Vacuum impregnation method

A vacuum impregnation and vacuum technology, applied in drying/dipping machine and other directions, can solve the problems of high cost, complex process, huge equipment, etc., and achieve the effect of low equipment cost, simple process and improved product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The vacuum impregnation method of the present embodiment, flow process is as image 3 As shown, the steps are as follows:

[0043] 1. Preheating, heating the capacitor, the heating temperature is 130~150°C, it can be preliminarily dried, and the limit on the electrolytic paper can also be removed;

[0044] 2. Canning, put the heated capacitor into the dipping tank 2 in the tank body 1;

[0045] 3. Vacuumize, start the vacuum unit 4, and keep the vacuum degree in the tank body 1 below 9Pa;

[0046] 4. Inflate, fill the tank body 1 with argon;

[0047] 5. Heating, heating the inside of the tank body 1, the heating temperature is 130~150°C;

[0048] 6. Secondary vacuuming, start the vacuum unit 4, and control the vacuum degree in the tank 1 below 8Pa;

[0049] 7. Liquid injection impregnation, inject electrolyte solution into the capacitor, make it impregnate for 10~13 hours, keep constant pressure and temperature during impregnation;

[0050] 8. Take it out, stop hea...

Embodiment 2

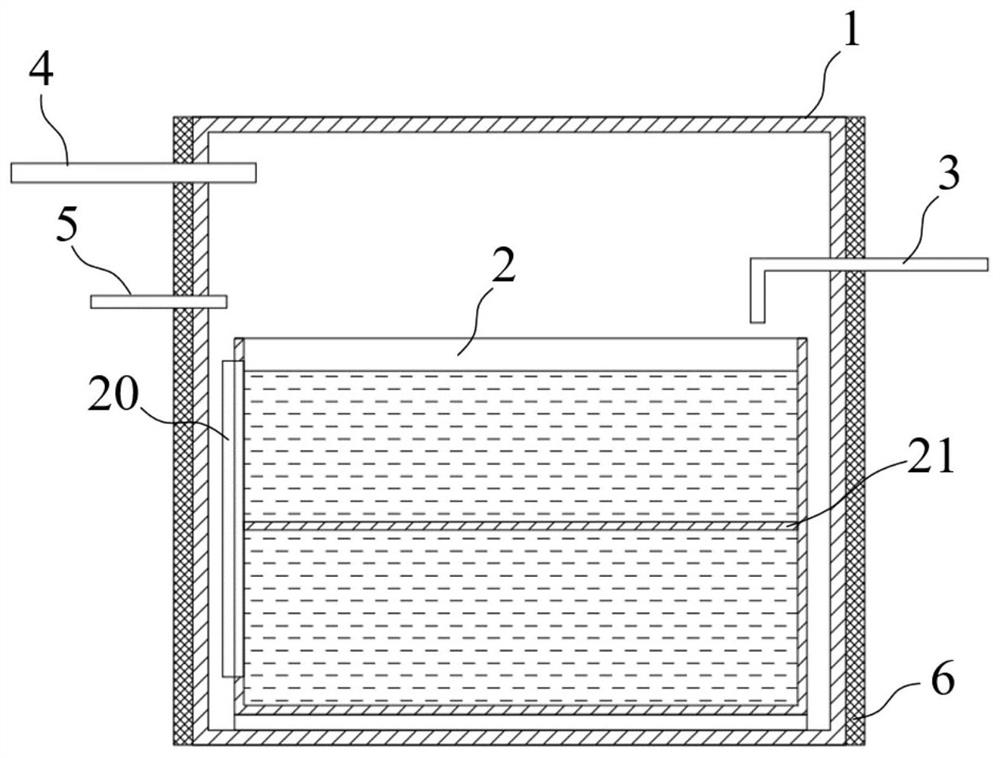

[0052] The vacuum impregnation method of this embodiment is further improved on the basis of Example 1, and vacuum impregnation is carried out based on the following vacuum impregnation tanks, including:

[0053] Tank 1;

[0054] An immersion tank 2, which is arranged inside the tank body 1, is used to accommodate capacitors and electrolyte;

[0055] Liquid injection unit 3, which is located outside the tank body 1 and communicates with the inside of the tank body 1, stores electrolyte and injects liquid into the dipping tank 2;

[0056] The vacuum unit 4 is located outside the tank body 1 and communicates with the inside of the tank body 1 to provide a negative pressure environment inside the tank body 1;

[0057] Inflatable unit 5, which is located outside the tank body 1, communicates with the inside of the tank body 1, and inflates the inside of the tank body 1;

[0058] The heating unit 6 provides heat to the inside of the tank body 1 .

[0059] The vacuum impregnation...

Embodiment 3

[0062] The vacuum impregnation method of this embodiment is further improved on the basis of embodiment 2. The dipping tank 2 is provided with a liquid level gauge 20 to detect the height of the electrolyte in the dipping tank 2 .

[0063] like figure 2 As shown, in this embodiment, the liquid level gauge 20 is set in the immersion tank 2, and the liquid level gauge 20 is connected with the signal of the liquid injection unit 3, so that the height of the electrolyte in the immersion tank 2 can be monitored in real time, so as to avoid electrolyte overflow or electrolyte leakage. Insufficiency occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com