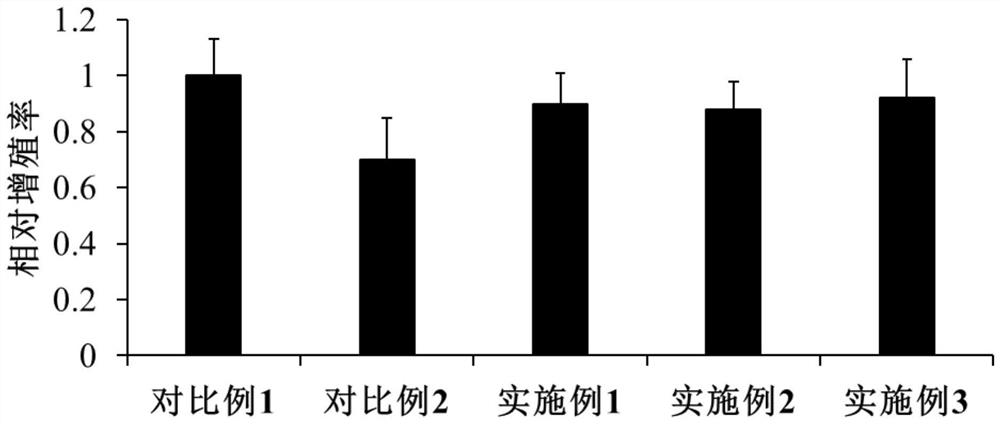

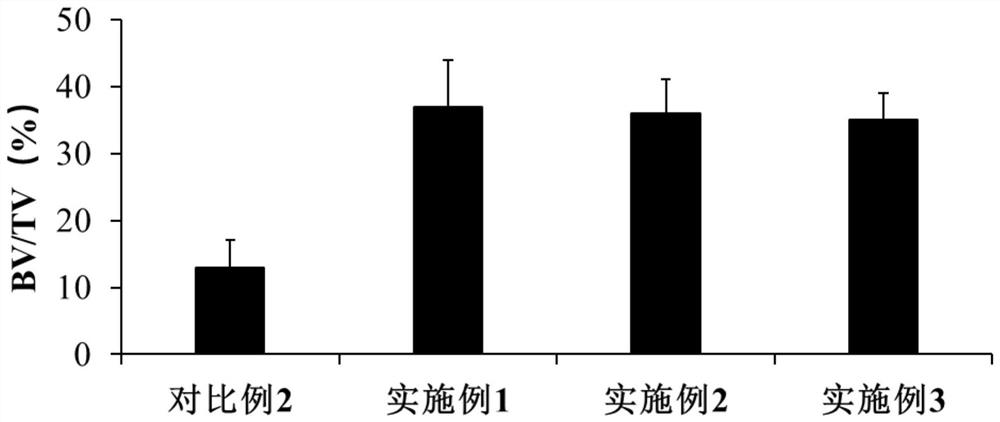

A kind of preparation method of composite bone repair material

ActiveCN110013566BFormation contributes toPromote formationTissue regenerationProsthesisBiotechnologyFreeze-drying

The embodiment of the invention discloses a preparation method of a composite bone repair material, which belongs to the technical field of biomedical engineering. The composite bone repair material is made of allogeneic freeze-dried bone (FDB), hot dog ridge polar extract (PRCHP) solution, and bone morphogenetic protein 2 (BMP‑2). The composite bone repair material of the embodiment of the present invention uses FDB as a scaffold material, and is compounded with RHCHP and BMP-2. RHCHP cooperates with BMP-2 to promote osteogenesis and inhibit osteoclastosis. On the basis of ensuring that the osteogenic activity of BMP-2 is not reduced On the one hand, reduce its local application concentration as much as possible, reduce cytotoxicity, so as to achieve the effect of promoting bone formation and reducing complications. The present invention adopts soaking and freeze-drying self-assembly technology to complete the composite steps of PRCHP-FDM-BMP-2, and has the advantages of simple operation, easy control and low production cost.

Owner:FIRST AFFILIATED HOSPITAL OF DALIAN MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com