Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

255 results about "Electrolytes fluids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid and Electrolyte Imbalance. Fluid inside the cells is called intracellular fluid, and fluid outside the cells is called extracellular fluid. Electrolytes are substances such as sodium and potassium and are found in body water or fluids.

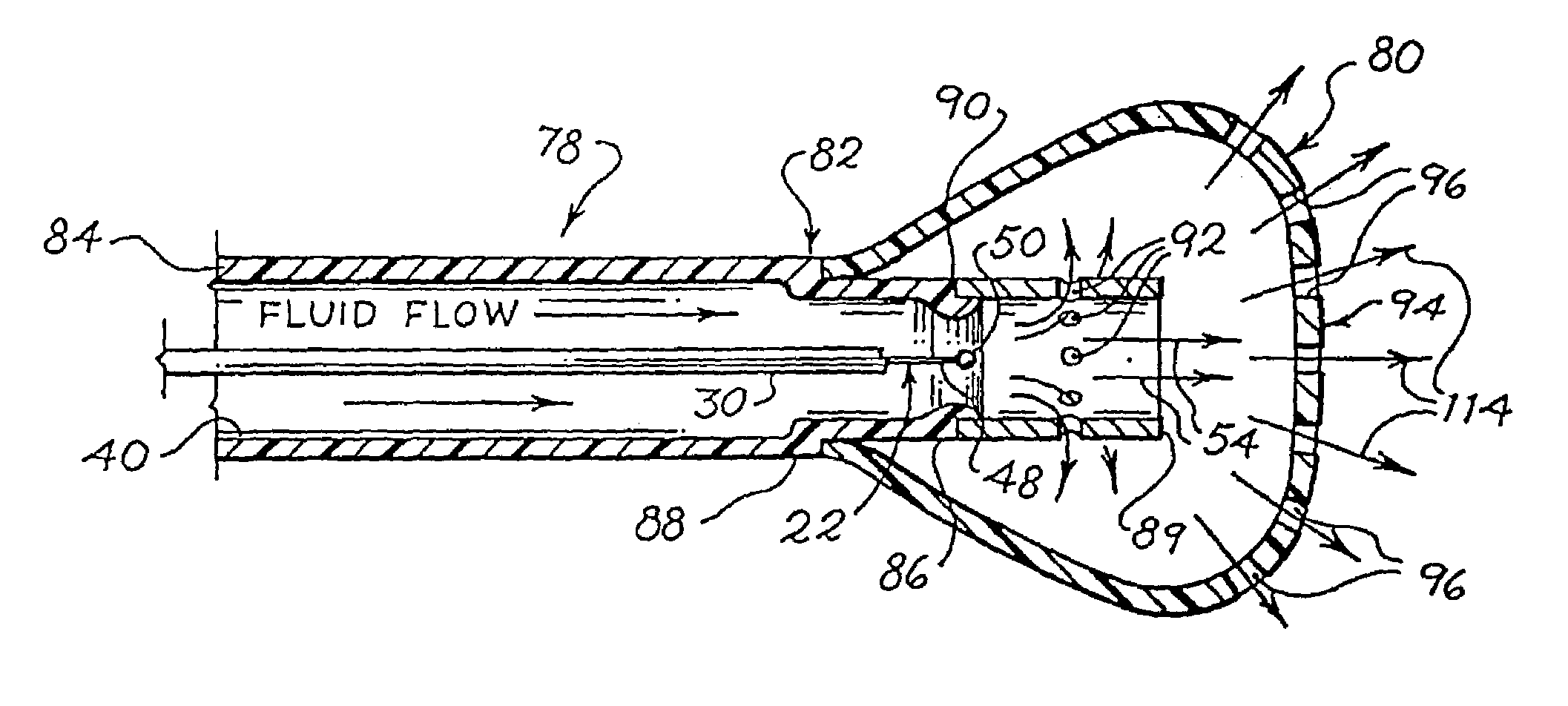

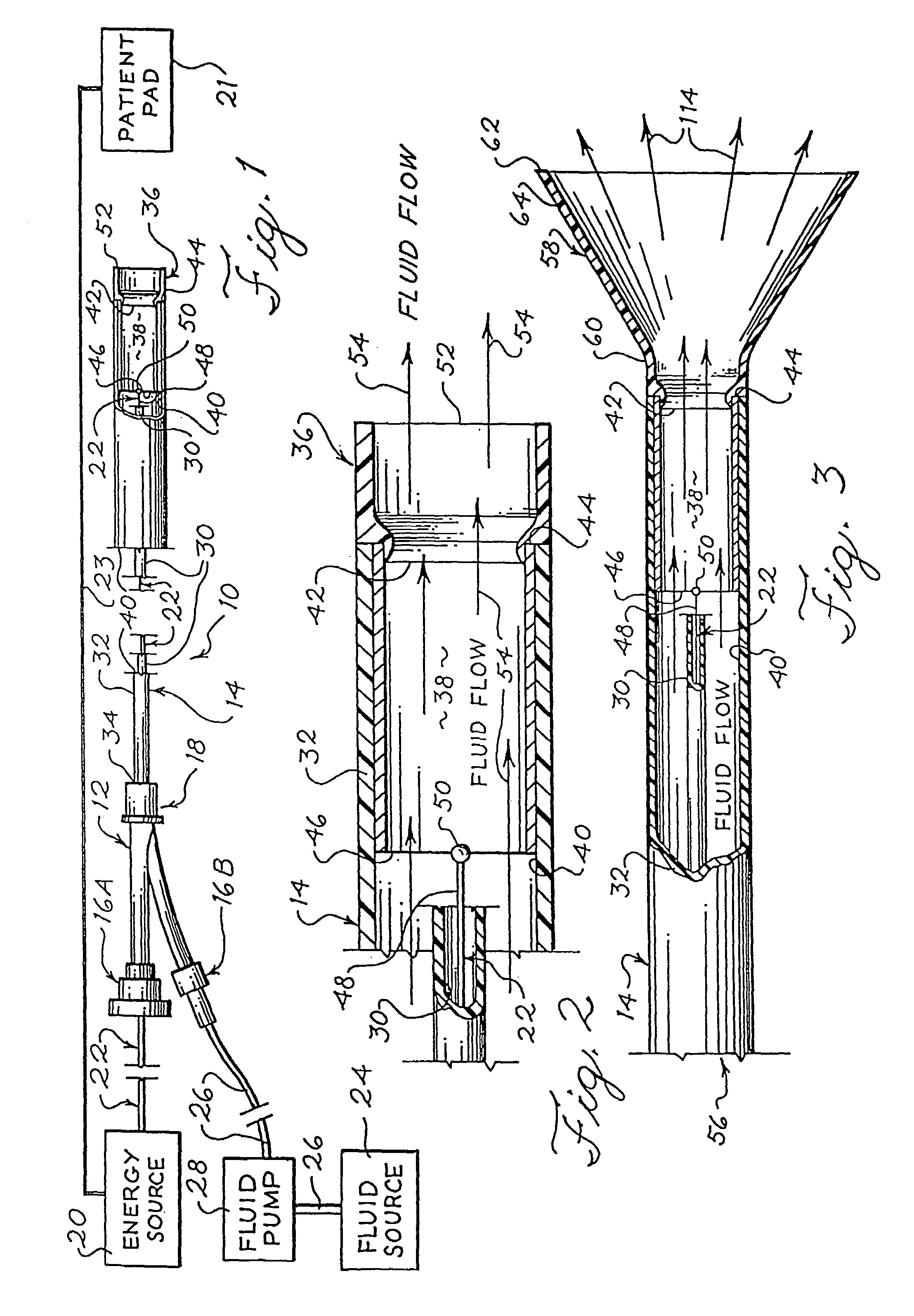

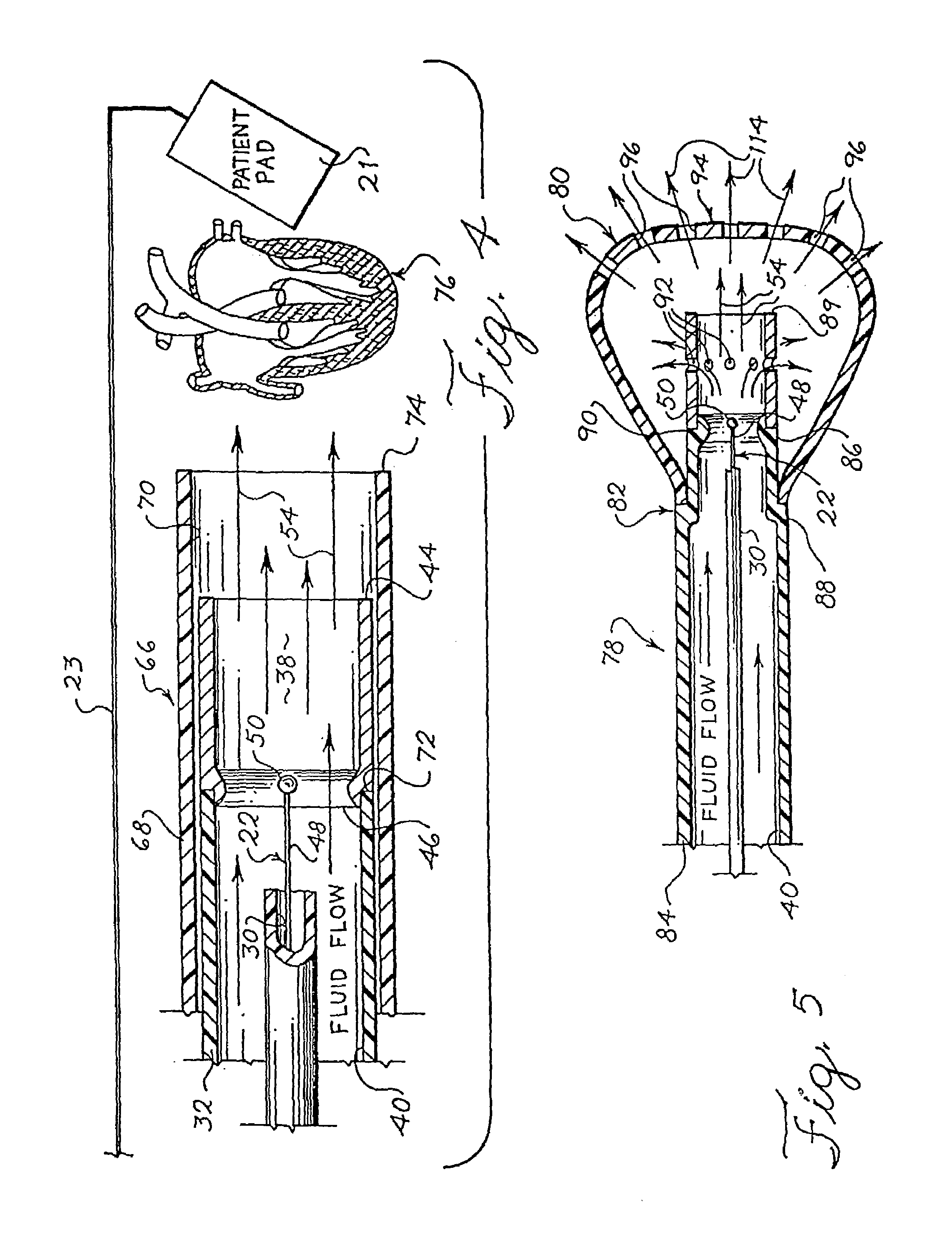

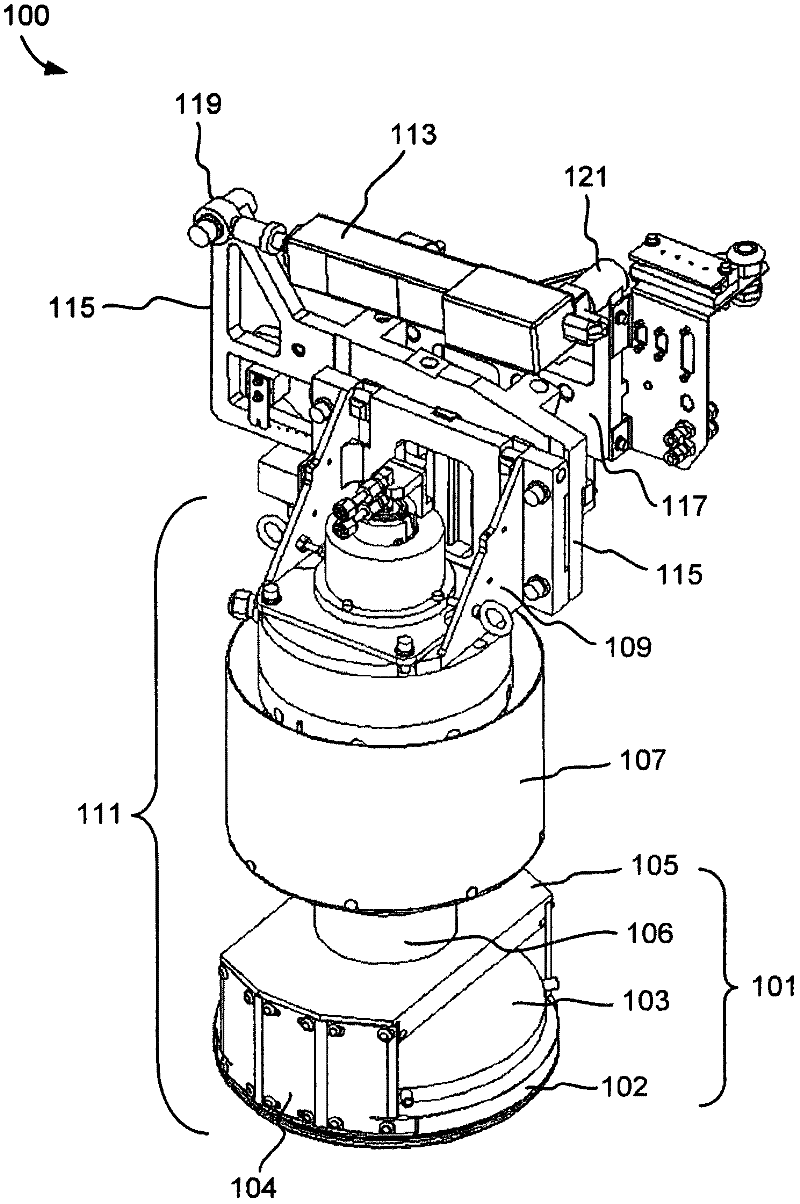

Electrophysiology energy treatment devices and methods of use

InactiveUS6923805B1Easy maintenanceElectrotherapySurgical instruments for heatingDistal portionCell electrophysiology

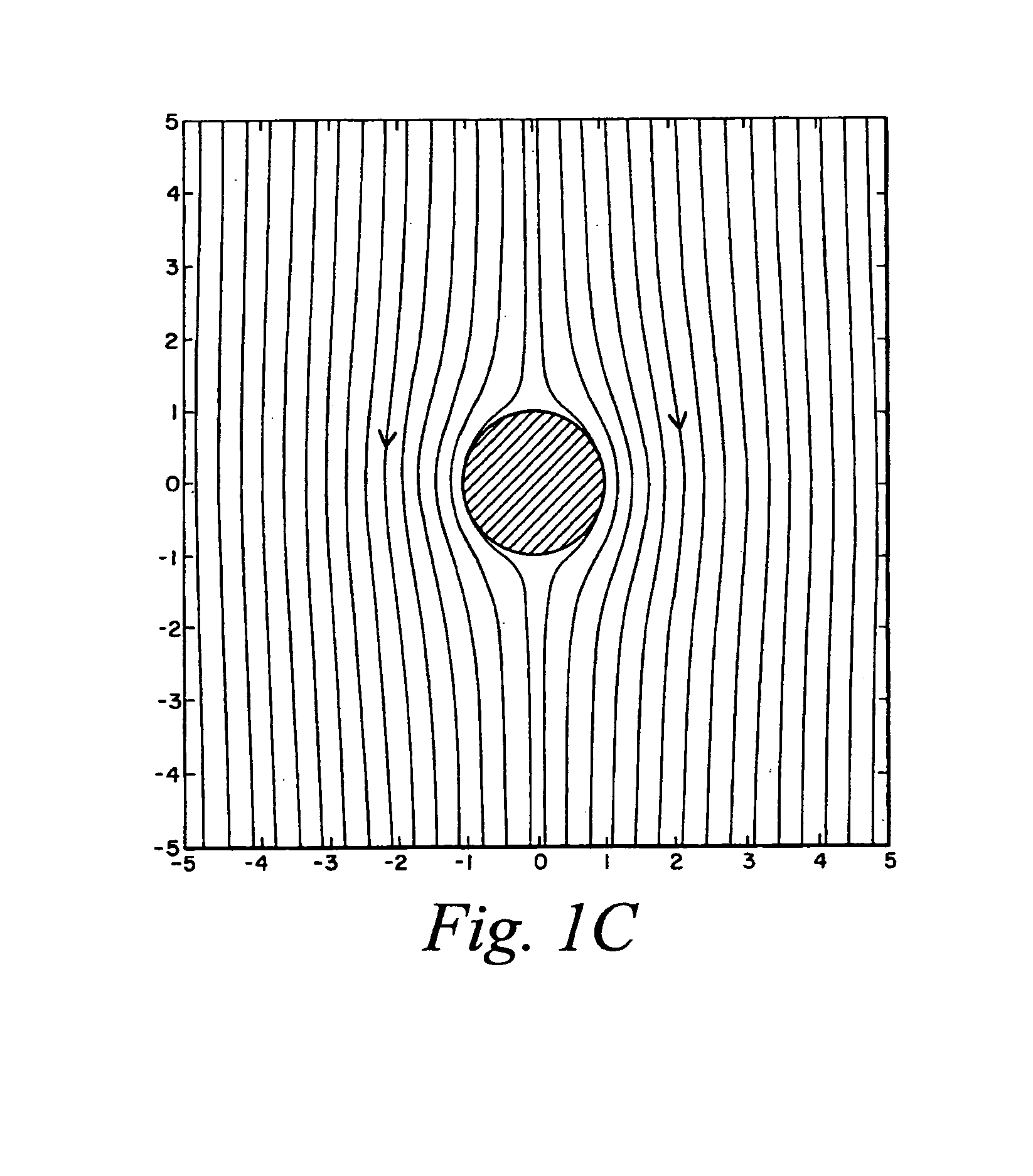

Apparatus and methods are provided for ablating body tissue using radio frequency (RF) energy. A catheter having a lumen for delivering fluid can be inserted into a patient's body. A porous member, which may be expandable, is attached to the distal portion of the catheter. The porous member defines an interior region in communication with the lumen, such that the interior region is capable of receiving electrolyte fluid delivered from the proximal portion of the catheter. An RF electrode is disposed in the interior region and is configured for coupling to a source of RF energy, whereby RF energy may be transferred from the electrode to selected tissue areas in a patient's body via electrolyte fluid delivered through the lumen and into the interior region of the porous member.

Owner:SCI MED LIFE SYST

Microfluidic pumps and mixers driven by induced-charge electro-osmosis

InactiveUS7081189B2Sludge treatmentElectrostatic separatorsElectrical conductorCondensed matter physics

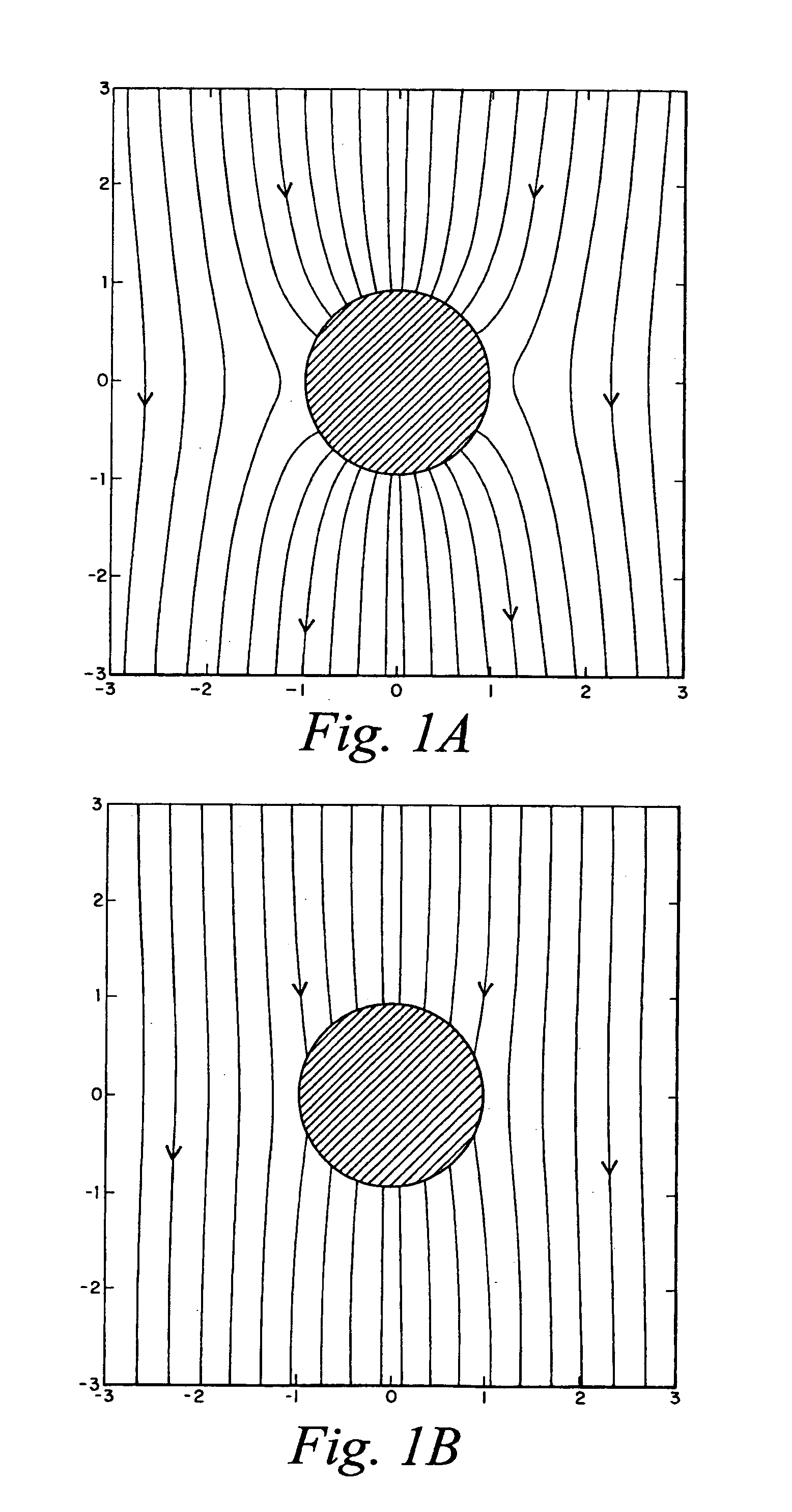

A microfluidic device includes one or more microchannels providing a passageway for transmitting an electrolyte fluid. A field source provides a defined field in the one or more microchannels, wherein at least one conductor element that is placed in at least one specific location in the device. Interactions between the defined field and the at least one conductor element produce electro-osmotic flows so that the electrolyte fluid is driven across the one or more microchannels.

Owner:MASSACHUSETTS INST OF TECH

Electrode systems, devices and methods

An electrode system include a flowable and cohesive surface contact element comprising a hydrophilic polymer swollen with an electrolyte fluid, the contact element having a Q′ ratio of at least 5 as defined by the equationQ′=WWWGwherein WG is the dry weight of the hydrophilic polymer and WW is weight of water in the sample after absorption of the electrolyte fluid comprising water and an electrolyte salt. The surface contact element can consist essentially of the hydrophilic polymer swollen by the electrolyte fluid. Another electrode system includes a contact element including a crosslinked hydrophilic polymer matrix. The contact element has a Q′ ratio of at least 5 as defined by the equationQ′=WWWG.The contact elements can also have a Q′ ratio of at least 6, at least 7, at least 10 or even at least 11.

Owner:UNIVERSITY OF PITTSBURGH

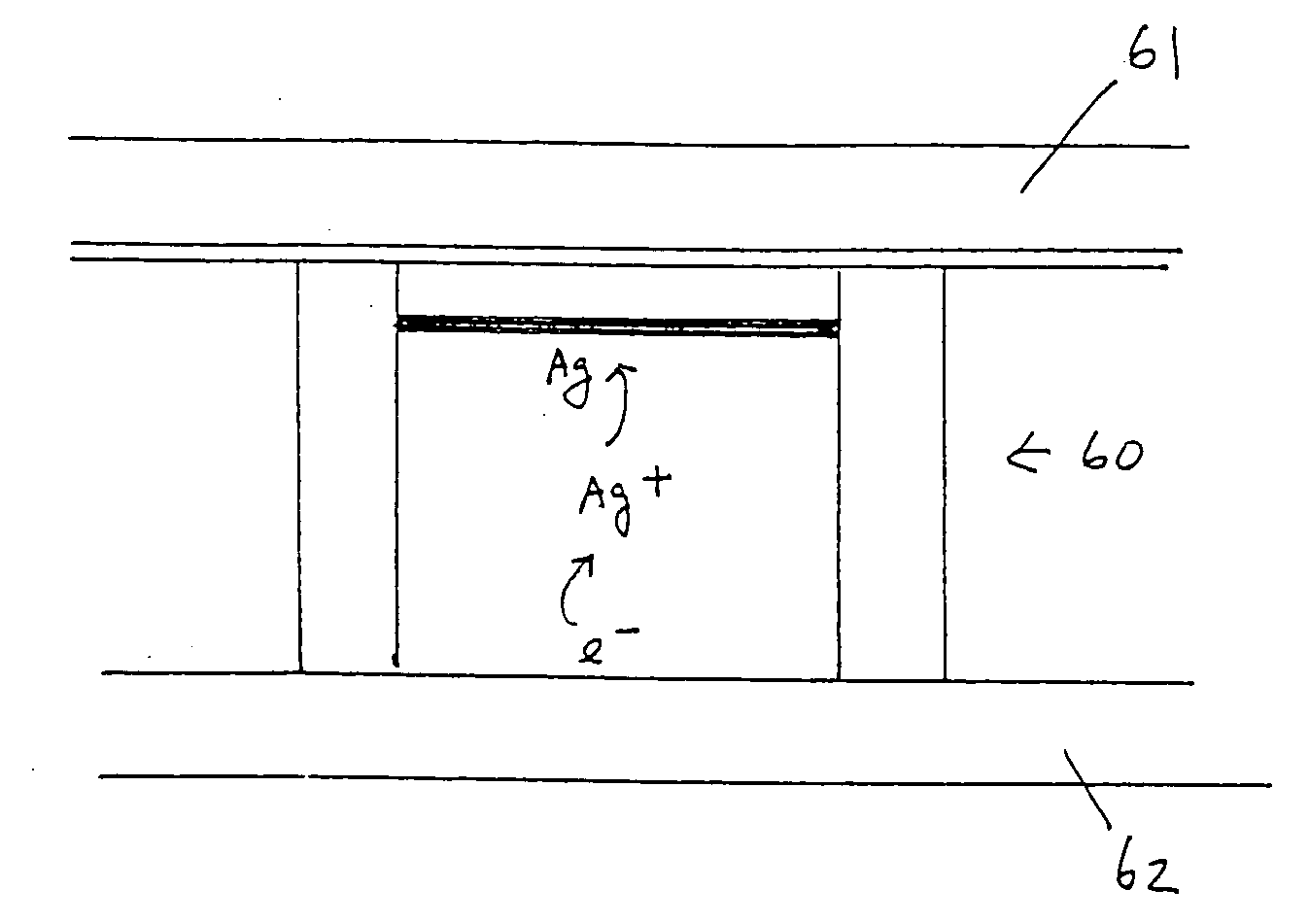

Electrochromic or electrodeposition display and novel process for their manufacture

ActiveUS7245414B2Extend your lifeImprove throughputNon-linear opticsOptical elementsEngineeringElectrochromism

The present invention is directed to an improved electrodeposition and an electrochromic display. The display cells formed from microcups are filled with an electrolyte fluid and are individually sealed with a polymeric sealing layer.

Owner:E INK CORPORATION

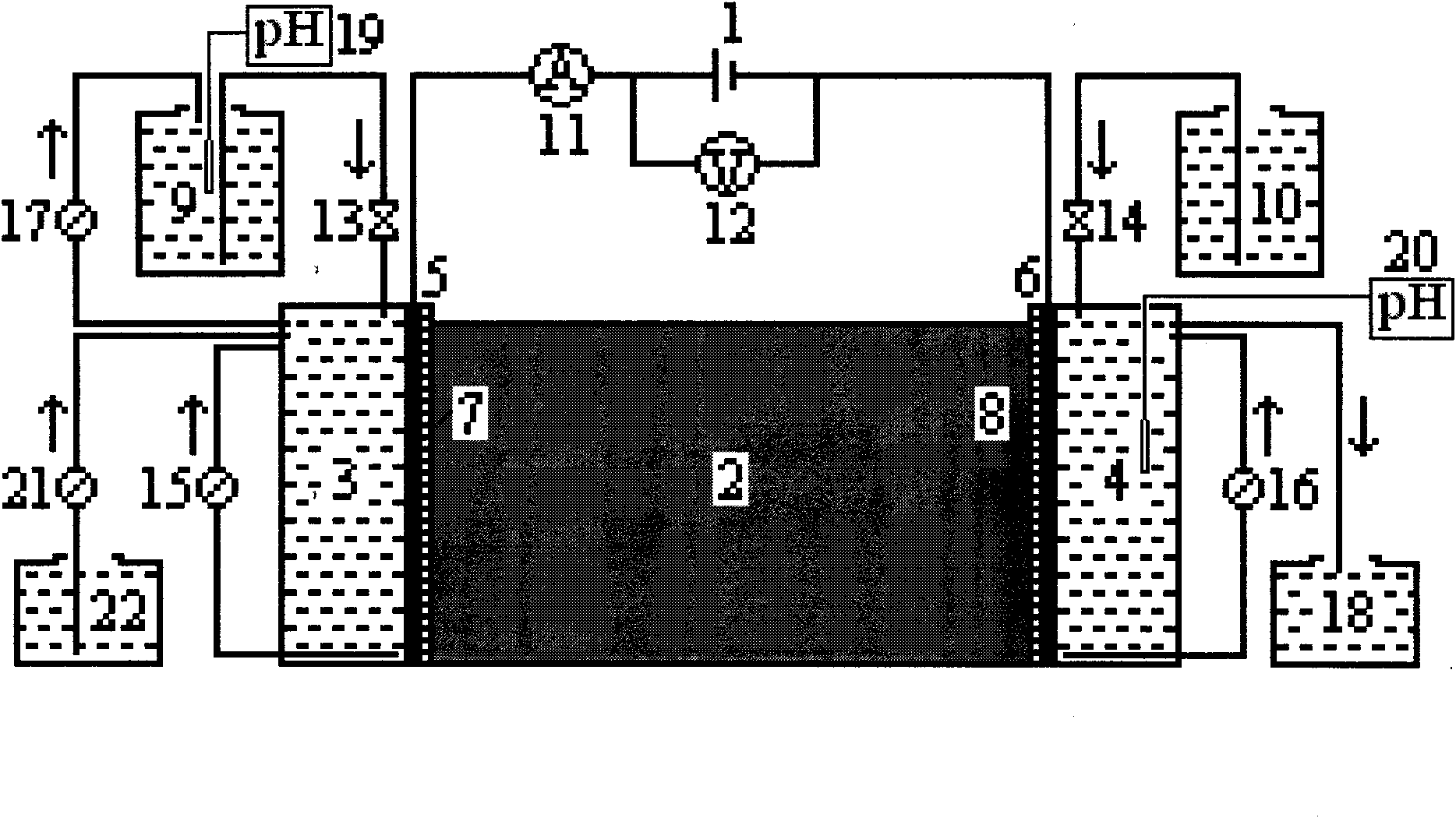

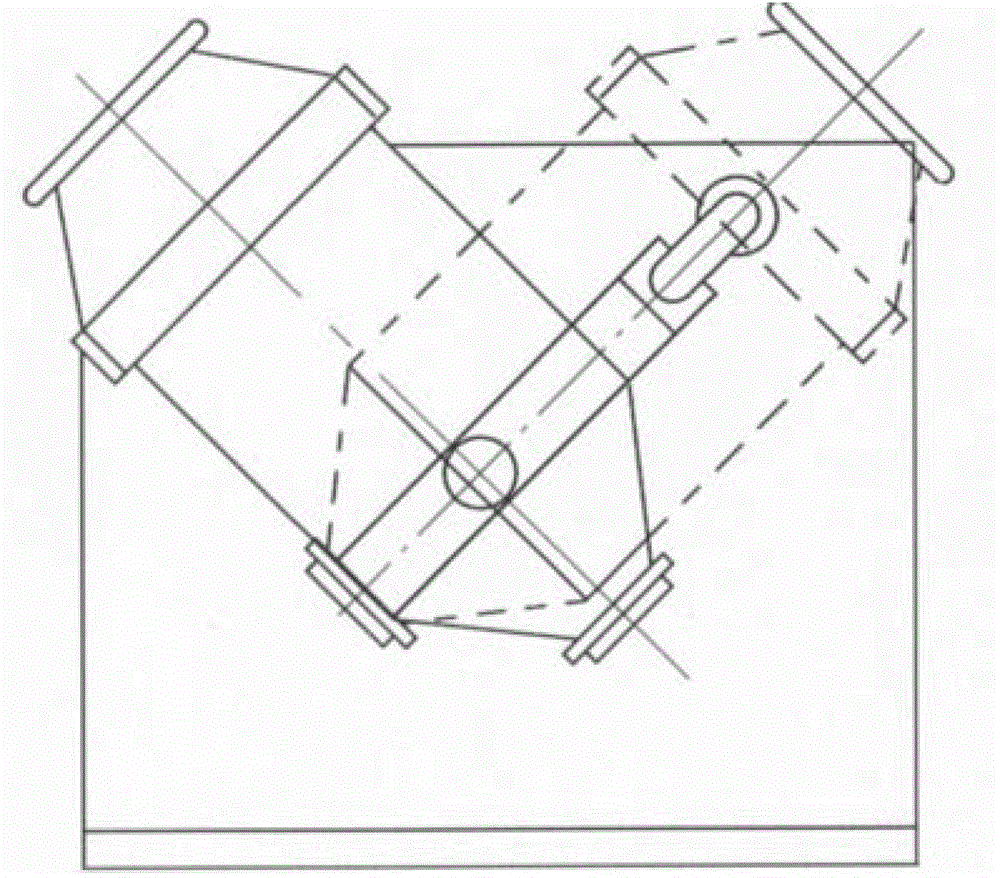

Electrodynamic method for removing fluorine contaminant in soil

InactiveCN101786099AWell mixedImprove removal efficiencyContaminated soil reclamationSodium acetateSodium acetrizoate

The invention discloses an electrodynamic method for removing fluorine contaminant in soil, which is as follows: an anion-exchange membrane is arranged between the anode and the contaminated soil to prevent the H+ generated by the anode from entering the electrolyzer so as to avoid the increase of the acidity of the contaminated soil; sodium acetate solution is put in an anode chamber to be used as electrolyte, deionized water is put in a cathode chamber to be used as electrolyte, and the liquid levels of the anode chamber and the cathode chamber are maintained to be parallel; in the rehabilitating process, the electrolytes circulate constantly to be stirred evenly so as to bring away the H2 and O2 which are generated by the anode and the cathode; the sodium acetate solution added in the anode chamber supplies OH- which neutralizes the H+ generated by the anode, and the surplus OH- and the OH- generated by the cathode promote the adsorbed fluorine in the soil to be desorbed to be free fluorinions; and the fluoride in the soil is removed through the electrodynamic approaches of electromigration, electroosmosis and the like. The method can effectively promote the adsorbed fluoride to be desorbed from the surface of the contaminated soil particles, remarkably improves the fluorine contaminant removal efficiency, reduces overpotential and saves energy consumption, and after the soil is rehabilitated, the pH value of the soil is basically maintained at the original state.

Owner:HENAN UNIV OF SCI & TECH

Triazine compounds for removing acids and water from nonaqueous electrolytes for electrochemical cells

A process is provided to produce non-aqueous electrolytic solution for use in batteries having low acid content and low water content. The invention involves removing acids and water from non-aqueous electrolytic solutions typically found in lithium or lithium-ion batteries by using nitrogen-containing compounds such as triazines. After treatment by a triazine such as melamine, the concentrations of acids and water in the electrolytic solutions are substantially decreased. The present invention provides a process to prepare extremely pure electrolytic solutions having low (<20 ppm) concentrations of both water and acids.

Owner:SHENZHEN CAPCHEM TECH

Preparation method for vanadyl sulfate electrolyte of all-vanadium flow battery

ActiveCN102683733AAchieve mass productionSimple processRegenerative fuel cellsVanadium compoundsAlkaline earth metalKerosene

The invention discloses a preparation method for vanadyl sulfate electrolyte of an all-vanadium flow battery. The preparation method is characterized by comprising the following steps of: adjusting pH value of vanadyl sulfate solution obtained from leaching vanadium slag and stone coal, back extracting and resin-analyzing treatments by using oxide or hydroxide of alkali metal or alkaline earth; adding an inorganic reducing agent; performing multi-grade counter-current extraction by using P204 or P507: TBP: sulfonated kerosene extracting agent; after the two-phase separation, washing the vanadium-loaded organic phase; performing 2-5 grades of multi-grade counter-current back extraction on the vanadium-loaded organic phase by using sulfuric acid solution to obtain the back extracting liquid of vanadyl sulfate; adjusting the pH value of the back extracting liquid of vanadyl sulfate, adding the organic reducing agent to adjust the potential value of the solution; extracting the solution by using the extracting agent; after the two-phase separation, washing the vanadium-loaded organic phase by using the sulfuric acid solution; performing multi-grade counter-current back extraction by using the sulfuric acid solution to obtain the vanadyl sulfate solution; and distilling until the concentration required for all-vanadium flow battery. The method provided by the invention can improve the purity, simplify the preparation procedure and reduce the cost.

Owner:GUANGDONG INST OF RARE METALS

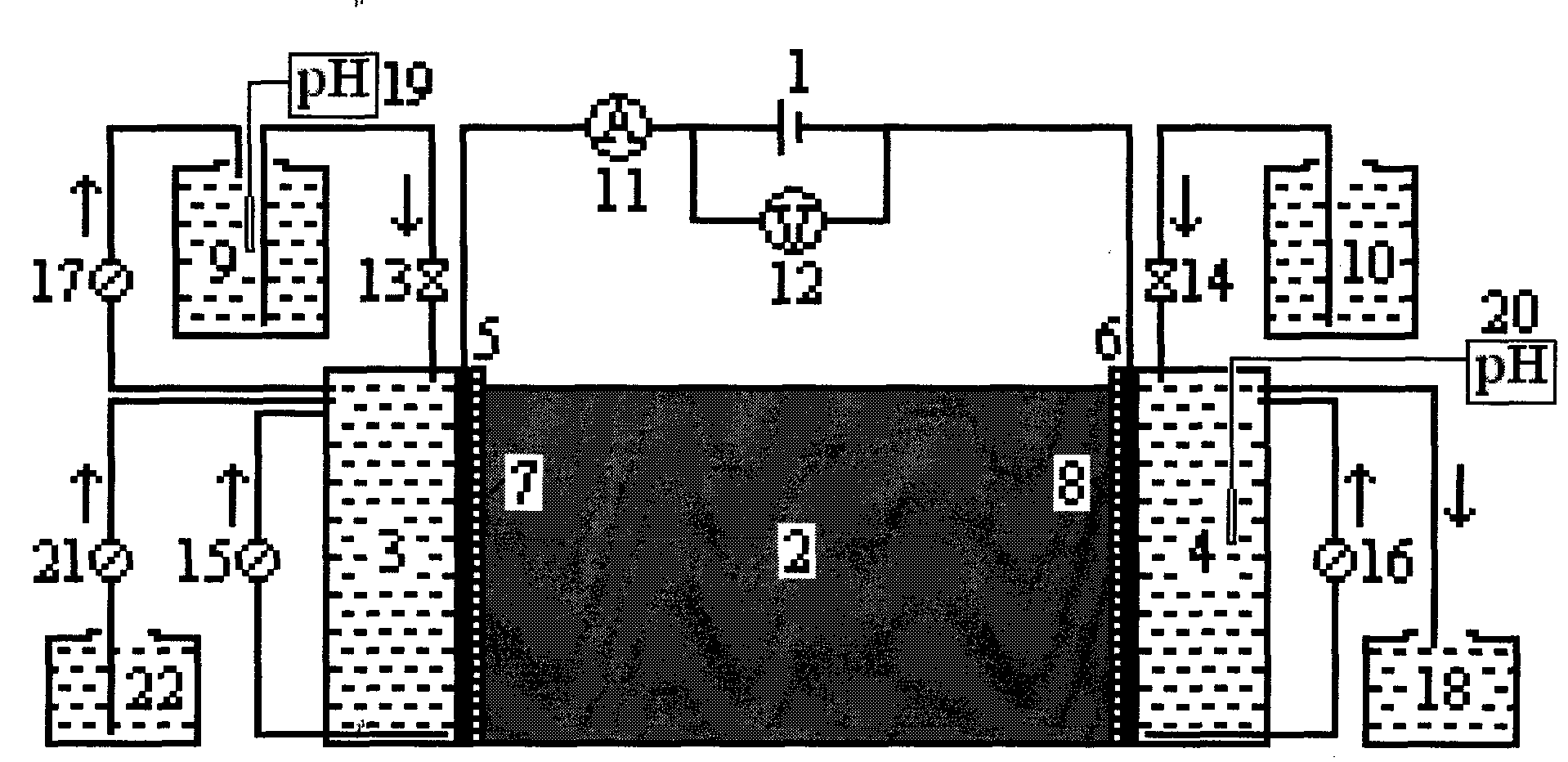

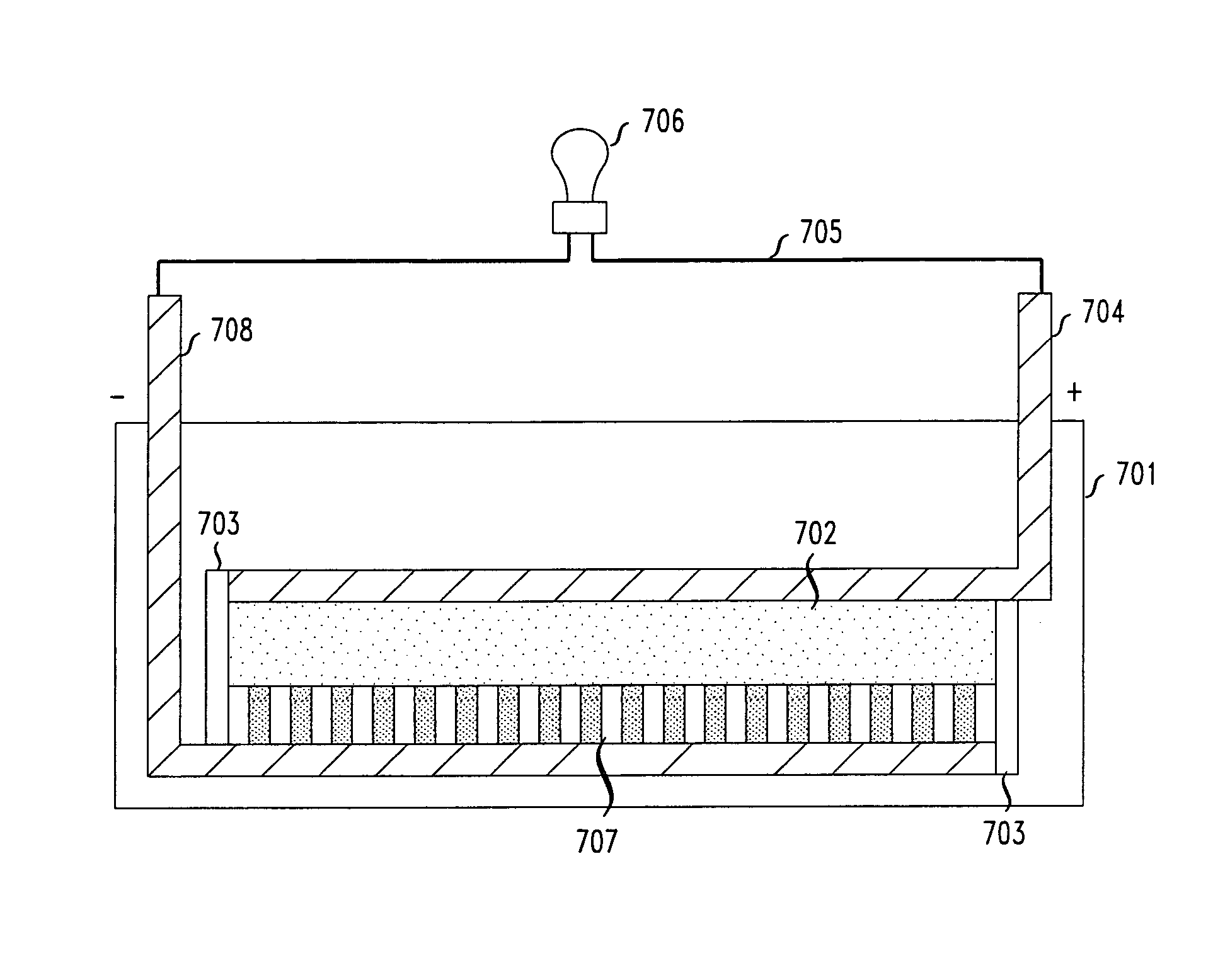

Electrowetting battery having a nanostructured electrode surface

InactiveUS7227235B2Avoid dischargeCell temperature controlElectrode carriers/collectorsElectricityElectrical battery

A method and apparatus are disclosed wherein a battery comprises an electrode having at least one nanostructured surface. The nanostructured surface is disposed in a way such that an electrolyte fluid of the battery is prevented from contacting the electrode, thus preventing discharge of the battery when the battery is not in use. When a voltage is passed over the nanostructured surface, the electrolyte fluid is caused to penetrate the nanostructured surface and to contact the electrode, thus activating the battery. In one illustrative embodiment, the battery is an integrated part of an electronics package. In another embodiment, the battery is manufactured as a separate device and is then brought into contact with the electronics package. In yet another embodiment, the electronics package and an attached battery are disposed in a projectile that is used as a military targeting device.

Owner:ALCATEL-LUCENT USA INC

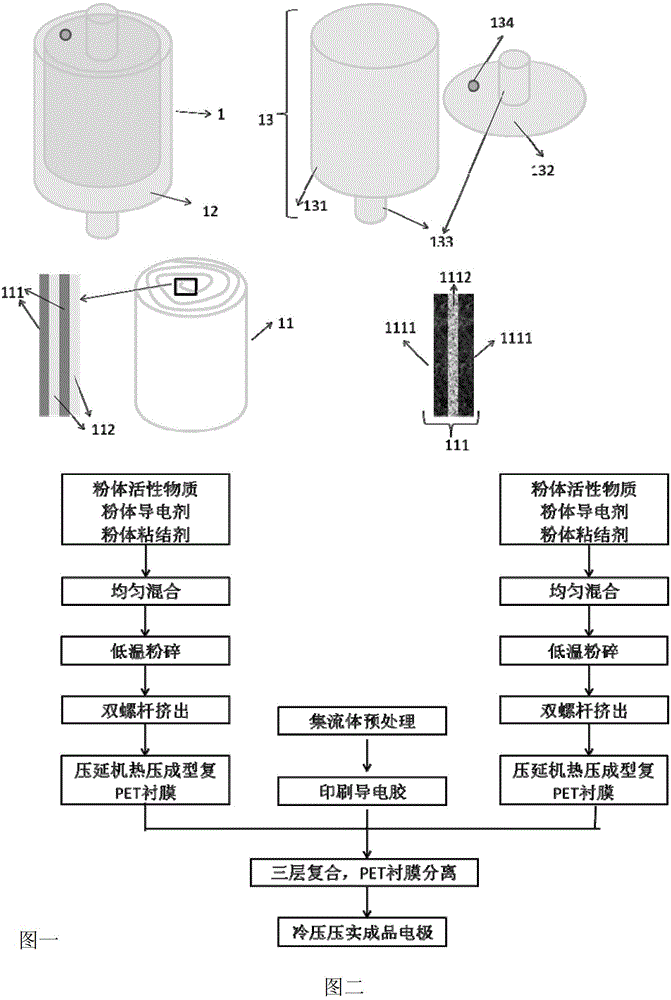

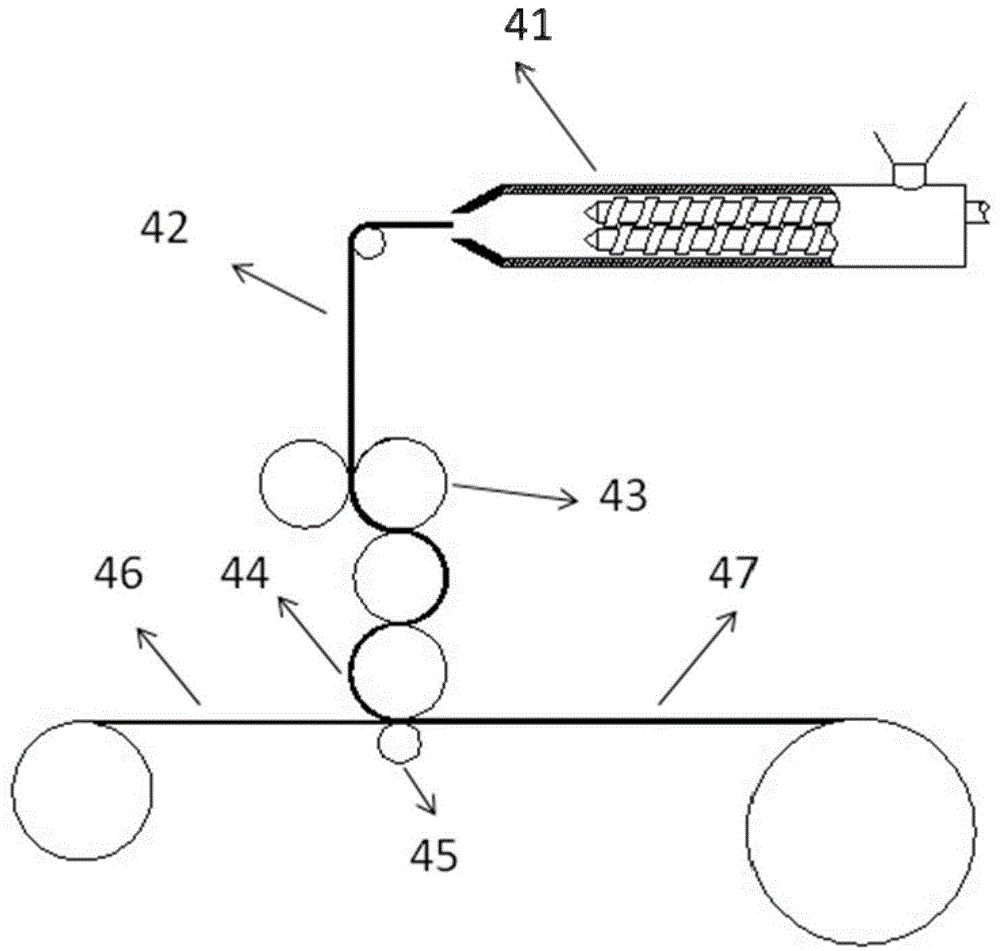

High performance super capacitor and manufacturing process thereof

ActiveCN102723211AWell mixedImprove the mixing effectElectrolytic capacitorsBiochemical engineeringSupercapacitor

The invention relates to a high performance super capacitor and a manufacturing process thereof. The super capacitor comprises an electrode core, an electrolyte and a shell. The manufacturing process comprises steps that: tabs and leading-out terminals of the prepared electrode core positive and negative poles are welded; the electrode core with the well-welded leading-out terminals is encased in the shell; the shell with the electrode core encased is put in a vacuum drying furnace for vacuum drying; and finally a vacuum liquid filling sealing test is carried out. In an aspect of the electrode manufacturing method, the manufacturing process of the invention abandons a method which uses a solvent for assisted processing, thus to the greatest degree, the purity of the electrode material is ensured. In addition, during the production process, the manufacturing process of the invention has no drying energy waste and drying time constraint, and therefore reduces cost, reduces energy loss, and improves working speed. The manufacturing process of the invention further adopts an advanced assembly process to avoid problems such as secondary pollution and processing consistency in the traditional assembly technology, and greatly improves the stability of the super capacitor.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

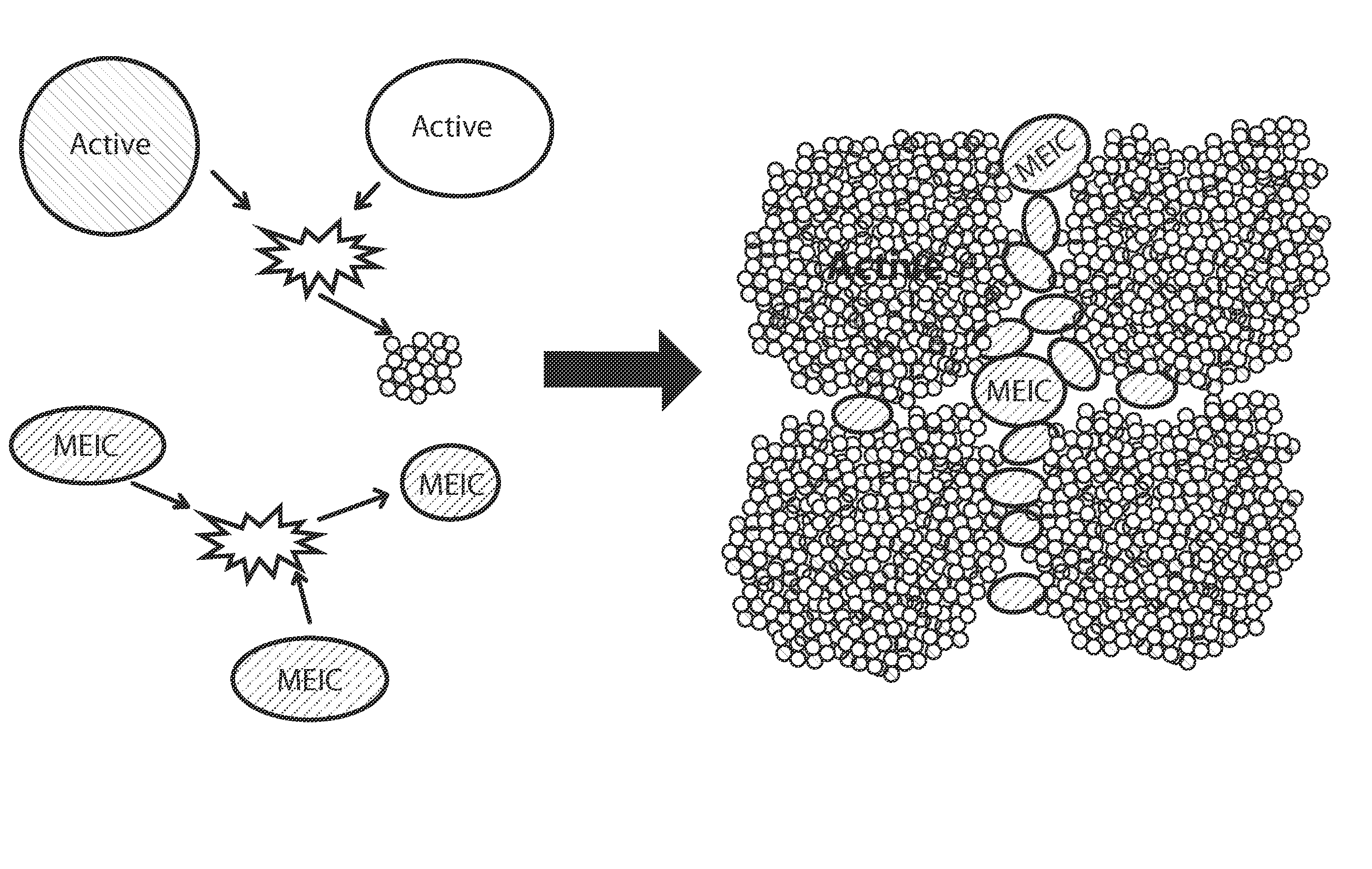

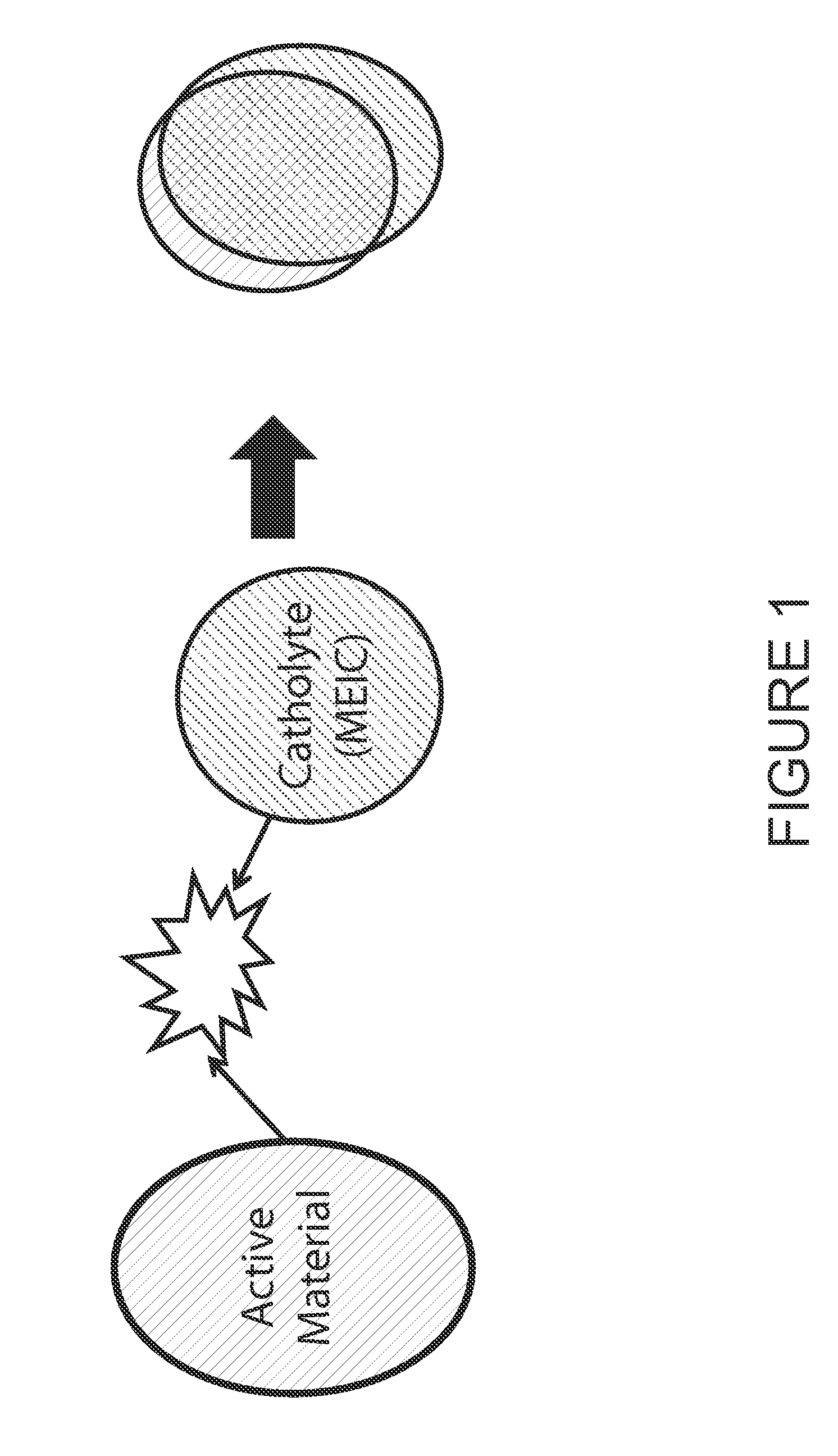

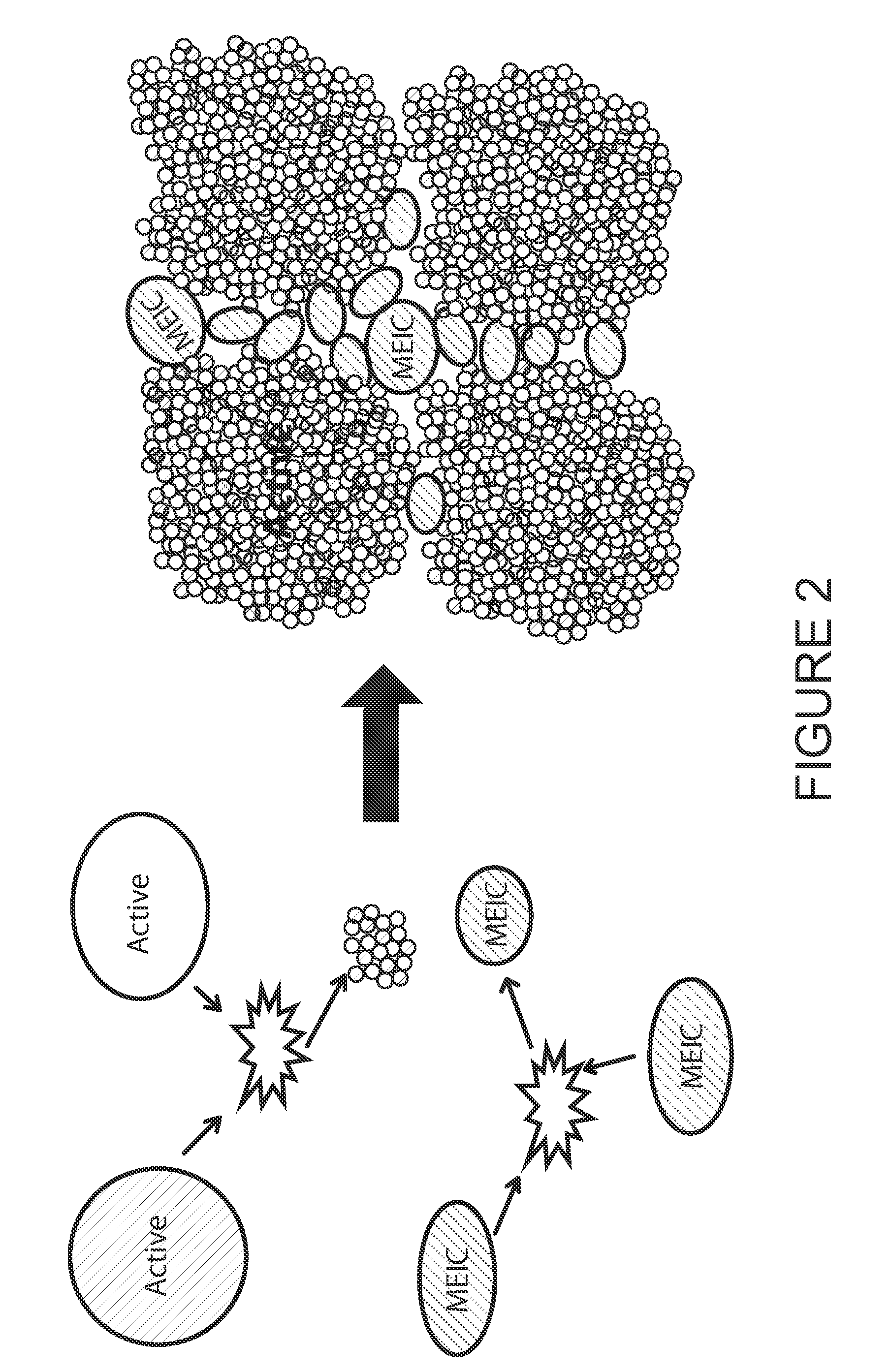

Solid state catholytes and electrolytes for energy storage devices

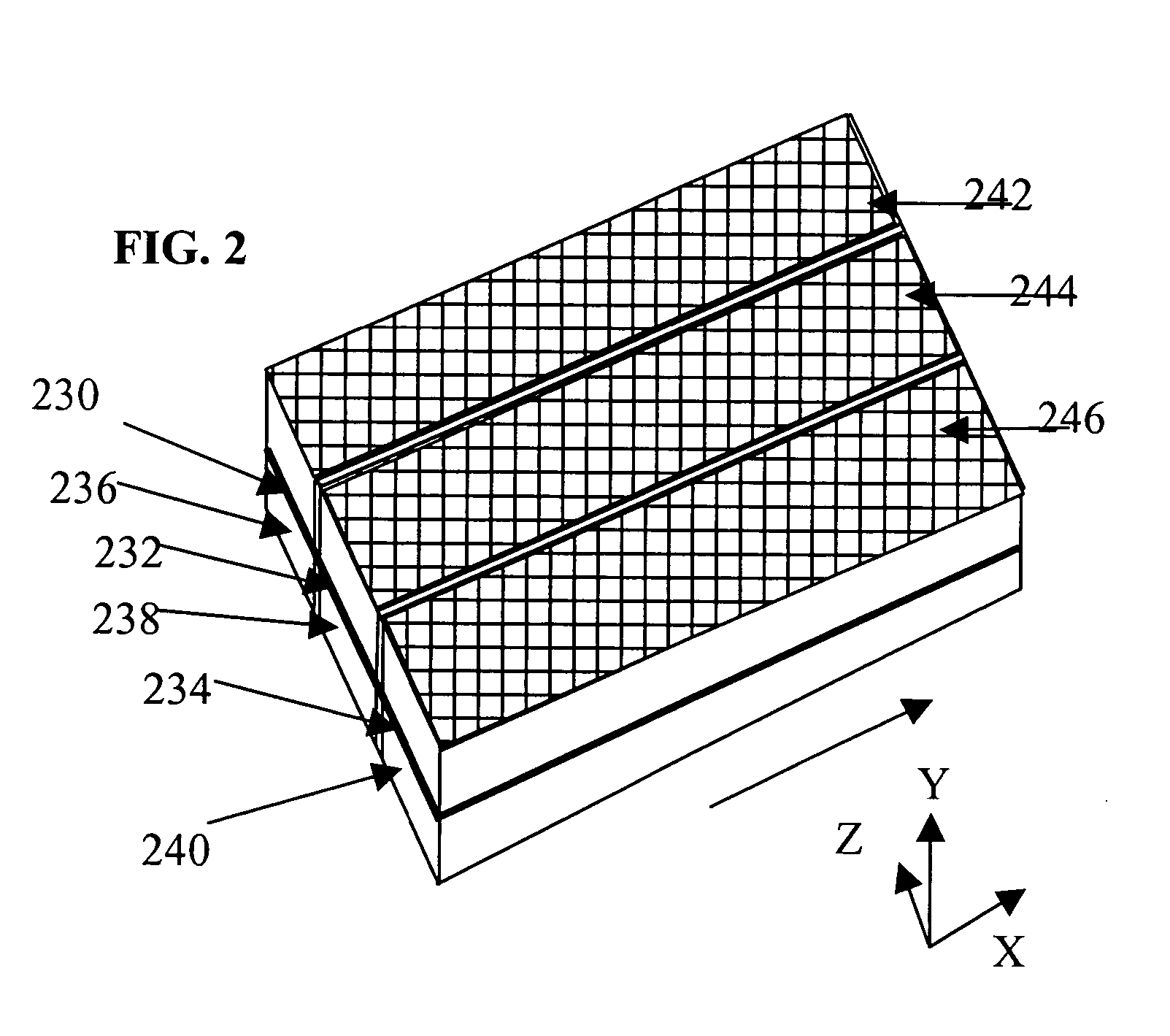

ActiveUS9172114B2Improve ionic conductivityImprove carrying capacitySolid electrolytesCell electrodesDopantSulfur

The present invention provides an energy storage device comprising a cathode region or other element. The device has a major active region comprising a plurality of first active regions spatially disposed within the cathode region. The major active region expands or contracts from a first volume to a second volume during a period of a charge and discharge. The device has a catholyte material spatially confined within a spatial region of the cathode region and spatially disposed within spatial regions not occupied by the first active regions. The device has a protective material formed overlying exposed regions of the cathode material to substantially maintain the sulfur species within the catholyte material. Also included is a novel dopant configuration of the LiaMPbSc (LMPS) [M=Si, Ge, and / or Sn] containing material.

Owner:QUANTUMSCAPE CORP

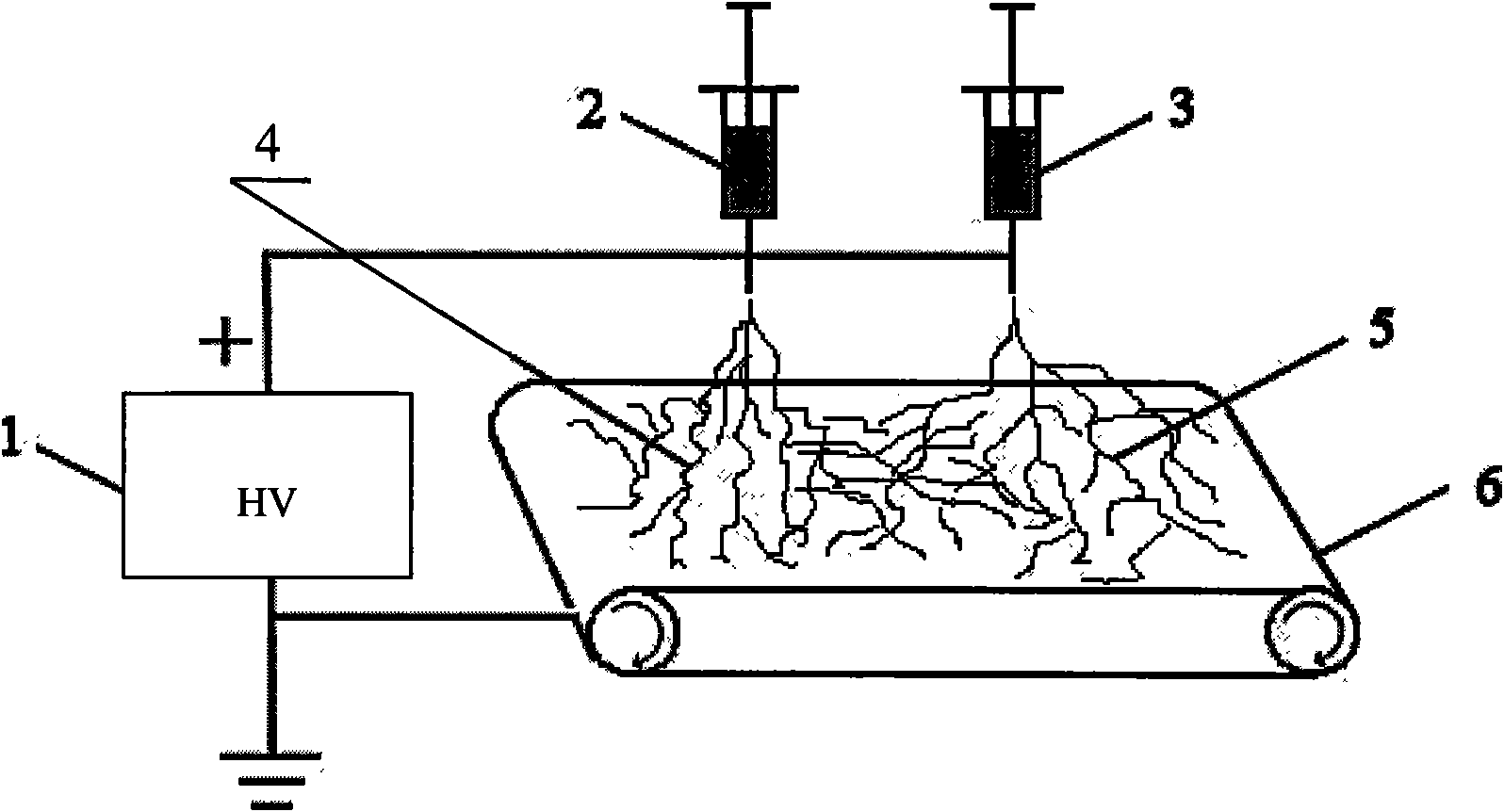

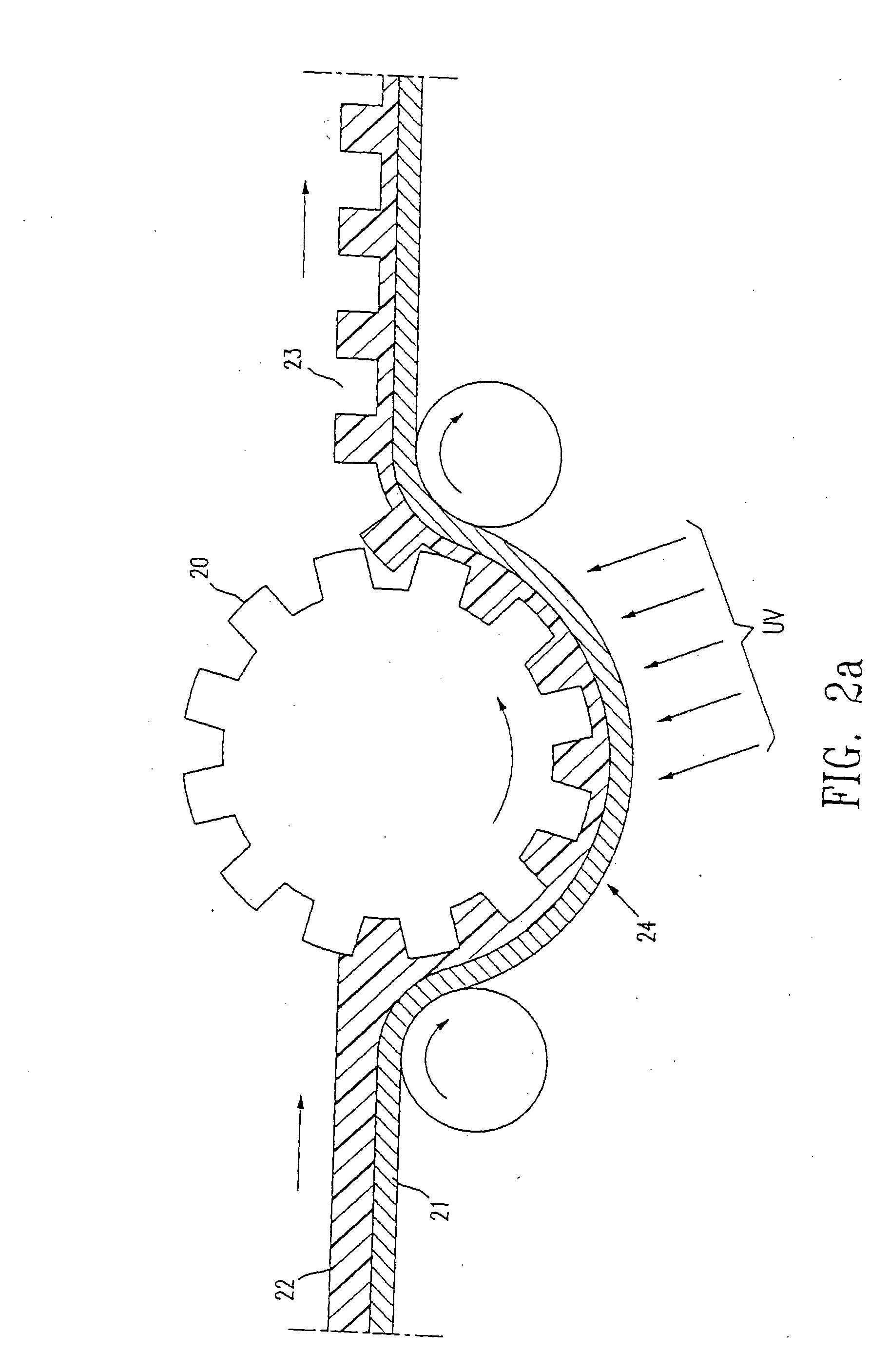

Method for manufacturing electrospinning of high-performance polyarylether resin lithium battery diaphragm

InactiveCN101562243AHigh ion transmission efficiencyImprove wettabilityFilament/thread formingCell component detailsElectrospinningNetwork structure

The invention provides a method for manufacturing electrospinning of a high-performance polyarylether resin lithium battery diaphragm, belonging to the technical field of high-voltage electrospinning. The method comprises the following steps of: using high-performance polyarylether resin solution and all-purpose engineering resin solution (or melt); simultaneously, mixing the electrospinning; and with intertwining which is caused by the flagellating effect of shooting flow in the process of spinning, forming a jointly weaved network structure so that polyarylether fiber is compounded with all-purpose resin fiber to obtain high-performance polyarylether fiber non-woven fabrics. The non-woven fabrics have the good heat-resistant performance of the polyarylether resin and the good self-closing performance of the all-purpose engineering resin. In addition, the non-woven fabrics also have good ion permeability and good wetting performance to electrolyte fluid so that the performance of the lithium battery with the polyarylether diaphragm can be obviously improved. The lithium battery with the polyarylether diaphragm has wide application in the fields such as national defense, aviation, space flight, civilian use, industry, and the like, and has higher application value.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

Control of electrolyte hydrodynamics for efficient mass transfer during electroplating

Owner:NOVELLUS SYSTEMS

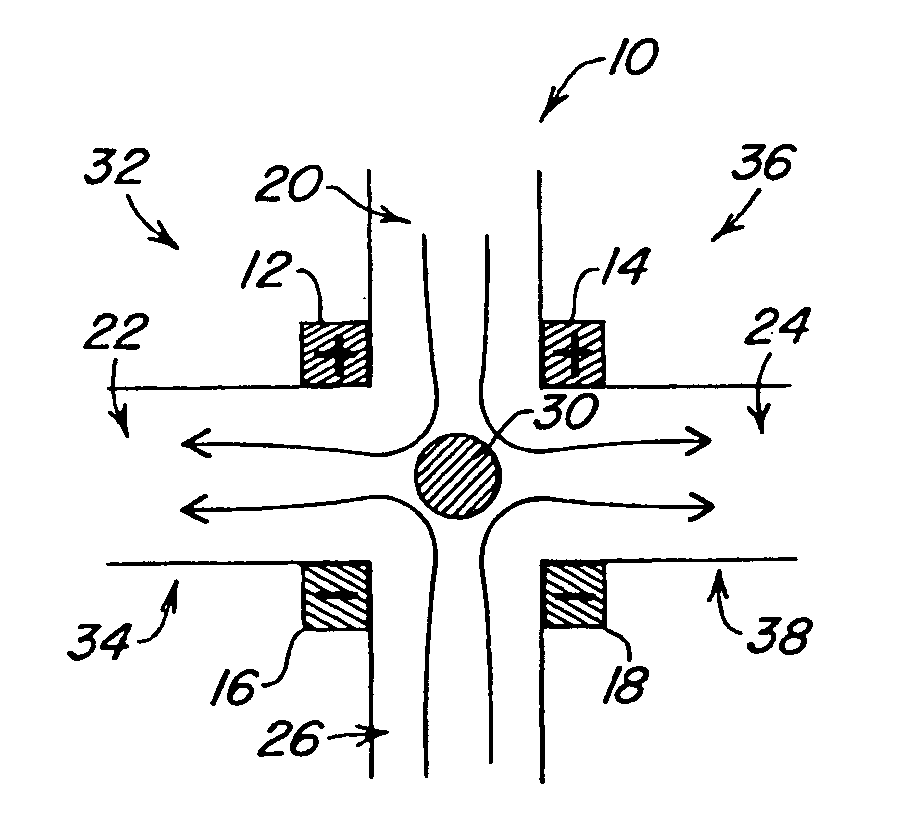

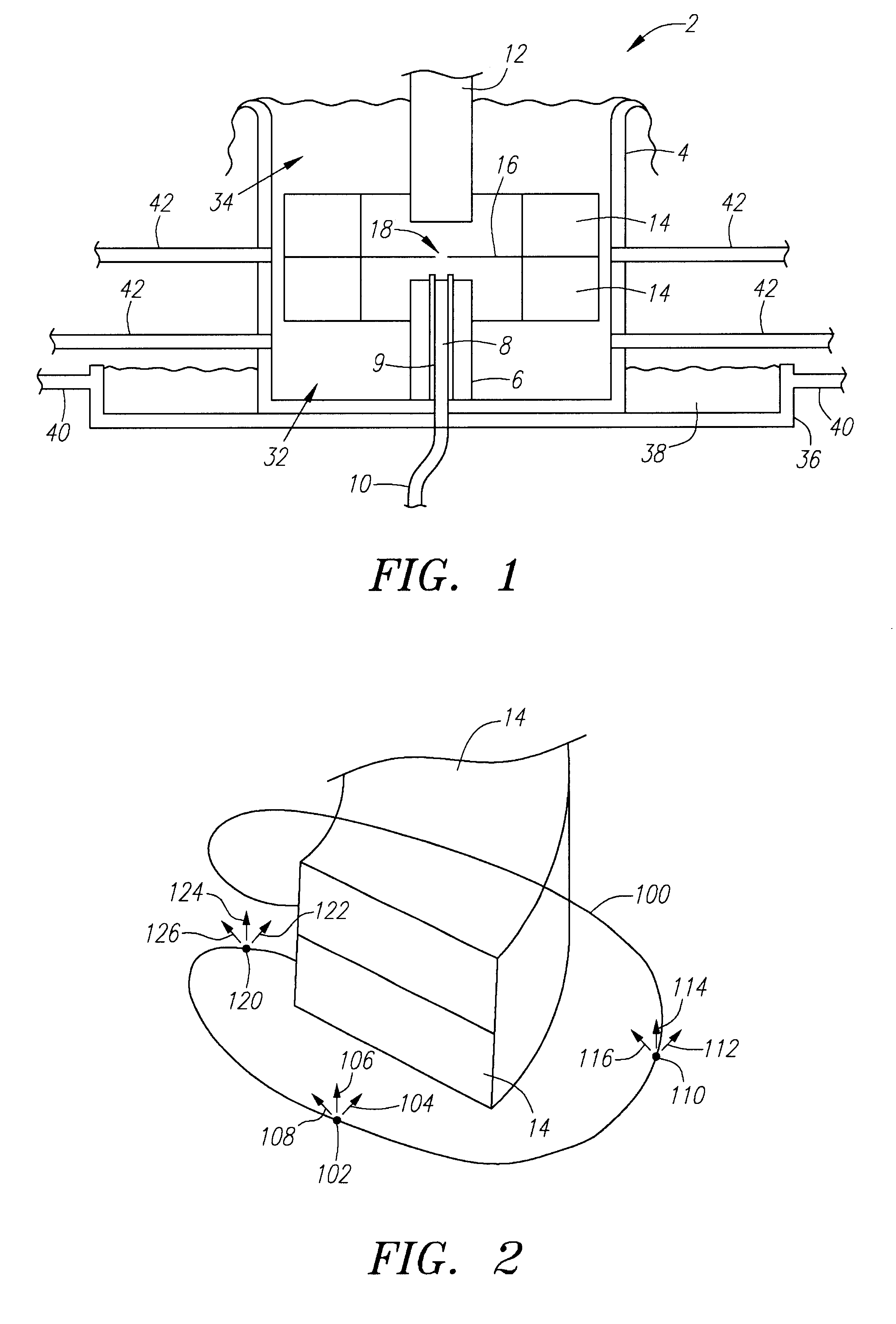

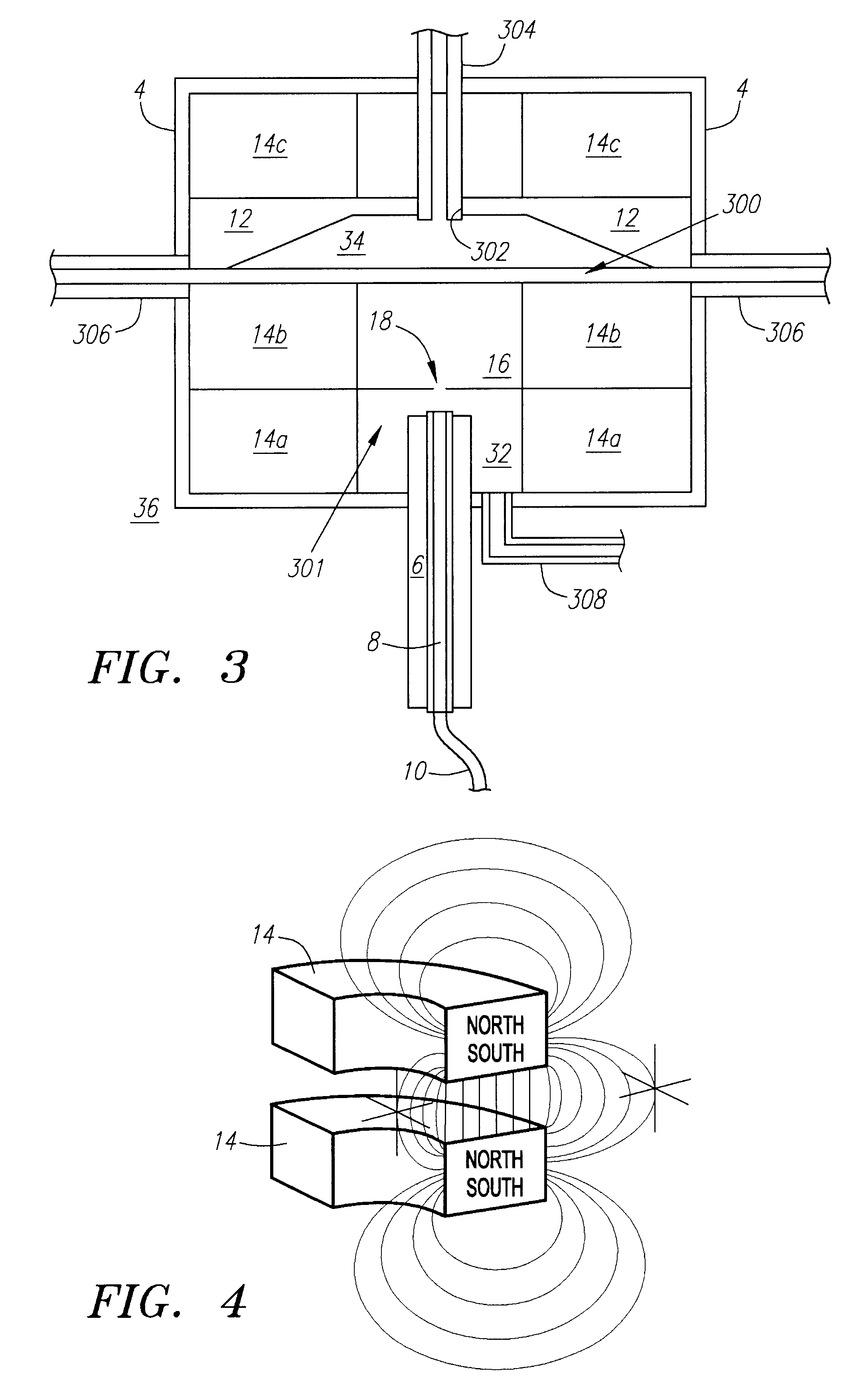

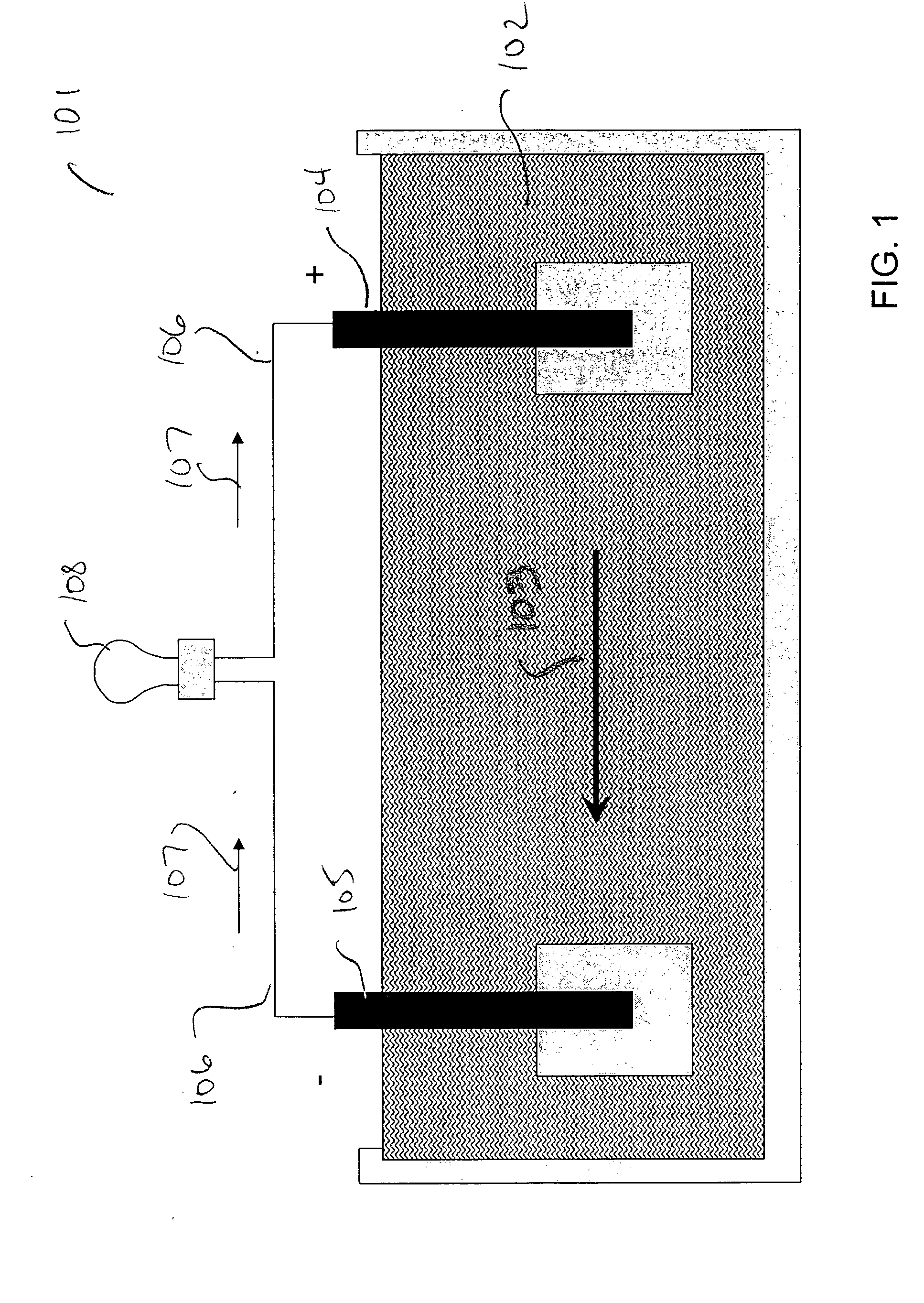

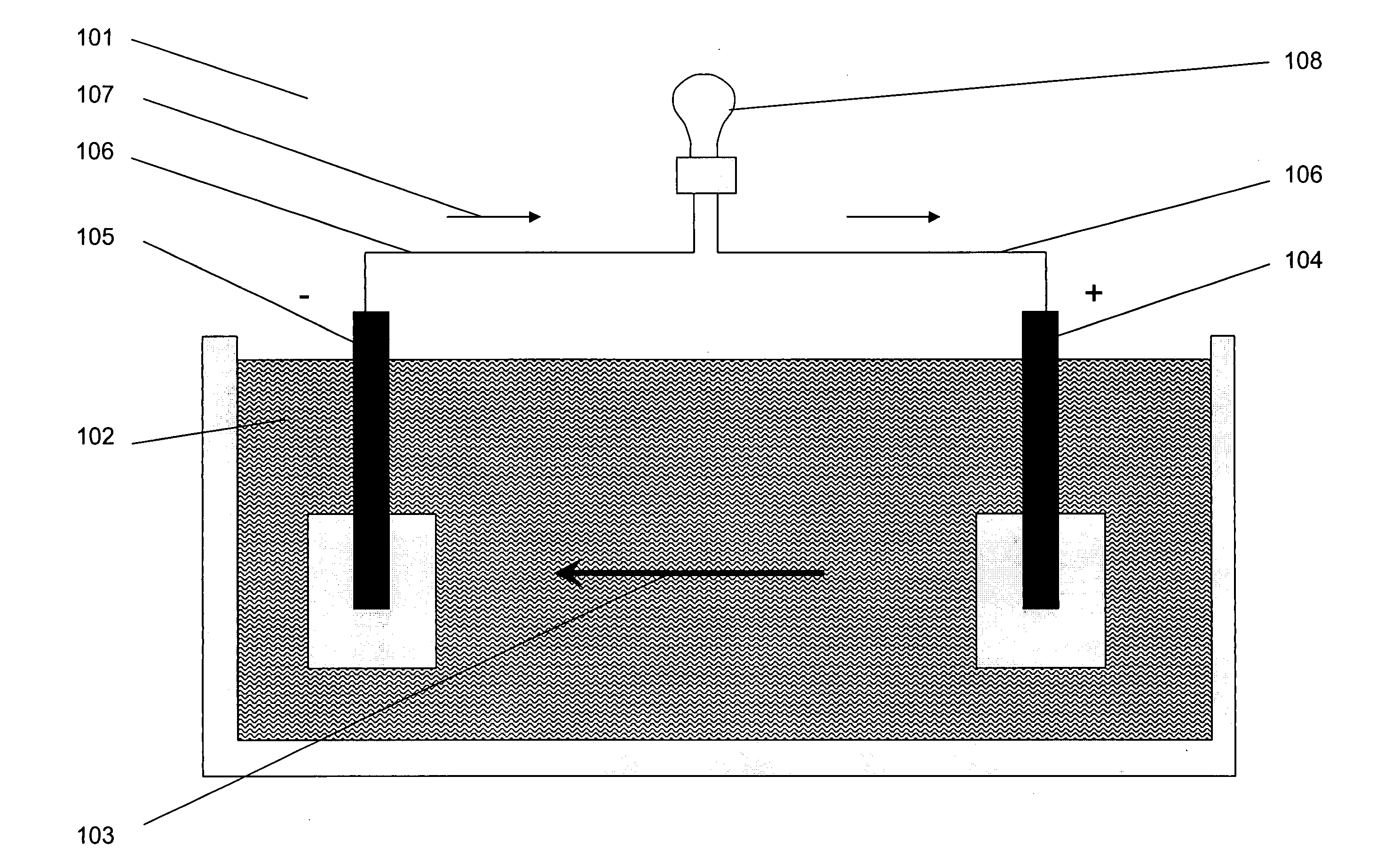

Apparatus and method for magneto-electrodynamic separation of ions within an electrolytic fluid

Apparatus and method in which an electric field and a magnetic field intersect in a flow path of an electrolytic fluid, producing a flow of ions and charged particles perpendicular to both the magnetic field and the electric field. Electrolytic fluid so treated is collected for use or further processing.

Owner:GONZALEZ PABLO DIAZ RIVERA +1

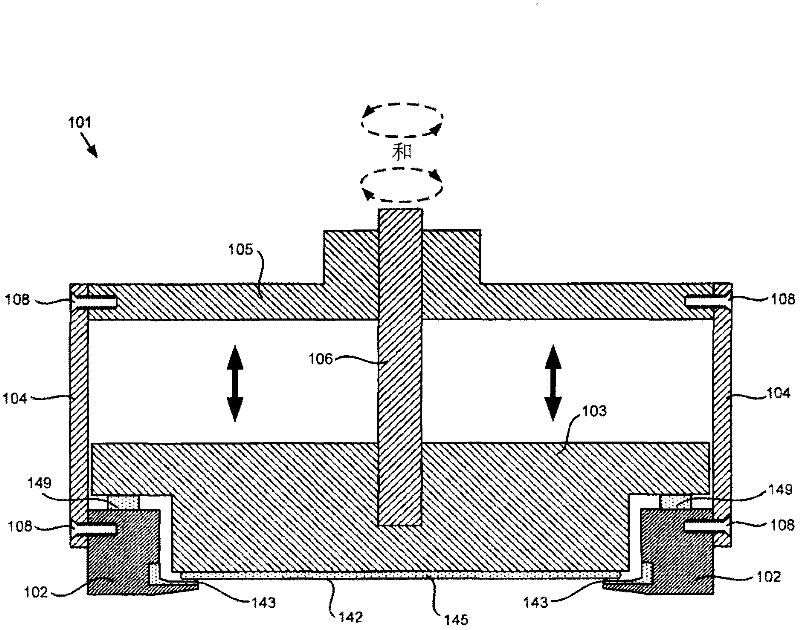

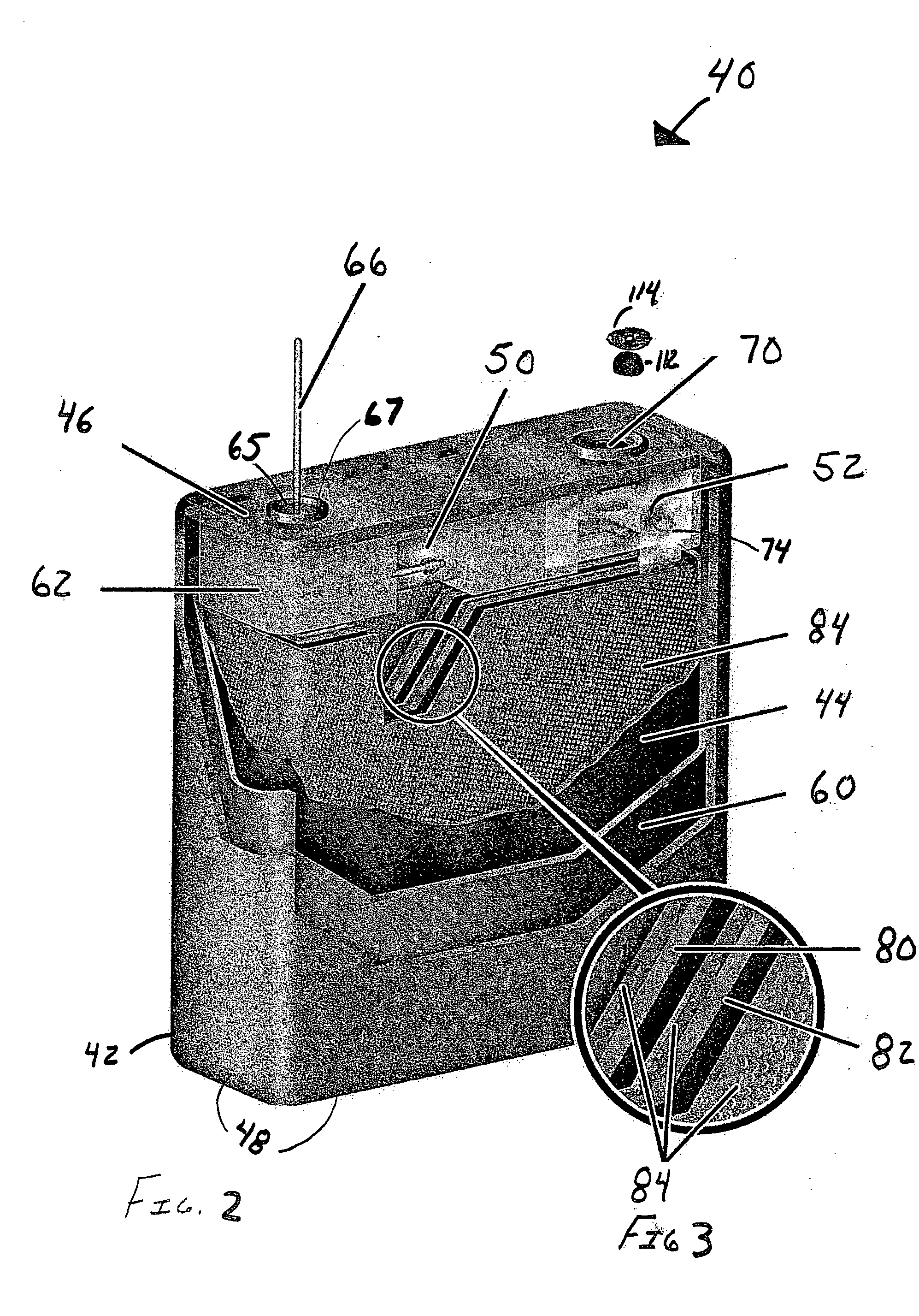

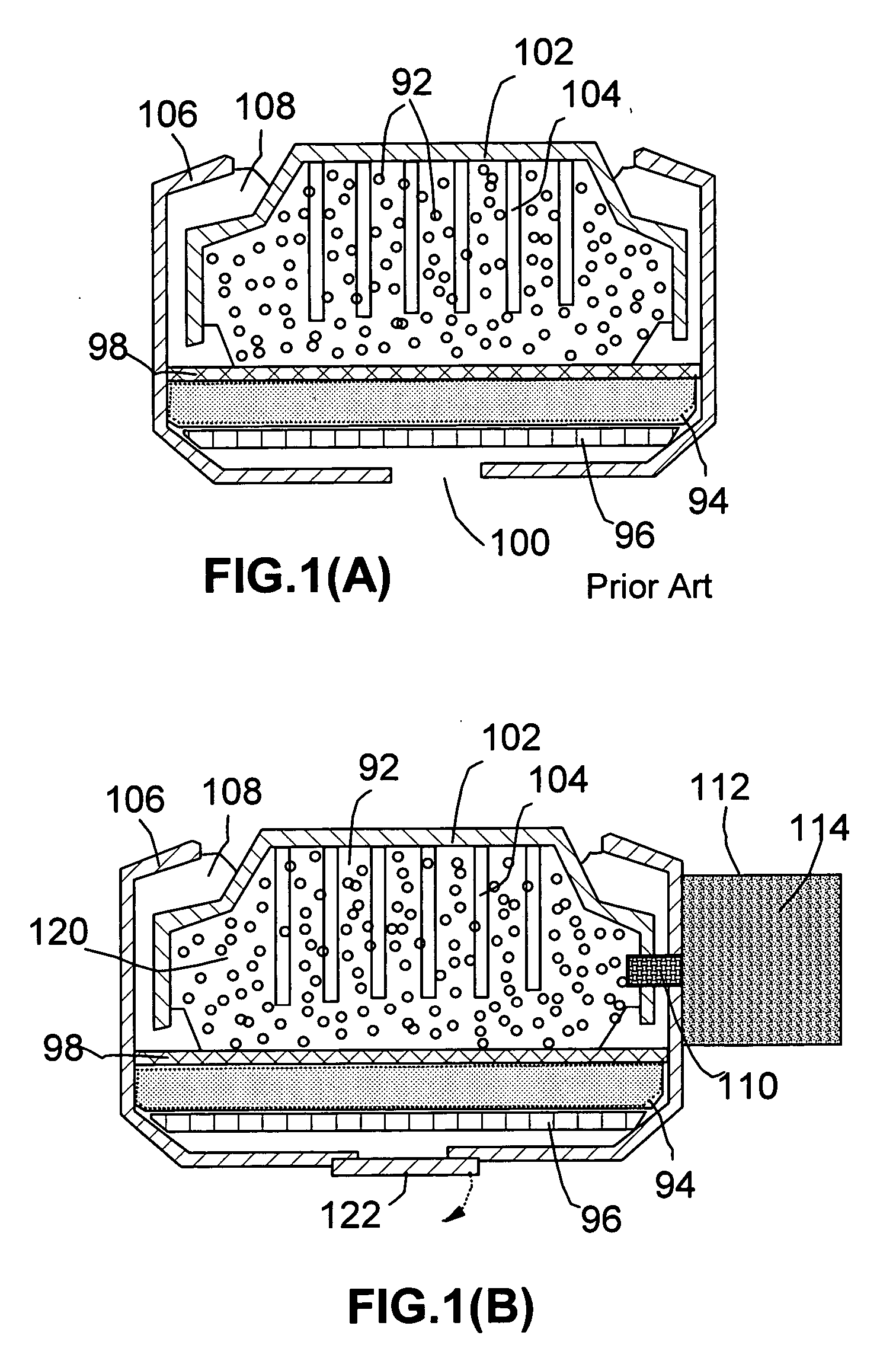

Actively controlled metal-air battery and method for operating same

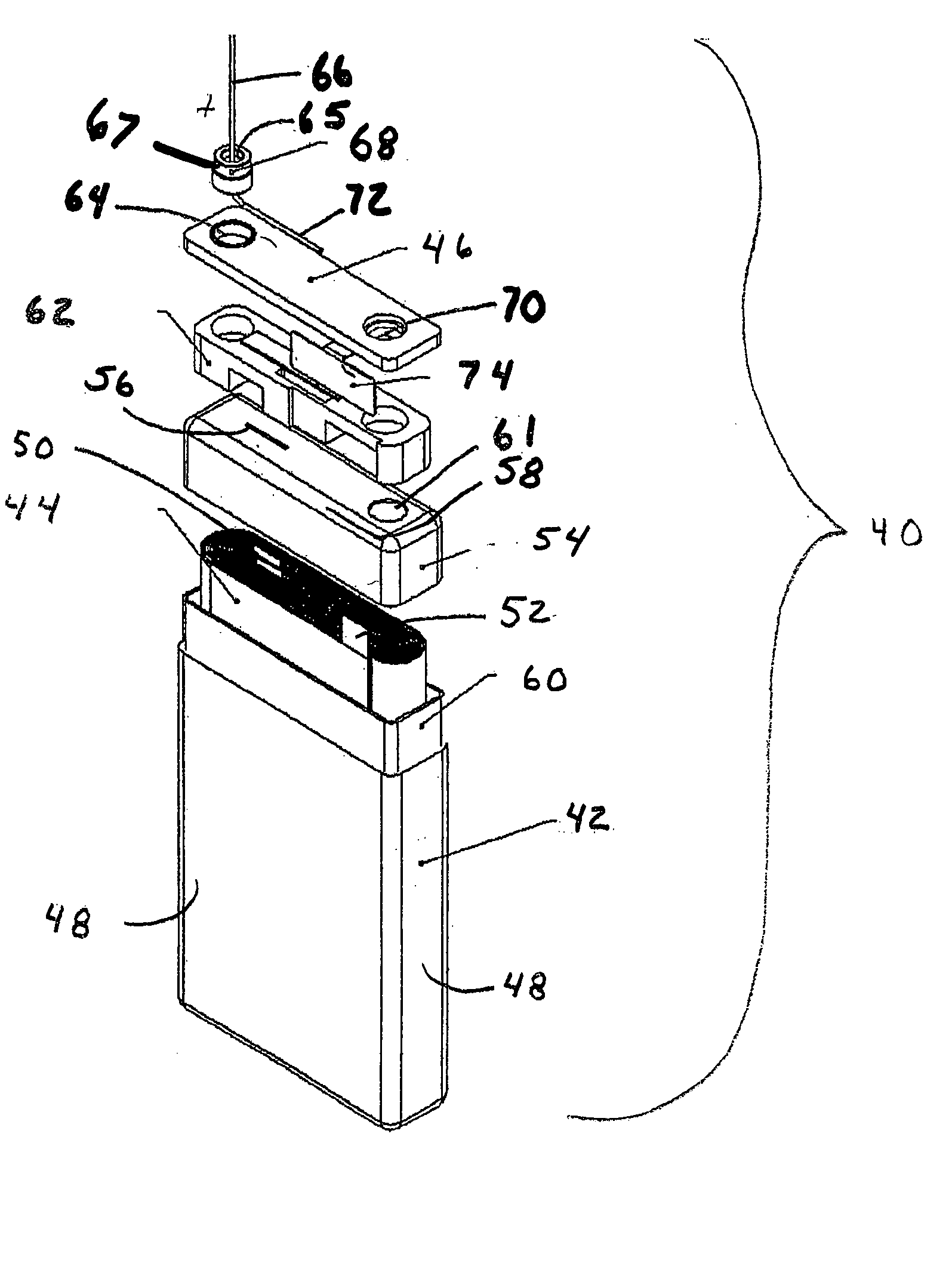

InactiveUS20050100781A1Improve power densityIncrease loadFuel and primary cellsBatteries circuit arrangementsElectrical batteryActuator

This invention provides an actively controlled electrochemical cell and a smart battery containing such a cell with a programmed-timing activation capability. As a preferred embodiment, the cell includes (a) a cathode, an anode, a porous separator electronically insulating the cathode from the anode, and an electrolyte, wherein the anode is initially isolated from the electrolyte fluid prior to the first use of the cell; (b) an actuator in actuation relation to the electrolyte or the anode; and (c) a control device in control relation to the actuator for sending programmed signals to the actuator to activate the cell by allowing a desired amount of an active anode material at a time to be exposed to the electrolyte during the first use and / or successive uses of the cell. The cell or battery has an essentially infinite shell life and an exceptionally long operating life. The battery is particularly useful for powering microelectronic or communication devices such as mobile phones, laptop computers, and palm computers.

Owner:NANOTEK INSTR

Headspace insulator for electrochemical cells

ActiveUS20050112460A1Final product manufactureElectrode carriers/collectorsEngineeringMedical device

A headspace insulator for a battery cell operatively coupled to circuitry within an implantable medical device in including one or more of the following: (a) a body of electrically and thermally insulating material disposed between a battery electrode assembly and a battery cover, (b) a receiving area within the body that receives and isolates a battery feedthrough pin, (c) an indentation within the receiving area retaining the feedthrough pin within the receiving area, (d) a raised portion coupled to a battery cover providing an air gap between the cover and the headspace insulator near case-to-cover weld areas, (e) a feedthrough aperture adapted to receive a feedthrough assembly, (f) a pin aperture that receives the feedthrough pin, (g) a fillport aperture for electrolyte fluid flow through the headspace insulator, and (h) a slot that locates a battery weld bracket and isolates it from the feedthrough pin.

Owner:MEDTRONIC INC

Electrochromic or electrodeposition display and novel process for their manufacture

ActiveUS20060139724A1Eliminates undesirable particle sedimentationResponse rateNon-linear opticsEngineeringElectrochromism

The present invention is directed to an improved electrodeposition and an electrochromic display. The display cells formed from microcups are filled with an electrolyte fluid and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

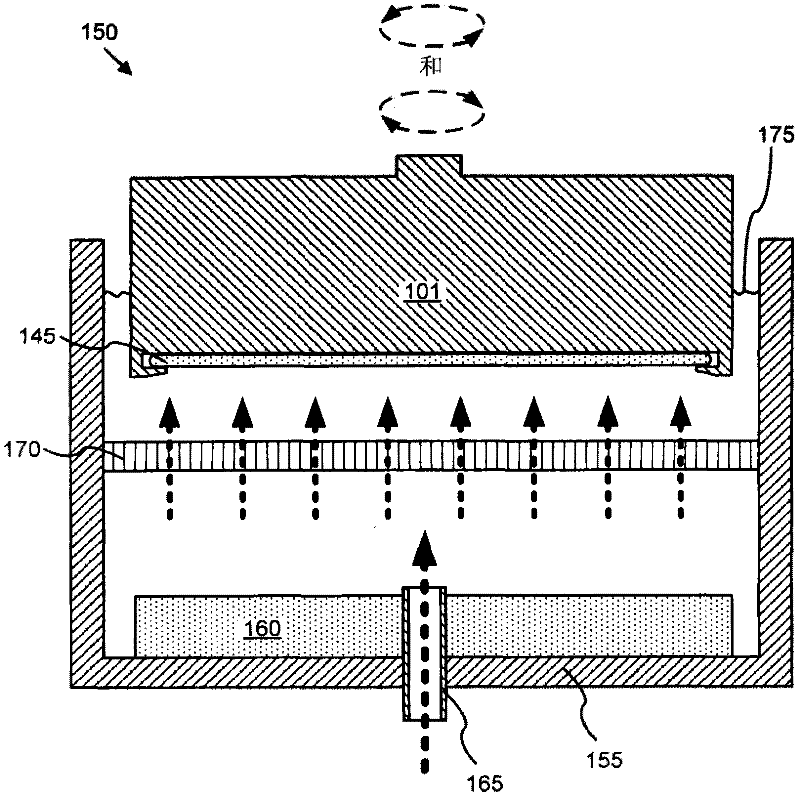

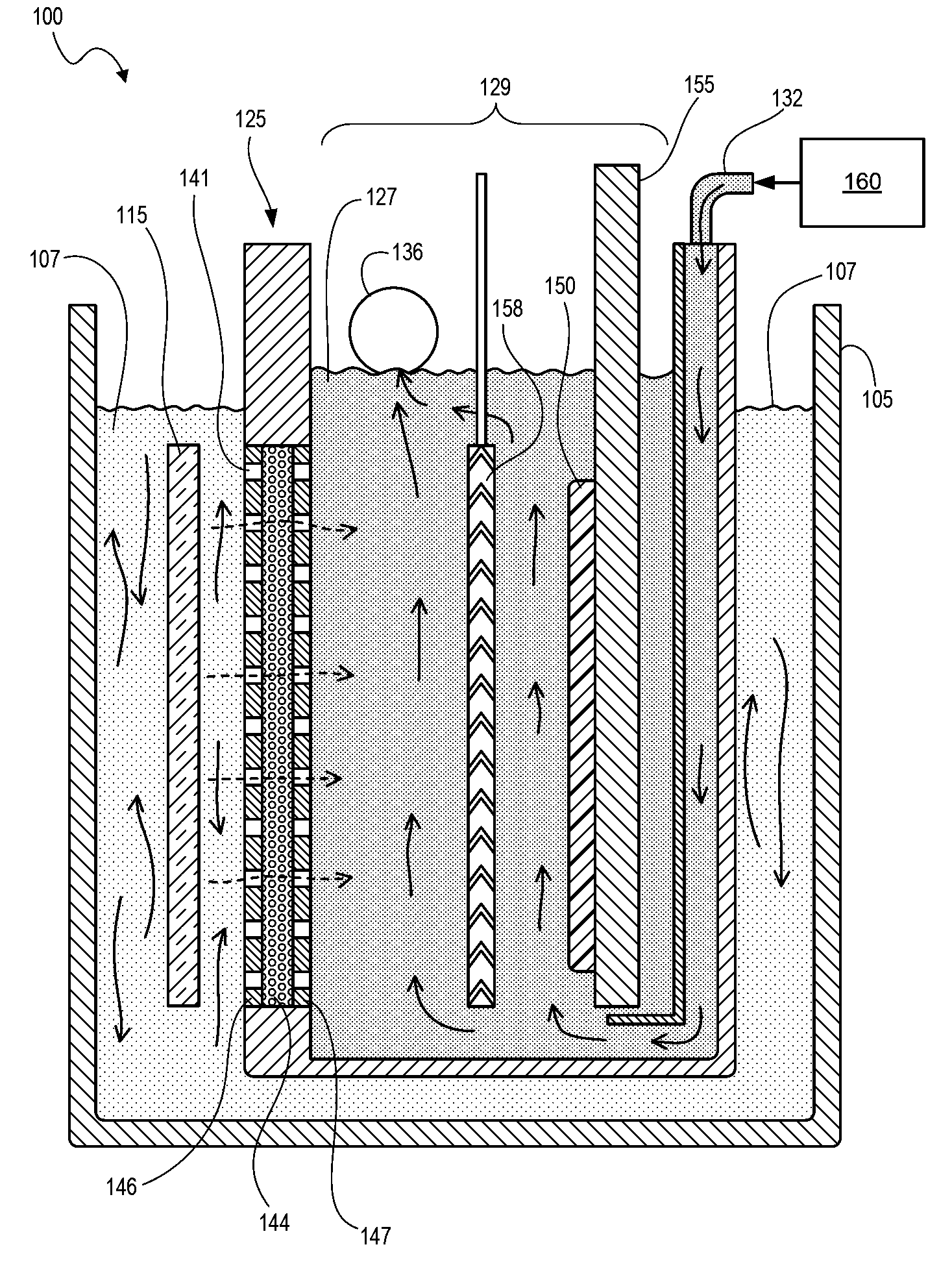

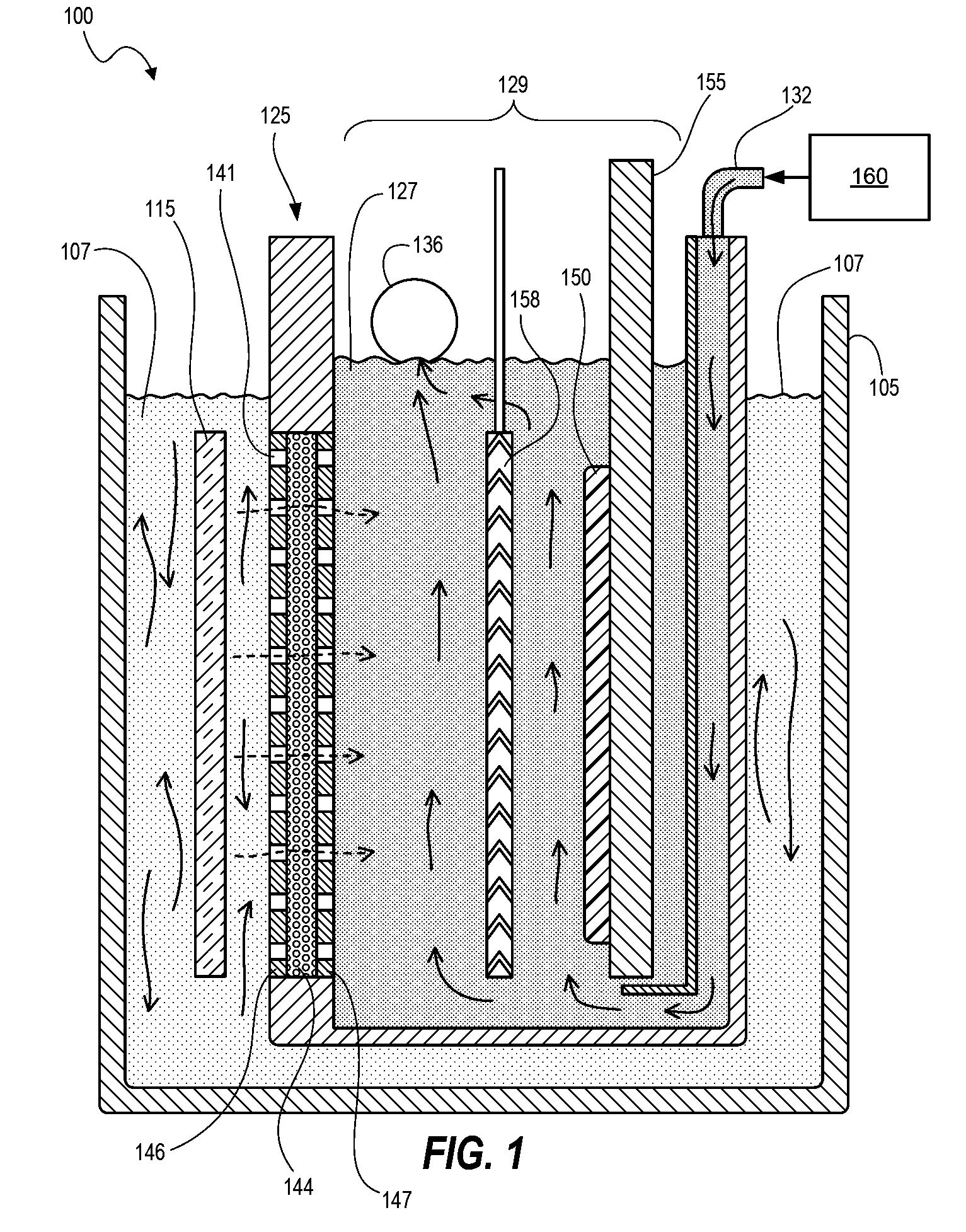

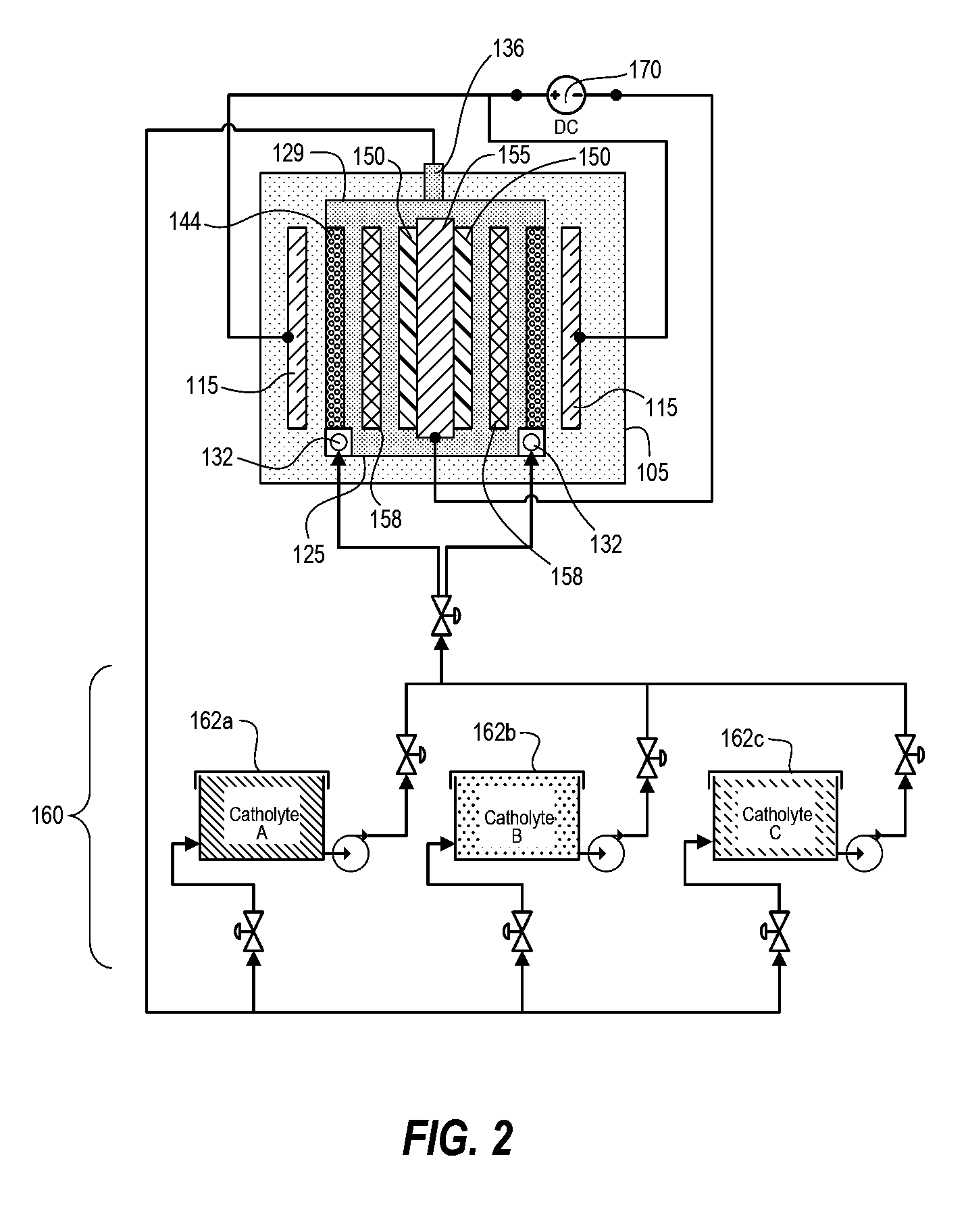

Electrochemical deposition apparatus with remote catholyte fluid management

ActiveUS20150129418A1Removal costRemove complexityCellsSemiconductor/solid-state device manufacturingFluid compartmentsElectrolytes fluids

Techniques disclosed herein include an electro-chemical deposition apparatus that provides an efficient circulation system, chemical management that provides reliable and uniform plating, and a configuration that provides short maintenance times and greater tool availability. Techniques include a processing tank containing an anolyte fluid, and one or more plating cells each having a catholyte fluid compartment with a circulation path that connects to a separate or remote catholyte reservoir. Thus, with such a configuration, a single pump can be used to flow catholyte (via manifolds) through one or more plating cells. Thus, with the catholyte reservoir maintained off board, instead of dumping catholyte over a weir into a reservoir, catholyte fluid—after flowing through a plating cell—is returned to the catholyte reservoir.

Owner:ASMPT NEXX INC

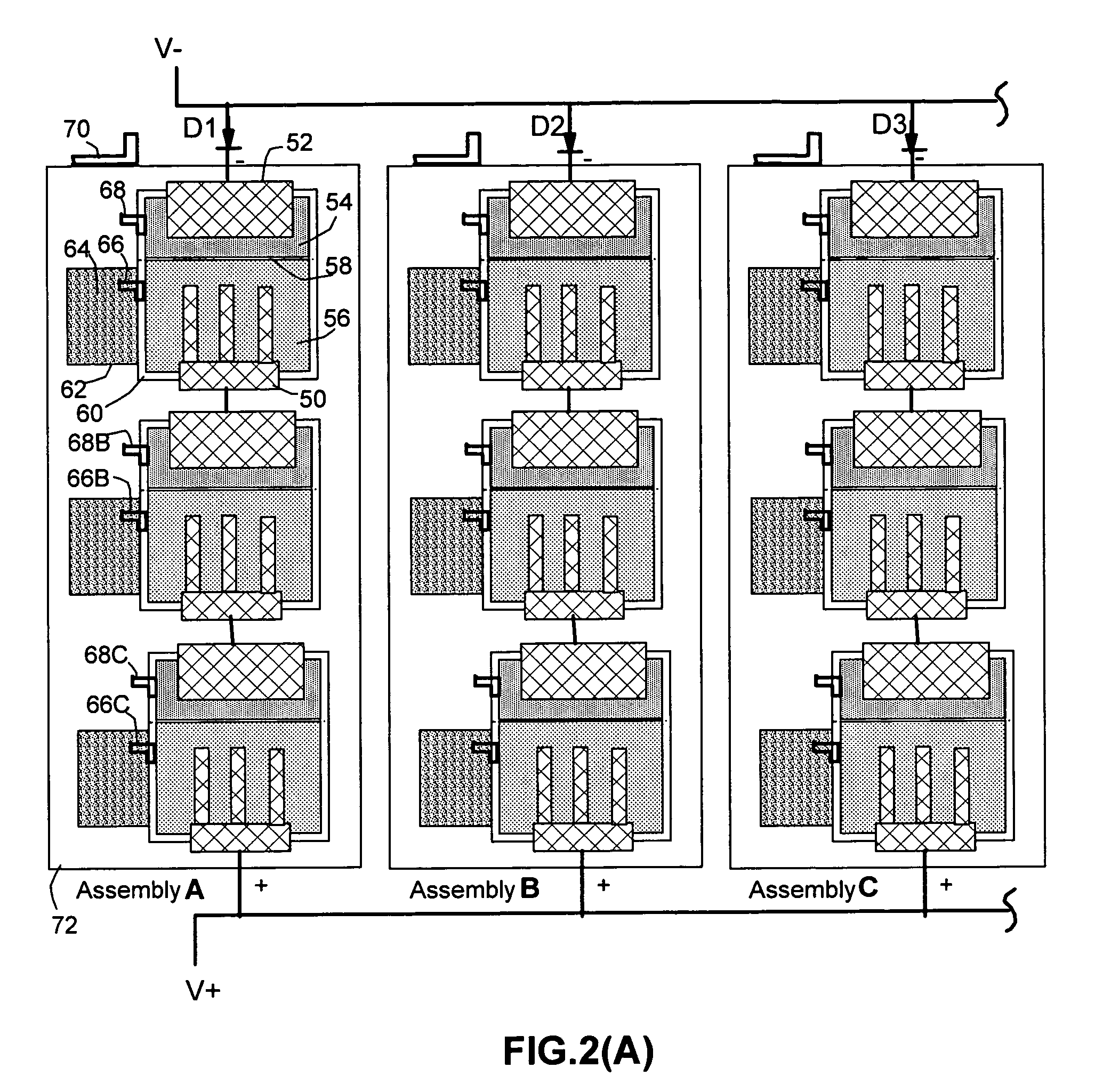

Metal-air battery system with programmed-timing activation

InactiveUS20070031714A1Fuel and primary cellsBatteries circuit arrangementsElectrical batteryBiological activation

This invention provides an actively controlled battery with a programmed-timing actuation capability. As a preferred embodiment, the battery comprises a first electrochemical assembly, at least a second electrochemical cell assembly electronically connected in parallel with the first assembly, and control means in control relation to the first assembly and the at least second assembly, wherein at least one of the assemblies comprises a metal-air cell comprising a cathode being isolated from outside air through a controllable air vent and at least one of the assemblies comprising an electrochemical cell comprising an anode active material being initially isolated from an electrolyte fluid through a control valve, with both the air vent and control valve being regulated by the control means to open the air vent and control valve in a programmed-timing fashion. The battery has an exceptionally long operating life and is particularly useful for powering microelectronic or communication devices such as mobile phones, laptop computers, and palm computers.

Owner:FORD CHEER INT

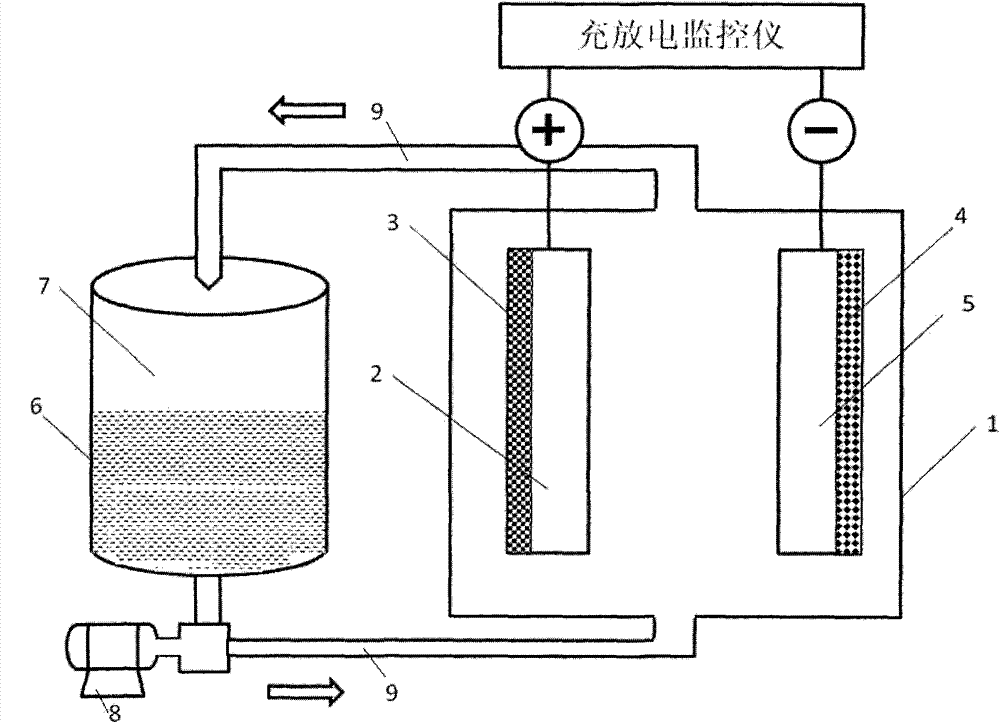

Aqueous lithium ion flow battery

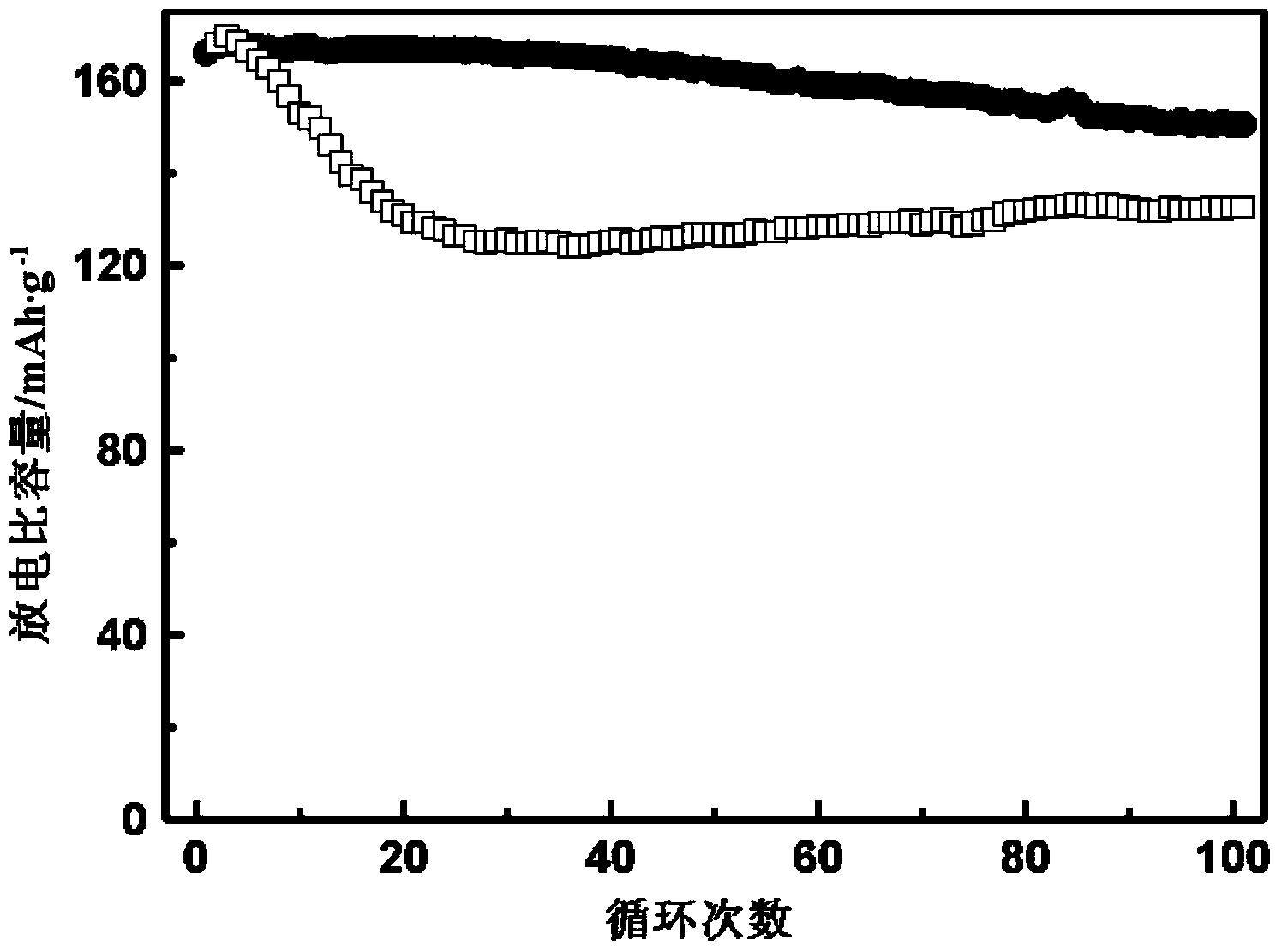

InactiveCN104716372AImprove cycle lifeHigh specific capacityCell electrodesRegenerative fuel cellsEnvironmental resistanceHigh energy

The invention relates to a novel aqueous lithium ion flow battery with high performances and low cost. A lithium ion intercalation-deintercalation mechanism and a flow battery metal ion deposition-dissolution mechanism are optically combined in an energy storage device. A positive electrode adopts a lithium ion intercalatable-deintercalatable solid oxide material, a negative electrode adopts a deposition type metal electrode material deposited-dissolved on an inert electrode, an electrolyte is an aqueous electrolyte containing lithium ions and capable of depositing and dissolving metal ions, and the separation of positive electrode and the negative electrode by a diaphragm is not needed. In the charge and discharge process, the electrolyte is promoted by a liquid pump to go through a pipeline and continuously circularly flow between a storage tank and a battery main body. The aqueous lithium ion flow battery has the characteristics of long cycle life, high energy efficiency, safety, low cost, less maintenance, environmental protection, high utilization rate and energy density of active substances, and large specific capacity, and is especially suitable for large scale power storage of off-grid renewable energy power generation and distributed power supply.

Owner:NO 63971 TROOPS PLA

Electrolyte

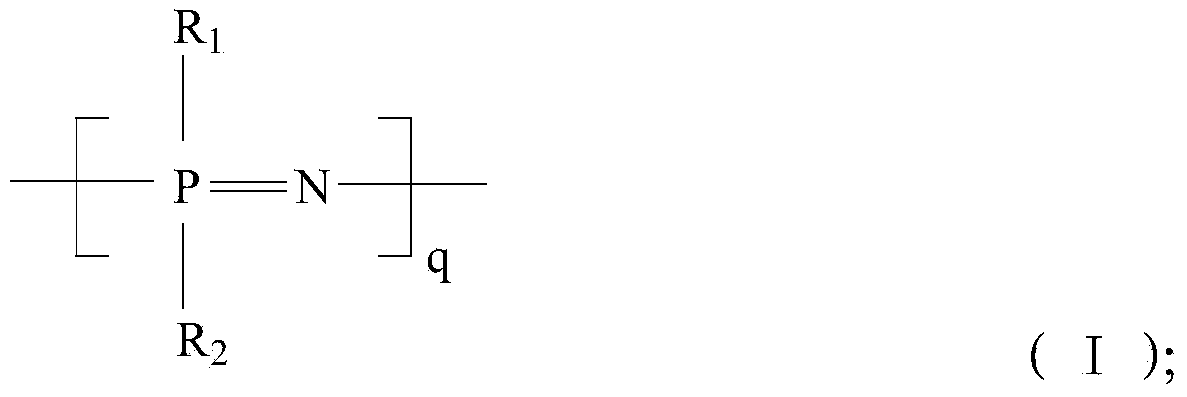

ActiveCN103762380AReduce oxidative decompositionGood chemical stabilitySecondary cellsSide chainLithium-ion battery

The invention provides an electrolyte which comprises a non-aqueous organic solvent, lithium salt and a polyphosphazene compound. According to the application, the side chain of the polyphosphazene compound added into the electrolyte is a long-chain group containing O, N or S and other heteroatom, so a compact high lithium ion conductive coating layer is formed on the surface of a cathode material of a lithium ion battery, therefore, the direct contact of the electrolyte and the cathode material is effectively inhibited; the oxygenolysis of the electrolyte is reduced; the circularity of the high voltage lithium ion battery is improved; meanwhile, the additive polyphosphazene compound has a flame-retardant property, so that the flammability of the electrolyte is lowered; the safety performance of the battery is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

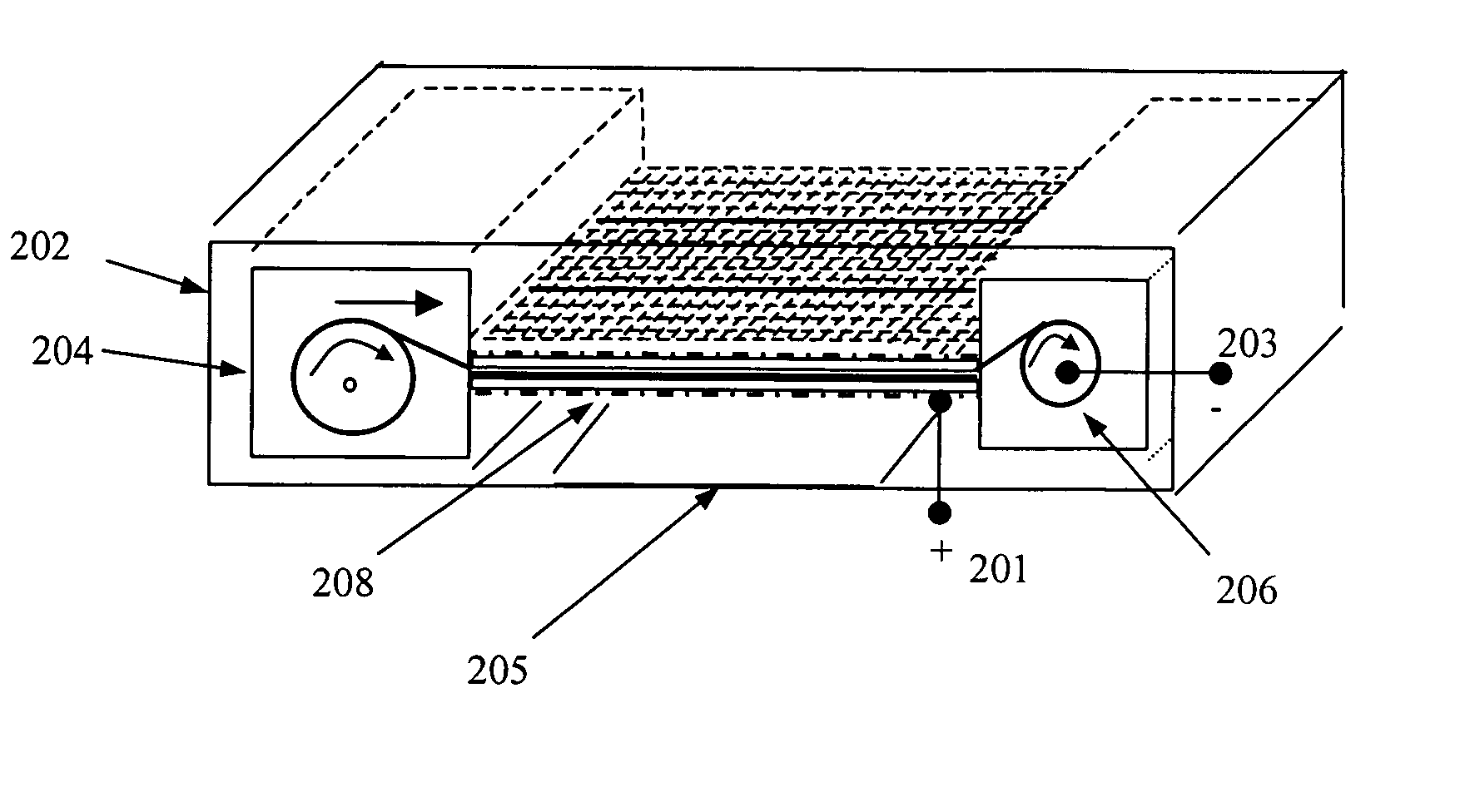

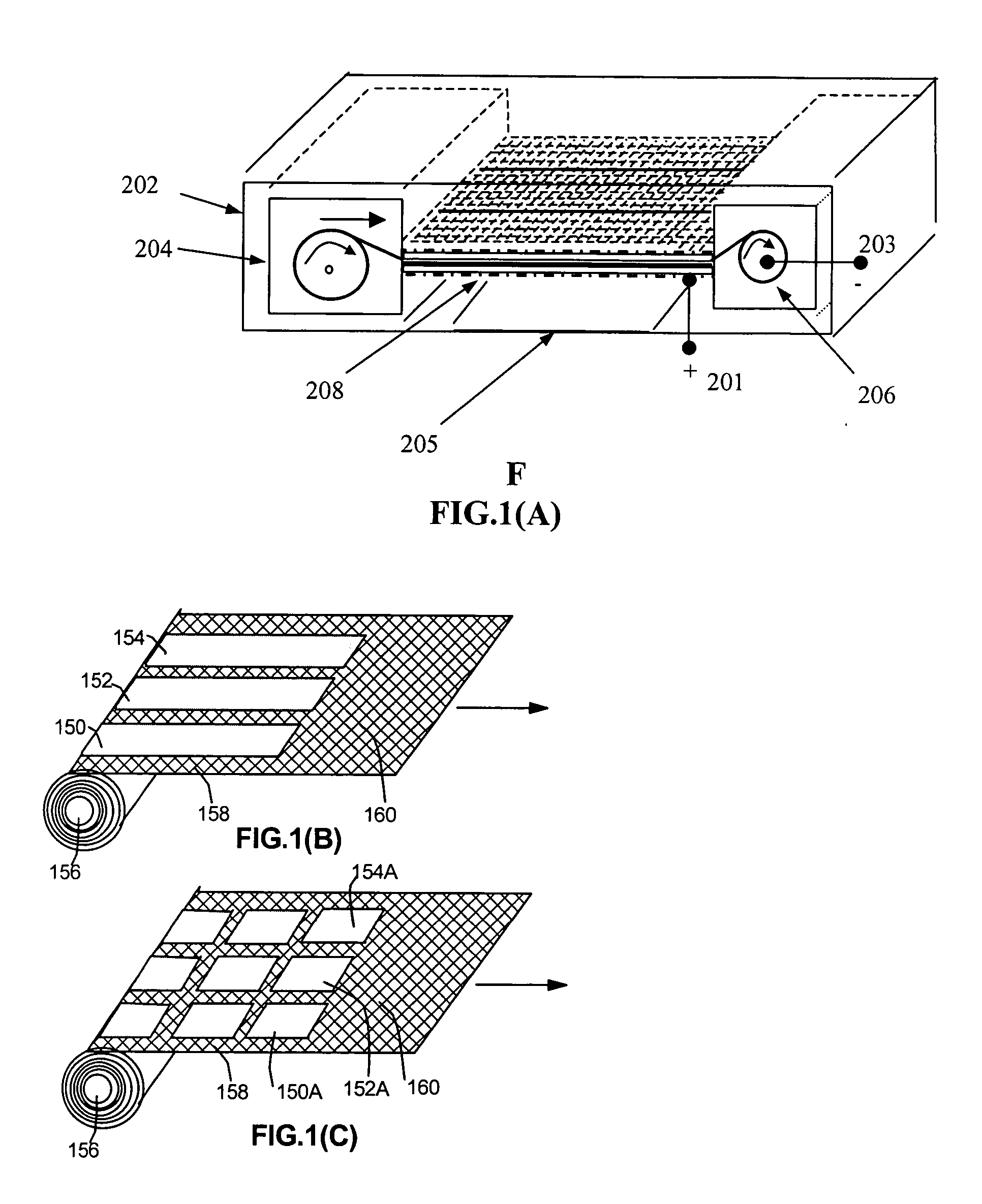

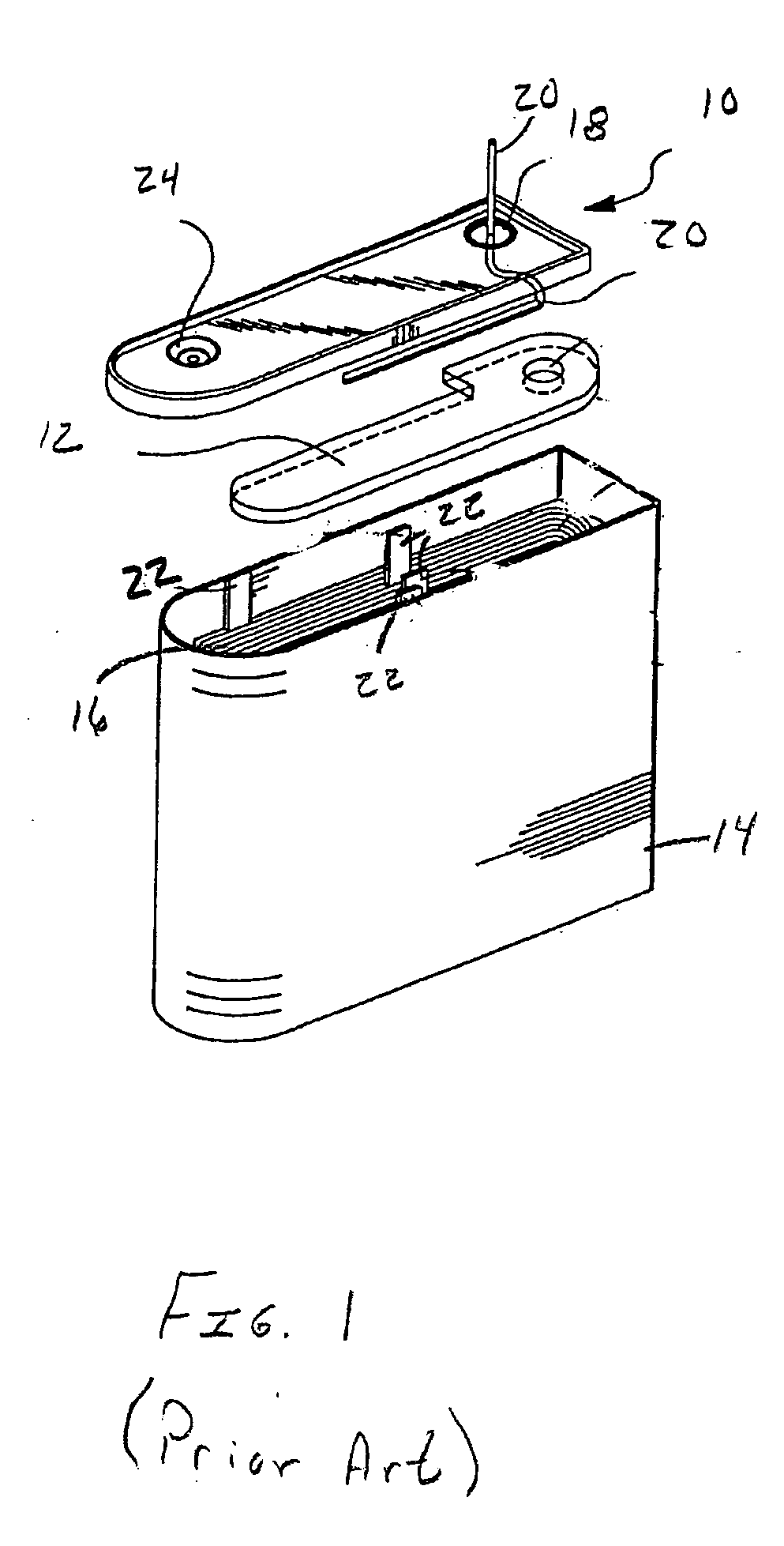

Electrowetting battery having a nanostructured electrode surface

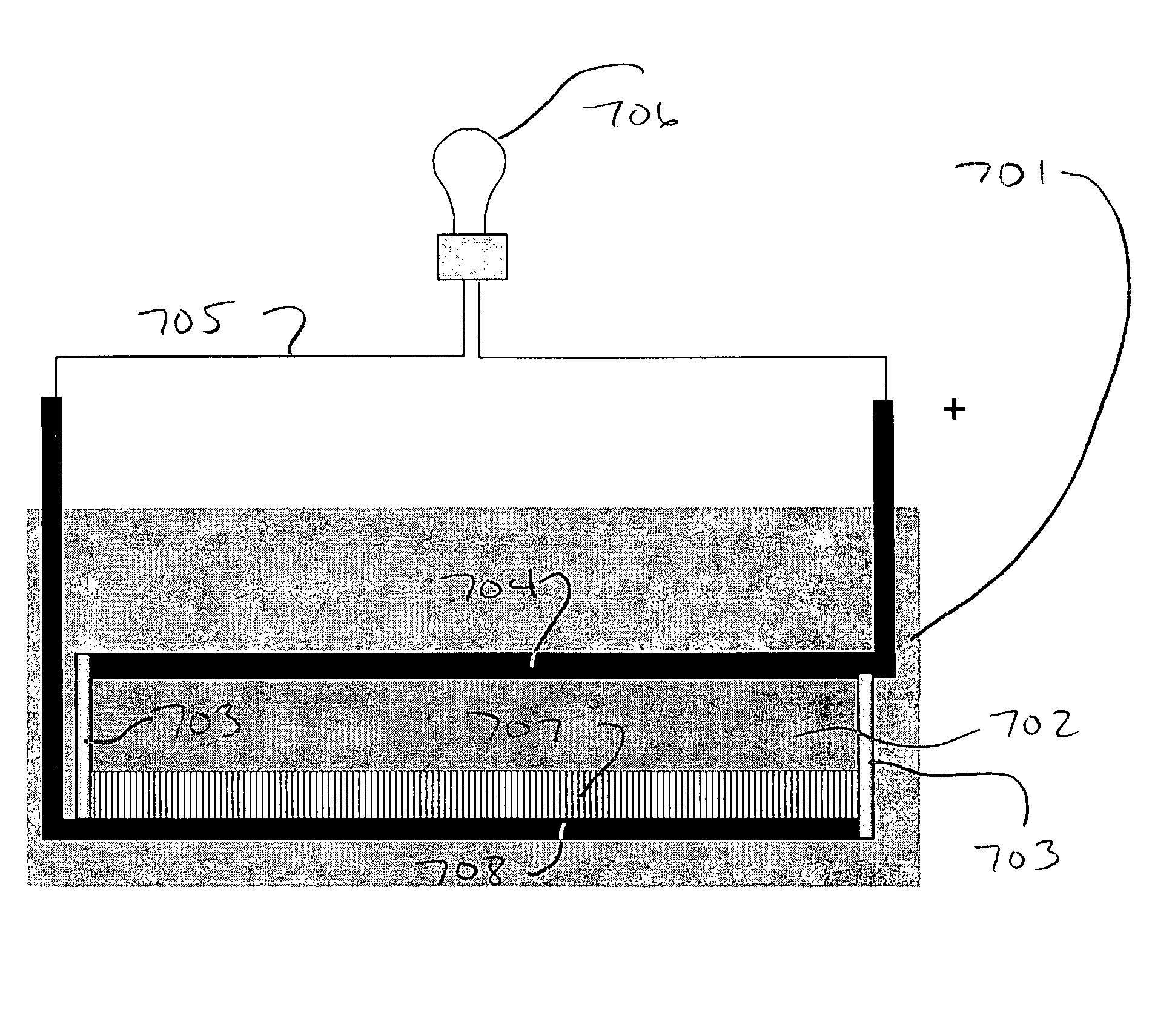

ActiveUS20050106459A1Avoid dischargeCell temperature controlElectrode carriers/collectorsElectricityElectrical battery

A method and apparatus are disclosed wherein a battery comprises an electrode having at least one nanostructured surface. The nanostructured surface is disposed in a way such that an electrolyte fluid of the battery is prevented from contacting the electrode, thus preventing discharge of the battery when the battery is not in use. When a voltage is passed over the nanostructured surface, the electrolyte fluid is caused to penetrate the nanostructured surface and to contact the electrode, thus activating the battery. In one illustrative embodiment, the battery is an integrated part of an electronics package. In another embodiment, the battery is manufactured as a separate device and is then brought into contact with the electronics package. In yet another embodiment, the electronics package and an attached battery are disposed in a projectile that is used as a military targeting device.

Owner:ALCATEL-LUCENT USA INC

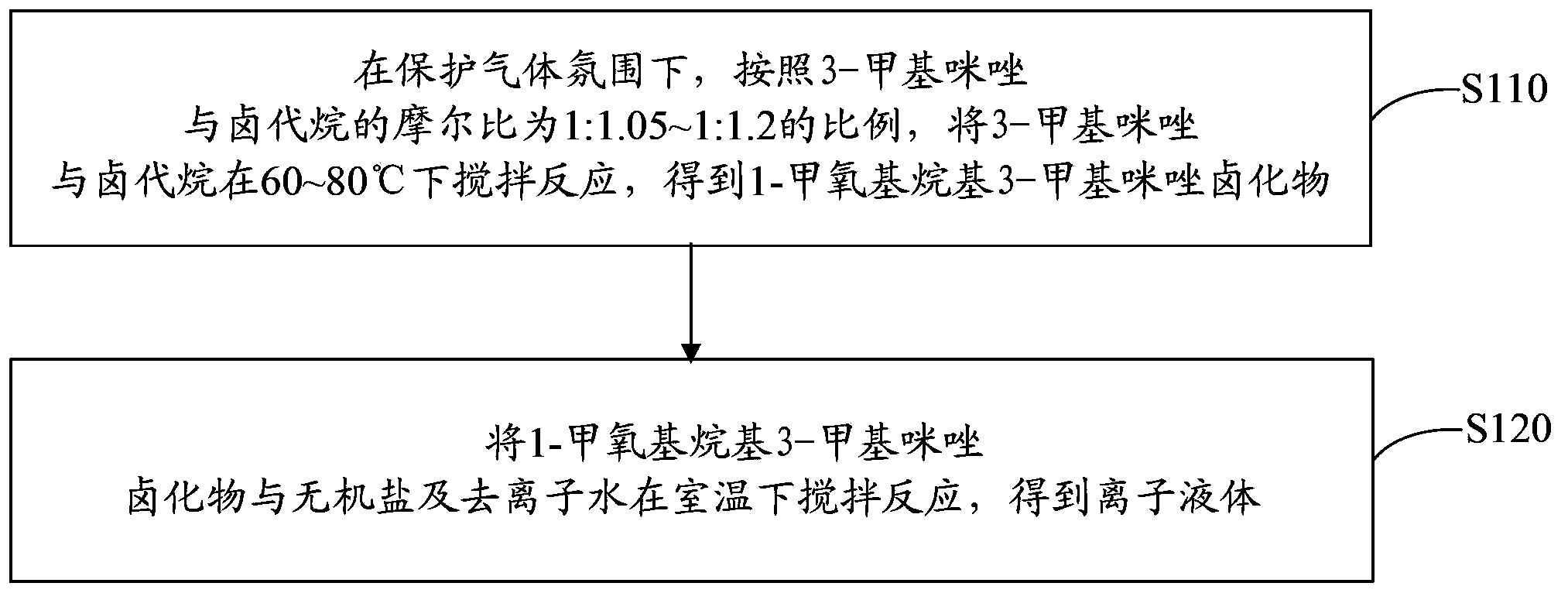

Imidazoles ionic liquid and ionic liquid electrolytic solution, and preparation methods and applications thereof

InactiveCN103787981AImprove stabilityImprove securityFinal product manufactureSulfonic acids salts preparationEtherStructural formula

The invention relates to an imidazoles ionic liquid having the following structural formula defined in the description, wherein R represents CH3O(CH2)n, n is 2, 3 or 4, and Y<-> represents BF4<->, PF6<->, (CF3SO2)2N<-> or CF3SO3<->. The imidazoles ionic liquid has lower melting point than a traditional alkyl imidazoles ionic liquid; moreover, introduction of methoxy alkyl allows the imidazoles ionic liquid to have a functionalizated ether bond, and the ability of the imidazoles ionic liquid to dissolve corresponding substances can be increased; at the same time, the imidazoles ionic liquid also has common advantages of ionic liquids. The invention also provides a preparation method of the imidazoles ionic liquid. The preparation method has the advantages of simple process, easily controlled reaction and higher product yield, and is suitable for industrialized production. In addition, the imidazoles ionic liquid has excellent electrochemical performance, and can be used for preparation of an electrolytic solution of a lithium ion battery.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Reversibly-activated nanostructured battery

InactiveUS20050208370A1Material nanotechnologyDeferred-action cellsNanostructureBiomedical engineering

A battery having a nanostructured battery electrode is disclosed wherein it is possible to reverse the contact of the electrolyte with the battery electrode and, thus, to return a battery to a reserve state after it has been used to generate current. In order to achieve this reversibility, the nanostructures on the battery electrode comprise a plurality of closed cells and the pressure within the enclosed cells is varied. In a first embodiment, the pressure is varied by varying the temperature of a fluid within the cells by, for example, applying a voltage to electrodes disposed within said cells. In a second illustrative embodiment, once the battery has been fully discharged, the battery is recharged and then the electrolyte fluid is expelled from the cells in a way such that it is no longer in contact with the battery electrode.

Owner:ALCATEL-LUCENT USA INC

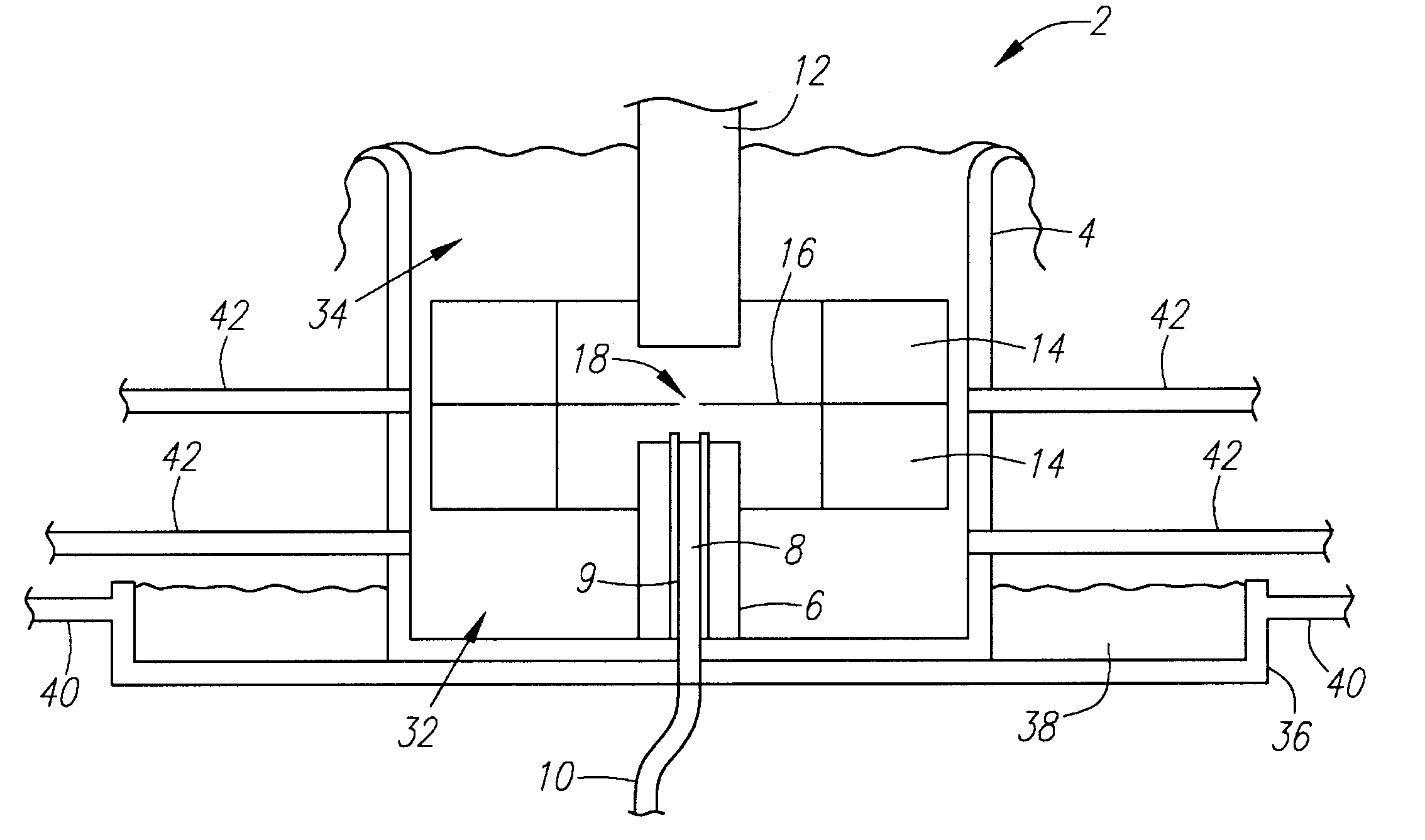

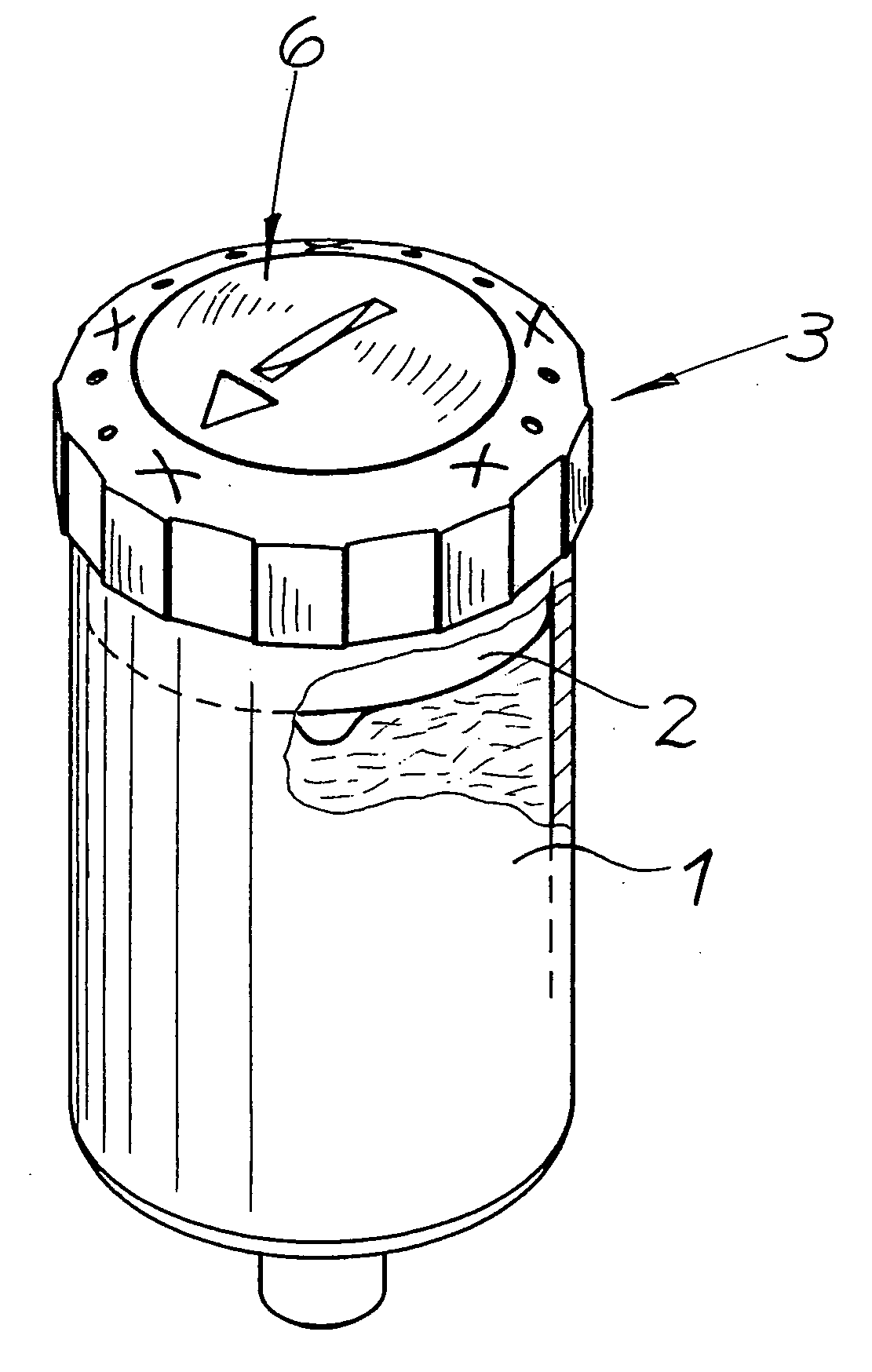

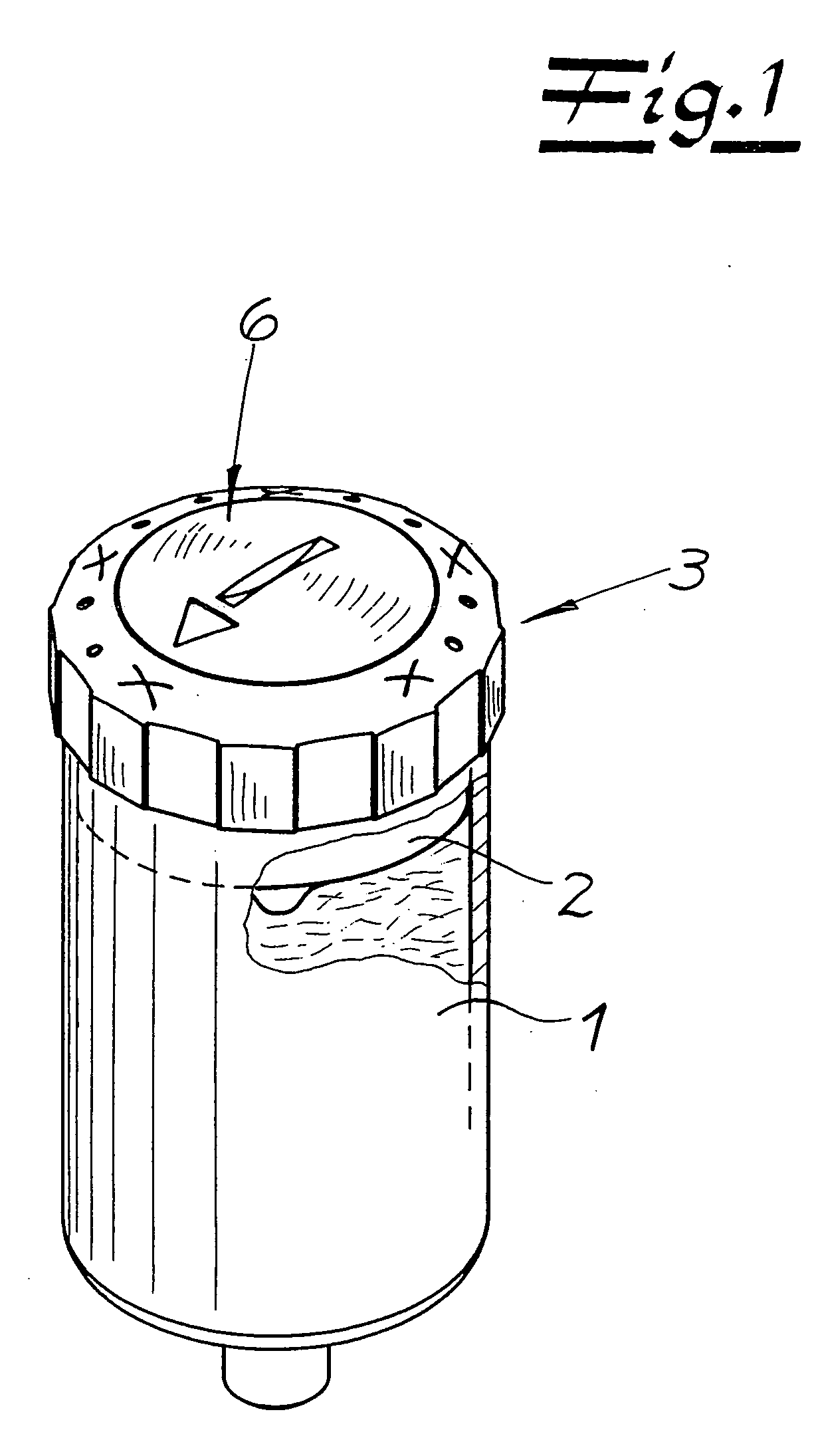

Lubricant dispenser

ActiveUS20060180395A1Reliable contactEasy to assembleLiquid transferring devicesLubricating pumpsElectricityElectrical connection

A lubricant dispenser includes a lubricant container that has an outlet opening for lubricant, a piston disposed in the lubricant container, and a cap connected with the lubricant container, having a device for generating a gas that impacts the piston. The device for gas generation has a gas cell with an electrolyte fluid and electrodes for electrochemical gas generation, a power source, as well as an electrical connection between the power source and the electrodes with a switch. The cap is a plastic injection-molded part produced in one piece, formed from several parts, using the multi-component injection-molding method, which part is made of an outer ring made of insulation material and an insert that forms the gas cell, having two electrically conductive wall regions as electrodes, as well as having an intermediate piece that separates the conductive regions. The insert contains a sponge saturated with electrolyte fluid, and is closed off with a plastic lid.

Owner:PERMA TEC

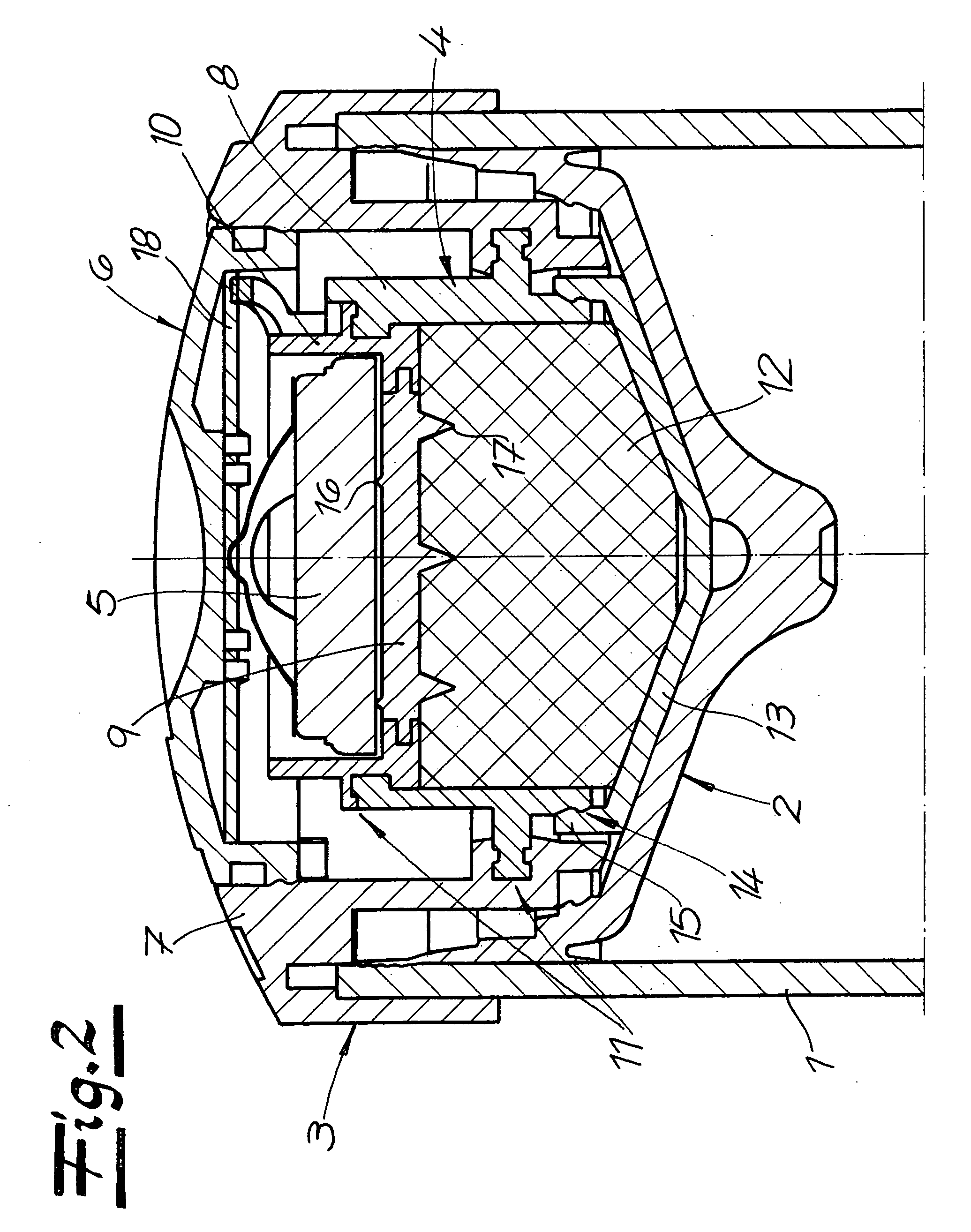

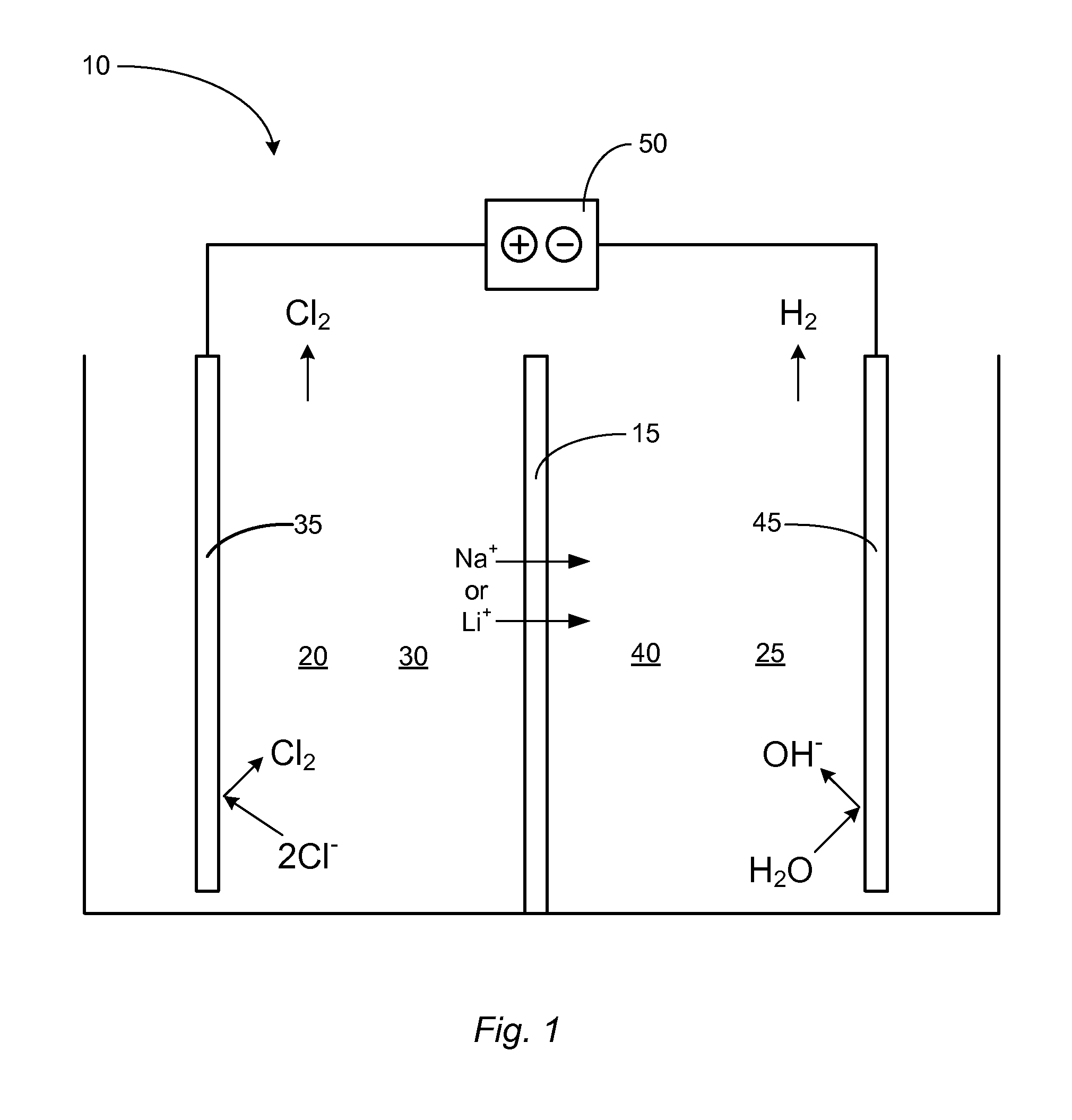

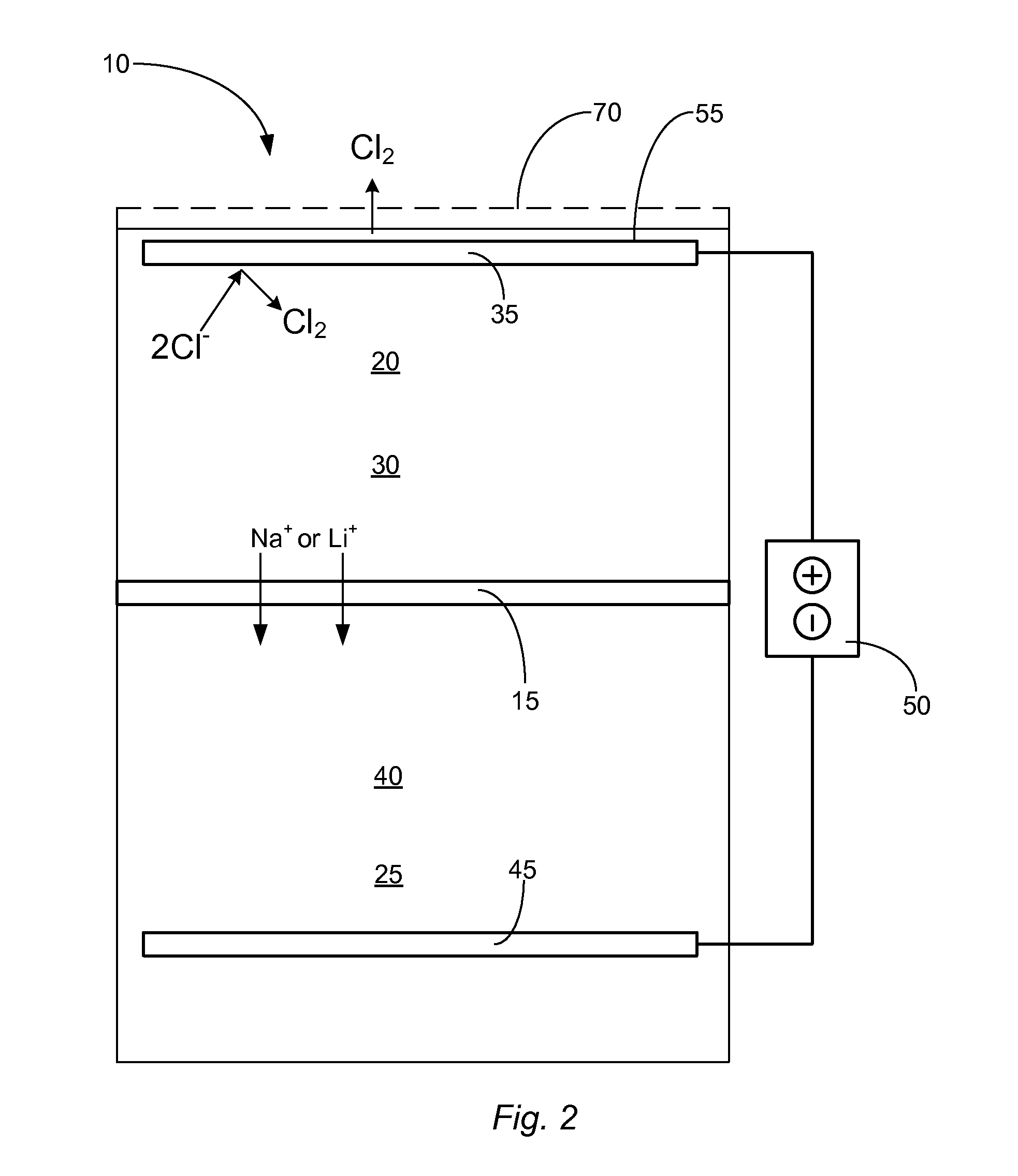

Control of ph kinetics in an electrolytic cell having an acid-intolerant alkali-conductive membrane

InactiveUS20120175267A1Reduce stressIncrease ratingsCellsPhotography auxillary processesAlkali ionsChemical reaction

Systems and methods for recovering chlorine gas or an alkali metal from an electrolytic cell having an acid-intolerant, alkali-ion-selective membrane are disclosed. In some cases, the cell has an anolyte compartment and a catholyte compartment with an acid-intolerant, alkali-ion selective membrane separating the two. While a cathode is disposed within a catholyte solution in the catholyte compartment, a chlorine-gas-evolving anode is typically disposed within an aqueous alkali-chloride solution in the anolyte compartment. As current passes between the anode and cathode, chlorine ions in the anolyte solution can be oxidized to form chlorine gas. In some cases, the cell is configured so the chlorine gas is rapidly removed from the cell to inhibit a chemical reaction between the chlorine gas and the anolyte solution. In some cases, a vacuum or a heating system is used to increase the rate at which chlorine gas exits the cell. Other implementations are also described.

Owner:CERAMTEC

Fuel for fuel battery, fuel battery, and power generating method using same

InactiveUS20070003803A1Low costAvoid shortingElectrolysis componentsCarbon compoundsElectrolysisFuel cells

A single cell comprising a fuel electrode, an air electrode, and an electrolytic layer or hollow layer interposed between those electrodes, or a fuel cell comprised of a stack of these single cells, wherein a supply port is formed on the fuel electrode side for supplying a hydrogen-based / oxygen-based mixed gas obtained by electrolyzing an electrolyte fluid by agitating and stirring and collecting the resulting gas; moreover the fuel electrode to which the hydrogen-based / oxygen-based mixed gas is supplied is gas-permeable. The hydrogen-based / oxygen-based mixed gas contains H, H2, H3, and / or HD, OH, 16O, and O2.

Owner:JAPAN TECH CO LTD (JP)

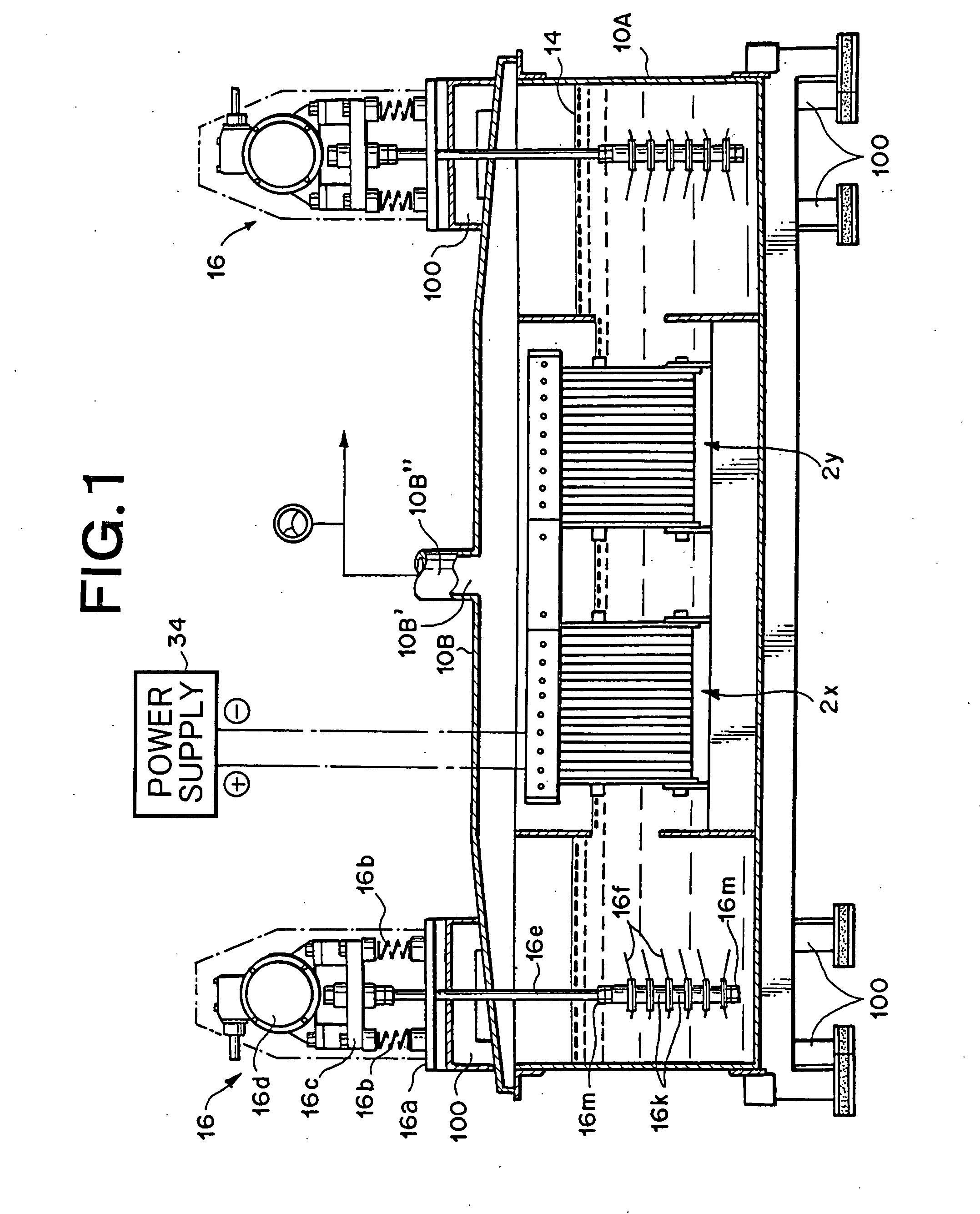

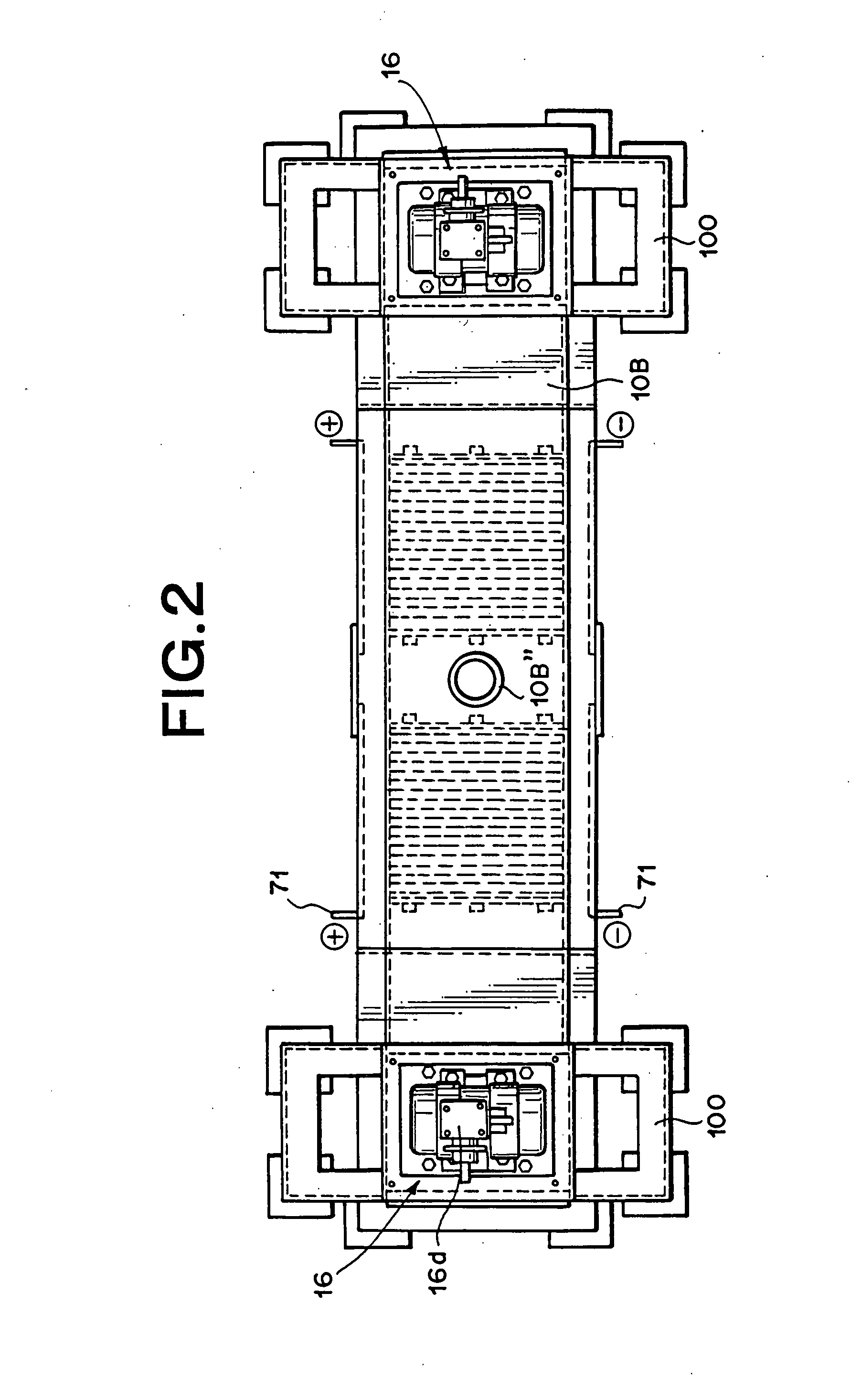

Hydrogen-oxygen gas generator and method of generating hydrogen-oxygen gas using the generator

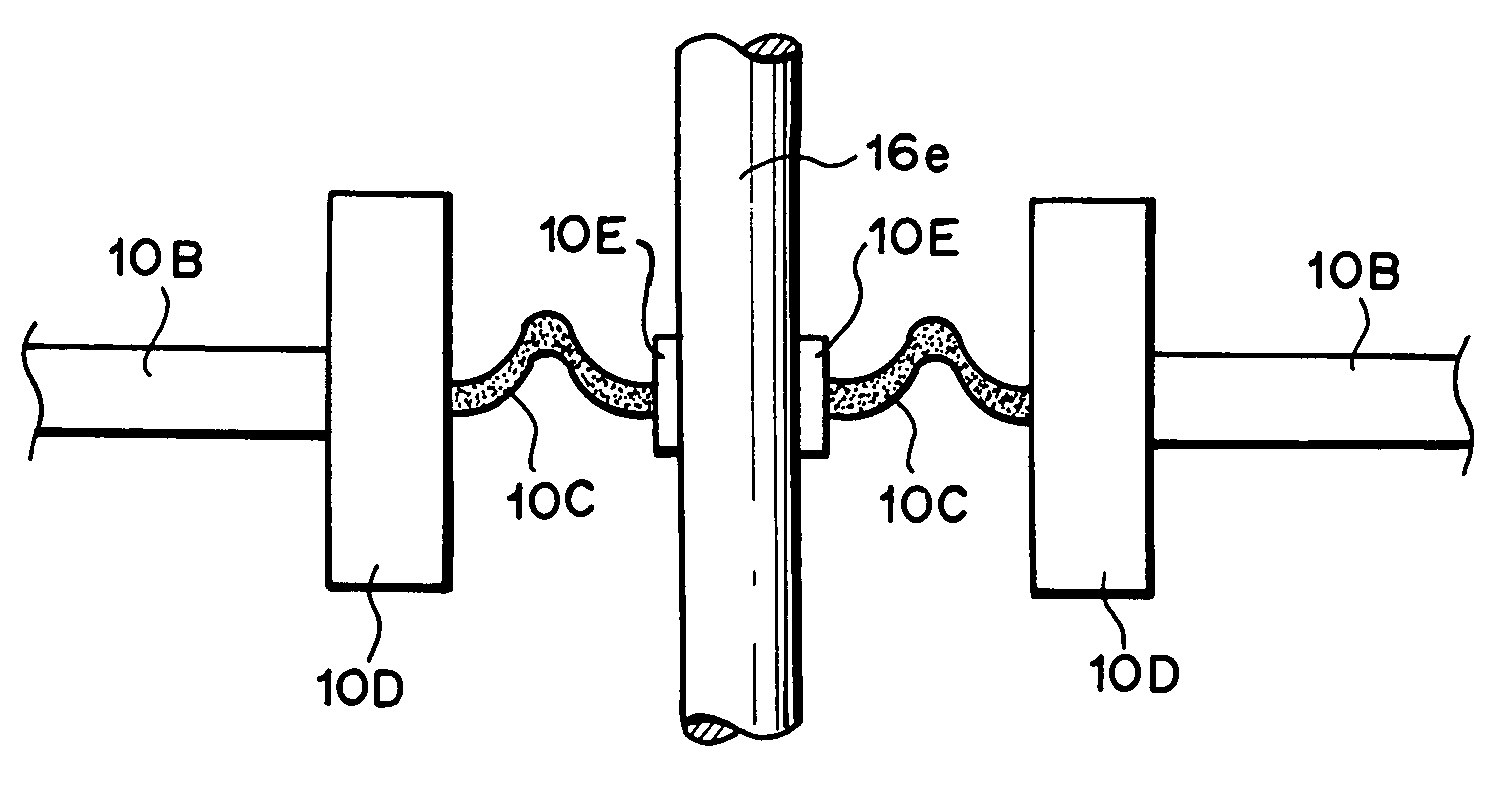

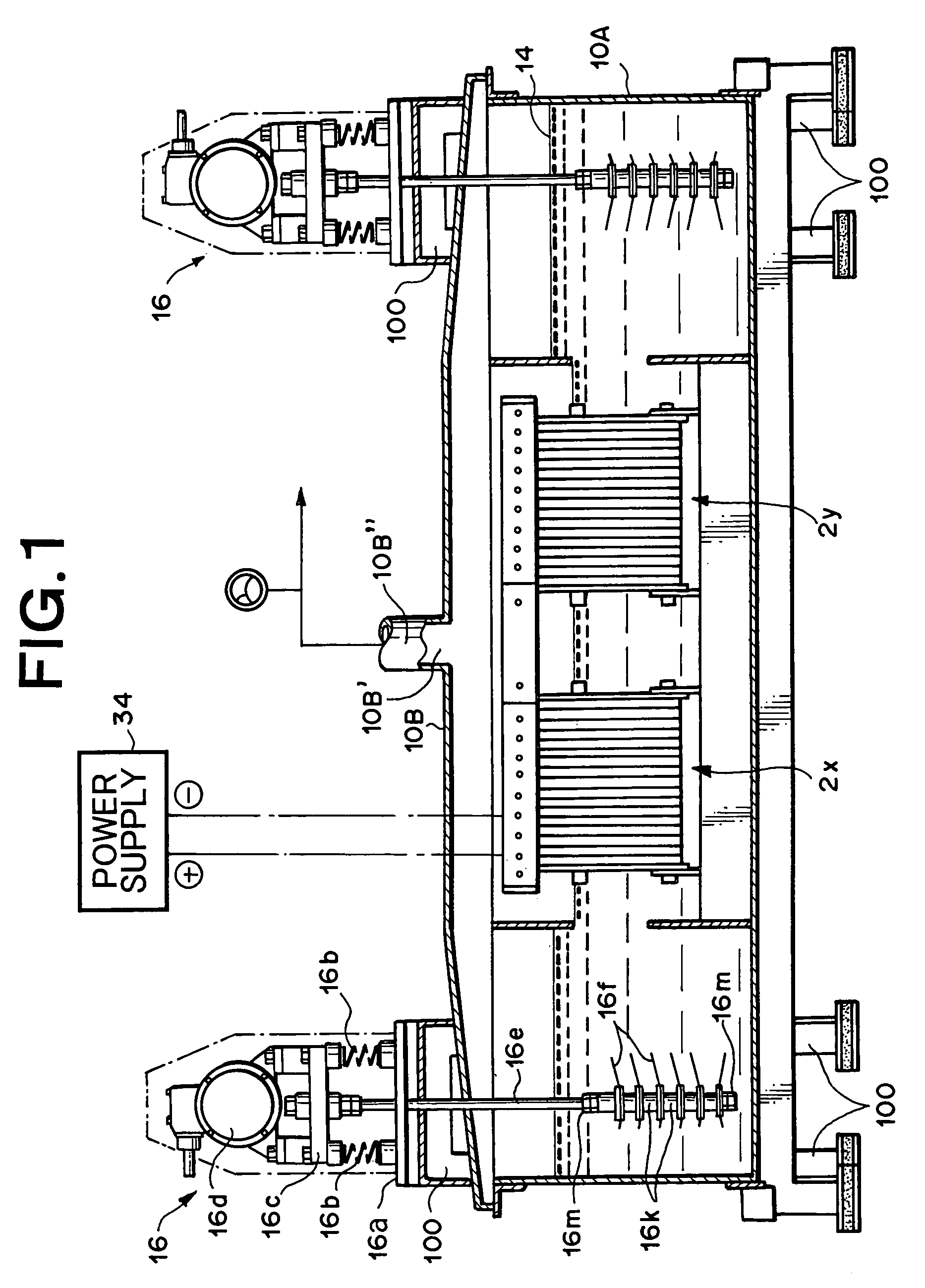

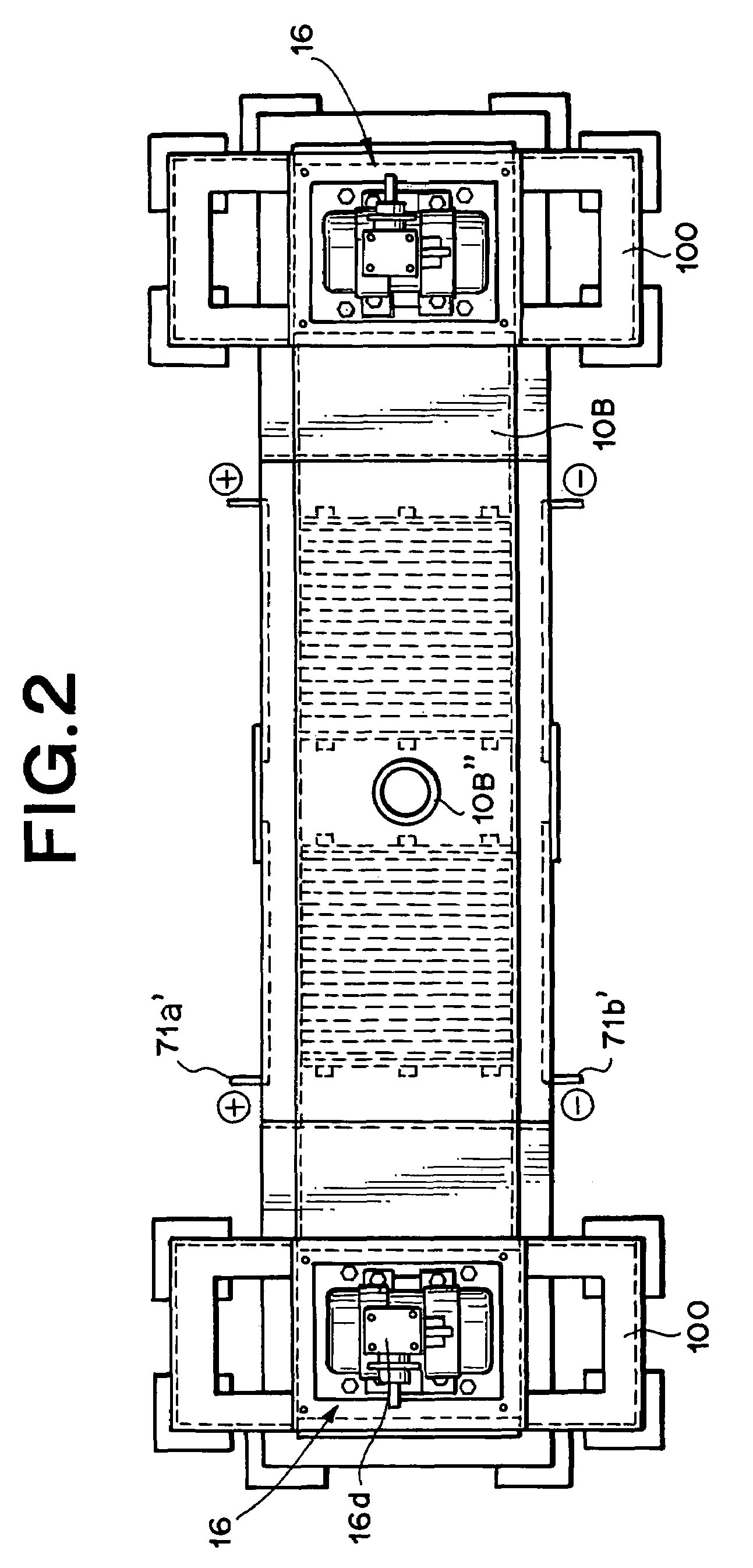

InactiveUS7459071B2Ample and satisfactory uniformityDissipate quicklyCellsPhotography auxillary processesHydrogenTrapping

A hydrogen-oxygen gas generator comprising an electrolytic cell, an electrode group formed from an anode and a cathode mutually installed in that electrolytic cell, a power supply for applying a voltage across the anode and cathode, a gas trapping means for collecting the hydrogen-oxygen gas generated by electrolyzing the electrolyte fluid and a vibration-stirring means. The gas trapping means is comprised of a lid member installed on the electrolytic cell, a hydrogen-gas extraction tube connecting to the hydrogen-oxygen gas extraction outlet of that lid member. A vibration-stirring means for stirring and agitating the electrolytic fluid is supported by support tables. The distance between the adjacent positive electrode and negative electrode within the electrode group is set within a range of 1 to 20 millimeters. The vibration-stirring means is comprised of vibrating motors vibrating at 10 to 200 Hertz, and vibrating blades vibrating within the electrolytic cell and unable to rotate are attached to a vibrating rod linked to the vibrating motors.

Owner:JAPAN TECH CO LTD (JP)

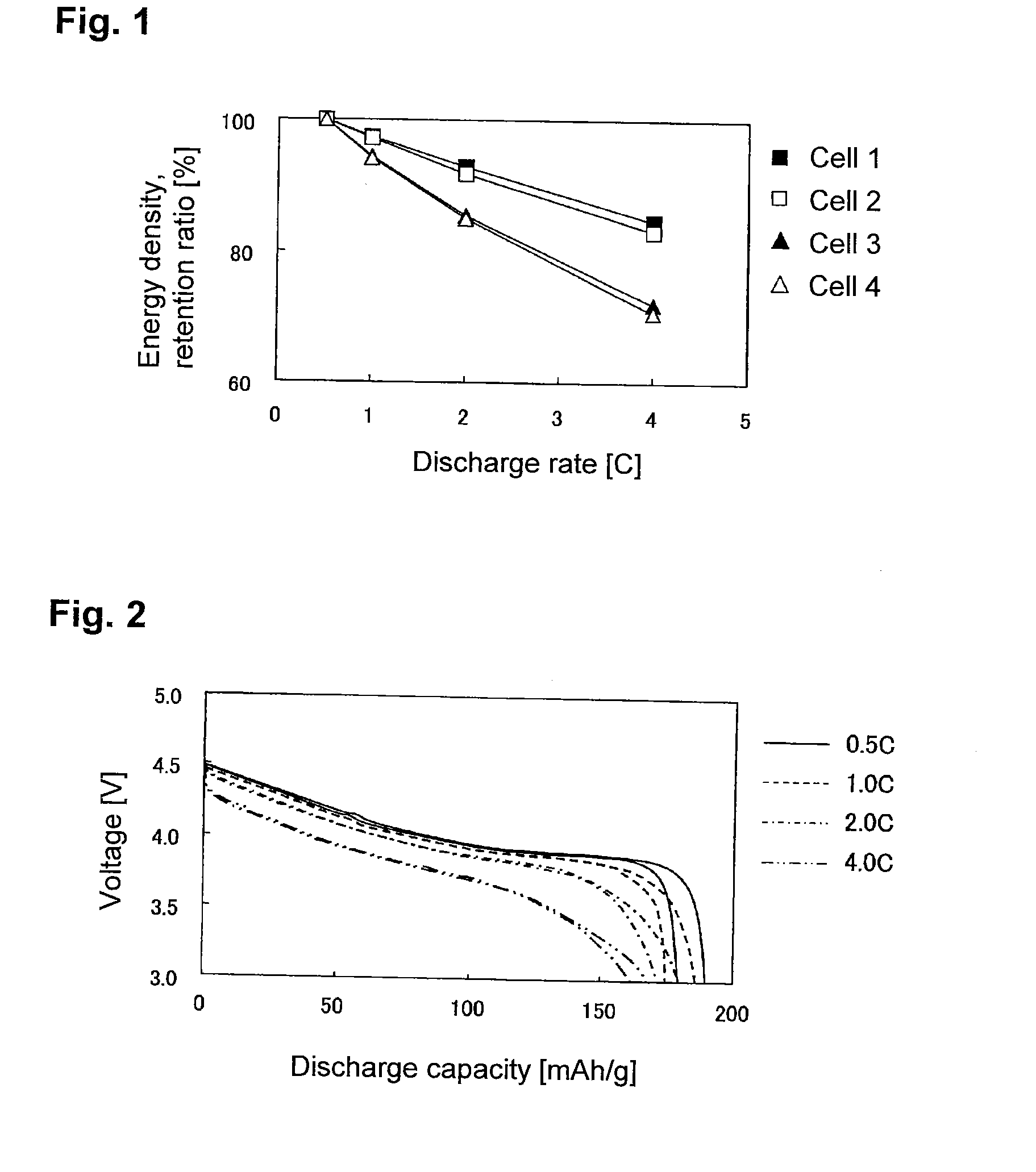

Non-aqueous electrolyte solution for secondary batteries, and secondary battery

InactiveUS20130108932A1Improve cycle performanceHigh rate charge/discharge propertiesOrganic electrolyte cellsSecondary cellsHigh rateElectrical battery

To provide a non-aqueous electrolyte solution for secondary batteries, which has a long term flame retardancy and which is excellent in cycle properties particularly under high voltage conditions and in high rate charge / discharge properties, and a secondary battery using such a non-aqueous electrolyte solution for secondary batteries. A non-aqueous electrolyte solution for secondary batteries, comprising a lithium salt and a solvent for dissolving the electrolyte salt, which comprises a specific hydrofluoroether, a specific ether compound and a specific carbonate compound, wherein the ratio (N0 / NLi) of the total number of moles (N0) of etheric oxygen atoms derived from the above ether compound to the total number of moles (NLi) of lithium atoms derived from the lithium salt, contained in the solvent for dissolving the electrolyte salt, is more than 1 and at most 6; and a secondary battery using such a non-aqueous electrolyte solution for secondary batteries.

Owner:ASAHI GLASS CO LTD

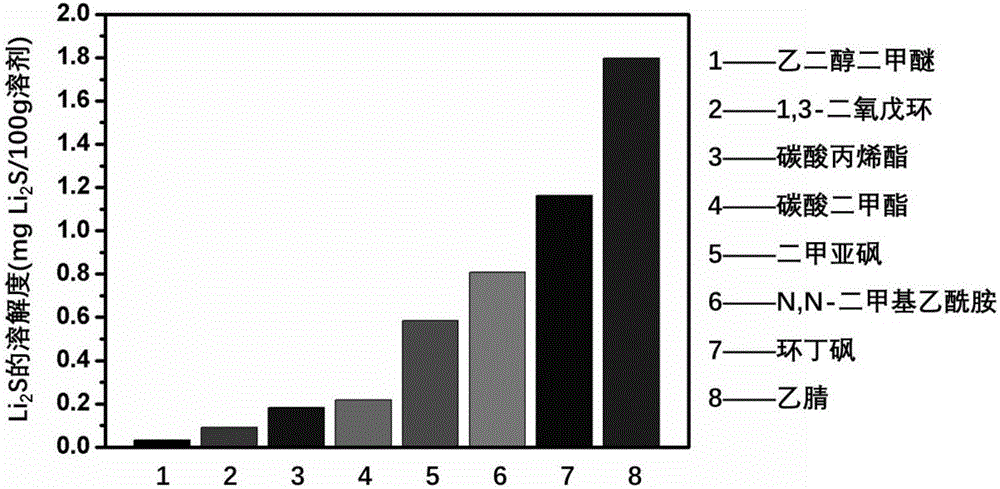

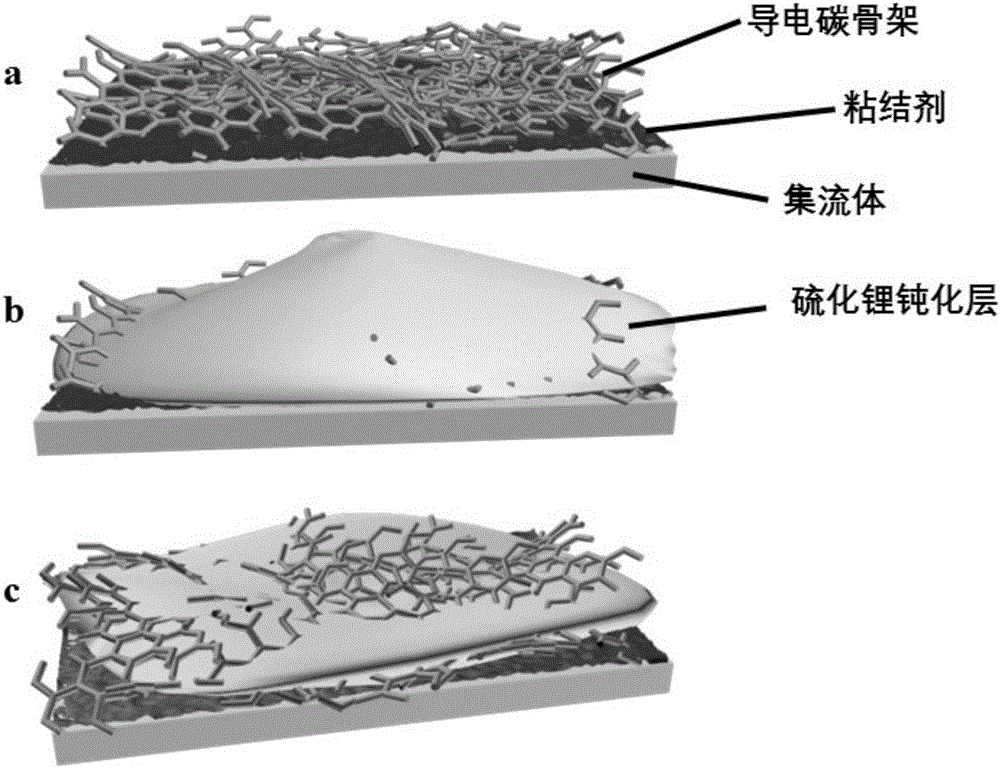

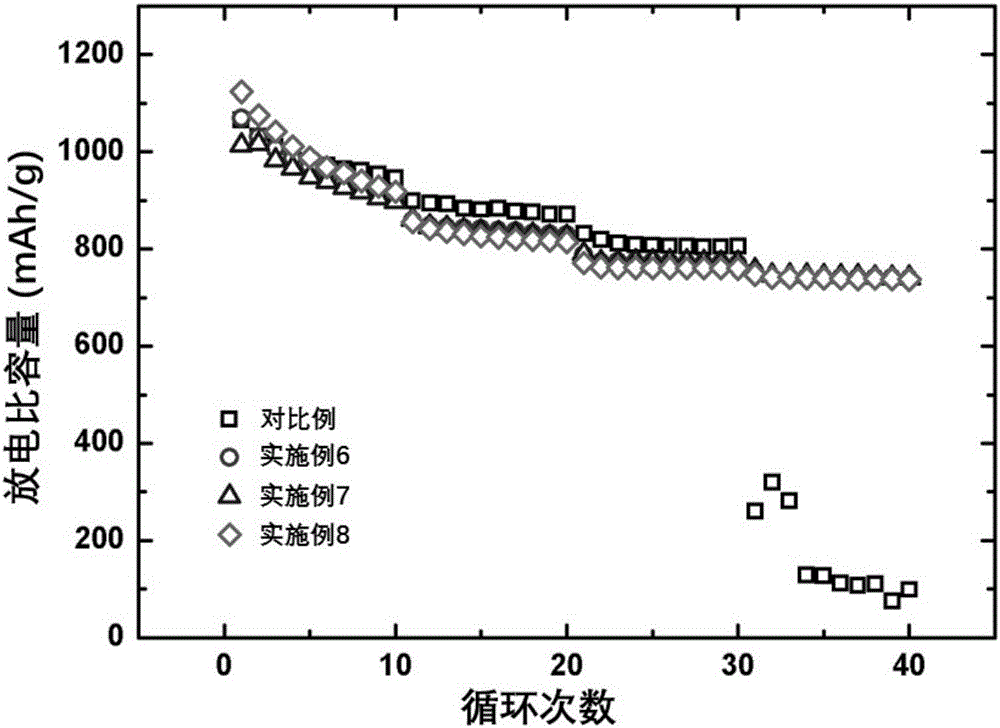

Electrolyte for lithium-sulfur battery containing sulfide solubilizer

ActiveCN106252726AUniform depositionReduce the precipitation rateLi-accumulatorsMaterial electrochemical variablesSolubilityAdhesive

The invention relates to an electrolyte for a lithium-sulfur battery containing a sulfide solubilizer. The electrolyte mainly comprises an electrolyte salt and an organic solvent, wherein the organic solvent comprises an ether organic solvent and the sulfide solubilizer. The invention discloses a determination method for the solubility of the sulfide in the organic solvent. The invention further discloses a composition method of the sulfide solubilizer. The invention provides the lithium-sulfur battery containing the electrolyte; a negative active material is a lithium metal or a lithium-containing alloy, a positive electrode is formed by alloying and ball-milling of the positive active material, a conductive agent and an adhesive at the ratio, and a positive active material is element sulfur or a sulfur-containing compound. The product provided by the invention has the advantages of being available in raw materials, simple in process and the like, and the rate capability of the lithium-sulfur battery can be improved.

Owner:NAT UNIV OF DEFENSE TECH

Secondary lithium battery and method for manufacturing the same

InactiveCN101431165AStable in natureReduce waterproof performance requirementsFinal product manufactureSmall-sized cells cases/jacketsOrganic solventLithium hydroxide

The invention relates to a lithium-ion secondary battery and a manufacturing method thereof. The battery comprises a positive electrode flake, a negative electrode flake, a diaphragm, electrolyte and a packaging shell body; positive electrode materials of the positive electrode flake comprise lithium salt with the positive electrode reversible extraction of lithium ions, a carbon conductive agent and a binding agent; the weight percentage of the three positive electrode materials is as follows, the lithium salt is 80 percent-98 percent, the carbon conductive agent is 0.5 percent-18.5 percent, and the binding agent is 1.5 percent-19.5 percent; negative electrode materials of the negative electrode flake comprise one of the lithium salt with the negative electrode reversible extraction of lithium ions, oxides with reversible extraction of lithium ions and sulfides with reversible extraction of lithium ions or the combination thereof, the carbon conductive agent and the binding agent; the weight percentage of the three negative electrode materials is as follows, the lithium salt is 80 percent-98 percent, the carbon conductive agent is 0.5 percent-18.5 percent, and the binding agent is 1.5 percent-19.5 percent; the electrolyte of electrolyte fluid is soluble lithium salt or lithium hydroxide which can not react with water, and the solvent is water or the organic solvent. The method comprises the steps of producing and packaging the positive and the negative electrode flakes, the diagram, the electrolyte and a battery cell and into the shell. The invention reduces the manufacturing difficulty and the production cost of the lithium-ion secondary batteries and expands the types and the scope of application of the lithium-ion secondary batteries.

Owner:耀安电池电源科技(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com