High performance super capacitor and manufacturing process thereof

A supercapacitor and manufacturing process technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of increased cycle life, reduced equivalent series internal resistance, insufficient assembly process control, etc., to achieve high mixing effect, short mixing time, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

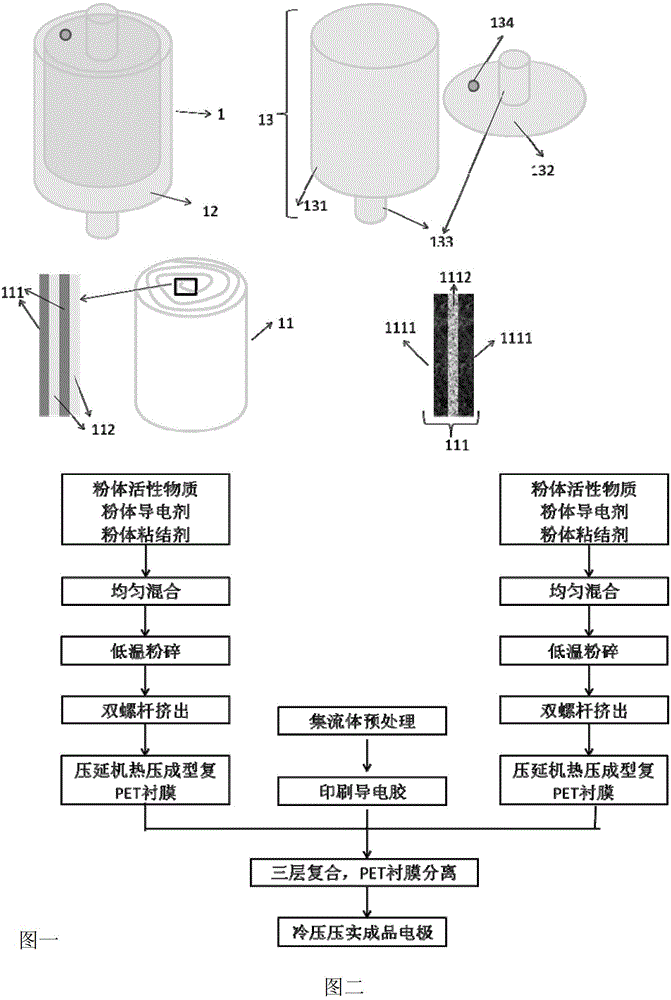

[0053] A method for fabricating high-performance supercapacitors, such as Figure 1 As shown in the example of the invention, the supercapacitor 1 is a winding cylindrical supercapacitor with a capacity of 3000F and a voltage of 2.7V. 112 is wound in four layers, and the positive and negative pole pieces 111 have a three-layer sandwich structure of electrode film 1111 / collector 1112 coated with conductive adhesive / electrode film 1111; the electrolyte 12 is an organic electrolyte; the shell 13 includes a tank Body 131, end cap 132, electrode lead-out 133 and liquid injection hole 134.

[0054] Invention example of 3000F 2.7V winding cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com