Control method of guillotine shear hydraulic system

A technology of a hydraulic system and a control method, applied in the field of hydraulic presses, can solve the problems of bulky and heavy equipment, reduced equipment stability, and high production costs, and achieves the effects of sensitive system action, compact structure and fewer pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

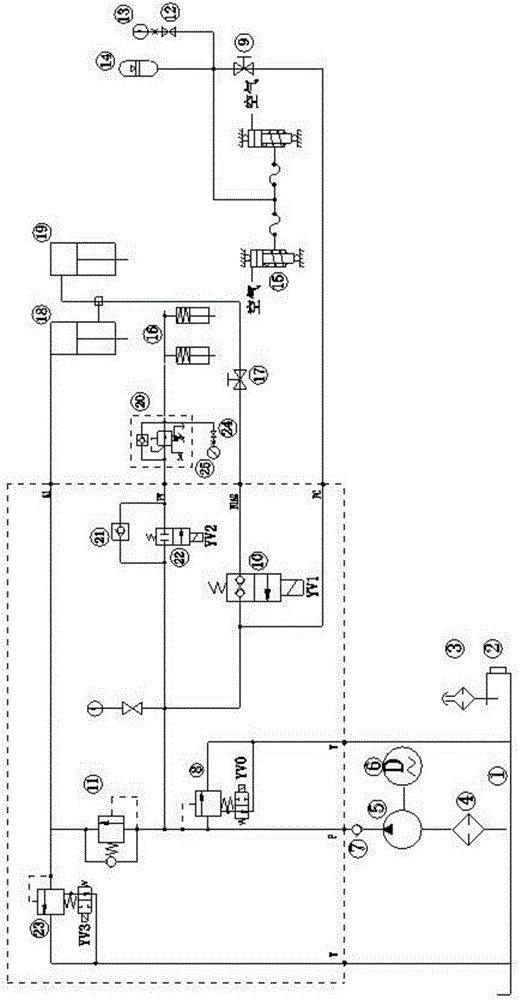

[0049] Such as figure 1 As shown, the hydraulic system of a gate-type shearing machine in this embodiment includes an oil tank 1, an oil pump 5, an electromagnetic overflow valve I8, an on-off valve 10, a sequence valve 11, an accumulator 14, a return cylinder 15, and a pressure cylinder 16. Main oil cylinder 18, auxiliary oil cylinder 19 and check valve II 21. Wherein, the piston rods of the main oil cylinder 18 and the auxiliary oil cylinder 19 are connected to the knife rest, and are used to drive the knife rest to move downward to complete the shearing of the plate. The auxiliary oil cylinder 19 adopts a plunger cylinder, and the return oil cylinder 15 is connected with the knife rest. It is used to drive the tool holder upward to make a return movement.

[0050] The oil tank 1 is equipped with a liquid level gauge 2 to monitor the liquid level in real time to prevent insufficient hydraulic oil and to replenish it in time. The oil tank 1 communicates with the air through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com