Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Prevent powdering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

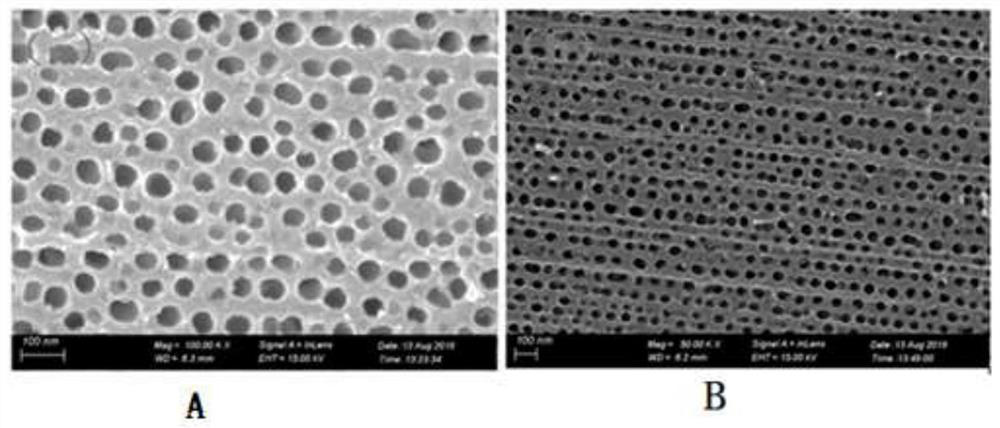

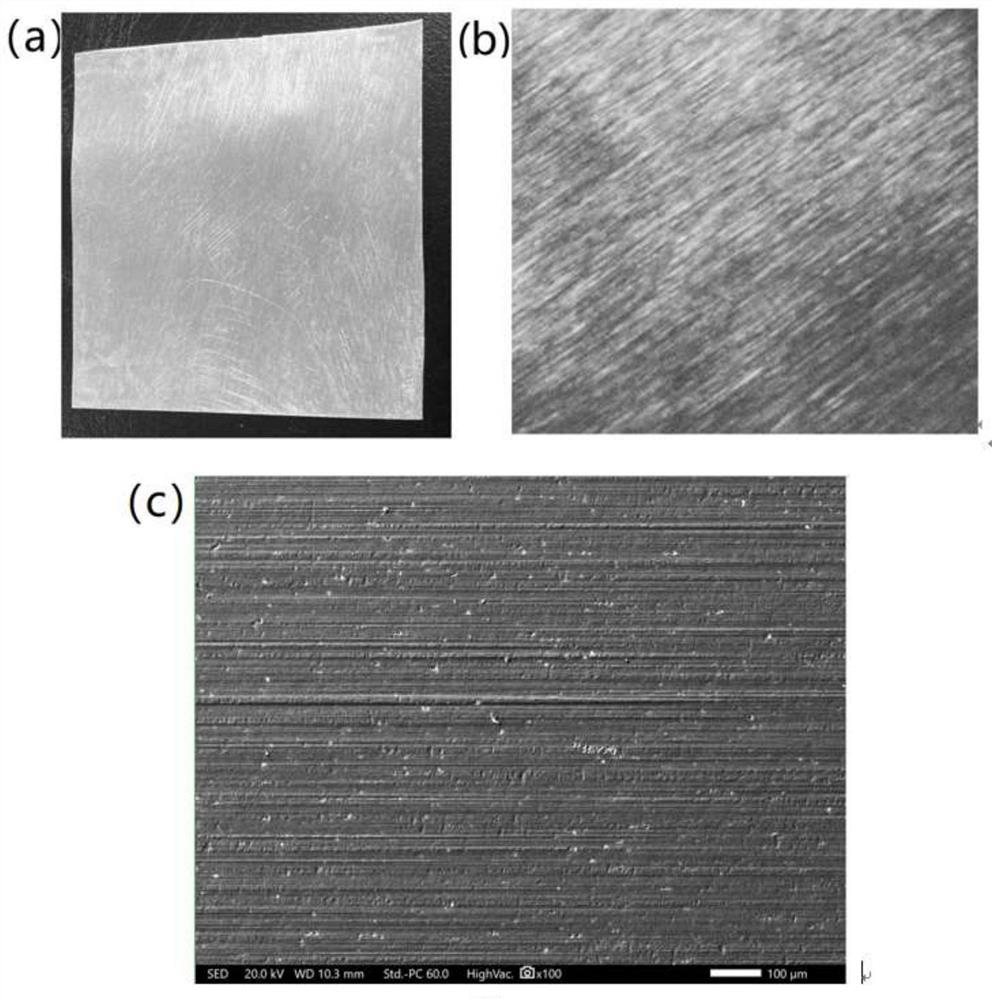

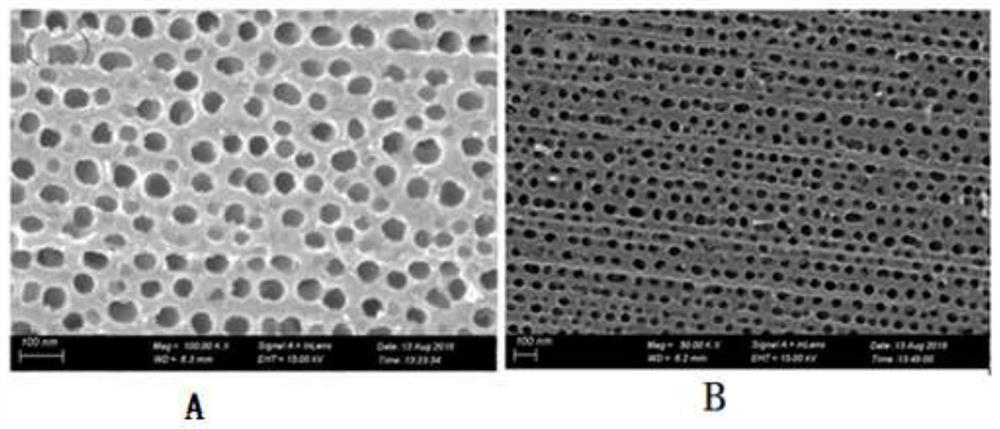

Colored ceramic coating film coated with aramid polymer, and preparation method thereof

InactiveCN108711603AImprove securityPlay the role of isolating the positive and negative polesCell seperators/membranes/diaphragms/spacersPorosityPolyolefin

The invention provides a colored ceramic coating film coated with aramid polymer, and a preparation method thereof, and belongs to the technical field of the lithium ion battery. The diaphragm prepared through the method can solve the problems of high-temperature thermal contraction, ceramic coating layer powder removing, bad in cohesive force with pole plate, and coating uniformity detection of coating diaphragm. The lithium battery diaphragm is high in porosity, uniform in coating, good in electrolyte wettability and high-temperature resistant, and the lithium ion battery security and the electrochemical performance are improved. The colored ceramic coating film coated with aramid polymer disclosed by the invention comprises a base material polyolefin microporous film, colored ceramic coating layer at one side or two side surfaces of the polyolefin diaphragm, and aramid coating layer at one side or two side surfaces of the ceramic coating. The colored ceramic coating film coated withthe aramid polymer disclosed by the invention can be used for preparing the lithium ion battery diaphragm and the lithium ion battery containing the diaphragm.

Owner:QINGDAO LANKETU MEMBRANE MATERIALS CO LTD

Binder for lithium ion battery diaphragm, preparation method and diaphragm using the same

ActiveCN104140502AImprove high temperature resistanceImprove overcharge resistanceCell component detailsCoatingsElectrical batteryLithium-ion battery

The invention discloses a binder for a lithium ion battery diaphragm, a preparation method and a diaphragm using the same. The binder comprises the following raw materials by weight: 0.5-1 part of a water-soluble polymer, 1-10 parts of a flexible segment monomer, 1-10 parts of a rigid segment monomer, 0.01-0.05 part of an initiator, and 1-10 parts of a plasticizer. The binder for the lithium ion battery diaphragm provided by the invention can be mixed with an inorganic matter to serve as a coating material of the lithium ion battery diaphragm, and the thermal stability and anti-thermal shrinkage performance of the diaphragm can be improved, so that the likely internal short circuit problem caused by poor thermal stability of the existing lithium ion battery diaphragms can be solved, and the diaphragm can have good safety and overcharge tolerance. At the same time, the binder contains polar groups, which can closely bonds with the inorganic matter to improve the wettability and liquid retention of the diaphragm. The flexible segment is introduced while the rigid segment exists, thereby improving the mechanical properties of the binder and guaranteeing the bonding force and the flexibility of the diaphragm.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

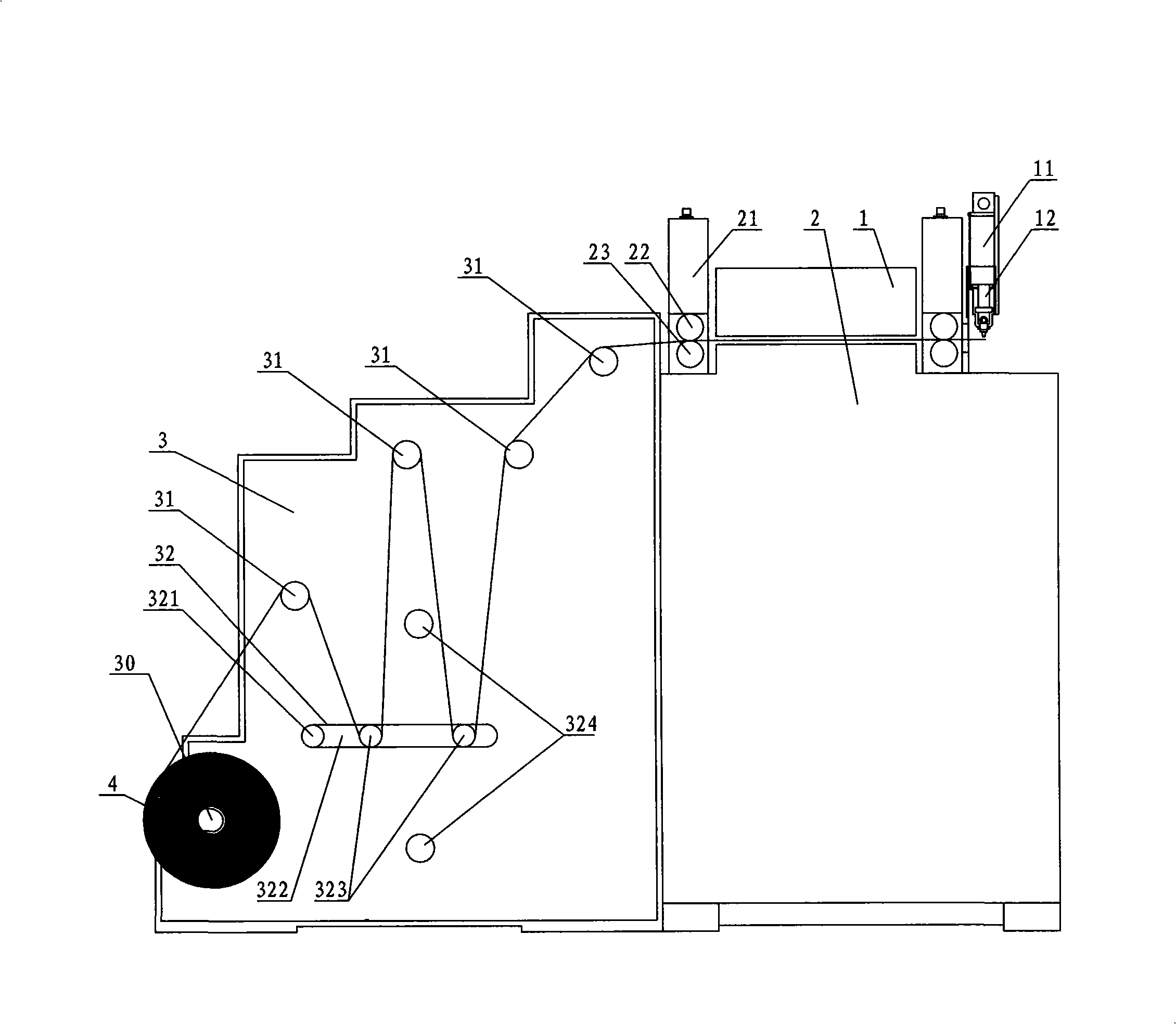

PP sheet cutting equipment and method thereof

ActiveCN101314194APrevent powderingRealize automatic cuttingWelding/soldering/cutting articlesLaser beam welding apparatusControl systemSheet film

The invention relates to PP film (prepreg film) cutting equipment and a method thereof. The cutting equipment comprises a main frame with a PP film transmission mechanism, a worktable arranged on the main frame, a feeding mechanism arranged on the upper stream of the worktable and a human-computer interaction interface control system. The worktable comprises a laser and a cutting head for receiving a laser beam output by the laser and forming a cutting light beam. Through the structure, the integral PP film laser cutting equipment is provided to avoid the phenomena of powder removal and silk removal in the cutting process, realize automatic cutting and reduce production cost.

Owner:HANS CNC SCI & TECH

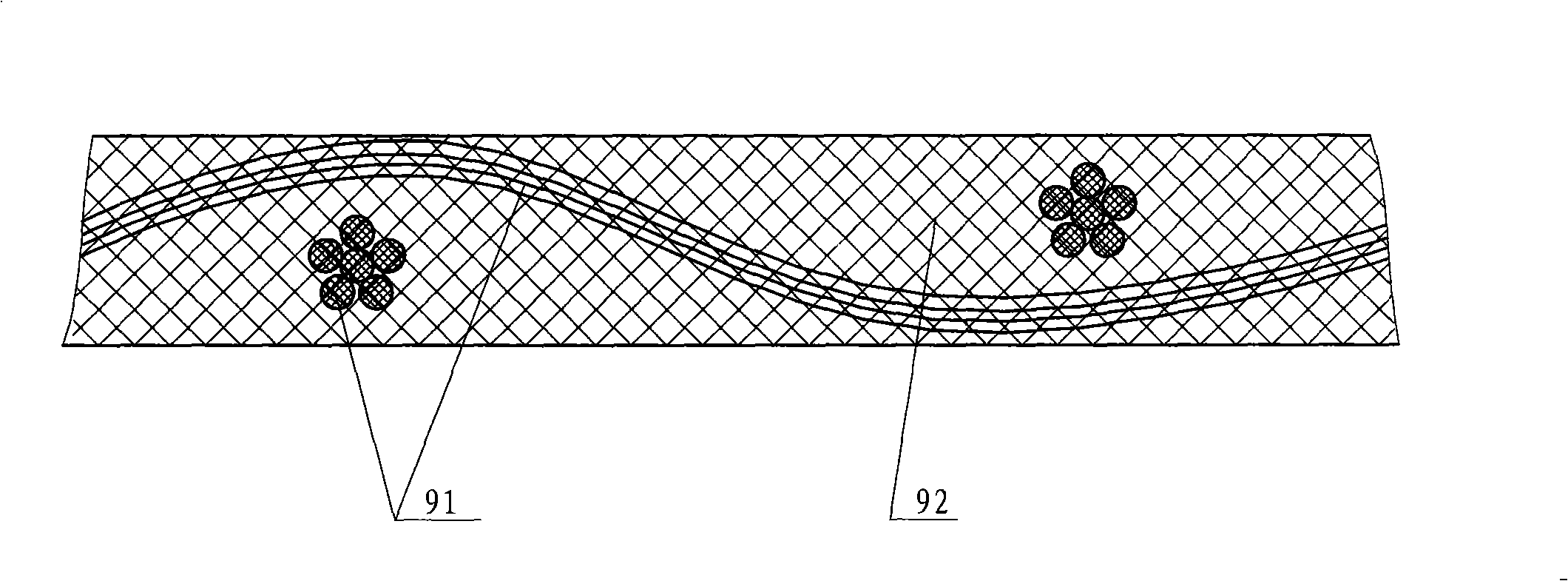

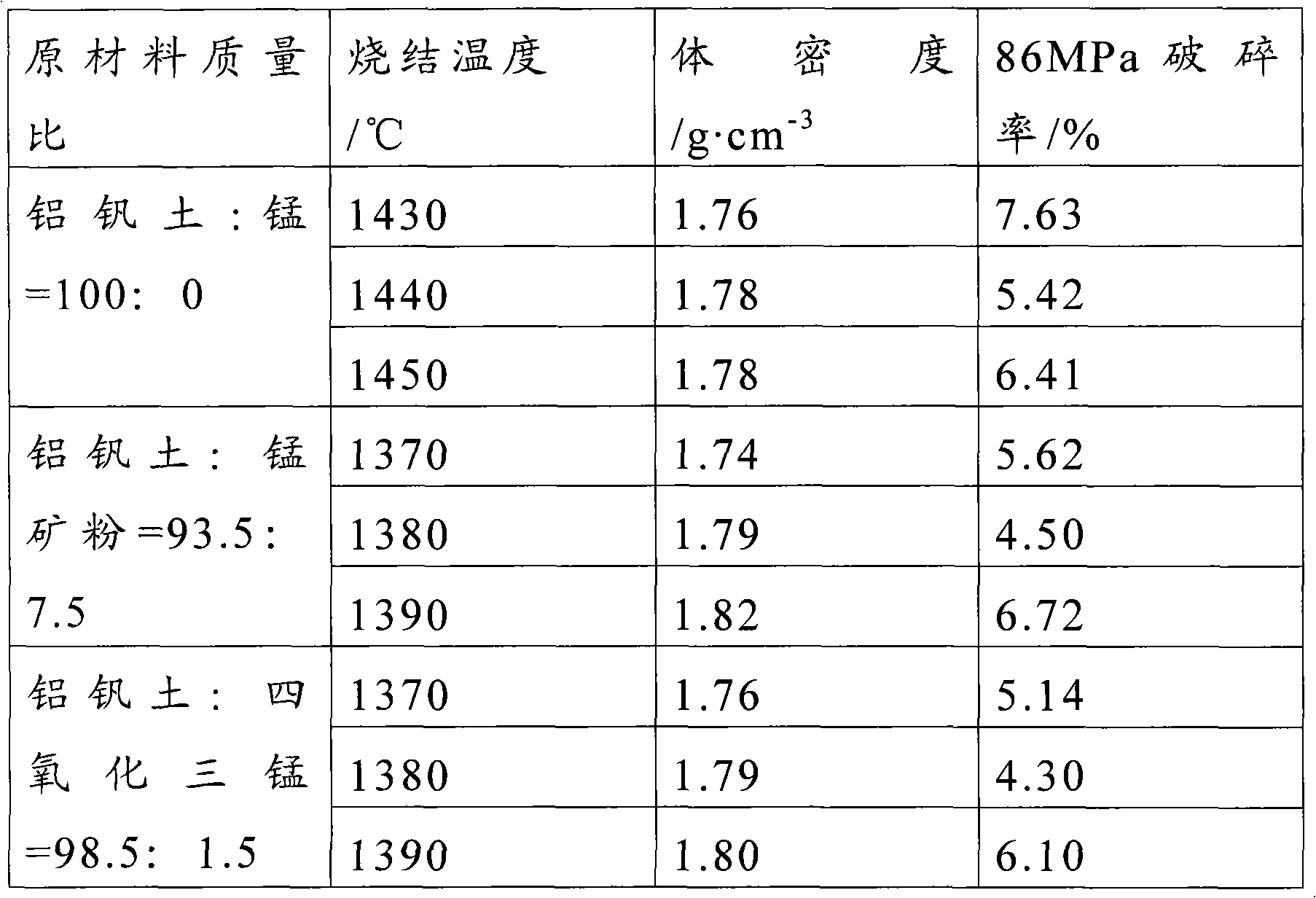

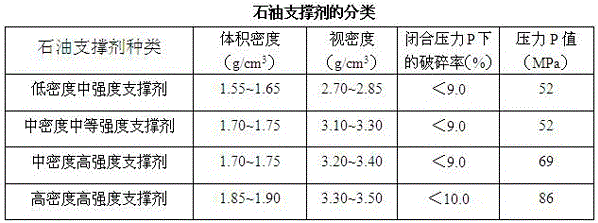

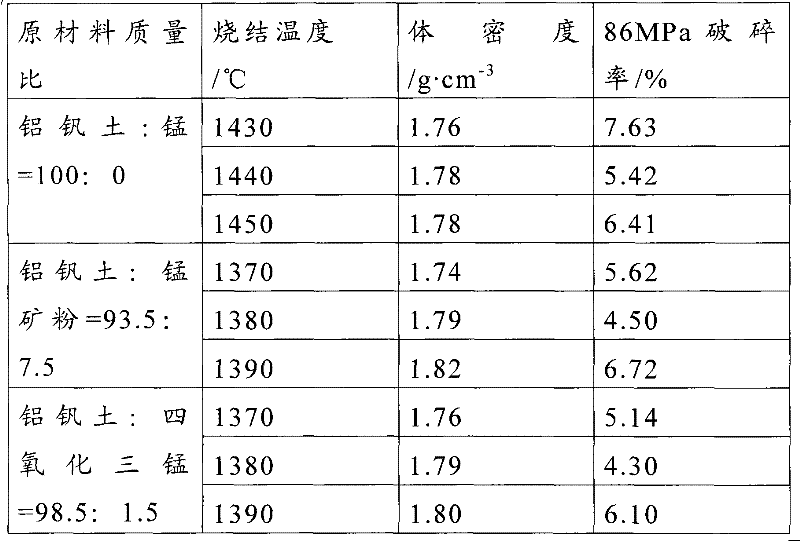

Ceramic proppant and preparation method thereof

The invention relates to a ceramic proppant and a preparation method thereof. The ceramic proppant comprises bauxite and trimanganese tetroxide and is characterized by comprising a water-based organic binder; and the mass ratio of the bauxite, the trimanganese tetroxide and the water-based organic binder is as follows: 93-99 mass proportion of bauxite; 1-7 mass proportion of trimanganese tetroxide, 8-15 mass proportion of water-based organic binder and total mass of bauxite and trimanganese tetroxide based on 100 mass proportion. The ceramic proppant has the advantages of lower rate of sintering temperature and low broken rate.

Owner:阳泉市长青石油压裂支撑剂有限公司

Ultralow-density cordierite petroleum fracturing propping agent and preparation method thereof

ActiveCN106431349AHigh hardnessHigh mechanical strengthFluid removalDrilling compositionCordieriteManganese oxide

The invention provides an ultralow-density cordierite petroleum fracturing propping agent and a preparation method thereof. A principal crystalline phase of the popping agent is of a cordierite structure and is formed by firing coal ash, caustic-burned magnesia powder, Jiaozuo clay and a composite mineralizer, and the composite mineralizer is formed by mixing manganese oxide and barium carbonate according to the equal weight ratio. A large amount of high-silicone, low-aluminum, low-calcium and low-ignition-loss neutral coal ash is adopted as a main raw material, and the density index of the popping agent is effectively reduced; through the special processing and treating processes such as special pre-sintering on an important raw material magnesite and ultrafine grinding on batches and the composite mineralizer technology, it is effectively guaranteed that high-hardness and low-density principal crystalline phase minerals are formed in a system at high temperature, therefore, and it is guaranteed that the finished ultralow-density popping agent has high mechanical strength; the firing temperature of the popping agent is reduced, and the purposes of energy saving and consumption reduction are achieved.

Owner:洛阳赛罗帕陶瓷科技有限公司 +1

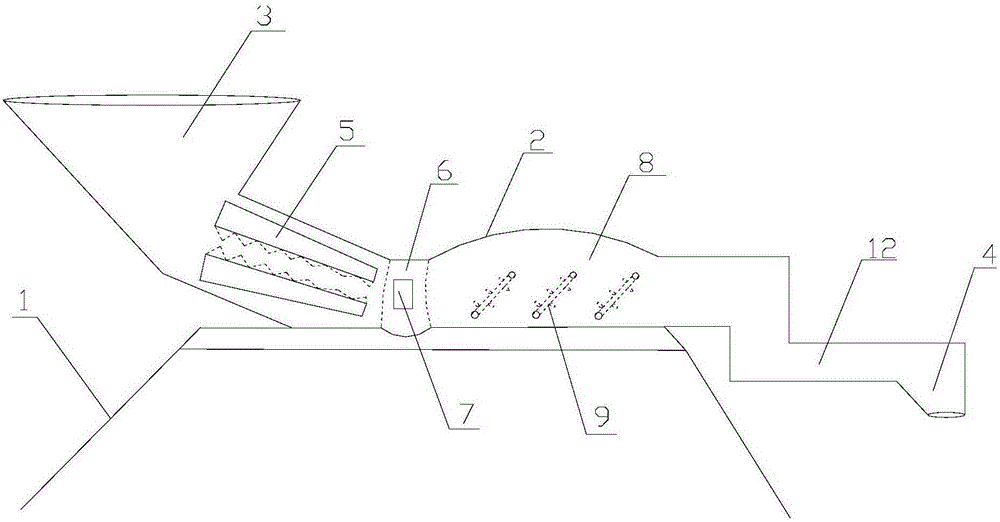

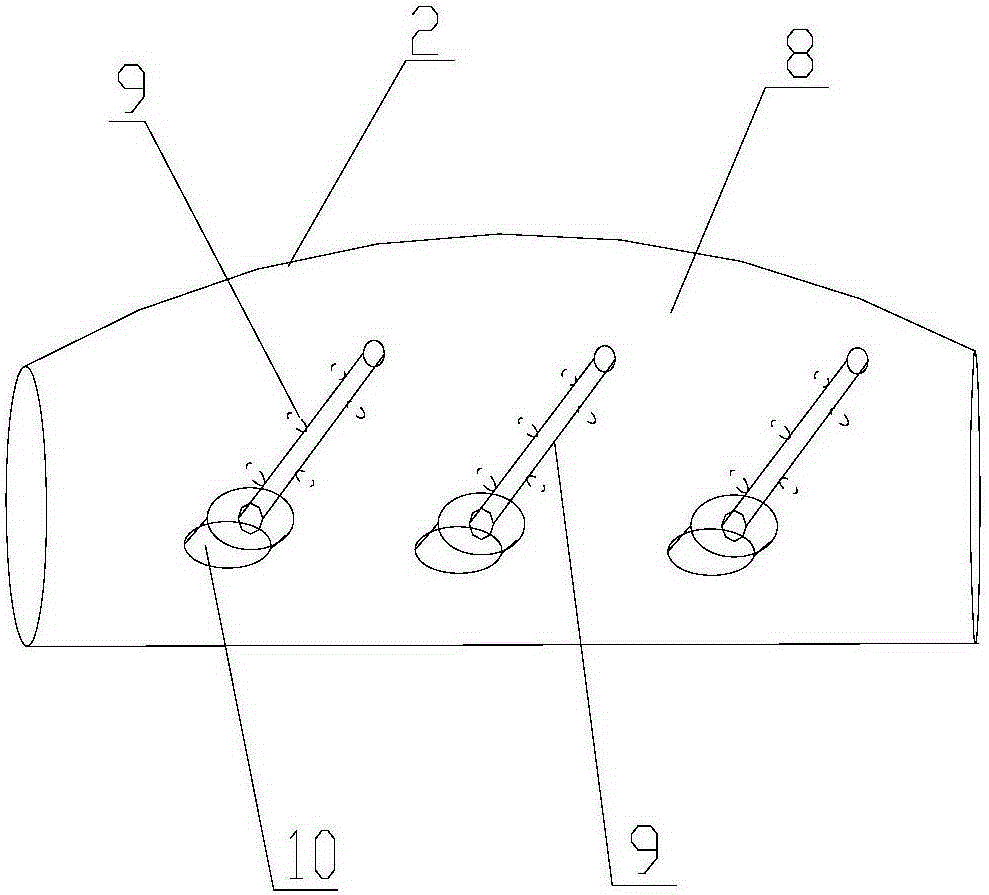

Exhaust heat airborne follow type hydrogen production plant with built-in thermostat

InactiveCN101082303APrevent powderingUniform heat transferHydrogenInternal combustion piston enginesSuperheaterHydrogen production

The waste-heat airborne follow device of the internal temperature-saving device relates to the hydrogen-preparing device of the power machine. The waste-heat airborne follow device which has compact structure, uniform heat transmission, stable hydrogen-preparing rate achieved from the splitting or reforming of the alcohol fuel using tail-gas as the head source and the internal temperature-saving device is developed against to the defects of unbalanced heat transmission, easily aging of catalyst, unable to load integral catalyst and fuel system structure and the complex control in the existing patents of ZL94116320.2 and CN1951718A. The adopted technology scheme is: the reactor 2 adopts the straight tube with large external diameter and thin catalyst. The evaporating superheater 16 has the tubular structure. The fuel system structure and the control method of the engine is simplified by the internal temperature-saving device 5.

Owner:李钢坤

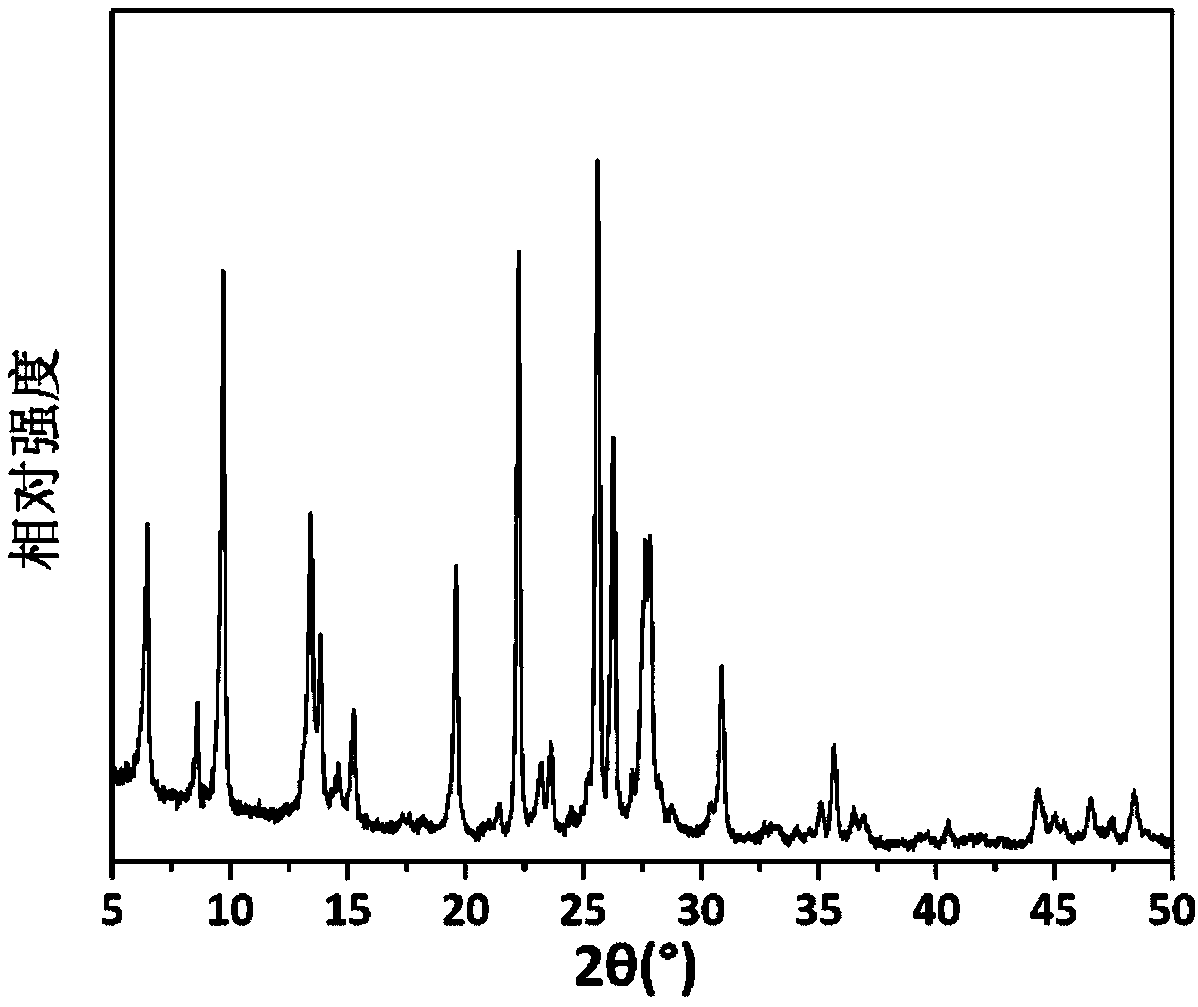

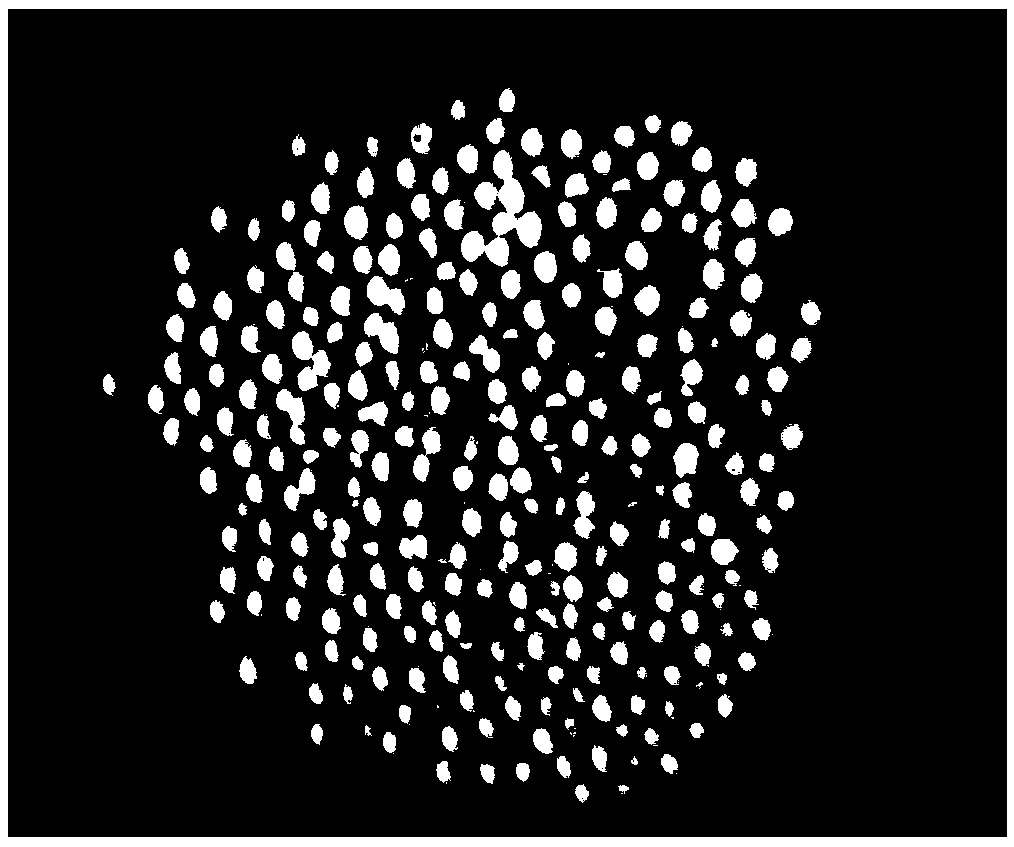

Mordenite molecular sieve as well as preparation method and application thereof

ActiveCN110615444AAdjustable sizeHigh mechanical strengthMolecular sieve catalystsOrganic compound preparationMolecular sieveFixed bed

The invention discloses a mordenite molecular sieve, which is a millimeter-scale spherical molecular sieve; wherein the mordenite molecular sieve is obtained by assembling micron-sized flaky mordenitecrystals; the specific surface area of the mordenite molecular sieve is 200-500 m<2> / g, and the pore volume is 0.1-0.3 cm<3> / g. The molecular sieve is binder-free spherical mordenite suitable for fixed bed and moving bed reactors, wherein the size of the molecular sieve is adjustable within a certain range, and the molecular sieve macroscopically has a millimeter-scale spherical structure and hashigh mechanical strength. The invention further discloses a preparation method of the mordenite molecular sieve and application of the mordenite molecular sieve in acid catalytic reaction and reaction for preparing carbonyl compounds through oxygen-containing compound conversion, the method is high in raw material conversion efficiency and simple and efficient in treatment process, and the mordenite molecular sieve prepared through the method shows good catalytic performance when used as a catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of powder lithium electrode

InactiveCN102437310ALarge specific surface areaLower reaction impedanceElectrode manufacturing processesElectric vehicleMaterials science

The invention relates to a preparation method of a powder lithium electrode, which comprises the steps that fillers containing powder lithium are filled in gaps of a foam metal current collector and are pressed to be molded, and then the powder lithium electrode is obtained. According to the preparation method, the electrode containing the powder lithium is adopted, so active substances are pulverized, the specific surface area of the electrode is effectively increased, the discharge current density of the electrode is enhanced, and the battery discharge rate capability is effectively improved, and a metal lithium battery prepared by adopting the electrode can satisfy the requirement of high-power electric energy output; foam copper or foam nickel with a three-dimensional porous structure is adopted as the current collector of the electrode, so direct contact parts of the powder lithium and the current collector of the electrode are guaranteed to be firmly bonded, the bonding force among the powder lithium is guaranteed as well, and powder is effectively prevented from shedding from the electrode when the electrode is used; and conductive powder is mixed into the powder lithium, so the discharge performance of the powder lithium electrode is further improved. The metal lithium battery prepared by adopting the electrode can be widely applied to the fields of high-power hybrid electric tools, electric vehicles, and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

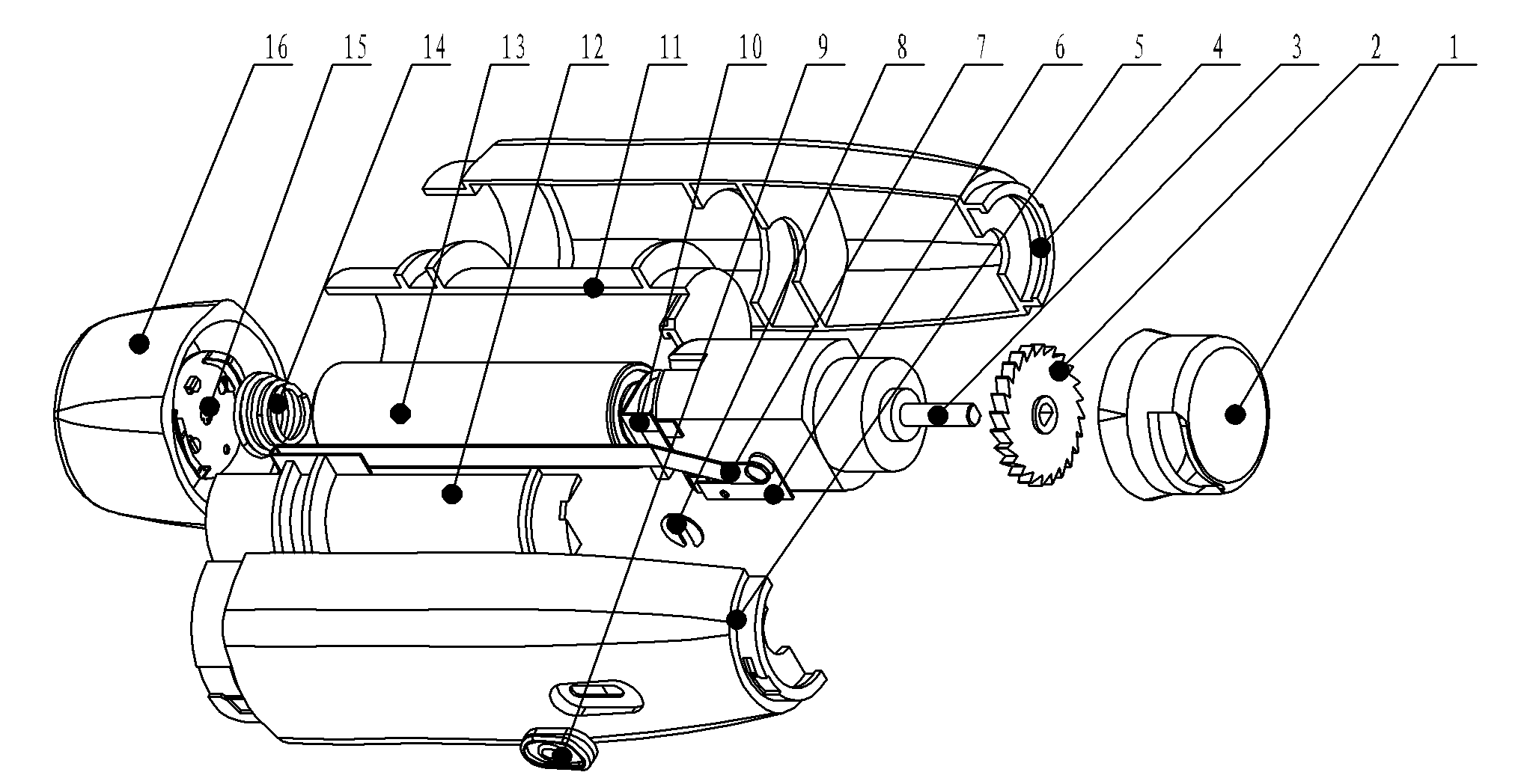

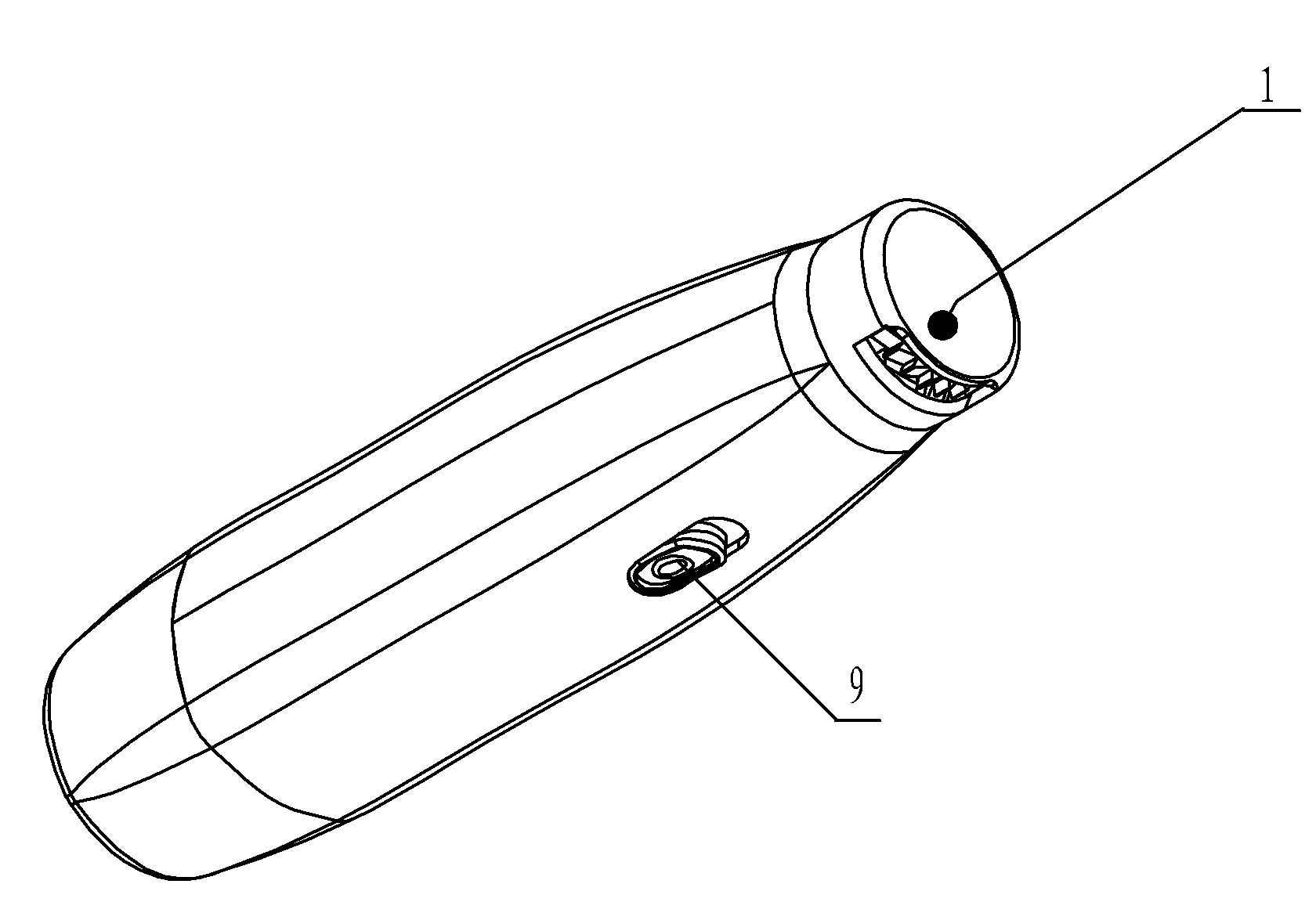

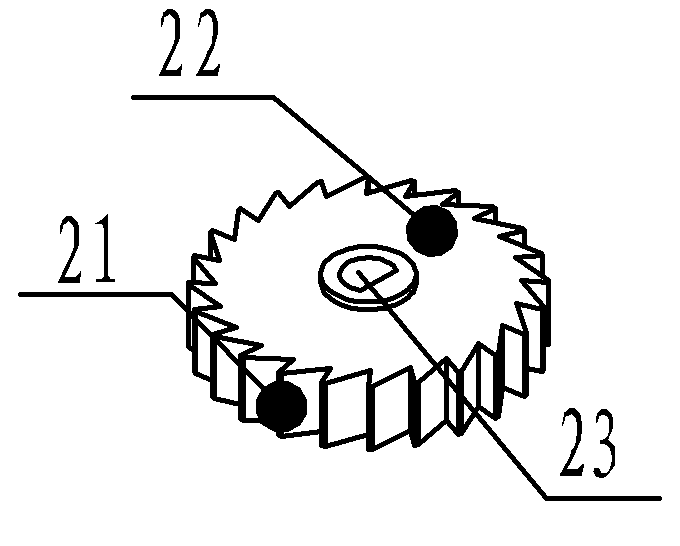

Automatic nail clipper

InactiveCN102217830AProtects against powder and odorsSharp edgeManicure/pedicureNail clipperEngineering

The invention discloses an automatic nail clipper which comprises a nail clipper. The nail clipper adopts a disk blade and comprises teeth and a body; and the teeth are arranged surrounding the body. The nail clipper also comprises an opening hole; and the opening hole is arranged in the middle of the body. The automatic nail clipper adopts a cutting way to prevent the generation of powder and peculiar smell; more importantly, the disk blade is sharp, but can not hurt hands or feet, thus achieving the function of pruning freely.

Owner:SHANGHAI ZHONGPENG YUEBO IND DEV

Tin alloy membrane electrode and application thereof

ActiveCN103094524AShape is easy to controlPrevent powderingCell electrodesLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a tin alloy membrane electrode and an application thereof. The tin alloy membrane electrode is prepared by the following steps: (1) preparing chemical plating solution by using thiourea, citric acid, sodium hypophosphite, concentrated sulfuric acid, stannous sulfate, nitrate of metal M and water, wherein the metal M is Ag, Fe, Ni, Co, Zn, Al, Mg or Cu; a pH (Potential Of Hydrogen) value of the chemical plating solution is in a range of 0.8-1.1, the concentration of the thiourea is 40-200g / L, the concentration of the citric acid is 20-80g / L, the concentration of the sodium hypophosphite is 30-160g / L, the concentration of the stannous sulfate is 0.1-0.4mol / L, and the concentration of the nitrate of the metal M is 0.1-1g / L; (2) corroding a copper foil by using sulfuric acid with the concentration of 0.3-0.6mol / L for 10-15 minutes, and then washing and drying by distilled water; and (3) placing the corroded copper foil in the chemical plating solution with the temperature kept within a range of 30-40 DEG C, and reacting for 30-120s; forming a tin alloy membrane on the surface of the copper foil; and drying to obtain the tin alloy membrane electrode. The invention further provides an application of the tin alloy membrane electrode as a cathode of a lithium ion battery, and has the advantages of high capacity and stable properties.

Owner:ZHEJIANG UNIV OF TECH

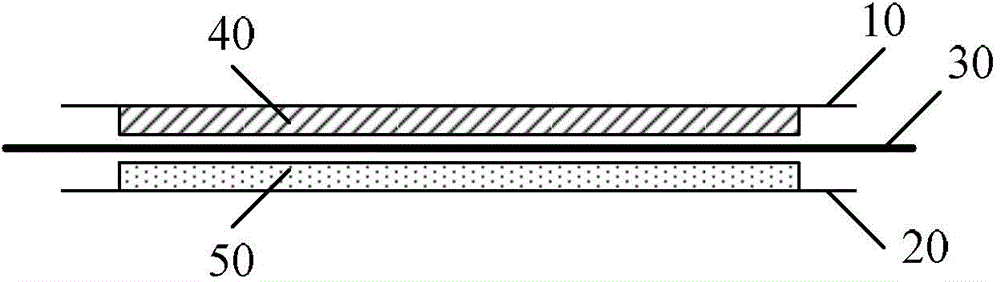

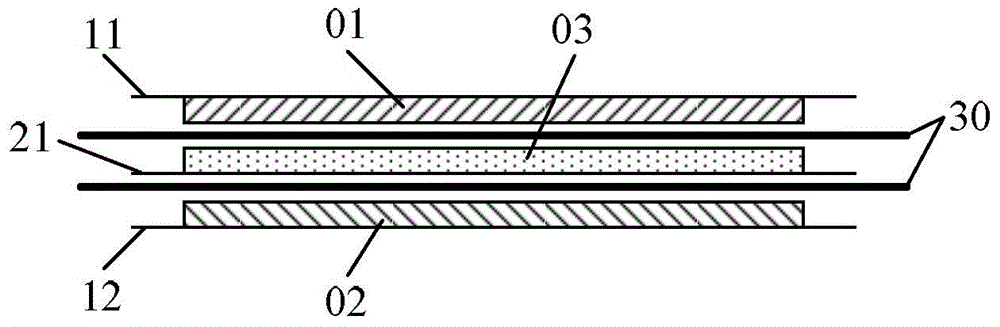

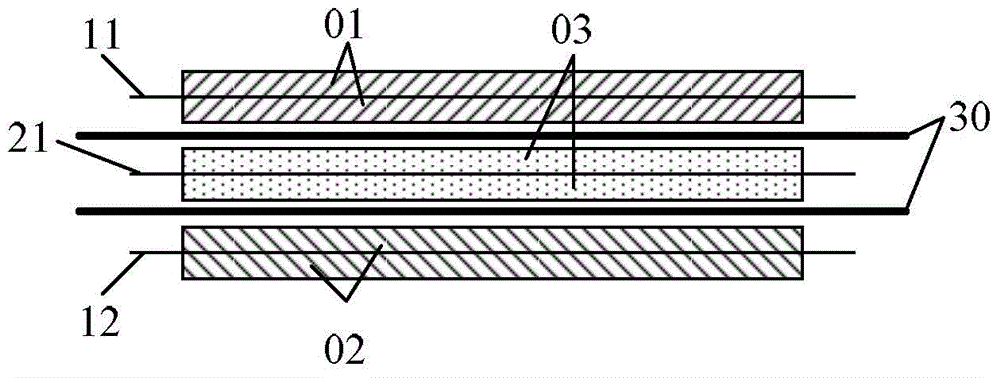

Base unit and battery

InactiveCN105449222AEnhanced feature complementarityGuaranteed service lifeFinal product manufactureElectrode carriers/collectorsPower flowElectrical battery

The invention discloses a base unit and a battery. The base unit comprises a first current collector set, a second current collector set and diaphragms, and the first current collector set and the second current collector are used for collecting currents; the first current collector set is composed of M first current collectors, each of the first current collectors is provided with a positive electrode material, one first current collector is provided with one type of the positive electrode material, and the quantity of the types of materials arranged on the first current collectors of the first current collector set is not greater than M; the second current collector set is composed of N second current collectors, each of the second current collectors is provided with a negative electrode material, one second current collector is only provided with one type of the negative electrode material, and the quantity of the types of materials arranged on the second current collectors of the second current collector set is not greater than N; the first current collectors and the second current collectors are arranged by rules, and adjacent current collectors are separated by the diaphragms; and the first current collectors are connected to the positive electrode end of the battery, and the second current collectors are connected to the negative electrode end of the battery, wherein M is an integer greater than 1, and / or N is an integer greater than 1.

Owner:LENOVO (BEIJING) LTD

High-magnesium limestone calcining method and lime produced by same

The invention belongs to the technical field of metallurgy, and particularly relates to a high-magnesium limestone calcining method and lime produced by the same. The high-magnesium limestone calcination method comprises the following steps: (1) preheating crushed and screened high-magnesium limestone, (2) carrying out water spraying and air cooling treatment on the preheated high-magnesium limestone, so that the temperature of the high-magnesium limestone is rapidly reduced to 100 DEG C or below, and (3) calcining the high-magnesium limestone pretreated in the step (2) to obtain lime. According to the method for calcining the high-magnesium limestone, the preheated high-magnesium limestone is subjected to cold water spraying and air cooling quenching temperature treatment, so that the organization structure of the limestone can be stabilized, the strength of the limestone is enhanced, and the situation that the kiln condition is deteriorated due to the fact that powder is generated inthe calcining process is avoided.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

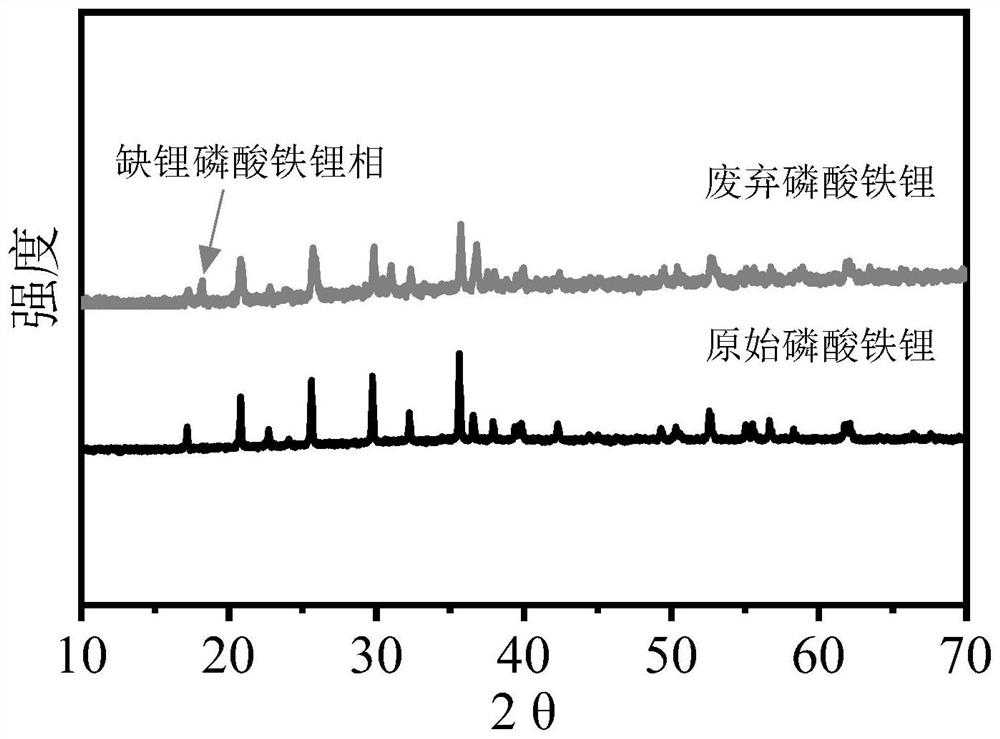

Method for comprehensively separating and recycling materials in retired batteries

ActiveCN114188626AReduce pollution and energy consumptionSimple methodWaste accumulators reclaimingBattery recyclingElectrical batteryMetallic foil

The invention belongs to the field of waste battery recycling, and particularly discloses a method for comprehensively separating and recycling materials in a decommissioned battery, which comprises the following steps of: (1) disassembling the decommissioned battery to obtain a mixture of a positive pole piece and a negative pole piece; (2) soaking the mixture of the positive pole piece and the negative pole piece in water and stirring, so that the positive component material and the negative component material are stripped from the current collector; and (3) secondary sieving is carried out, so that a powdery negative electrode component material, a sheet-shaped positive electrode component material, copper and aluminum are obtained through separation and recovery. Based on the principle that positive and negative binders have different properties and the characteristic of good ductility of a metal foil material, for a waste battery with low binder content (less than or equal to 6%) in a positive material, a mixture of a positive pole piece and a negative pole piece is stirred in a water environment and is matched with secondary sieving treatment, so that the positive and negative binders in the waste battery are uniformly mixed. Powdery negative electrode component materials, sheet-shaped positive electrode component materials, copper and aluminum can be recycled, and efficient separation and recycling of the positive electrode materials and the negative electrode materials and the current collector are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

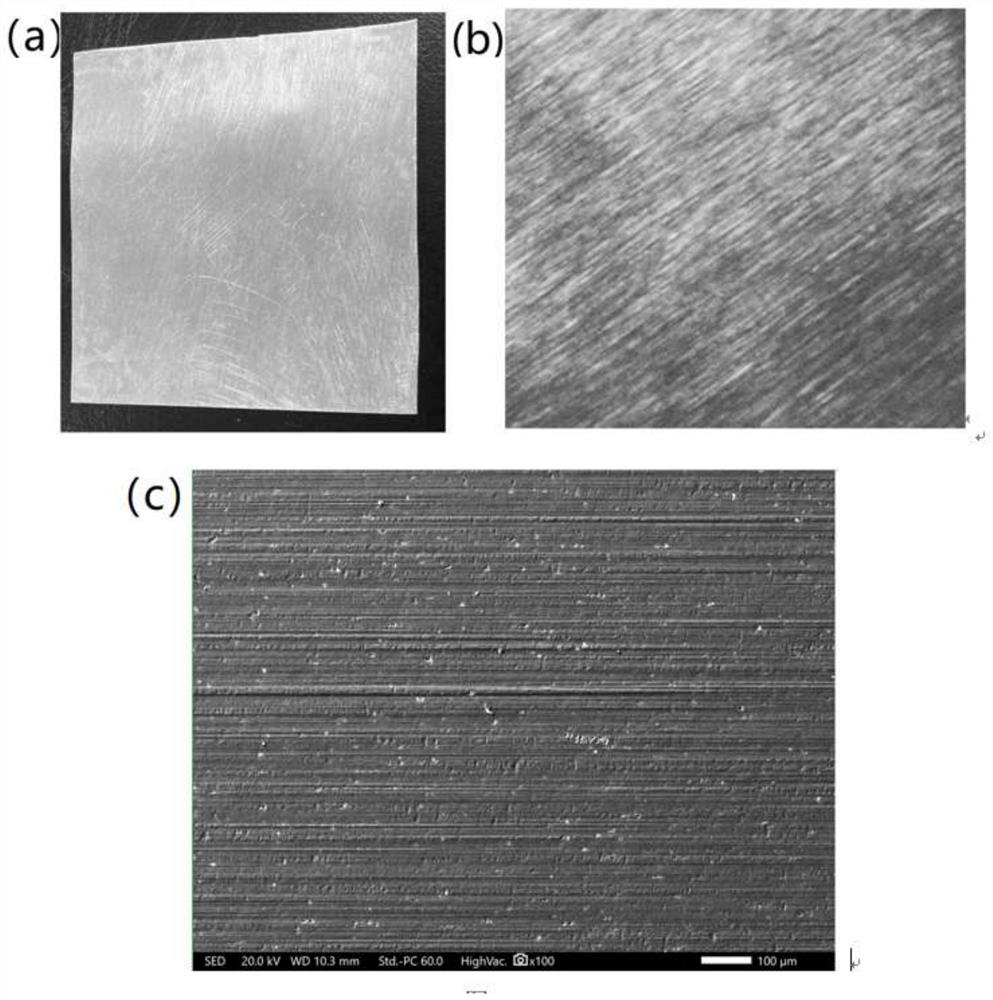

Two-dimensional catalytic material and preparation and application thereof

InactiveCN112958060AImprove mass transfer efficiencyLow mass transfer efficiencyDispersed particle separationCatalyst activation/preparationAcid etchingMicron scale

The invention discloses a two-dimensional catalytic material and preparation and application thereof. The two-dimensional catalytic material is characterized in that a transition metal foil with the micron-order thickness serves as a base material, a two-dimensional matrix carrier with light weight, flexibility, high specific surface area and roughness is prepared through pretreatment, anodic oxidation, acid etching regulation and control, hole breaking and thermal stabilization treatment, and on the basis of the carrier, the two-dimensional ozone catalytic material is prepared by taking metal salt and / or organic matter as a precursor and adopting vacuum impregnation, in-situ deposition and thermal reduction technologies to load active metal and / or non-metal active components in situ. The two-dimensional material has the advantages of high specific surface area, high roughness, high mechanical strength, light weight, flexibility and the like; when applied to water treatment, the catalytic material has the advantages of rapid interface mass transfer, excellent catalytic performance and the like; and meanwhile, the preparation process of the two-dimensional catalytic material has the characteristics of simple method, easiness in adjustment of process parameters, easiness in large-scale production, low preparation cost and the like.

Owner:NANJING UNIV OF SCI & TECH

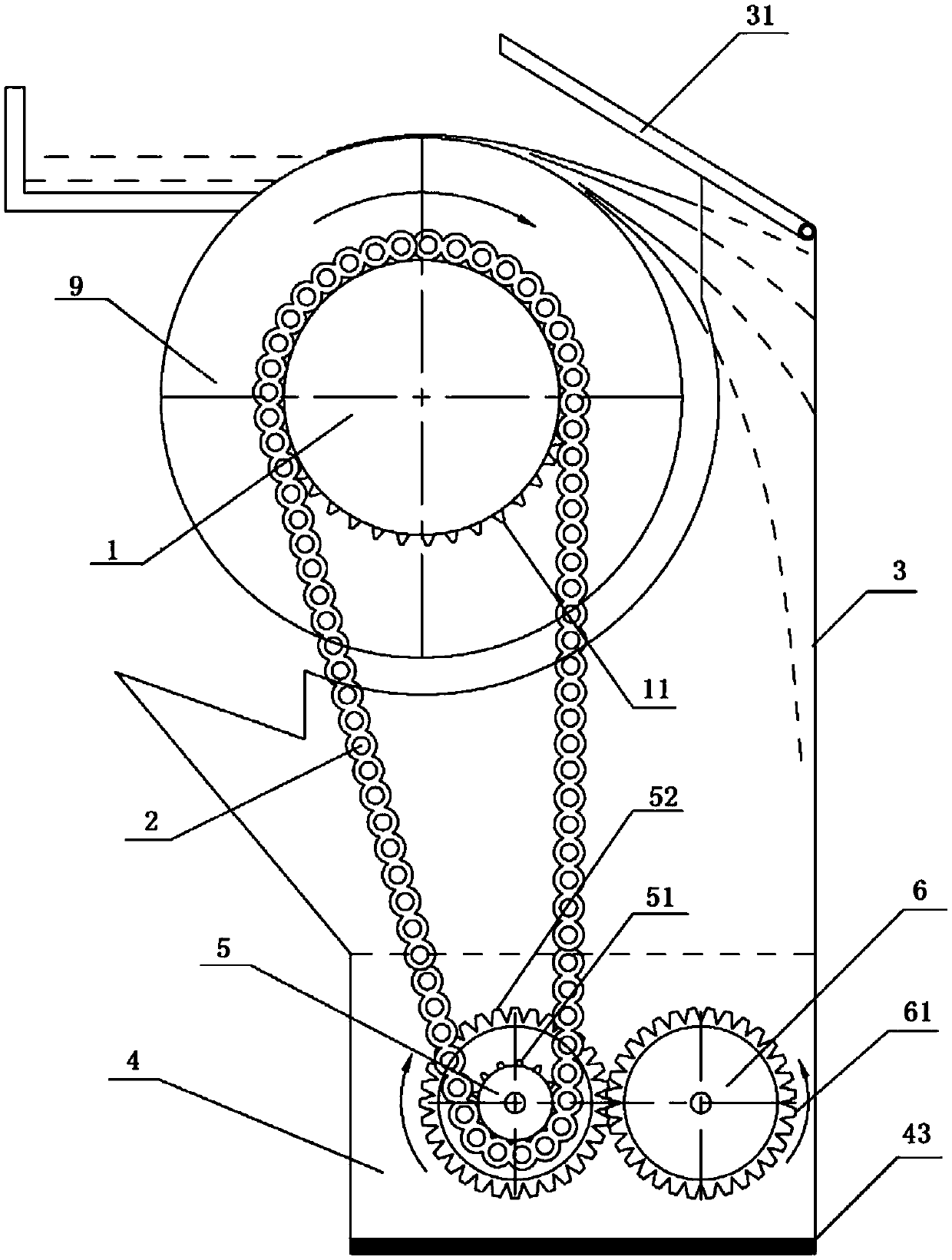

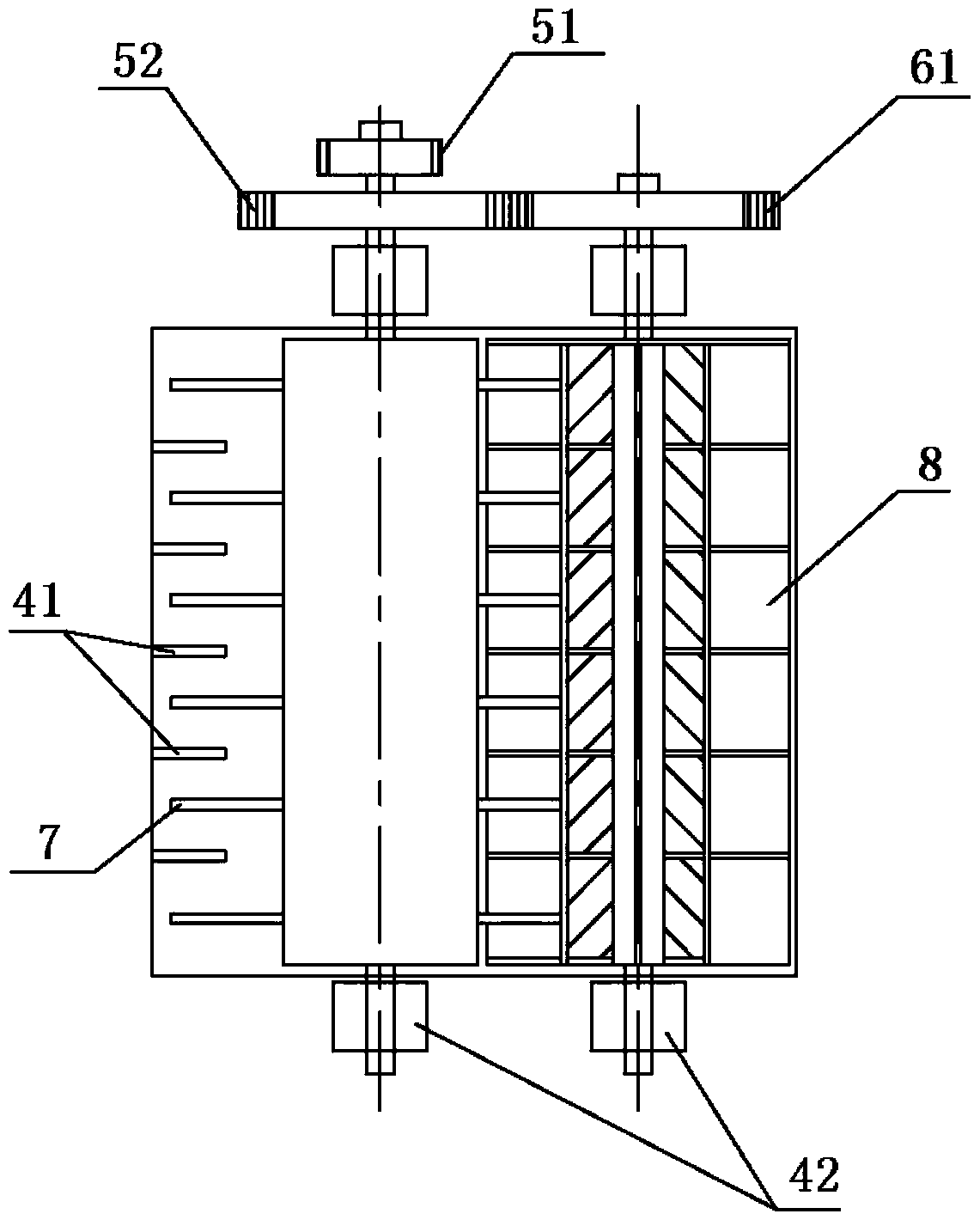

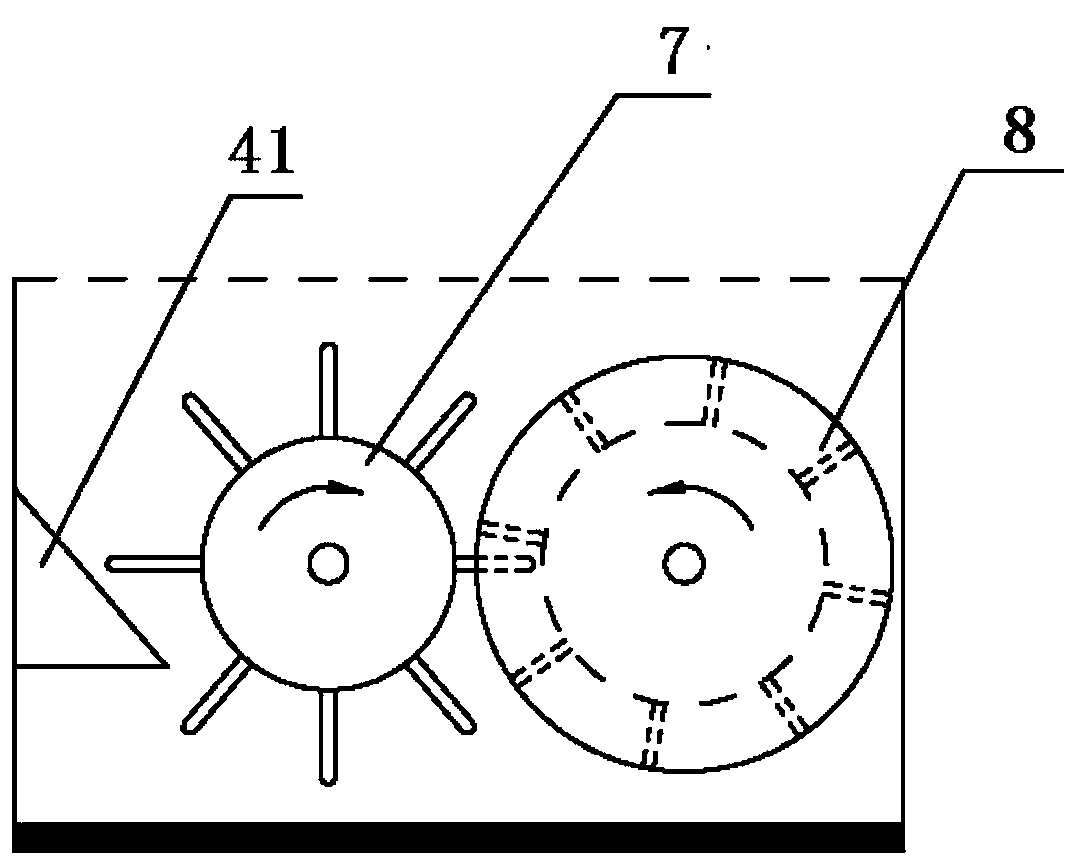

Crushing device for thrown cast sheets

The invention discloses a crushing device for thrown cast sheets. The crushing device comprises a driving wheel disc, a collecting bin and a crushing bin; the driving wheel disc is fixed to the side surface of a roll wheel, is coaxial with the roll wheel and is driven to rotate by a copper roll motor, and first transmission teeth are arranged on the outer edge of the driving wheel disc; the collecting bin is located at the lower side of the roll wheel and is used for collecting the thrown cast sheets; the crushing bin is located at the lower side of the collecting bin and is provided with crushing teeth and crushing hoppers meshed with the crushing teeth, bearing supports are arranged at one ends of the crushing teeth and one ends of the crushing hoppers, and first driven wheel discs and second driven wheel discs meshed with the first driven wheel discs are arranged at the other ends of the crushing teeth and at the other ends of the crushing hoppers respectively; the first driven wheel discs are driven by the driving wheel disc to rotate through a transmission chain and drive the crushing teeth and the crushing hoppers to rotate axially and reversely. According to the invention, the cast sheets can be uniformly crushed, and the work efficiency of crushing the thrown cast sheets can be greatly improved.

Owner:SINO MAGNETICS TECH

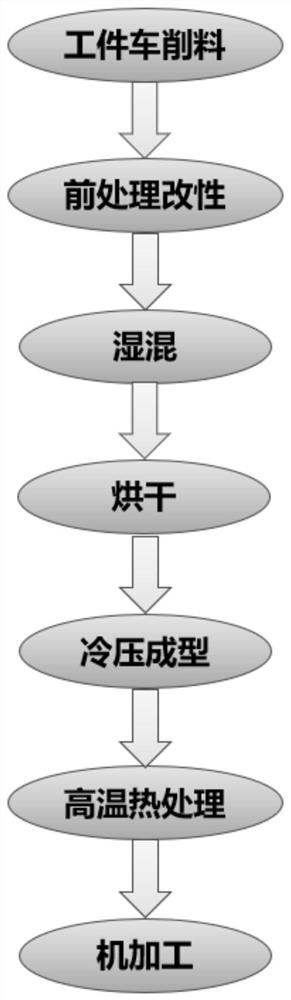

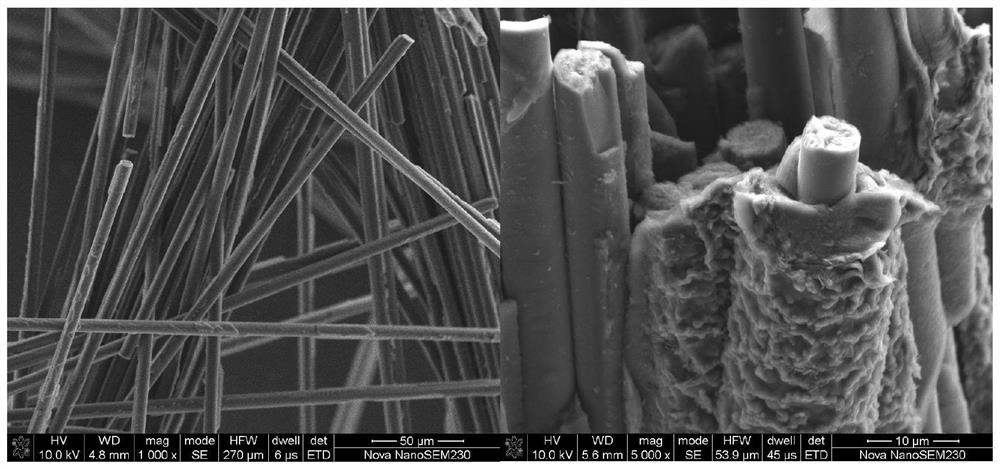

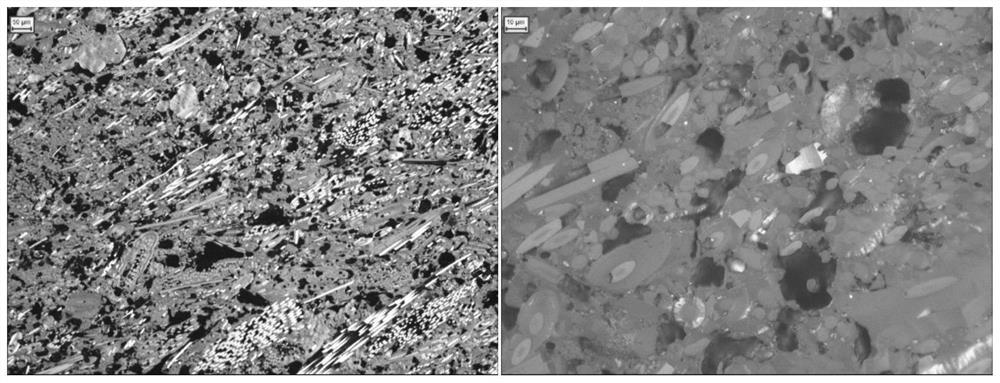

Preparation method of chopped carbon fiber composite material

The invention mainly relates to a method for preparing a carbon fiber composite material by taking a turning material of a carbon / carbon composite material as a main raw material and commercial chopped carbon fibers as a reinforcing phase, mainly aiming at the problems of resource recovery and reutilization in the production process of the carbon / carbon composite material. According to the method, turning materials and leftover materials generated in the workpiece turning process serve as main raw materials, the raw materials are subjected to pretreatment modification, wet mixing, drying, cold press forming, heat treatment and the like, the carbon / carbon composite material with high mechanical performance is prepared, and the material has wide application in the photovoltaic field, the heat treatment field, the friction field and the like. According to the invention, the effective utilization of resources is realized, the production cost is reduced, the solid wastes generated in the production process are effectively reduced, and the problem of environmental pollution is also well improved.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Foamed cement insulating material and posttreatment process thereof

The invention belongs to the technical field of insulating materials for building walls, and particularly relates to a treatment fluid formula of a foamed cement insulating material and a posttreatment process of the foamed cement insulating material. The foamed cement insulating material is provided with a treatment fluid protective layer outside the insulating material, wherein the treatment fluid protective layer has a thickness of 0.3-2mm; an organic silicon water-repellent protective layer is arranged outside the treatment fluid protective layer; the organic silicon water-repellent protective layer has a thickness of 0.2-1mm; and the treatment fluid is composed of the following components: 50-100 parts of liquid sodium silicate or potassium silicate, 0-50 parts of lithium silicate and 10-20 parts of silicasol. According to the invention, the foamed cement insulating material can be prevented from powder shedding, the strength can be improved, the water absorptivity can be reduced, and the service life can be prolonged, wherein the strength can be improved by 20-220%, the volume water absorptivity can be reduced to 10% or below, and the service life can be prolonged 3-5 times.

Owner:SHANDONG JIANZHU UNIV

High-performance long-service life silicon-silver cell positive and negative plates and preparation method thereof

InactiveCN102468482AImprove corrosion resistanceImprove adhesionElectrode carriers/collectorsLead-acid accumulator electrodesAlloySilicon

The invention discloses high-performance long-service life silicon-silver cell positive and negative plates and a preparation method thereof. The high-performance long-service life silicon-silver cell positive and negative plates comprise positive and negative grid plates, and are characterized in that a raw material of the positive and negative grid plates is a Pb-Ag-Ca-Ce alloy. The high-performance long-service life silicon-silver cell positive and negative plates have the advantages that the single sheet capacity of the high-performance long-service life silicon-silver cell positive and negative plates is 1.38 times that of the existing common products having surfaces same as surfaces of the high-performance long-service life silicon-silver cell positive and negative plates; a cell weight-capacity ratio is greatly improved; and the high-performance long-service life silicon-silver cell positive and negative plates provide a power energy storage guarantee and an early solution scheme for electric automobile development.

Owner:陈清利 +2

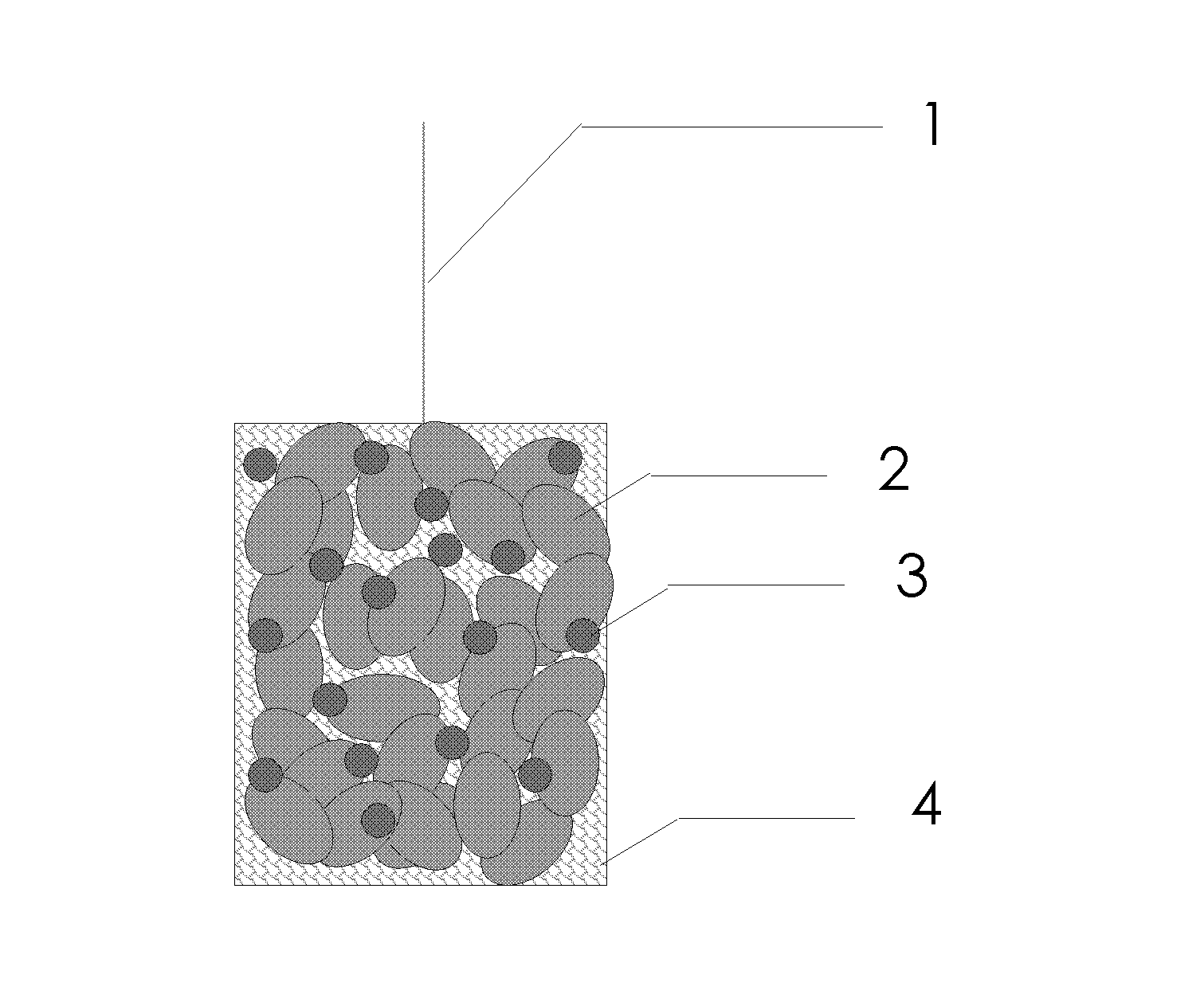

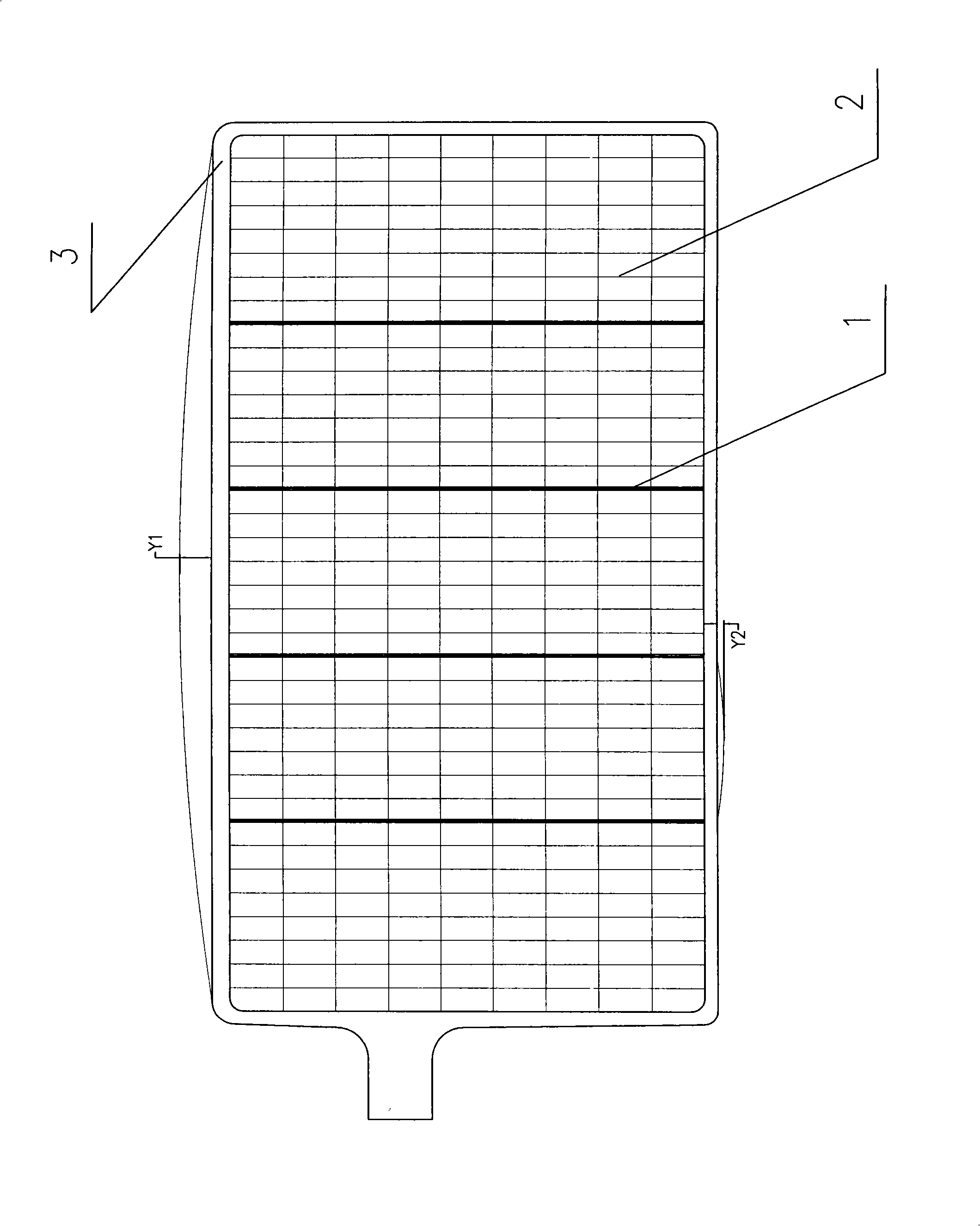

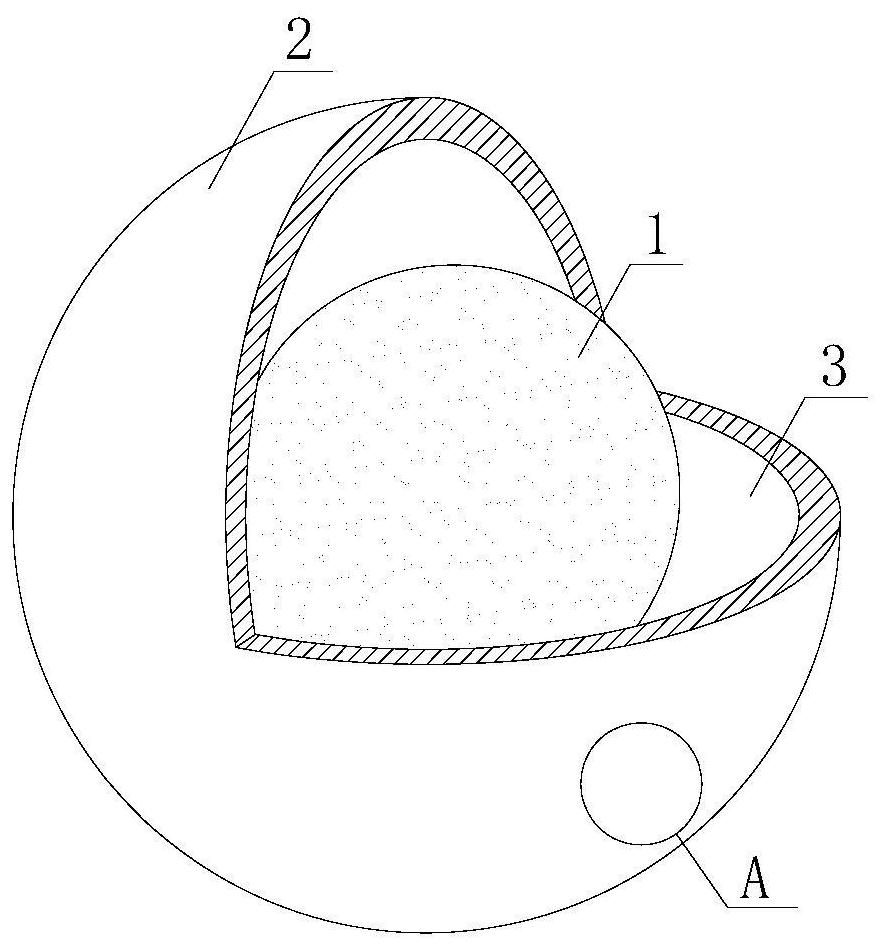

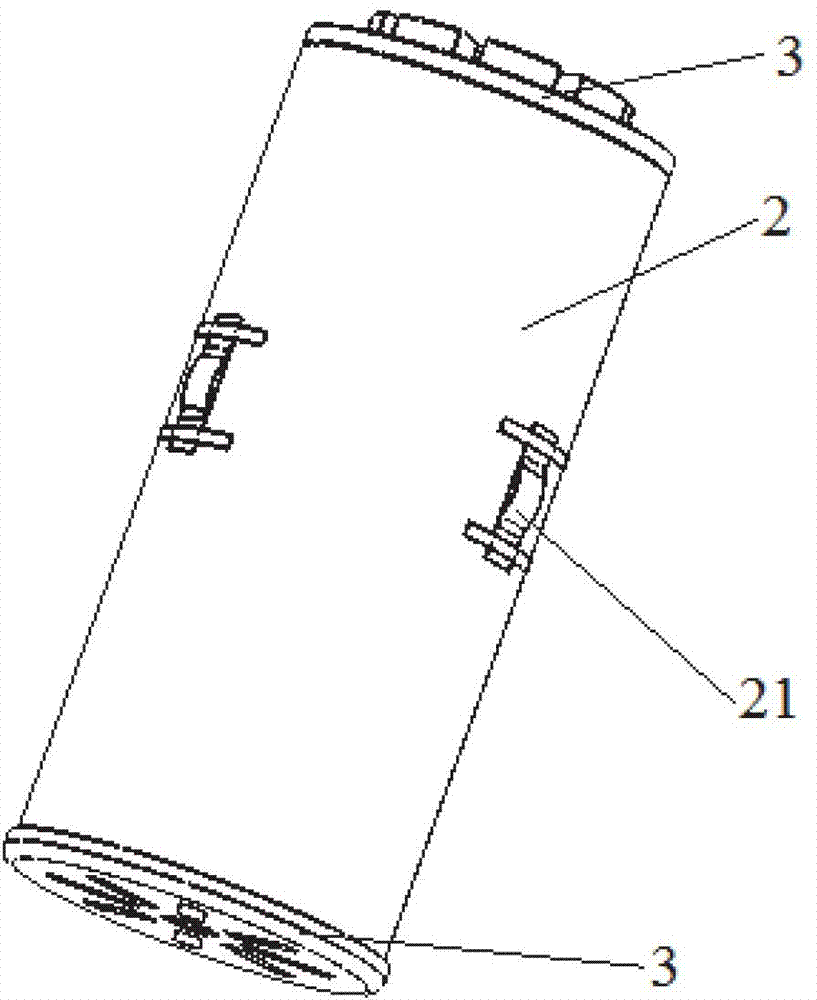

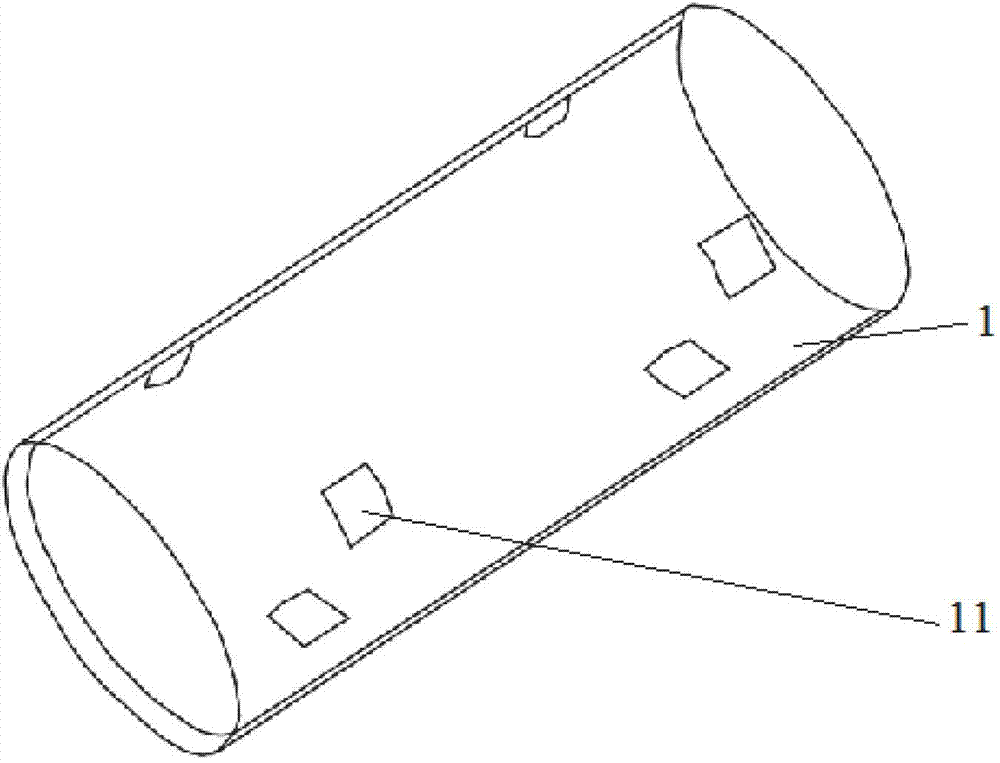

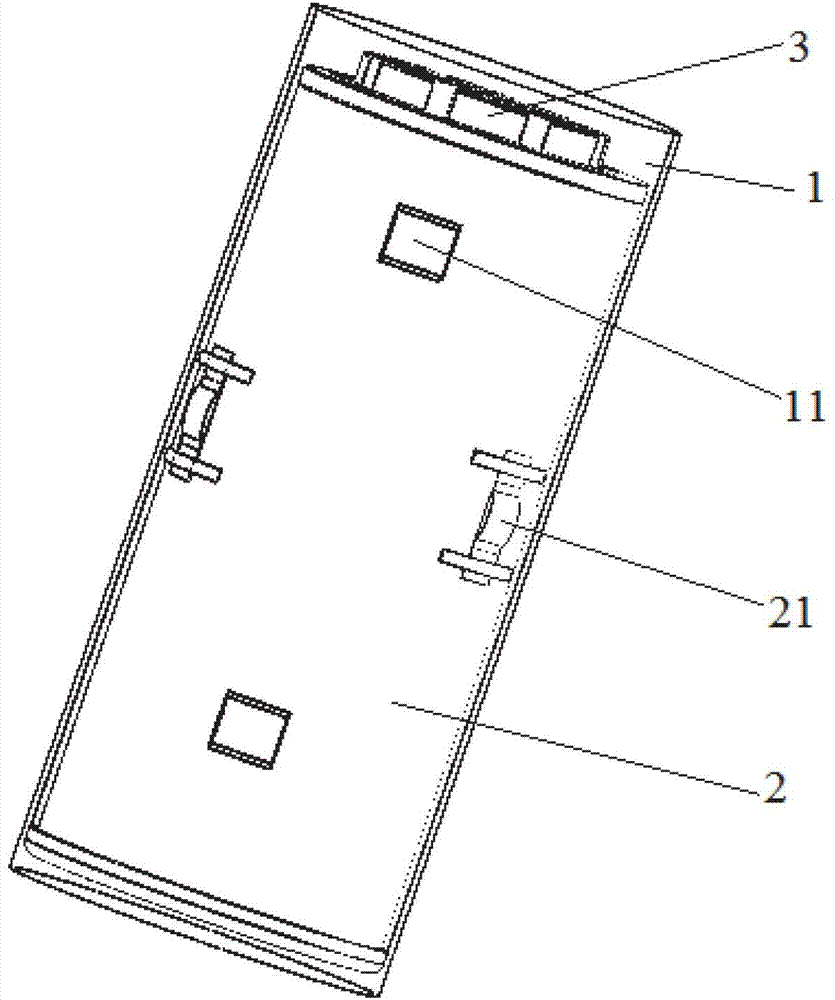

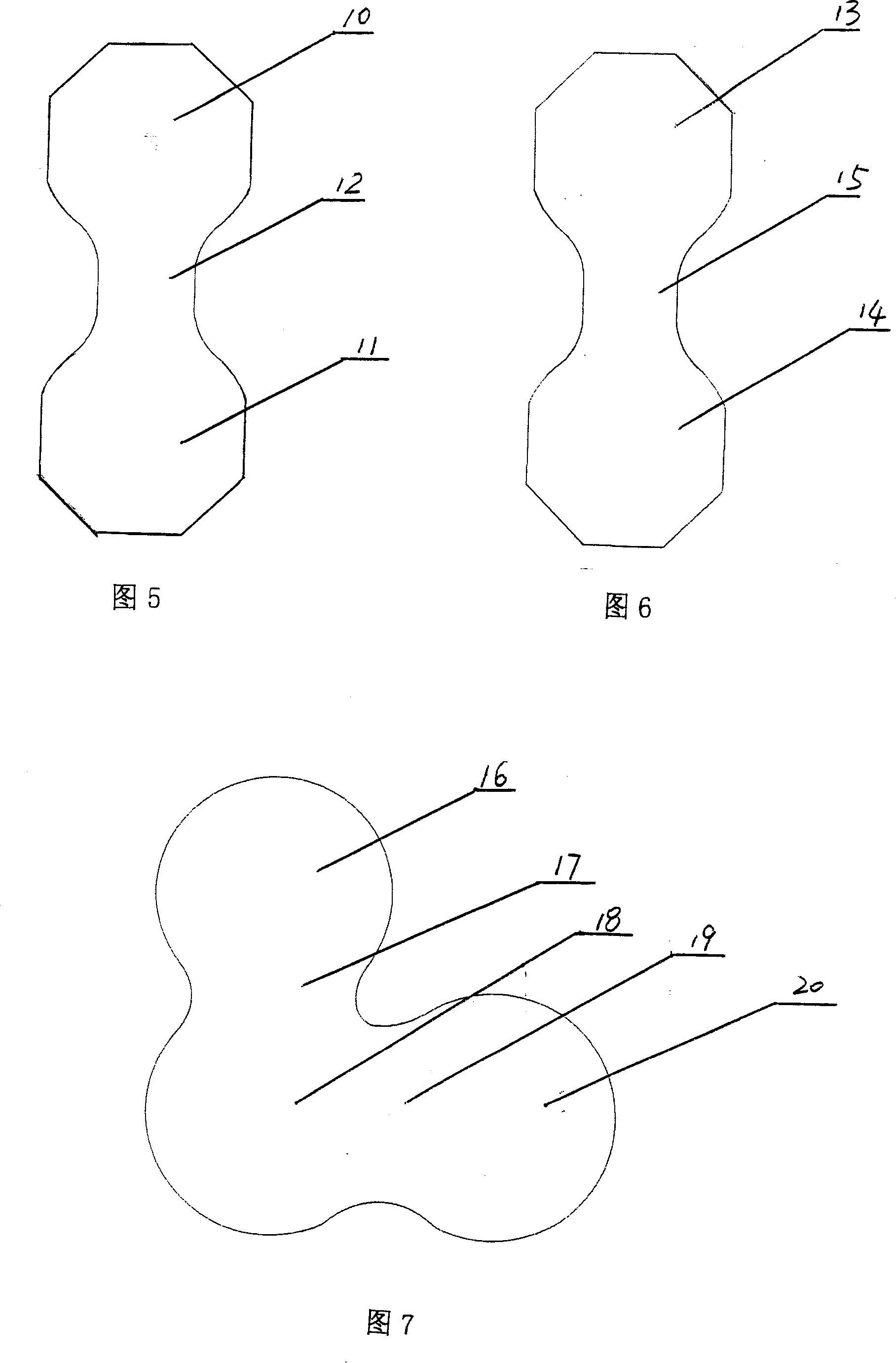

Iso-deflection for accumulator

InactiveCN101330143AReduce distortionReduce headroomElectrode carriers/collectorsLead-acid accumulator electrodesManufacturing technologyBattery capacity

An isodeflection pole plate for a storage battery belongs to the manufacturing technical field of the lead-acid storage battery, and is mainly composed of a frame (3), thin ribs (2) crosswise distributed vertically and horizontally in the frame (3), and thick ribs (1) disposed every 3 to 5 thin ribs among the vertical thin ribs (2). The section area of the thick rib (1) is 3 to 6 times that of the thin ribs (2). The isodeflection pole plate has the advantages that the structural design of the pole plate tends to be more reasonable and the arrangement structure in the height direction of the storage battery grid is improved, so as to reduce the deflection of the edge in the height direction, thereby reducing the deformation of the pole plate during the processes of manufacturing and application and improving the performance of the pole plate; and during the process of the battery design, the reserved space of the pole plate in a battery jar can be reduced and the width of the pole plate can be appropriately increased, so that the capacity of the pole plate can be increased and the battery capacity can further be increased, thereby improving the service performance and the service life of the battery.

Owner:WOLONG ELECTRIC GRP CO LTD +1

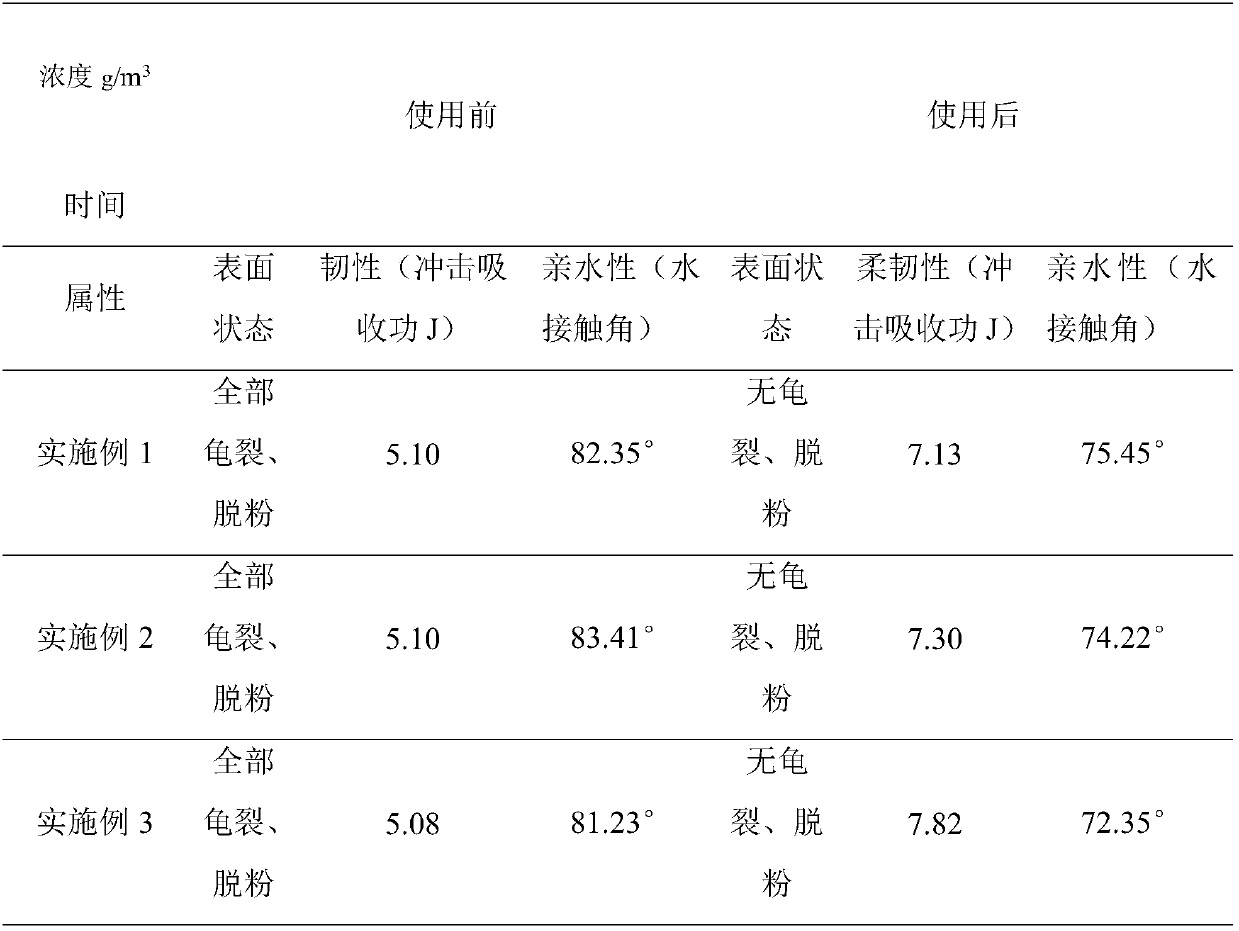

Glue for battery pole piece surface treatment and preparation process thereof

ActiveCN109554144AUniform mechanical propertiesImprove mechanical propertiesMacromolecular adhesive additivesUnsaturated alcohol polymer adhesivesFiberPolyvinyl alcohol

Glue for battery pole piece surface treatment is provided. The glue includes, by mass, 0.1-2% of carboxymethylcellulose sodium, 0.1-4% of polyvinyl alcohol, 0.3-3% of acrylic acid-vinyl alcohol copolymer, and 0.1-1% of chopped fibers, with the balance being water. A preparation process of the glue is also provided. The hydrophilicity and flexibility of a battery pole piece coated with the glue areobviously improved than those of a battery pole piece coated with tissue paper, and the battery pole piece coated with the glue is free of cracking and powder falling. In addition, a process of applying the glue on the surface of a battery pole piece can replace the original process of wrapping a battery pole piece with tissue paper, which can greatly improve the production efficiency and is beneficial to large-scale production.

Owner:森克创能(天津)新能源科技有限公司

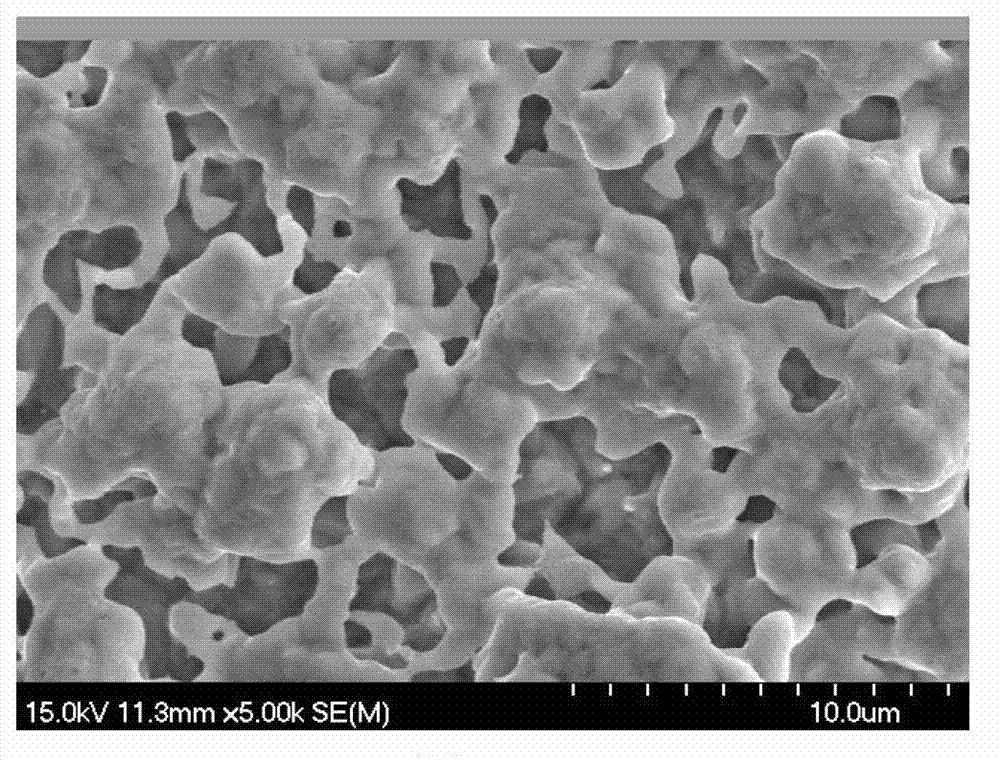

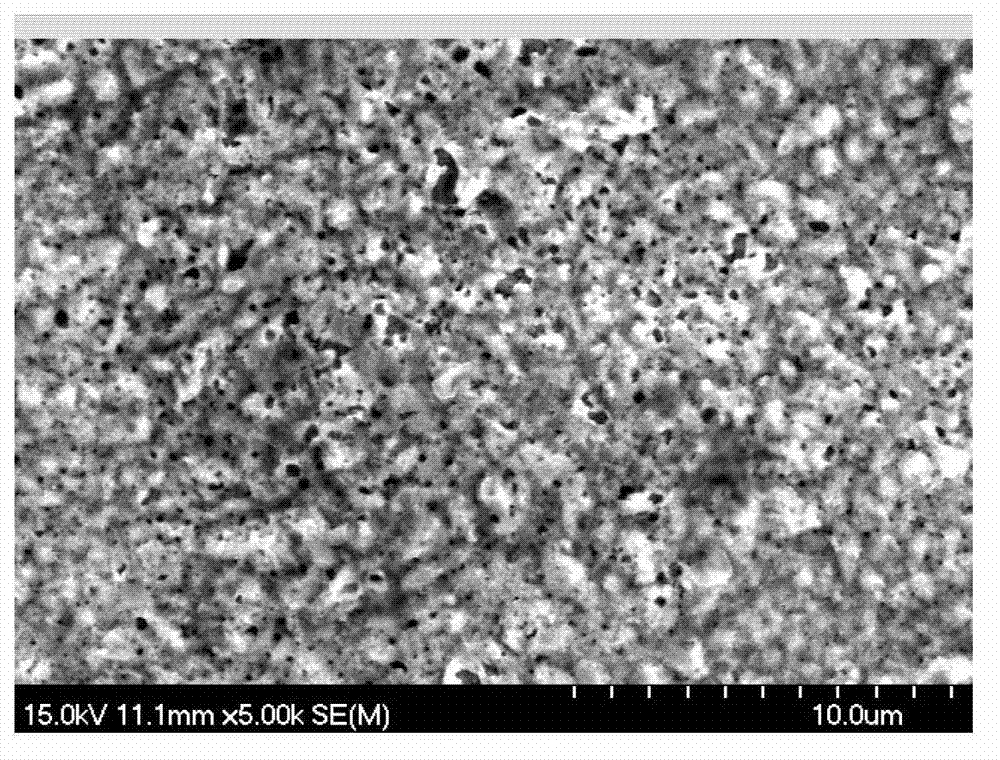

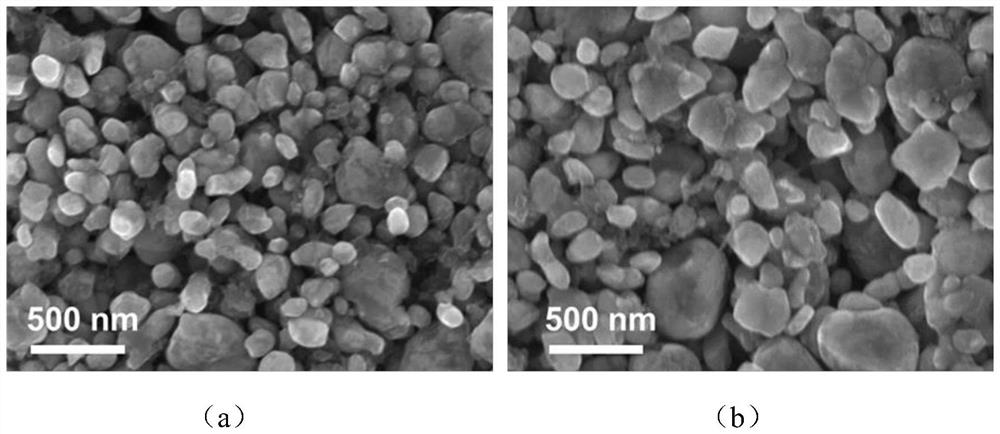

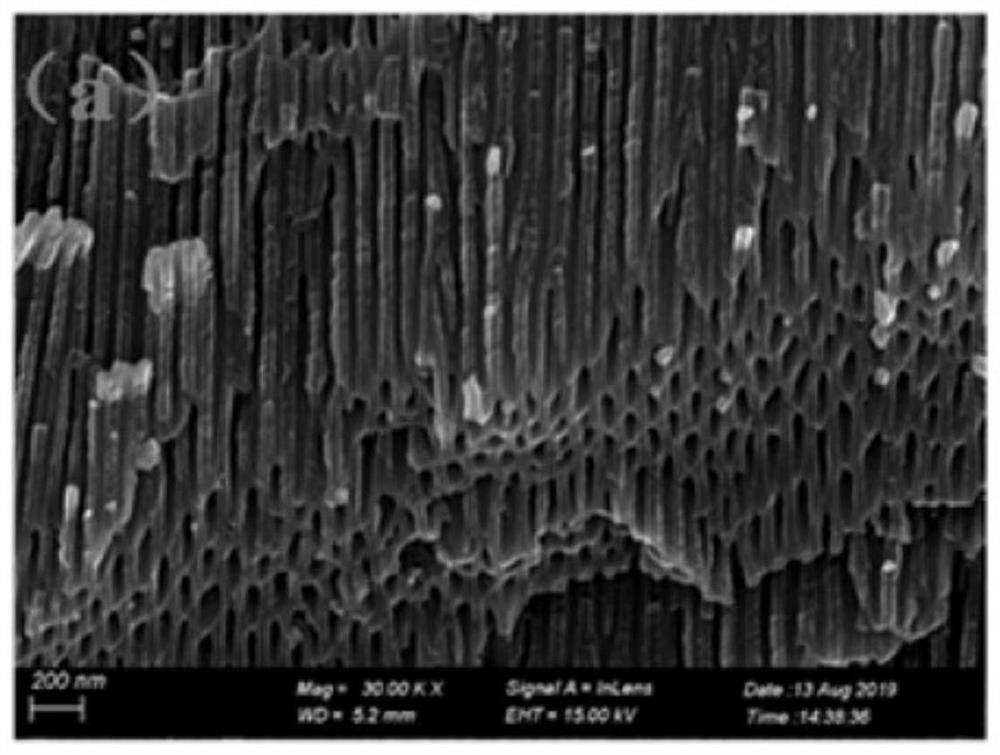

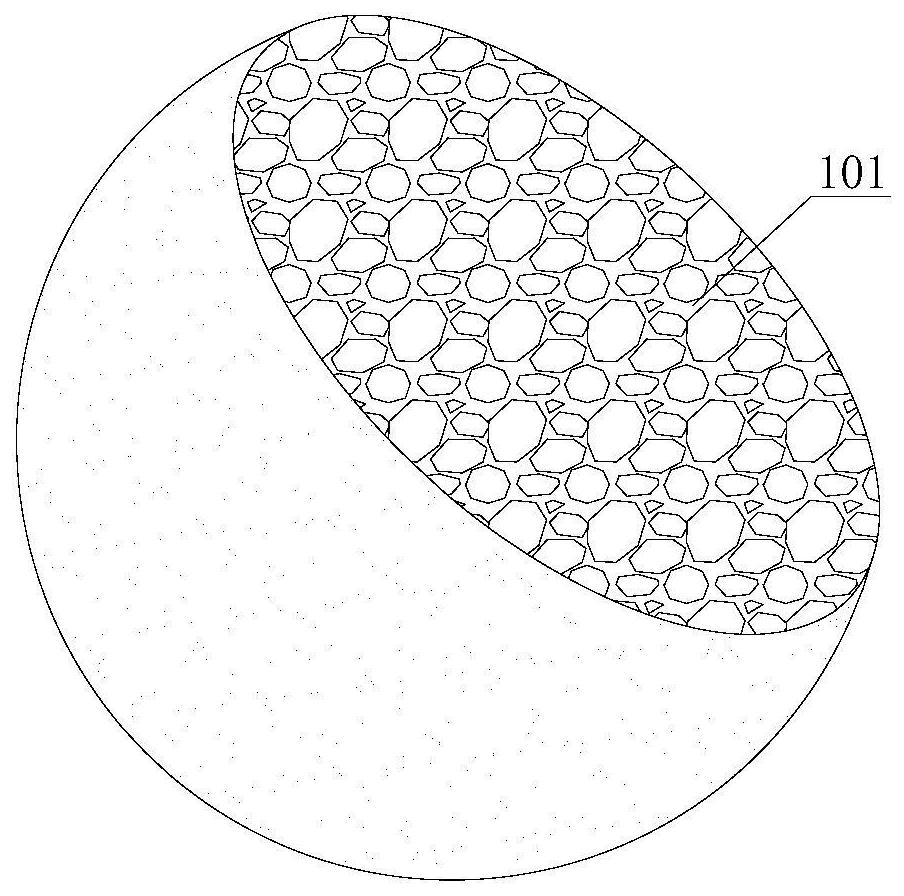

High-stability silicon-carbon negative electrode material and preparation method thereof

InactiveCN111816862AImprove stabilityPrevent powderingNegative electrodesSecondary cellsAcid etchingCarbon coating

The invention discloses a high-stability silicon-carbon negative electrode material and a preparation method thereof. The high-stability silicon-carbon negative electrode material comprises a porous silicon core and a carbon coating shell, wherein the outer side of the porous silicon core is coated with the carbon coating shell, and an expansion gap is reserved between the porous silicon core andthe carbon coating shell. The preparation method comprises the following steps of carrying out high-temperature treatment on micron-sized SiO2 powder at 950 DEG C for 5 hours; obtaining Si / SiO2 mixture; carrying out HF acid etching treatment on the Si / SiO2 mixture; removing SiO2, further, forming a porous silicon core with a porous structure; the porous structure providing an expansion space for volume expansion formed by the porous silicon core in the charging and discharging process; and preventing the phenomenon that the silicon-carbon negative electrode material is powdered after the porous silicon core is not shrunk and expanded so that the silicon-carbon negative electrode material has higher stability, an expansion gap is formed between the porous silicon core and the carbon coatingshell, an expansion gap provides an expansion space for volume expansion formed by the porous silicon core in the discharge process, and a problem of expansion of the porous silicon core in the carbon coating shell is more effectively solved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Two-dimensional catalytic material and preparation and application thereof

ActiveCN113648985AImprove mass transfer efficiencyHigh active specific surface areaDispersed particle separationCatalyst activation/preparationAcid etchingMicron scale

The invention discloses a two-dimensional catalytic material and the preparation and the application thereof.The two-dimensional catalytic material is characterized in that a transition metal foil with the micron-order thickness serves as a base material, a two-dimensional matrix carrier with light weight, flexibility, high specific surface region and roughness is prepared through pretreatment, anodic oxidation, acid etching adjustment and control, hole breaking and thermal stabilization treatment, and the two-dimensional catalytic material is prepared on the basis of the carrier. The two-dimensional ozone catalytic material prepared by taking metal salt and / or organic matter as a precursor and adopting vacuum impregnation, in-situ deposition and thermal reduction technologies to load active metal and / or non-metal active components in situ has the advantages of high specific surface region, high roughness, high mechanical strength, light weight, flexibility and the like; when the catalyst is applied to water treatment, the catalyst has the advantages of quick interface mass transfer, excellent catalytic performance and the like; meanwhile, the preparation process of the two-dimensional catalytic material has the characteristics of simple method, easiness in adjustment of process parameters, easiness in large-scale production, low preparation cost and the like.

Owner:NANJING UNIV OF SCI & TECH

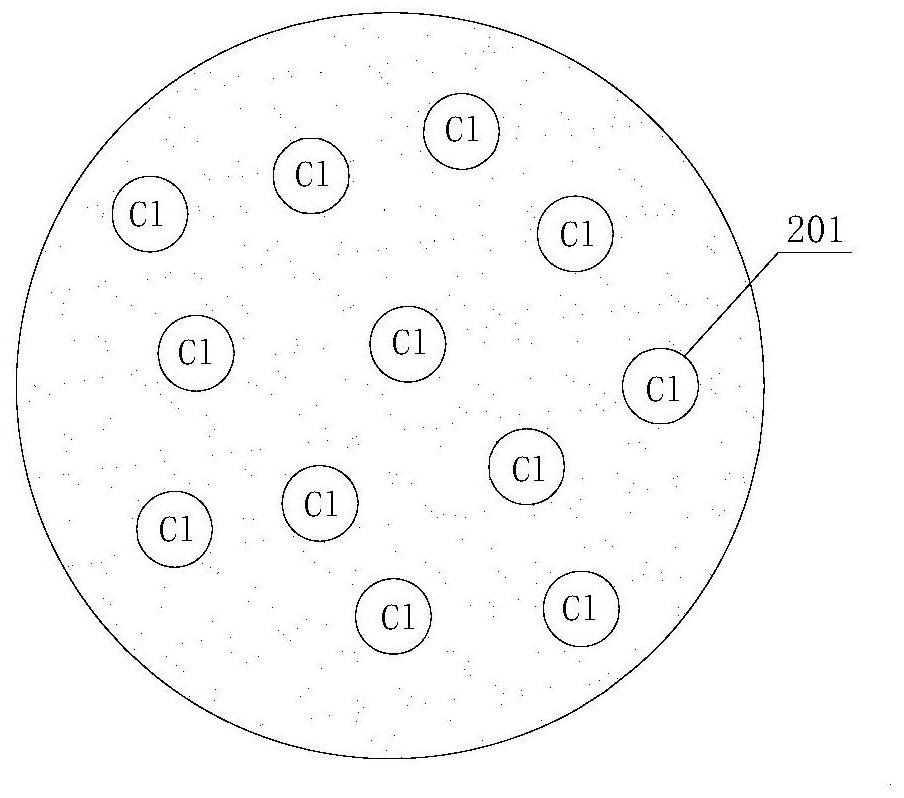

High reliability electrochemical energy storage device vibration-proof structure

ActiveCN102930994AImprove stabilityPrevent desoldering failureCapacitor housing/encapsulationVibration amplitudeElectricity

The invention discloses a high reliability electrochemical energy storage device vibration-proof structure. The high reliability electrochemical energy storage device vibration-proof structure comprises an outer shell, an electricity core and a current collector, the electricity core is arranged in the outer shell and electrically connected with the current collector, and an electrolyte is filled between the outer shell and the electricity core. The high reliability electrochemical energy storage device vibration-proof structure is characterized in that a plurality of grooves are arranged on the outer shell, a plurality of elastic parts are disposed on the outer surface of the electricity core, and the position of the electricity core in the outer shell is limited through the grooves and the elastic parts. According to the high reliability electrochemical energy storage device vibration-proof structure, a plurality of elastic sheets are introduced on the electricity core, the grooves are introduced on the outer shell, the electricity core is limited in a three-dimensional direction through the elastic sheets and the grooves, the elastic sheets can buffer the vibration amplitude, the stability of a device at vibration occasions is greatly improved, effectiveness loss caused by loose weld of the welding position between the electricity core and the current collector at the vibration occasions is effectively prevented, and conditions of electrode shelling, uncoiling and the like are effectively prevented.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

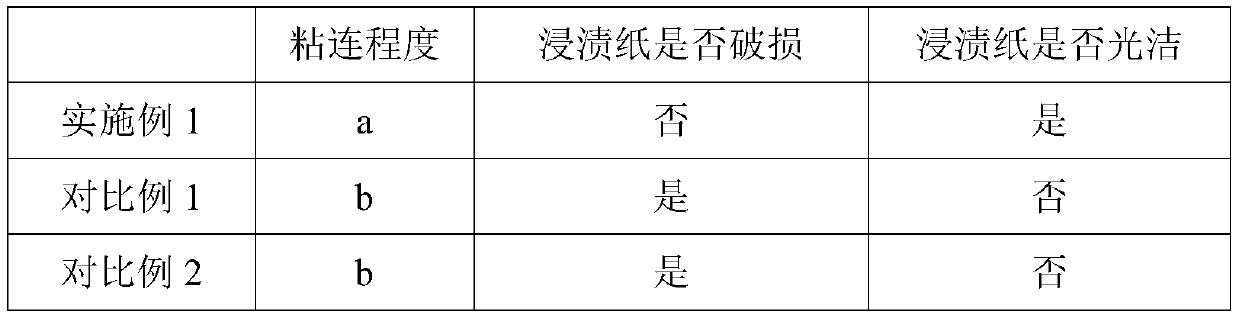

Anti-sticking agent and preparation method thereof

InactiveCN111593604ALow costMaintain propertiesNon-fibrous pulp additionPaper coatingOrganic acidPolymer science

The invention relates to the technical field of anti-sticking agents, and particularly provides an anti-sticking agent and a preparation method thereof. The first aspect of the invention provides theanti-sticking agent which at least comprises the following preparation raw materials in parts by weight: 30-40 parts of an organic acid, 4-8 parts of an organic amine, 10-20 parts of a dispersing agent, 20-30 parts of a penetrating agent and 15-30 parts of a solvent, wherein the penetrating agent is a long-carbon-chain polyoxy hydroxyl compound.

Owner:HANGZHOU LINAN DIEN CHEM CO LTD

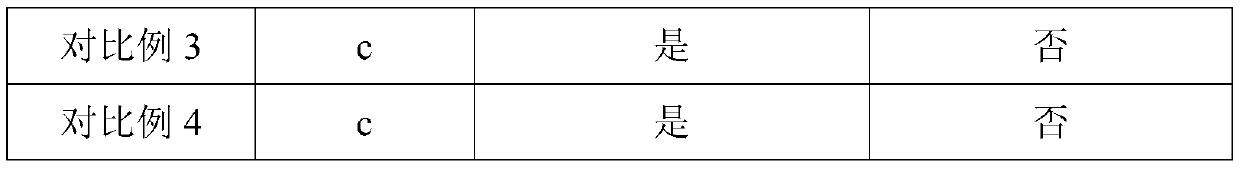

Steel strip substrate MH-Ni buckle type rechargeable battery

ActiveCN101110486APrevent powderingSolve the problem of powder removalNickel accumulatorsButton batteryEngineering

The present invention relates to a steel strip basal body hydrogen-nickel rechargeable button cell, which comprises a positive plate provided with a nickel electrode, a negative plate composed of complex multiphase electrochemical hydrogen storage alloy powders, a diaphragm arranged between the positive plate and the negative plate, a cell shell to hold an assembly of all components above with a gasket ring and a cell cover, a meshed gasket arranged between an internal bottom of the cell shell and the positive plate, a meshed gasket and a spring cushion positioned between the negative plate and the cell cover. The present invention eliminates a problem that powder easily falls off for negative hydrogen electrodes with steel strips as basal bodies, thus enhancing performance of heavy current charge and discharge, reducing cost and saving resource.

Owner:河南创力新能源科技股份有限公司

Wood pulverizer

The invention discloses a wood pulverizer and relates to the field of wood production equipment. The wood pulverizer comprises a base and a pulverizing bin. The base is located at the bottom of the pulverizing bin. A feeding port is formed in the front end of the base. A discharging port is formed in the rear portion of the base. A pair of screw-in cylinders is arranged at the front end of the pulverizing bin. The diameter of the front section of the screw-in cylinders is larger than that of the rear end of the screw-in cylinders. A filtering groove is formed in the tail portions of the screw-in cylinders. A magnet is arranged on the side edge of the filtering groove. A pulverizing room is arranged in the middle of the pulverizing bin. Three sets of independent rotating shafts are arranged in the pulverizing room. Motors are arranged on the rotating shafts. Cutting blades are arranged on the rotating shafts. The wood pulverizer is reasonable in structure and high in practicability, feeding is convenient, first-level cutting of wood is completed, meanwhile, the wood is sent to the pulverizing bin, and multilevel pulverizing efficiency is high.

Owner:涟水县中林木制品厂

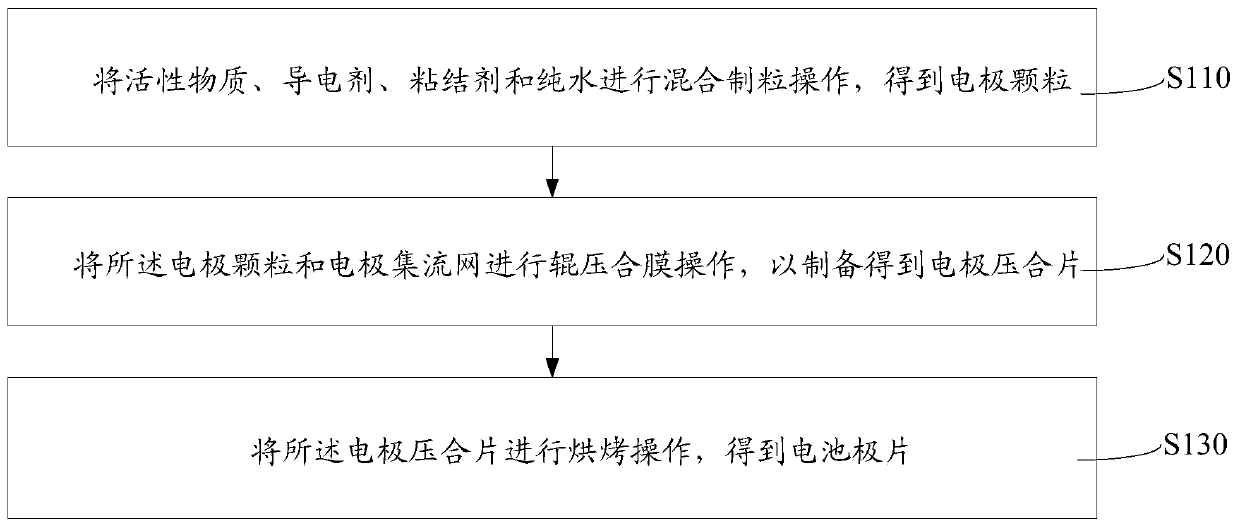

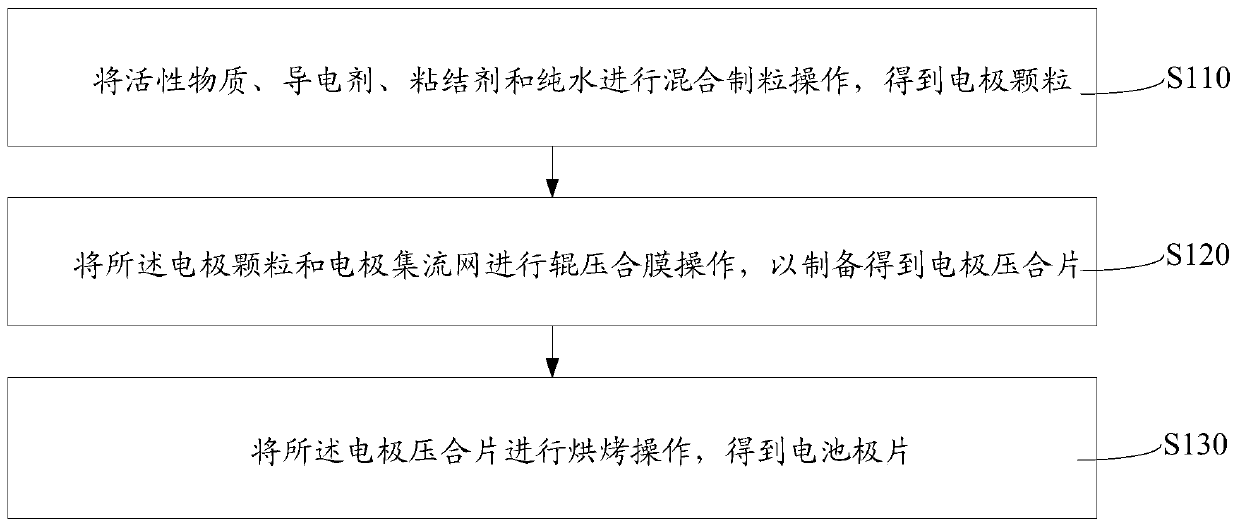

Preparation method of battery pole piece and battery

InactiveCN111146401AImprove discharge performanceReduce usageElectrode thermal treatmentElectrical batteryPhysical chemistry

The preparation method of the battery pole piece comprises the following steps: carrying out mixing granulation operation on an active substance, a conductive agent, a binder and pure water to obtainelectrode particles; performing roll-in film laminating operation on the electrode particles and an electrode current collecting net to prepare an electrode laminated sheet; and carrying out baking operation on the electrode lamination sheet to obtain the battery pole piece. Thus, various components are mixed and granulated to obtain the electrode particles instead of conventional slurry, so thatthe non-uniformity caused by subsequent combination with the current collector can be avoided, and the porosity can be improved; and the electrode current collecting net and the electrode particles are adopted to carry out roll-in film laminating operation, so that the electrode particles can be clamped and embedded into the electrode current collecting net, the combination firmness is improved, the powder falling problem is avoided, the use of a binding agent can be reduced, and the discharge performance of the battery pole piece is also greatly improved. In addition, the invention also provides a battery comprising the battery pole piece.

Owner:EVE ENERGY CO LTD

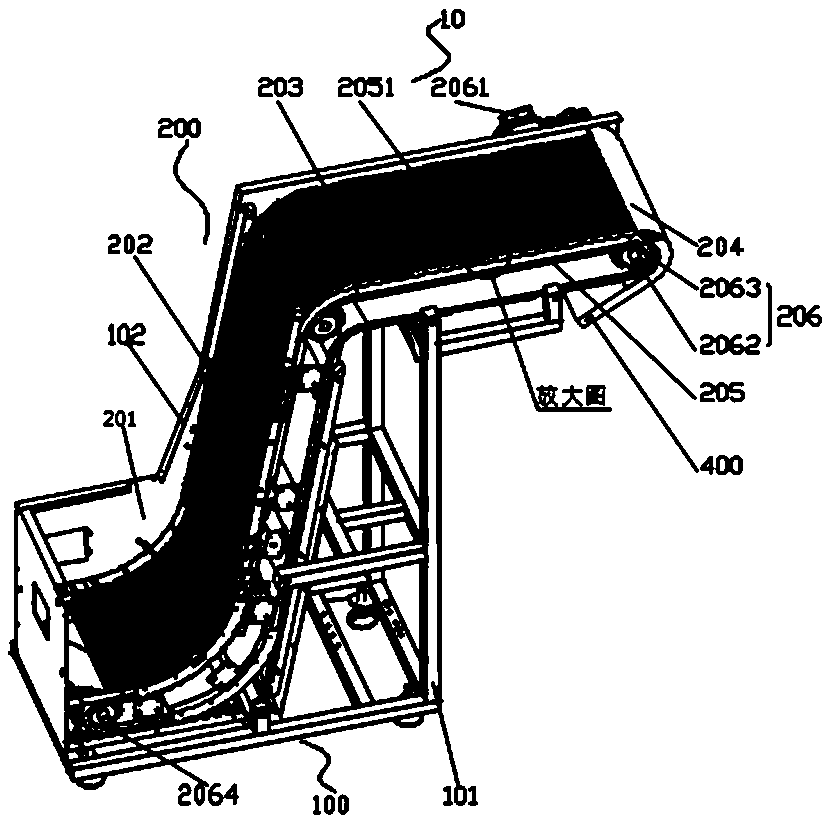

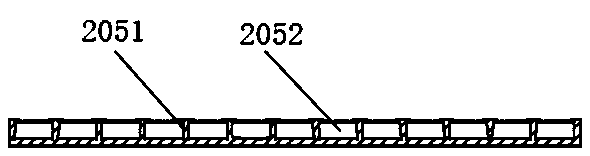

Cap arranging machine

The invention discloses a cap arranging machine, which is used for arranging high covers. The cap arranging machine comprises: a main machine frame, wherein the main machine frame is in an oblique ladder shape; a conveying belt mechanism, wherein the conveying belt mechanism is arranged on the main machine frame and is sequentially provided with a lower horizontal section, a cap arranging section,an upper horizontal section and a cap reversing section which are smoothly connected with each other from the bottom to the top of the main machine frame; the bottom of the main machine frame and thelower horizontal section of the conveying belt mechanism form an accommodating space, and the accommodating space is configured as a material pool; the material pool is used for storing the high capsto be arranged; the cap reversing section of the conveying belt mechanism is connected with next processing equipment; the high caps to be arranged are arranged by passing through the material pool,the lower horizontal section, the cap arranging section, the upper horizontal section and the cap reversing section of the conveying belt mechanism, and the high caps are conveyed to next processing equipment, a projecting disc or a belt conveyor or other equipment. The machine has the advantages of less energy consumption, less noise, high production efficiency and no damage to the bottle caps.

Owner:上海宇田机电设备有限公司

Ceramic proppant and preparation method thereof

ActiveCN101560381BHigh strengthImprove diversion capacityFluid removalWater basedManganese(II,III) oxide

The invention relates to a ceramic proppant and a preparation method thereof. The ceramic proppant comprises bauxite and trimanganese tetroxide and is characterized by comprising a water-based organicbinder; and the mass ratio of the bauxite, the trimanganese tetroxide and the water-based organic binder is as follows: 93-99 mass proportion of bauxite; 1-7 mass proportion of trimanganese tetroxide, 8-15 mass proportion of water-based organic binder and total mass of bauxite and trimanganese tetroxide based on 100 mass proportion. The ceramic proppant has the advantages of lower rate of sintering temperature and low broken rate.

Owner:阳泉市长青石油压裂支撑剂有限公司

Modified aerogel for filling internal hollow cavity of hollow glass

InactiveCN107381582ASettle settlementPrevent powderingSilicon compoundsGel preparationThermal insulation

The invention discloses modified aerogel for filling an internal hollow cavity of hollow glass and relates to the technical field of hollow glass processing. The modified aerogel is prepared by the steps as follows: (1) gel preparation, (2) gel aging, (3) modification and (4) drying. According to the modified aerogel, conventional aerogel is modified with a self-made modifier, so that the modified aerogel is prepared, the outstanding thermal-insulation property can be developed after the hollow glass is filled with the modified aerogel, tests show that the U value is as low as 0.01 W / m<2>.K and the Sc value is as low as 0.06 when filling thickness of the modified aerogel is 30 mm; besides, with the adoption of the modified aerogel, the problem of settlement of the conventional aerogel after long-time use can be effectively solved, and the problems of powdering, damage and the like caused by production, transportation, frame attaching, hoisting, mounting and the like are solved.

Owner:安徽艺云玻璃有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com