Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Real-time monitoring height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

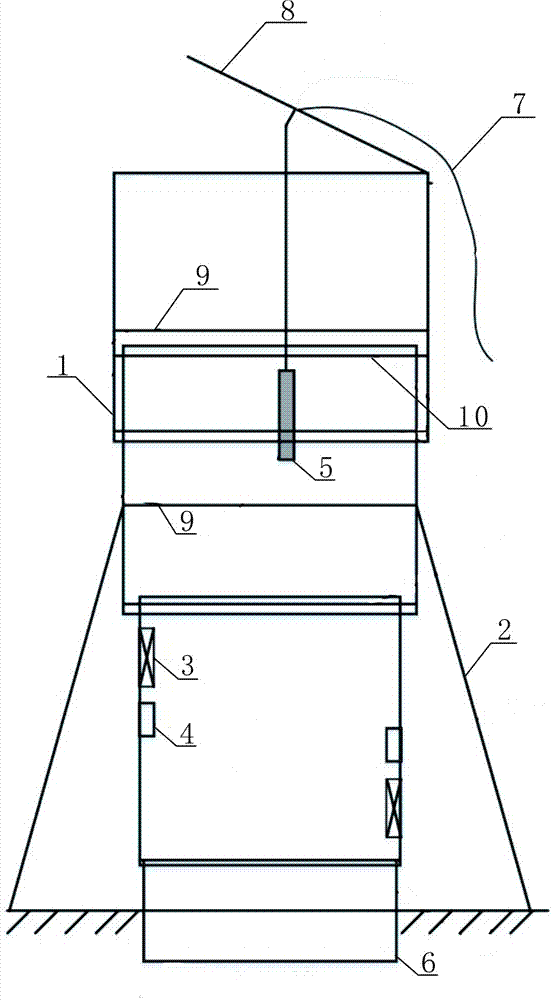

Equipment and method for intelligently automatically cleaning vehicle

ActiveCN105857264AAvoid damageSimple mechanical structureCleaning apparatus for vehicle exteriorsFailure rateGrounding grid

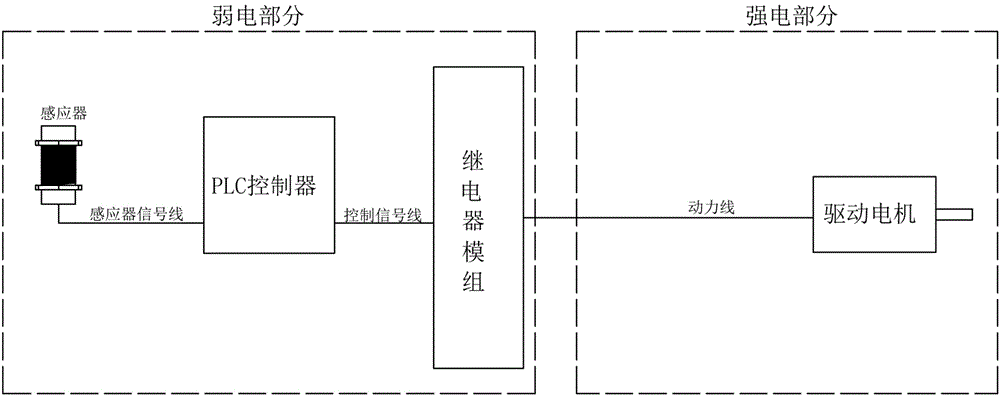

The invention relates to equipment and a method for intelligently automatically cleaning vehicles. The equipment comprises a pull guide rail. The pull guide rail is arranged on a side of a ground grid, a first upright column is vertically mounted at the right end of the ground grid, a first transverse beam is fixedly connected with the top of the first upright column, a second upright column is mounted at the rear of the first upright column, a second transverse beam is fixedly connected with the top of the second upright column, longitudinal beams are mounted between the first transverse beam and the second transverse beam, and a third transverse beam is mounted at the tail ends of the longitudinal beams. A second water spray pipe and a water wax spray pipe are arranged between the first transverse beam and the second transverse beam, and a top brush device is mounted on the second upright column. A vertical brush device is mounted on the third transverse beam. Wheel brush devices are symmetrically mounted on the side surfaces of the pull guide rail and are positioned between the first upright column and the second upright column. The equipment and the method have the advantages that mechanical structures can be simplified, power consumption and water consumption can be reduced, failure rates of machinery can be decreased, and the later-stage maintenance cost can be saved; the equipment is additionally provided with an automatic control system, accordingly, the vehicles can be fully automatically cleaned, and the work efficiency can be improved.

Owner:李勇

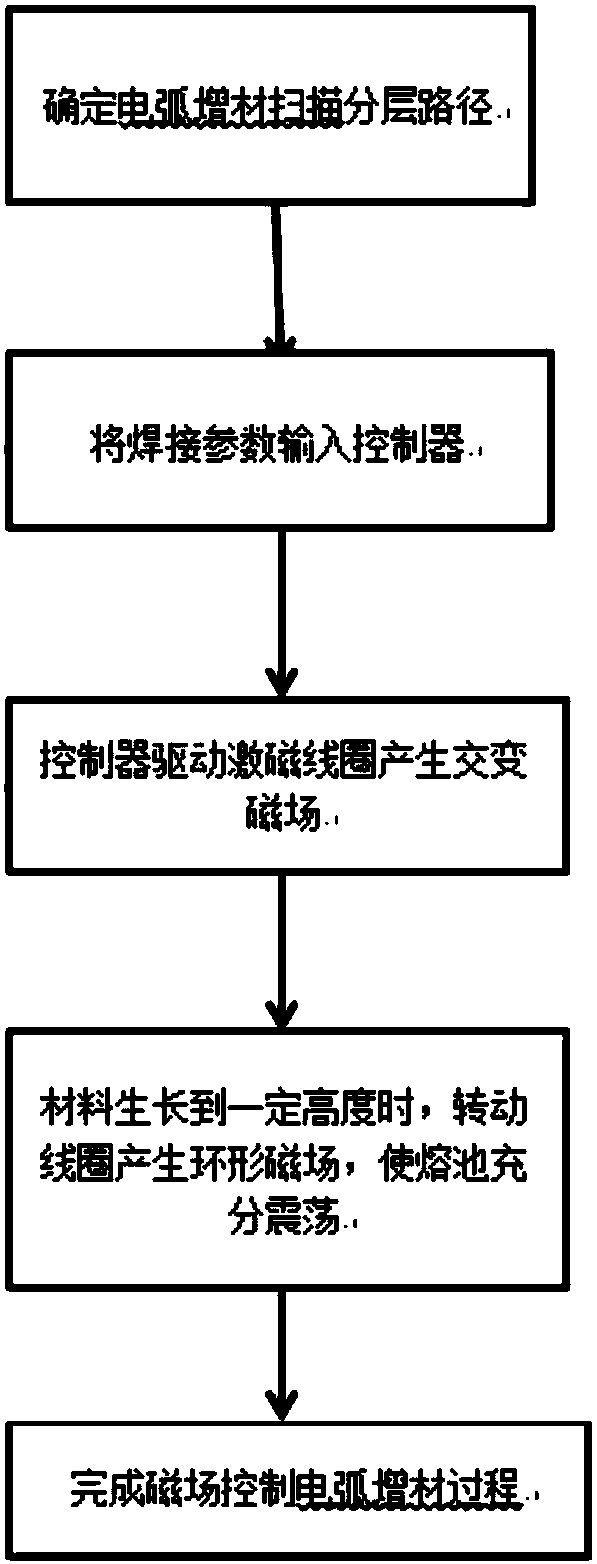

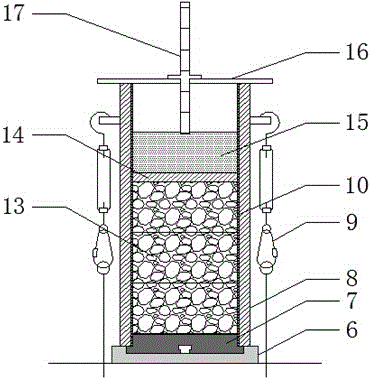

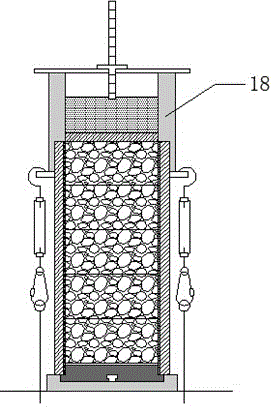

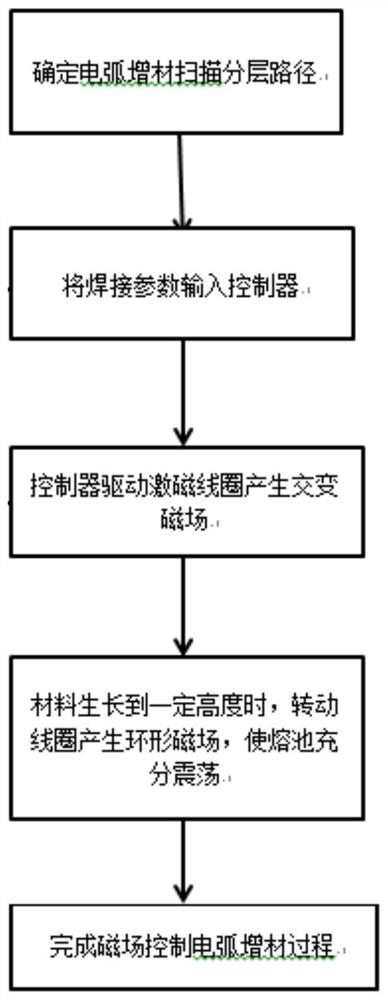

Magnetic field control type additive forming method and device adopting electric arc robot

The invention discloses a magnetic field control type additive forming method adopting an electric arc robot. The method comprises the steps that welding parameters of electric arc additive manufacturing are input into a controller; the controller drives an excitation power supply in a magnetic field generating device to generate longitudinal magnetic fields with different intensities according tothe real-time change of the manufacturing parameters; when air pores are generated on the overlaying surface of an additive part, a hollow shaft motor is used to control exciting coils to rotate to generate an annular magnetic field, and oscillation stirring is carried out on a molten pool at different degrees; and finally the magnetic fields control the electric arc robot to carry out layer-by-layer accumulation for automatic additive forming on molten wire material according to the forming path. According to the magnetic field control type additive forming method adopting the electric arc robot, control over the form and the motion state of an electric arc in the material adding process can be facilitated; and the annular magnetic field is adopted for stirring so that the floating speedof inclusions such as the air pores in the molten pool can be increased, rotary spray transfer with good stability and good controllability can be obtained, the defects of the air pores and the likein an additive manufacturing part can be greatly reduced, and continuous consistency of the forming morphology of an additive forming part formed through the electric arc robot is improved.

Owner:NANJING UNIV OF SCI & TECH

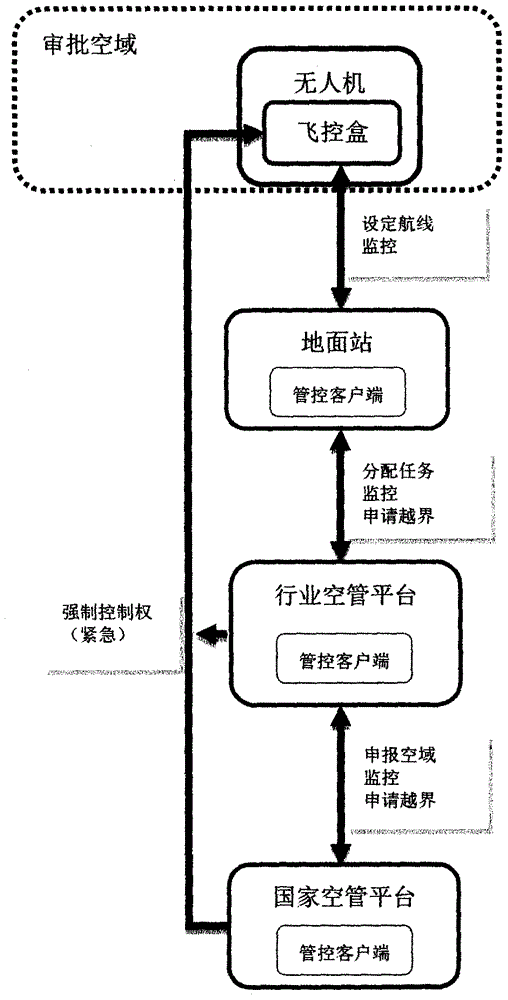

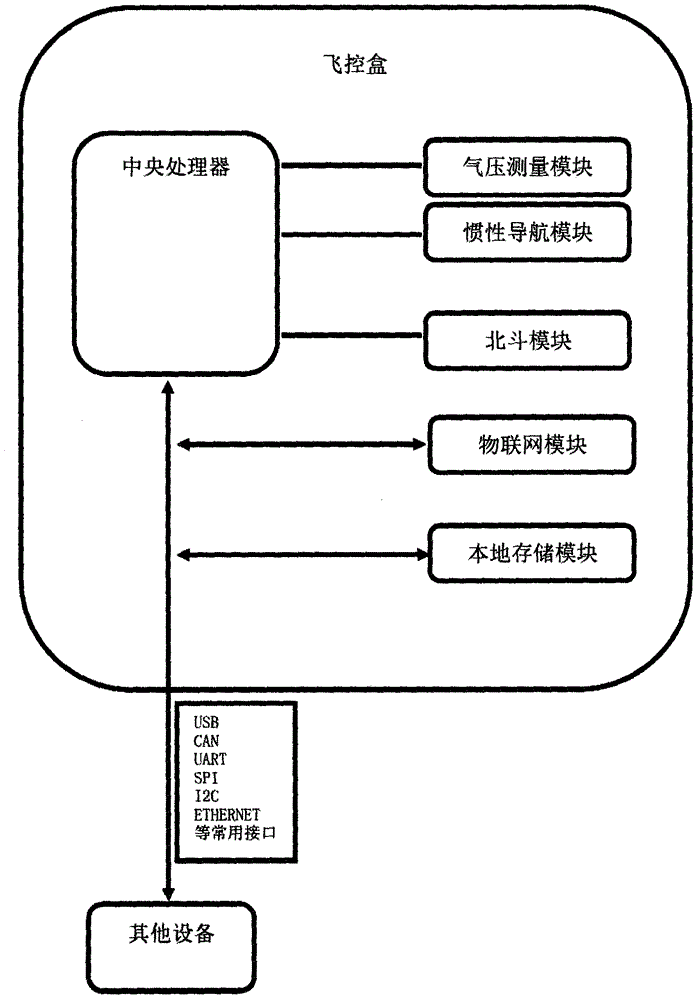

Industrial UAV management and control system and method

InactiveCN106710315ASolve management problemsRealize real-time monitoringAircraft traffic controlFlight heightControl power

The invention discloses an industrial UAV management and control system and an industrial UAV management and control method. The industrial UAV management and control system comprises flight control boxes, a ground station, an industrial air traffic control platform, a national air traffic control platform and a management and control client. The industrial air traffic control platform declares fixed task airspace to the national air traffic control platform, limited information of a UAV such as flight airspace and flight height is prestored while the UAV is registered in the flight control boxes after successful declaration, thus the UAV can fly without declaration in the approved airspace, and the flight space is automatically limited; and the UAV needs to declare to the industrial air traffic control platform and even the national air traffic control platform by utilizing the ground station when entering unapproved airspace. The national air traffic control platform grasps geological positions of all flight control boxes and the ultimate control power, and can cope with emergencies. The industrial UAV management and control system and the industrial UAV management and control method aim at industrial-grade UAVs in all industries, allow state institutions to delegate part of management and control power to departments of all industries, divide clear responsibility regions, omit the tedious fixed task region takeoff declaration, and standardize the airspace management while facilitating the usage of the UAV.

Owner:广州激速智能航空科技有限公司

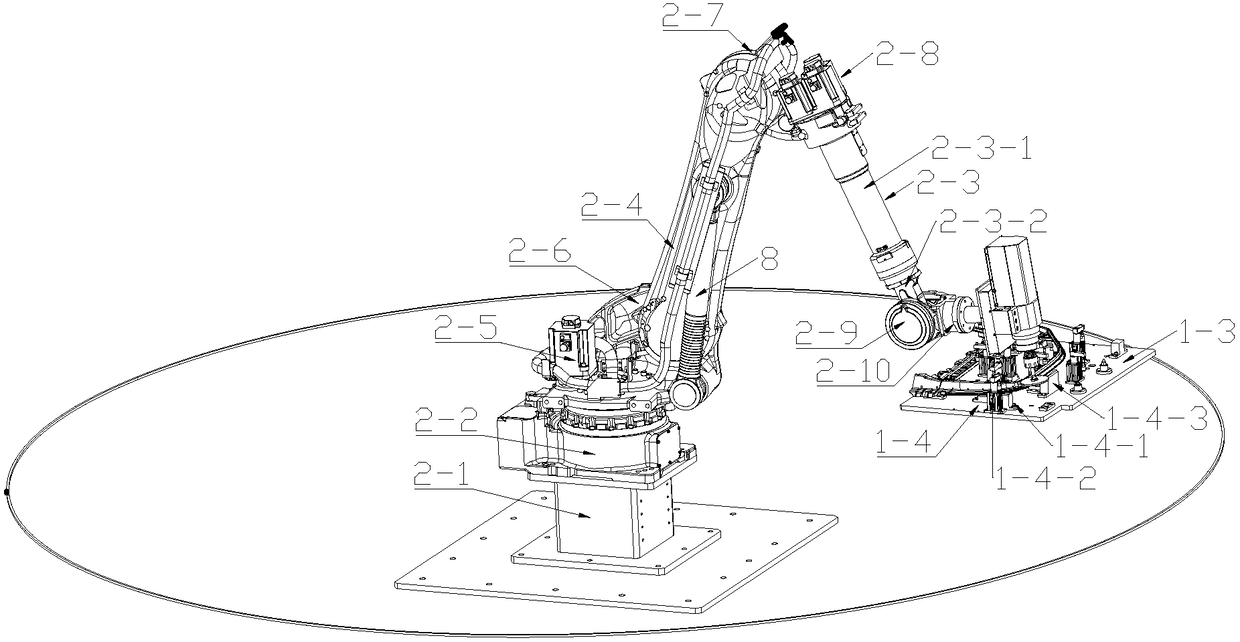

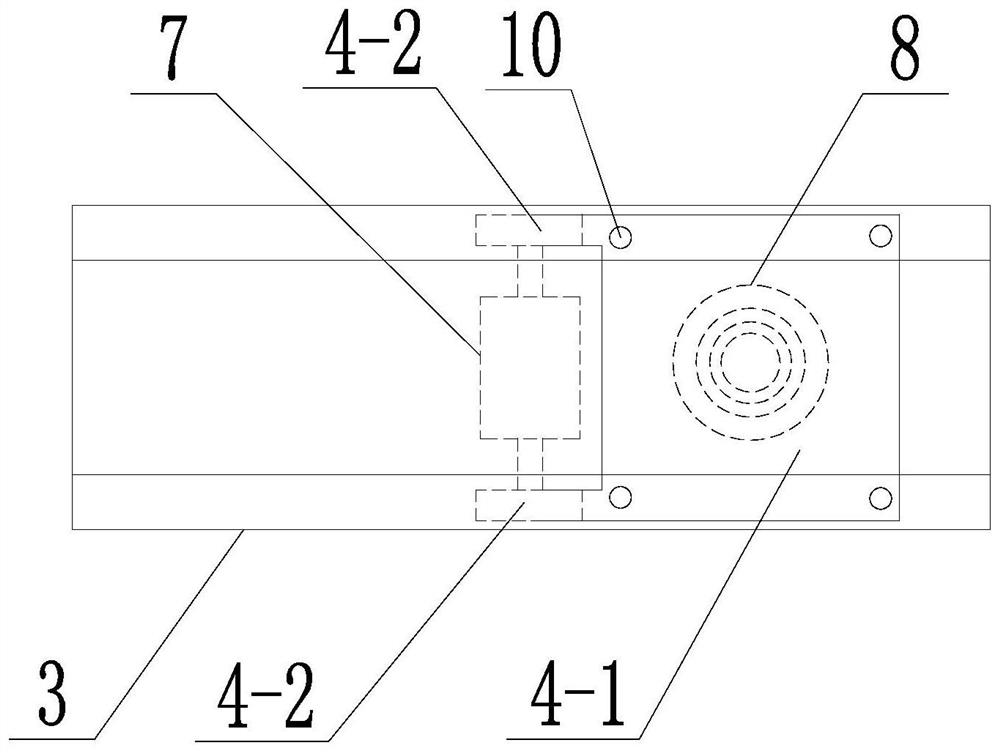

Flexible polishing device and flexible polishing system

InactiveCN108481120AReal-time monitoring heightReal-time monitoring of the diameter change of the abrasive sheetEdge grinding machinesGrinding feed controlLaser rangingControl system

The invention relates to a flexible polishing device comprising a material supply assembly, a polishing mechanical arm assembly, a polishing head assembly, a laser range finder, an abrasive wheel replacing assembly, a control console and a protective separation net. According to the flexible polishing device, a laser measuring instrument and the laser range finder are adopted to monitor the weld joint height of a workpiece and the diameter change of an abrasive sheet in real time correspondingly, and meanwhile a PLC control system online reregulates the polishing path of the workpiece according to all information and controls and adjusts the angles of polishing branch arms and the abrasive sheet and the polishing depth at the same time; and in this way, a qualified polished product is obtained, and on the premise of guaranteeing the polishing quality, the polishing efficiency is improved.

Owner:NINGBO HUIZHIHENGDONG AUTOMATION TECH CO LTD

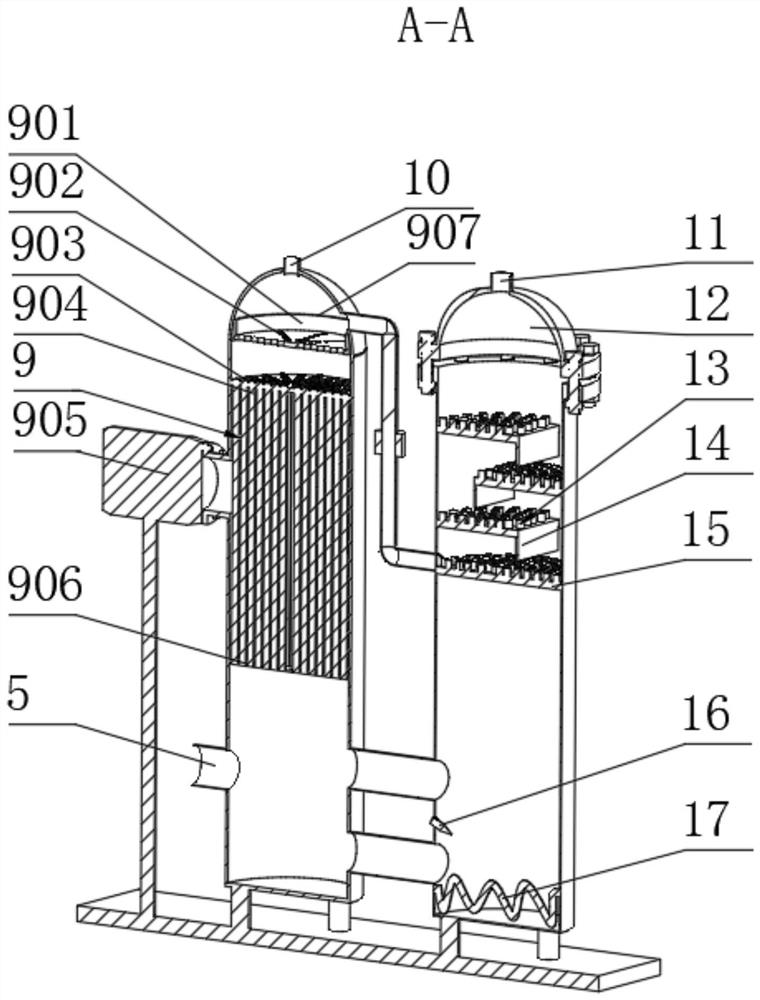

Leachate height monitoring device for domestic waste landfill

InactiveCN102121842ALow costSolve the high cost of measurementLevel indicators by physical variable measurementElectricityElectrical wiring

The invention discloses a leachate height monitoring device for a domestic waste landfill, and the device provided by the invention comprises annular electrodes, a drive pipe and a high-density resistivity instrument, wherein the drive pipe vertically extends into the waste landfill and is horizontally provided with annular grooves at intervals; the annular electrodes are arranged in the annular grooves; and an electric wire is electrically connected with the annular electrodes, extends out of the drive pipe and is electrically connected to the high-density resistivity instrument arranged outside the waste landfill. By utilizing the leachate height monitoring device for the domestic waste landfill, the effects of real-time monitoring, low cost, convenience and fastness can be achieved, and the problems of high measuring cost and long cycle after excavation of the traditional waste can also be solved.

Owner:HUAQIAO UNIVERSITY

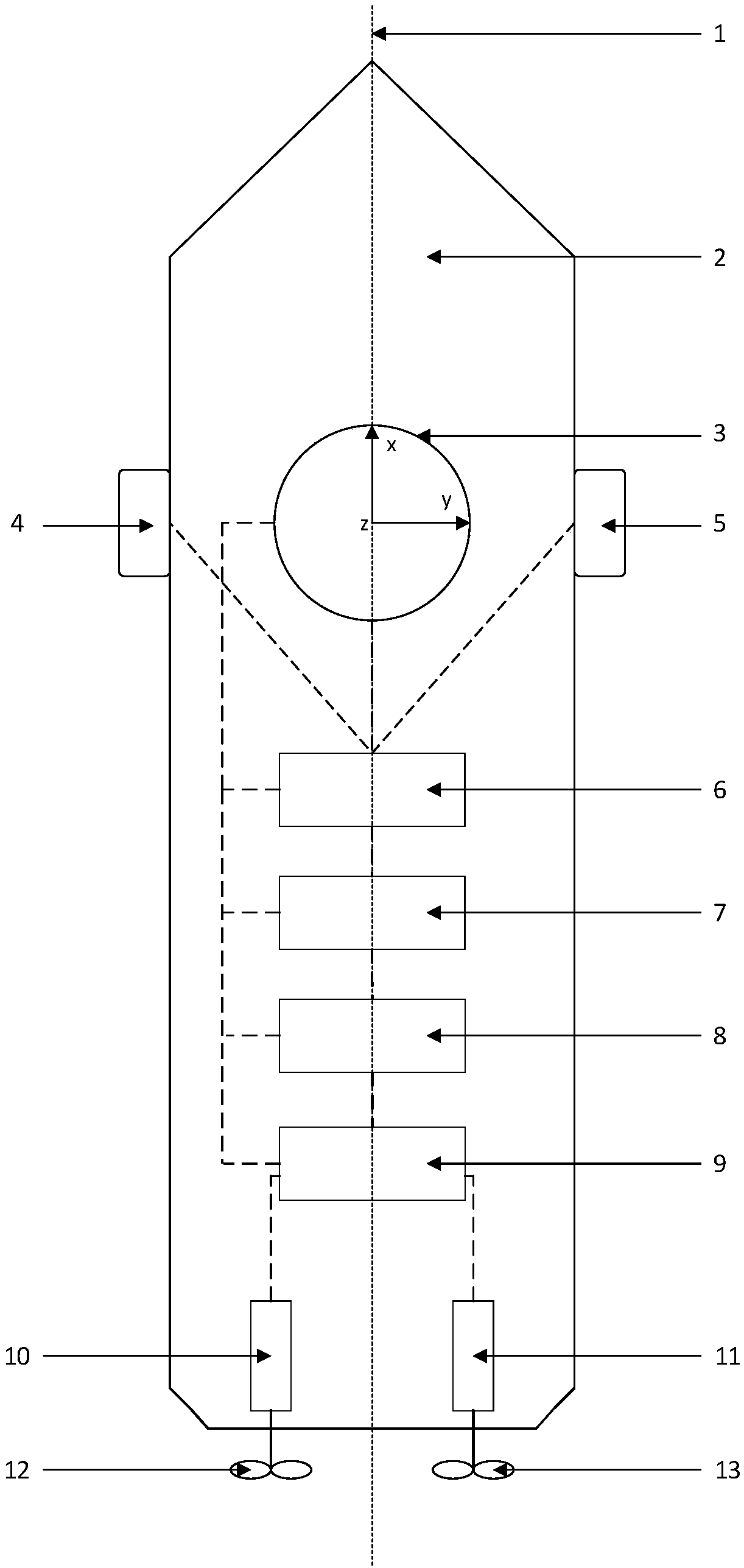

Sea wave travelling parameter detecting method and attitude self-adjustment unmanned ship

ActiveCN109373983AReal-time monitoring directionReal-time monitoring heightMeasuring open water movementVessel stability improvementSea wavesMulti axis

The invention discloses a sea wave travelling parameter detecting method and an attitude self-adjustment unmanned ship. The sea wave travelling parameter detecting method comprises acquiring sea wavetraveling parameters through detection and calculation of a multi-axis sensor, a left distance sensor and a right distance sensor, including time cycles, frequency, direction, speed and effective waveheight of traveling sea waves, and the included angle between a ship body and the sea waves, and further self-adjusting the attitude of the unmanned ship to maintain an orthogonal state with the waves all along, thereby effectively avoiding roll-over of the ship body, improving the safety and reliability of the unmanned ship during marine navigation, improving the power generating efficiency of amovable power generating ship and enhancing the traveling stability of the ship body on sea.

Owner:SOUTH CHINA AGRI UNIV

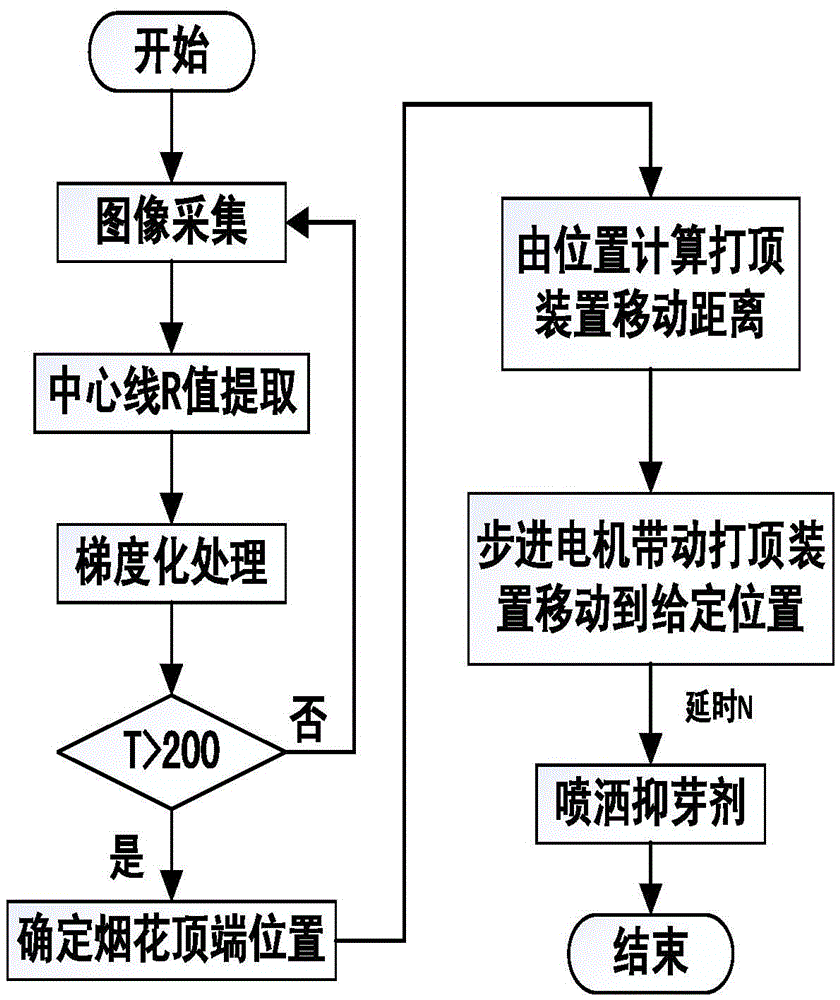

Tobacco topping sprouting inhibition detection control system based on machine vision

ActiveCN105549486AReal-time monitoring heightReduce the labor intensity of toppingProgramme controlComputer controlImaging processingMachine vision

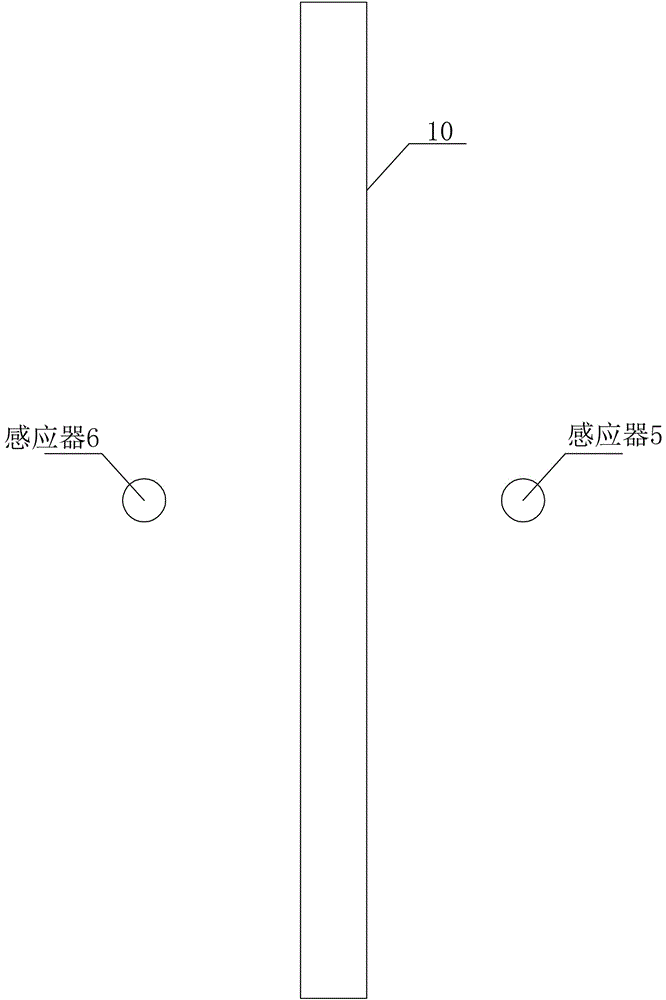

The invention provides a tobacco topping sprouting inhibition detection control system based on machine vision. The system comprises a tobacco plant top position detection system and a topping sprouting inhibition control system. The tobacco plant top position detection system comprises an image collection module, an image processing module, and a tobacco plant top position positioning module. The image collection module comprises a camera and a background plate, and is used for collecting image information. The image processing module is used for the analysis of the image information collected by the image collection module, and enables the information to be transmitted to the tobacco plant top position positioning module. The tobacco plant top position positioning module achieves the positioning of the information of tobacco flowers, and determines a distance that the topping device needs to move. The system can quickly monitor the height of the top of a tobacco plant in real time, controls the topping device to complete the precise topping operation, reduces the topping labor intensity of tobacco, improves the topping efficiency of tobacco, and speeds up the intelligentization process of tobacco processing.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Liquid lubricating oil winter filling system

InactiveCN104776308AMeet filling requirementsGuaranteed heating safetyMachines/enginesLubricant filling/drainingProduction lineControl system

The invention discloses a liquid lubricating oil winter filling system, comprising an oil storage tank; the oil storage tank is communicated with a heating control system by a liquid replenishing pipeline; the heating control system heats lubricating oil fed by the oil storage tank and controls temperature of the lubricating oil; the heating control system is connected with a filling control system; the filling control system conveys the lubricating oil to filling points of a production line by a pipeline. By the lubricating oil filling system, the problem that the lubricating oil is slowly filled in winter, and cannot meet the production pace is solved; in the past, when vehicles are produced, oil is slowly filled and can only meet the demands of 8 vehicles every day, by heating the lubricating oil through the lubricating oil filling system, the viscosity of the lubricating oil is reduced, the fluidity is increased, the production demand on 40 vehicles every day is met, and the efficiency is improved by more than 5 times; the heating temperature is below 35 DEG C, the performance of the lubricating oil is not changed and good oil quality is ensured.

Owner:SINO TRUK JINAN POWER

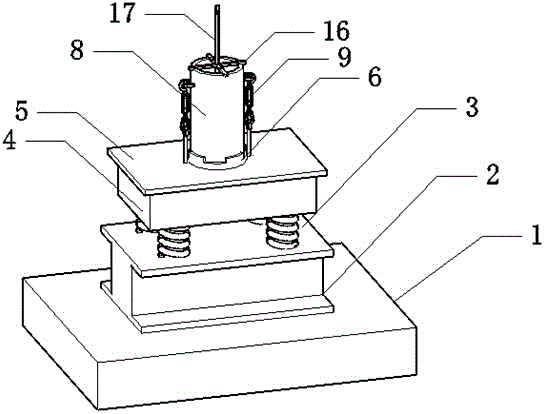

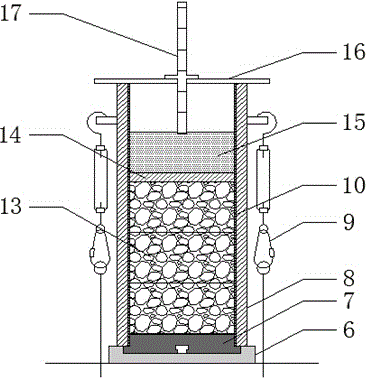

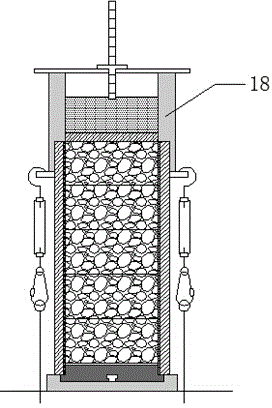

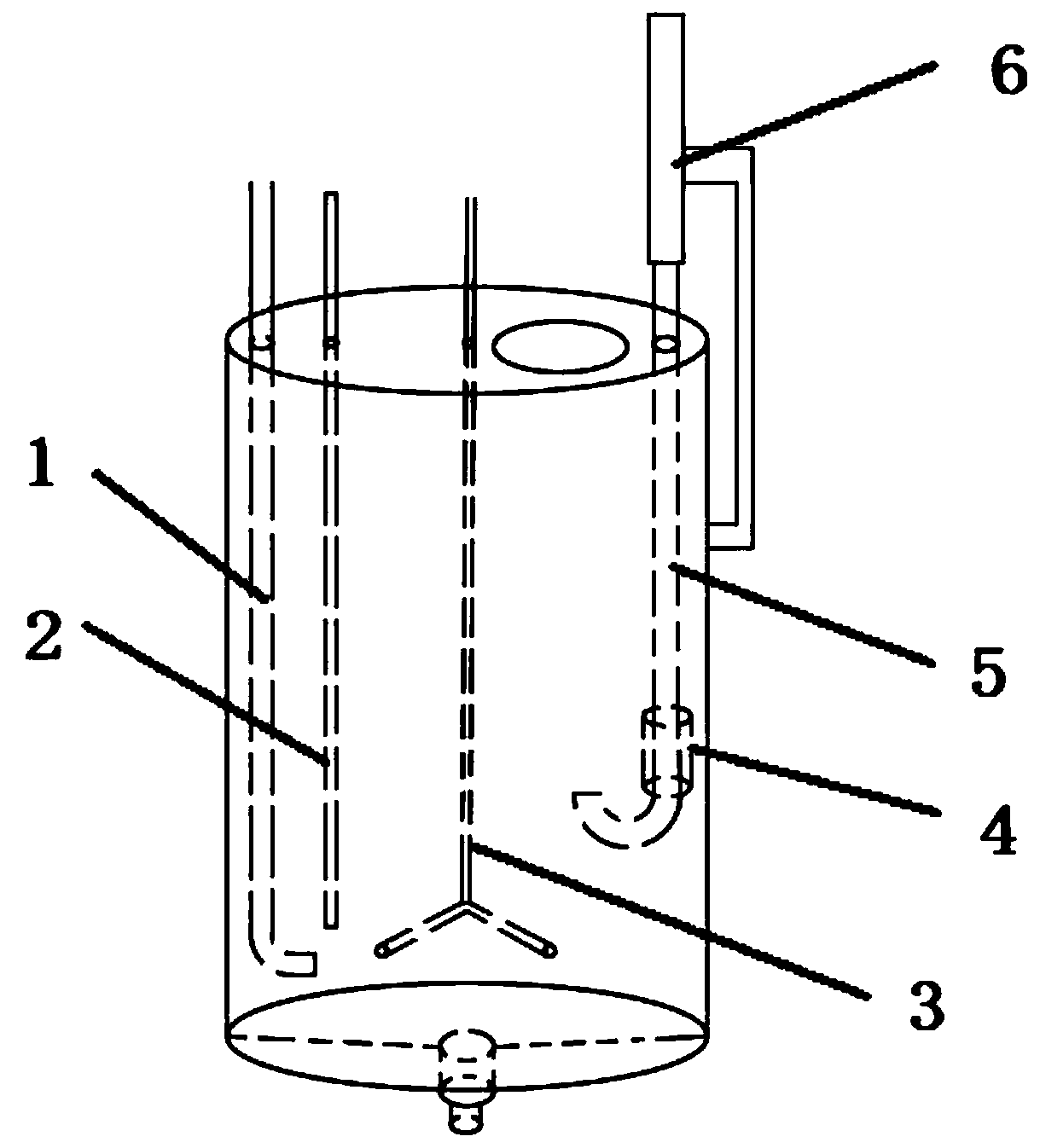

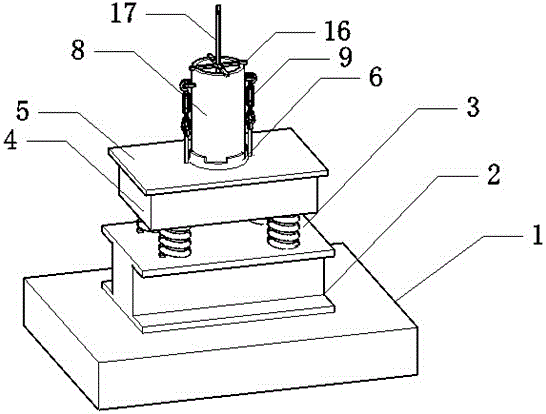

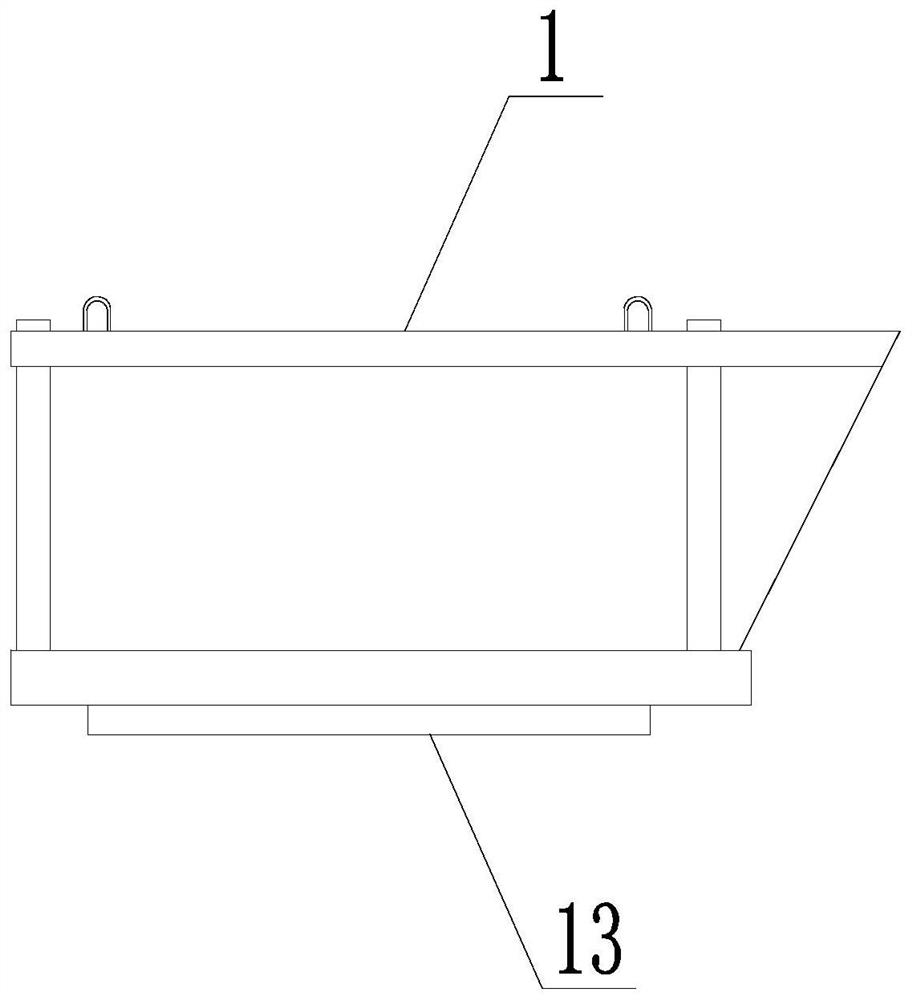

Vibration table-based sample preparation device and vibration table-based sample preparation method for large-scale triaxial test of coarse grained soil

ActiveCN104655463AReduce breakage rateReal-time monitoring heightPreparing sample for investigationSoil scienceTriaxial shear test

The invention discloses a vibration table-based sample preparation device and a vibration table-based sample preparation method for a large-scale triaxial test of coarse grained soil. An improved table top of a vibration table is adopted, so that a sample base and a protective arm can be fixed and conveniently disassembled and lifted; based on the vibration effect of the vibration table, samples are compacted by vibration layer by layer, so that the grain breakage rate of the coarse grained soil samples can be reduced in the sample preparation process; the heights of all the layers of samples can be monitored in real time by a vernier caliper capable of freely moving along the vertical direction, so that the density of the samples can be better controlled; the prepared samples are placed on a GDS large dynamic triaxial test apparatus by a small-sized crane; after the device and the method are used, low breakage rate, easy control and high accuracy are realized in the large-scale triaxial test process on the whole; the device and the method have great promotion and popularization functions for large-scale triaxial static and dynamic tests related to the coarse grained soil in the future.

Owner:ZHEJIANG UNIV

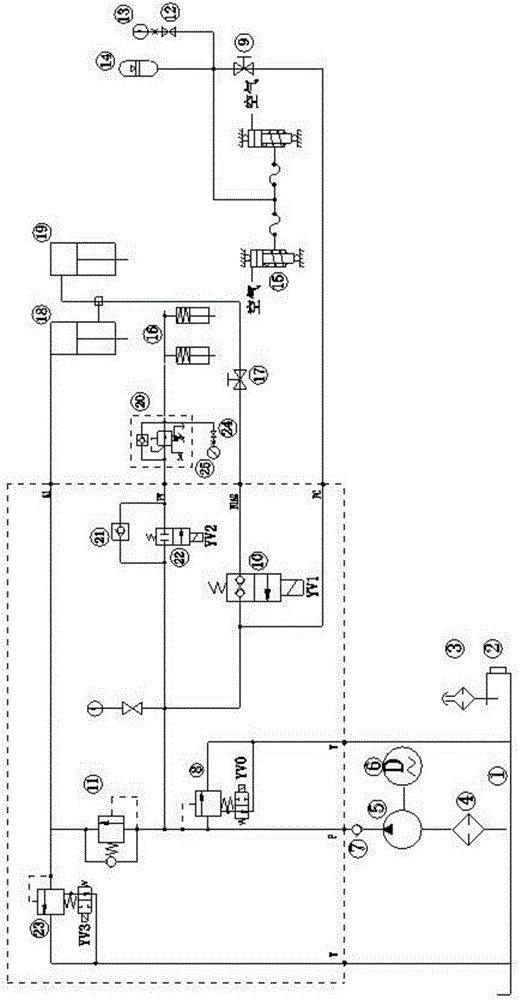

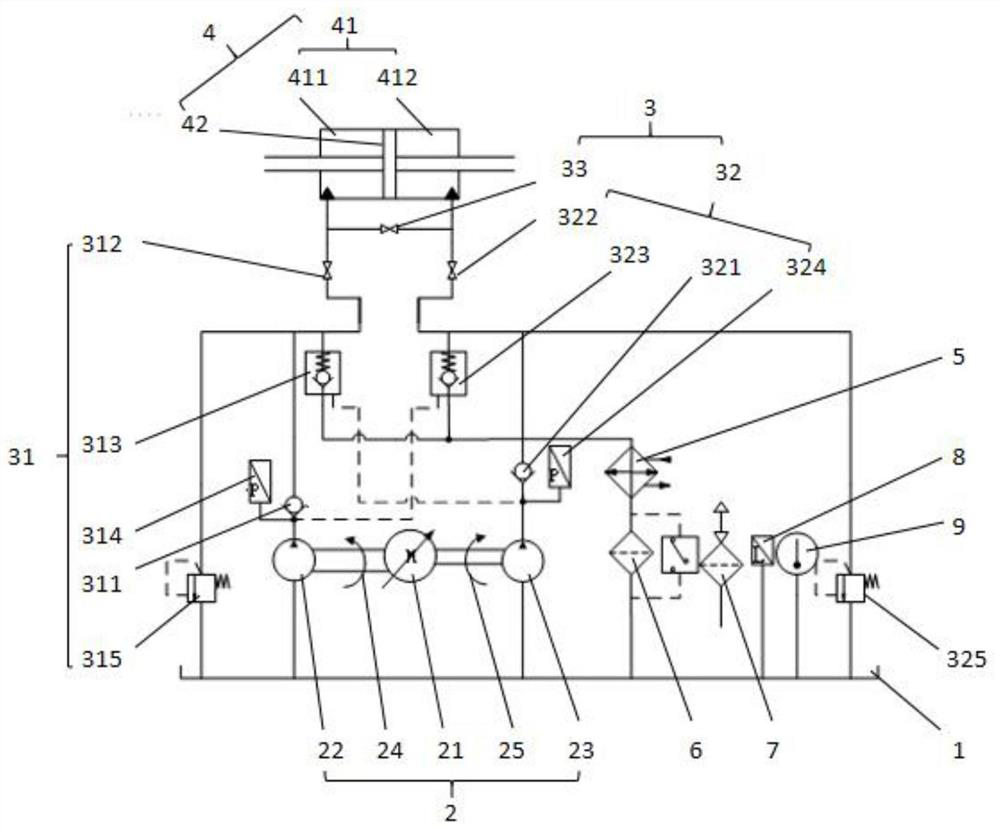

Control method of guillotine shear hydraulic system

ActiveCN106270722ALow costReduce layoutFluid-pressure actuator safetyFluid-pressure actuator testingCharge controlRisk stroke

The invention discloses a control method of a guillotine shear hydraulic system and belongs to the technical field of hydraulic machines. The control method controls the hydraulic system to finish system unloading stand-by state control of a plate shear, material preloading control, shearing control, return stroke control, tool rest shear angle decrease or increase control, energy accumulator charging control and oil cylinder charging control through sequential control of an electromagnetic relief valve I, a switching valve, a two-position two-way electromagnetic valve and an electromagnetic relief valve II in combination with a check valve I and a check valve II. Compared with the existing hydraulic system, the guillotine shear hydraulic system has the advantages that the the structure greatly simplified and the production cost is reduced. The control method enables the system to operate stably and can meet various working operation requirements. The material pressing action can be controlled independently and the pressure is controllable, and it is convenient to overhaul and maintain.

Owner:安徽省华夏机床制造有限公司

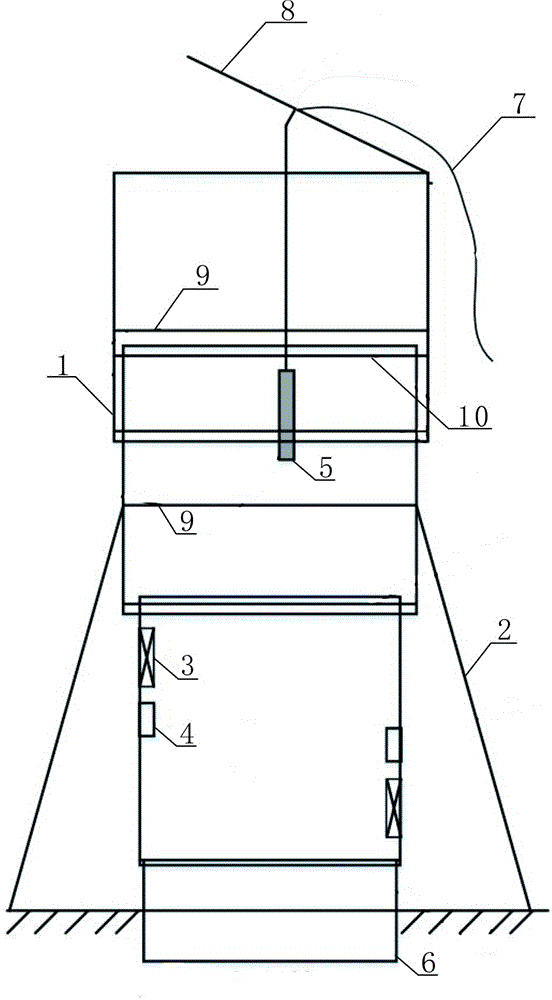

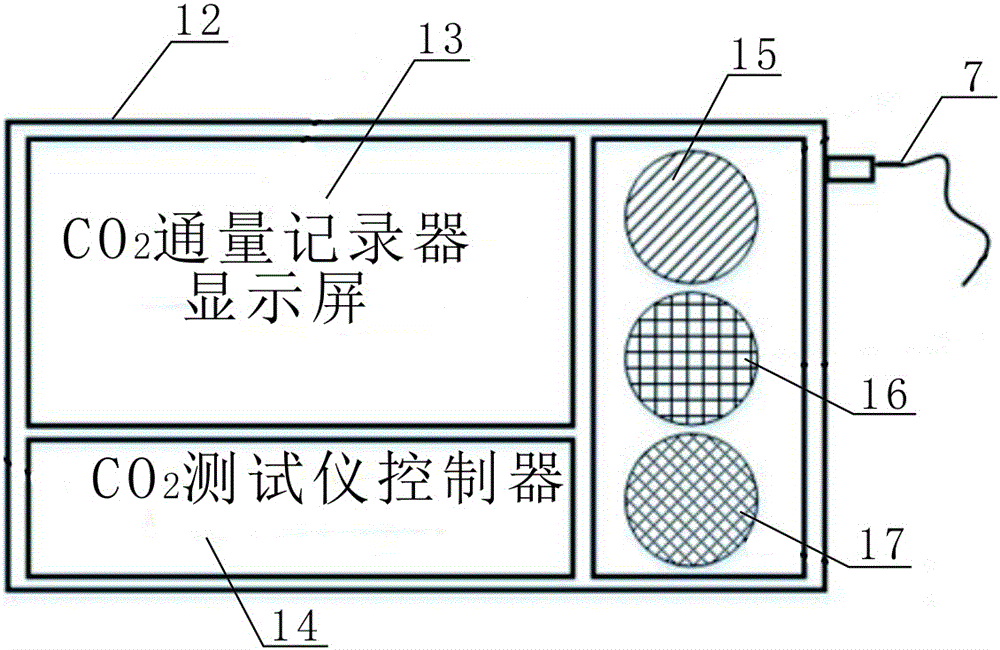

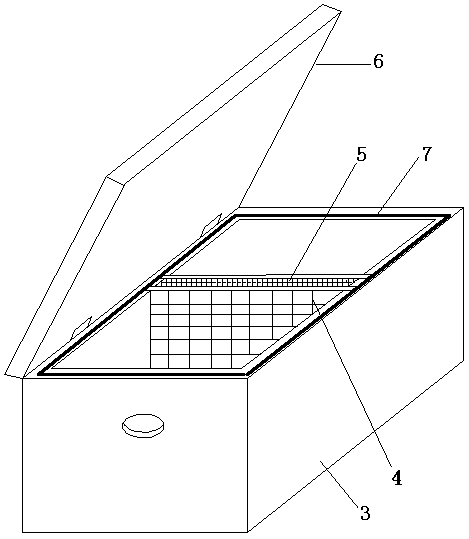

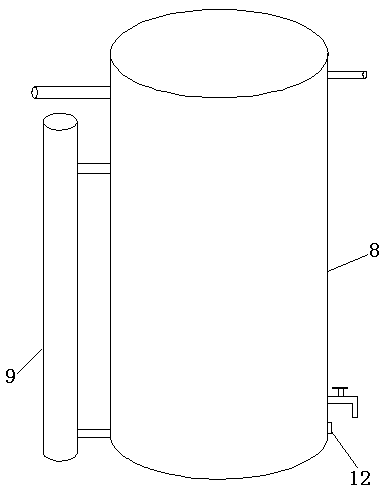

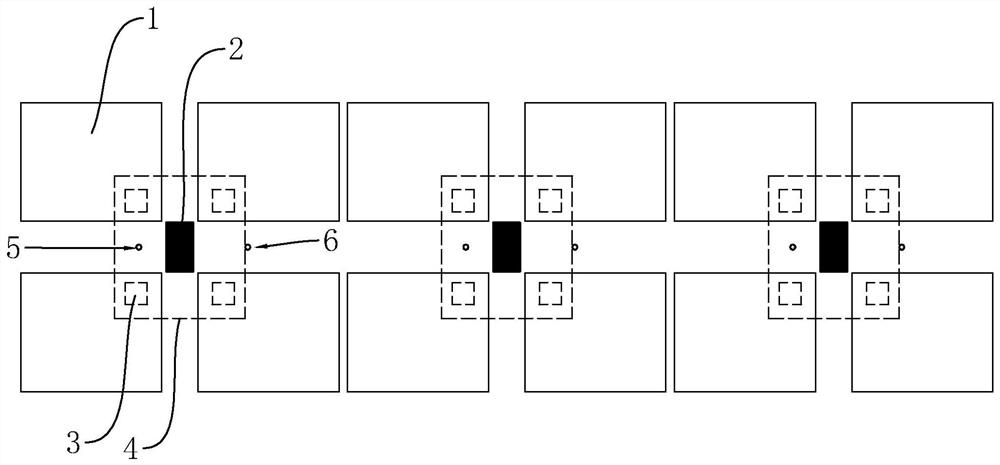

CO2 flux automatic monitoring system of farmland ecosystem

ActiveCN106370790ARealize regulationReal-time adjustmentTesting plants/treesMonitoring systemEngineering

The invention discloses a CO2 flux automatic monitoring system of a farmland ecosystem. The CO2 flux automatic monitoring system comprises a plurality of static visible boxes, automatic lifting machines and CO2 monitoring devices which are sleeved, wherein the CO2 monitoring devices are arranged in the static visible boxes and are used for detecting the CO2 concentration in the static visible boxes in real time; the automatic lifting machines are used for clamping the static visible boxes to adjust the heights of the boxes; the multiple static visible boxes and the automatic lifting machines which are sleeved are used for enabling the CO2 monitoring devices to detect the CO2 concentration at different heights. The CO2 flux automatic monitoring system has the characteristics of convenience for operation, continuity of monitoring and easiness in carrying and assembling, and can be used for monitoring the research on discharging of CO2 flux of the farmland ecosystem in different growing stages under different height conditions.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Automatic kitchen water heating system

InactiveCN107761817AExpand the scope of useEasy to useGeneral water supply conservationService pipe systemsRainwater harvestingHeating system

The invention discloses an automatic kitchen water heating system which comprises a rainwater collecting device located on a planar roof, a rainwater filtering device connected with the rainwater collecting device, a water storage device and an automatic heating system. The water storage device and the automatic heating system are located in a kitchen. The automatic heating system comprises a human body detecting module, a microprocessor, a reset circuit module, a crystal oscillator circuit module and a relay module. The reset circuit module and the crystal oscillator circuit module are connected with the microprocessor to form a single chip microcomputer minimum system. The input end of the microprocessor is electrically connected with the human body detecting module, the output end of the microprocessor is electrically connected with the relay module, a normally opened contact in the relay module is serially connected in a heating circuit of the water storage device for power supplyconnection or disconnection. Rainwater can be widely used after preliminary processing, and the application range of rainwater is greatly widened.

Owner:HENAN NORMAL UNIV

Low-noise bidirectional servo pump source

PendingCN114658707ARealize reciprocating motionAchieve direct controlFluid-pressure actuator testingServomotor componentsControl setHydraulic cylinder

The invention relates to a low-noise two-way servo pump source which comprises an oil tank, a pump source assembly, a valve control set, a hydraulic cylinder, a cooler and an oil return filter. The pump source assembly comprises a double-shaft-extension servo motor, a first hydraulic pump, a second hydraulic pump, a first clutch and a second clutch. The valve control sets comprise the first valve control set and the second valve control set, the hydraulic cylinder comprises a cylinder body and a piston, and the piston is slidably connected to an inner cavity of the cylinder body and divides the inner cavity of the cylinder body into a first cavity and a second cavity. Reciprocating motion of the hydraulic cylinder is achieved through forward rotation and reverse rotation alternate motion of the double-shaft-extension servo motor, the reciprocating motion speed of the hydraulic cylinder is achieved by adjusting the rotating speed of the double-shaft-extension servo motor, and therefore bidirectional speed regulation and direction control of the whole hydraulic transmission system are achieved. The device is simple in structure, low in noise, high in reliability and wide in speed regulation range.

Owner:中国船舶集团有限公司第七零七研究所九江分部

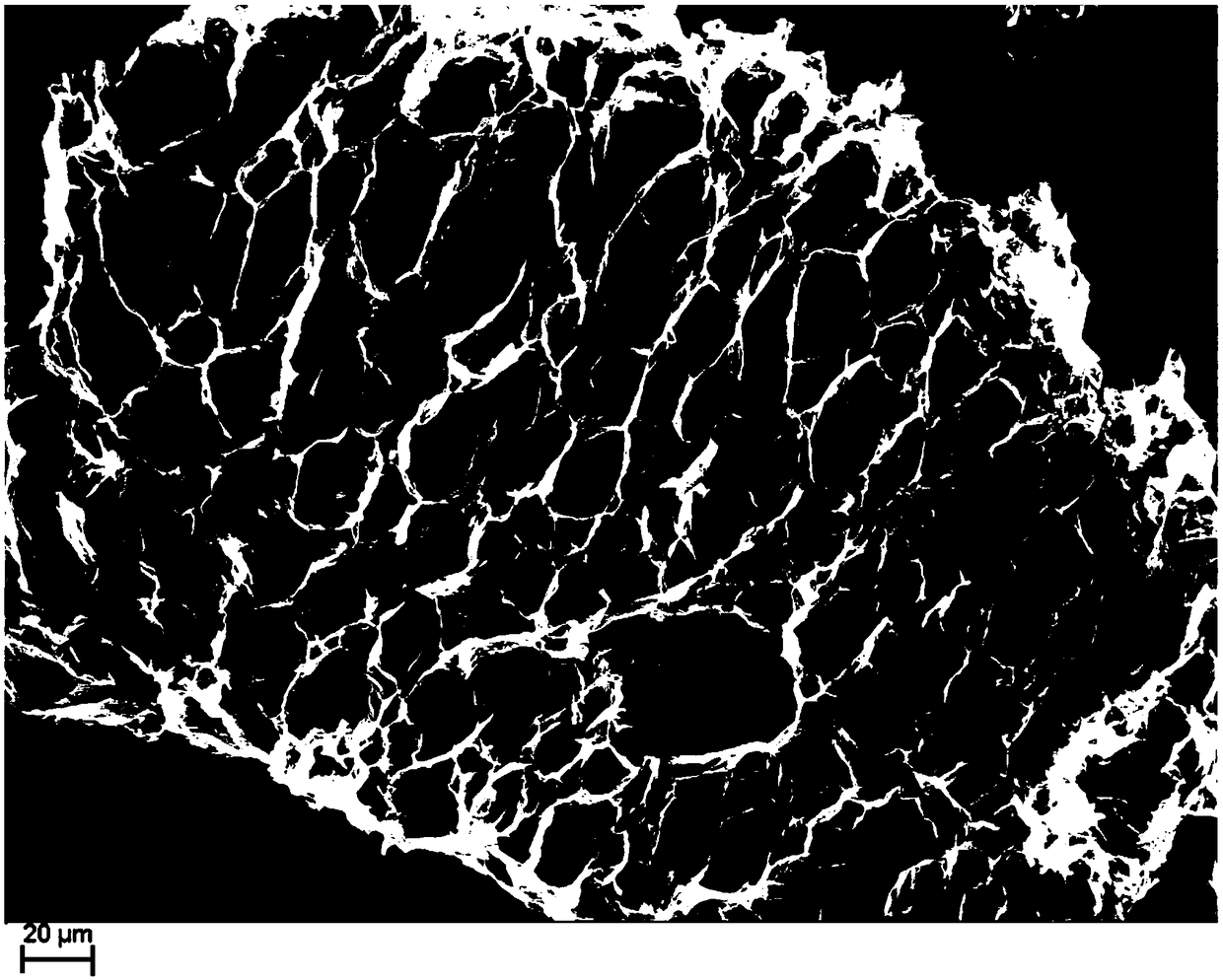

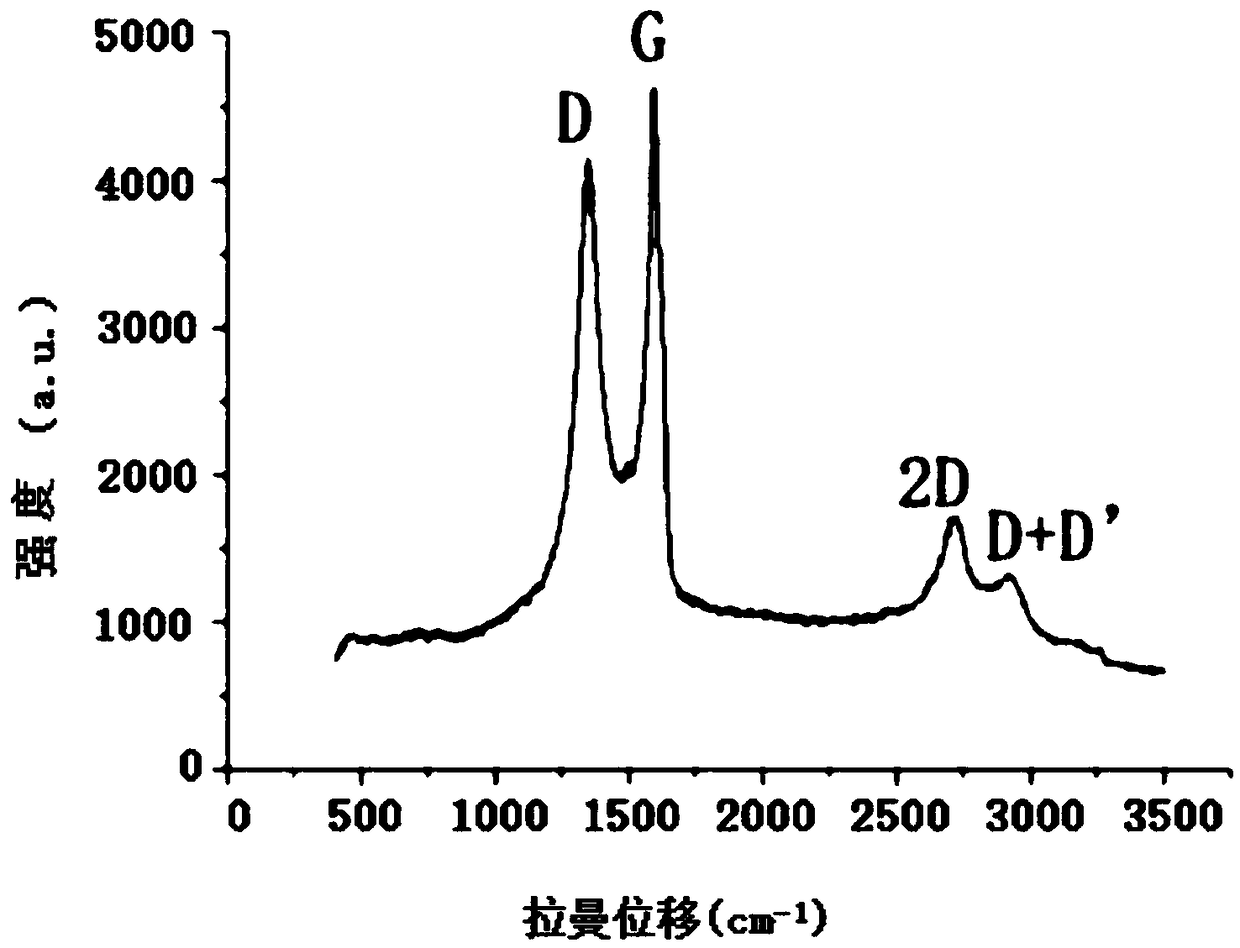

Preparation method of graphite oxide capable of being washed directly

The invention provides a preparation method of graphite oxide capable of being washed directly. The preparation method comprises the following steps that step one, crystalline flake graphite is takenas a raw material, a main intercalator and an auxiliary intercalator are added for intercalation treatment to obtain a graphite intercalation compound; the main intercalator is at least one of formicacid, acetic acid, phosphoric acid, concentrated nitric acid and concentrated sulfuric acid; the auxiliary intercalator is at least one of an aqueous hydrogen peroxide solution, performic acid and peracetic acid; step two, after redundant main intercalator and auxiliary intercalator of the graphite intercalation compound are filtered out, the filtered graphite intercalation compound is put into ice water, tiny impurity particles and water are filtered and washed off with a sieve, and the graphite intercalation compound with less impurities is obtained; step three, an oxidizing agent is added in the filtered graphite intercalation compound, oxidation is carried out for 0.5-50 hours under the condition of 0-45 DEG C, and the graphite oxide of which a PH value is 0-1 and capable of being washed directly by the water is obtained. By the method, the volume of the raw material is swelled to 300 times to 500 times or above.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

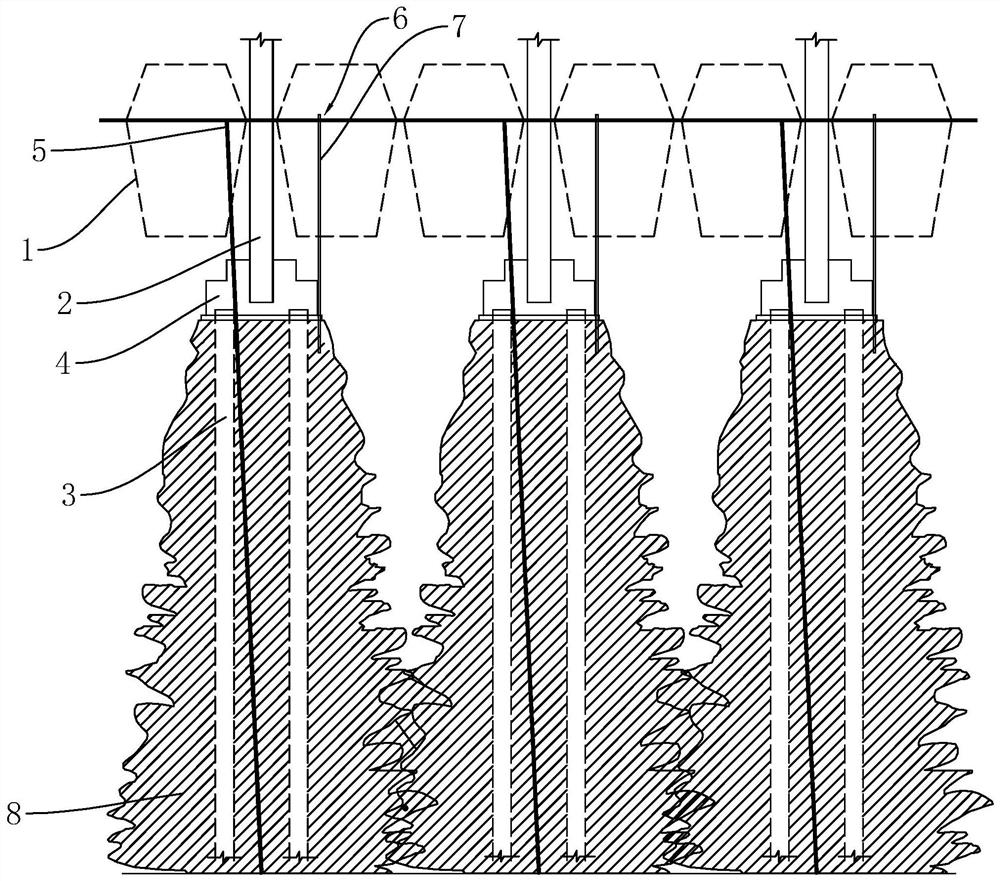

Settlement reinforcement method for independent foundation of building brewing workshop

InactiveCN112081159AAvoid disturbanceAvoid destructionFoundation repairSoil preservationArchitectural engineeringStructural engineering

The invention relates to a settlement reinforcement method for an independent foundation of a building brewing workshop. The settlement reinforcement method comprises the following steps that S1, grouting holes are formed, wherein one grouting hole is formed in one side of each stand column, and the depths of the grouting holes are determined according to the geological condition; S2, observationholes are formed, wherein the observation holes are formed in one sides, away from the grouting holes, of the stand columns, the observation holes are drilled to the position below a bearing platform,the observation holes are located in the outer edges of contour lines of pile foundations, on the sides, away from the grouting holes, of the stand columns, guide pipes are inserted into the observation holes, and monitoring devices used for detecting the grouting heights and diameters are arranged at the top ends of the guide pipes; and S3, grouting reinforcement is conducted, wherein grouting is conducted in the grouting holes to reinforce the independent foundation, during grouting, pressure grouting is conducted firstly, then permeation grouting is conducted, and whether grouting is completed or not is judged according to the monitoring devices. The method has the advantages of being suitable for construction in a narrow area, simple in process and small in stratum disturbance.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

Spice continuous rectification production control system

PendingCN114307218AIncrease labor intensityLong processing timeDistillation regulation/controlEssential-oils/perfumesThermodynamicsControl system

The invention discloses a perfume continuous rectification production control system, and the system specifically comprises a distillation device which comprises a raw material conveying module, a water source preheating module, a distillation module, a water level detection module and a cooling molding module, and then the water source preheating module is started. Then a water source is pumped into the top end in the first distillation tower through a water inlet, then the water source regularly flows to a heating pipe through a round hole formed in a round fixing block in a primary heating mechanism, the temperature of the water source in the heating pipe is increased through heating of a heater, and then the water source flows out from the bottom end and is mixed with perfume at the bottom end; according to the invention, the water source does not need to be heated for a long time, so that the situation that the processing efficiency is reduced due to overlong heating time is effectively prevented, and then boiling water and water vapor simultaneously permeate into plant raw material tissues, so that essential oil in the tissues is gradually and continuously diffused to the surfaces of plants.

Owner:吉安市中香天然植物有限公司

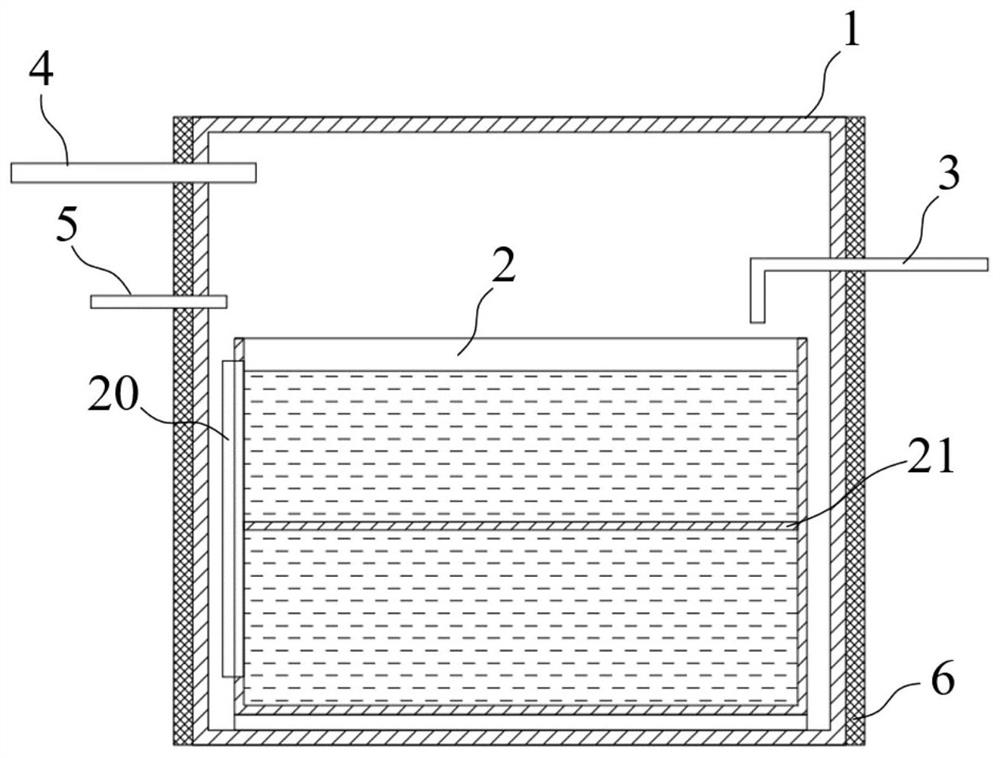

Vacuum impregnation method

InactiveCN112435872ASimple processImprove impregnation effectDrying/impregnating machinesThermodynamicsEngineering

The invention discloses a vacuum impregnation method, and belongs to the technical field of vacuum impregnation. The vacuum impregnation method comprises the following steps of: 1, preheating, namelyheating a capacitor; 2, canning, namely putting the heated capacitor into a dipping tank in a tank body; 3, vacuumizing, , namely starting a vacuum unit to keep a negative pressure state in the tank body; 4, gas charging, namely charging argon into the tank body; 5, heating, namely heating the interior of the tank body; 6, secondary vacuumizing, namely starting a vacuum unit, and controlling the vacuum degree in the tank body to be below 8Pa; 7, liquid injection and impregnation, which is implemented by injecting an electrolyte into the capacitor to impregnate the capacitor for 1013 hours, andkeeping constant pressure and constant temperature during impregnation; and 8, taking out, namely stopping heating the tank body, and taking out the capacitor after the tank body returns to a normal-temperature and normal-pressure state. The vacuum impregnation method is simple in process, good in impregnation effect and high in impregnation efficiency, and the product performance is improved.

Owner:WUXI XIYUAN BOILER

A farmland ecosystem co 2 Flux automatic monitoring system

ActiveCN106370790BRealize regulationReal-time adjustmentTesting plants/treesMonitoring systemProcess engineering

The invention discloses a CO2 flux automatic monitoring system of a farmland ecosystem. The CO2 flux automatic monitoring system comprises a plurality of static visible boxes, automatic lifting machines and CO2 monitoring devices which are sleeved, wherein the CO2 monitoring devices are arranged in the static visible boxes and are used for detecting the CO2 concentration in the static visible boxes in real time; the automatic lifting machines are used for clamping the static visible boxes to adjust the heights of the boxes; the multiple static visible boxes and the automatic lifting machines which are sleeved are used for enabling the CO2 monitoring devices to detect the CO2 concentration at different heights. The CO2 flux automatic monitoring system has the characteristics of convenience for operation, continuity of monitoring and easiness in carrying and assembling, and can be used for monitoring the research on discharging of CO2 flux of the farmland ecosystem in different growing stages under different height conditions.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

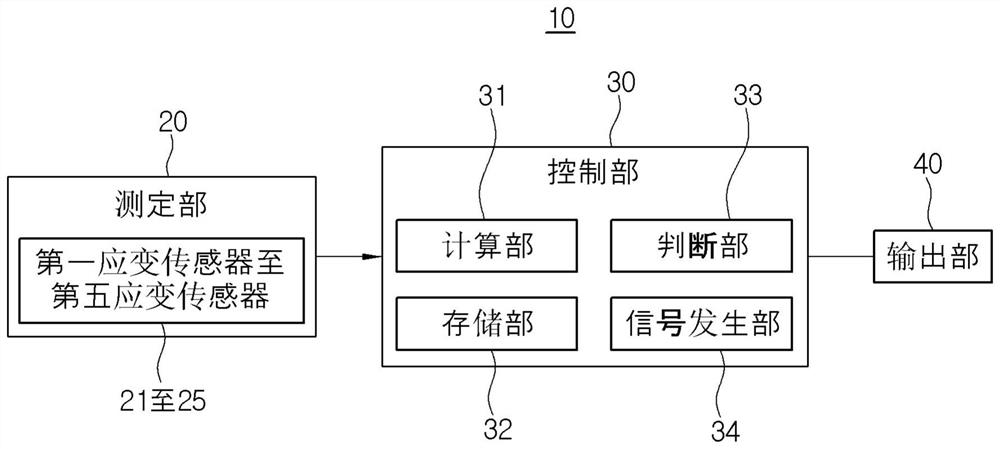

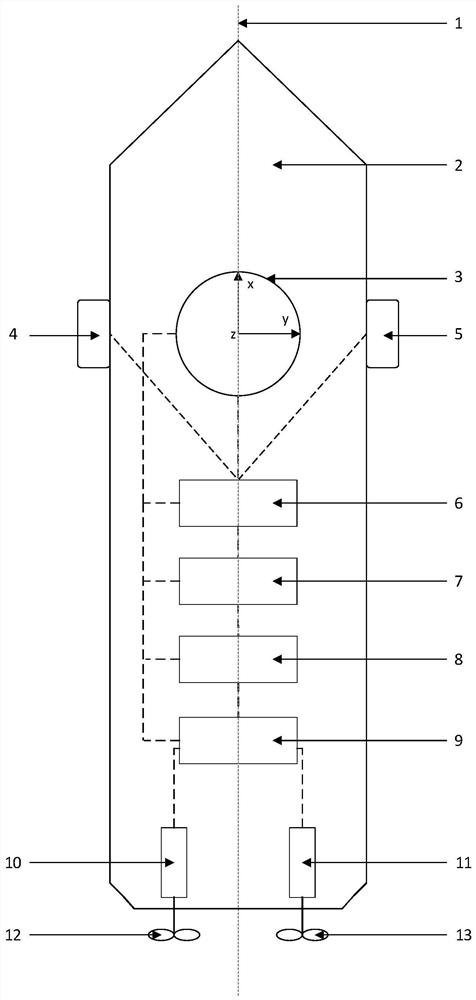

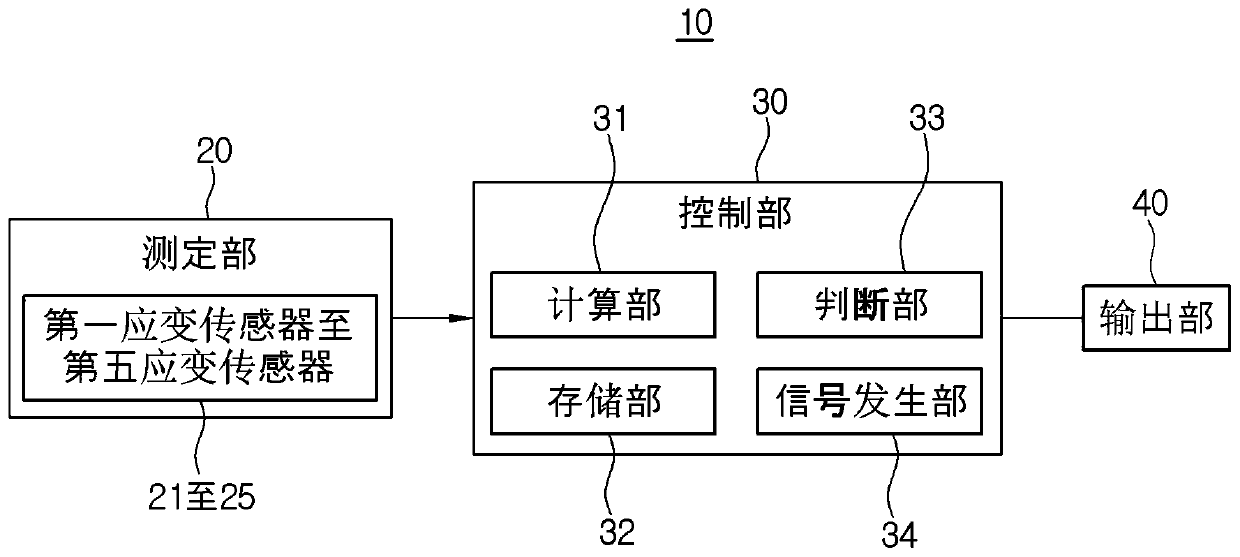

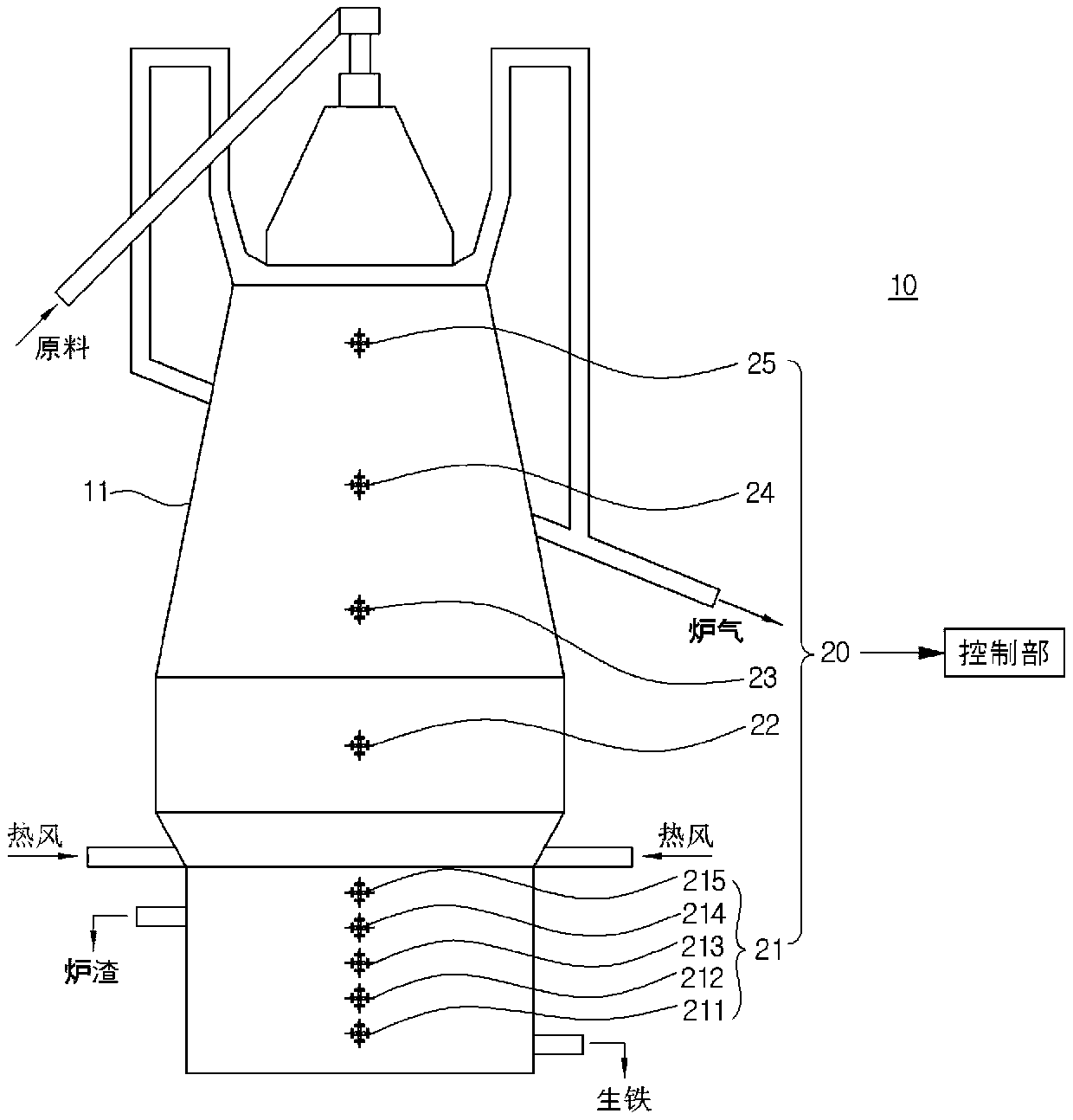

Device and method for measuring melt height of melting furnace

ActiveCN110691855BReal-time monitoring heightPrompt notificationMachines/enginesLevel indicatorsGratingFiber gratings

The present invention relates to a melting material height measuring device and method of a melting furnace. The melting material height measuring device of the melting furnace includes: a measuring part arranged on the surface of the melting furnace for measuring the vertical deformation of the melting furnace surface based on the height change of the melting material The rate of deformation and the rate of deformation in the horizontal direction; and the control part, which monitors the height of the melt by using the rate of deformation in the vertical direction and the rate of deformation in the horizontal direction measured in the above-mentioned measurement part, controls the operation of the furnace based on the monitoring results, and can use the applicable optical fiber The strain sensor of the grating sensor measures the deformation rate in the vertical and horizontal directions of the furnace surface, and measures the height of the melt based on the change in the deformation rate based on the amount of the melt.

Owner:FBG KOREA INC +1

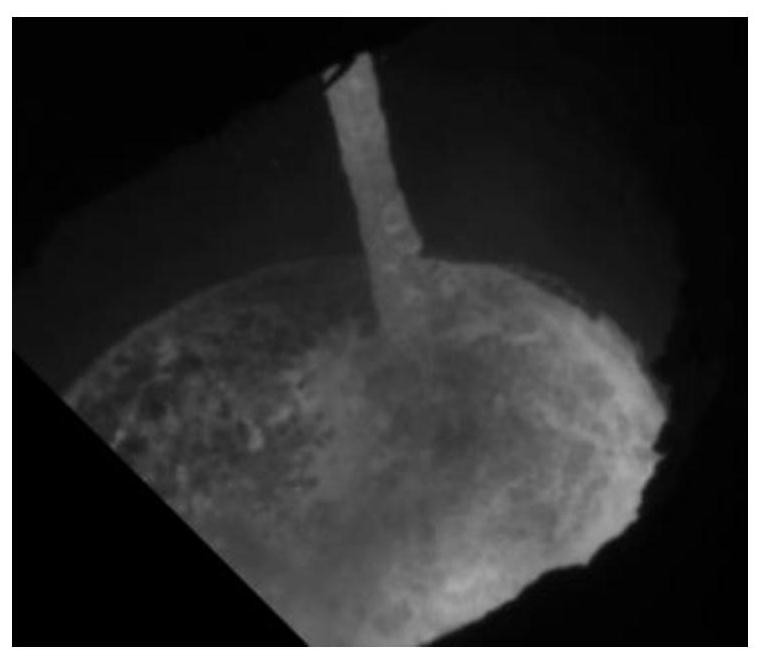

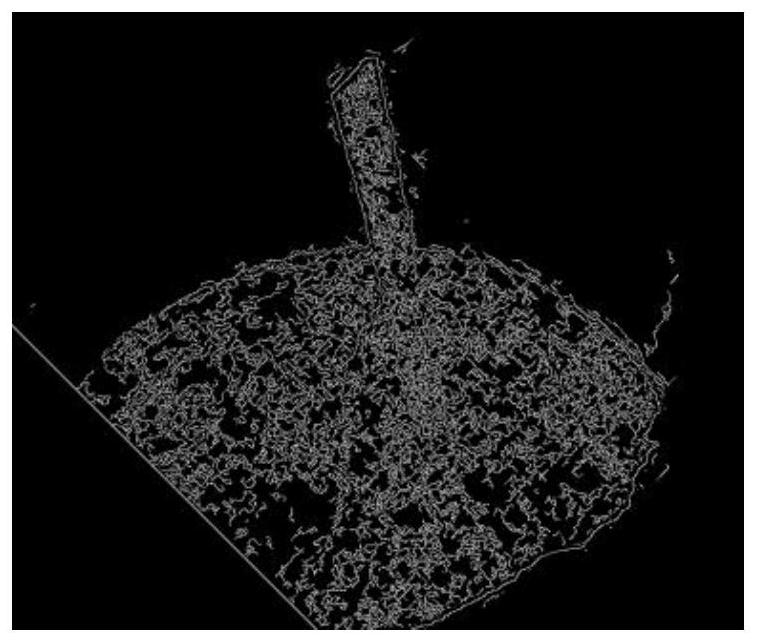

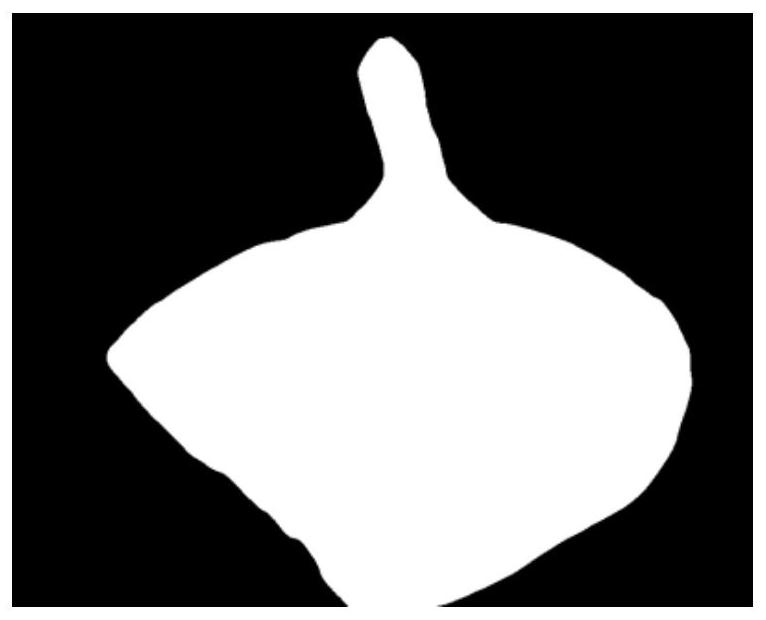

Converter tapping ladle liquid level identification method and system, medium and terminal

PendingCN112819749AValid location informationAvoid human involvementImage enhancementImage analysisImaging processingStructural engineering

The invention provides a converter tapping steel ladle liquid level identification method and system, a medium and a terminal. The method comprises the steps: obtaining the image information of the liquid level of converter tapping molten steel; performing image processing on the image information to obtain a plurality of edge contours; connecting the edge contours through dilation operation; restoring the image obtained after edge contour connection through erosion operation, and obtaining the position of the molten steel liquid level; recognizing the restored image, and deleting contour points in a steel flow area if the steel flow exists in the molten steel liquid level image; performing ellipse fitting on the contour of the contour point in the deleted steel flow area to obtain a fitting result, and taking the fitting result as a molten steel liquid level contour. According to the method, the position information of the steel ladle in the image can be effectively identified, the height of the liquid level of the molten steel in the buggy ladle below the converter can be monitored in real time, whether converter tapping needs to be finished or not is judged, manual participation in the steel ladle identification process is avoided, and the production efficiency and safety are improved.

Owner:CISDI INFORMATION TECH CO LTD

Leachate height monitoring device for domestic waste landfill

InactiveCN102121842BReal-time monitoring heightLow costLevel indicators by physical variable measurementElectricityHigh density

The invention discloses a leachate height monitoring device for a domestic waste landfill, and the device provided by the invention comprises annular electrodes, a drive pipe and a high-density resistivity instrument, wherein the drive pipe vertically extends into the waste landfill and is horizontally provided with annular grooves at intervals; the annular electrodes are arranged in the annular grooves; and an electric wire is electrically connected with the annular electrodes, extends out of the drive pipe and is electrically connected to the high-density resistivity instrument arranged outside the waste landfill. By utilizing the leachate height monitoring device for the domestic waste landfill, the effects of real-time monitoring, low cost, convenience and fastness can be achieved, and the problems of high measuring cost and long cycle after excavation of the traditional waste can also be solved.

Owner:HUAQIAO UNIVERSITY

A sample preparation device and method for a large-scale triaxial test of coarse-grained soil based on a shaking table

ActiveCN104655463BReduce breakage rateReal-time monitoring heightPreparing sample for investigationTriaxial shear testVernier scale

The invention discloses a vibration table-based sample preparation device and a vibration table-based sample preparation method for a large-scale triaxial test of coarse grained soil. An improved table top of a vibration table is adopted, so that a sample base and a protective arm can be fixed and conveniently disassembled and lifted; based on the vibration effect of the vibration table, samples are compacted by vibration layer by layer, so that the grain breakage rate of the coarse grained soil samples can be reduced in the sample preparation process; the heights of all the layers of samples can be monitored in real time by a vernier caliper capable of freely moving along the vertical direction, so that the density of the samples can be better controlled; the prepared samples are placed on a GDS large dynamic triaxial test apparatus by a small-sized crane; after the device and the method are used, low breakage rate, easy control and high accuracy are realized in the large-scale triaxial test process on the whole; the device and the method have great promotion and popularization functions for large-scale triaxial static and dynamic tests related to the coarse grained soil in the future.

Owner:ZHEJIANG UNIV

A magnetic field controlled arc robot additive forming method and device

Owner:NANJING UNIV OF SCI & TECH

Height limiter for crane

The invention discloses a height limiter for a crane. The height limiter comprises a suspension arm, a sliding groove, a screw rod, a second bolt and connecting rods; a guide wheel is rotatably connected with the upper left end of the suspension arm, and a steel wire rope is arranged on the outer side of the guide wheel in an attached mode; fixing discs are fixedly installed on the front side andthe rear side of the upper left end of the suspension arm through first bolts; and rotary frames are suspended below the left part of the guide wheel, and the tops of the rotary frames are fixedly connected with the lower sides of rotary arms. The height limiter for the crane is provided with the rotary arms, the rotary frames, the connecting rods and fixed frames, and when the angle between the steel wire rope and the suspension arm is changed, the steel wire rope pulls the rotary frame to rotate with one end of the rotary arm as a fulcrum, so that the rotary frame is still fixed on the steelwire rope and the suspension arm; when the steel wire rope shakes, the fixed frame is pushed by the guide shaft to rotate with one end of the connecting rod as a fulcrum, the steel wire rope is keptin the center of the fixed frame, the structure plays a role in compensation and positioning, rigid friction is reduced while the steel wire rope shakes, abrasion is reduced, and the service life is prolonged.

Owner:徐州长航科技有限公司

Monitoring tray for tower crane

Provided is a monitoring tray for a tower crane. A tray used in cooperation with the tower crane can hardly carry out monitoring in the whole process, and consequently a dead zone is generated in thelifting process, and the rising and falling position is not accurate or safe. The monitoring tray comprises a tray body and a monitoring assembly. The monitoring assembly comprises a plurality of monitoring monomers, the monitoring monomers are arranged at the bottom of the tray body, and each monitoring monomer comprises a shell, a first shielding assembly, a camera, a controller and multiple photosensitive sensors. Each first shielding assembly comprises a cover plate, a gear rack, a gear and a motor. The cover plates are driven by the gear racks to do reciprocating motion in the length direction of the shells, the cameras are arranged in the shells, the camera shooting ends of the cameras faces openings, the multiple photosensitive sensors are all arranged on the outer walls of the shells and are arranged around the openings, and each photosensitive sensor is connected with the corresponding motor through the corresponding controller. The first shielding assemblies can be replaced with second shielding assemblies. The monitoring tray is used for the hoisting process.

Owner:广西建工大都租赁有限公司

Aluminum bar casting monitoring alarm device

InactiveCN109782685AReal-time monitoring heightAvoid safety accidentsProgramme control in sequence/logic controllersLaser rangingLower limit

The invention discloses an aluminum bar casting monitoring and alarming device, which is composed of a laser range finder installation box, a laser range finder, a laser range finder installation fixing frame, a system control cabinet and an acousto-optic alarm. the laser range finder is installed in the laser range finder installation box, the laser range finder installation box is fixed on the range finder installation frame, the range finder installation frame is installed at an inlet where a launder flows into a casting mold disc, the laser range finder is located above the launder, and alaser point is aligned with the middle of the launder. The height of molten aluminum in the mold disc can be monitored in real time, when the height exceeds upper and lower limits (can be set), a system gives an alarm to remind, and risks of aluminum overflowing and drying are eradicated; and the height of the molten aluminum in the mold disc can be monitored in real time, when the molten aluminumlevel drops too fast in a short time, the system gives an alarm, the aluminum leakage problem is solved in time, and safety accidents caused by aluminum leakage are eradicated.

Owner:NANJING YUNHAI SPECIAL METALS CO LTD

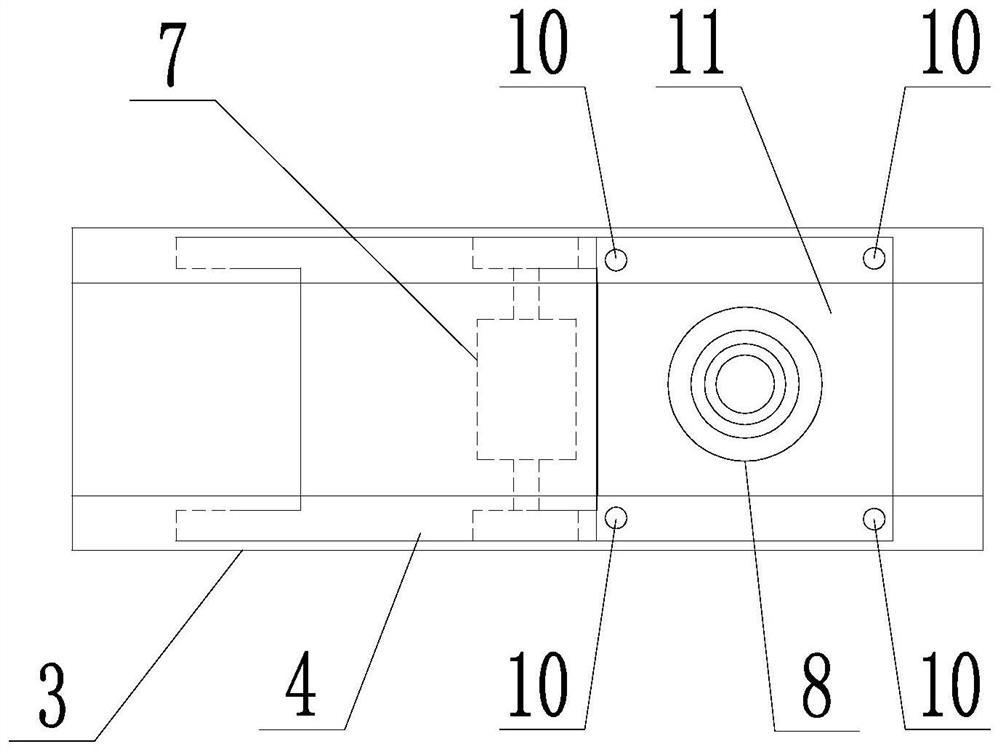

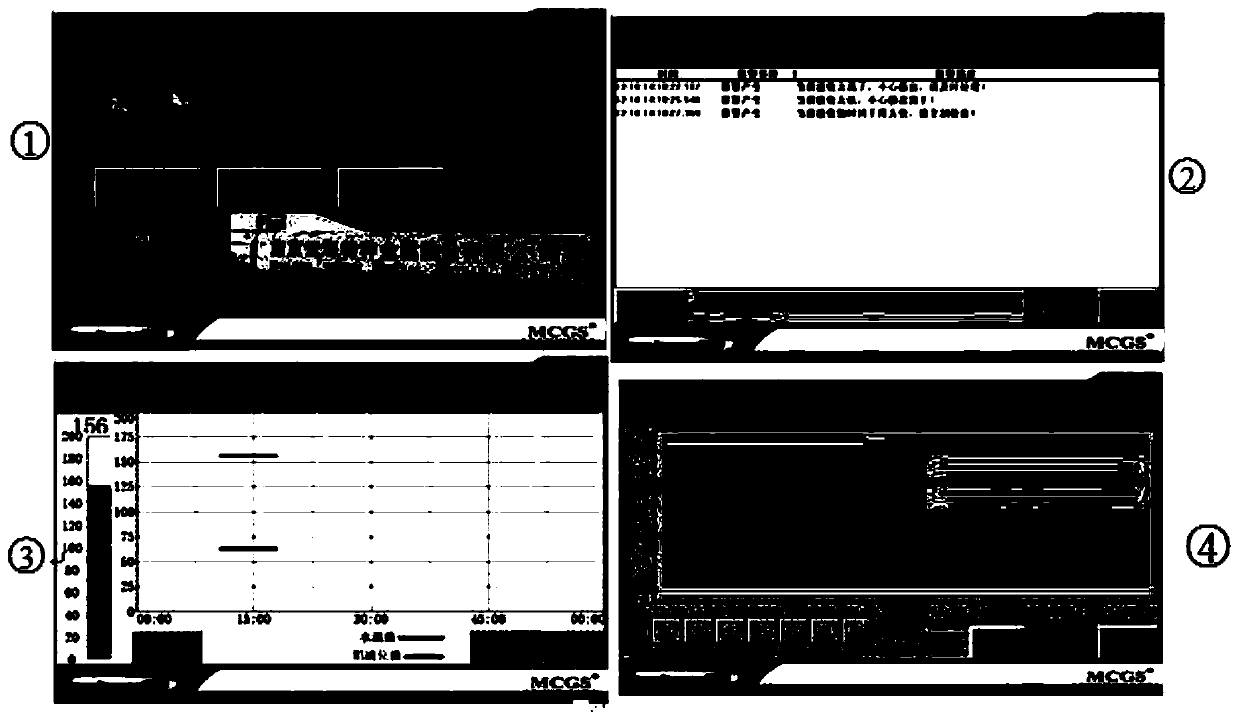

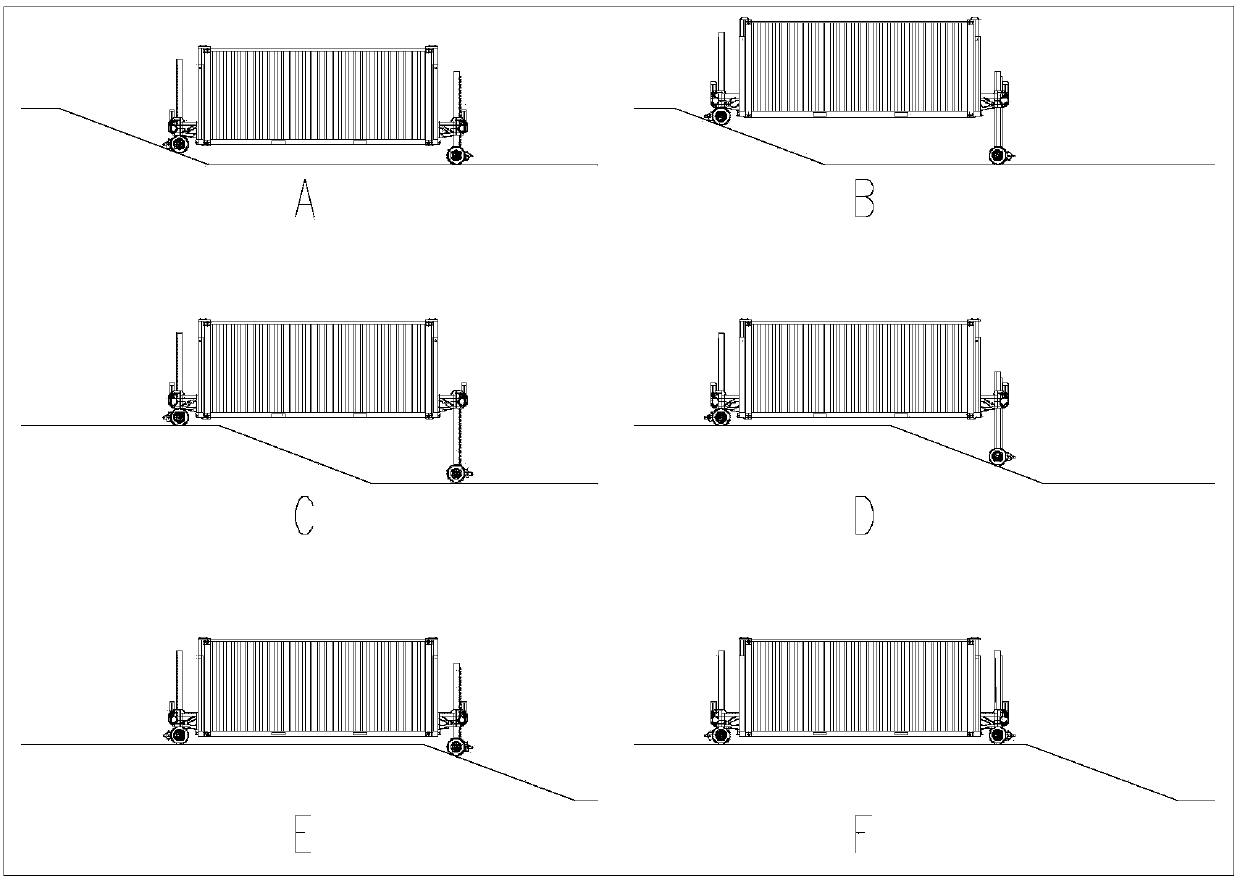

A method of transporting containers onto aircraft

ActiveCN106697323BReal-time monitoring heightReal-time monitoring of height conditionsFreight handling installationsAviationEngineering

Owner:SICHUAN EAST SPRING MACHINERY EQUIP MFG CO LTD

A method for detecting ocean wave parameters and an unmanned ship with self-adjusting attitude

ActiveCN109373983BReal-time monitoring directionReal-time monitoring heightMeasuring open water movementVessel stability improvementSea wavesClassical mechanics

The invention discloses a sea wave travelling parameter detecting method and an attitude self-adjustment unmanned ship. The sea wave travelling parameter detecting method comprises acquiring sea wavetraveling parameters through detection and calculation of a multi-axis sensor, a left distance sensor and a right distance sensor, including time cycles, frequency, direction, speed and effective waveheight of traveling sea waves, and the included angle between a ship body and the sea waves, and further self-adjusting the attitude of the unmanned ship to maintain an orthogonal state with the waves all along, thereby effectively avoiding roll-over of the ship body, improving the safety and reliability of the unmanned ship during marine navigation, improving the power generating efficiency of amovable power generating ship and enhancing the traveling stability of the ship body on sea.

Owner:SOUTH CHINA AGRI UNIV

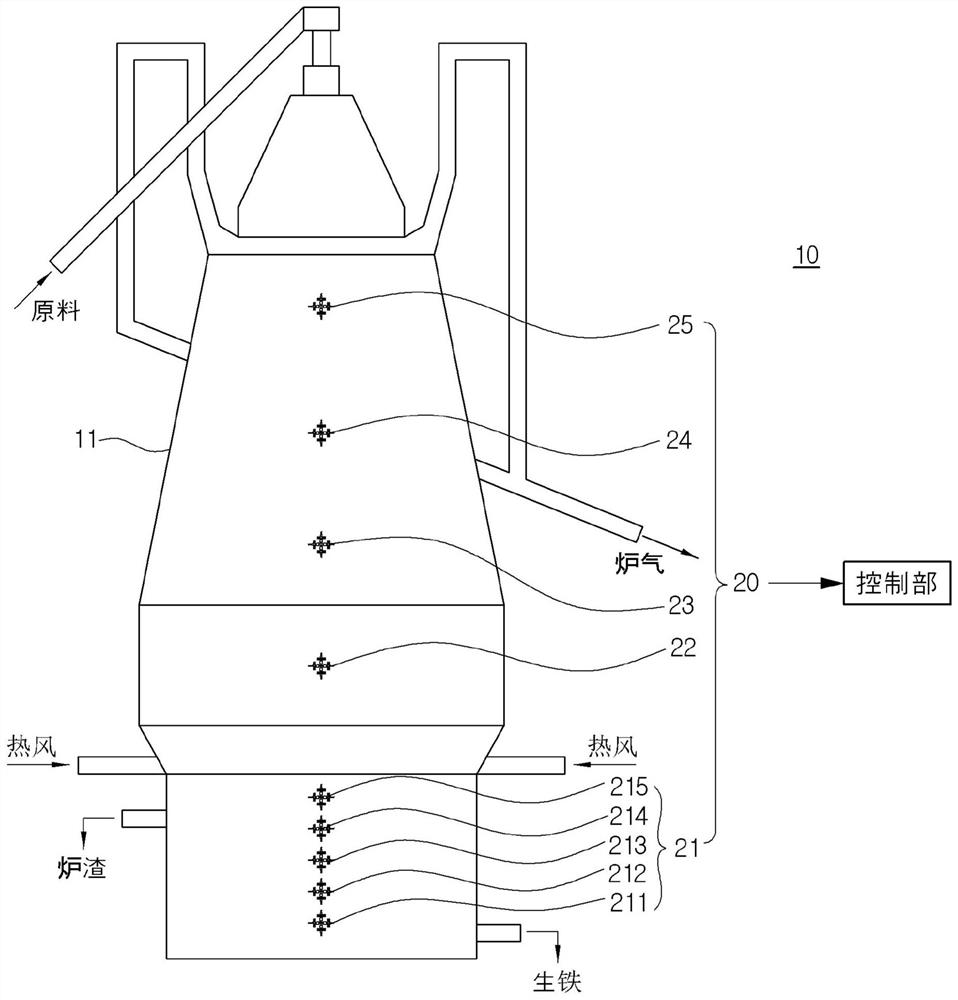

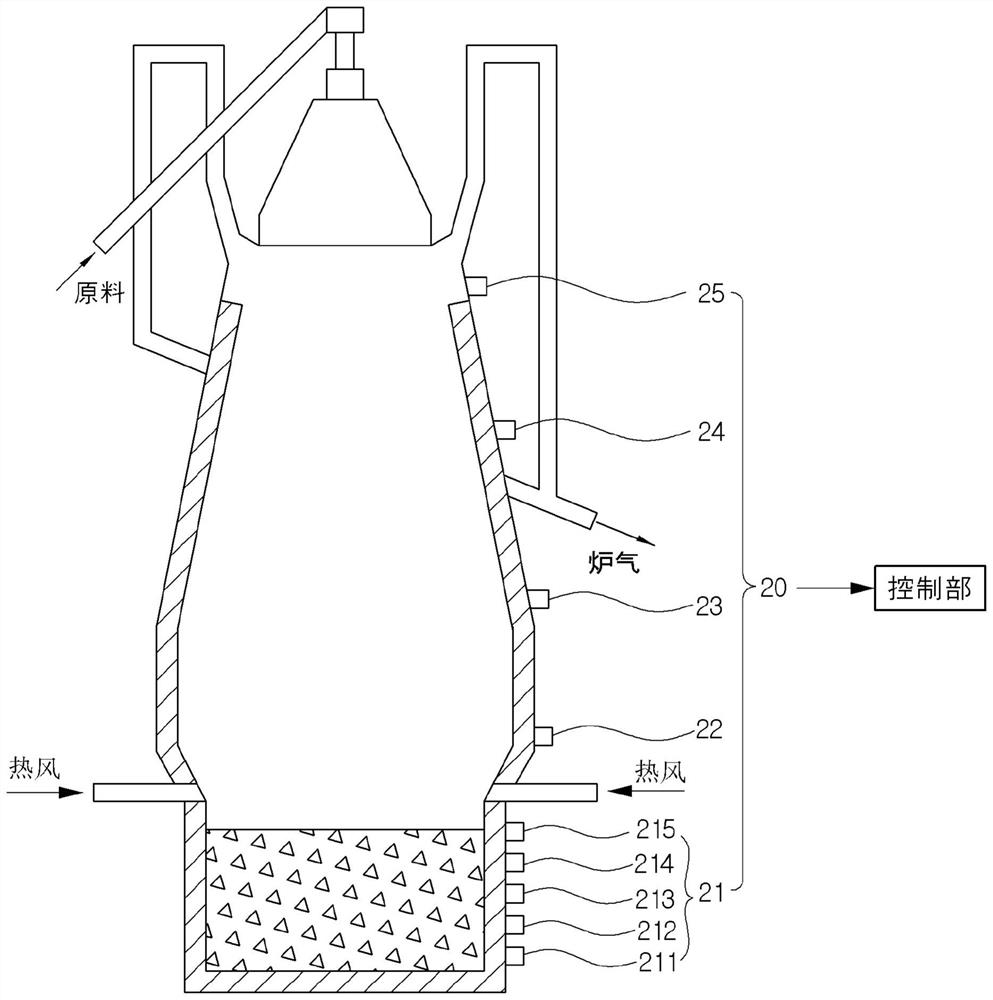

Apparatus and method for measuring height of molten material in blast furnace

ActiveCN110691855AReal-time monitoring heightPrompt notificationMachines/enginesLevel indicatorsGratingFiber gratings

Provided are an apparatus and a method for measuring the height of a molten material in a blast furnace, the apparatus comprising: a measurement part provided on the surface of the blast furnace and measuring the vertical and horizontal strain rates, of the surface of the blast furnace, caused by the height change of the molten material; and a control part for monitoring the height of the molten material by using the vertical and horizontal strain rates measured by the measurement part, and controlling the operations of the blast furnace on the basis of a result of monitoring, thereby measuring the vertical and horizontal strain rates of the surface of the blast furnace by using a strain sensor having an optical fiber grating sensor applied thereto, and enabling the height of the molten material to be measured on the basis of the strain rate change according to the amount of the molten material.

Owner:FBG KOREA INC +1

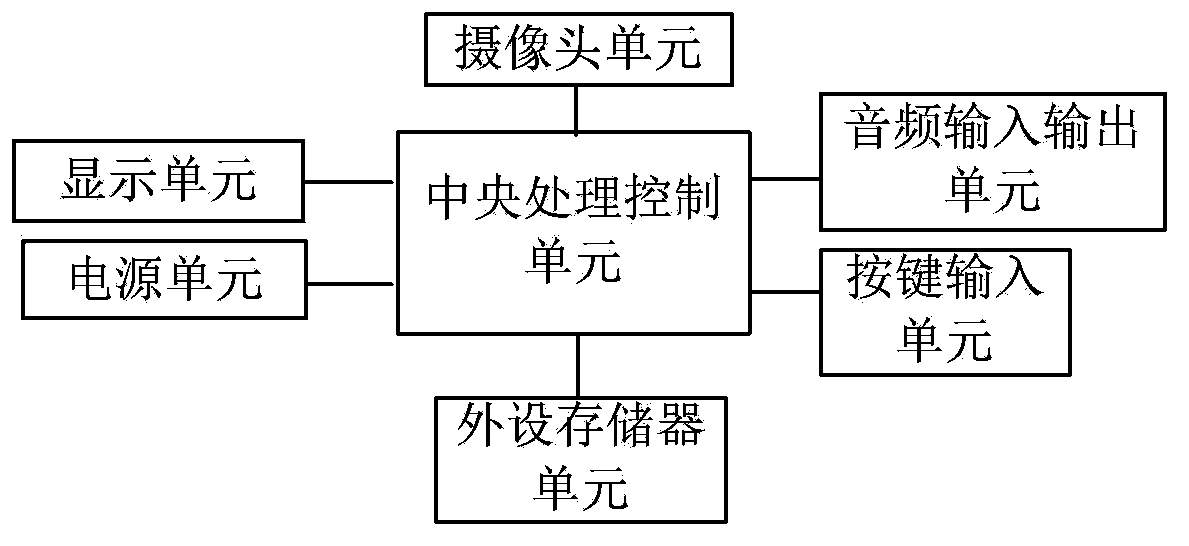

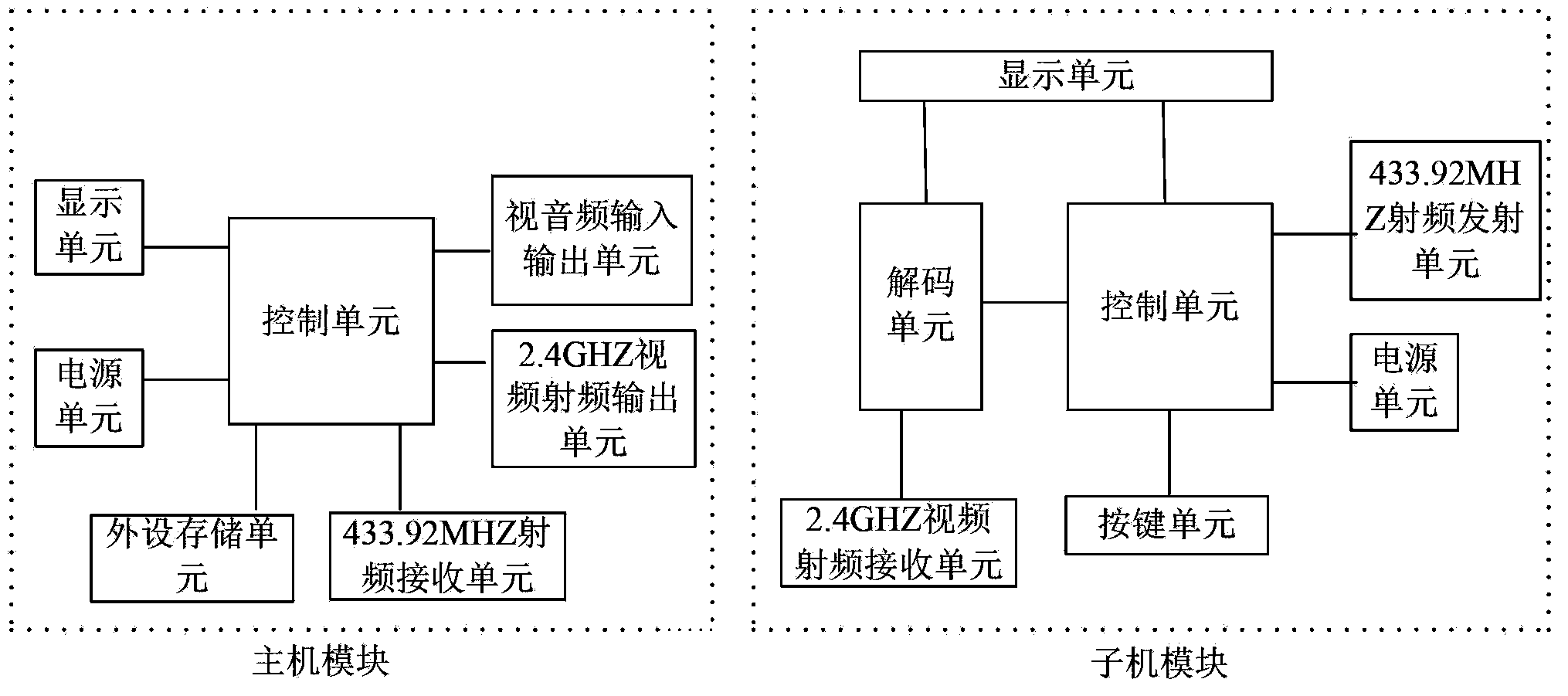

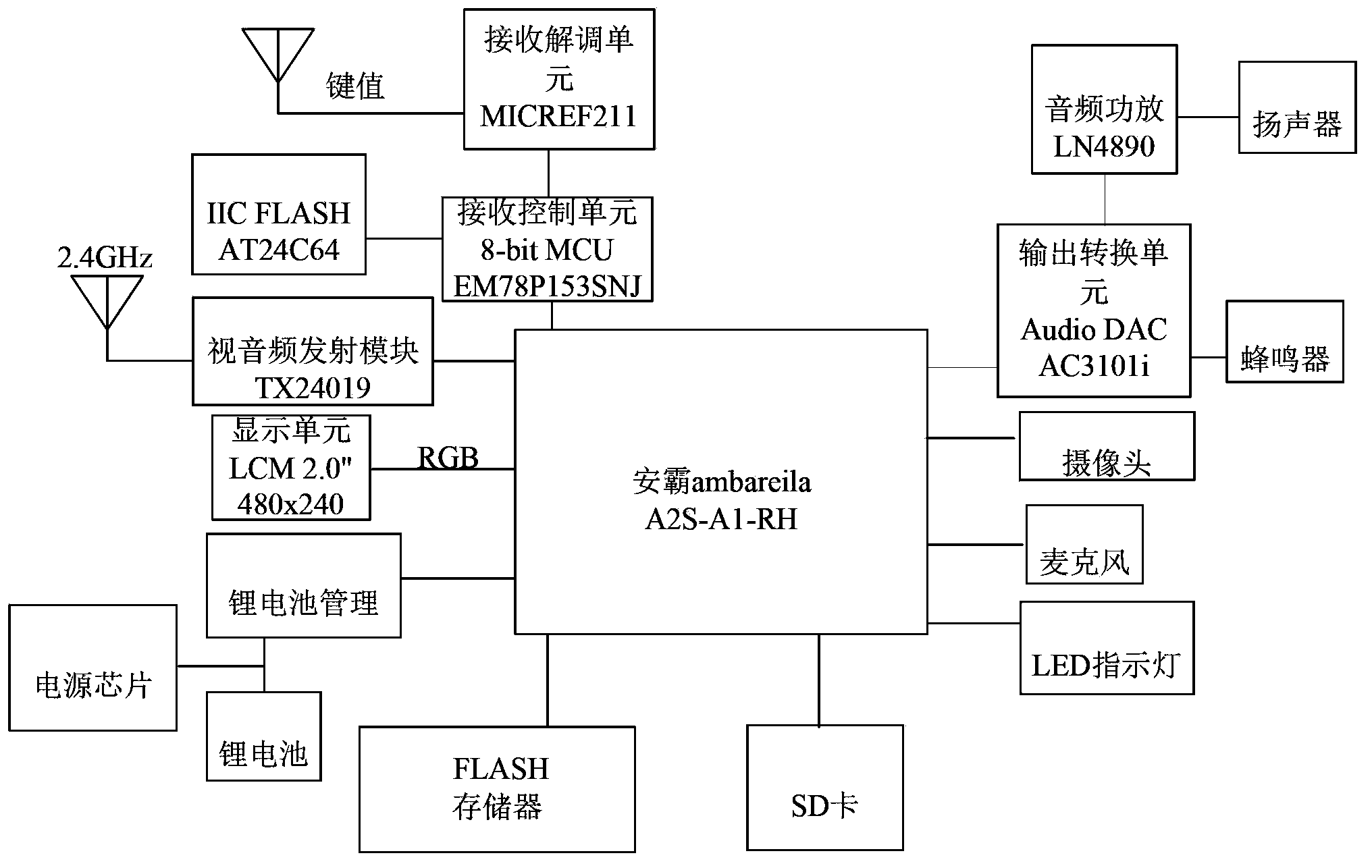

Video and audio recorder

InactiveCN103369304AOvercoming the shortcomings of insufficient concealmentImprove concealmentClosed circuit television systemsRadio frequencyComputer science

The invention discloses a video and audio recover, which comprises a host module and a sub-machine module. The host module comprises a control unit, a display unit, a video and audio input and output unit, a radio frequency receiving unit and a radio frequency transmission unit, wherein the control unit is connected with the display unit, a photographic unit, the video input and output unit, the radio frequency receiving unit and the radio frequency transmission unit respectively. The sub-machine module comprises a control unit, a display unit, a key unit, a decoding unit, a radio frequency transmission unit and a radio frequency receiving unit, wherein the control unit is connected with the display unit, the key unit, the decoding unit and the radio frequency transmission unit respectively; and the decoding unit is connected with the radio frequency receiving unit and the display unit respectively. The video and audio recorder comprises the host module and the sub-machine module, which transmit information to each other through radio frequency modules, so that the shortcoming that the conventional video and audio recorder only can display videos and audios on a host, and is low in concealment is overcome.

Owner:SICHUAN CCO DISPLAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com