Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

245results about How to "Avoid human involvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast Fisheye Image Correction Method for Panoramic Parking Assist System

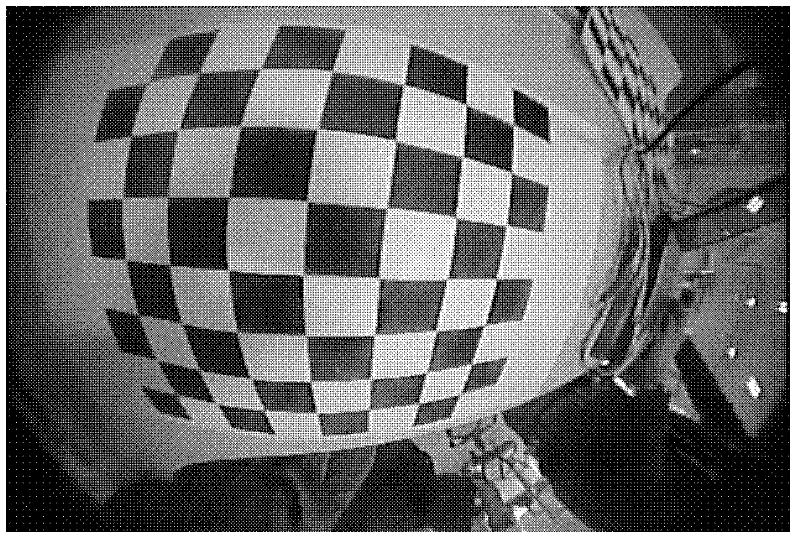

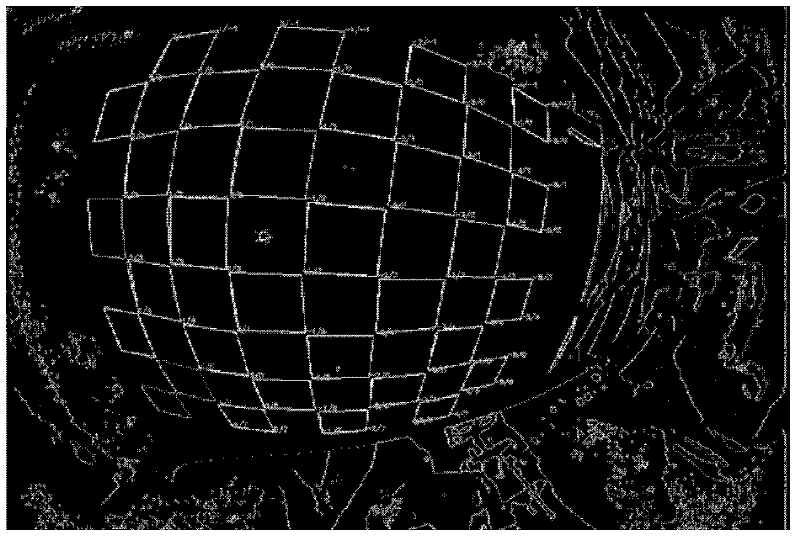

InactiveCN102298771AAvoid human involvementEdge distortion is not obviousImage enhancementOptical viewingDistortion correctionCorrection method

The invention discloses a method for quickly correcting a fisheye image of a panoramic parking assistance system, which comprises the following steps: (1) constructing a black and white checkerboard using an adaptive Harris algorithm; (2) constructing a fisheye using the constraints of spherical perspective projection The mapping relationship between the image point and the spherical correction image point; (3) expand the spherical correction image point into a plane latitude and longitude image point according to the latitude and longitude expression; (4) store the fisheye image point and its corresponding plane latitude and longitude image point (5) According to the mapping table, the bilinear interpolation algorithm is used to correct the fisheye image points in real time. Therefore, the present invention has the characteristics of automatic calibration for the first time, can quickly correct fisheye distortion after calibration, has good versatility, avoids cumbersome steps and manual intervention, and is suitable for use in products. At the same time, it has the characteristics of fast correction speed and meets real-time requirements.

Owner:HUAIAN YINGKE WEILI TECH

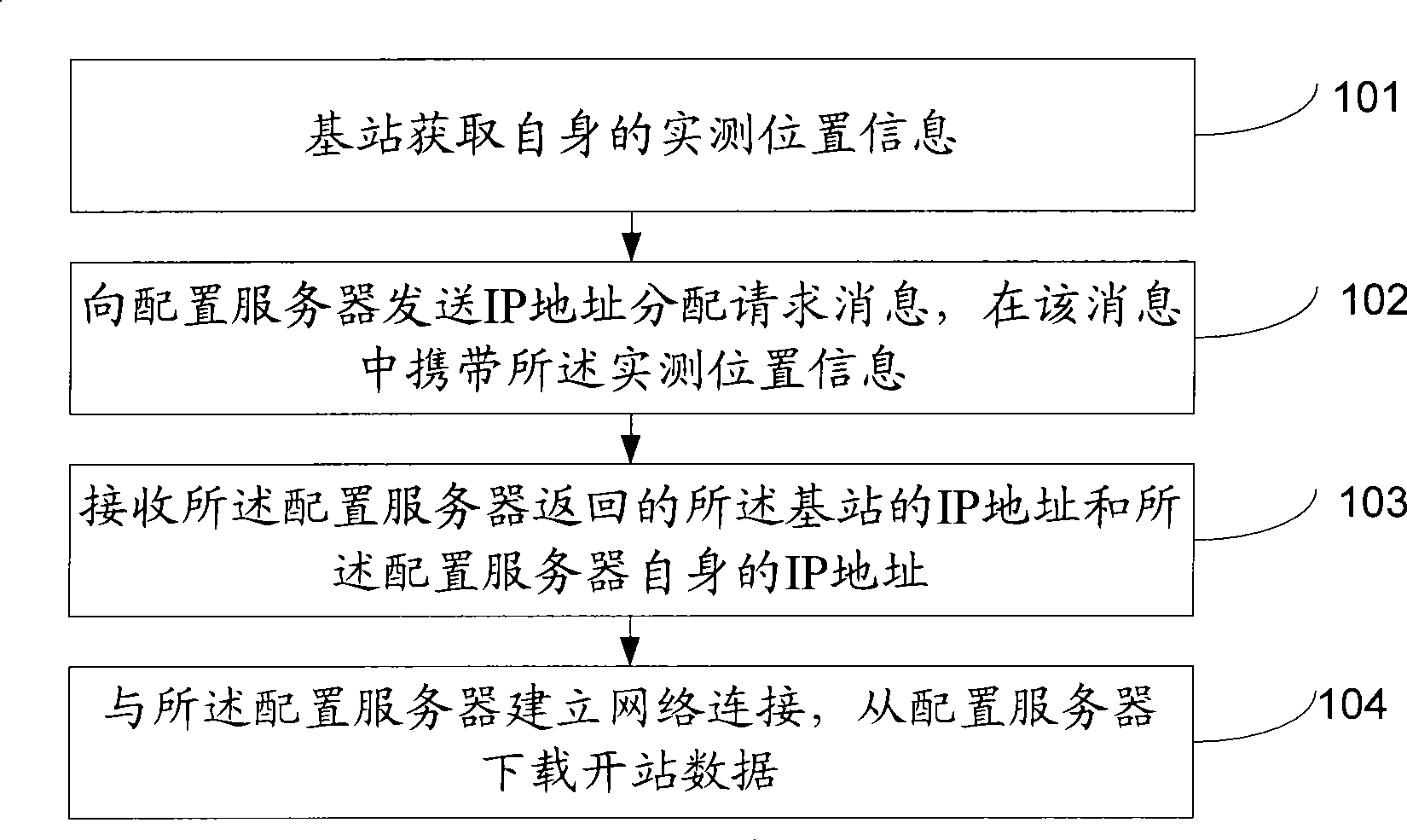

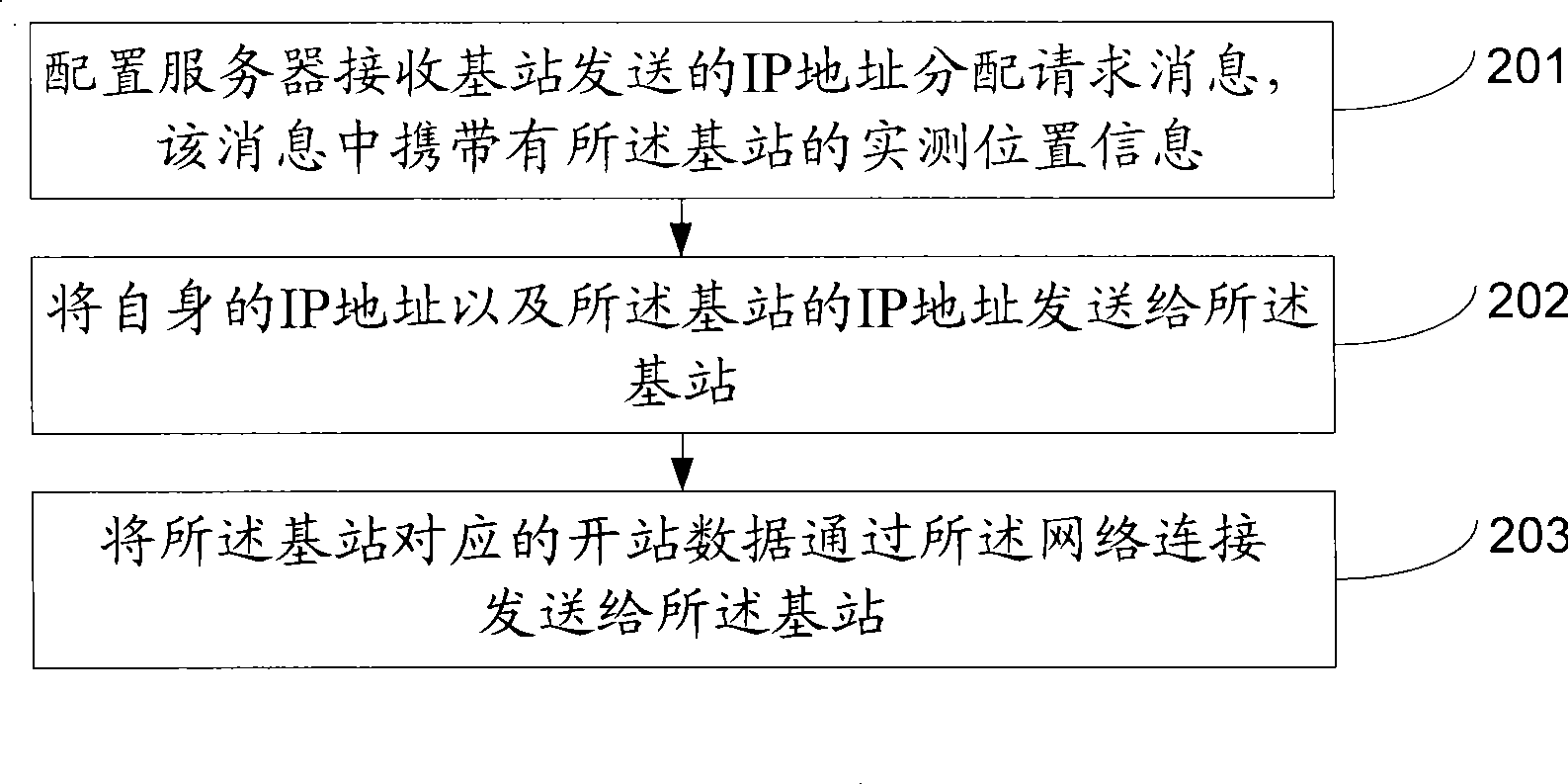

Method, equipment and system for obtaining and sending public station data

ActiveCN101437327AImprove acquisition efficiencyAvoid human involvementWireless communicationIp addressNetwork connection

The invention discloses a method for acquiring and sending open station data, equipment and a system thereof. The method for acquiring the station data comprises the following steps: a base station acquires actually self measured position information; the base station sends IP address allocation requesting message to a configured server, and the message carries the actually-measured position information; the base station receives the IP address of the base station and IP address of the configured server which are returned by the configured server, and the IP address of the base station is acquired by the configured server according to the actually-measured position information; the base station utilizes the IP address of the base station and the IP address of the configured server to establish network connection of the configured server, and downloads open station data from the configured server. Through the method, the base station of the deployment position can automatically establish network connection with the configured server for obtaining the open station data so as to avoid manual involvement when obtaining the open station data in the process of opening station and improve efficiency of acquiring the open station data.

Owner:SHANGHAI HUAWEI TECH CO LTD

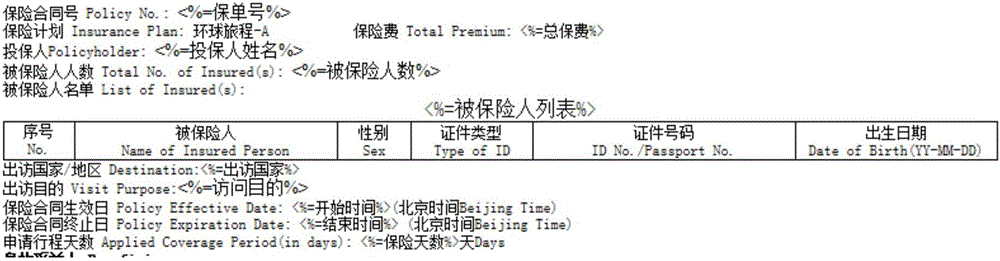

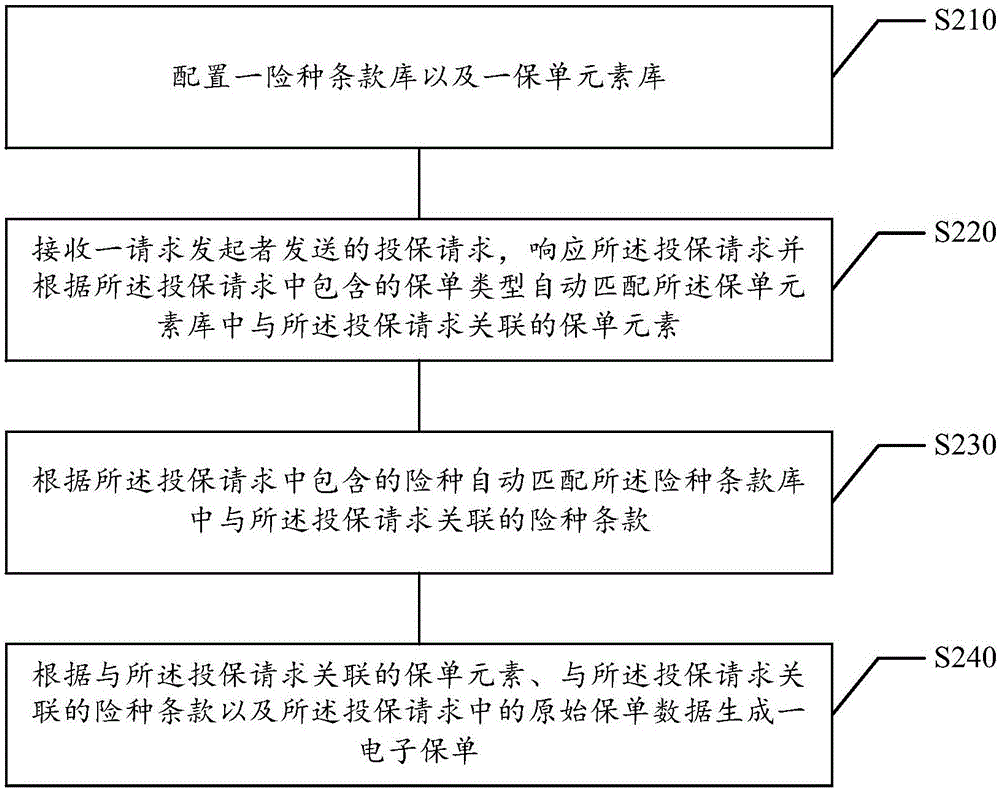

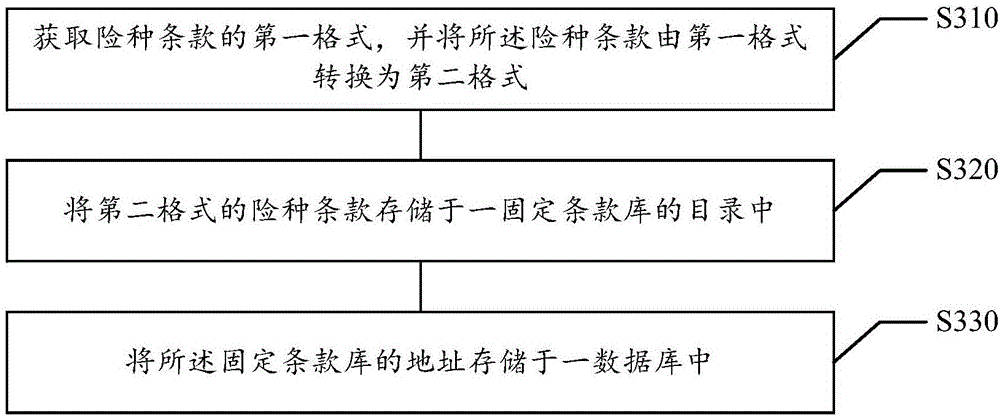

Insurance policy generating method and device

ActiveCN106600428AImprove readabilityReduce satisfactionFinanceBuying/selling/leasing transactionsTime costComputer science

The invention relates to an insurance policy generating method and an insurance policy generating device. The insurance policy generating method comprises the steps of: configuring an insurance type clause library and an insurance policy element library; receiving an insurance request sent by a request initiator, responding to the insurance request and automatically matching insurance policy elements associated with the insurance request in the insurance policy element library according to an insurance policy type contained in the insurance request; automatically matching insurance type clauses associated with the insurance request in the insurance type clause library according to insurance types contained in the insurance request; and generating an electronic insurance policy according to the insurance policy elements associated with the insurance request, the insurance type clauses associated with the insurance request and original insurance policy data in the insurance request. The insurance policy generating method can reduce the time cost.

Owner:TAIKANG LIFE INSURANCE CO LTD

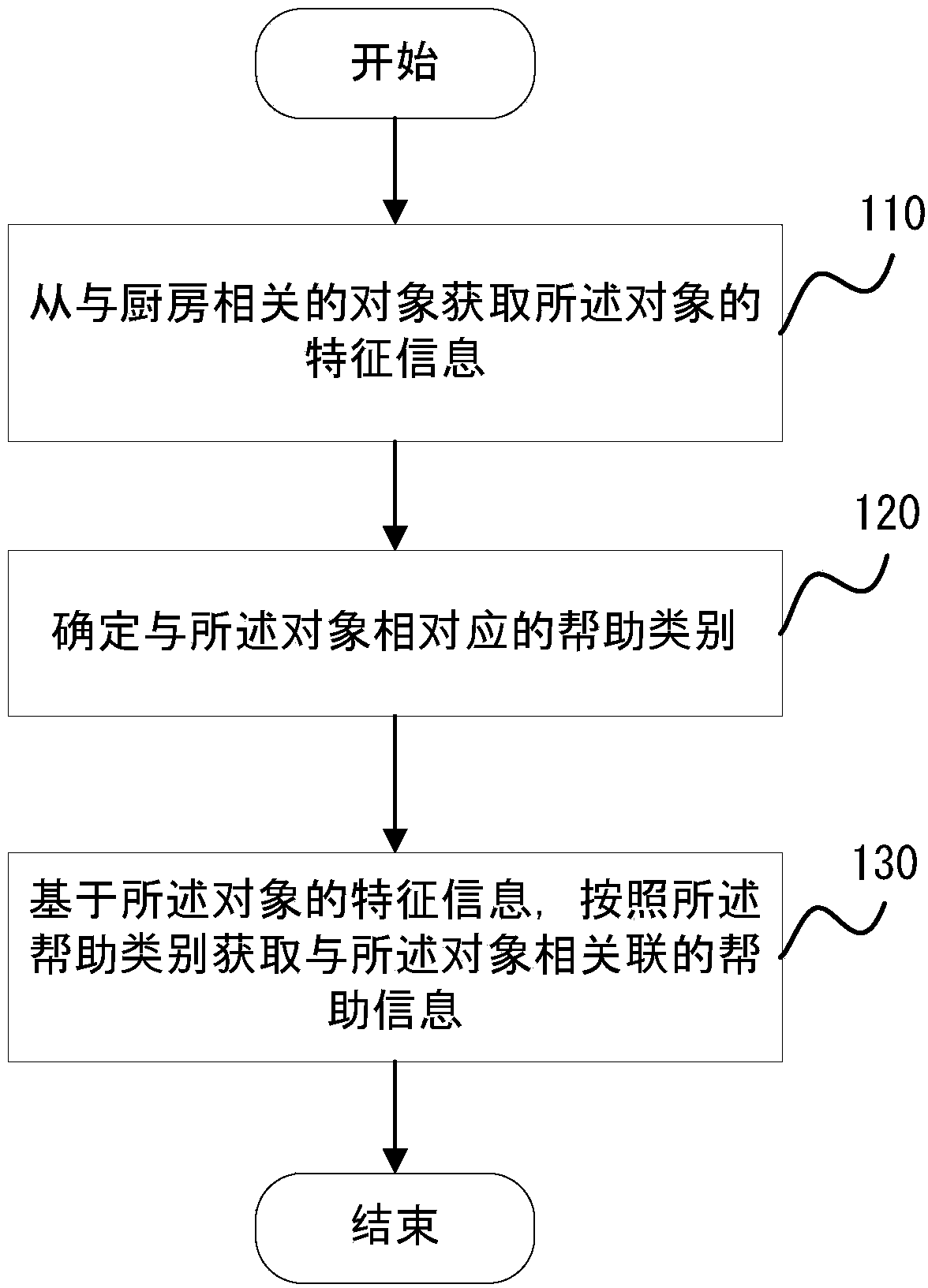

Kitchen management method and device

InactiveCN103810284AEfficient managementReduce inputWeb data retrievalCharacter and pattern recognitionApproaches of managementComputer terminal

Owner:北京微酷客科技有限公司

Waste material collection and treatment device for metal machining

InactiveCN110624930AAvoid human involvementReduce volumeSolid waste disposalCleaning using liquidsDrive shaftMetal machining

The invention discloses a waste material collection and treatment device for metal machining. The waste material collection and treatment device comprises a smashing box and a cleaning tank, the output end of the smashing box fixedly communicates with the input end of the cleaning tank, a putting opening is fixedly connected to the middle of the upper end of the smashing box, a first partition plate is fixedly connected to the middle of the inner side of the smashing box, a first air cylinder is fixedly connected to the position, corresponding to the first partition plate, of one side of the smashing box, a piston rod of the first air cylinder transversely penetrates through the smashing box to be fixedly connected with a first pushing plate, the interior of the smashing box is fixedly connected with two transmission shafts, the rear surface of the smashing box is fixedly connected with a motor, the output end of the motor is fixedly connected with one of the transmission shafts, the two transmission shafts are connected with smashing discs in a sleeved mode correspondingly, one ends of the two transmission shafts are fixedly connected with a driving wheel and a driven wheel correspondingly, and the driving wheel and the driven wheel are in engaged connection. According to the waste material collection and treatment device, subsequent using of waste materials is facilitated, the labor intensity of staff is reduced, the size is small, and the waste material collection and treatment device does not occupy the great storage space.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

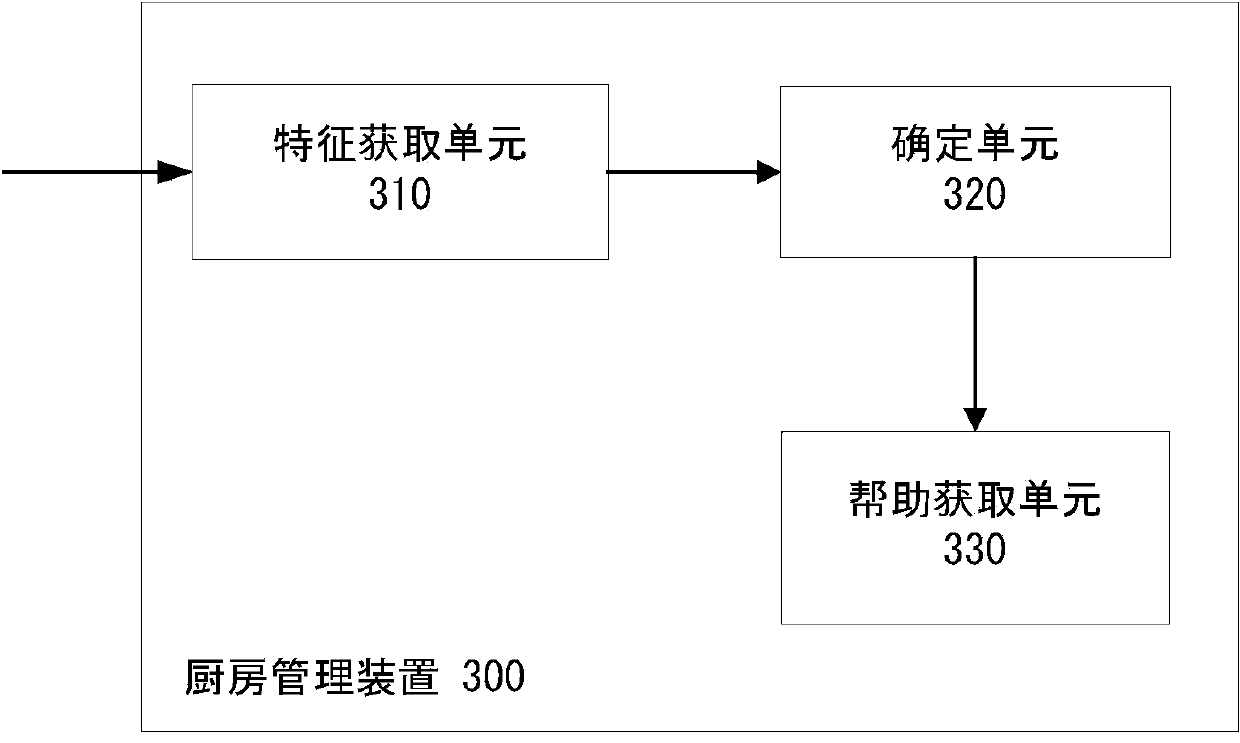

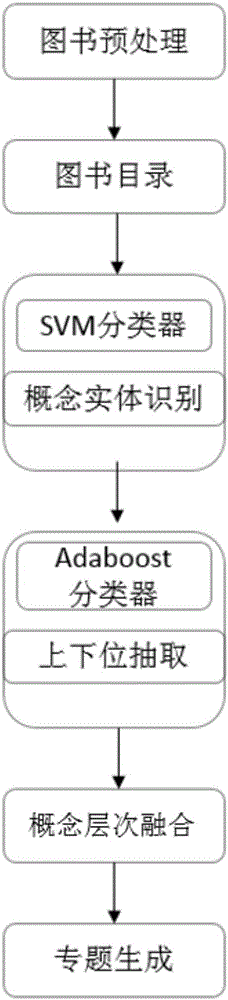

Automatic special subject generating method based on book catalogue

ActiveCN105893485AThe result of knowledge extraction is accurateAutomaticMetadata text retrievalCharacter and pattern recognitionWeb pageInformation retrieval

The invention discloses an automatic special subject generating method based on a book catalogue. For each book, each chapter in the catalogue is regarded as a word, features of the words are extracted, a classifier is trained out to recognize entities in the book catalogue, and a chapter pair meeting the hyponymy is extracted out for each pair of superior and subordinate chapter words belonging to the entities in the book catalogue. The concept hierarchical structure of each word is constructed according to the hyponymy, and the same or similar concept hierarchies in all the books are fused; for each concept word in the concept hierarchies, the content of the concept word in a webpage and a book is searched to serve as the description content of the word; finally, the concept hierarchies and the concept word contents are organized into the form of a special subject. By means of the automatic special subject generating method, the structured information of the book catalogue and a machine learning related algorithm are utilized, extraction and reorganization of knowledge are achieved, reference can be provided for compiling the special subject, the manpower cost of related work can be greatly reduced, and high practicability is achieved.

Owner:ZHEJIANG UNIV

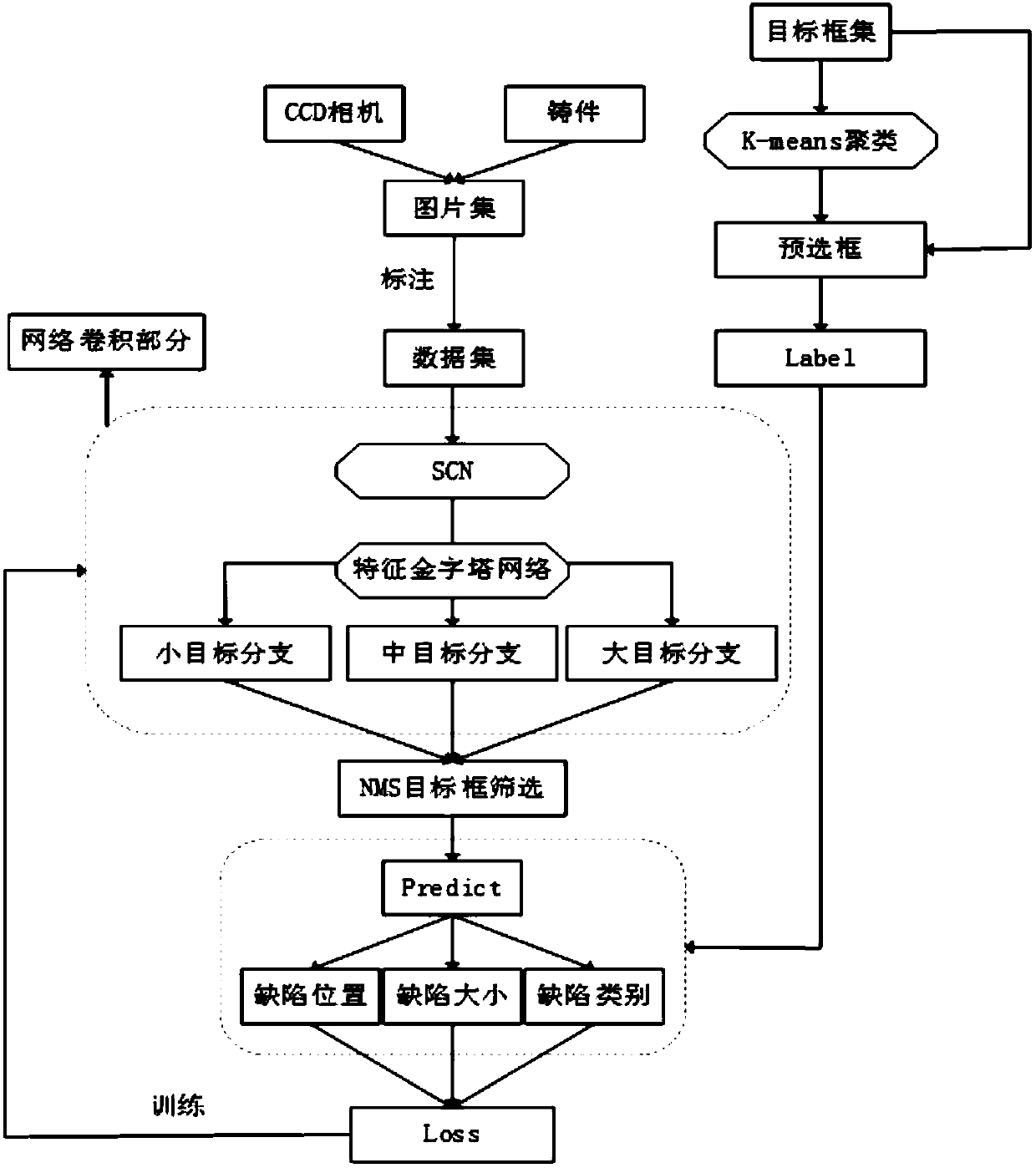

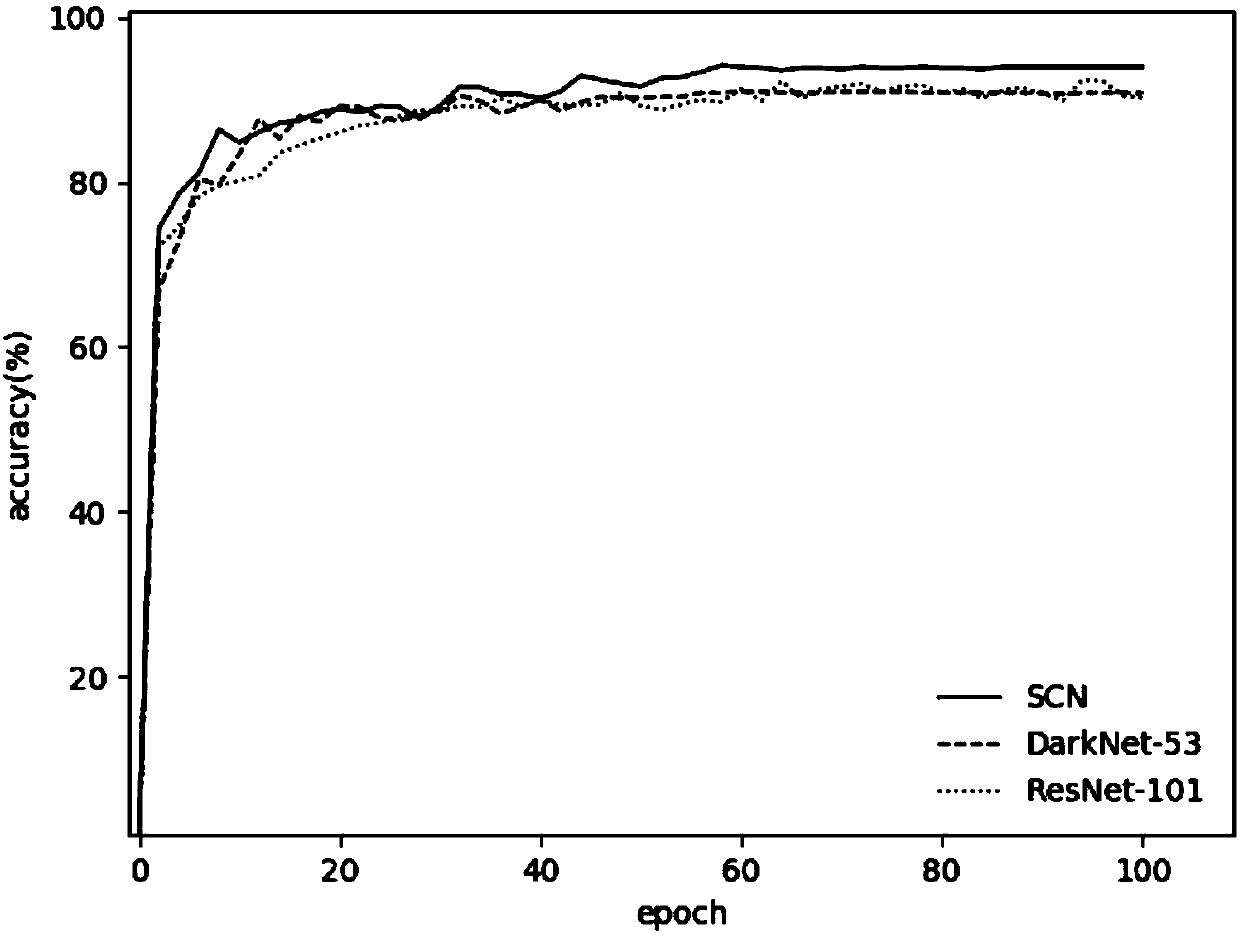

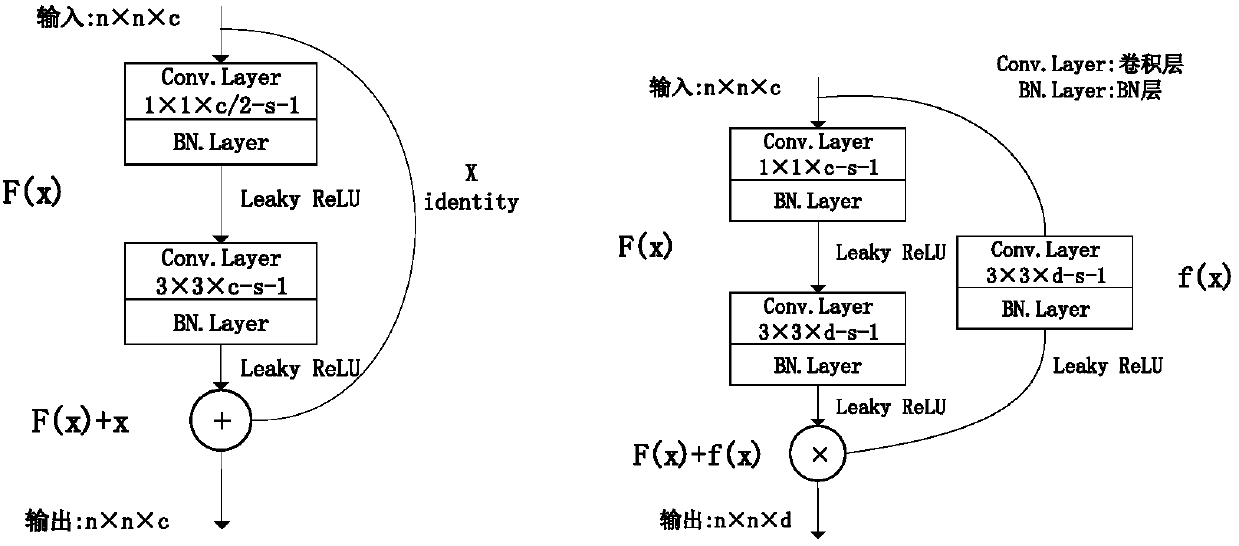

Casting surface defect identification method based on deep convolutional neural network

ActiveCN111223088AAccurate targetingPrecise target positionImage enhancementImage analysisData setEngineering

The invention discloses a casting surface defect identification method based on a deep convolutional neural network. The method comprises the following steps: 1, collecting a casting surface defect image, marking the image, and establishing a data set of common casting surface defects; 2, constructing a deep convolutional neural network defect recognition model; 3, constructing a network loss function; 4, dividing the data set into a training set and a test set, and training the defect recognition network by using the training set; 5, inputting the test image into the trained network to identify the position, the type and the size of the defect. According to the invention, the recognition precision and recognition performance of the casting surface defects are improved, and the online, intelligent and automatic development of casting quality detection is promoted.

Owner:SOUTHEAST UNIV

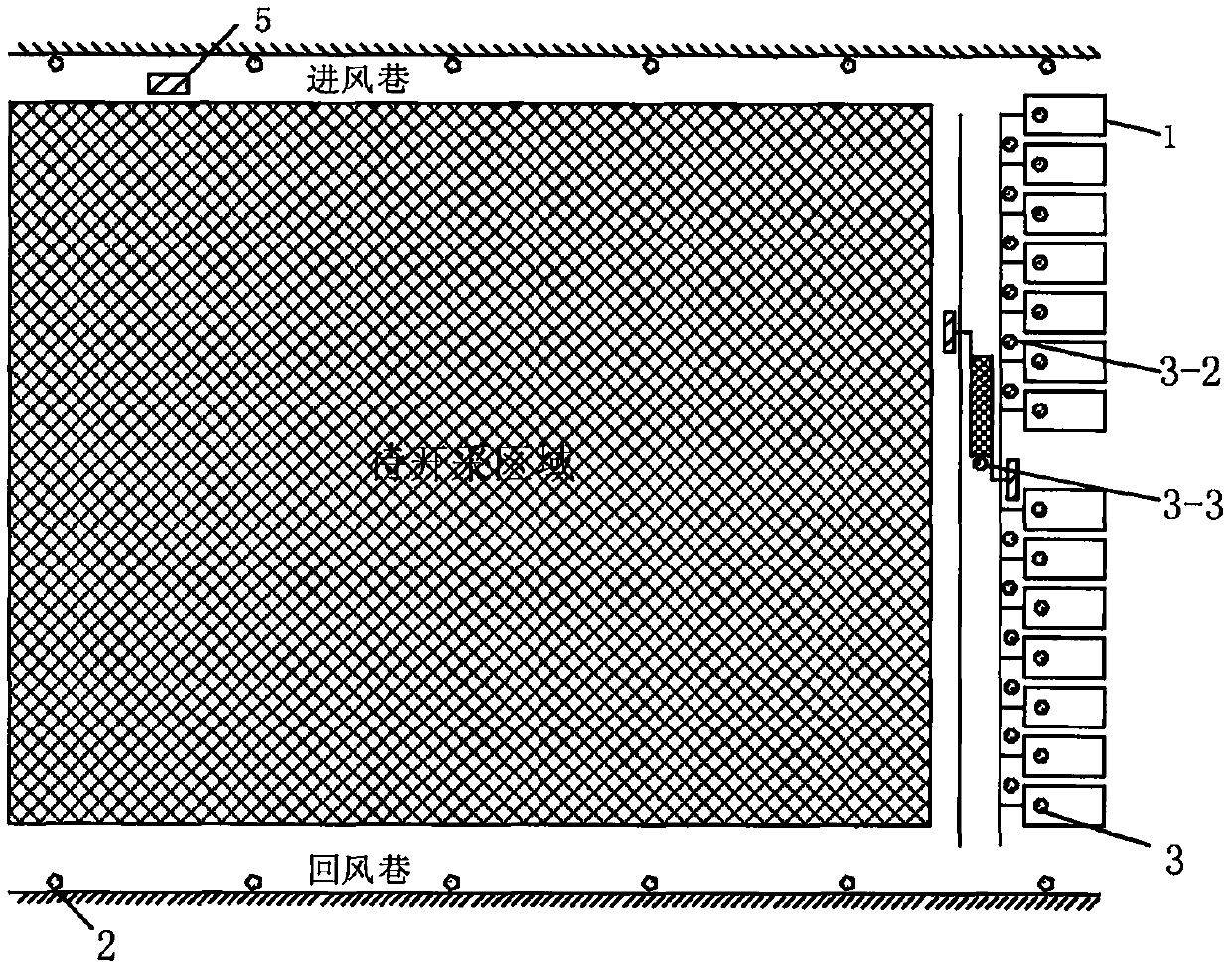

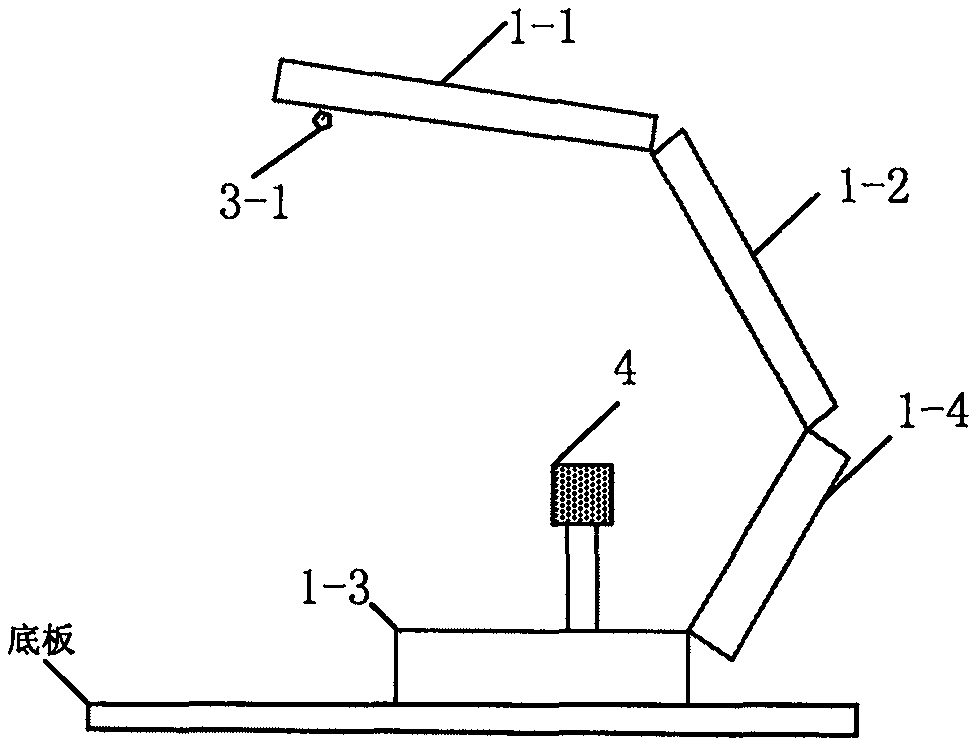

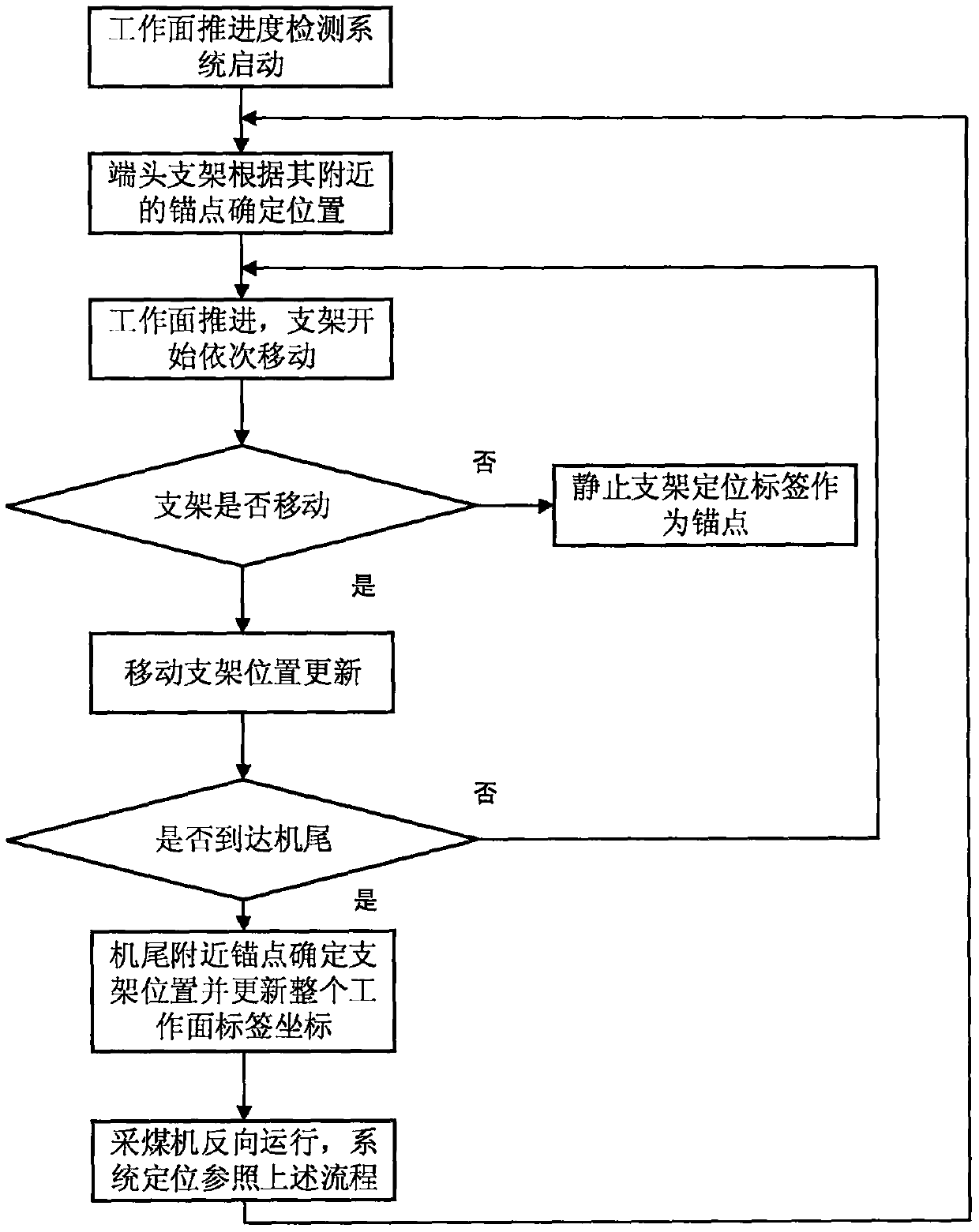

Fully mechanized mining face advancing degree detection system and method

ActiveCN107905846AAvoid human involvementSmall sizeMining devicesPosition fixationCoal miningEnvironmental geology

The invention discloses a coal mine fully mechanized mining face advancing degree detection system and method. The coal mine fully mechanized mining face advancing degree detection system is composedof positioning anchor points, positioning tags, positioning controllers, a master control system and the like. The positioning anchor points are fixedly installed on the rock walls of an air intake roadway and an air return roadway at equal distances, the positioning tags and the positioning controllers are deployed on a hydraulic support, a coal mining machine and the like, the distances betweenevery two positioning nodes are measured, distance measurement data are transmitted to a main control computer by the positioning controllers through communication network, the positions of the equipment in the mining face advancing process are worked out by the main control computer according to the data, and therefore automatic detection can be achieved in the mining face advancing process.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

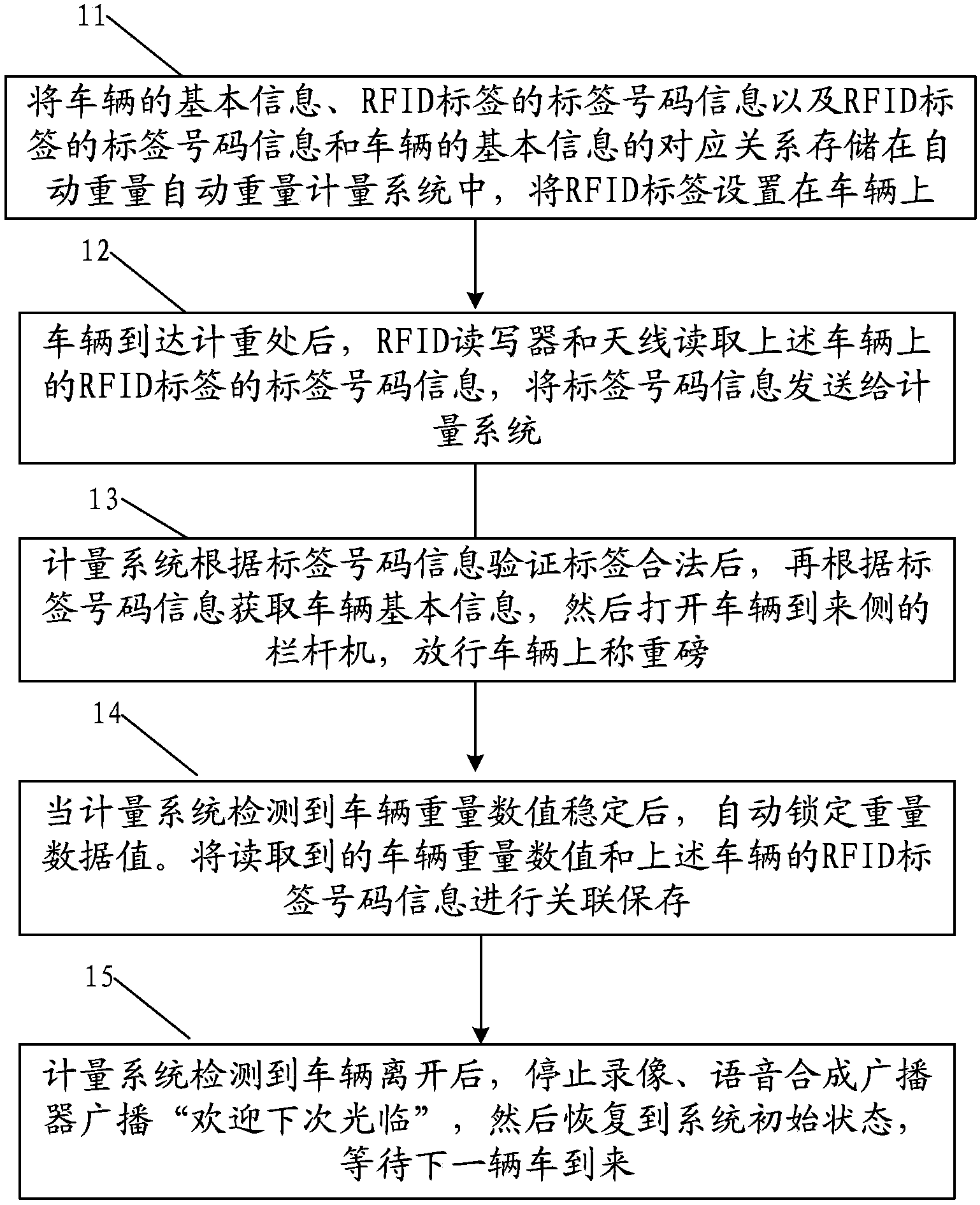

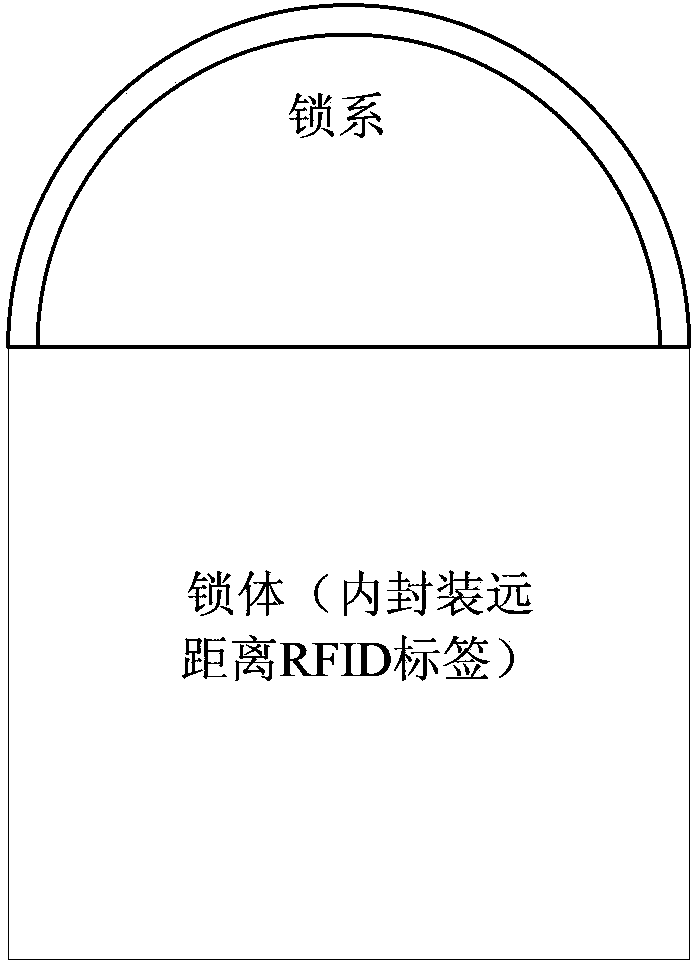

Automatic vehicle weight measuring method and device based on radio frequency identification tag

InactiveCN103852152AFully automatedAvoid human involvementCo-operative working arrangementsWeighing auxillary devicesFully automaticReader writer

The embodiment of the invention provides an automatic vehicle weight measuring method and device based on a radio frequency identification tag. The method mainly comprises the steps that the basic information of a vehicle, the number information of the RFID tag and the corresponding relation between the basic information of the vehicle and the number information of the RFID tag are saved in an automatic weight measuring system, and the RFID tag is arranged on the vehicle; after the vehicle reaches a weighing position, an RFID reader-writer and an antenna at the weighing position read the number information of the RFID tag on the vehicle, and the automatic weight measuring system obtains the basic information of the vehicle according to the number information of the RFID tag; the automatic weight measuring system obtains the weight value of the vehicle automatically and conducts correlation saving on the weight value of the vehicle and the number information of the RFID tag on the vehicle, and then correlation between the weight value and the basic information of the vehicle is realized. According to the method and device, fully-automatic vehicle weight measurement can be achieved, manual intervention is avoided during vehicle weight measurement, labor resources are saved, and vehicle weight measuring efficiency is improved.

Owner:AEROSPACE INFORMATION

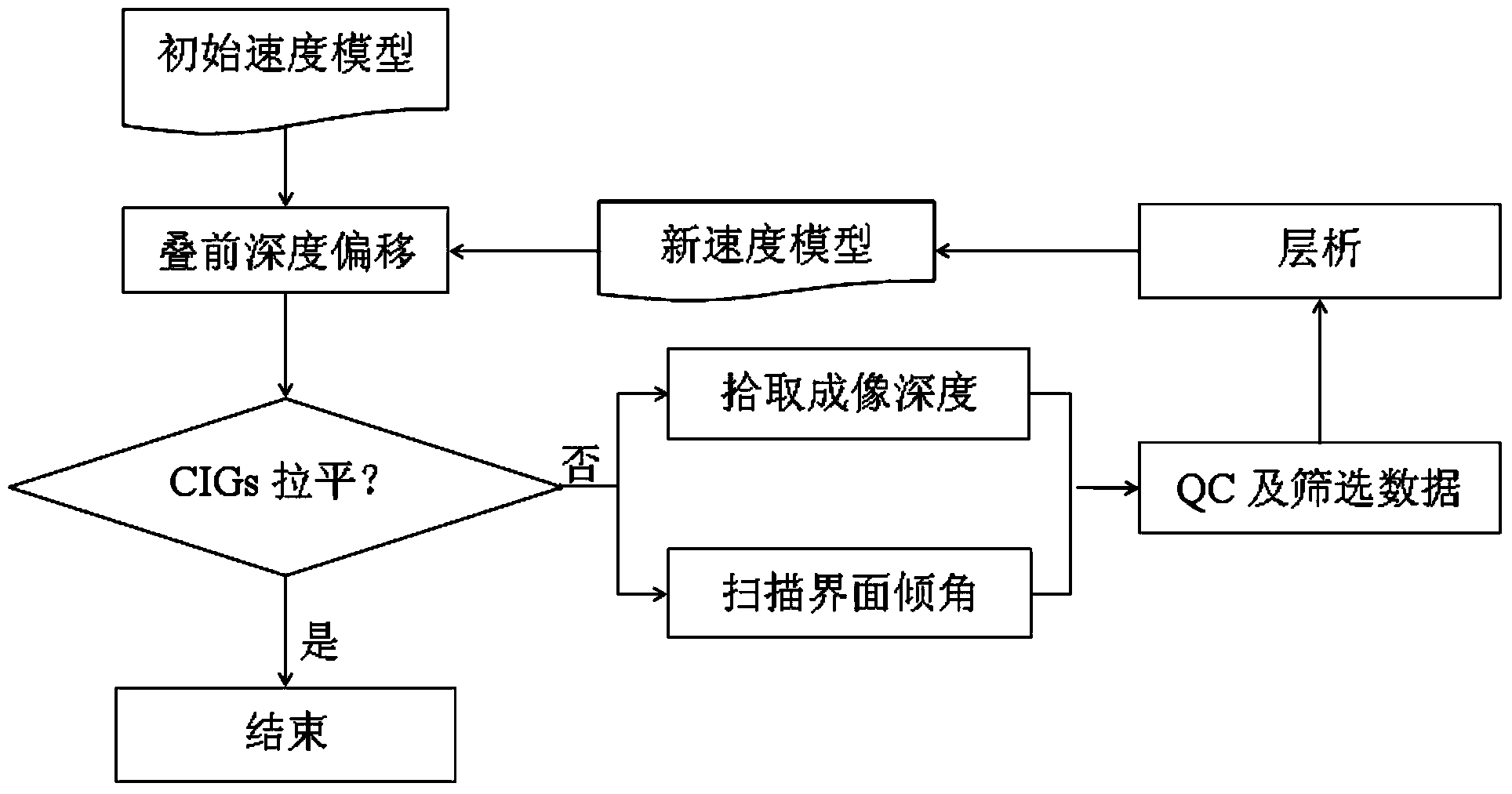

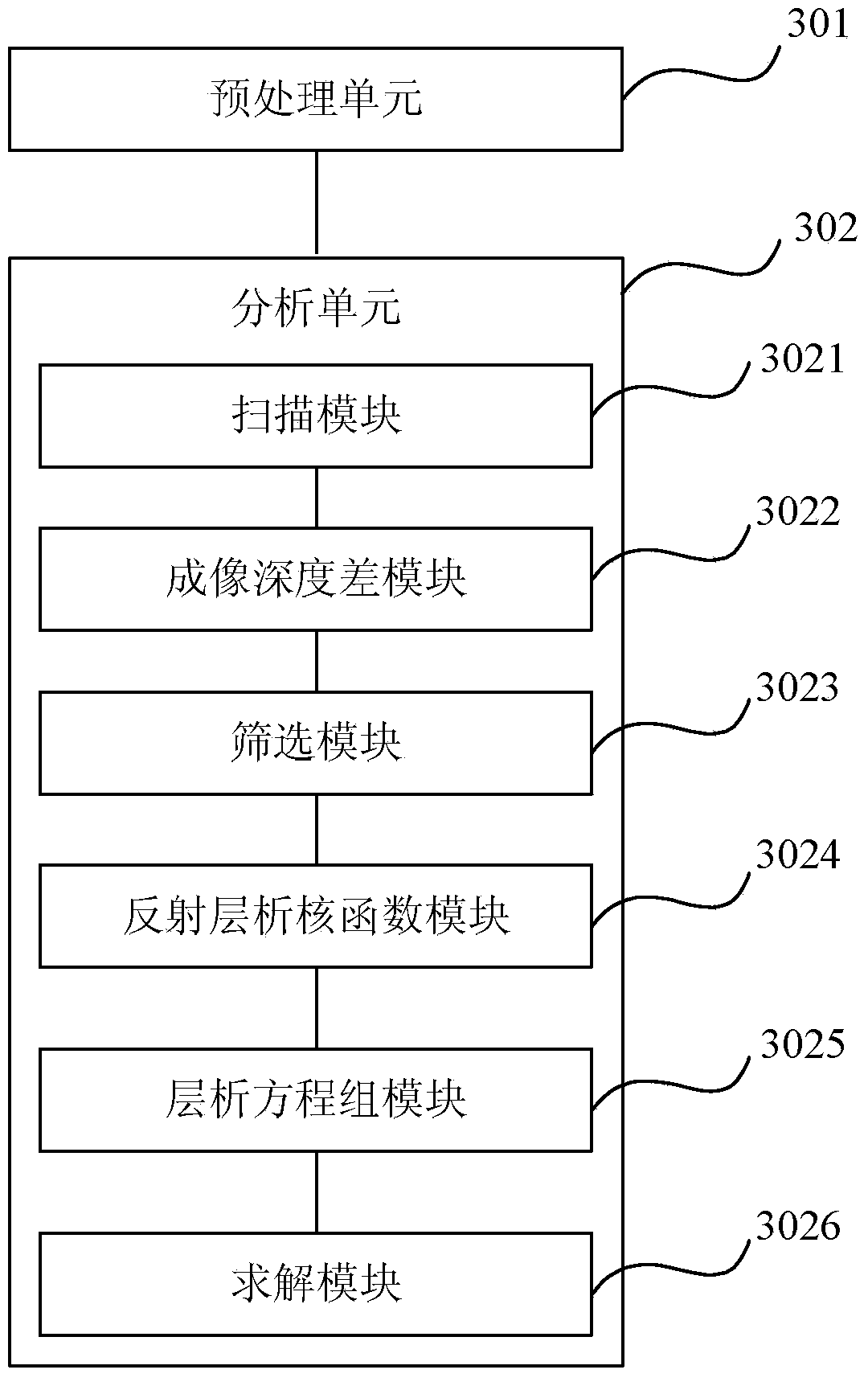

Angle gather ray chromatography migration velocity analyzing method and device

ActiveCN104268412AAvoid human involvementReduce subjectivitySeismic signal processingSpecial data processing applicationsDomain imagingQuality monitoring

The invention relates to an angle gather ray chromatography migration velocity analyzing method and device. The method includes utilizing a velocity model to perform migration processing on outdoor collected seismic data after being preprocessed to acquire migrated section and angle domain imaging gather; judging whether an event in the angle domain imaging gather is horizontal or not; if not, updating the velocity model. A method for updating the velocity model includes scanning reflection faces of the migrated section to acquire reflection face inclination angles; selecting points on the reflection faces of the migrated section as reflection points, acquiring residual curvature of the reflection points, automatically picking imaging depth of the reflection points on the angle domain imaging gather by taking the residual curvature as a constraint condition, and acquiring imaging depth difference at different reflection angles; screening out the reflection points meeting quality monitoring criteria; tracking ray paths corresponding to different reflection angles by utilizing the reflection face inclination angles corresponding to the selected reflection points, acquiring a reflection chromatography kernel function, and building a chromatography equation set; acquiring updating quantity of the velocity model, and updating an initial velocity model.

Owner:PETROCHINA CO LTD

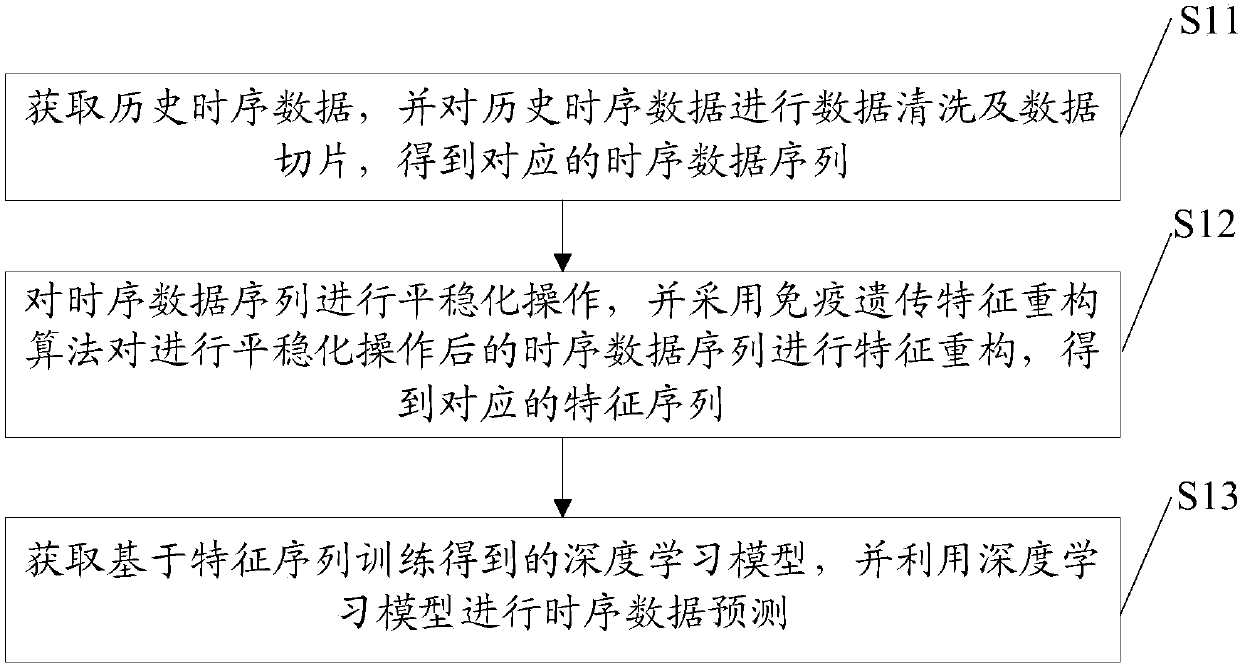

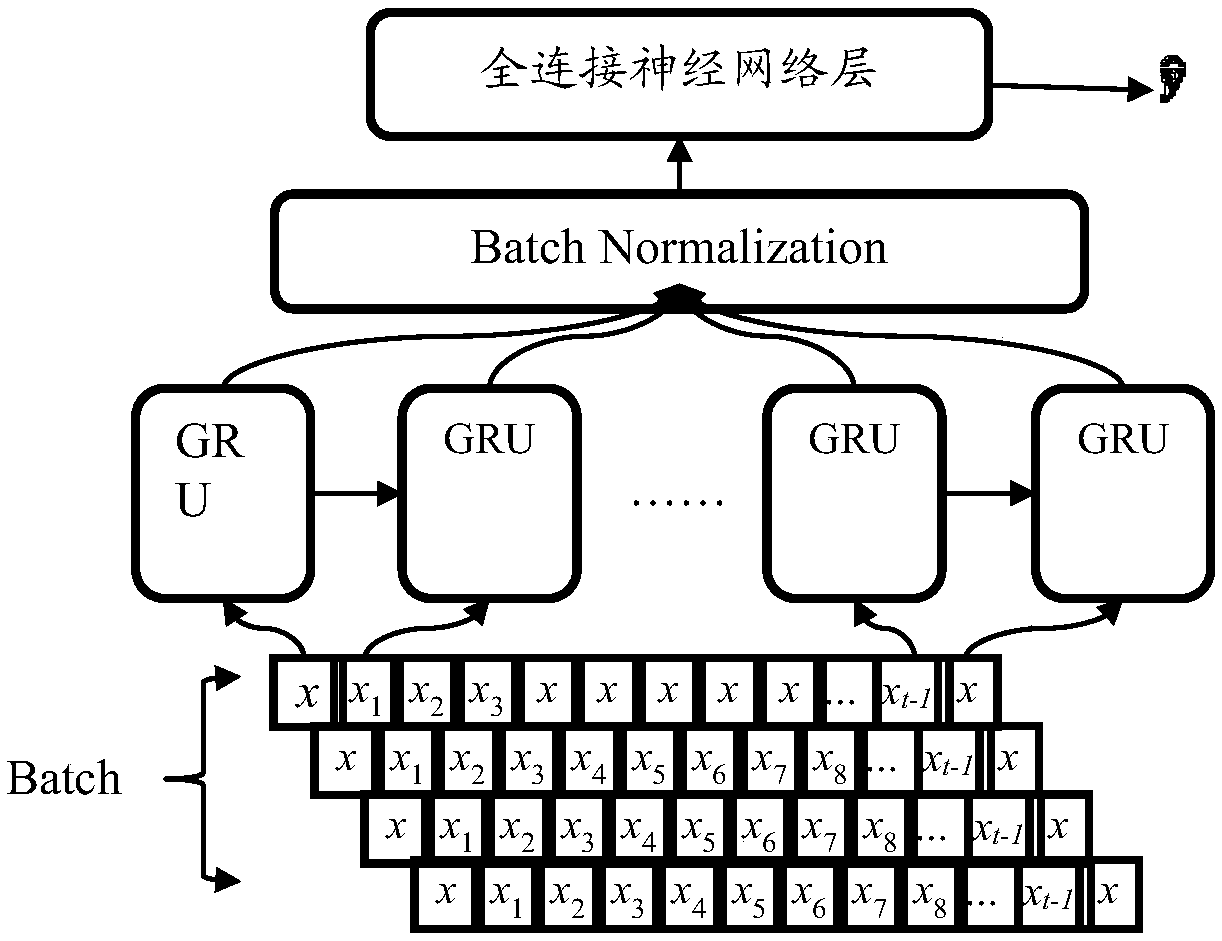

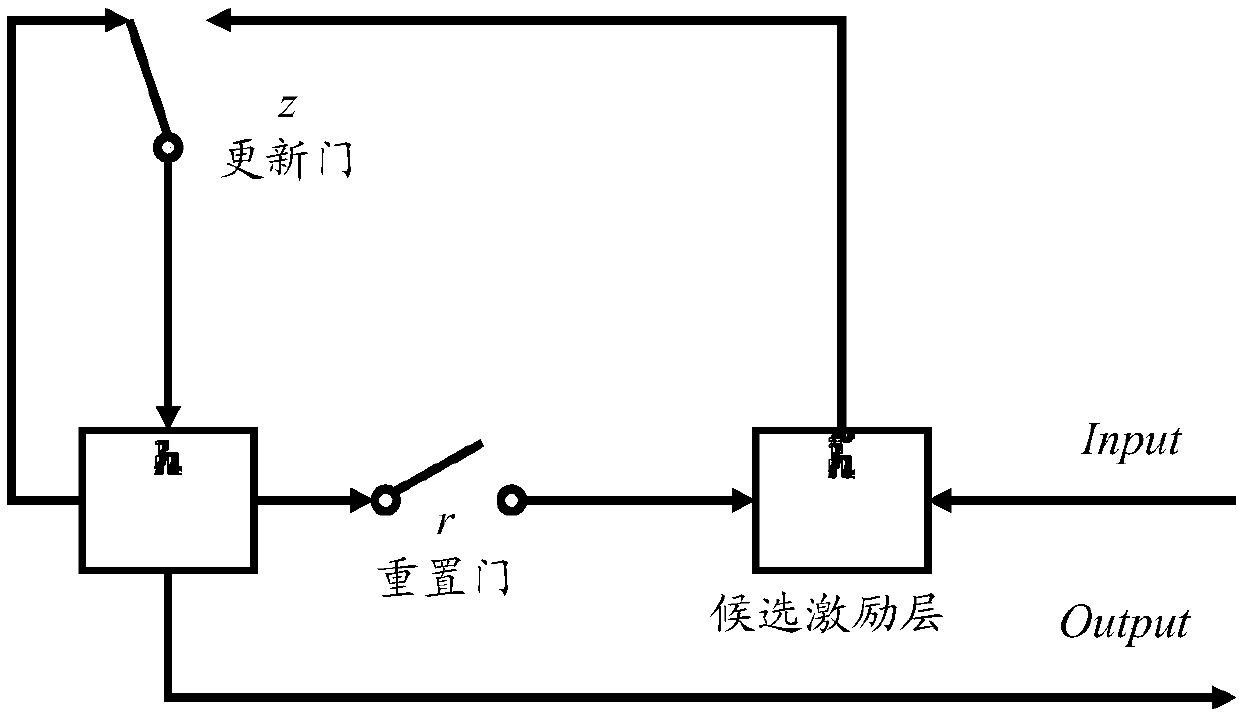

Time series data prediction method, device and equipment

InactiveCN108399248AGuaranteed accuracyGuaranteed stabilityNeural architecturesComplex mathematical operationsData setAlgorithm

The invention discloses a time series data prediction method, device and equipment. The method includes: acquiring historical time series data, and subjecting the historical time series data to data cleaning and data slicing to obtain a corresponding time series data sequence; subjecting the time series data sequence to stabilization, and adopting an immunogenetic feature reconstruction algorithmfor feature reconstruction of the stabilized time series data sequence to obtain a corresponding feature sequence; acquiring a deep learning model based on training of the feature sequence, and adopting the deep cleaning model for time series data prediction. Different from the prior art in which data set feature acquisition is realized according to a sampling method, the time series data prediction method guarantees effectiveness of the acquired time series data features by steps of data preprocessing, stabilization, feature reconstruction and the like, and accordingly the deep learning modelis enabled to learn the time series features of the time series data, and prediction accuracy of the deep learning model is guaranteed.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

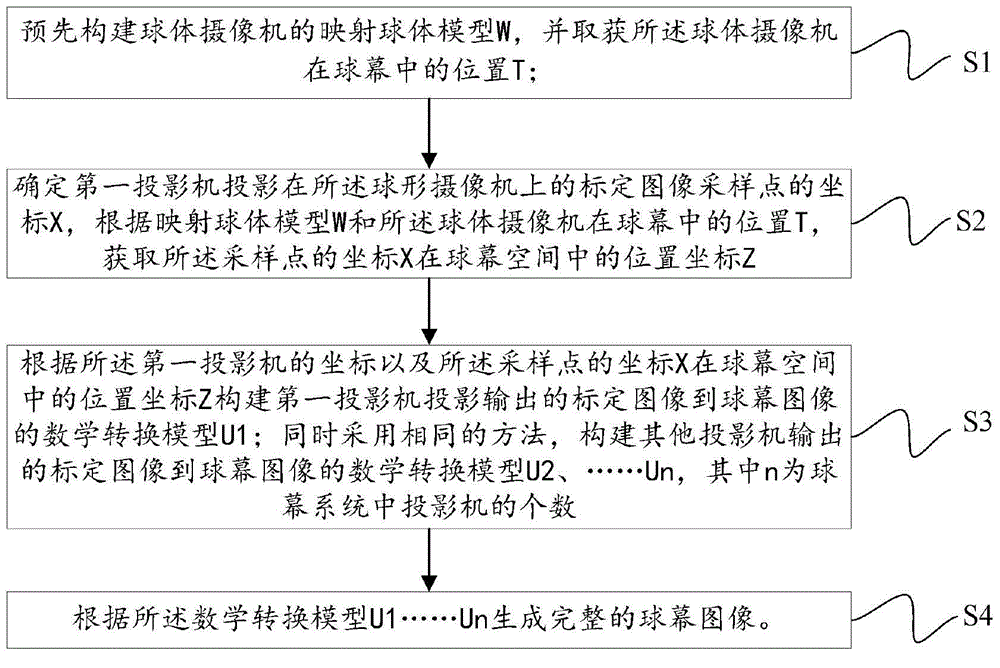

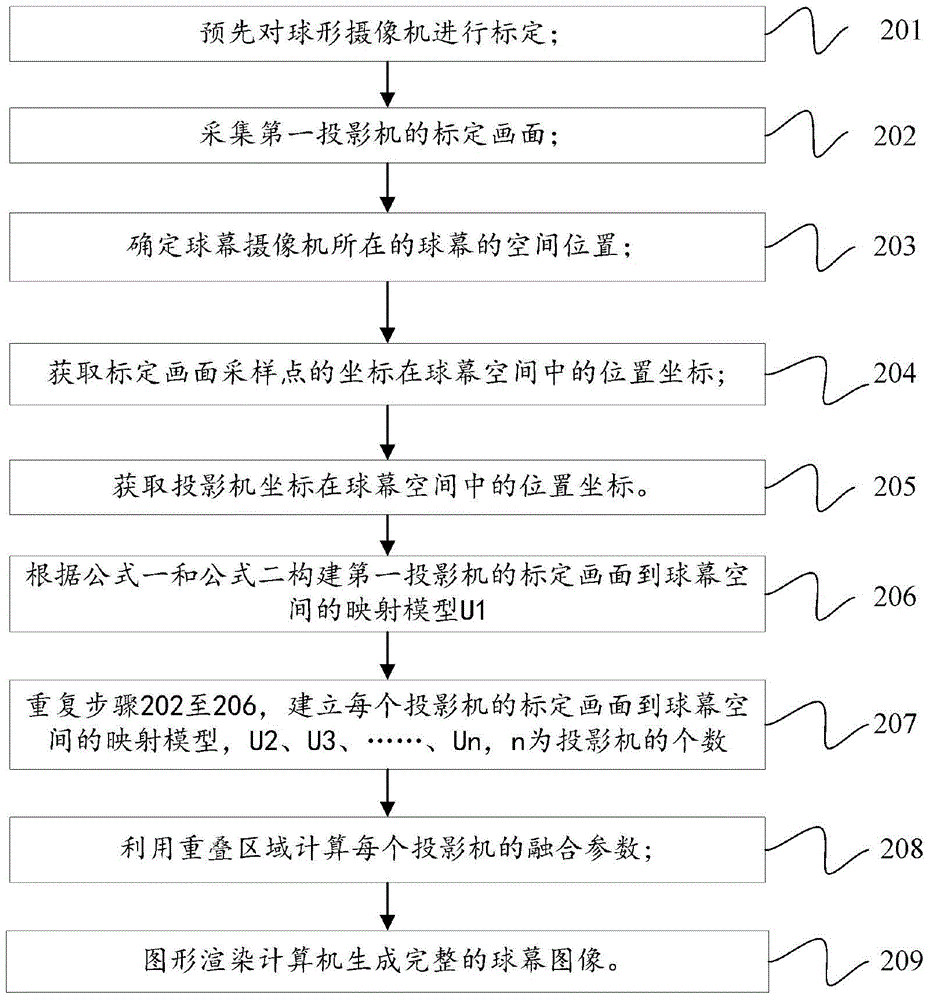

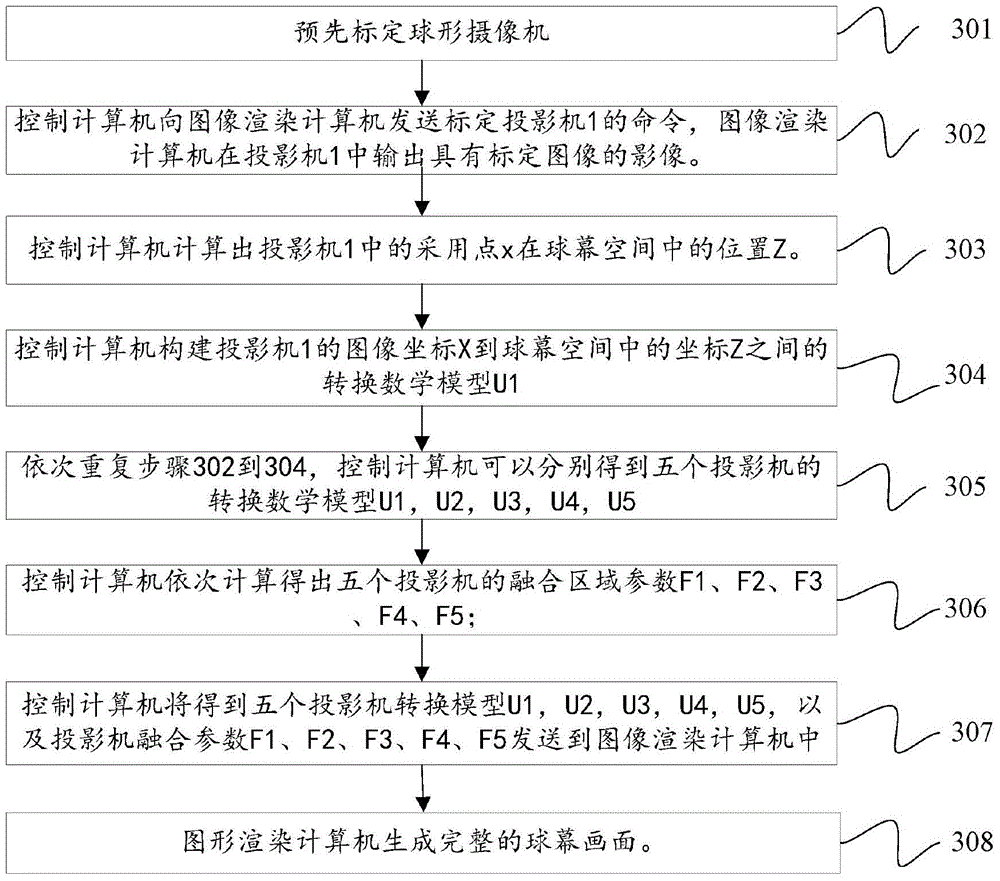

Dome screen demarcating method, demarcating system and control device

ActiveCN105787920AImprove splicing efficiencyGood splicing effectImage analysisScreen spaceControl equipment

The embodiments of the invention provide a dome screen demarcating method, a demarcating system and a control device. The method includes the following steps: constructing in advance a mapping sphere model W of a sphere camera, and acquiring a position T of the sphere camera in a dome screen space; determining a coordinate X of a sampling point of a demarcating image which is projected by a first projector on the sphere camera, in accordance with the mapping sphere model W and the position T of the sphere camera in the dome screen, acquiring a position coordinate Z of the coordinate X of the sampling point in the sphere screen space; in accordance with the coordinate V of the first projector and the coordinate Z of the coordinate X of the sampling point in the sphere screen space, constructing a mathematics conversion model U1 of the demarcating image projected by the first projector to a dome screen image; using the aforementioned method, constructing mathematics conversion models U2......Un of demarcating images output by other projectors to the dome screen images, in which n is the number of the projectors; in accordance with the mathematics conversion models U1......Un, generating the complete dome screen image.

Owner:上海智幻软件科技有限公司

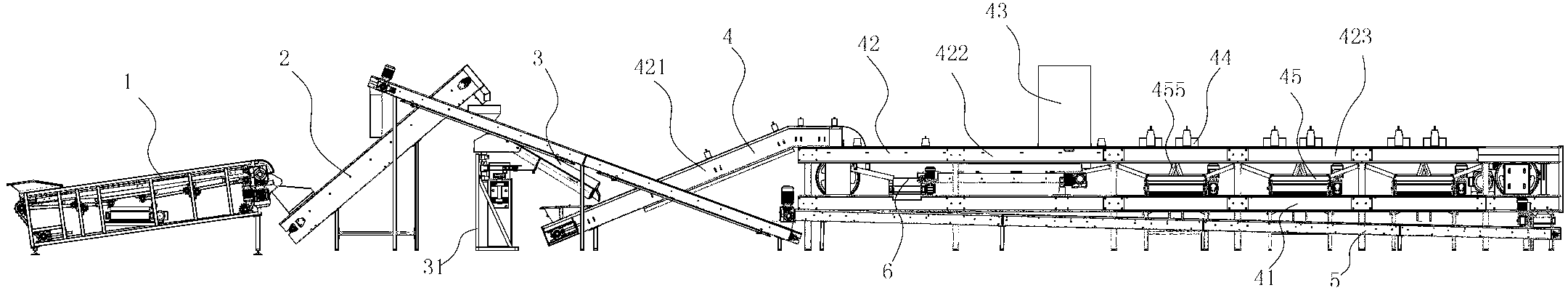

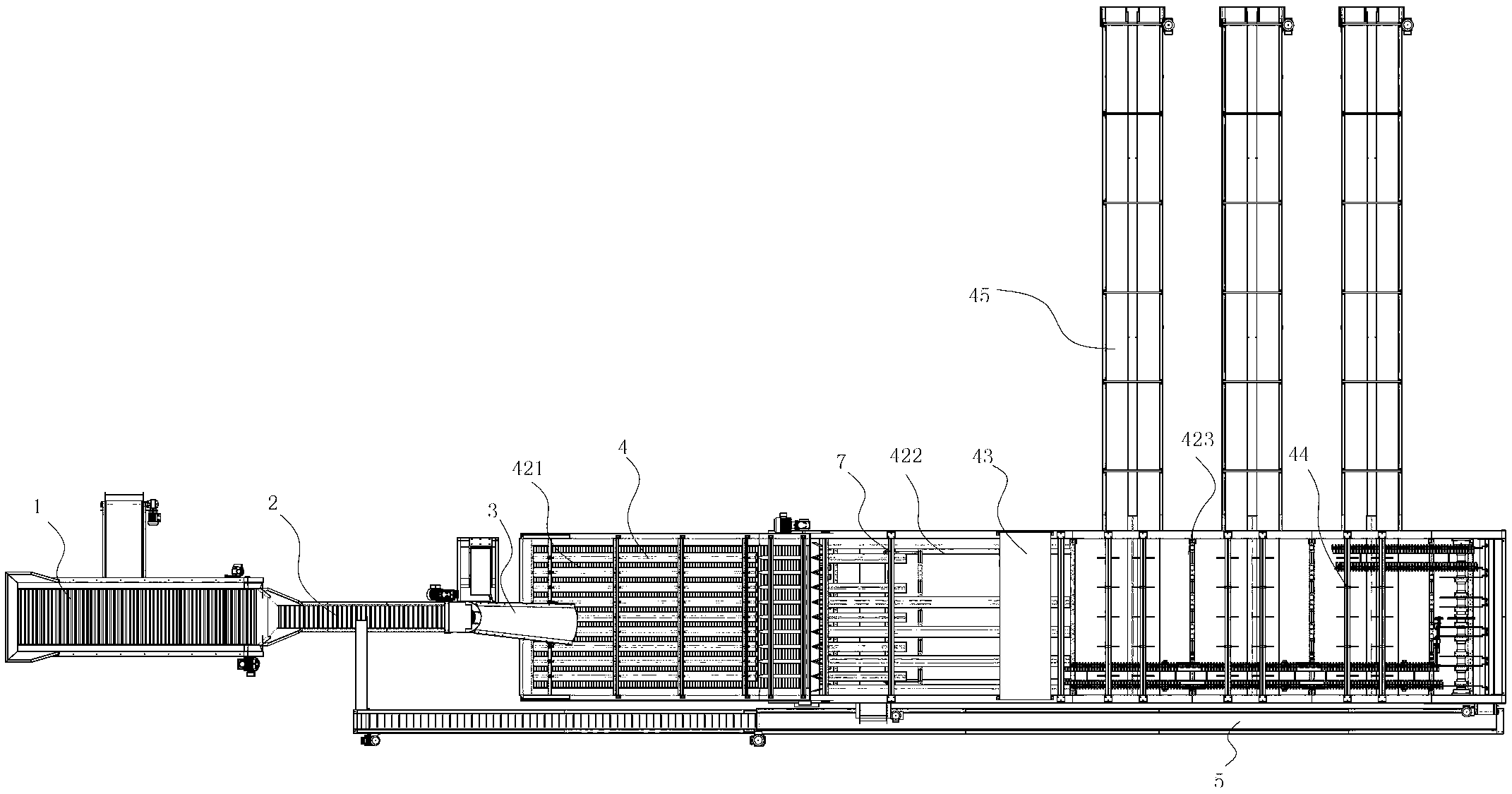

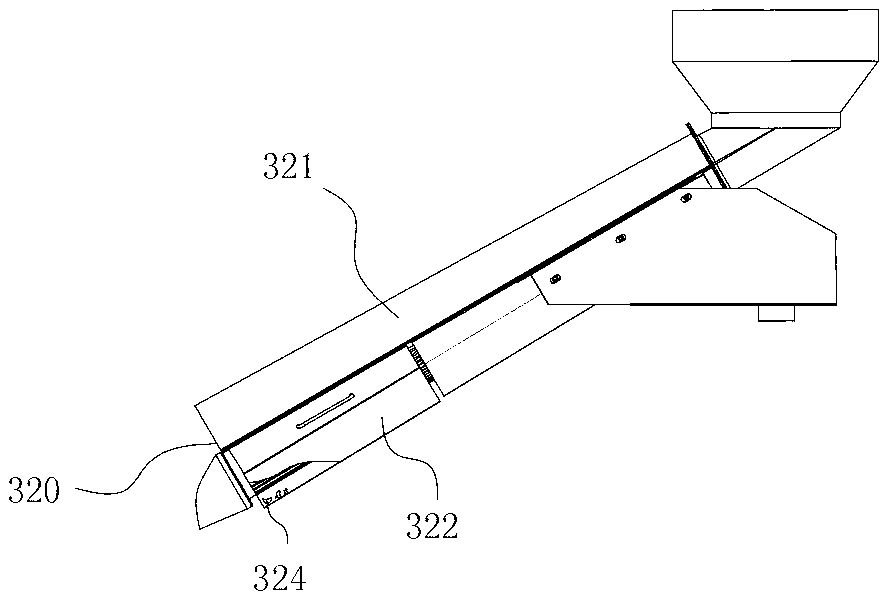

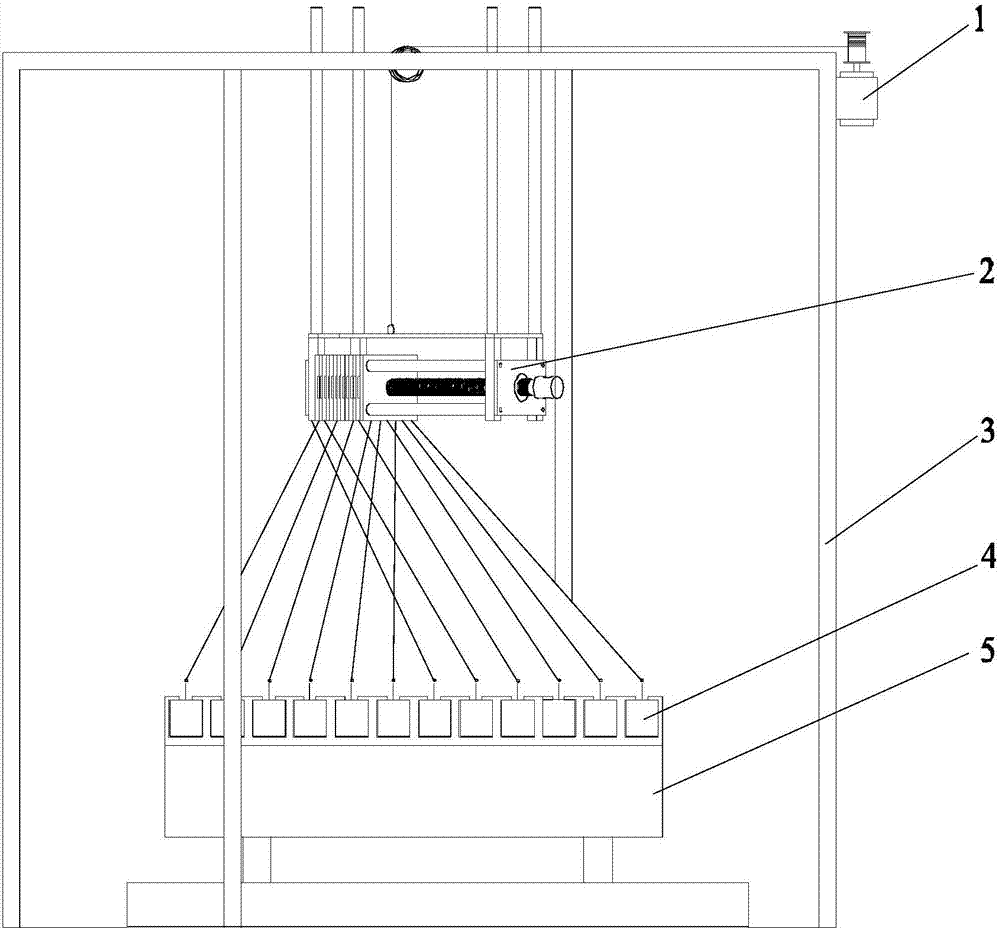

Photoelectric fructus jujubae grading production line

The invention discloses a photoelectric fructus jujubae grading production line which has the advantages of ensuring high automation degree of fructus jujubae, increasing the working efficiency and lowering the production cost. The photoelectric fructus jujubae grading production line comprises a roller pre-screening machine, a scraper charging machine, a turtle shell distributor and a sorting and conveying device, wherein the sorting and conveying device comprises a rack, a grading and conveying mechanism, an image detecting mechanism, a grading executing mechanism, a control host and a grading and discharging mechanism, the grading and conveying mechanism is arranged on the rack and sequentially comprises a feeding section, a detecting section and a grading section; the image detecting mechanism is arranged on the detecting section, the grading executing mechanism is arranged on the grading section; the grading and discharging mechanism is arranged on the rack, and positioned below the grading executing mechanism; the control host is connected with the image detecting mechanism and the grading executing mechanism for controlling the sorting of the fructus jujubae; and a discharging hole of the turtle shell distributor is connected with the feeding section of the grading and conveying mechanism. The photoelectric fructus jujubae grading production line is high in continuous distribution and grading automation degree; and the fructus jujubae is not easily damaged and the working efficiency is increased.

Owner:扬州福尔喜果蔬汁机械有限公司

Data processing method and computer system

ActiveCN104798043AAvoid human involvementResource allocationEnsemble learningData setClassification methods

The invention provides a data processing method and a computer system. The computer system can achieve the discretized processing of a data sample, and obtains a matrix-form data sample (S101). According to a preset classification method, the training of the matrix-form data sample (S101) is carried out, thereby obtaining a classification rule set (S102). Moreover, the classification rule set (S102) is converted into a classification rule set (S103) recognized by a data decision-making platform, and then is provided for the data decision-making platform (S104). Therefore, the data decision-making platform (S104) can carry out data decision making according to the classification rule set (S103) recognized by the data decision-making platform (S104). According to the invention, the training of the matrix-form data sample (S101) and the obtaining of the classification rule set (S102) are completed by a computer automatically, thereby avoiding manual operation. When the data sample changes or an original classification rule needs to be updated, an updated classification data set can be obtained timely.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

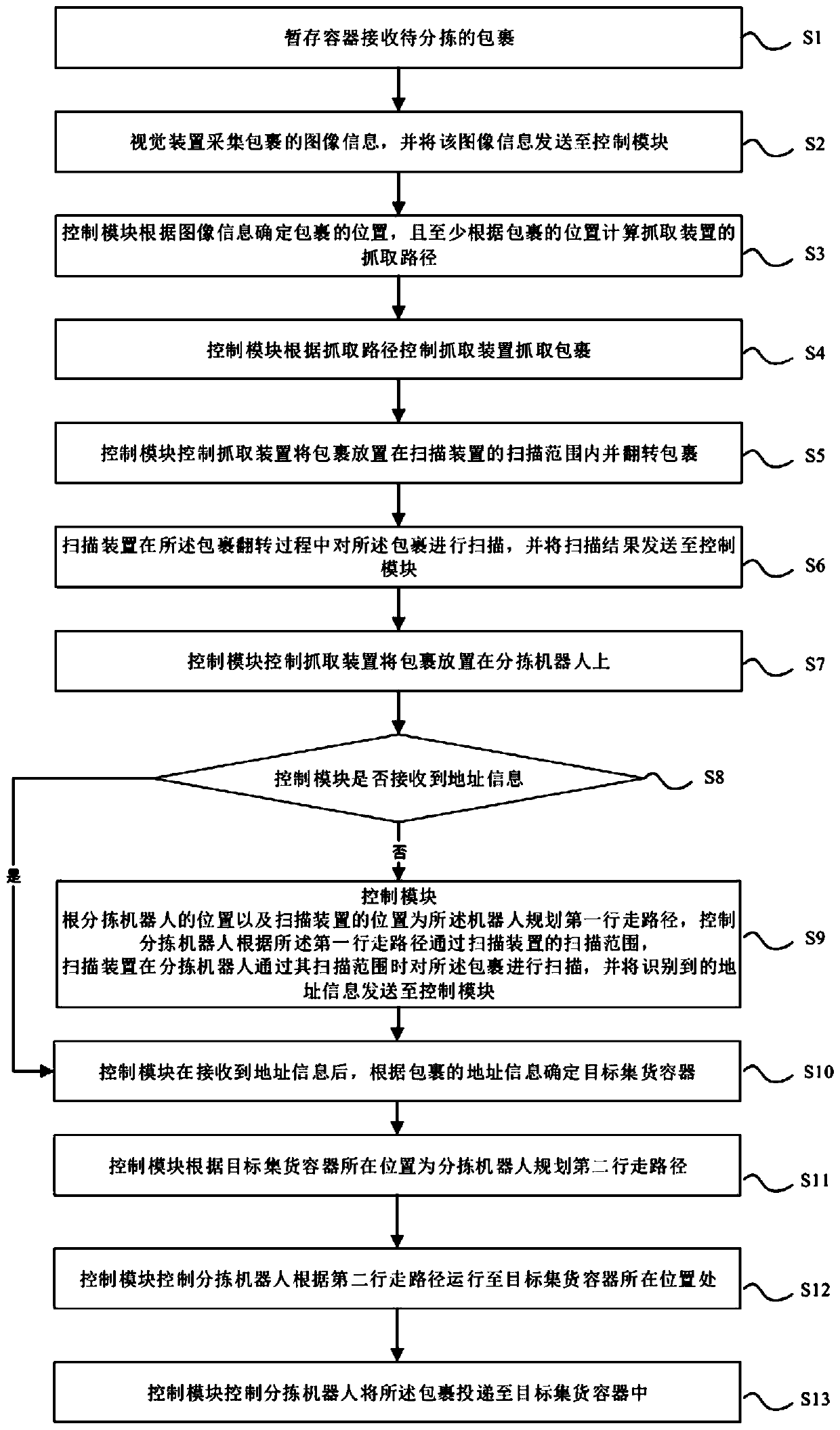

Package address identification system, package address identification method, package sorting system and package sorting method

ActiveCN109772718AAvoid damageImprove recognition efficiencySortingLogistics managementIdentification system

The invention belongs to the technical field of storage logistics, and particularly discloses a package address identification system, a sorting system, a package address identification method, and apackage sorting method. According to the package address identification system, a label is arranged on at least one side surface of a package; the label at least carries address information of the package; the package address identification system comprises a vision device, a grabbing device, a sorting robot, a scanning device and a control module; and the control module is correspondingly in communication connection with the vision device, the grabbing device, the sorting robot and the scanning device. The sorting system comprises the package address identification system. With the adoption of the package address identification system, the sorting system, the package identification method and the package sorting method, labor participation in the package identification process is avoided,the package identification efficiency and the package sorting efficiency are improved, and the labor cost of package identification and package sorting is reduced.

Owner:BEIJING JIZHIJIA TECH CO LTD

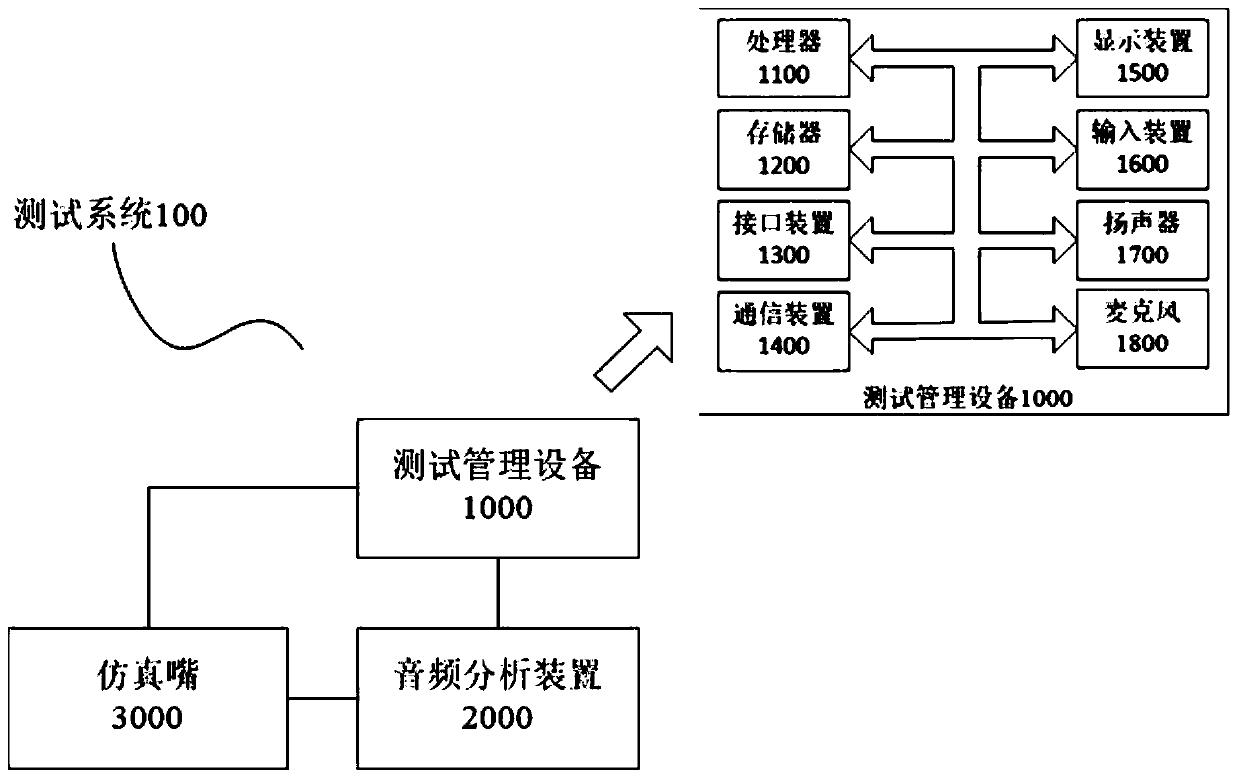

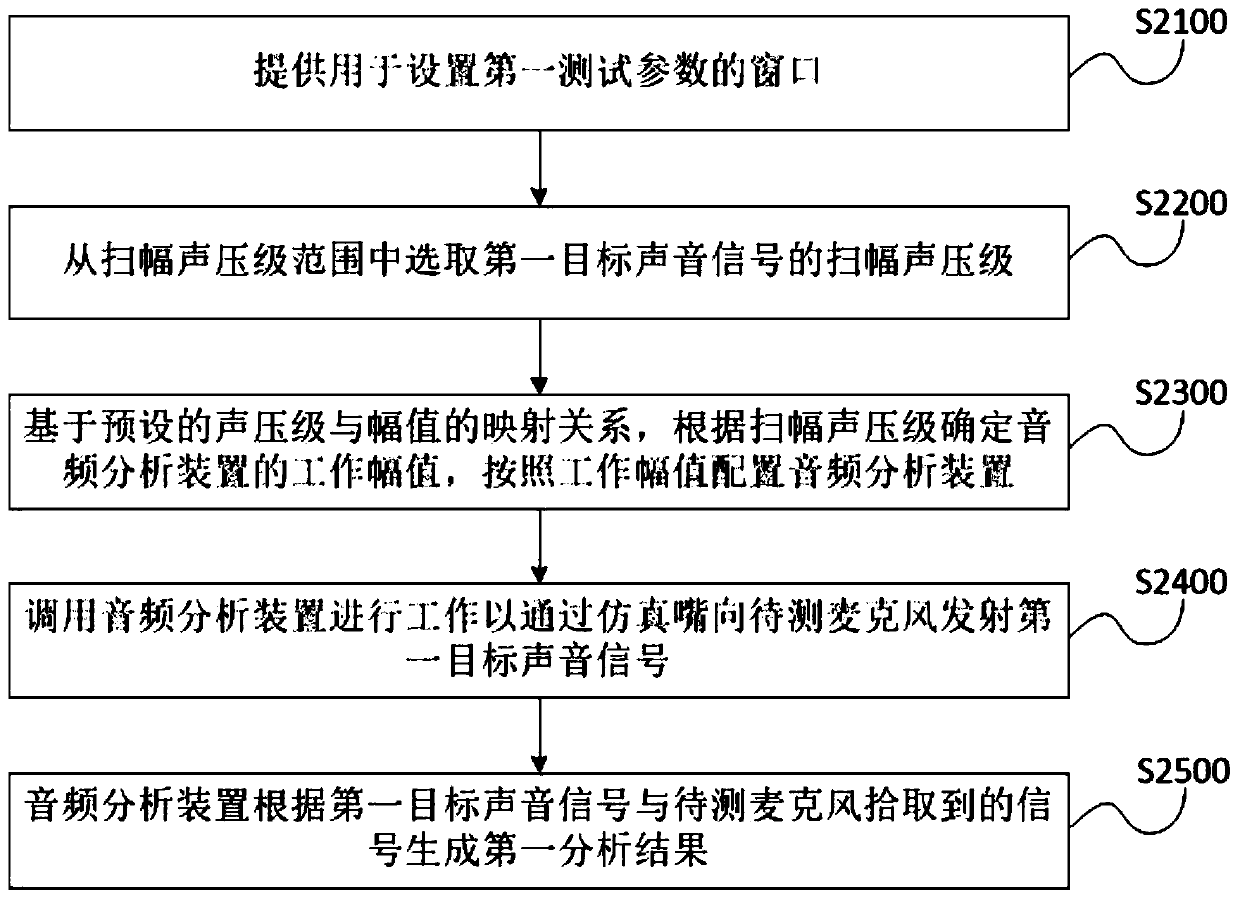

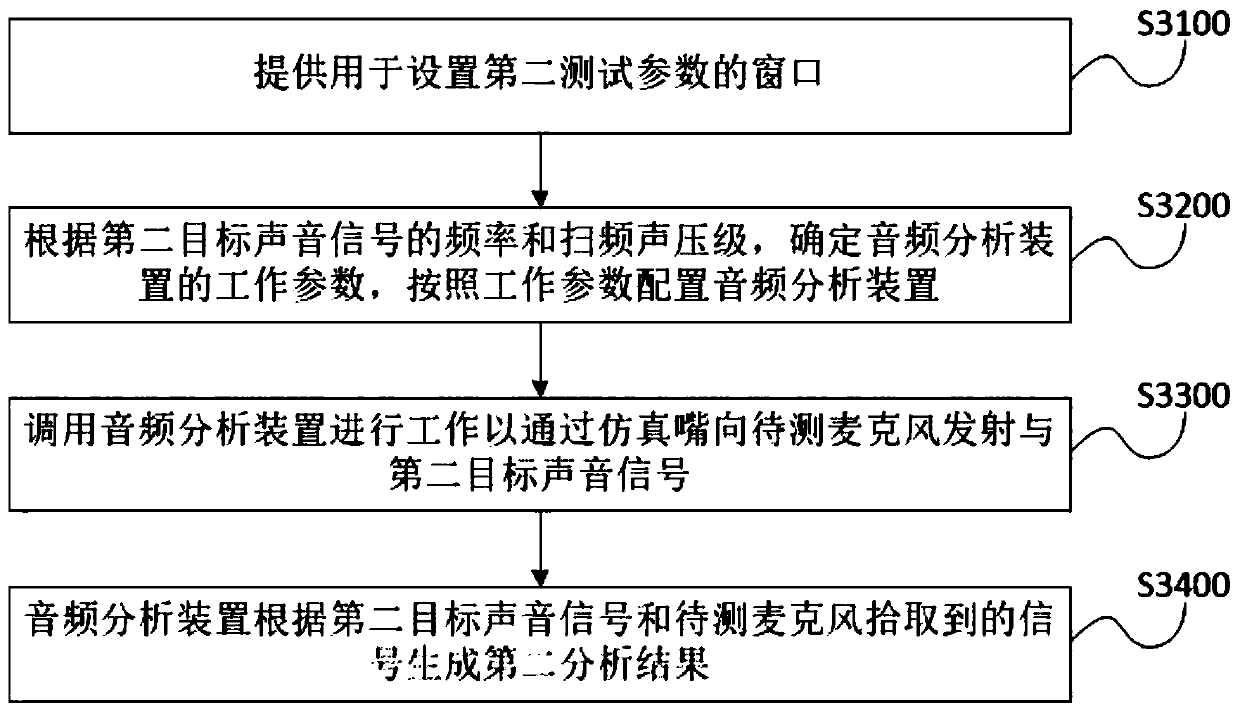

Microphone performance test method, test management equipment and test system

ActiveCN111083625AReduce error rateAvoid human involvementElectrical apparatusEngineeringTest management

The invention discloses a microphone performance test method, test management equipment and a test system. The test management equipment is in communication connection with an audio analysis device and a simulation nozzle; the audio analysis device outputs a sound signal to a microphone to be tested through the simulation nozzle. The method comprises the steps: providing a window used for settinga first test parameter, wherein the first test parameter comprises a sweep amplitude sound pressure level range of a first target sound signal; selecting a sweep amplitude sound pressure level of thefirst target sound signal from the sweep amplitude sound pressure level range; determining a working amplitude of the audio analysis device according to the swept-amplitude sound pressure level basedon a preset mapping relation between the sound pressure level and the amplitude, and configuring the audio analysis device according to the working amplitude; calling the audio analysis device to workso as to emit a first target sound signal to a to-be-tested microphone through the simulation nozzle; and enabling the audio analysis device to generate a first analysis result according to the firsttarget sound signal and a signal picked up by the to-be-tested microphone.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

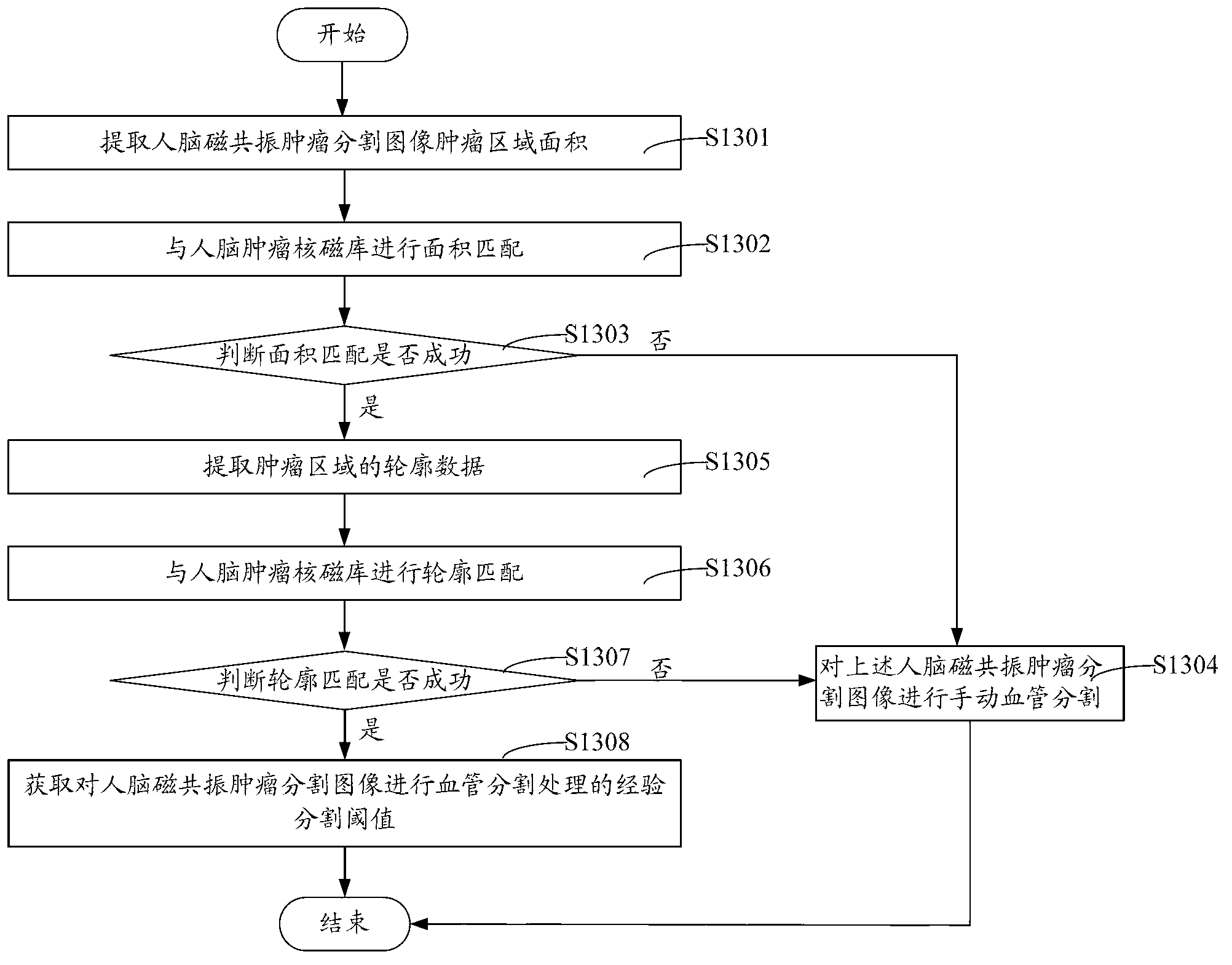

Magnetic resonance imaging blood vessel segmentation method and system based on human brain tumor nuclear magnetic library

ActiveCN103236062ARealize automatic segmentationAvoid human involvementImage analysisOrgan movement/changes detectionHuman brain tumorResonance

The invention discloses a magnetic resonance imaging blood vessel segmentation method based on a human brain tumor nuclear magnetic library. On the basis of a human brain magnetic resonance tumor segmentation image, an experience segmentation threshold for blood vessel segmentation is obtained from the human brain tumor nuclear magnetic library in accordance with data of a tumor area of the human brain magnetic resonance tumor segmentation image, the human brain magnetic resonance tumor segmentation image is analyzed to obtain a blood vessel gray threshold in accordance with the experience segmentation threshold, and the blood vessel gray threshold is adopted to perform blood vessel segmentation on the human brain magnetic resonance tumor segmentation image. By using the segmentation method, automatic blood vessel segmentation of a human brain tumor magnetic resonance image is realized, manual intervention is avoided, the segmentation accuracy is increased, and an algorithm for blood vessel segmentation of the human brain magnetic resonance tumor segmentation image is simpler, so as to be more favorable for system productization. Additionally, the invention further discloses a magnetic resonance imaging blood vessel segmentation system based on the human brain tumor nuclear magnetic library.

Owner:CRSC COMM & INFORMATION GRP CO LTD +1

Button engraving device

The invention provides a button engraving device. The button engraving device comprises an engraving tooling capable of fixing a button workblank, a detector, a laser emitting device and a control device, wherein the detector is used for detecting a hole position of the button workblank on the engraving tooling and capable of sending a detection signal, the laser emitting device is used for emitting laser to engrave the button workblank on the engraving tooling, and the control device is used for receiving the detection signal sent by the detector and comparing the detection signal with preset standard position data so that the laser emitted by the laser emitting device can be adjusted to an engraving position on the button workblank. According to the button engraving device, the detector and the control device are cooperated so as to change laser emitting angles instead of manual movement and correction of the button workblank, automatic production of the button workblank during engraving can be achieved, manual interference is avoided, the producing efficiency of buttons is greatly increased, the workload of an operator is reduced, and economic benefits of button production can be further improved.

Owner:ZHEJIANG WEIXING IND DEV

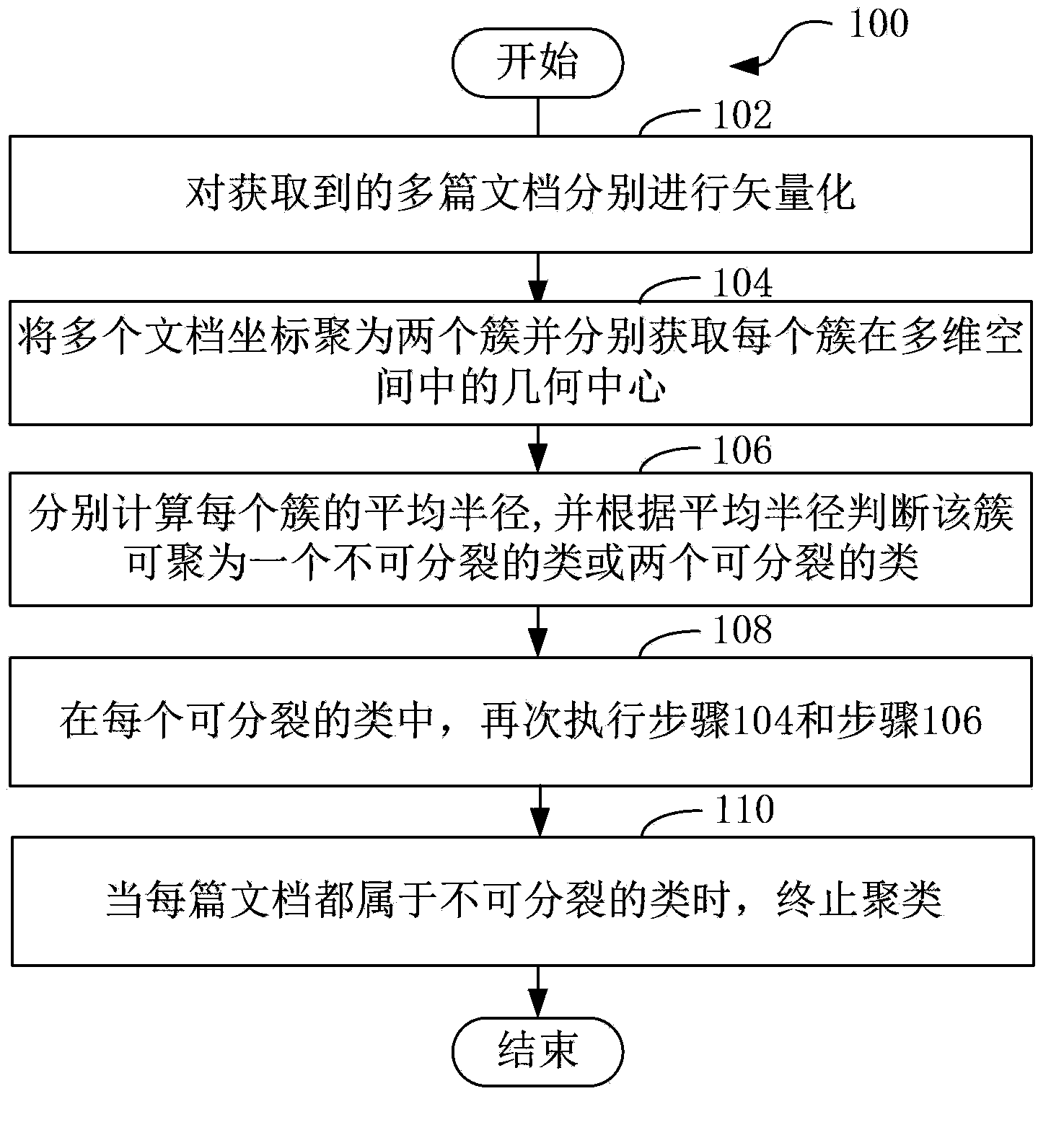

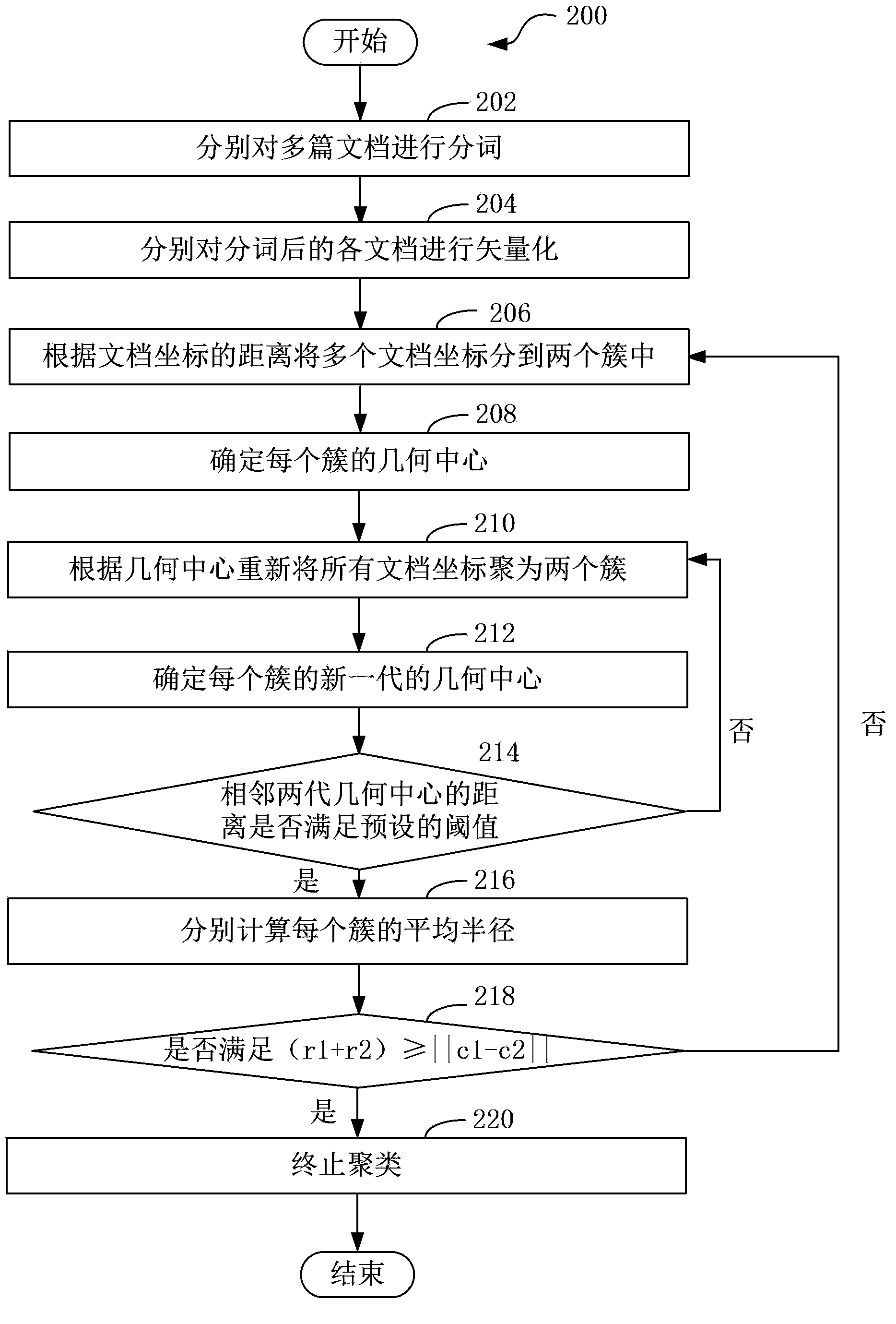

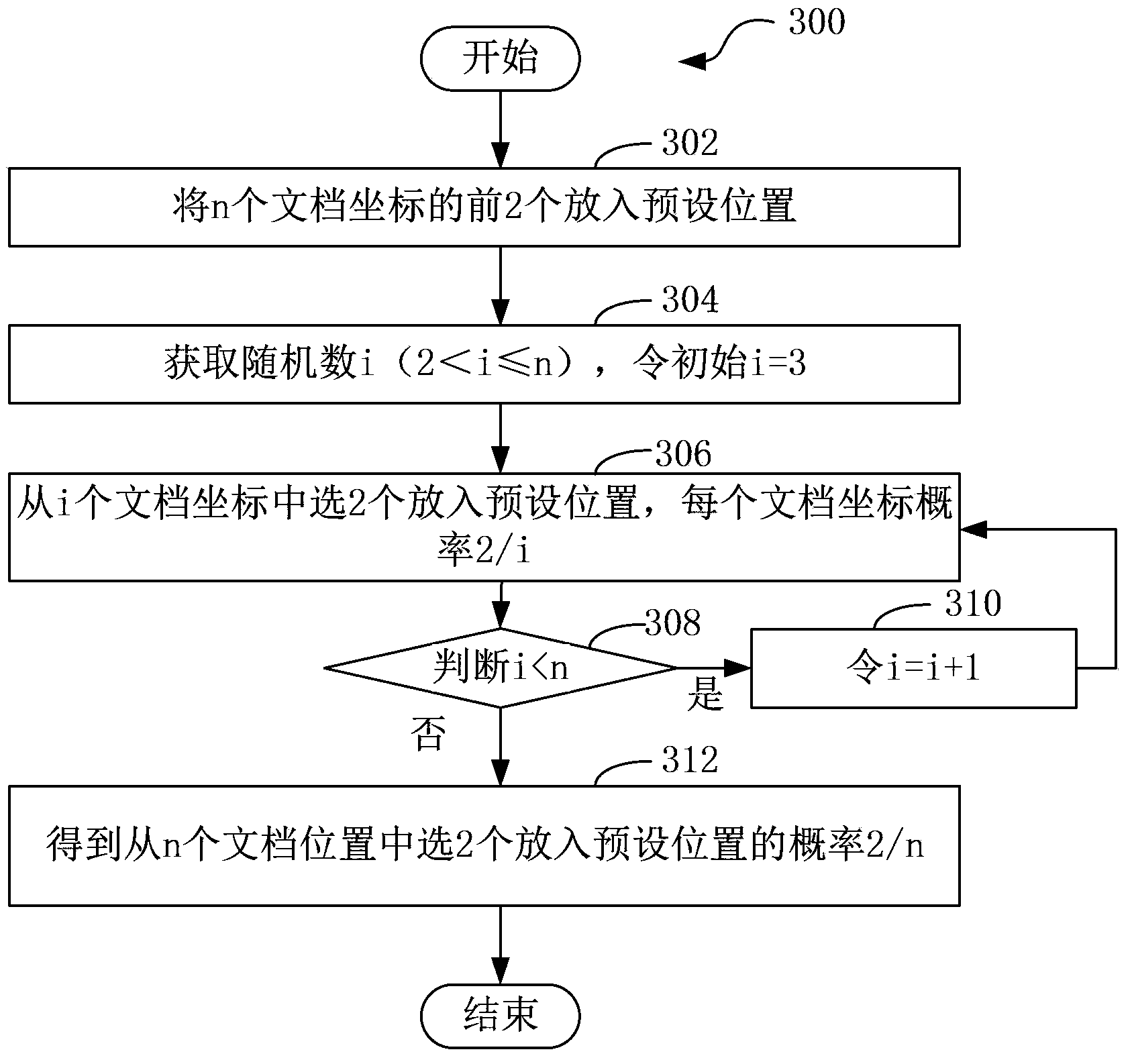

Document clustering method and device

ActiveCN103455534AAccurate clusteringImprove accuracySpecial data processing applicationsDocument management systemsDocumentationMulti dimensional

The invention provides a document clustering method and device. The method includes the steps of A, vectorizing each document to allow each vectorized document to correspond to a document coordinate in a multi-dimensional space; B, clustering the documents into two clusters and acquiring geometric center of each cluster in the multi-dimensional space; C, calculating average radius of each cluster, clustering documents corresponding to the document coordinates in the two clusters into a inseparable category if the average radius satisfies a preset condition, and corresponding the two clusters into two separable categories if the average radius does not satisfy the preset condition; D, executing step B and C in each separable category; E, terminating clustering when each document belongs to the inseparable category; wherein the average radius the average value of the distance from all document coordinates to the geometric centers. By the method, document clustering accuracy and intelligence are increased.

Owner:NHORIZON INNOVATION BEIJING SOFTWARE LMT

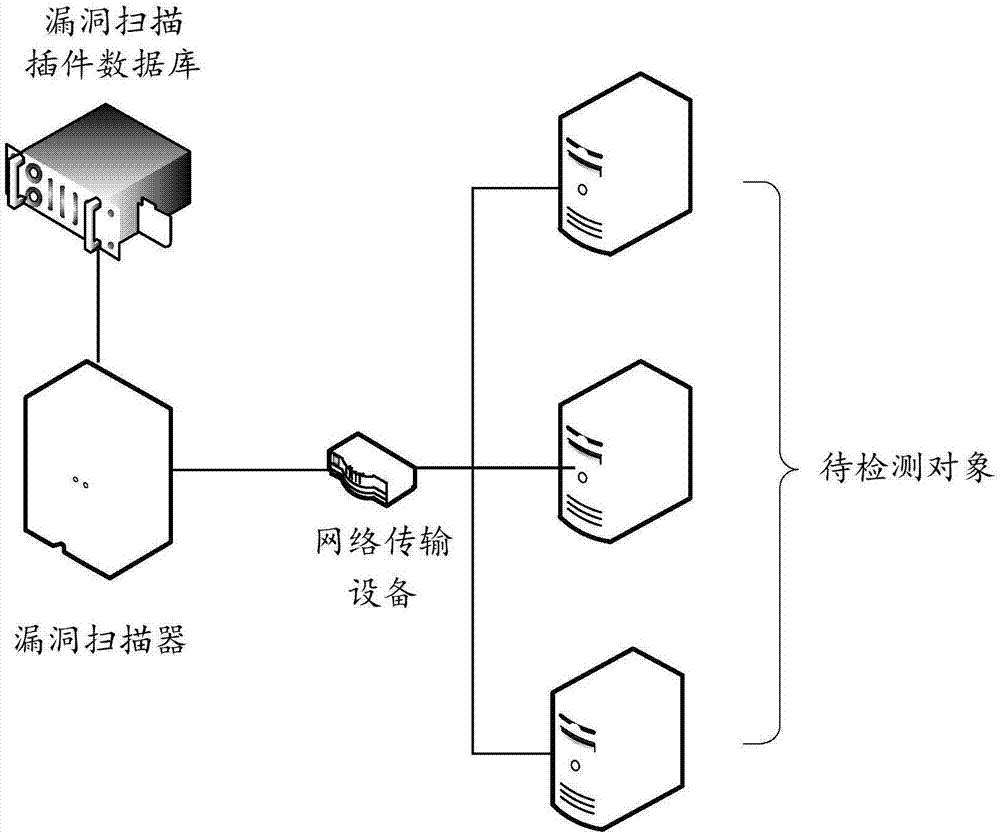

Vulnerability scanning method and device and computer readable medium

ActiveCN107145784AImprove scanning efficiencyEasy to callPlatform integrity maintainanceInformation processingEngineering

The embodiment of the invention provides a vulnerability scanning method and device and a computer readable medium and relates to information processing field for solving the problems that an existing universal mode is very low in scanning efficiency and poor in precision. The method comprises the following steps of: collecting basic parameter information of a vulnerability scanning plug-in through an appointed interface; determining the vulnerability scanning plug-in corresponding to the basic parameter information on the basis of a recording mode corresponding to the appointed interface according to the basic parameter information; storing the vulnerability scanning plug-in in a vulnerability scanning plug-in database; and scanning vulnerability based on the stored vulnerability scanning plug-in in the vulnerability scanning plug-in database. The embodiment of the invention is suitable for a process of scanning vulnerability.

Owner:TENCENT TECH (SHENZHEN) CO LTD

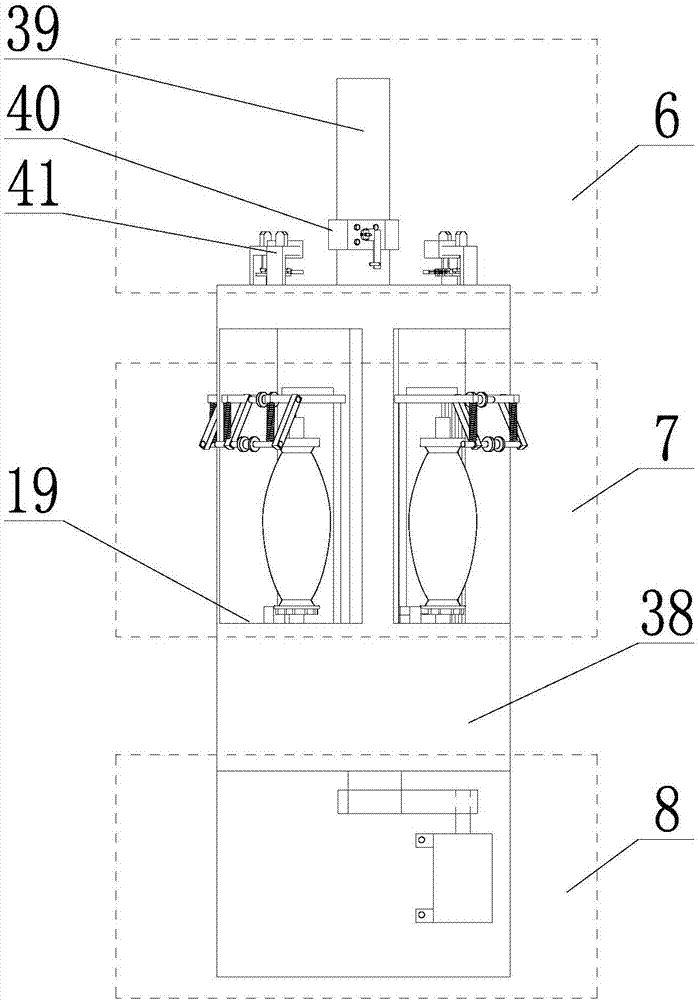

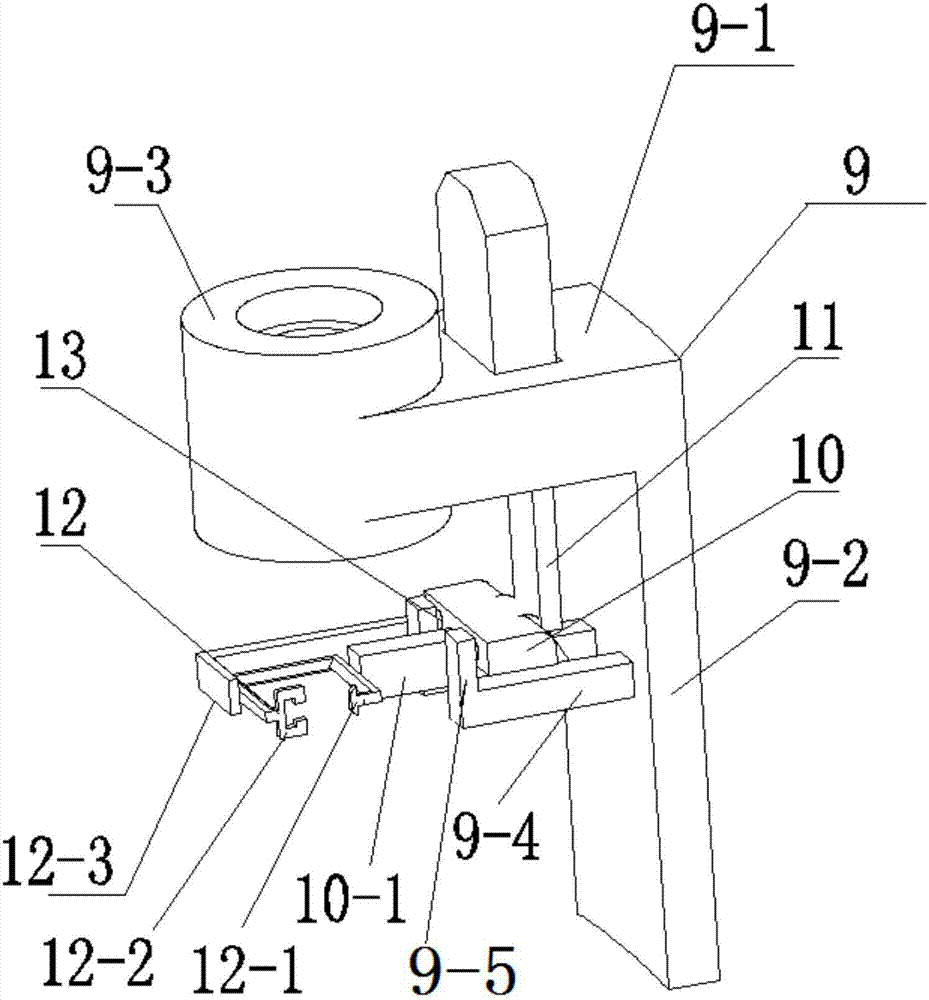

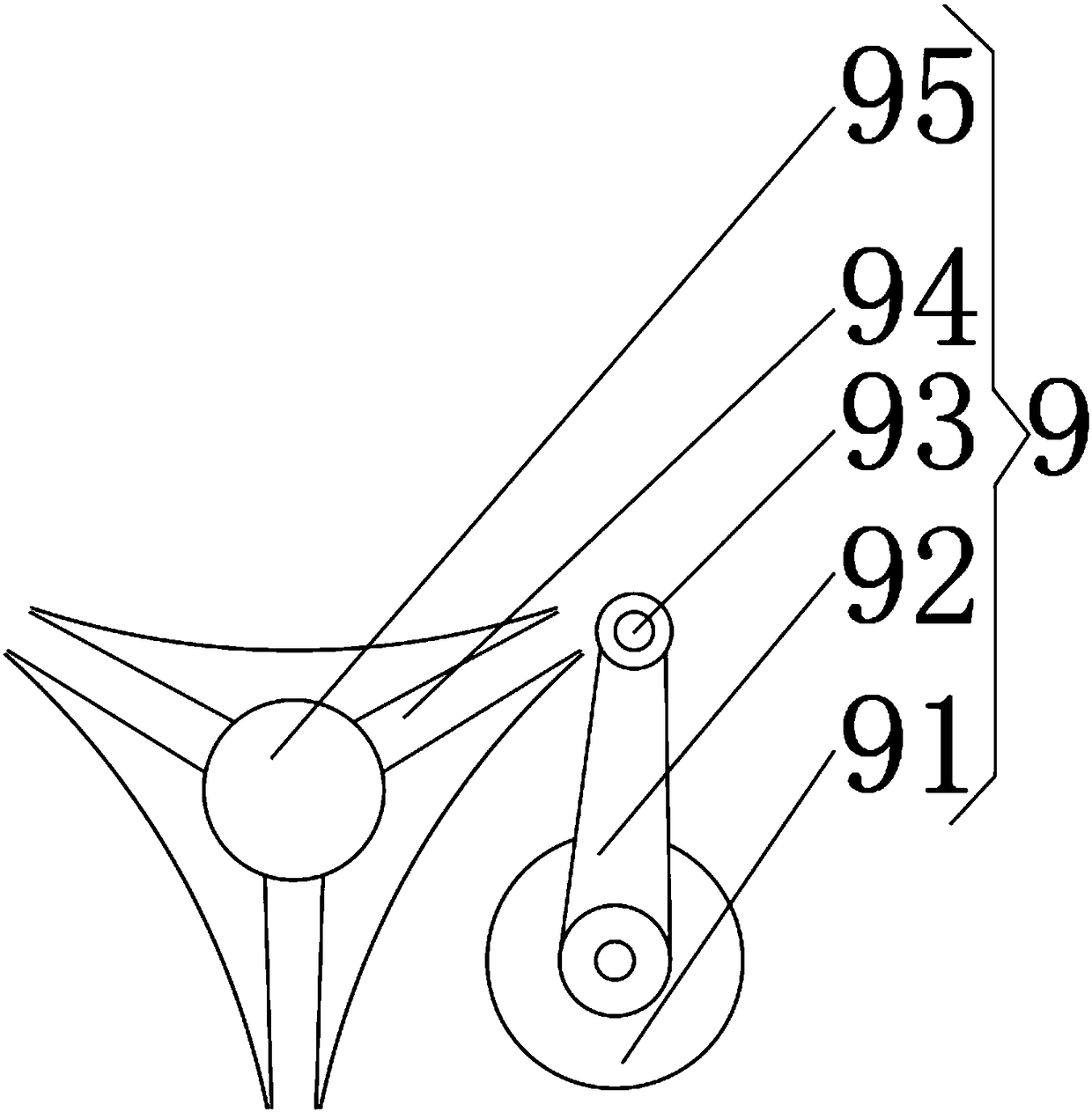

Yarn carrier capable of automatically replenishing and discharging yarns and three-dimensional knitting machine utilizing yarn carrier

The invention discloses a yarn carrier capable of automatically replenishing and discharging yarns. The yarn carrier comprises a yarn carrier main body, a yarn replenishing-discharging mechanism, a yarn carrying mechanism and a driving mechanism, wherein the yarn replenishing-discharging mechanism, the yarn carrying mechanism and the driving mechanism are arranged on the yarn carrier main body, the yarn replenishing-discharging mechanism is located at the upper part of the yarn carrier main body, the yarn carrying mechanism is located in the middle of the yarn carrier main body, and the driving mechanism is located at the bottom of the yarn carrier main body. According to the yarn carrier, the problem that the yarns need to be replenished and discharged by manually changing the fineness of knitted yarns, changing the motion track of the yarn carrier or introducing impurities in a knitting process of a variable cross section of an existing yarn carrier is solved. The invention further discloses a three-dimensional knitting machine utilizing the yarn carrier. The three-dimensional knitting machine comprises a knitting stander, a drive-off motor, a pre-forming chuck, a chassis and a plurality of yarn carriers, wherein the drive-off motor, the pre-forming chuck, the chassis and the yarn carriers are arranged on the knitting stander, the chassis is located at the lower part of the knitting stander, the yarn carriers are arrayed and mounted on the chassis, and the pre-forming chuck is located right above the yarn carriers and is fixed on the knitting stander through a connecting rod.

Owner:XI'AN POLYTECHNIC UNIVERSITY

RPA process file generation method and device, computer equipment and storage medium

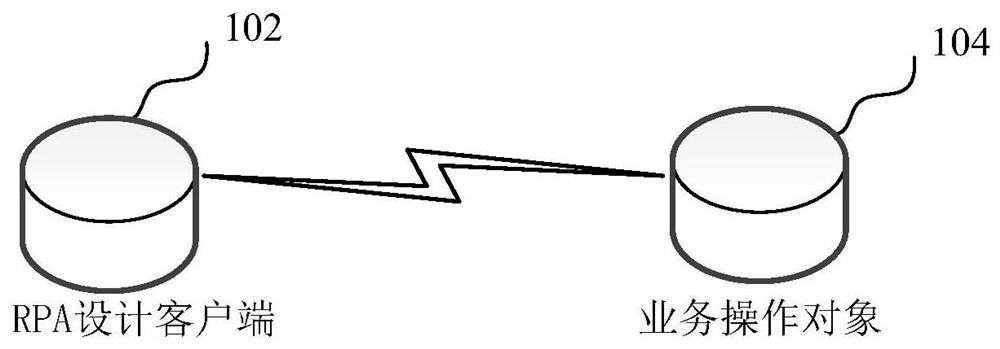

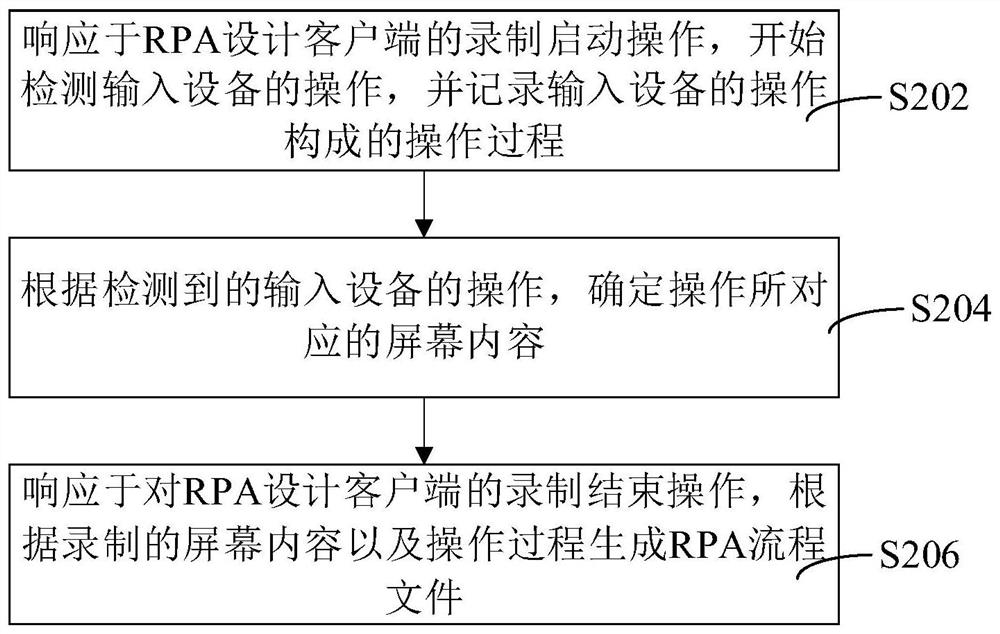

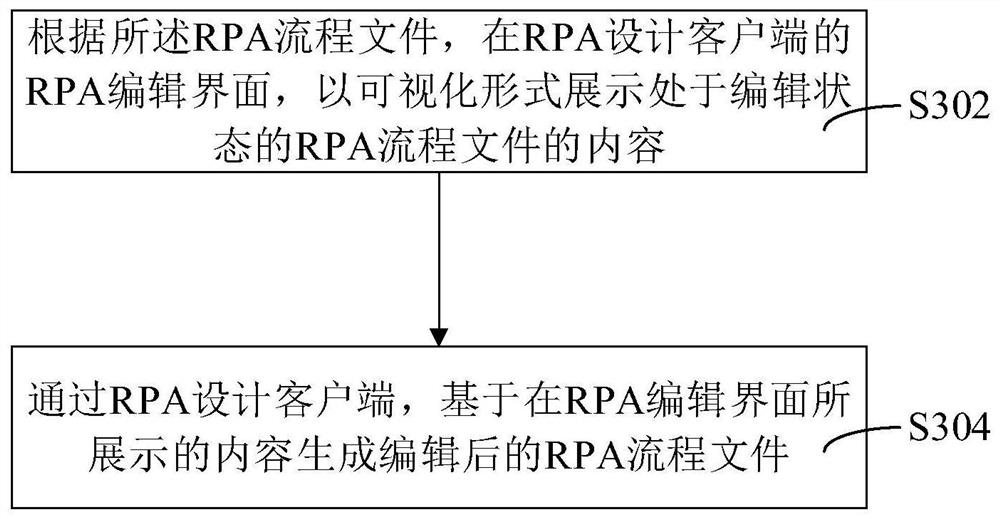

PendingCN112464623AShort time consumptionImprove efficiencyNatural language data processingOffice automationComputer equipmentInput device

The invention relates to an RPA process file generation method and device, computer equipment and a storage medium. The method comprises the following steps: in response to a recording starting operation on an RPA design client, starting to detect an operation of input equipment, and recording an operation process formed by the operation of the input equipment; determining screen content corresponding to the operation according to the detected operation of the input equipment; wherein the screen content comprises at least one of control information and an interface screenshot; in response to arecording ending operation on the RPA design client, obtaining a recording process file generated according to the recorded screen content and the operation process. By adopting the method, the efficiency of generating the RPA process file can be improved.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

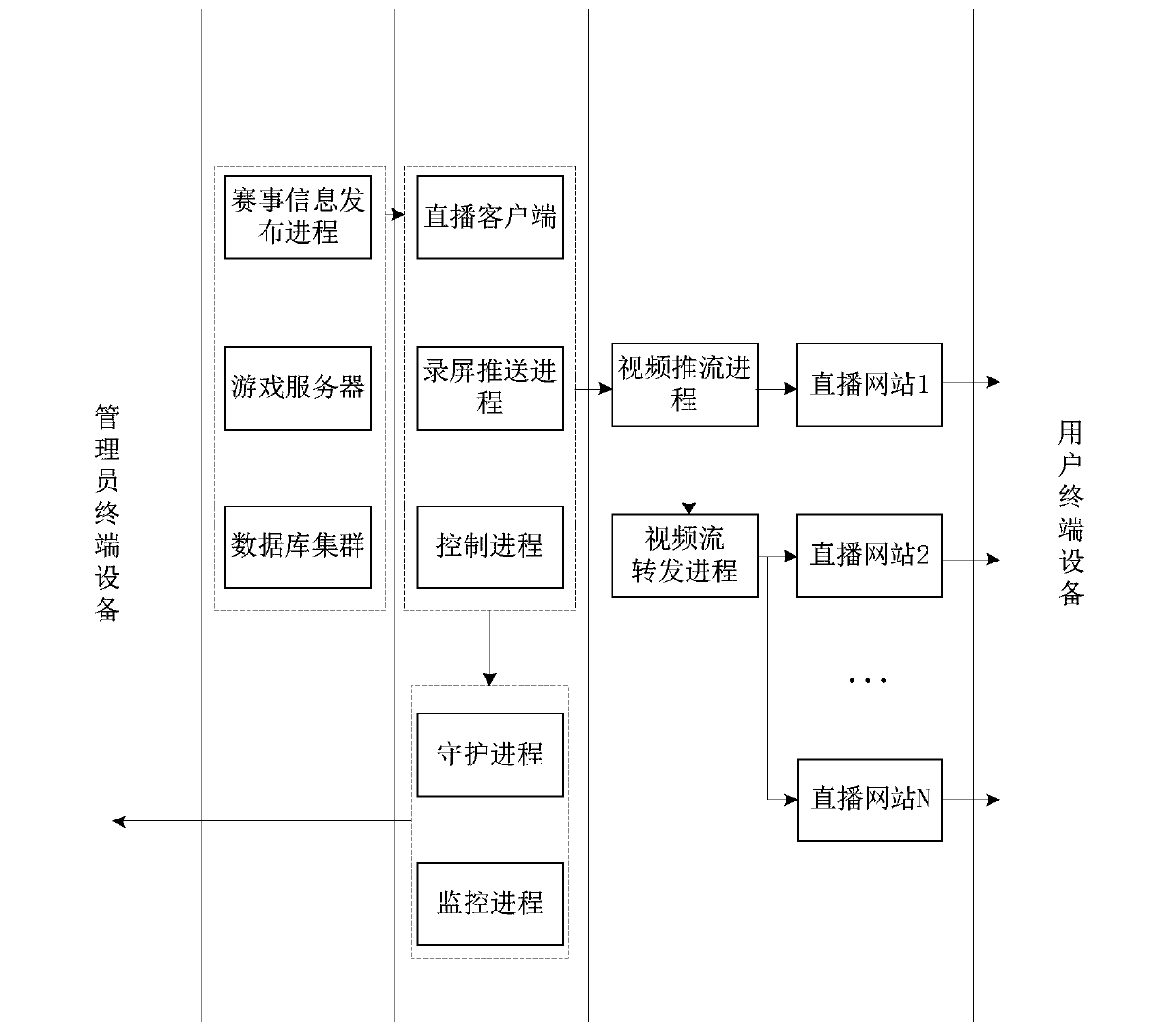

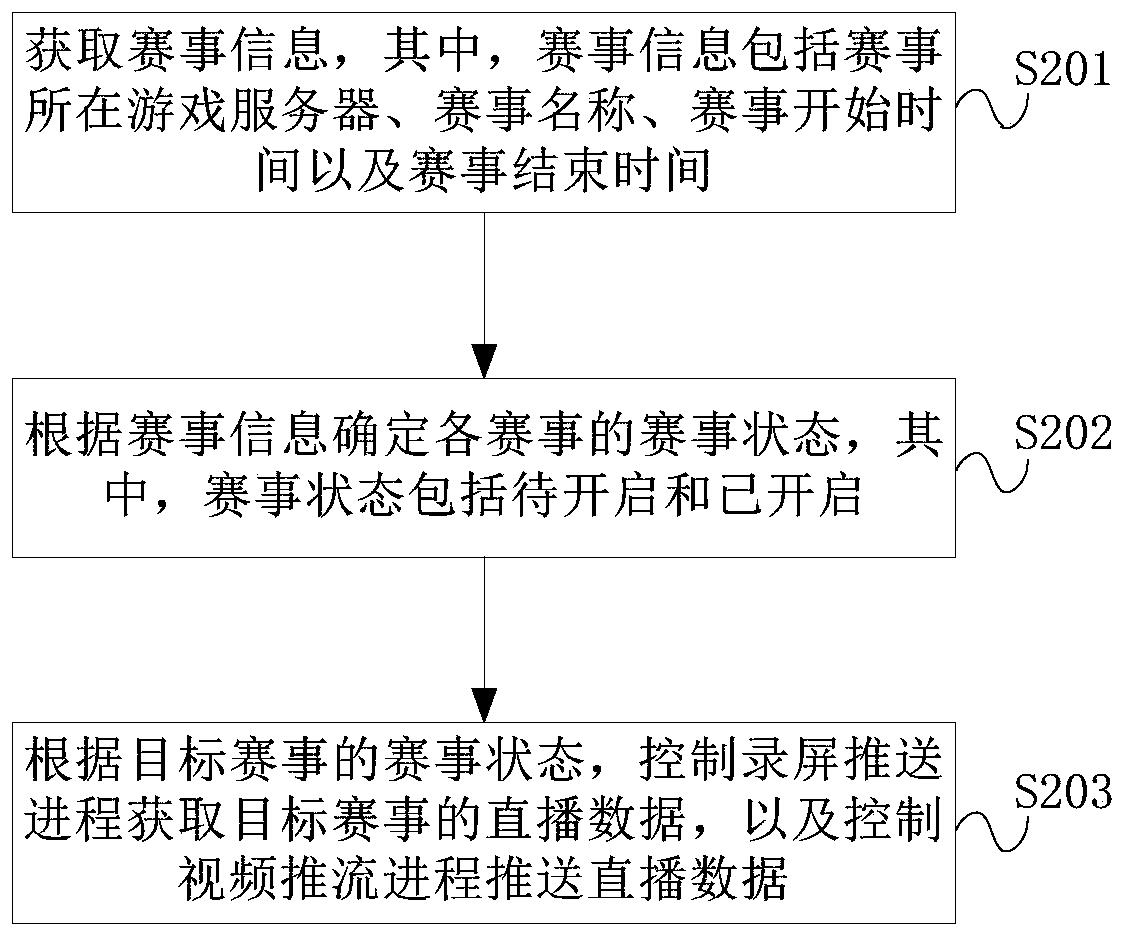

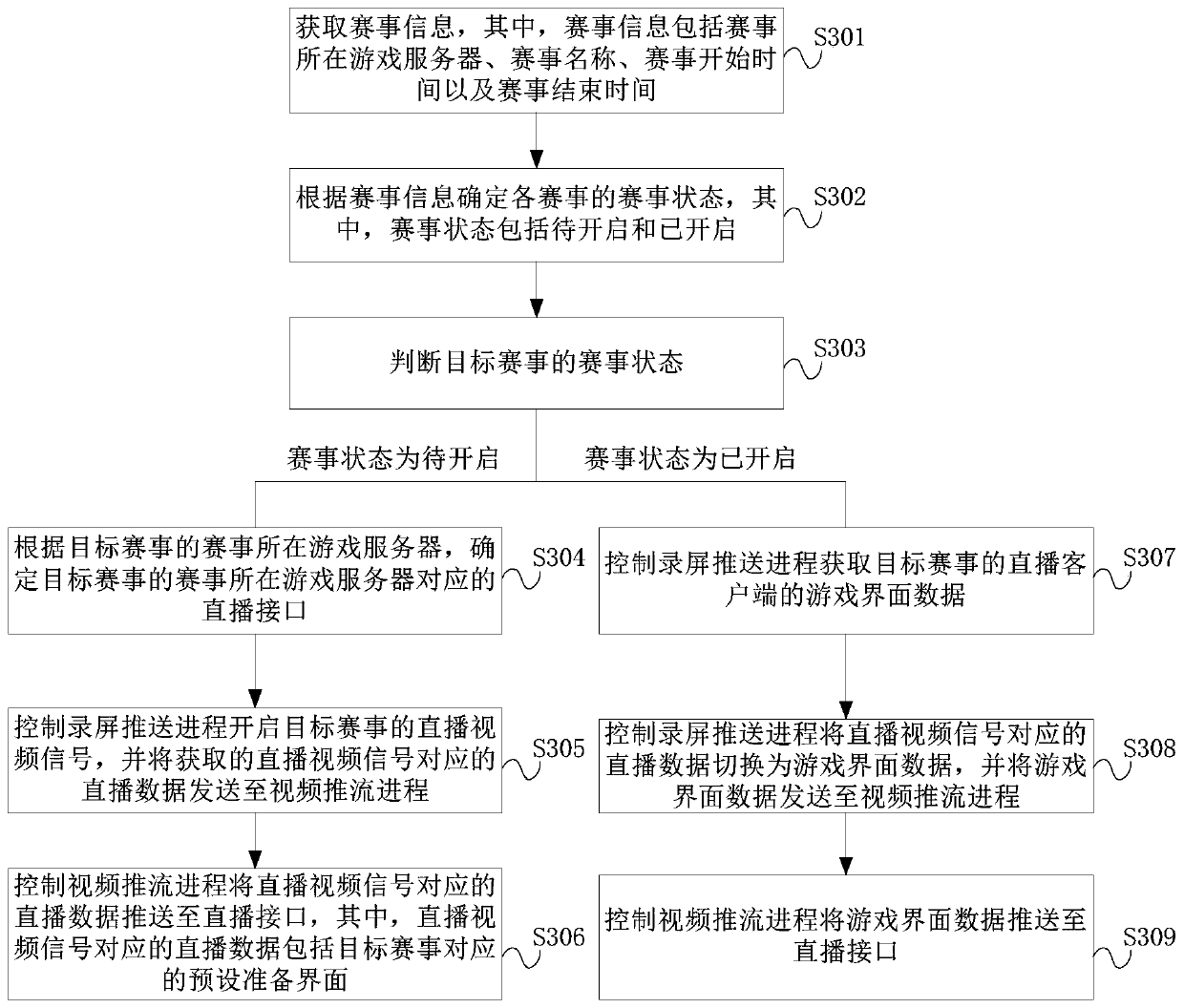

Game competition live broadcast method and device

The embodiment of the invention provides a game competition live broadcast method and a game competition live broadcast device. The method comprises the following steps: acquiring competition information, wherein the competition information comprises game server of the competitions, competition names, competition starting time and competition finishing time; determining the competition states of the competitions according to the competition information, wherein the competition states comprise to-be-started state and started state; and according to the competition state of target competition, controlling a screen recording pushing process to acquire live broadcast data of the target competition and controlling a video flow pushing process to push the live broadcast data. By controlling theprocess, according to the competition states, the screen recording pushing process and the video flow pushing process are controlled to push the live broadcast data, and thus the automatic processingfor live broadcast of the game competitions is realized.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

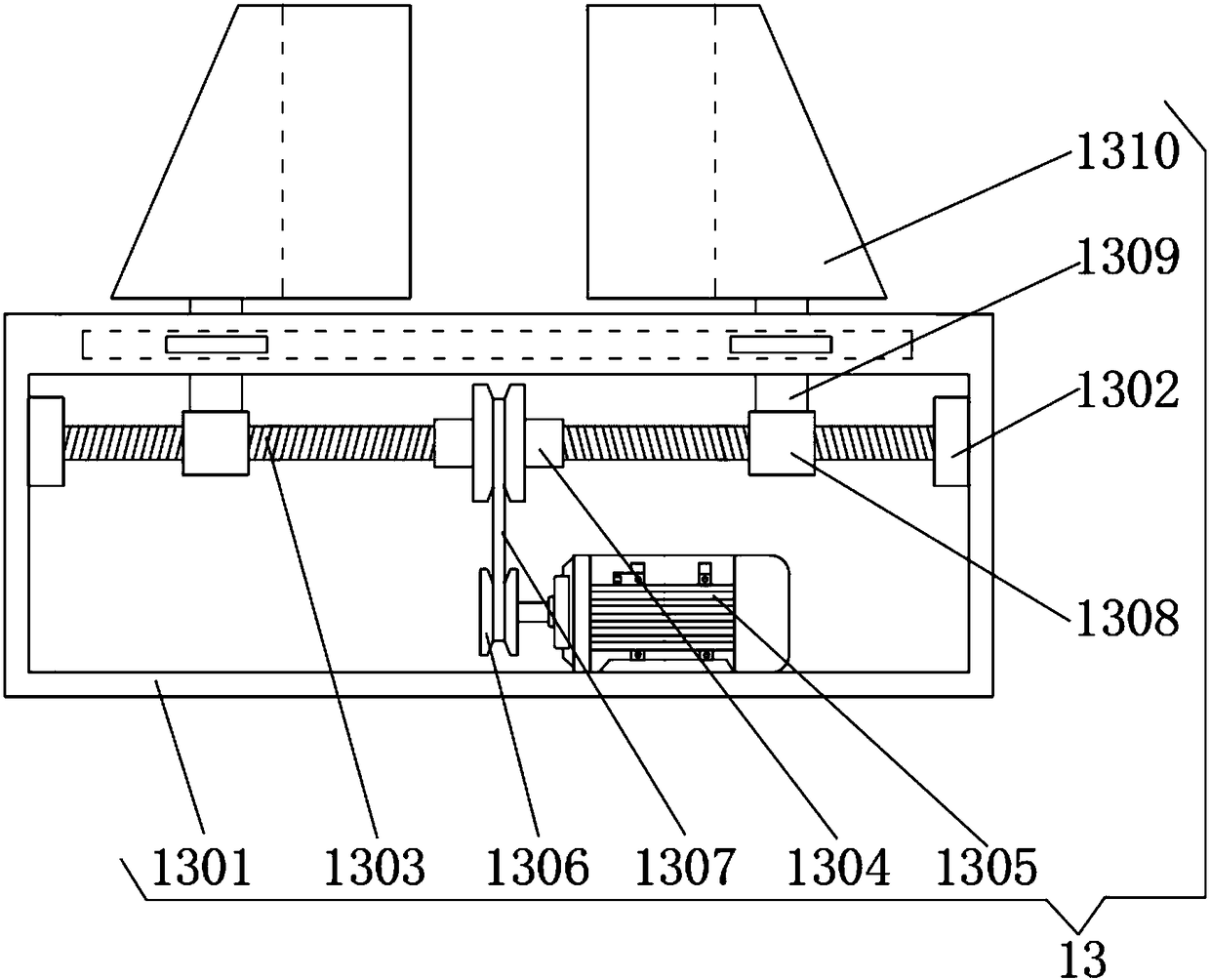

Edge trimming device for plastic cup

InactiveCN108453966AImprove work efficiencyQuality assuranceDomestic articlesEngineeringAssembly line

The invention discloses an edge trimming device for a plastic cup. The device comprises a box body, two sides of the bottom of the inner wall of the box body are respectively connected to a first transmission wheel and a second transmission wheel through a first support column and a second support column, the surfaces of the first transmission wheel and the second transmission wheel are connectedby a synchronous transmission belt, the surface of the synchronous transmission belt is fixedly connected with a clamping device, the top of the box body is rotatably connected with a first rotating disc, the side surface of the first rotating disc is fixedly connected with a driving device, the bottom of the first rotating disc is fixedly connected with a second rotating disc through a connectingrod, the bottom of the second rotating disc is fixedly connected with a moving device through a top box, an edge trimming device body is fixedly connected to the bottom of the moving device, and thebottom of the edge trimming device body is fixedly connected with a trimming knife; the invention relates to the technical field of plastic product processing; the edge trimming device for the plasticcup solves the problem of low precision and low efficiency brought by traditional manual operation of a knife for trimming, improves the working efficiency, and is suitable for assembly line production.

Owner:湖州南浔博逸金属材料经营部

Data processing method and device based on block chain system and electronic equipment

PendingCN111311407AImprove processing efficiencyHigh precisionFinanceDigital data protectionChain systemData processing

The invention provides a data processing method and device based on a block chain system and electronic equipment, and relates to the field of block chains. The blockchain system comprises a service node sub-network and an accounting node sub-network, the service node sub-network comprises a service node, the accounting node sub-network comprises an accounting node, the data processing method is executed by the accounting node, and the data processing method comprises the following steps: receiving a data processing request sent by the service node; analyzing the data processing request to obtain the type of the data processing request; and calling a target logic module from an intelligent contract stored in the accounting node sub-network according to the type of the data processing request, processing effective data corresponding to the data processing request through the target logic module, and returning a processing result to the service node. According to the invention, data processing is carried out through a simplified and normalized smart contract, and the efficiency and accuracy of data processing are improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

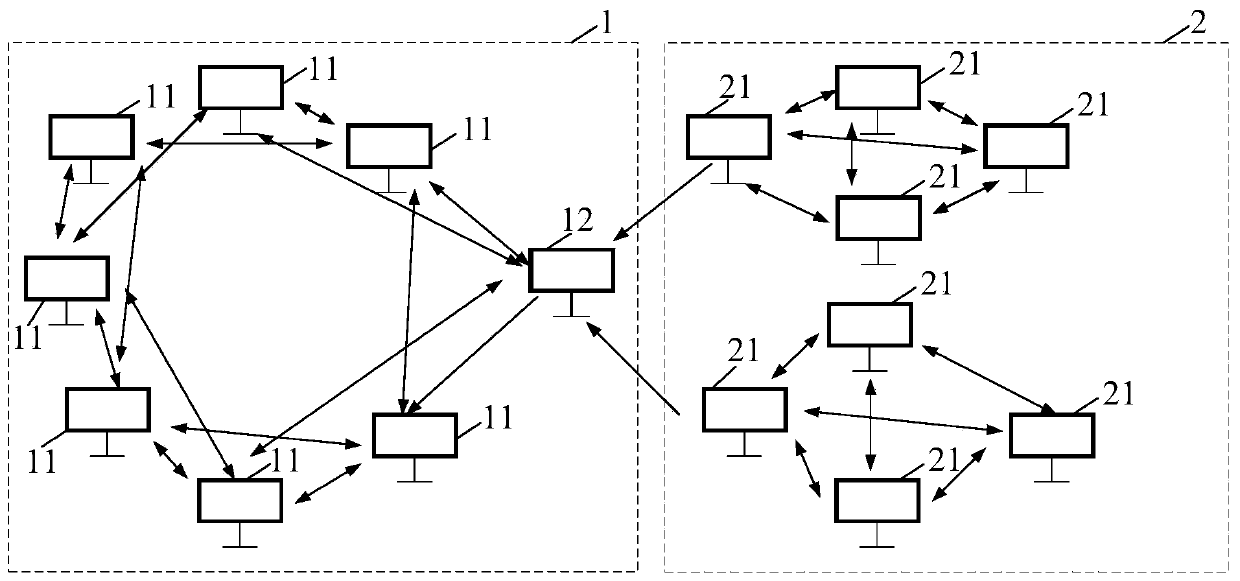

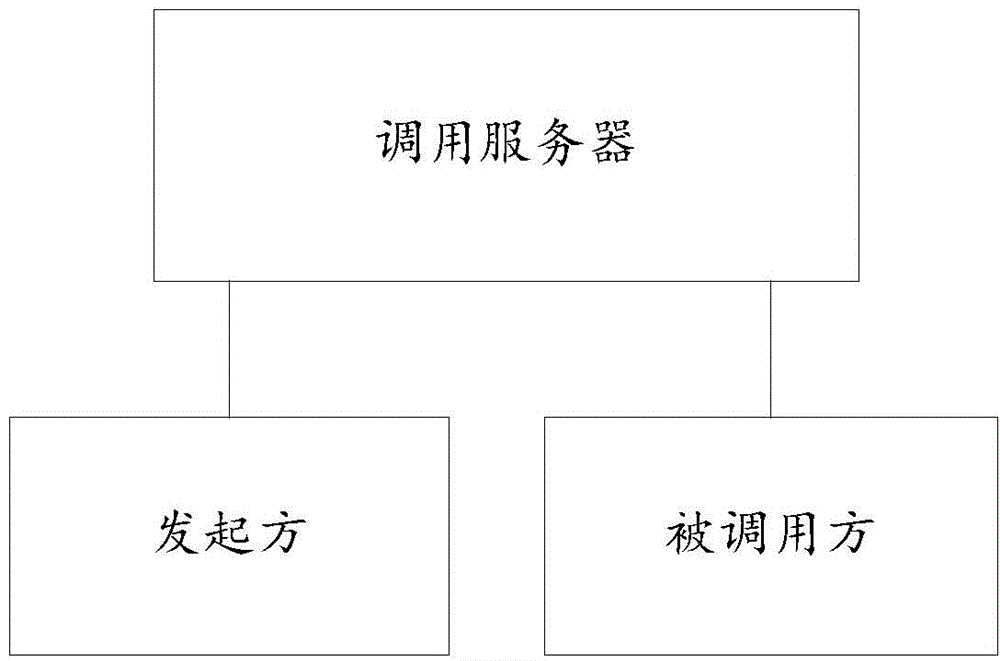

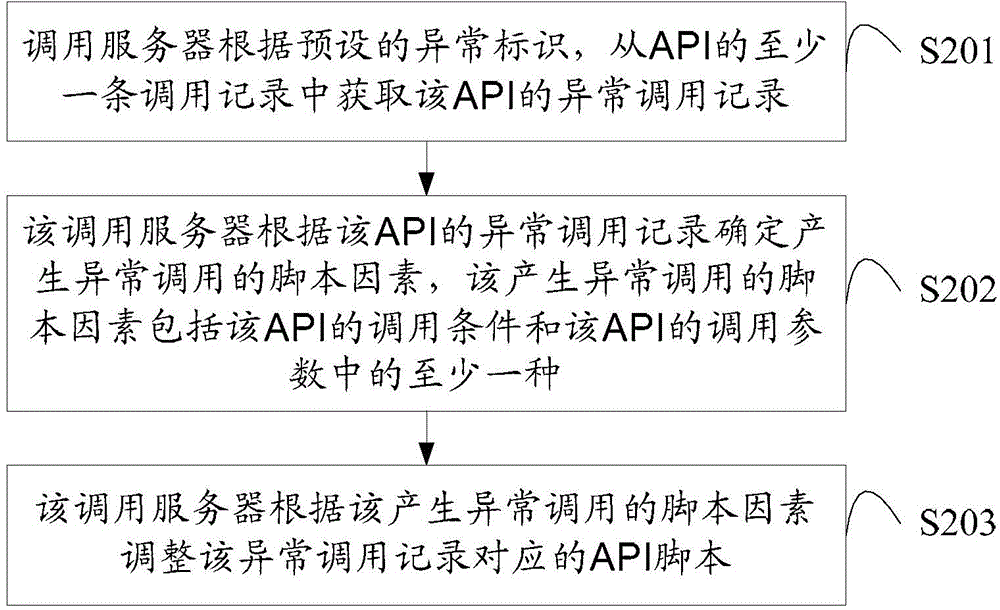

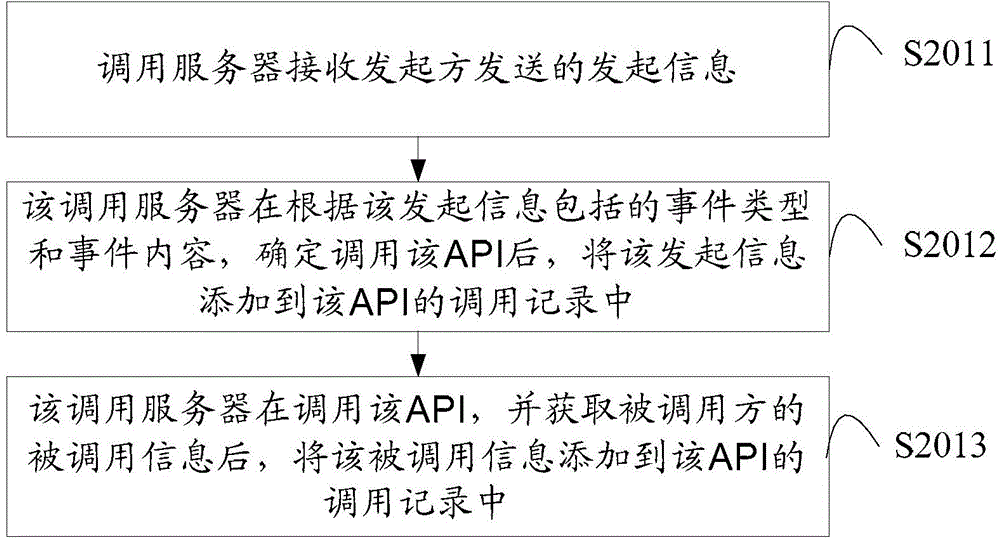

Management method, device and system of system docking

ActiveCN104618162ASolve the problem of abnormal callImprove efficiencyData switching networksSystem of systemsManagement efficiency

The invention provides a management method, a management device and a management system of system docking, relates to the communication field, and aims at solving the problems that management efficiency of the system docking is low and manpower resources are consumed. The management method of the system docking includes: obtaining an abnormal invoking record from at least one invoking record of an API (application program interface) according to a preset abnormal identification; confirming a script factor of generation of abnormal invoking according to the abnormal invoking record of the API, wherein the script factor of the generation of the abnormal invoking contains an invoking condition of the API and at least one of invocation parameters of the API; adjusting an API script corresponding to the abnormal invoking record according to the script factor of the generation of the abnormal invoking. The management method, the management device and the management system of the system docking are used to manage the system docking.

Owner:HUAWEI TECH CO LTD

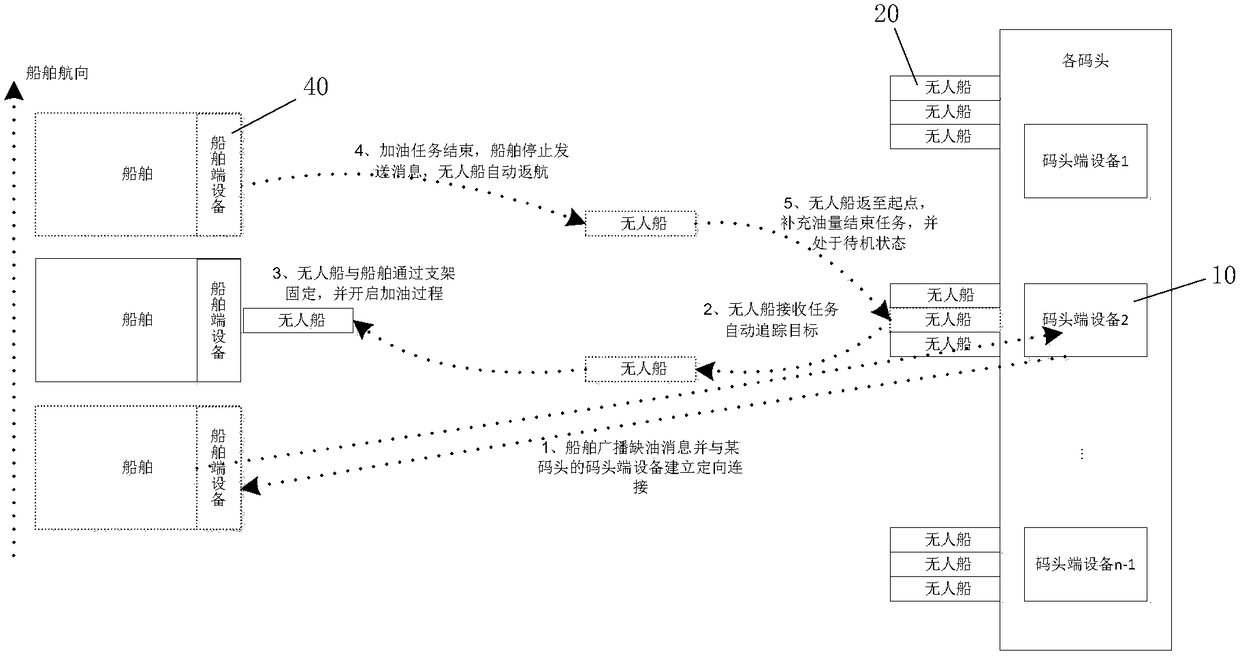

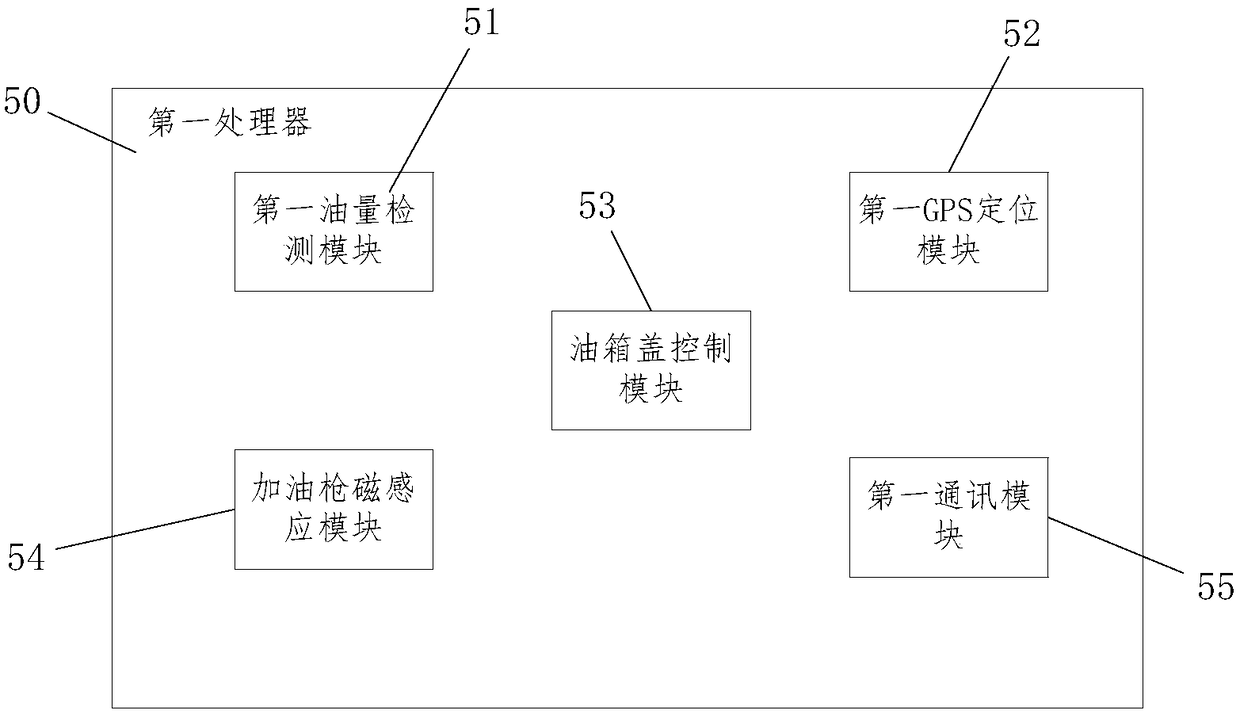

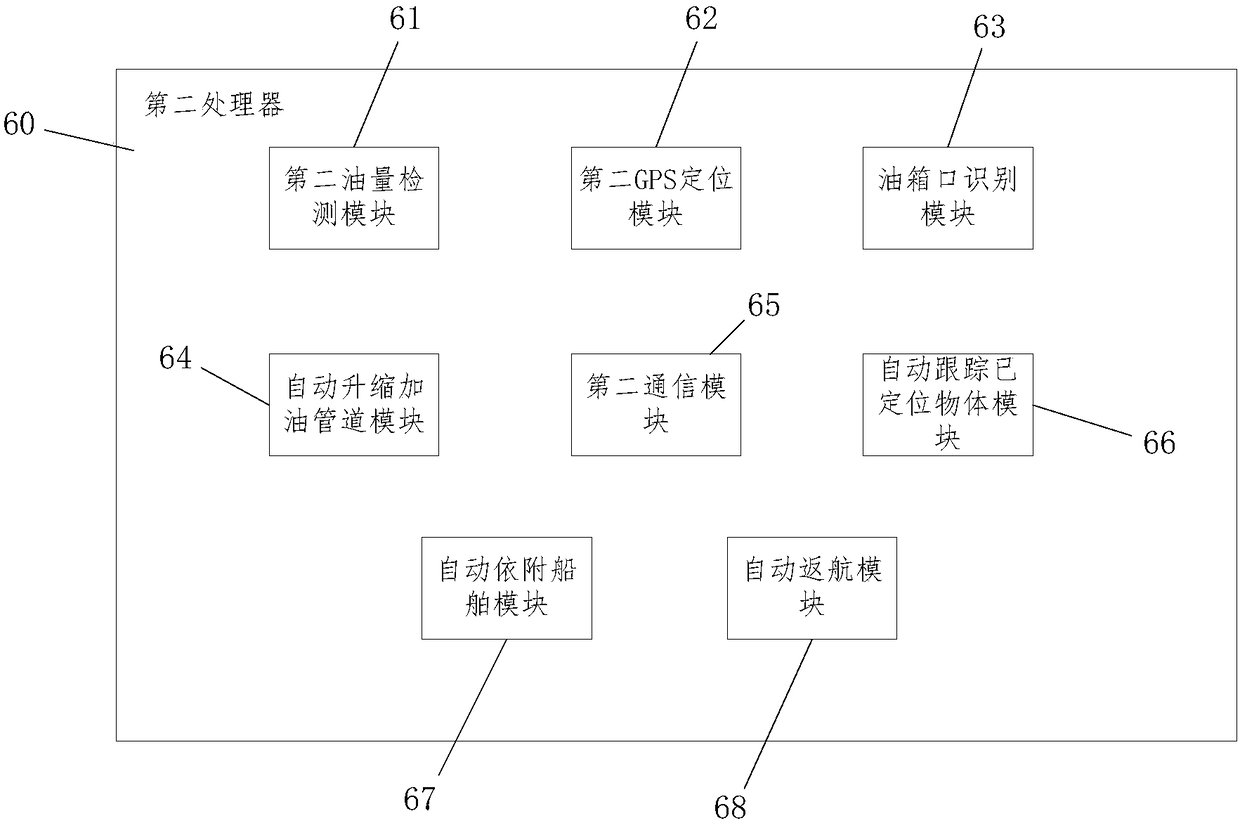

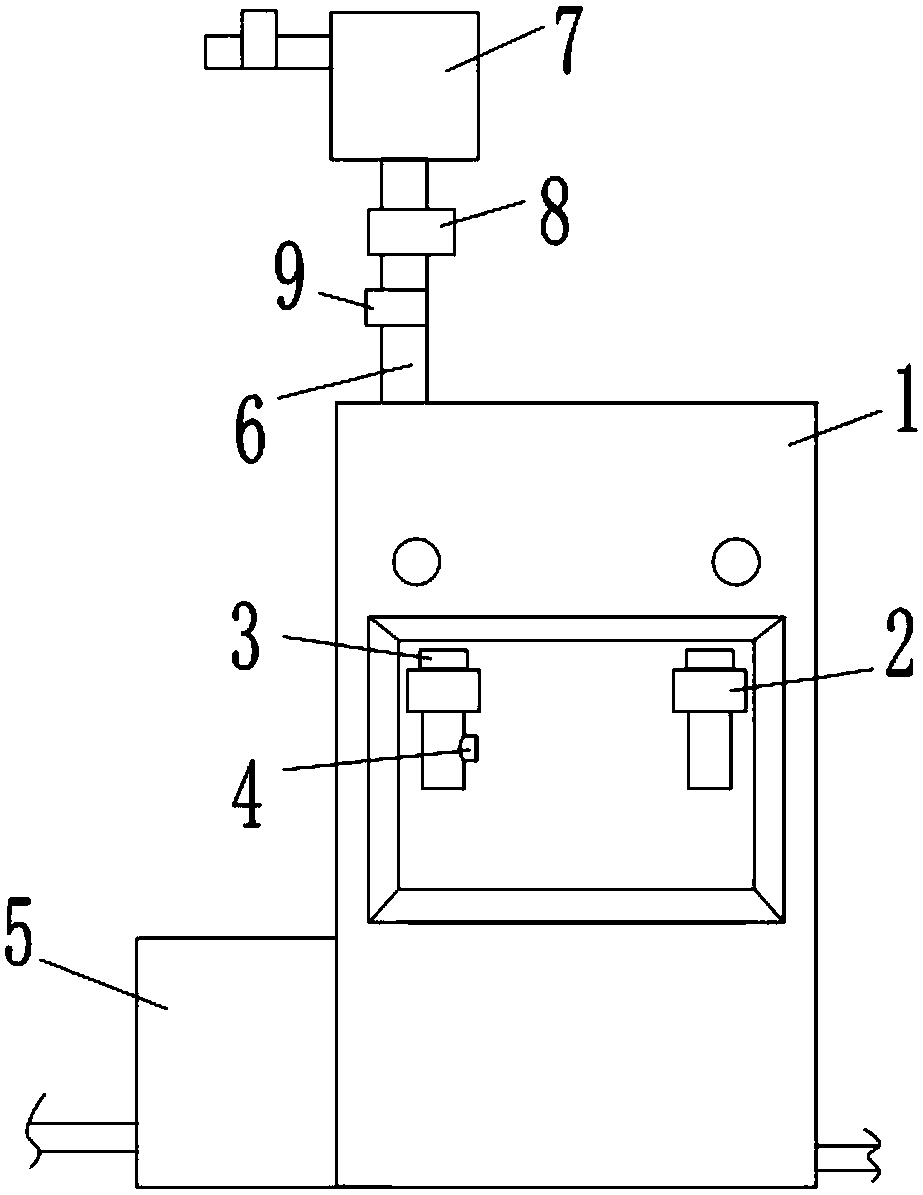

Automatic ship refueling system and method based on unmanned ship

InactiveCN108089206AReduce fuel consumptionReduce pollutionSatellite radio beaconingTerminal equipmentShip control

The invention provides an automatic ship refueling system and method based on an unmanned ship and relates to the technical field of unmanned ship control. The system includes one or more harbor terminal devices, each harbor terminal device is provided with one or more unmanned ships, each ship is provided with a ship terminal device, the harbor terminal device can receive the fuel shortage warning information of each ship terminal device, and the harbor terminal device controls the unmanned ship to realize the automatic refueling of the ship and return automatically. The system and the methodeliminate the inadequacies of traditional fueling methods, and make ships more convenient, efficient, and labor-saving.

Owner:安徽科微智能科技有限公司

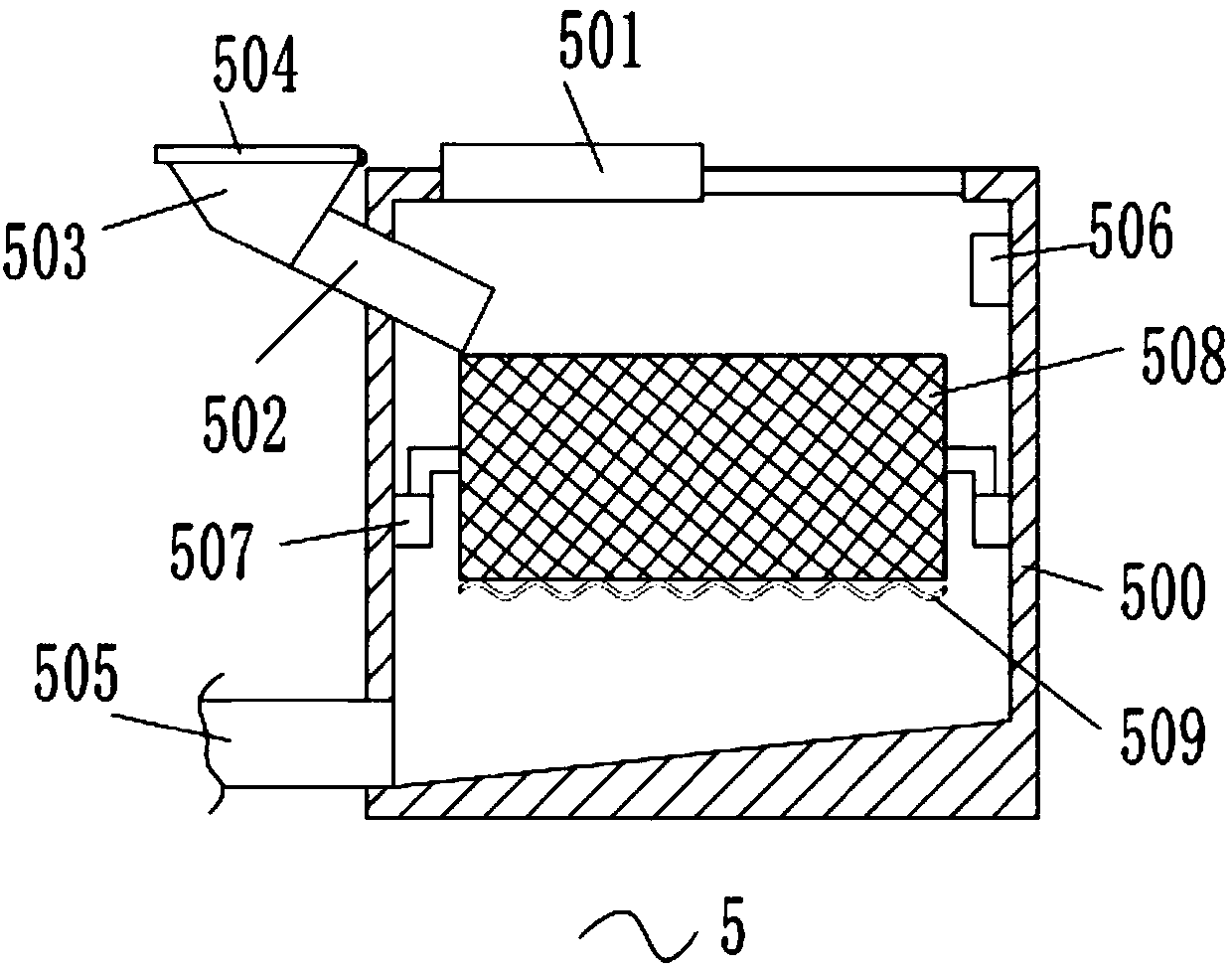

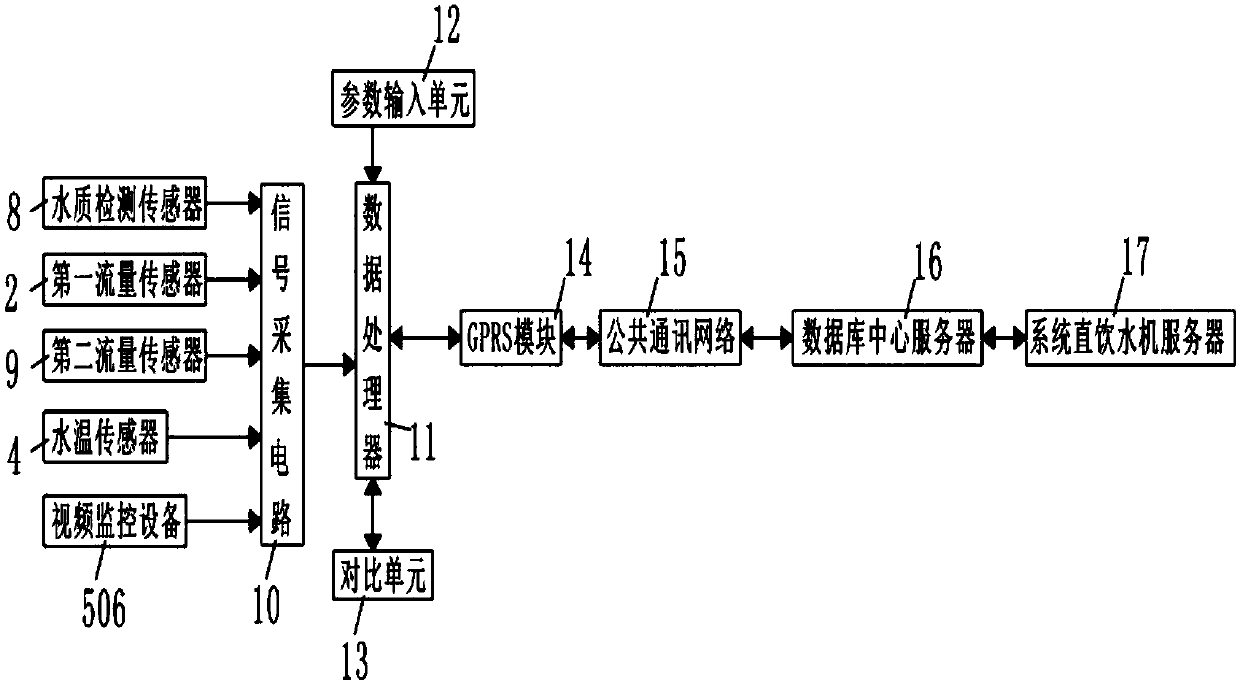

Internet-of-things direct drinking water system

The invention discloses an internet-of-things direct drinking water system, and belongs to the technical field of water fountains. The internet-of-things direct drinking water system comprises a direct drinking water purifier body, wherein a cold / hot water output pipe of the direct drinking water purifier body is provided with a first flow sensor and an infrared induction valve; further, an infrared induction probe of the infrared induction valve is located at the top of the surface of a shell of the direct drinking water purifier body; a hot water output pipe of the direct drinking water purifier body is provided with a water temperature sensor; the left side of the direct drinking water purifier body is provided with a tea oven-drying device; the top of the direct drinking water purifierbody is provided with a water inlet pipe; the top of the water inlet pipe is provided with a tap water purification device. The real-time monitoring and management on the equipment running state, theequipment failure condition and the like of each direct drinking water purifier are realized; meanwhile, hot water is controlled by utilizing the infrared induction valve to flow out; a child is prevented from using the internet-of-things drinking water system in the condition of being not accompanied by an adult; a scald is avoided; the manual participation is reduced; the management and maintenance times are reduced; thus, the management and maintenance costs are decreased and the market application prospect is wide.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

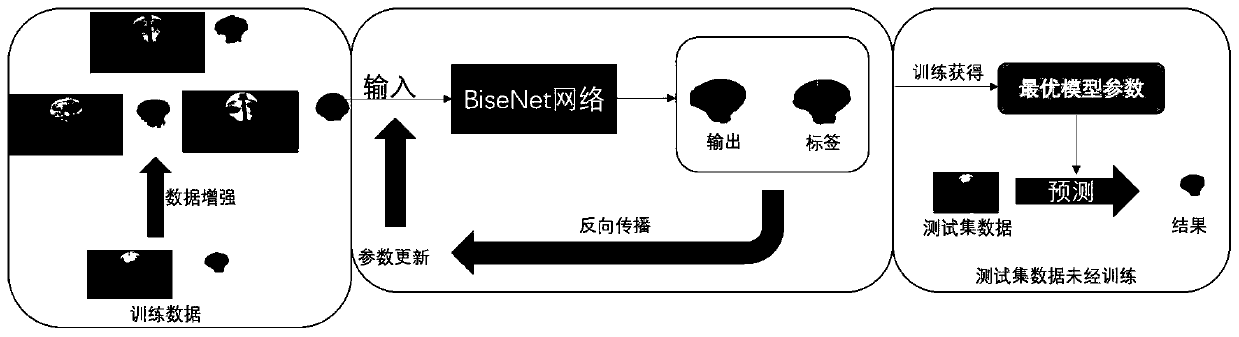

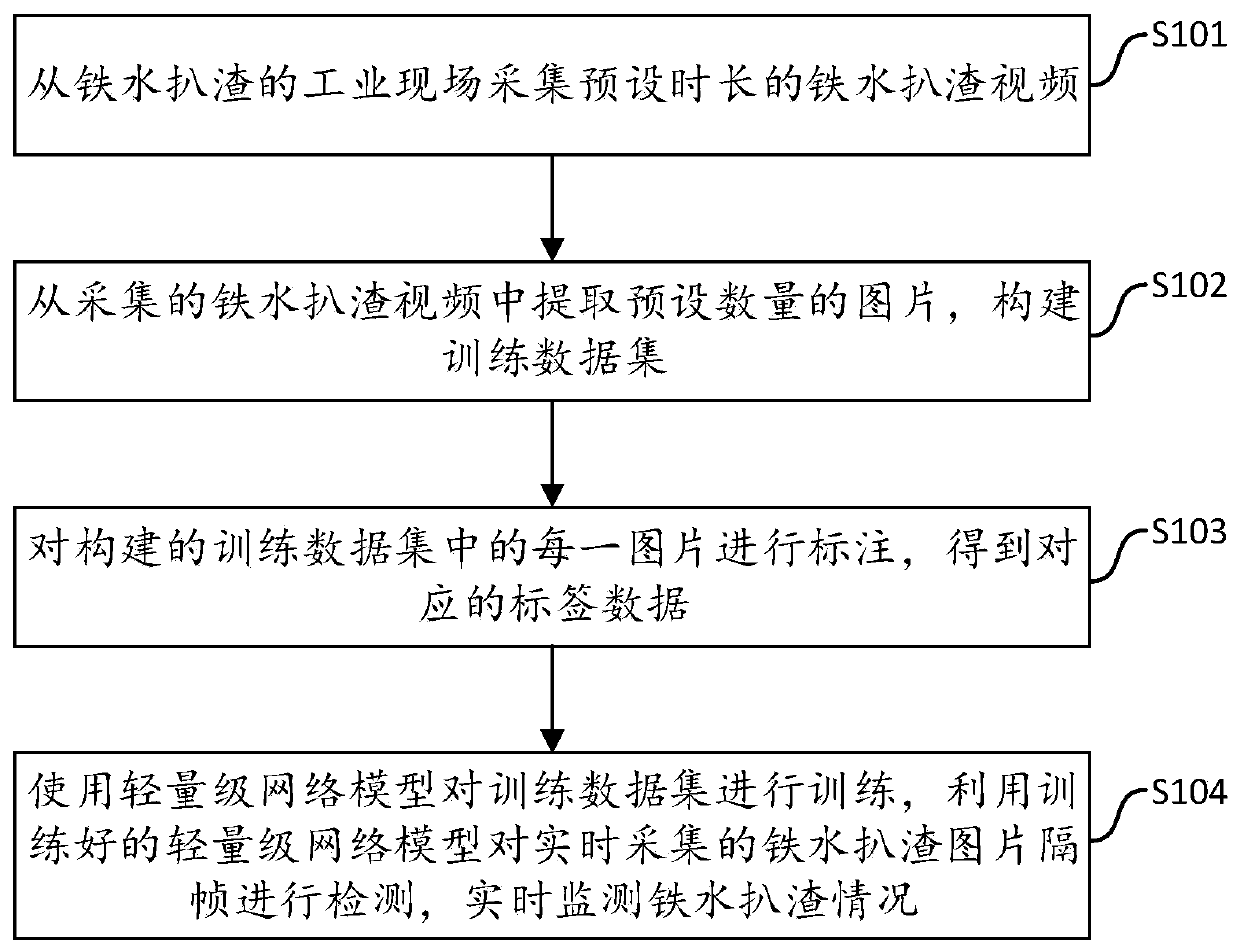

Molten iron slagging-off detection method based on lightweight convolutional neural network

ActiveCN110532902AImprove anti-interference abilityAnti-interferenceImage enhancementImage analysisData setSlag

The invention provides a molten iron slagging-off detection method based on a lightweight convolutional neural network. The molten iron slagging-off detection method comprises the following steps: collecting a molten iron slagging-off video with a preset duration from an industrial site of molten iron slagging-off; extracting a preset number of pictures from the collected molten iron slagging-offvideo, and constructing a training data set; labeling each picture in the constructed training data set to obtain corresponding label data; and training the training data set by using the lightweightnetwork model, and detecting the molten iron slagging-off pictures acquired in real time by using the trained lightweight network model in a framing manner to monitor the molten iron slagging-off condition in real time. The method provided by the invention has better anti-interference capability, improves the precision of molten iron and desulfurization slag detection in molten iron slagging-off,can effectively detect molten iron and desulfurization slag, and can also effectively identify the inner ladle wall of molten iron and a slagging-off device at the same time. The molten iron slagging-off process can be stably detected, meanwhile, the real-time performance can meet the actual monitoring requirement, and great application value is achieved in the production process.

Owner:UNIV OF SCI & TECH BEIJING

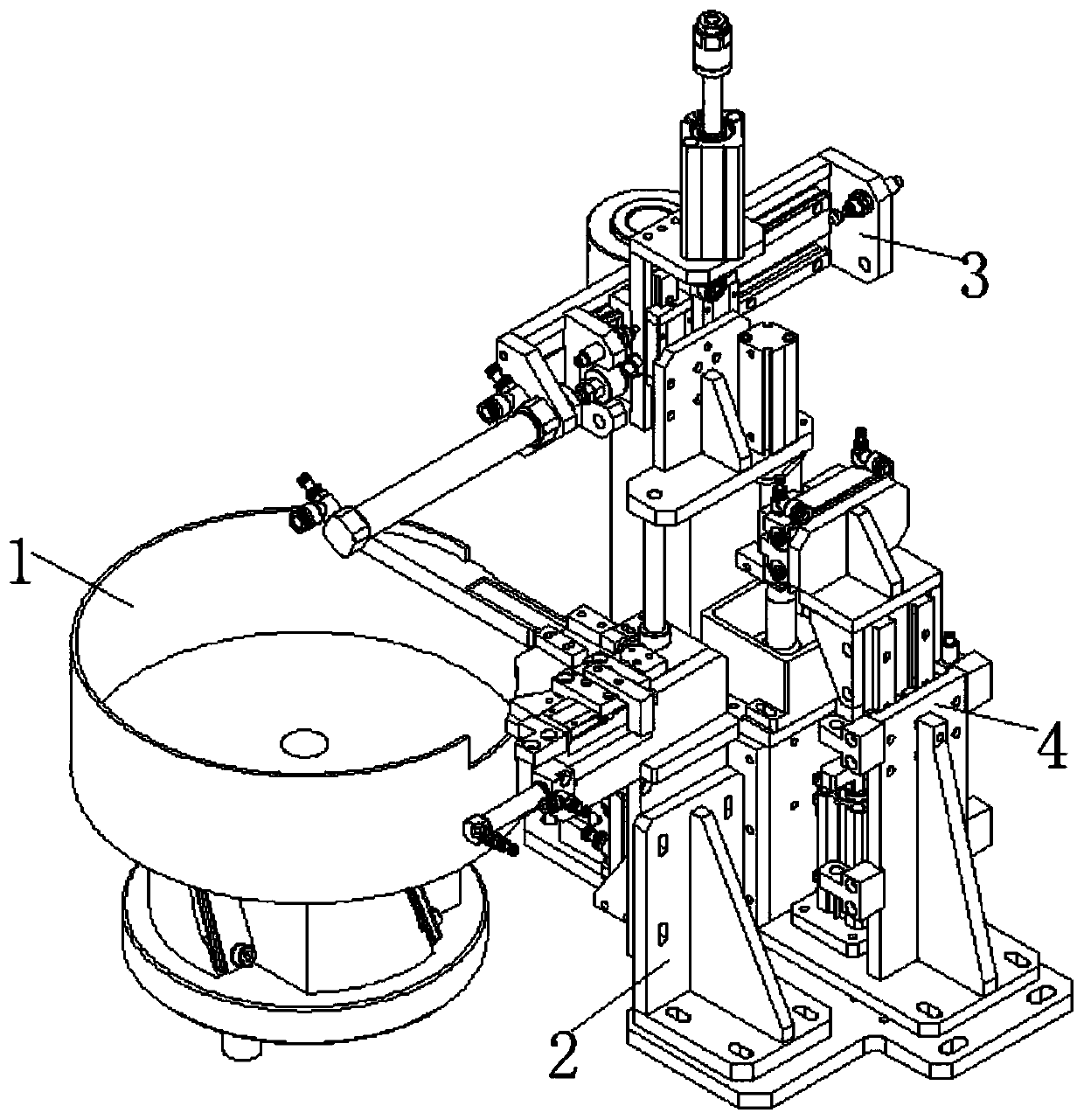

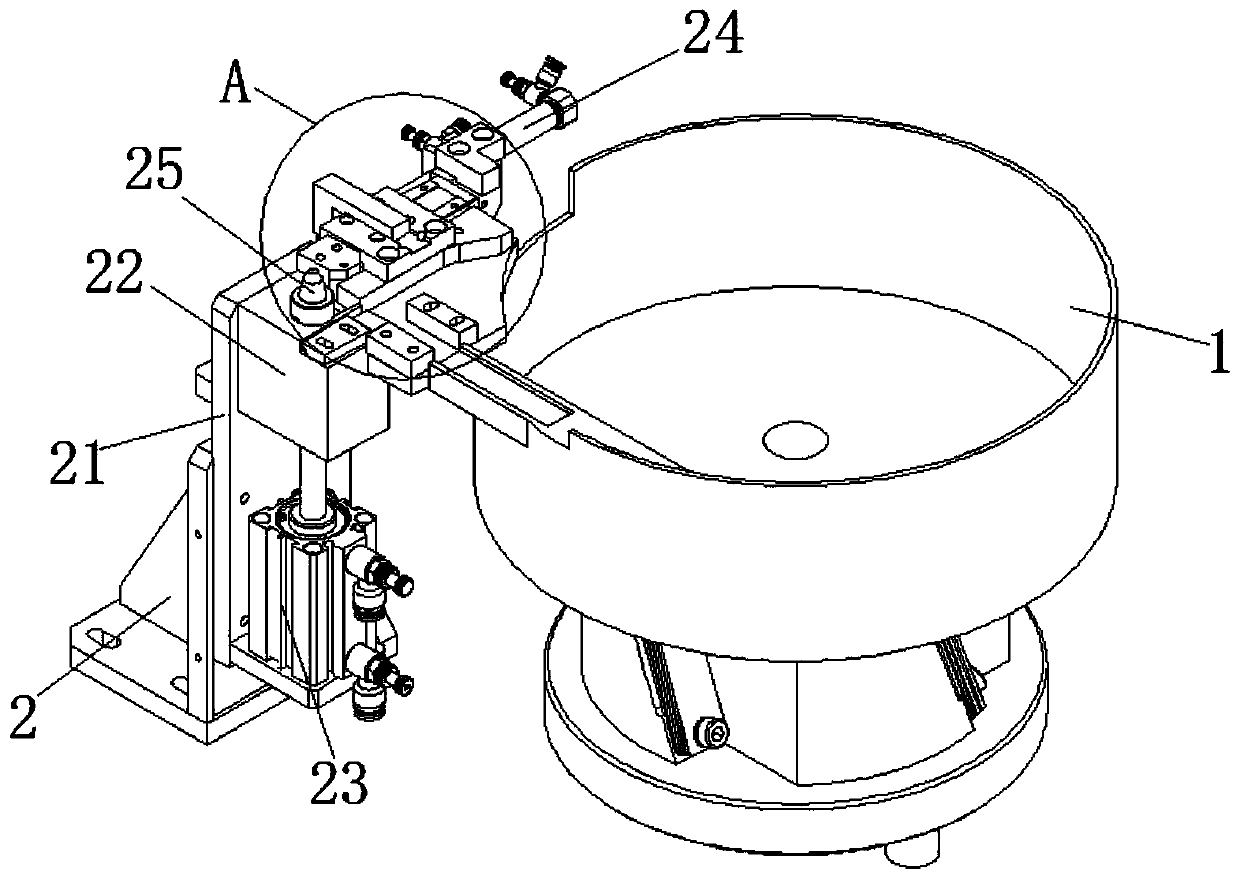

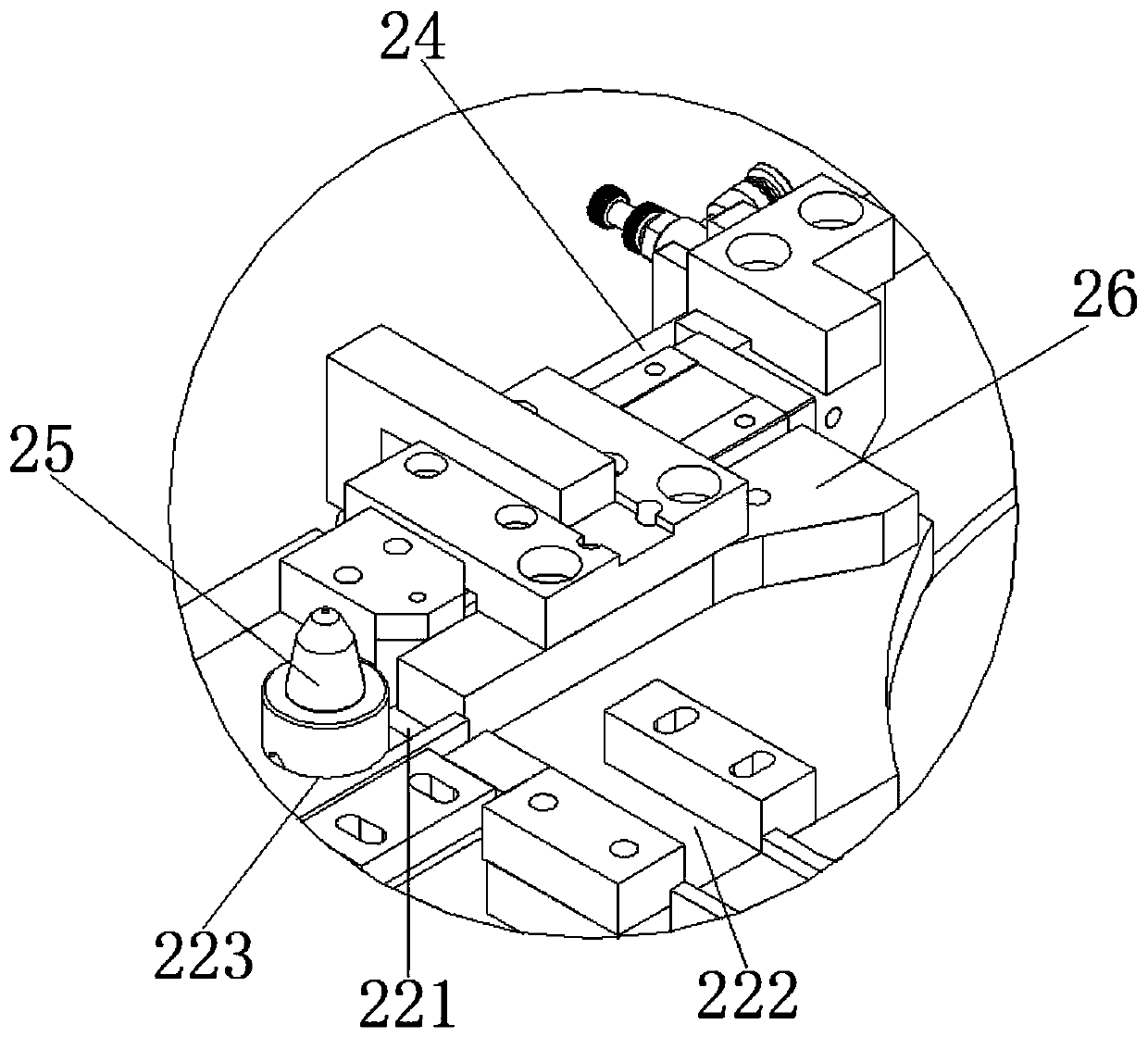

Cylinder sealing ring feeding device

InactiveCN109956300AUnloading is in place and positioning is accurateAvoid misalignmentConveyorsMetal working apparatusComputer moduleEngineering

The invention relates to a cylinder sealing ring feeding device comprising a vibration feeding tray, an interval discharging module, a conveying discharging module and a restoration module. The interval discharging module is connected with an outlet of the vibration feeding tray, the restoration module and the interval discharging module are arranged side by side, the conveying discharging moduleis opposite to the restoration module, and the interval discharging module and the restoration module are located within the working range of the conveying discharging module; the interval dischargingmodule comprises a first supporting frame, an interval feeding table, a material ejecting cylinder, an interval feeding cylinder and a material ejecting head; the material ejecting cylinder is located under the interval feeding table, and a piston rod of the material ejecting cylinder is connected with the material ejecting head; the bottom end of the material ejecting head is provided a cylinderbody, and the top end of the cylinder body is provided with a bullet-shaped convex portion; the restoration module comprises a positioning column, a sliding table finger cylinder, a lifting mechanismand a clamping jaw; and the cylinder sealing ring feeding device adopts automatic feeding, discharging is in place, positioning is accurate, and manual participation is avoided.

Owner:昆山庄正精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com