High-stability silicon-carbon negative electrode material and preparation method thereof

A negative electrode material, high stability technology, applied in the direction of carbon preparation/purification, negative electrode, chemical instruments and methods, etc., can solve the problems of complicated operation steps, insignificant volume expansion, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

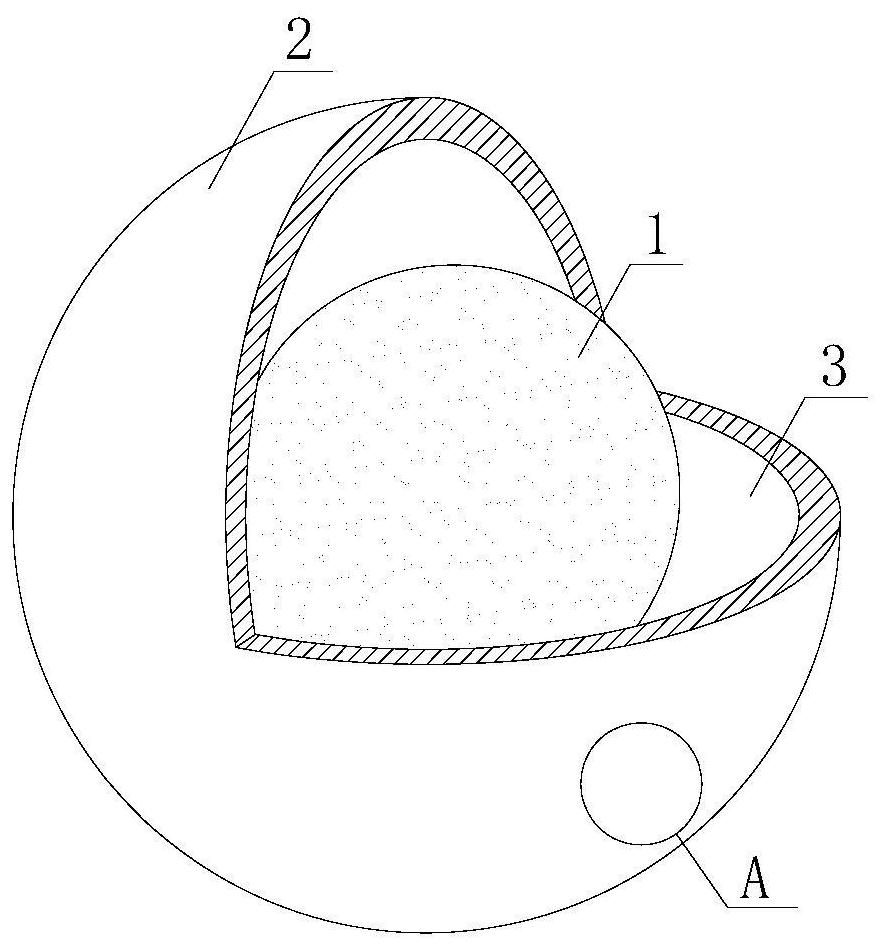

[0037] see Figure 4 In order to further better explain the above examples, the present invention also provides an embodiment, a method for preparing a highly stable silicon-carbon negative electrode material, comprising the following steps:

[0038] S01: Micron-sized SiO2 powder was treated at 950°C for 5 hours to obtain a Si / SiO2 mixture;

[0039] S02: Remove SiO2 by etching with HF acid to obtain a porous silicon core;

[0040] S03: A layer of SiO2 shell is coated on the surface of the porous silicon core;

[0041] S04: Put the porous silicon core coated with SiO2 layer shell on the surface into the CVD vapor deposition carbon coating rotary furnace, and input the carbon source organic precursor;

[0042] S05: Carrying out carbon coating on the Si02 layer shell;

[0043] S06: Etching and removing the SiO2 shell with HF acid to obtain a silicon-carbon composite material.

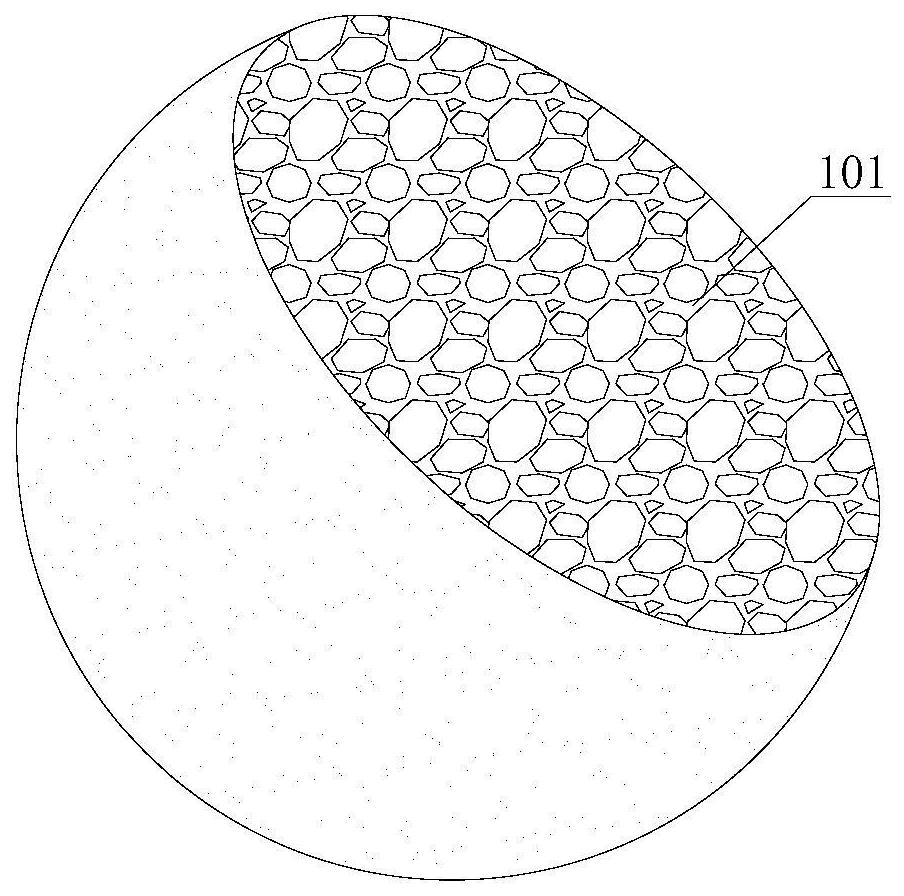

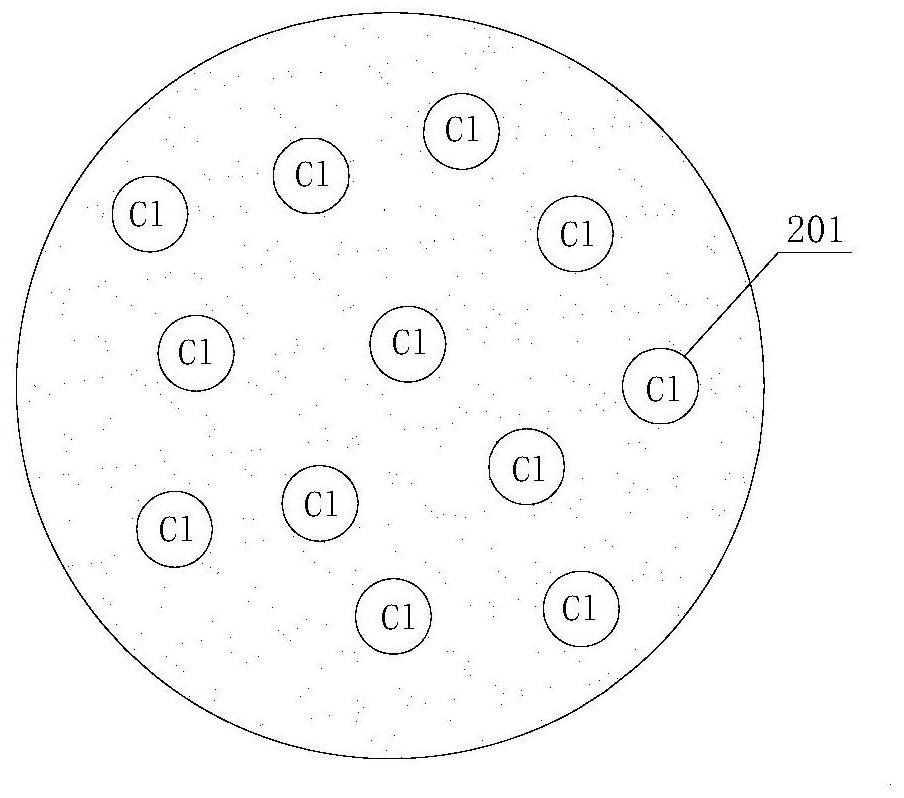

[0044] In the above embodiment, further, in step S03 , a layer of SiO 2 shell 301 is coated on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com