Spice continuous rectification production control system

A production control and distillation technology, applied in the field of steel fiber, can solve the problems of increasing the labor intensity of processing personnel, unable to peel off the essence and oil, and increasing the processing cost, so as to prevent the processing efficiency from slowing down, long processing time, and slow processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

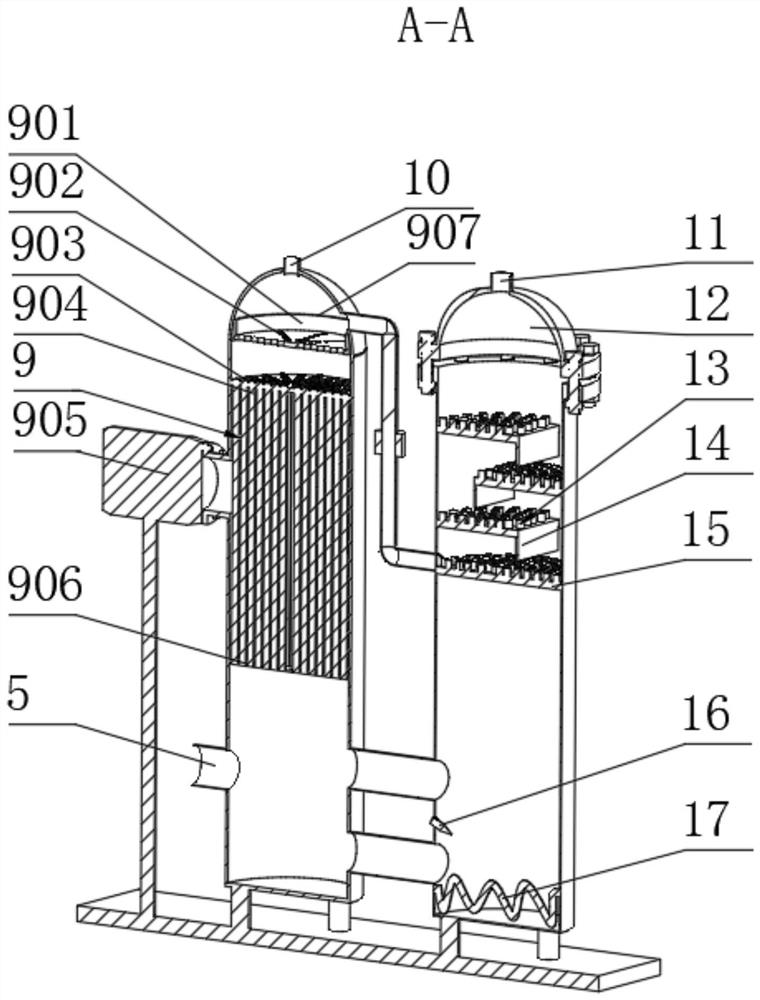

[0034] A continuous distillation production control system for spices, specifically as follows:

[0035] Distillation device, which includes a raw material delivery module, a water source preheating module, a distillation module, a water level detection module, and a cooling forming module. Preheat the mold to preheat the water source;

[0036] The water source preheating mold sucks the water source from the water inlet through the pump body, and then heats the water source to a certain temperature through the preliminary heating mechanism, and then discharges the preheated water source through the heating tube, and carries out the process with the raw material at the bottom of the first distillation tower. Mixing, after the water level reaches a certain level, the mixed raw materials are discharged into the second distillation tower through the connecting pipe, and the distillation module is started at this time;

[0037]The distillation module uses a heating wire to reheat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com