Method for manufacturing electrospinning of high-performance polyarylether resin lithium battery diaphragm

A lithium battery diaphragm, high-performance technology, applied in the direction of battery pack components, circuits, electrical components, etc., can solve the problem of battery self-closing performance degradation, and achieve good self-closing performance, good wetting performance, and excellent heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

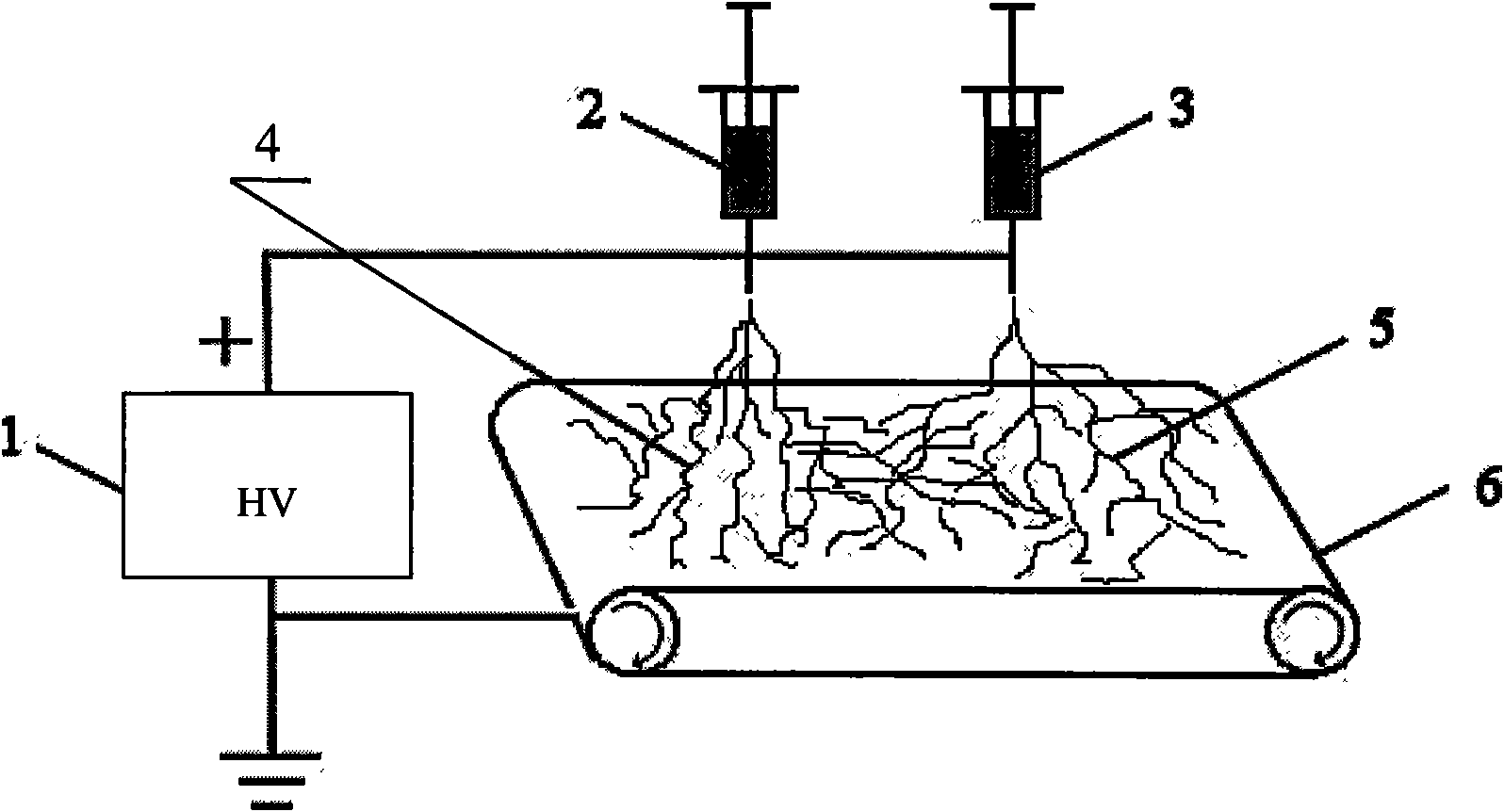

Embodiment 1

[0021] Polyarylether sulfone ketone (PPESK) was dissolved in N, N-dimethylacetamide (DMAc) to prepare a solution with a concentration of 20 wt%. Polyvinylidene fluoride (PVDF) was dissolved in N-methylpyrrolidone (NMP) solvent to prepare a solution with a concentration of 25 wt%. Put the above two solutions into different syringe pumps 2 and 3 of the electrospinning equipment respectively, and connect the nozzle of the syringe pump to one pole of the high-voltage power supply through a wire, and a pole on the other side about 15 cm away from the syringe pump. A metal roller electrode connected to the other pole of the high-voltage power supply acts as a collection device. Slowly increase the voltage of the power supply 1 to 25KV. Under the action of the high voltage, the two solutions are sprayed out from their respective injection pump nozzles. The high-performance polyarylether resin fiber 4 and the general engineering resin fiber 5 are collected in the form of non-woven On...

Embodiment 2

[0024] Polyaryletherketone (PEK-C) was dissolved in dichloromethane to prepare a solution with a concentration of 12 wt%. Polyacrylonitrile (PAN) was dissolved in N,N-dimethylacetamide (DMAC) solvent to prepare a solution with a concentration of 10 wt%. Put the above two solutions into different syringe pumps 2 and 3 of the electrospinning equipment respectively, and connect the nozzle on the syringe pump to one pole of the high-voltage power supply through a wire, and the other side about 10 cm away from the syringe pump is A flat metal electrode connected to the other pole of the high-voltage power supply serves as a collecting device. Slowly increase the voltage of power supply 1 to 20KV. Under the action of high voltage, the two solutions are ejected from the nozzles of their respective syringe pumps. High-performance polyarylether resin fibers 4 and general-purpose engineering resin fibers 5 are collected in the form of non-woven fabrics. On the metal collection device 6...

Embodiment 3

[0027] Polyether ketone (PPEK) was dissolved in N-methylpyrrolidone (NMP) to prepare a solution with a concentration of 15 wt%. Polymethyl methacrylate (PMMA) was dissolved in N,N-dimethylacetamide (DMAc) solvent to prepare a solution with a concentration of 10 wt%. Put the above two solutions into different syringe pumps 2 and 3 of the electrospinning equipment respectively, and connect the nozzle of the syringe pump to one pole of the high-voltage power supply through a wire, and a pole on the other side about 20 cm away from the syringe pump. A metal mesh electrode connected to the other pole of the high-voltage power supply acts as a collection device. Slowly increase the voltage of the power supply 1 to 23KV. Under the action of the high voltage, the solution is ejected from the nozzle of the syringe pump with high-performance polyarylether resin fibers 4 and general-purpose engineering resin fibers 5, which are collected in the form of non-woven fabrics in the metal coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com