Device and method for measuring melt height of melting furnace

A measuring device and molten material technology, applied in the direction of measuring device, inspection device, lubrication indicator device, etc., can solve problems such as furnace breakage, furnace overflow, charge leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the melt height measuring apparatus and method of the furnace of the preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

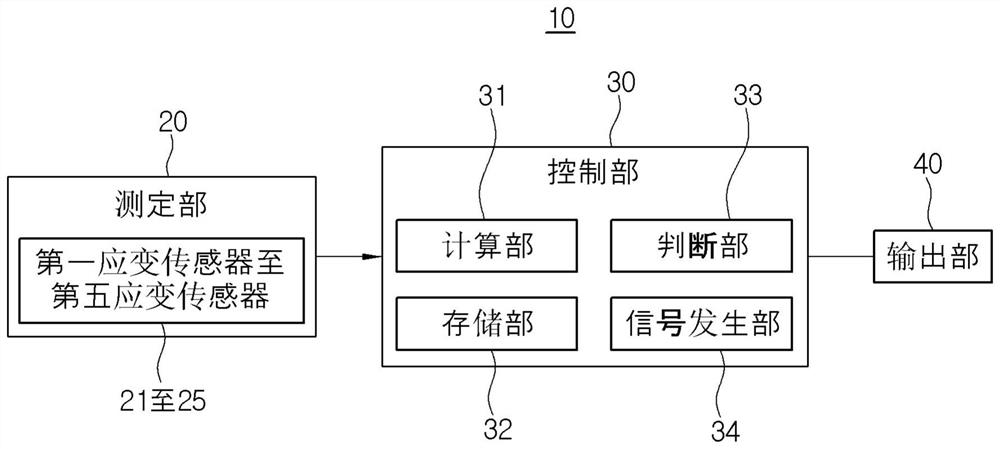

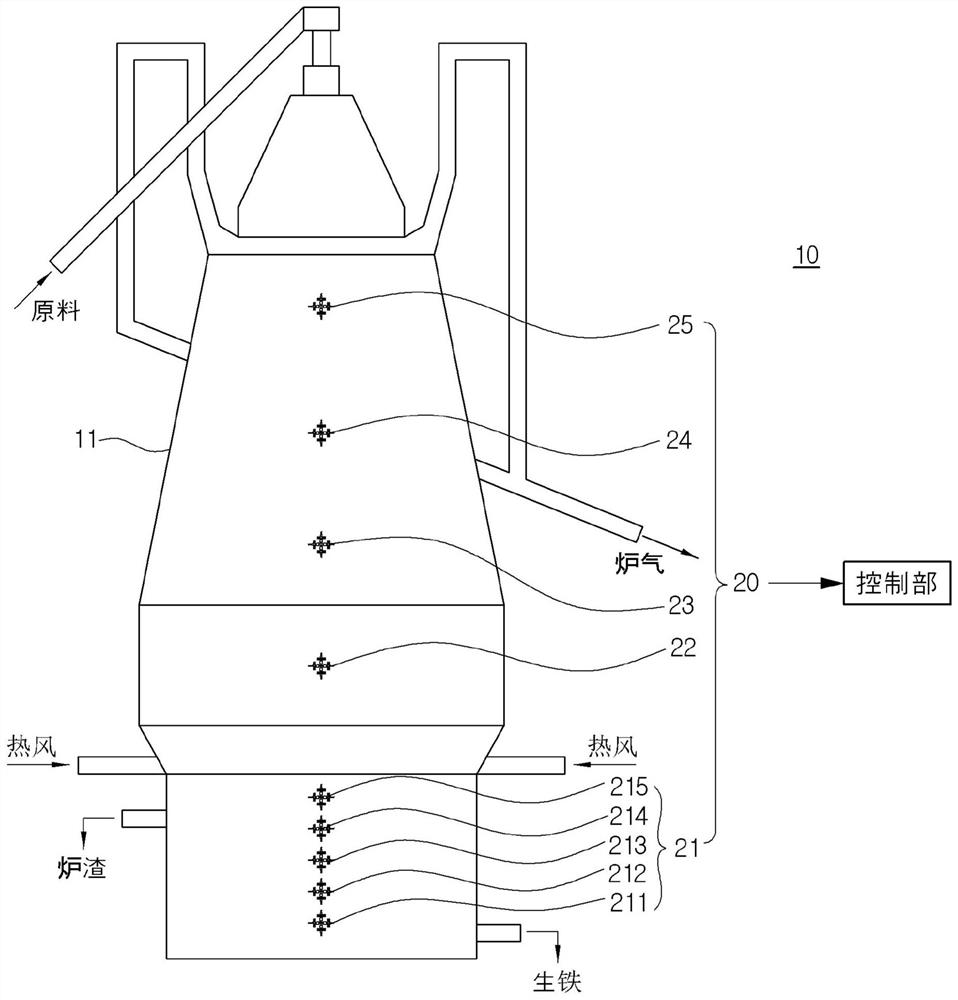

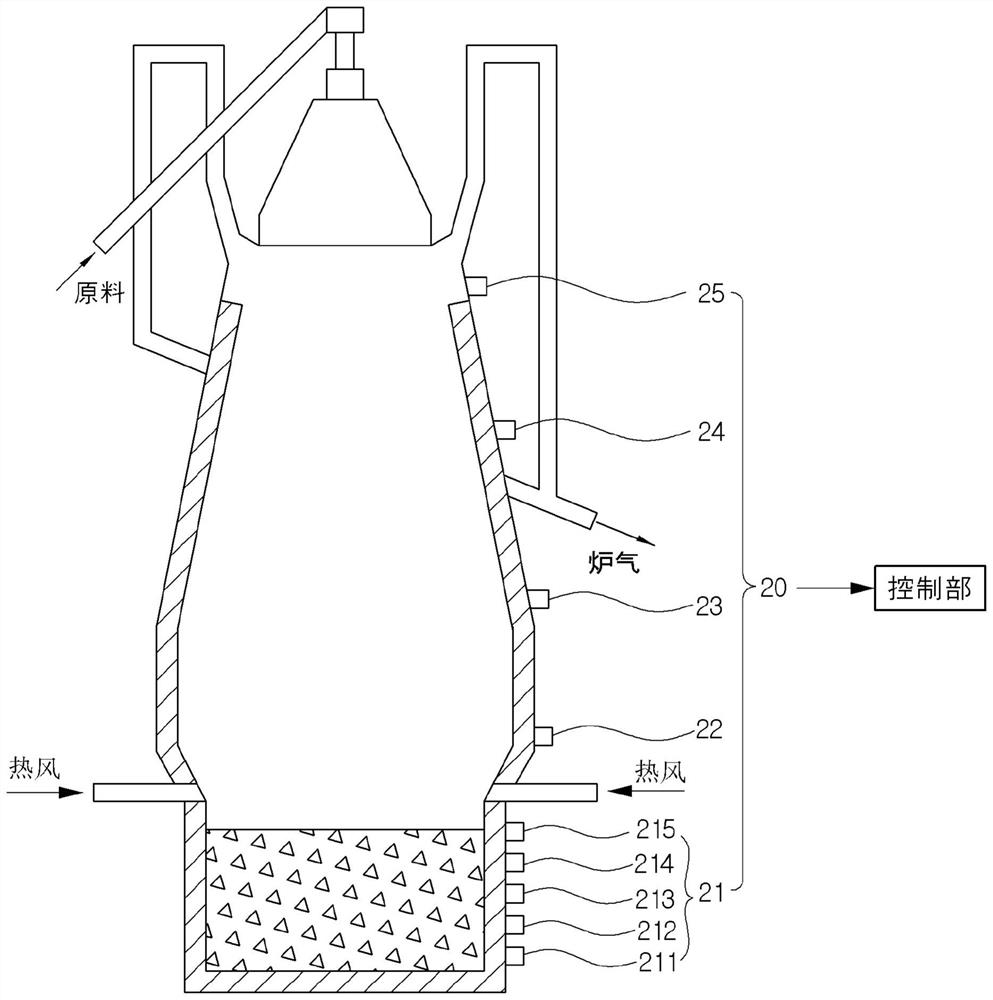

[0032] figure 1 A structural diagram of a height measuring apparatus for a furnace of a preferred embodiment of the present invention. figure 2 and image 3 A view showing the configuration of a measuring portion provided in the furnace.

[0033] figure 2 A main view of the furnace provided with the measurement unit, image 3 A side cross-sectional view of the furnace is shown.

[0034] Hereinafter, the term "left", "right", "front", "rear", "above" and "lower", in the indication direction, in each of the states shown in each of the figures.

[0035] The present invention determines based on the temperature and vertical deforities of the temperature of the melt to the furnace, the horizontal direction deformed and the vertical direction of the furnace surface of the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com