Wood pulverizer

A technology of wood shredders and shredder bins, which is applied in the direction of grain processing, etc., and can solve the problems of unreachable shredding effect, unadjustable shredding accuracy, and difficult shredding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

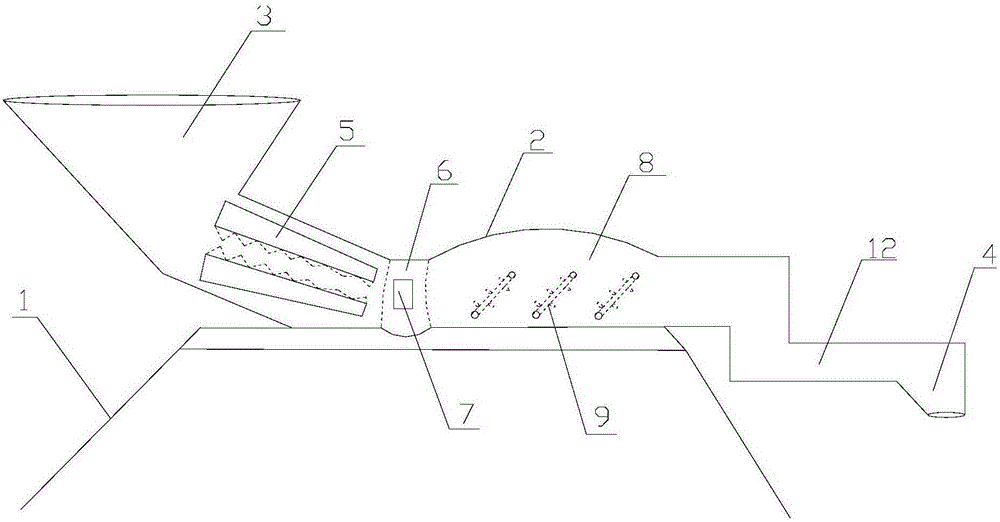

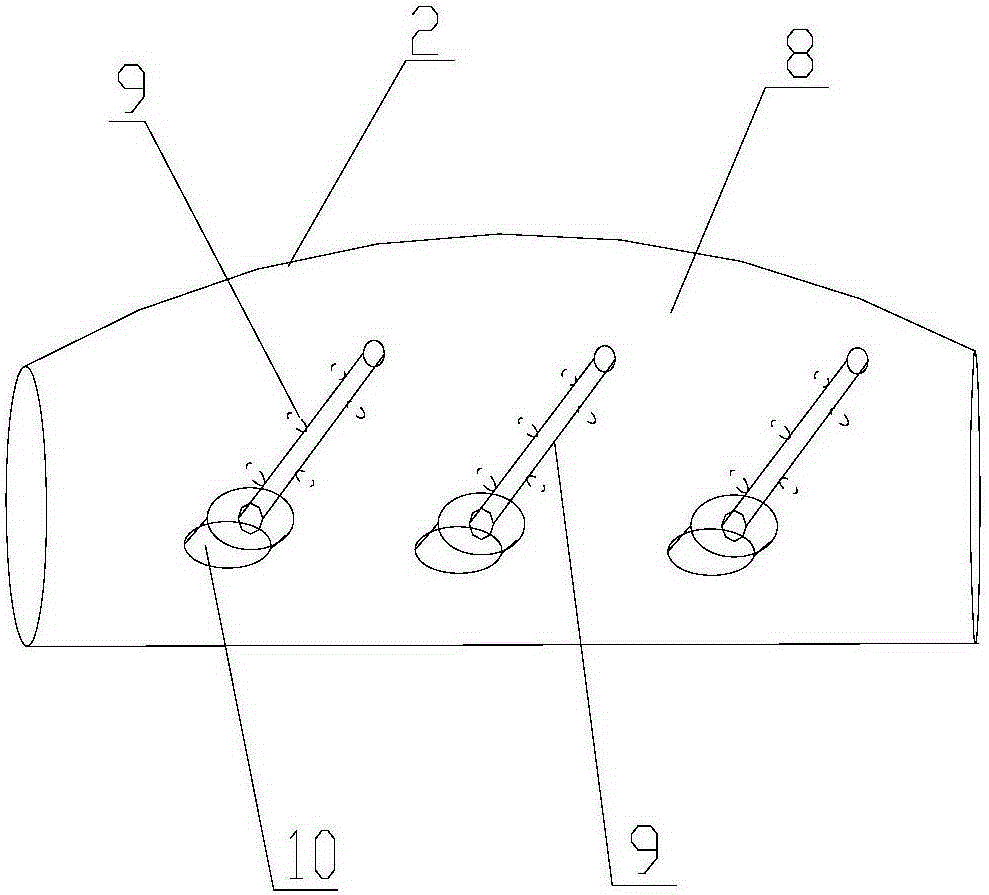

[0013] A wood shredder, comprising a base 1 and a crushing bin 2, the base 1 is located at the bottom of the crushing bin 2, the front end of the base 1 is provided with a material inlet 3, and the rear of the base 1 is provided with a discharge port 4, The front end of the crushing bin is provided with a pair of screw-in cylinders 5, the diameter of the front section of the screw-in cylinder 5 is greater than the diameter of the rear end, and the tail of the screw-in cylinder 5 is provided with a filter tank 6, and the side of the filter tank 6 A magnet 7 is provided, and a crushing chamber 8 is arranged in the middle of the crushing chamber. There are three sets of independent rotating shafts 9 in the crushing chamber 8, and a driving motor 10 is arranged on the rotating shafts 9, and a cutting blade is arranged on the rotating shafts 9. 11. The base 1 is the main structure of the pulverizer, which mainly plays a supporting role. The 3 inlets are used for feeding the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com