Magnetic field control type additive forming method and device adopting electric arc robot

An arc robot and additive forming technology, which is applied in the field of additive manufacturing, can solve problems such as difficulty in controlling the surface quality of formed parts, poor stability control of the welding process, etc., and achieve good additive manufacturing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

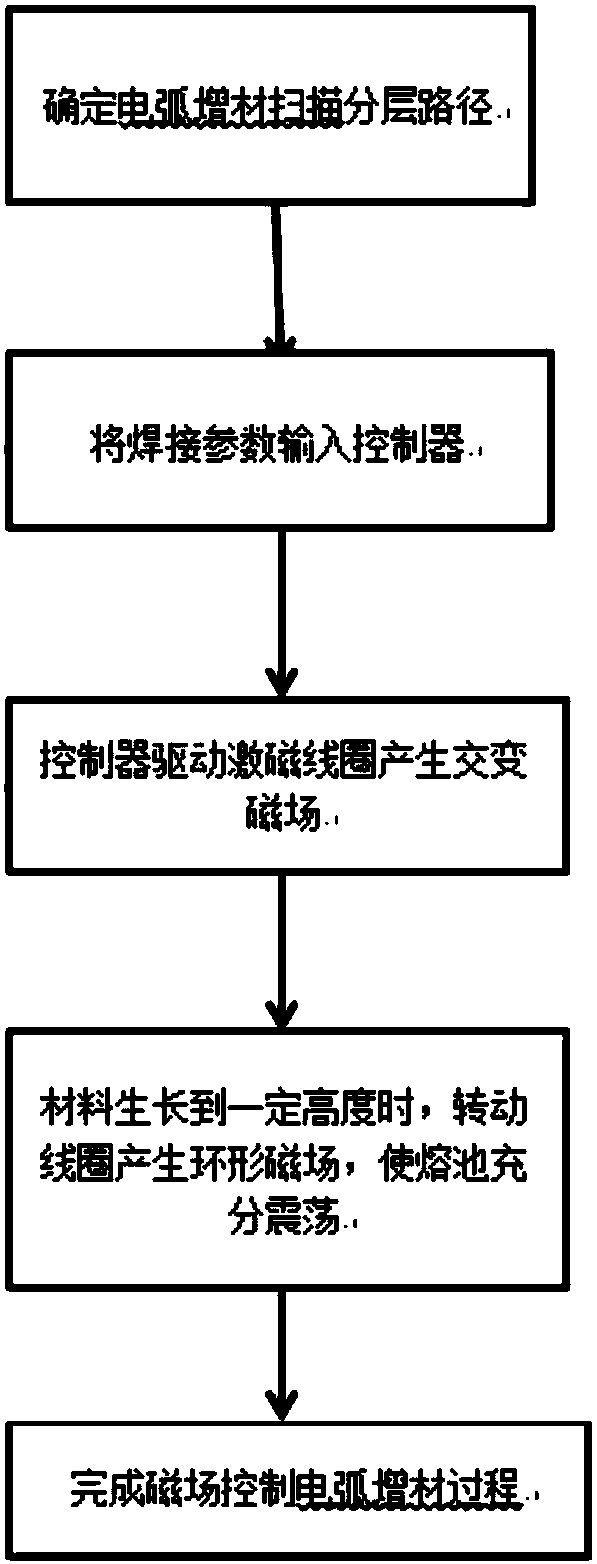

Image

Examples

Embodiment Construction

[0034] In order to express the manufacturing advantages of the present invention more clearly, the present invention will be further described below in conjunction with specific examples.

[0035] The following examples serve to illustrate the invention, but do not limit it thereto. The details and working conditions of the method and device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] In conjunction with the accompanying drawings, the magnetic field controlled arc robot additive forming method and equipment of the present invention include a mechanical and control system composed of a robot and a positioner, and a welding system composed of a welding power supply, an arc controller, a wire feeder, and a welding torch. And a magnetic field generating device, an AC power supply and a controller 3 . The magnetic field generating device includes a symmetrical excitation coil 2 and a hollow shaft motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com