Vibration table-based sample preparation device and vibration table-based sample preparation method for large-scale triaxial test of coarse grained soil

A triaxial test and shaking table technology, applied in the field of soil dynamics laboratory test, can solve the problems of limited excitation force of the surface vibrator, inability to monitor the height of each layer of samples in real time, and inability to control the density of samples well, etc. Achieve good compactness and reduce breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

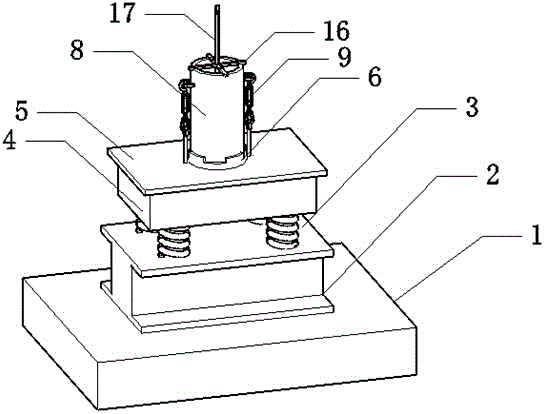

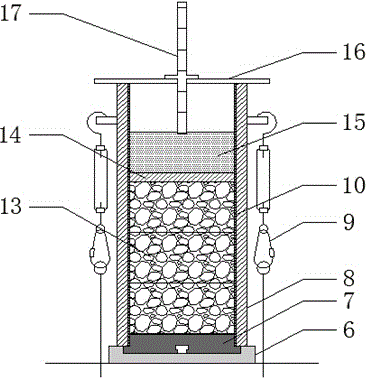

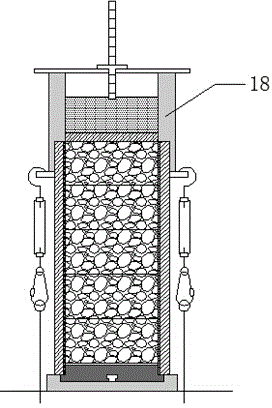

[0023] Such as Figure 1~6 As shown, the entire improved vibrating table is fixed on the concrete foundation 1 with expansion bolts to avoid vibrating tiles during the vibration of the vibrating table, resulting in uneven bottom of the vibrating table and eccentric force, which affects the sample preparation effect. The lower part 2 of the vibrating table is equipped with a special frequency modulation motor, which can control the vibration frequency and amplitude with low noise. Four vibrating springs 3 lower ends are fixedly installed on the bottom top surface of the vibrating table, and the vibrating table top 4 is fixedly installed on the four vibrating springs 3 upper ends; the vibrating table top 5 has been coated with an antirust oil layer and protected with a transparent plastic. The center of the vibrating table is fixed as Figure 4 The sample chassis 6 is shown for constraining the sample base 7 . There are four symmetrically distributed chassis grooves 6a on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com