Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Optimize production steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

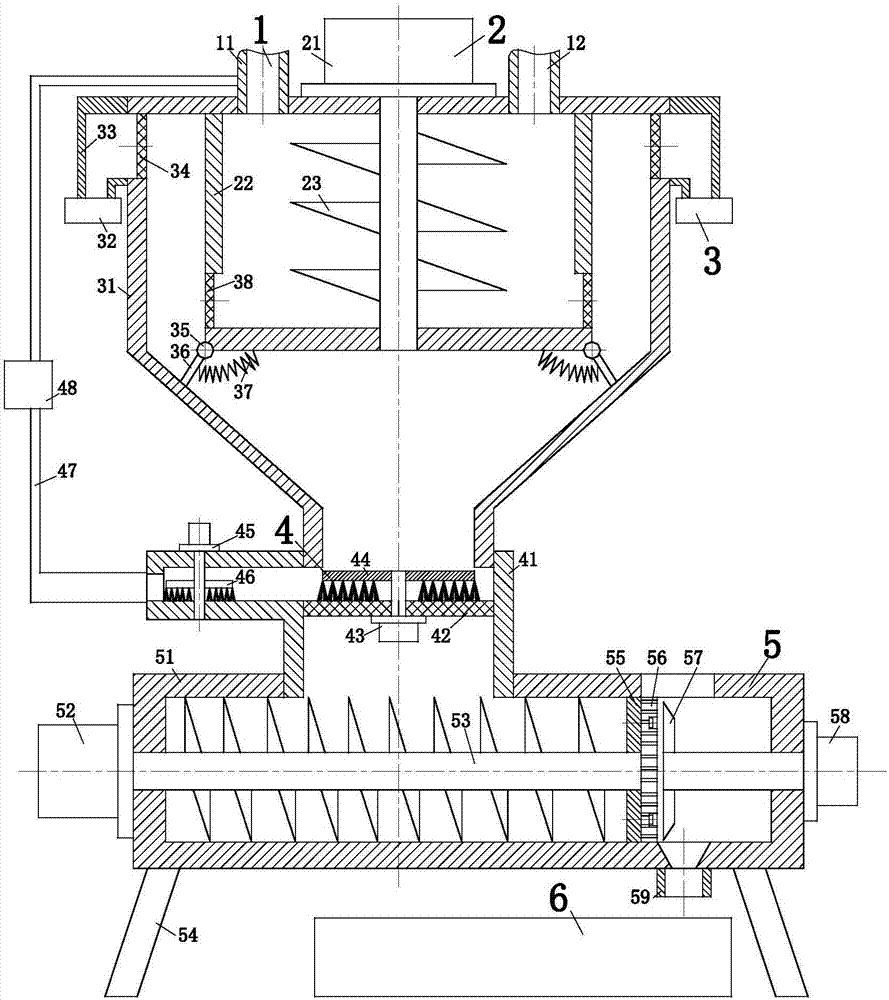

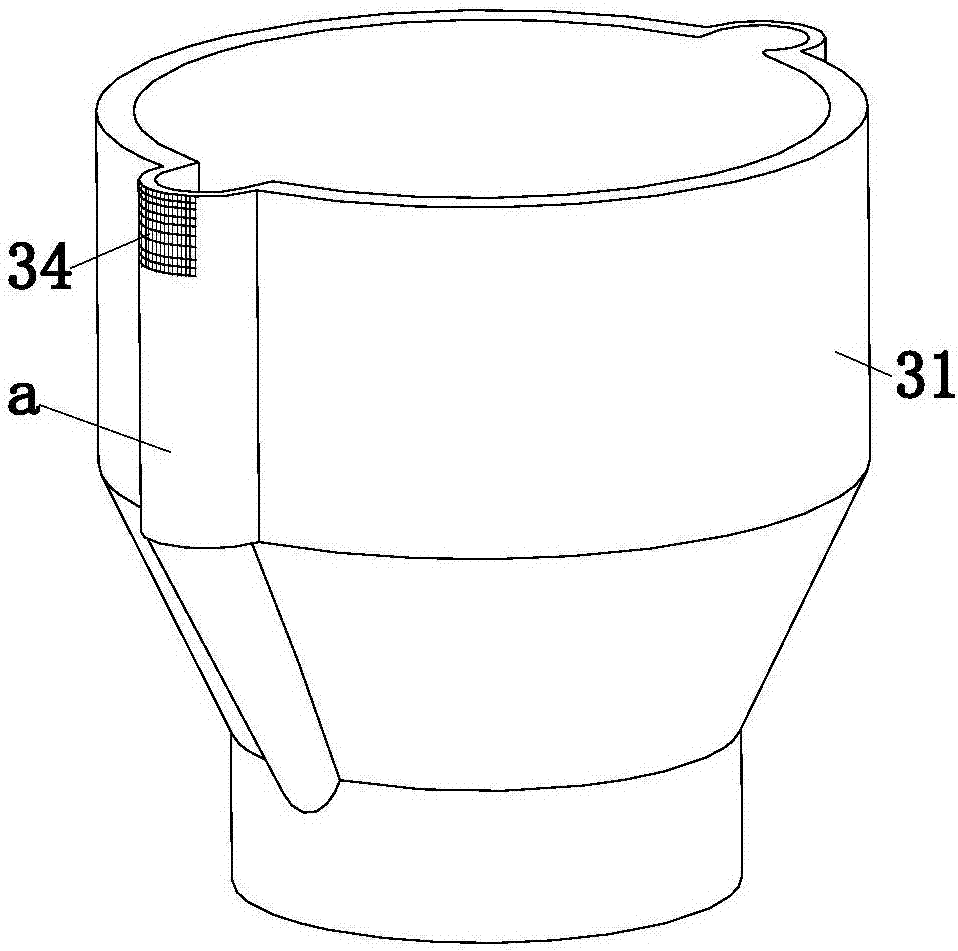

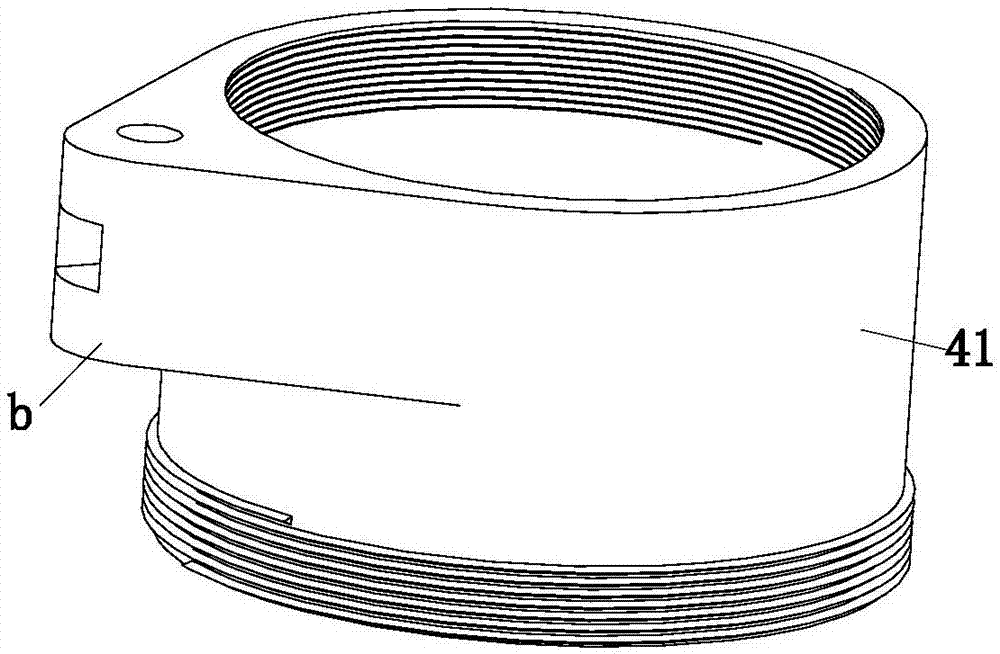

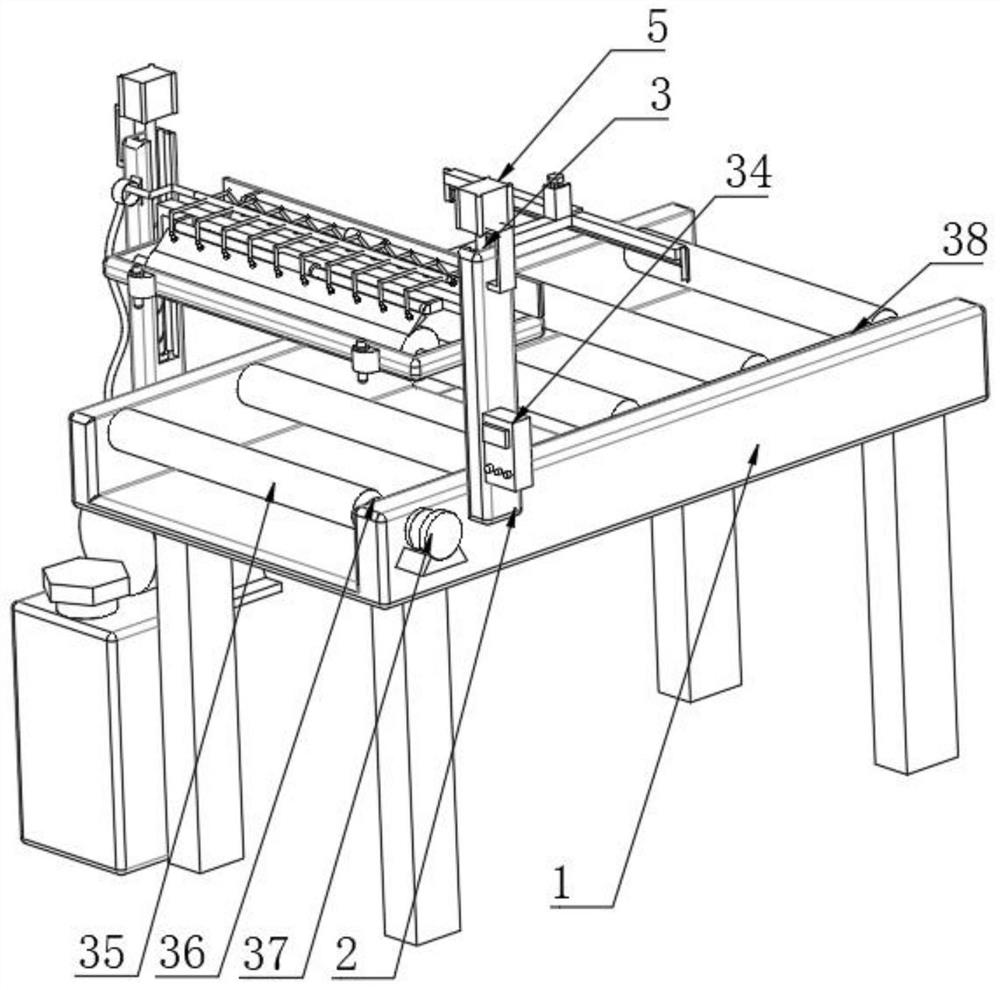

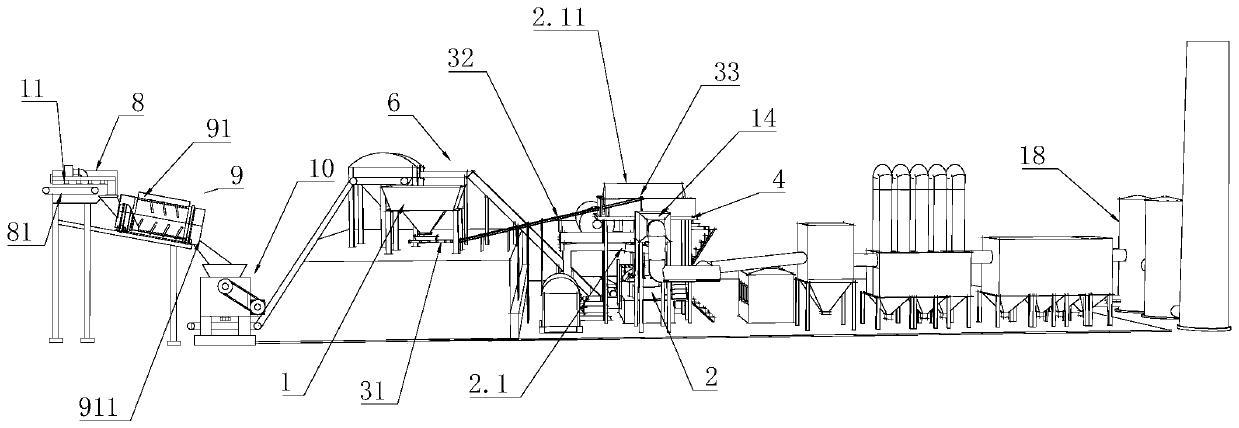

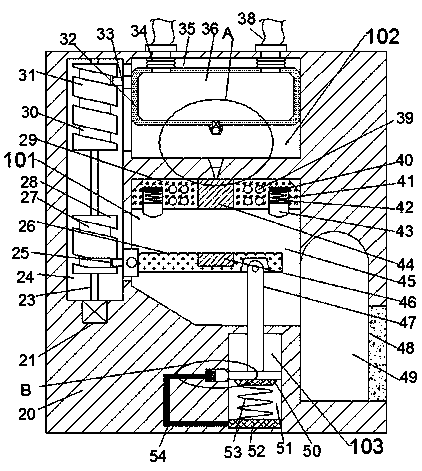

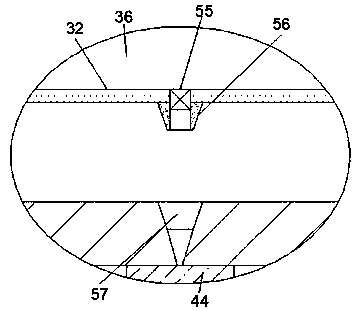

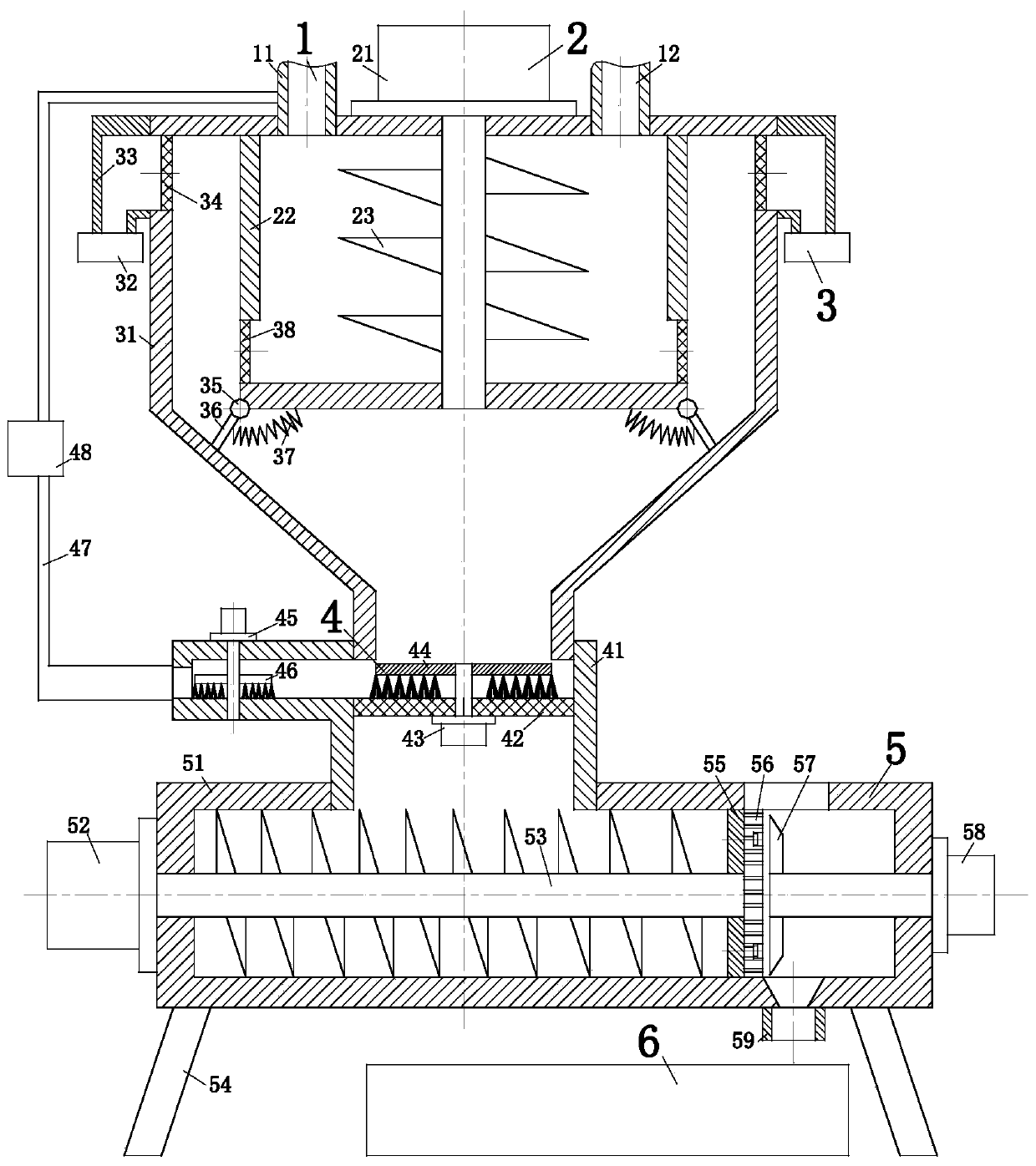

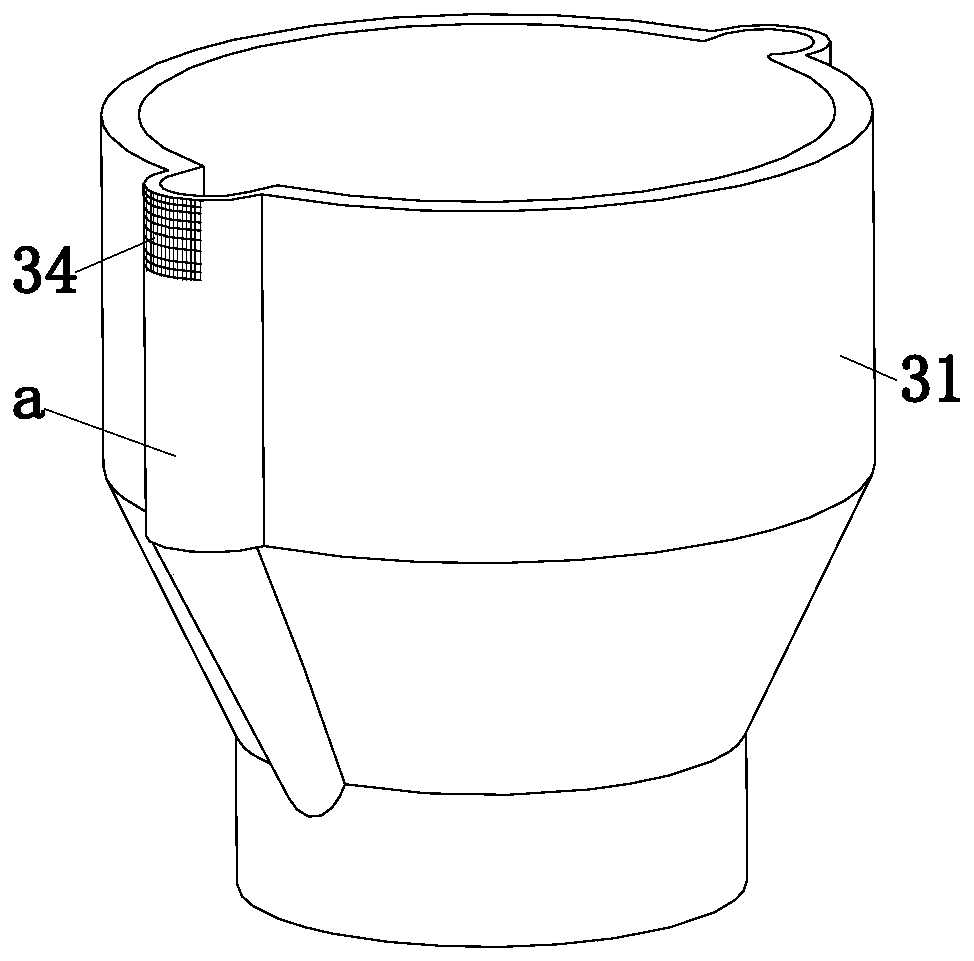

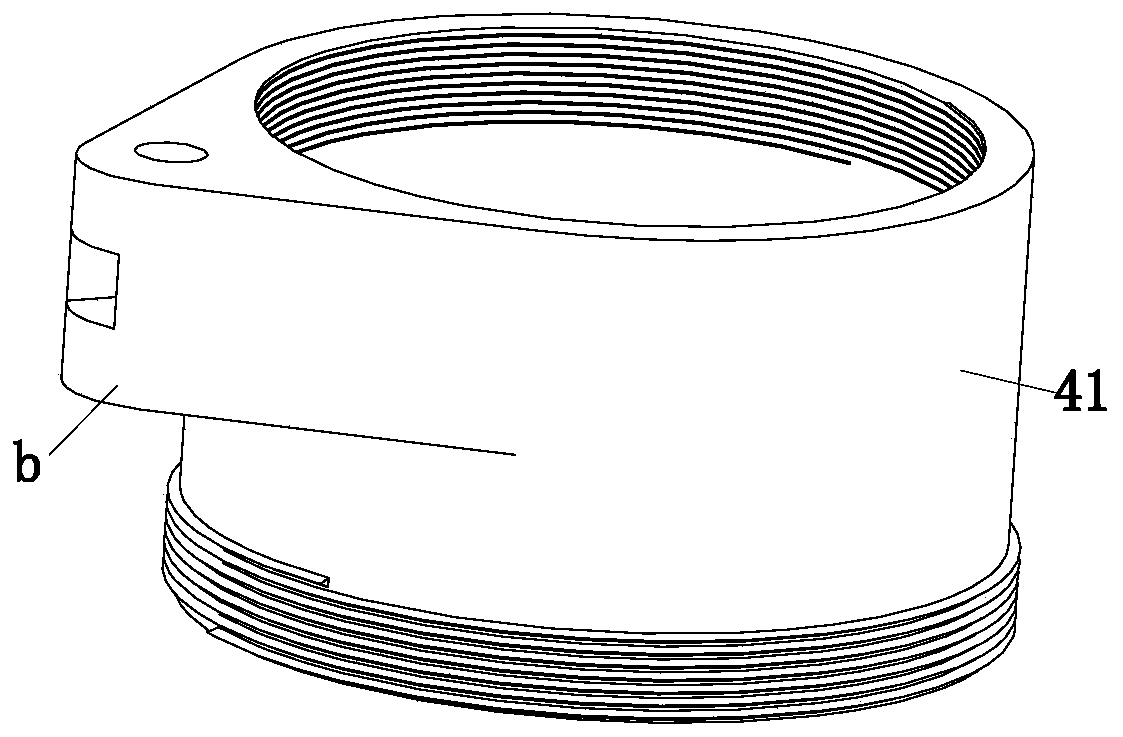

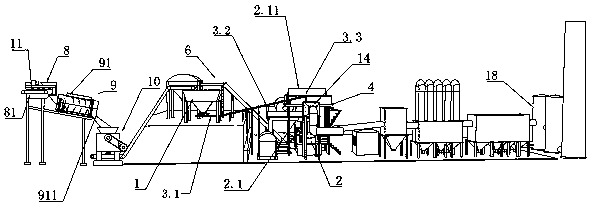

Plant straw pellet feed production equipment

ActiveCN107411149AOptimize production stepsIncrease productivitySievingGas current separationFiltrationFilter system

The invention relates to the field of feed production equipment and particularly relates to plant straw pellet feed production equipment which comprises a feeding system, a stirring and crushing system, a primary filtration system, a secondary filtration system, a forming system and a supporting body, wherein the feeding system comprises a straw conveying port for conveying straw raw materials and an auxiliary material conveying port for conveying auxiliary materials, and the straw conveying port and the auxiliary material conveying port are connected with the stirring and crushing system; the stirring and crushing system is used for crushing the straw raw materials; the primary filtration system is connected with the stirring and crushing system; the secondary filtration system is connected with the primary filtration system; the forming system is connected with the secondary filtration system; and the supporting body is positioned below the forming system. By virtue of integrated treatment of crushing, mixing, filtration and pellet forming, the production steps of the plant straw pellet feed are greatly optimized, and the production efficiency is improved.

Owner:共青城市正邦生物科技有限公司

Biomass anti-mosquito and anti-mite finishing agent and preparation method thereof

InactiveCN110656505ARaw materials are easy to getExcellent anti-mosquito and anti-mite effectBiochemical fibre treatmentVegetal fibresPulp and paper industryFilm-forming agent

The invention discloses a biomass anti-mosquito and anti-mite finishing agent and a preparation method thereof. The biomass anti-mosquito and anti-mite finishing agent is prepared from, by weight, 3-8parts of biomass anti-mosquito and anti-mite volatile oil, 2-5 parts of biomass solidification particles, 1-3 parts of a dispersing agent, 4-9 parts of a film forming agent and 125-140 parts of a solvent. Raw materials of the biomass anti-mosquito and anti-mite finishing agent are all biomass sources and easy to acquire, the biomass anti-mosquito and anti-mite finishing agent is simple and convenient to prepare and harmless to human bodies and can be applied to surfaces of various fabrics and other materials, effective components are slowly released through microcapsules, and by solidification stability of the biomass active particles, long-lasting and prominent anti-mosquito and anti-mite performances are achieved.

Owner:无锡德冠生物科技有限公司

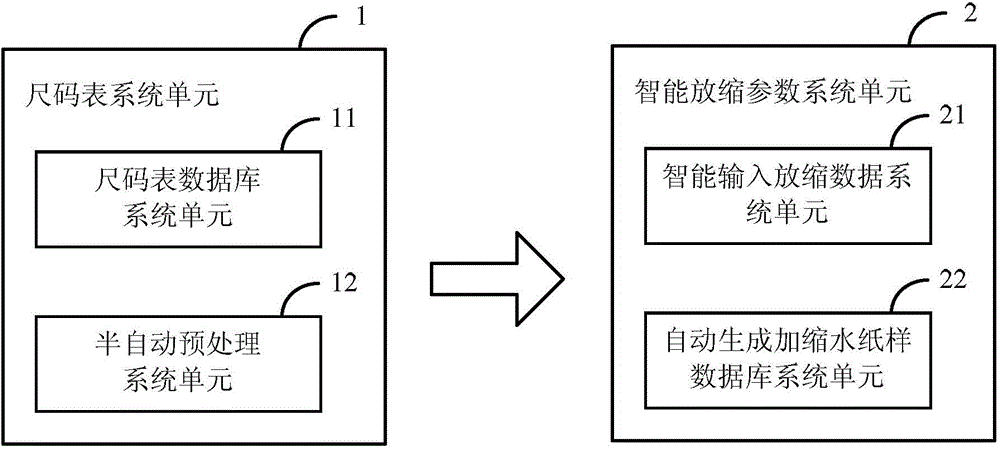

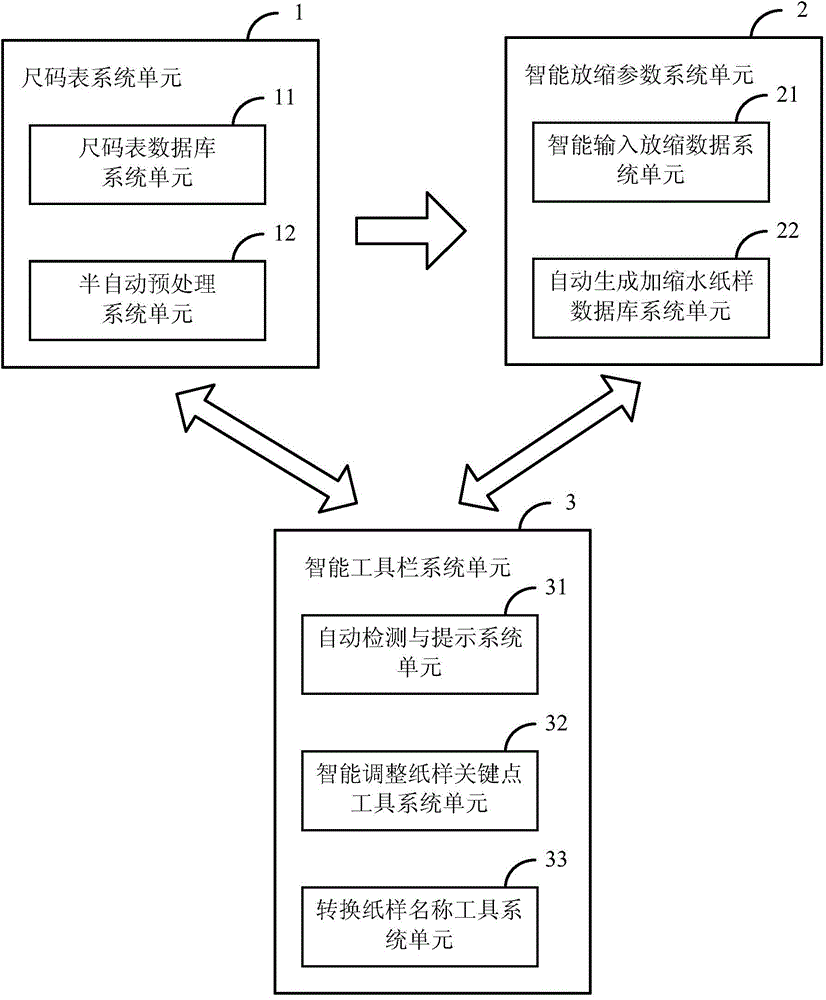

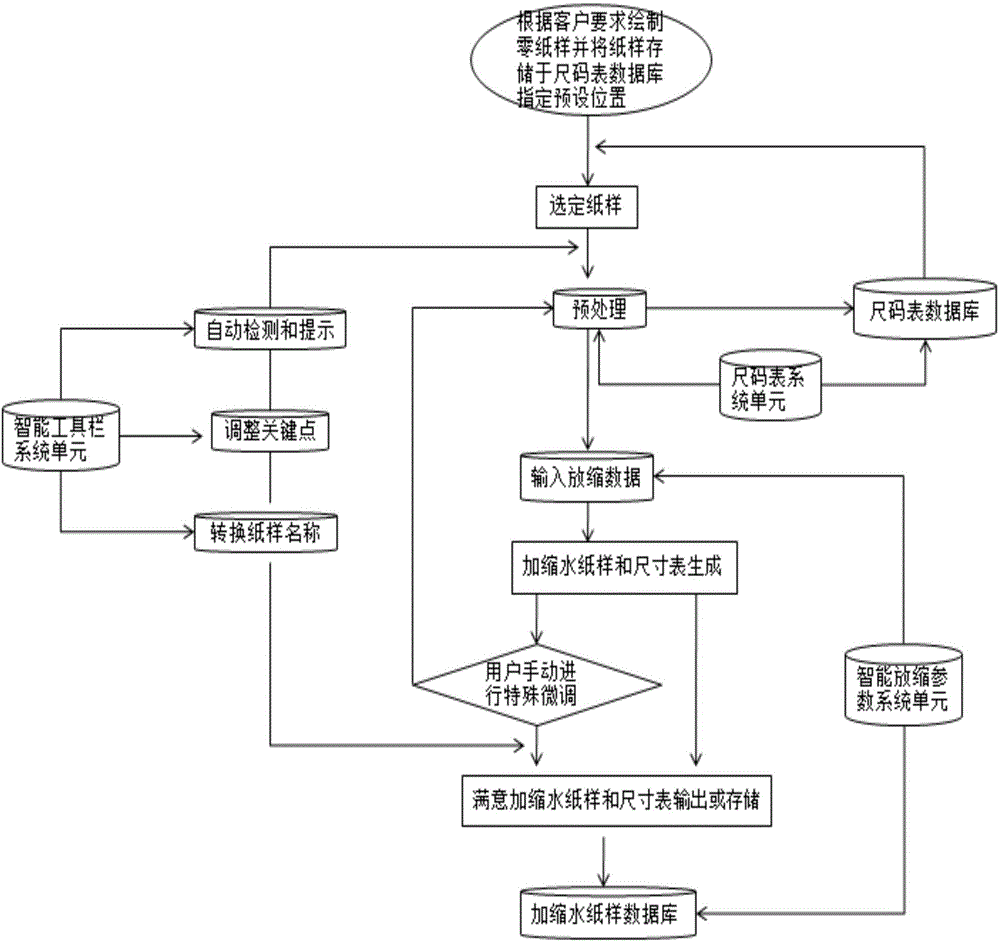

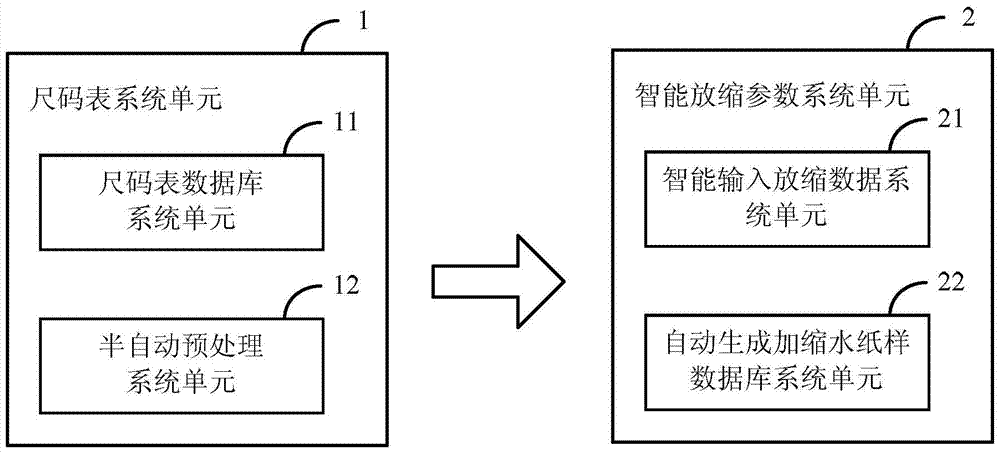

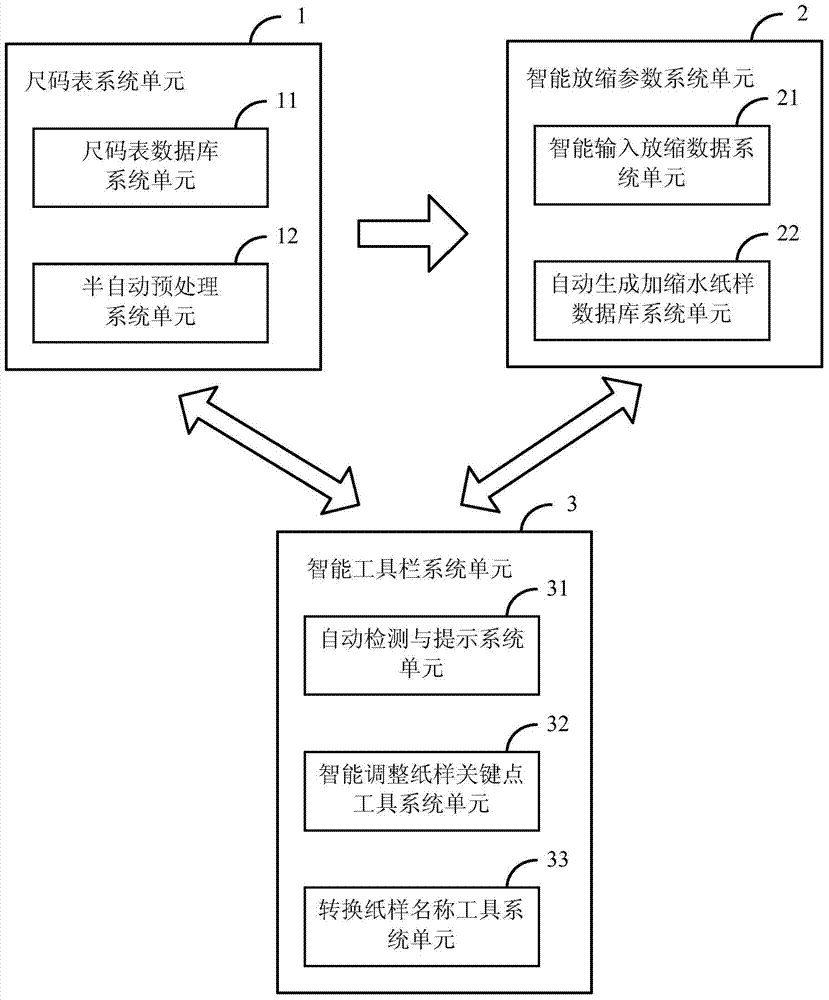

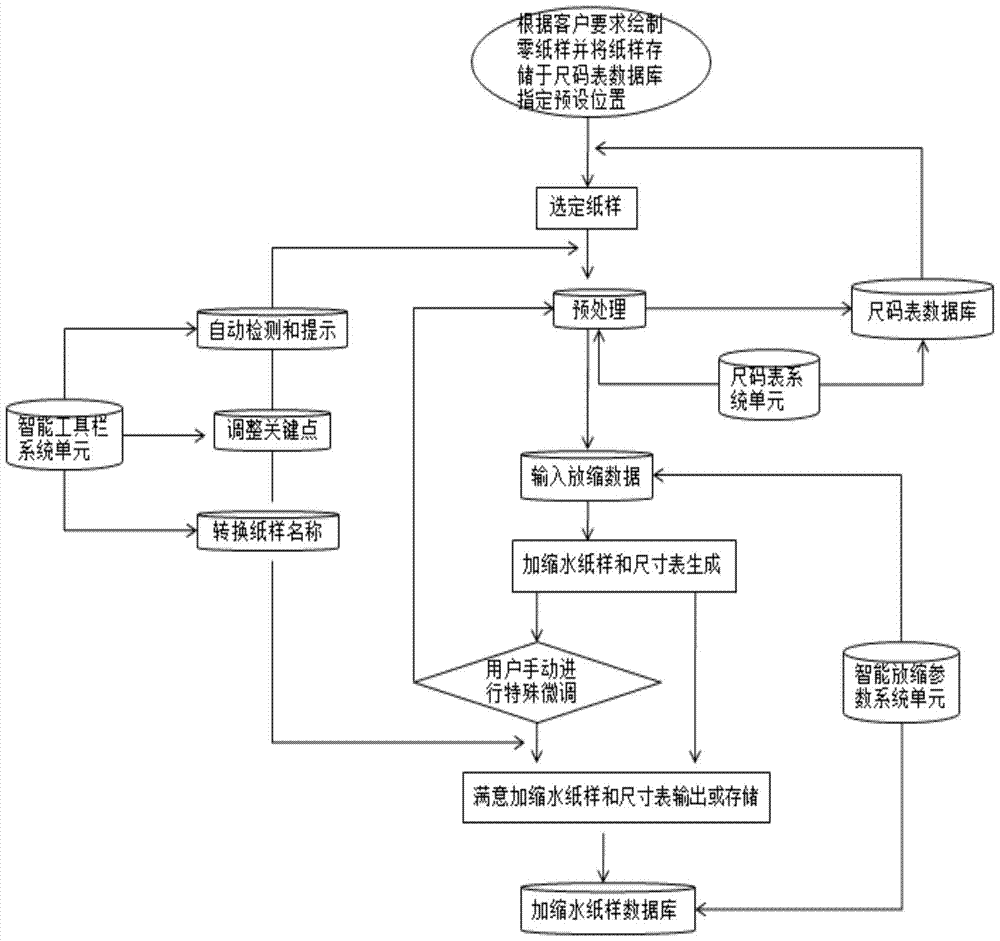

Automatic shrinkage rate adjustment system and method of clothing pattern

ActiveCN104699896AOptimize production stepsRealize automated productionSpecial data processing applicationsShrinkage rateUser input

The invention discloses an automatic shrinkage rate adjustment system and a method of a clothing pattern. The system comprises a size chart database system unit for storing the pattern and classification information and size information of the pattern in a size chart database, a semi-automatic pretreatment system unit for pretreatment of the pattern selected by a user in the size chart database before shrinkage rate adjustment to general a pretreated pattern, an intelligent input shrinkage data system unit for receiving shrinkage data input by the user, and an automatic shrinkage rate adjustment pattern generation database system unit for adjusting the pretreated pattern according to the shrinkage data input by the user and preset shrinkage rate adjustment rules and generating a shrinkage rate adjustment pattern and a shrinkage rate adjustment pattern size chart, wherein the pattern comprises a reference pattern and a zero pattern drawn according to user requirements. The system and the method can improve working efficiency and shorten a production cycle.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

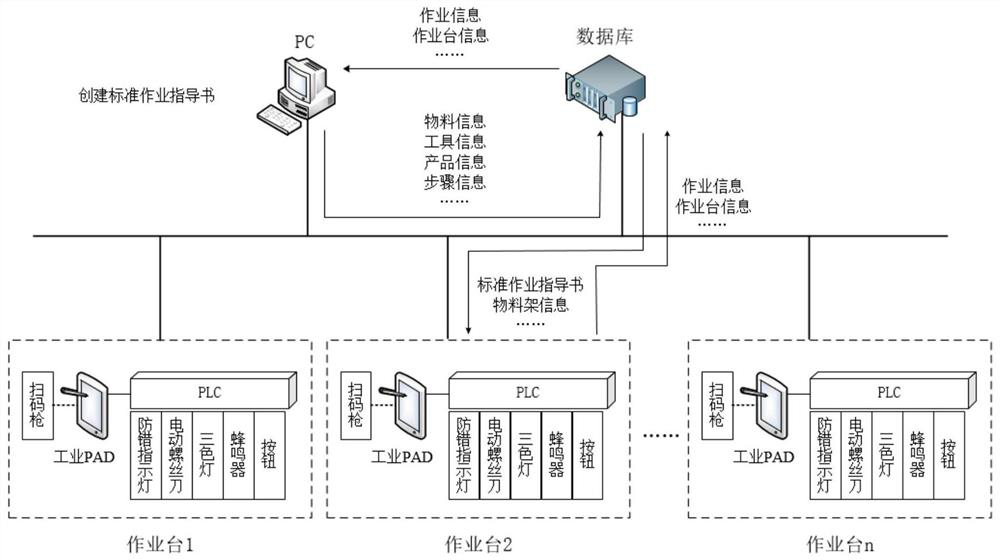

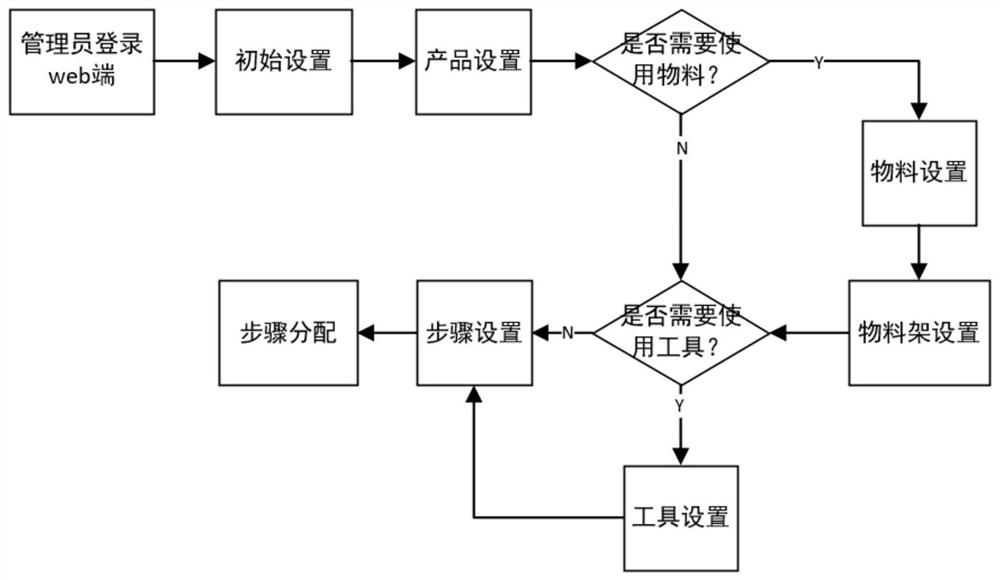

Standard operation guidance system for intelligent manufacturing, processing and production, and operation method

PendingCN111932392AAvoid mistakesAvoid errorData processing applicationsSpecial data processing applicationsProcess engineeringComputer science

The invention discloses a standard operation guidance system for intelligent manufacturing, processing and production, and an operation method. The system comprises a Web terminal, an APP terminal andan operation platform, wherein the Web terminal provides the configuration information, the data analysis information and an operation instruction of a specific product standard so that background management personnel can check the specific operation information, master the operation condition of an operator and distribute the operation instruction to the corresponding operation platform, the APPterminal displays an operation instruction book to provide the operation instruction, guides workers to realize intelligent material taking and intelligent error prevention through coordination workof the working platform according to the operation method of the standard operation instruction system, and improves operation efficiency, all operation information is collected in real time, and visualization of a production site is achieved.

Owner:NANJING PANDA ELECTRONICS +1

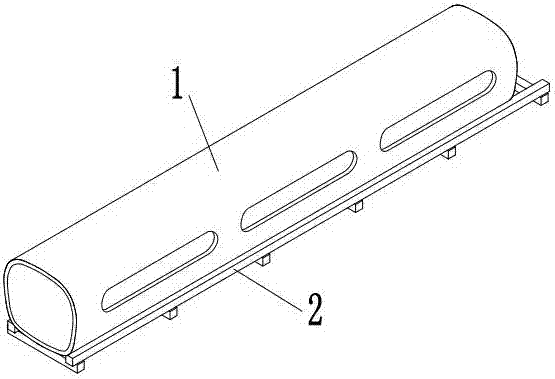

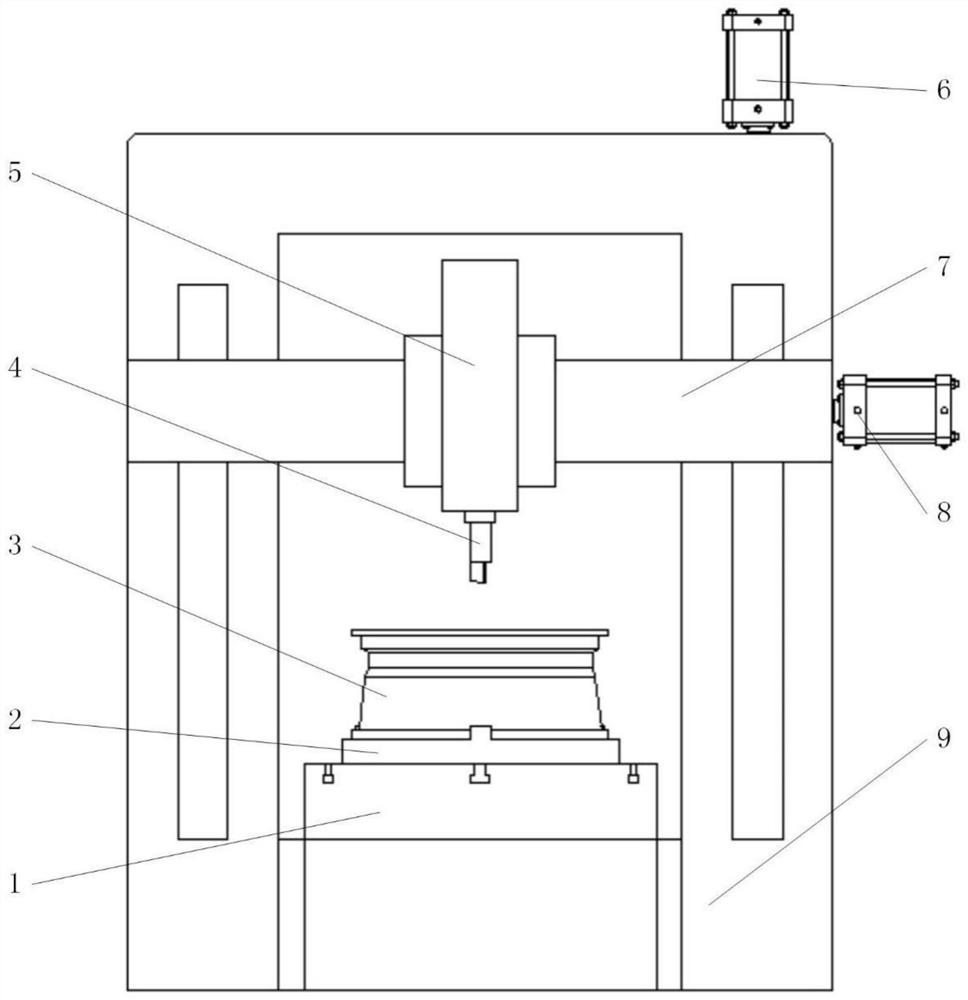

Automatic machining equipment of cylindrical shell

InactiveCN108044361APrevent slippingReduce the need for manual laborOther manufacturing equipments/toolsMetal working apparatusEngineeringMechanical equipment

The invention relates to the field of mechanical equipment, in particular to automatic machining equipment of a cylindrical shell. The automatic machining equipment of the cylindrical shell comprisesa sheet metal feeding device, a coiling device, a transporting device, a welding device, a conveying device, a polishing device and a bottom shell feeding device. The coiling device comprises a shaping column, a shaping shell, a fixing frame, a conveying roller and a driven roller. The lower end of the shaping column is provided with a top plate. The fixing frame is provided with a first motor used for driving the conveying roller. The output end of the first motor penetrates the fixing frame to be in transmission connection with one end of the conveying roller. A gap between the shaping shelland the shaping column is gradually changed in the direction close to the conveying device to form a circular ring. According to the automatic machining equipment of the cylindrical shell, automaticmachining of the cylindrical shell is achieved through cooperation of the sheet metal feeding device, the coiling device, the transporting device, the welding device, the conveying device, the polishing device and the bottom shell feeding device, the demand for manual labor is reduced, the production cost is reduced, the production efficiency is improved, and the production steps are optimized.

Owner:ZHEJIANG UNIV OF TECH FENGHUA SMART ECONOMY RES INST

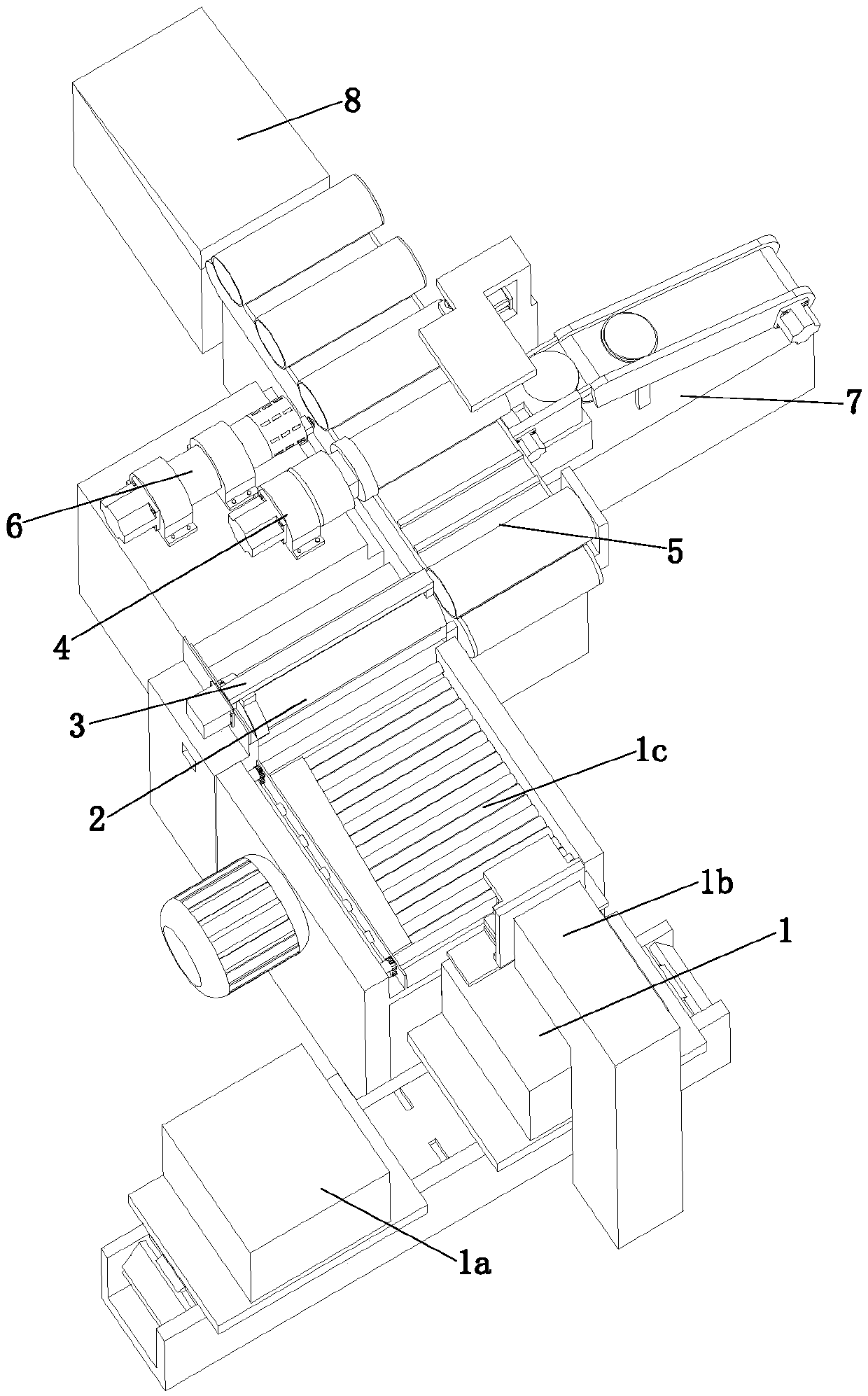

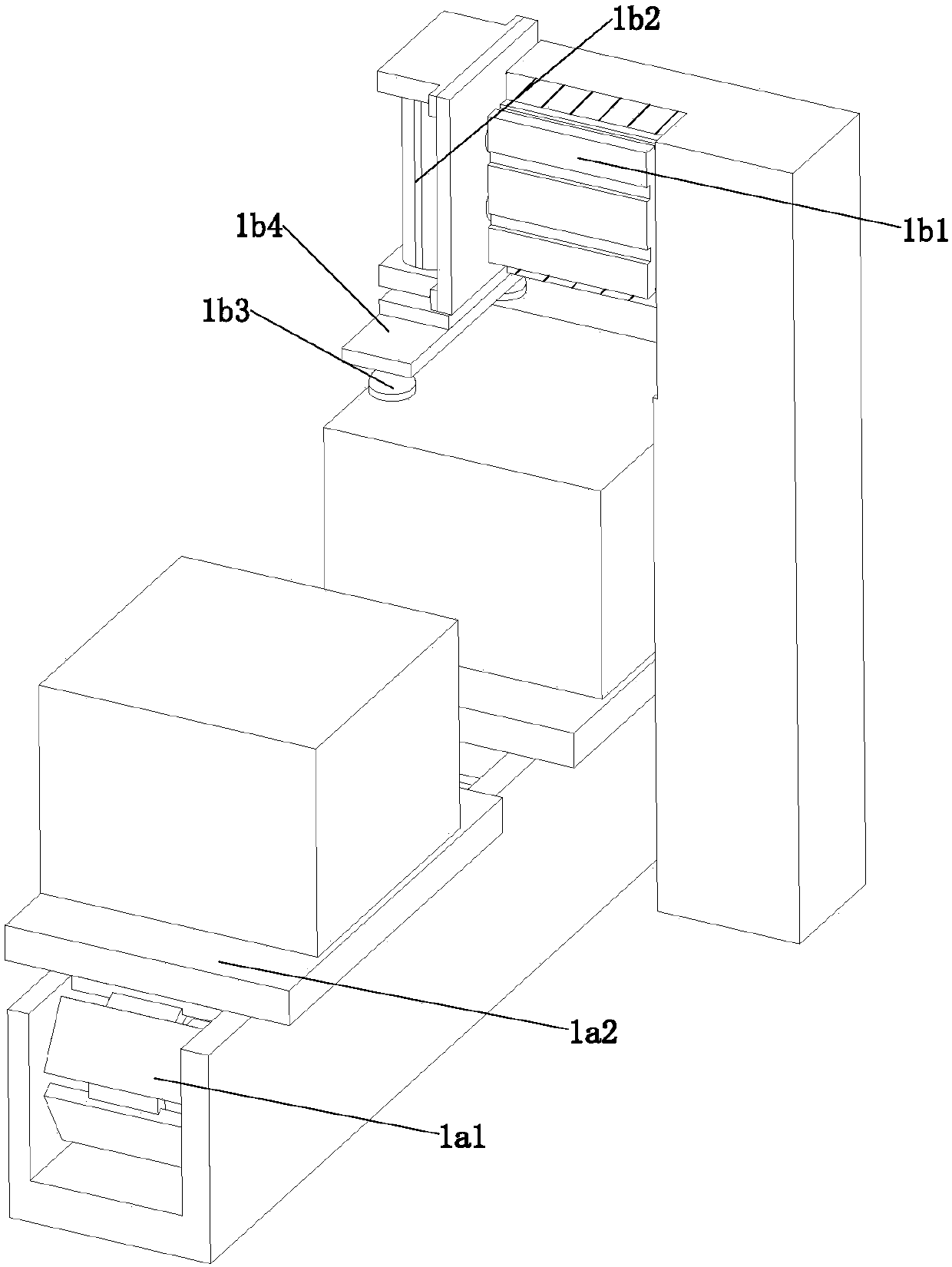

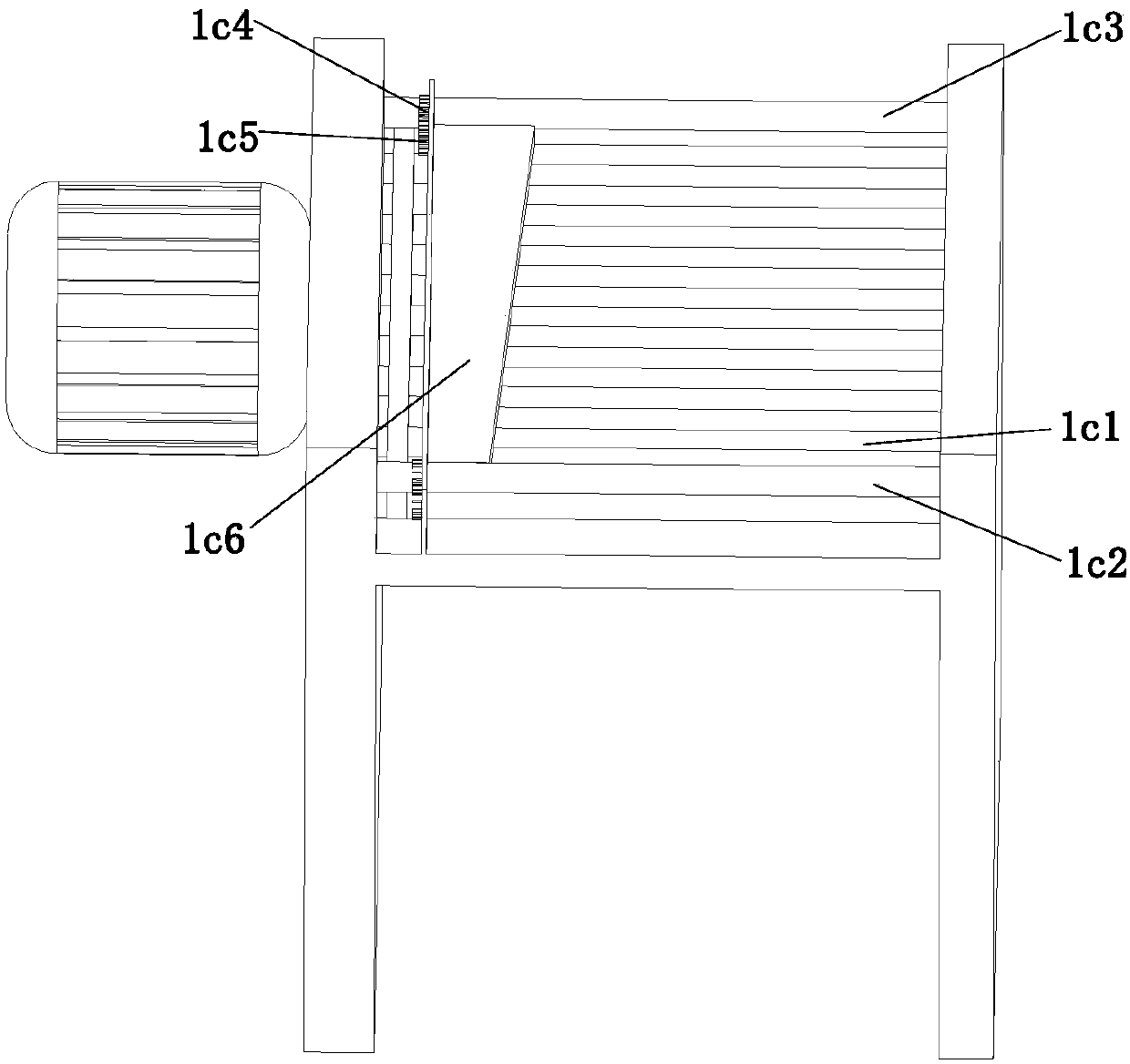

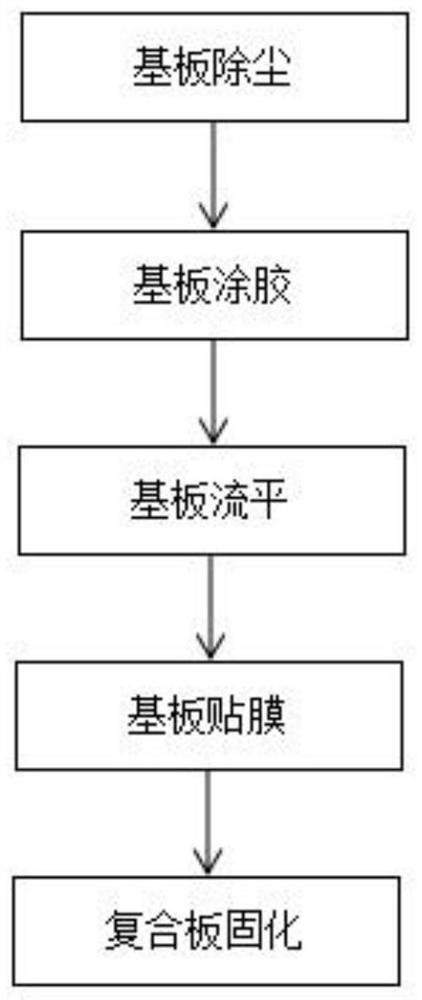

Manufacturing process and gluing equipment for composite board based on PET film flat pasting

PendingCN113731717AShort cycleImprove production efficiencyLiquid surface applicatorsCoatingsManufacturing technologyComposite plate

The invention discloses a manufacturing process and gluing equipment for a composite board based on PET film flat pasting. The manufacturing process comprises the following steps: step 1, dedusting a substrate; step 2, gluing the substrate; step 3, leveling the substrate; step 4, pasting a film on the substrate; and step 5, curing a composite board. The manufacturing process disclosed by the invention is environment-friendly, simple to operate, short in period and high in manufacturing efficiency. According to the gluing equipment, an automatic adjusting mechanism is adopted, so that when substrates with different thicknesses and models are glued, the gluing distance can be automatically determined, automatic downward moving operation is achieved, the surfaces of the glued substrates are accurately positioned, and the distance consistency between the surface positions of the substrates and the position of a linkage frame is always kept. According to the gluing equipment, original manual adjustment is replaced, automatic adjustment is achieved, operation is easy, use is easy, the adjusting method is optimized, and the machining efficiency of the composite board is effectively improved.

Owner:上海阿斯纳新材料科技有限公司

Method for preparing hollow hot melt nonwoven cloth force fit plate of polypropylene

InactiveCN101342785AOptimize production stepsIncrease productivityFlat articlesPolymer scienceHot melt

The invention relates to a method for preparing polypropylene hollow hot melt non-woven fabric laminates. In the method, polypropylene granule is fed to a hopper; the polypropylene granule is melted and extruded through a screw extruder, extruded through a die, cooled, formed and moulded, tempered and heated up, thermally compressed; blown and cooled; subsequently, scrapped parts are cut off; the size is finalized through cutting, and a finished product is warehoused. The preparation method is mechanized; the product quality is high; the preparation method significantly improves the production steps of polypropylene hollow hot melt non-woven fabric laminates and the production efficiency of laminates, which reduces the production cost of polypropylene hollow hot melt non-woven fabric laminates.

Owner:无锡嘉旺精密包装材料有限公司

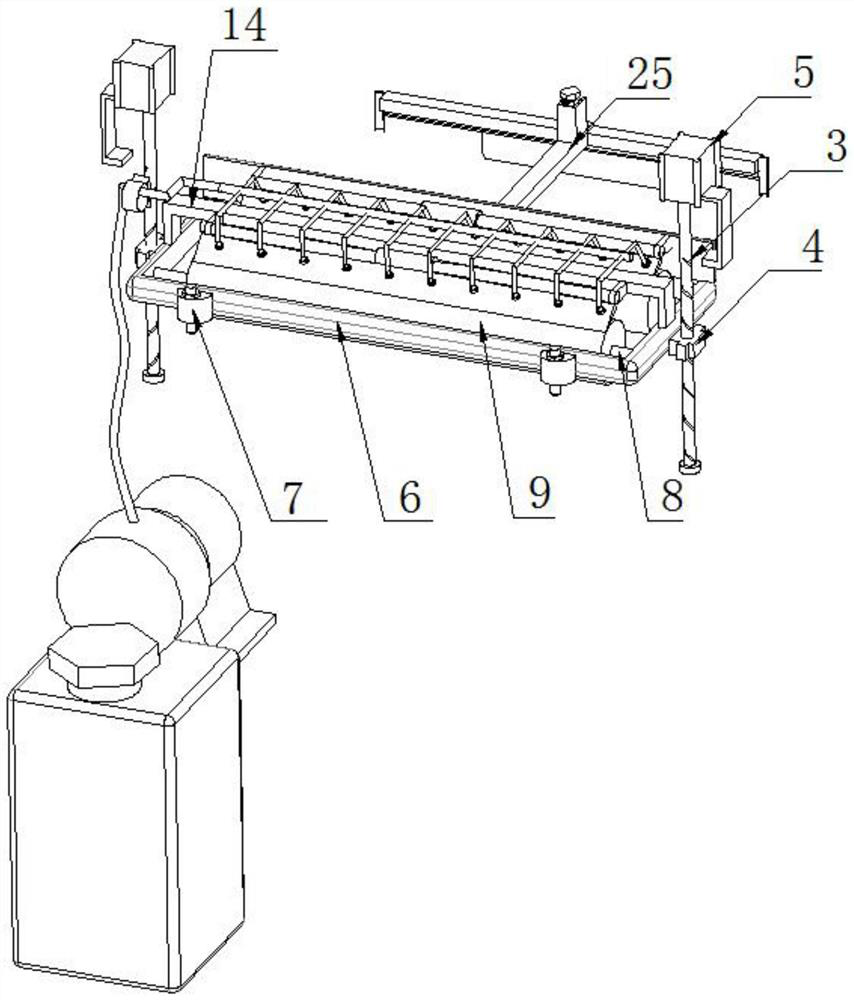

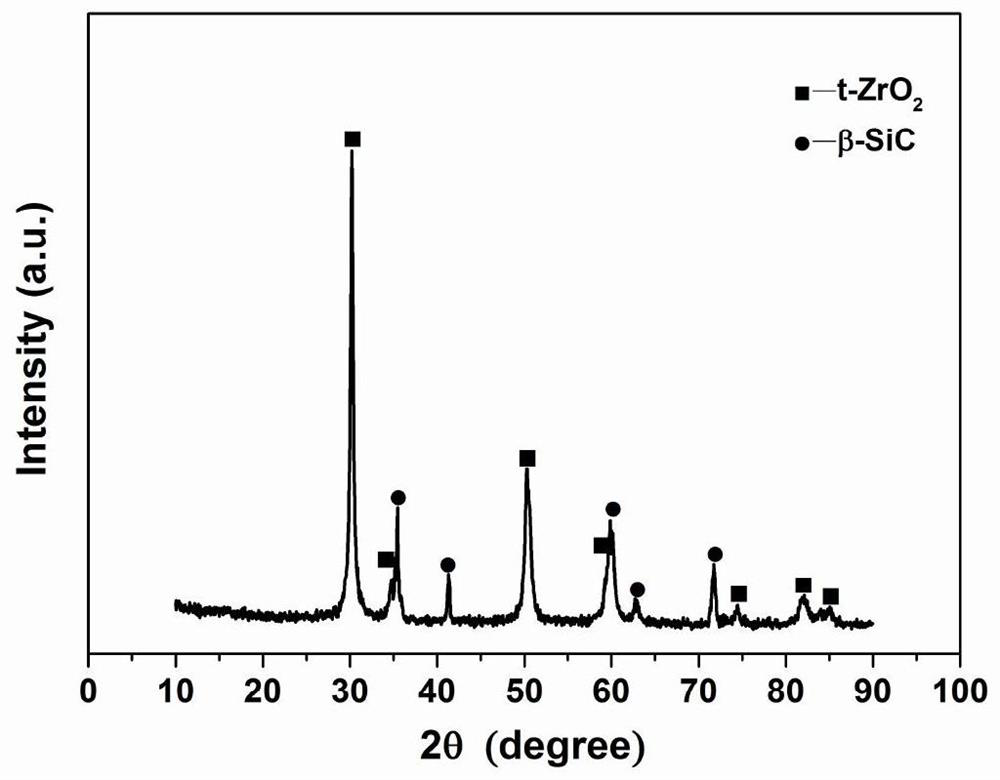

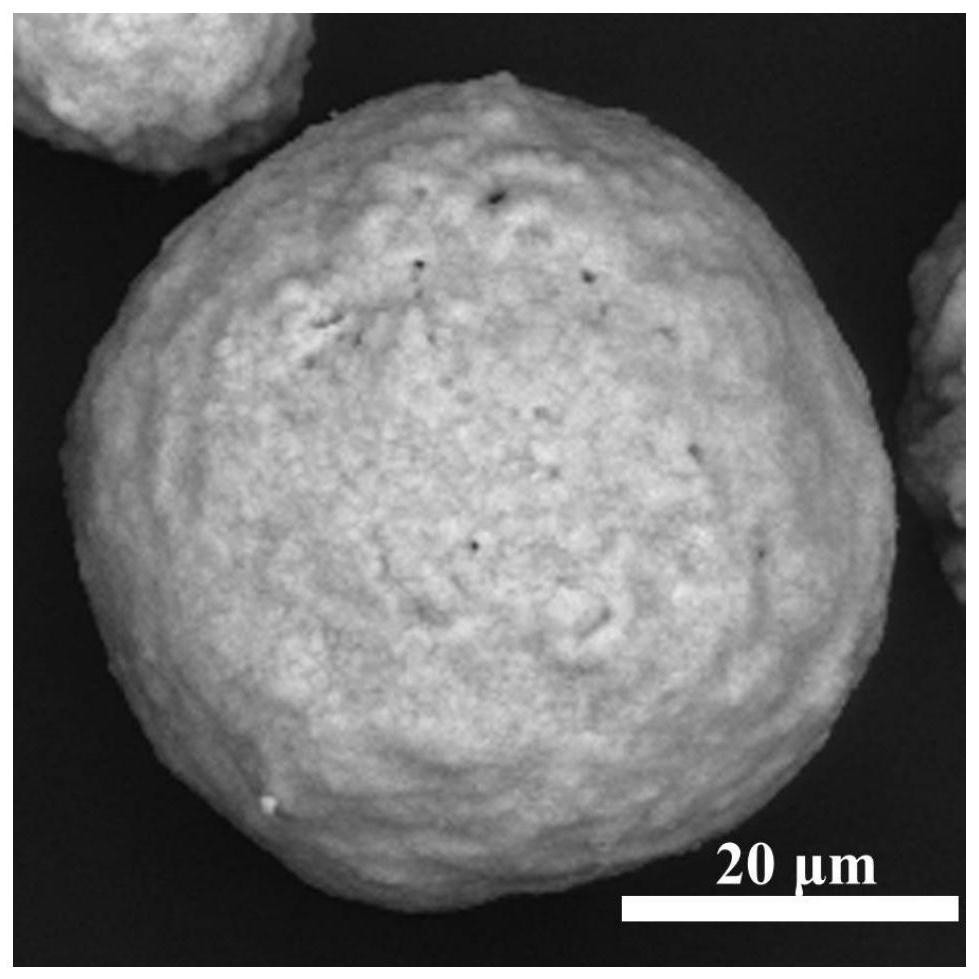

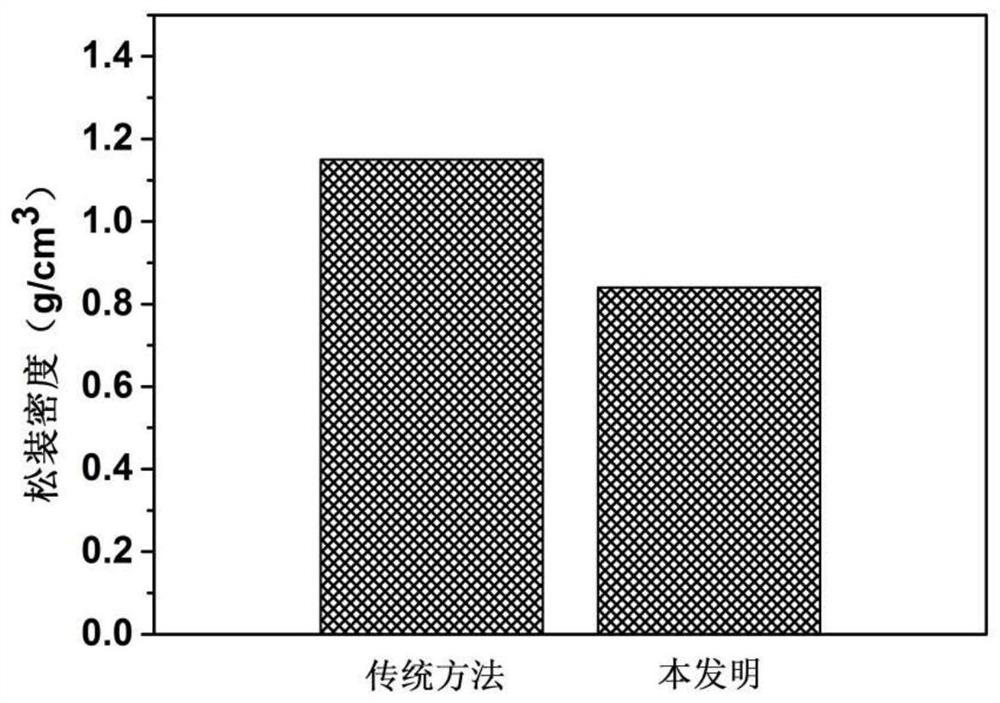

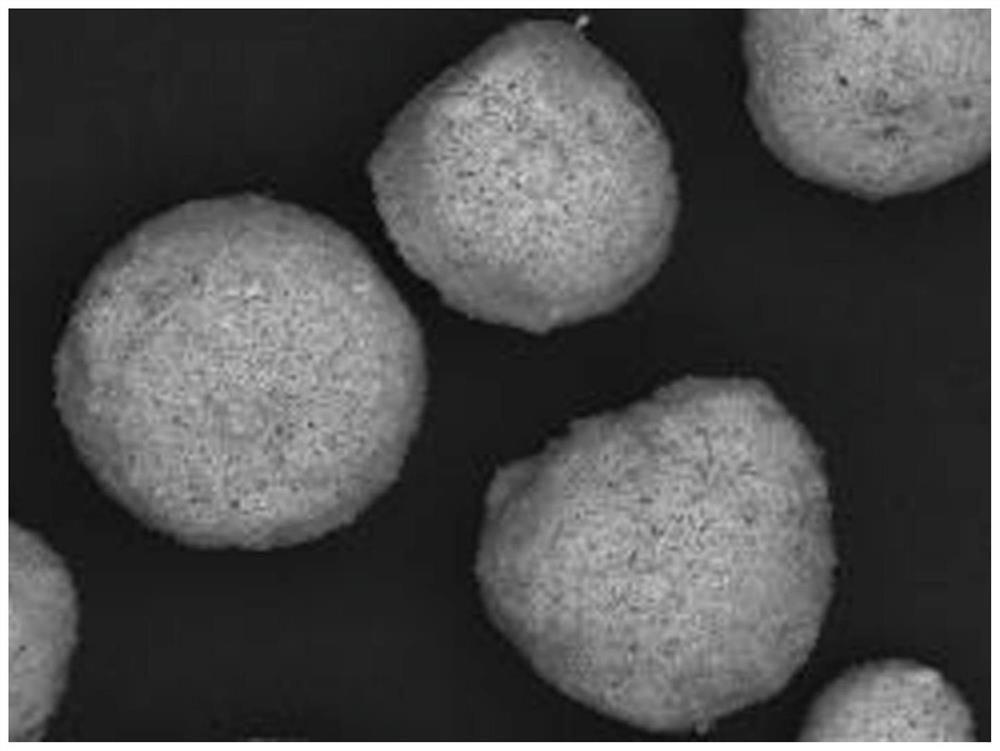

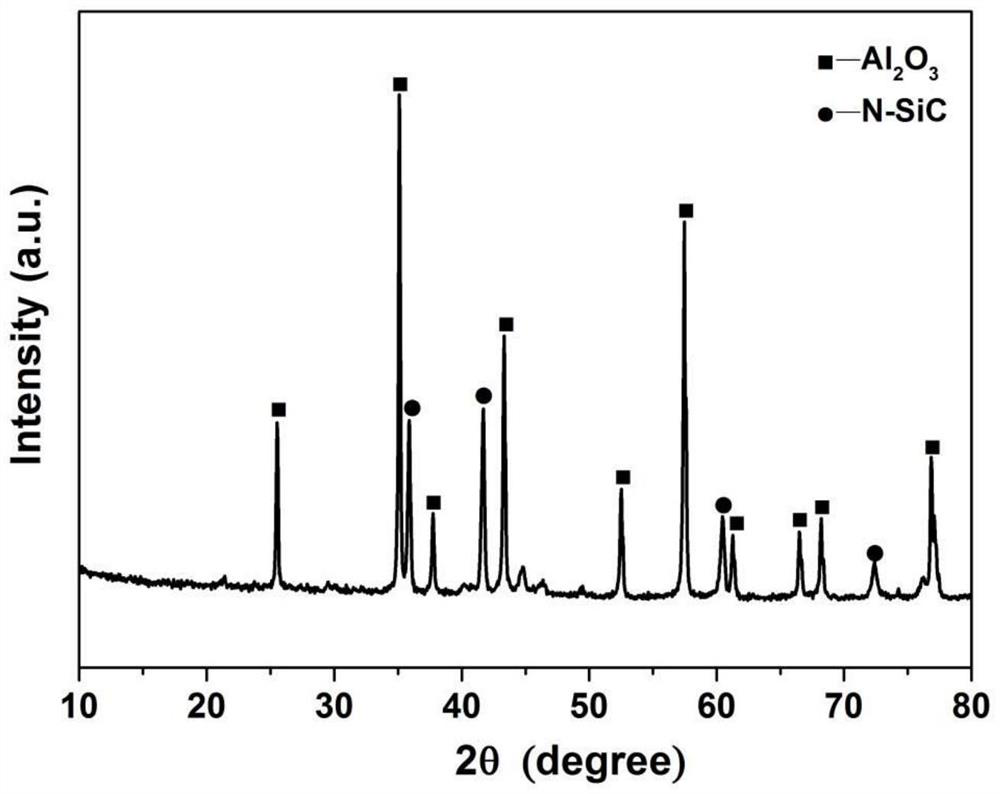

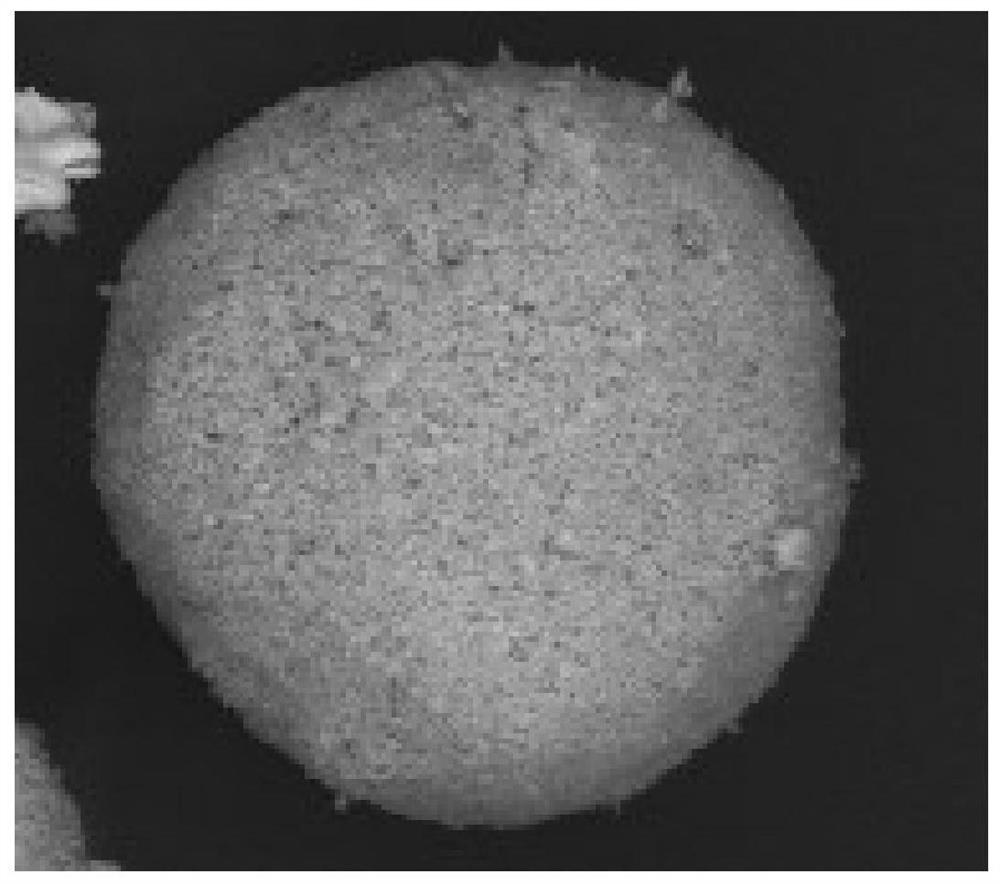

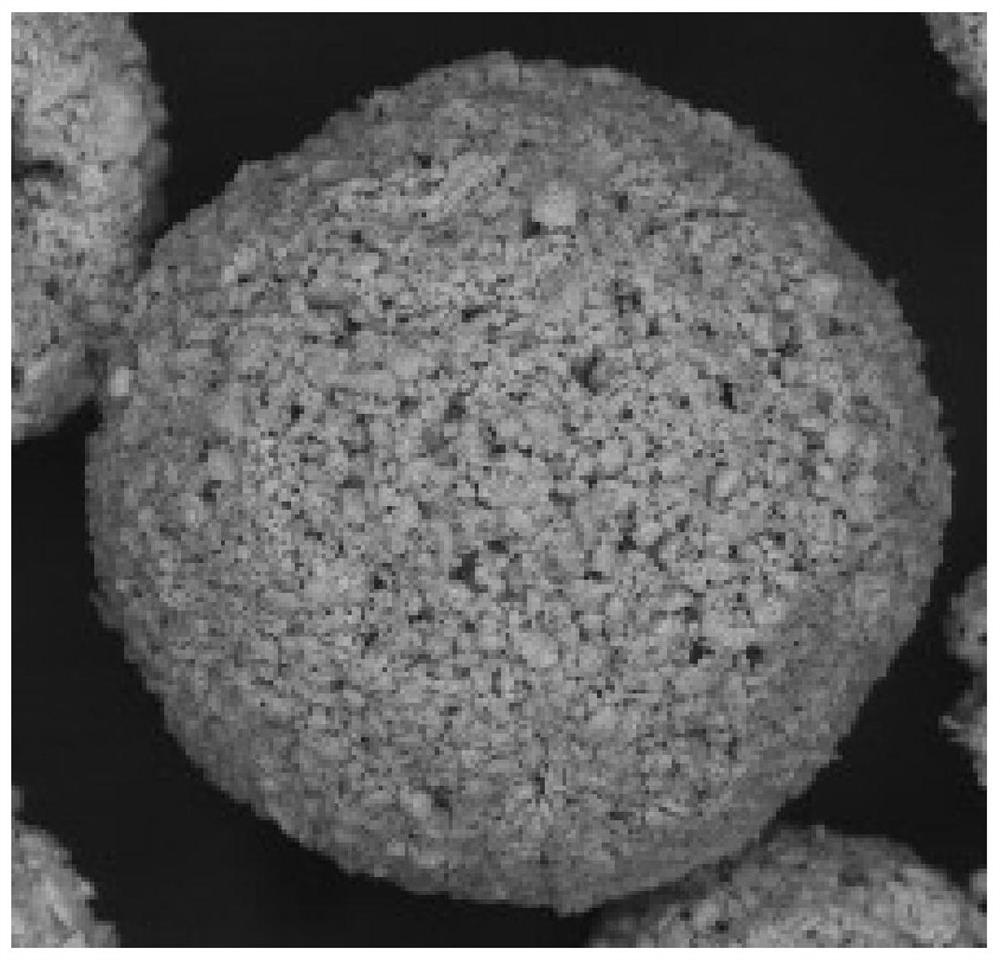

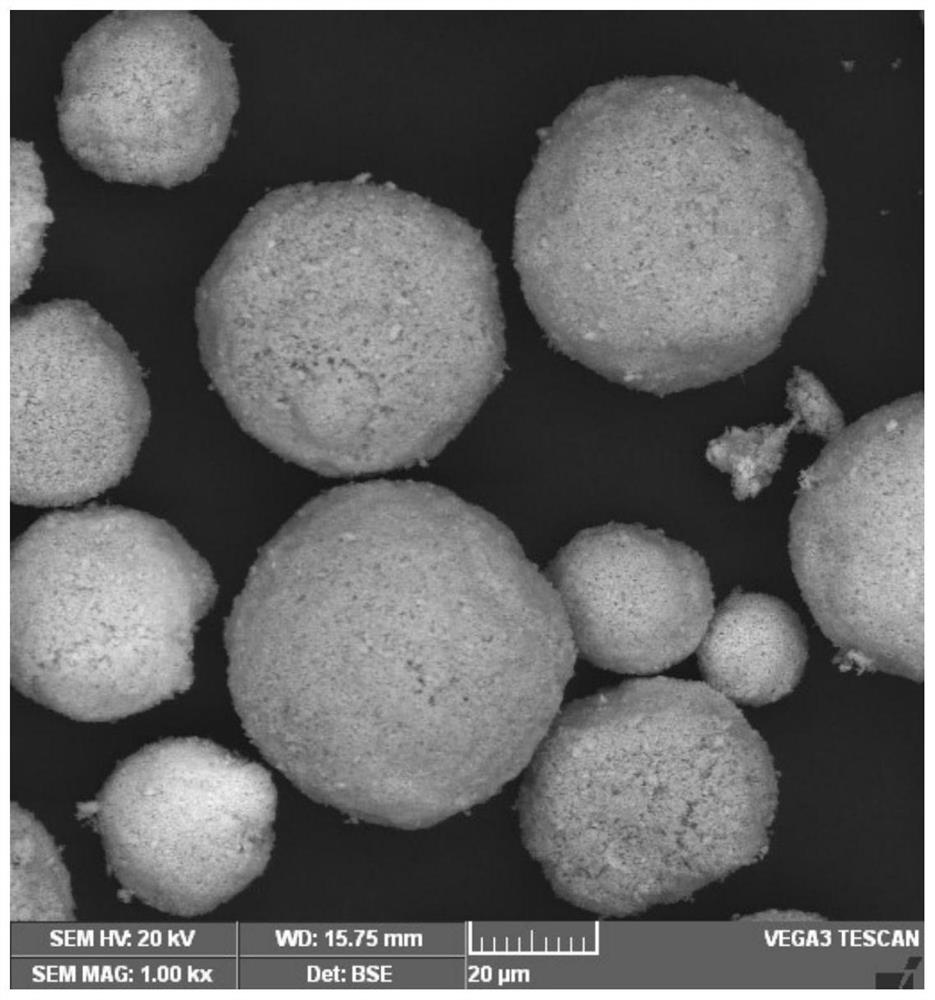

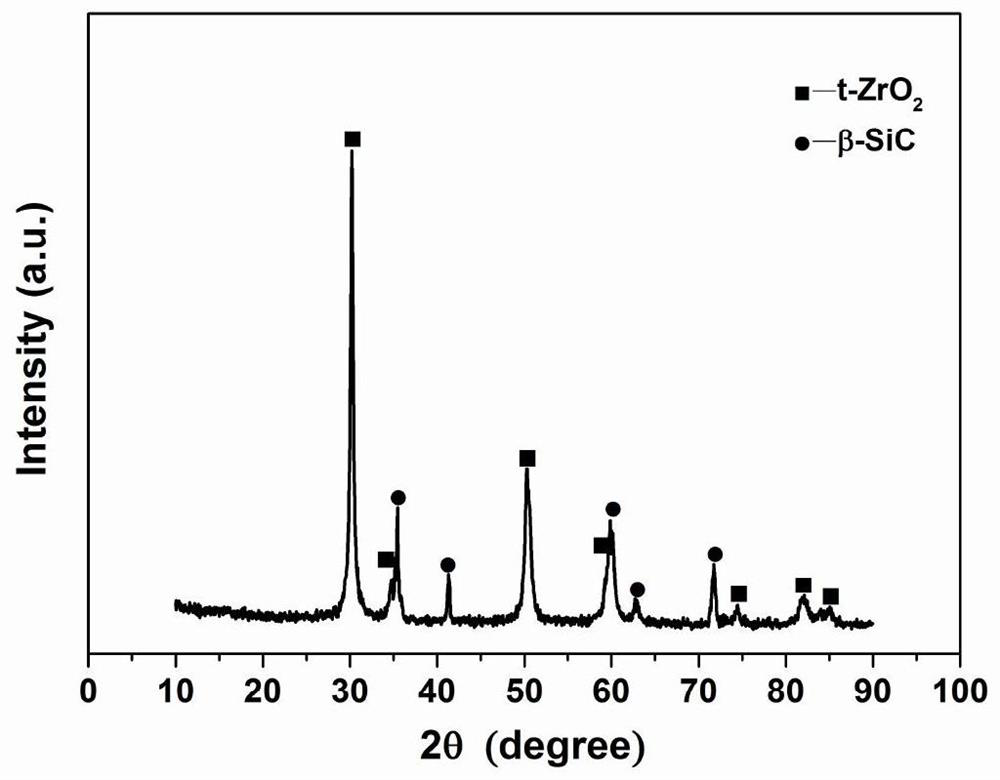

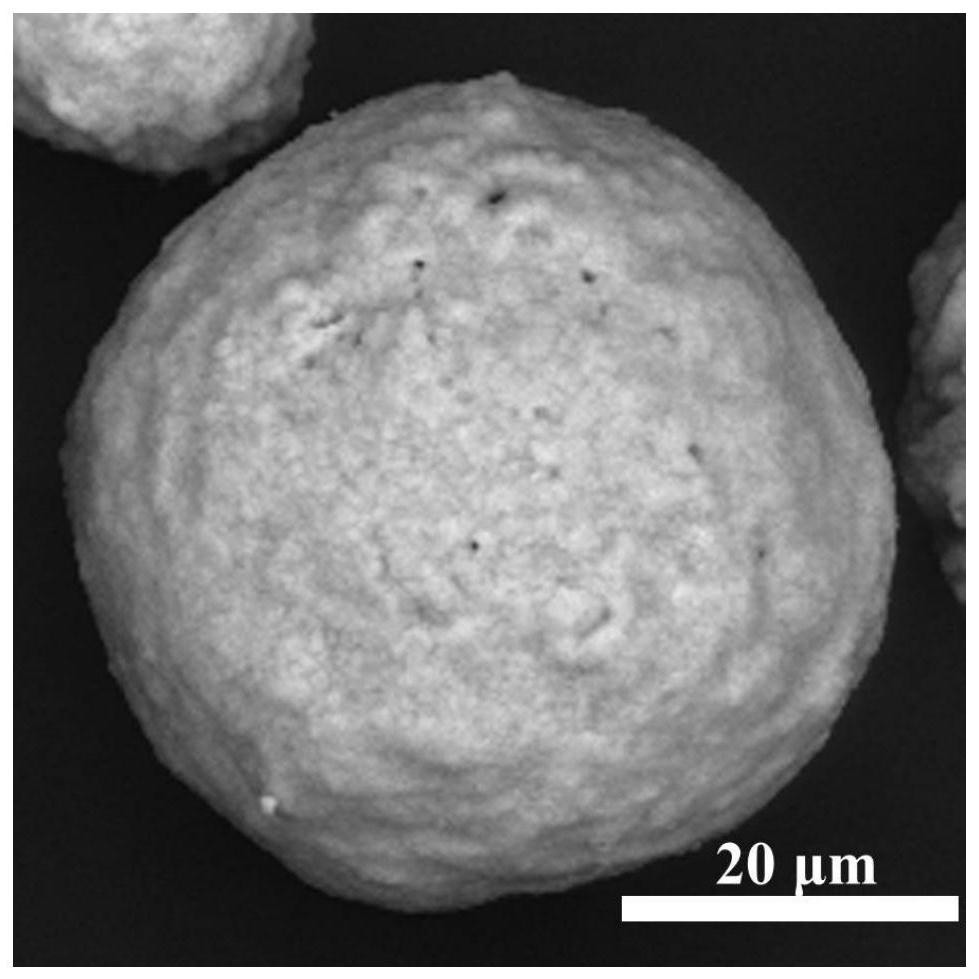

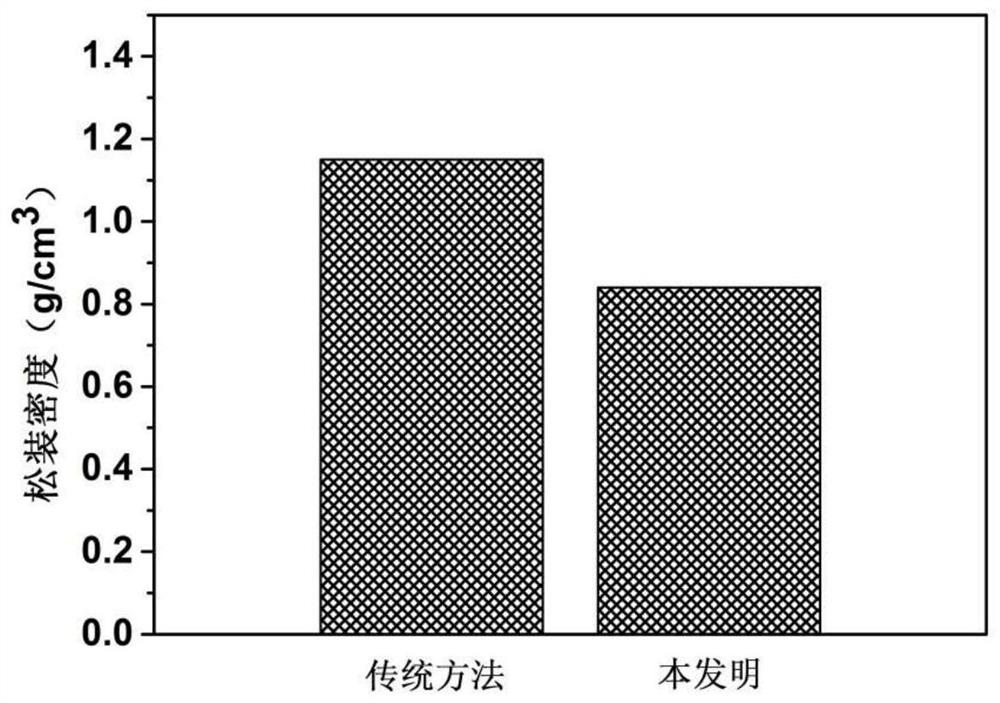

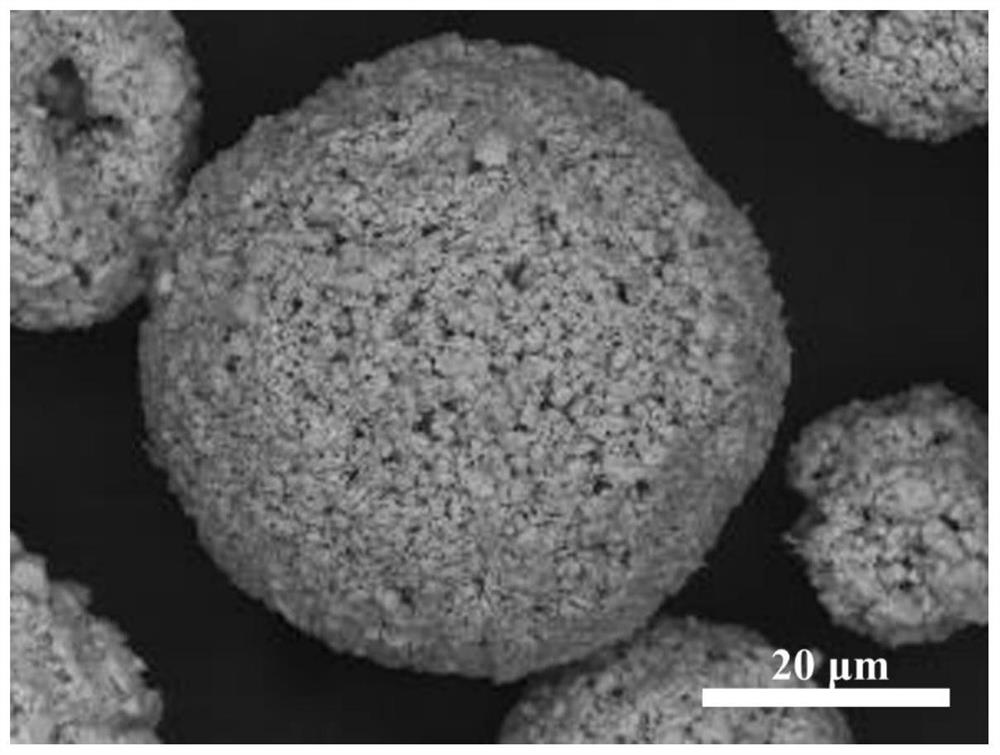

Micro-nano silicon carbide/calcium oxide stabilized zirconia spherical feed and preparation method thereof

The invention relates to a micro-nano silicon carbide / calcium oxide stabilized zirconia spherical feed and a preparation method thereof. The preparation method comprises the following steps: step 1, preparing a ZrOCl2.8H2O / Ca(NO3)2.4H2O mixed solution; step 2, adding excessive ammonia water into the mixed solution, and continuously stirring to generate white precipitate, so as to form a solution A; step 3, dissolving polycarbosilane in a p-xylene solution to form a solution B; step 4, adding the solution B and a PVA aqueous solution into the solution A to obtain a mixture; step 5, performing ball milling on the mixture in the step 4 in a roller ball mill to obtain ball-milled slurry; step 6, granulating the slurry subjected to ball milling on a spray granulator, and removing moisture to obtain dried spherical mixed powder of Zr(OH)4, Ca(OH)2 and polycarbosilane; 7, putting spherical powder obtained after granulation into a corundum crucible, putting the corundum crucible into a vacuum sintering furnace to be calcined under the high-temperature condition, and Zr(OH)4, Ca(OH)2 and polycarbosilane (PCS) are subjected to high-temperature decomposition to form uniform SiC / CSZ spherical feed.

Owner:XIAN THERMAL POWER RES INST CO LTD

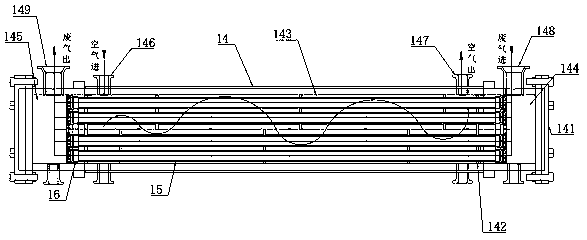

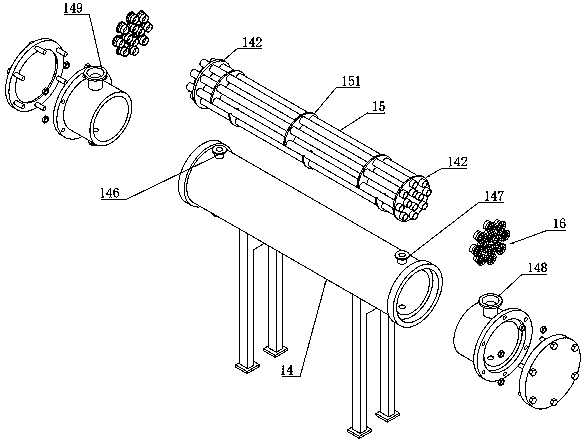

Hazardous waste recovery processing production line

ActiveCN110804699AReduce consumptionIncrease contact areaCombination devicesSludge treatment by de-watering/drying/thickeningWater useProduction line

The invention discloses a hazardous waste recovery processing production line which is reasonable in flow layout and capable of improving the production efficiency, saving energy and reducing emissions. According to the technical scheme, the hazardous waste recovery processing production line is characterized by comprising a smelting device, a collection tank and a slag fishing device; the smelting device comprises a smelting furnace arranged on the right side a storage tower; a feed port of the smelting furnace receives electroplating sludge coming from the storage tower through a conveyor belt, and the electroplating sludge is made into a melt through roasting; a water jacket for cooling a furnace body is arranged on the outer side of the smelting furnace; the water jacket is connected with a water tank through a pipeline; the water tank is arranged on a mounting rack erected on the outer side of the smelting furnace; the collection tank is arranged on the lower side of the smeltingfurnace and used for receiving the smelted melt coming from the smelting furnace; the upper end of the collection tank is provided with a slag discharge port used for discharging waste slag on the upper layer of the melt; and the slag fishing device is arranged on one side of the collection tank and suede for collecting waste slag discharged from the slag discharge port. The hazardous waste recovery processing production line is suitable for the technical field of environmental protection production lines.

Owner:宁波双能环保科技有限公司

Device for quickly manufacturing rubber mobile phone accessories

InactiveCN111113777AReduce mechanical structureSave productivityDomestic articlesMechanical engineeringMobile phone

The invention discloses a device for quickly manufacturing rubber mobile phone accessories. The device comprises a machine body, an injection cavity is formed in the machine body, a transmission cavity is formed in the left side of the injection cavity, a lifting cavity is formed in the upper side of the injection cavity, and an embedding cavity used for injecting hot-melt rubber liquid is formedbetween the bottom wall of the lifting cavity and the top wall of the injection cavity. When an embedding block is inserted into the embedding cavity, an injection pump conveys the hot-melt rubber liquid in a storage cavity into the embedding cavity to arrive into an upper-side injection mold; and when the embedding block leaves the embedding cavity, the injection pump stops working to achieve theinjection effect. According to the device, falling off of products is accelerated by shaking, operation of staff is not required, the productivity is greatly reduced, and the production efficiency isgreatly improved while the production cost is lowered.

Owner:威海市复点电子科技有限公司

Tomato juice beverage

The invention discloses a production process of a tomato juice beverage. The production process is characterized by comprising the following steps: pulping a fresh mature tomato, then removing fiber particles with diameters of more than 0.05mm by a two-stage centrifugal separation method, subsequently, performing biological enzymolysis on a separating medium by virtue of pectinase and cellulose, and finally blending and sterilizing to produce the tomato juice beverage.

Owner:张锐源

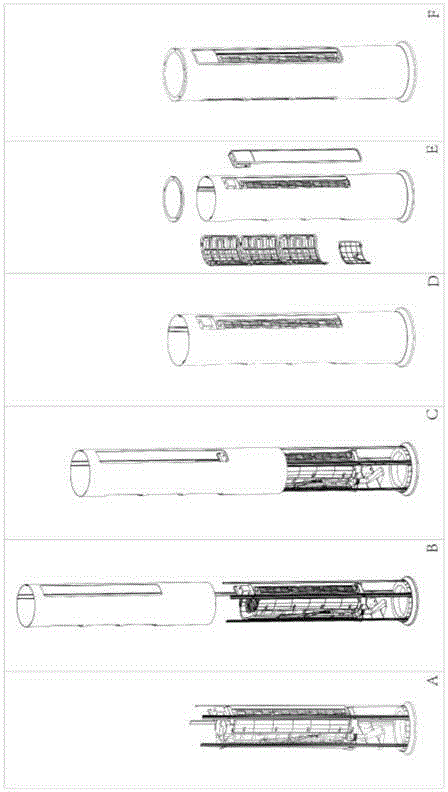

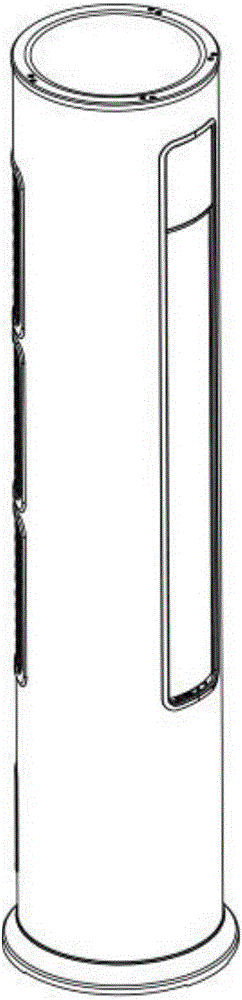

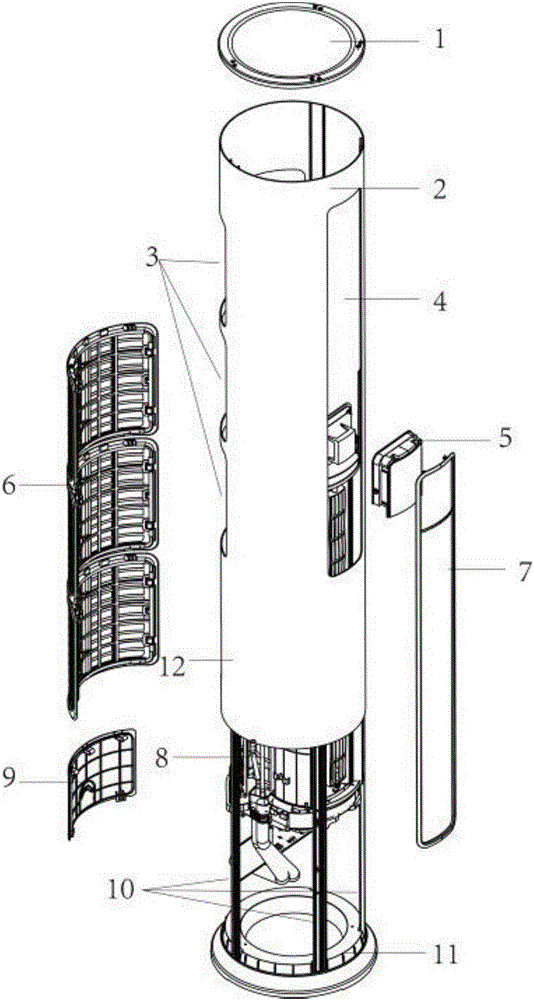

Extrusion type vertical air conditioner

ActiveCN105222310AOptimize production stepsReduce manufacturing costHeating and ventilation casings/coversEngineeringExtrusion

The invention relates to an extrusion type vertical air conditioner which comprises a shell (2). The extrusion type vertical air conditioner is characterized in that the shell is of an integrally-formed structure, and is manufactured through an integrated extrusion and secondary machine-forming technology, and the middle of the shell is hollow to form an inner cavity; at least one air outlet (4) in a vertical strip shape is formed in the front side of the shell in the height direction; at least one air inlet (3) is formed in the rear side of the shell in the height direction; openings communicated with the inner cavity are formed in the upper end and the lower end of the shell; and a plurality of protruding ribs (51) are arranged on the inner wall of the shell (2) in the height direction. The shell of the extrusion type vertical air conditioner is manufactured through the integrated extrusion and secondary machine-forming technology; the number of product assembling components is effectively lowered, and the development cost, production cost, material cost and transportation cost of the vertical air conditioner are reduced; and meanwhile product performance and appearance design are both achieved.

Owner:CHUZHOU PRIMST IND DESIGN CO LTD

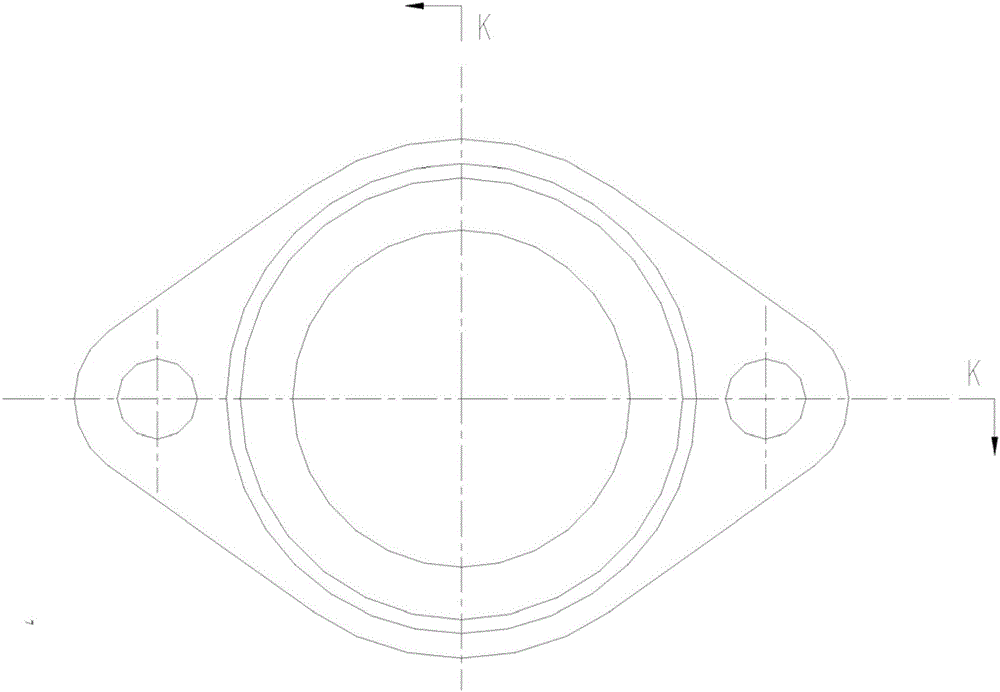

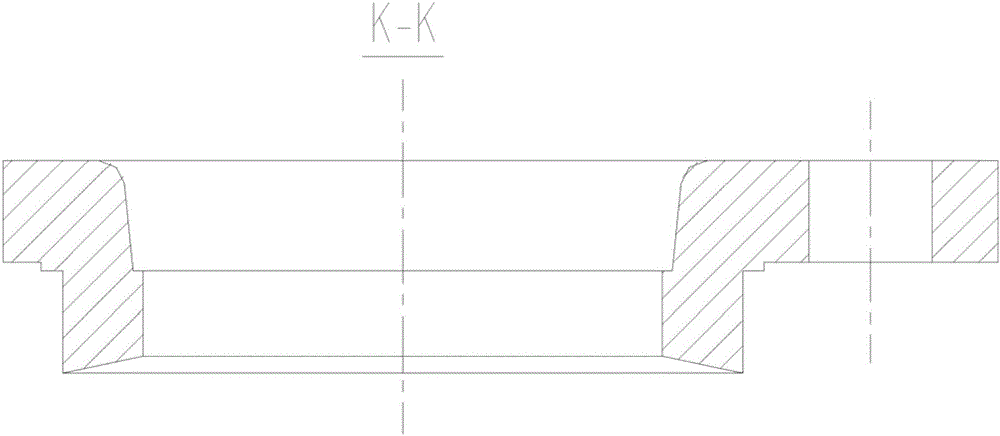

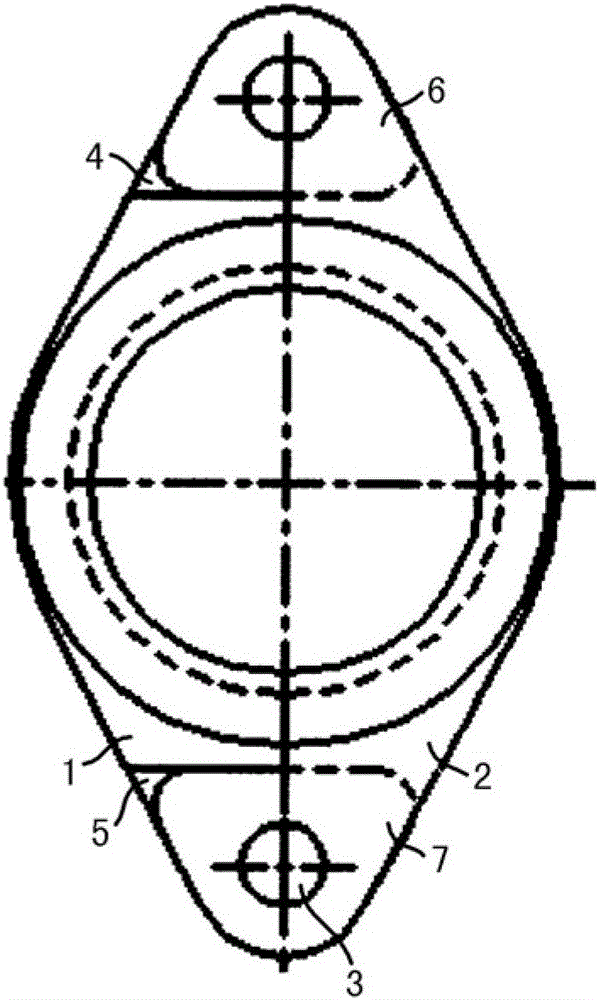

A split packing gland

ActiveCN103148218BSimplify production stepsOptimize production stepsEngine sealsPositive displacement pump componentsPulp and paper industry

The invention discloses a split-type packing gland, comprising a left splicing part and a right splicing part symmetric to the left splicing part, wherein U-shaped connecting pieces are symmetrically arranged at the two ends of each of the left and right splicing parts, and a U-shaped opening is arranged in each U-shaped connecting piece; and the left splicing part can be spliced with the right splicing part correspondingly, the U-shaped connecting pieces on the two splicing parts are mutually overlapped, and the U-shaped openings mutually coincide. The split-type packing gland has the beneficial effects that the two splicing parts can be axially limited under the condition that no fixed bolts are mounted; the split-type packing gland can be directly cast and meet the mounting demands without being further machined, and the production procedures are effectively simplified; after the two splicing parts are spliced, the inner diameter of each U-shaped opening is adjustable, the limitation on the diameter of bolts when the fixed bolts are mounted is omitted, and the mounting step is greatly facilitated; the fixed bolts only need to rotate or slide towards the outside of the U-shaped openings, so that the fixed bolts can be disassembled, and the disassembly efficiency is effectively improved.

Owner:SHANGHAI KAIQUAN PUMP IND GROUP

Phosphorization process for baby carriage tubes

InactiveCN104278262AOptimize production stepsHigh speedMetallic material coating processesMegasonic cleaningSurface conditions

The invention discloses a phosphorization process for baby carriage tubes and relates to the production field of baby carriages. The phosphorization process comprises the following steps: 1) ultrasonically cleaning a steel tube to degrease the steel tube; 2) washing the degreased steel tube with water and drying; 3) performing rust removal treatment on the steel tube processed in the step 2 by virtue of a physical method; 4) washing the steel tube (processed in the step 3) with water and drying; 5) performing surface conditioning on the steel tube processed in the step 4; 6) performing phosphorization on the steel tube processed in the step 5; 7) passivating the steel tube processed in the step 6; and 8) washing the steel tube (processed in the step 7) with water and drying. The phosphorization process has the advantages that steel tube production steps are optimized, a neutralization step in the phosphorization process is omitted, the phosphorization speed of the steel tube is increased and the corrosion prevention effect of the steel tube is improved.

Owner:ANHUI HAPPYANG CHILDRENS ARTICLES

Car body of track vehicle

InactiveCN107499321AHigh strengthWide range of raw materialsSynthetic resin layered productsLaminationAutomotive engineeringCorrosion resistant

The invention belongs to the technical field of railway transportation and discloses a car body of a track vehicle. The car body comprises a carriage body and a chassis, wherein the carriage body is fixed on the chassis; the carriage body successively comprises structure layers and an outer protective layer from inside to outside; the structure layers comprise a first structure layer and a second structure layer; the first structure layer is constituted through winding and binding of multiple layers of continuous fibers which are soaked with a first resin adhesive; the second structure layer is constituted through winding and binding of multiple layers of one type or multiple types of materials among bamboo, wood, hemp stalks, rattans, straws, reed stalks and silvergrass stalks which are soaked with a second resin adhesive; and the outer protective layer is made of an anti-aging and corrosion-resistant material. The car body of the track vehicle provided by the invention has the advantages of high intensity, wide sources of raw materials, green and environment-friendly effects, resource recycling, light mass and lower cost. The car body made of composite materials has an excellent high-damping characteristic; sound attenuation is high; and anti-vibration performance and acoustic performance of a train are improved greatly.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

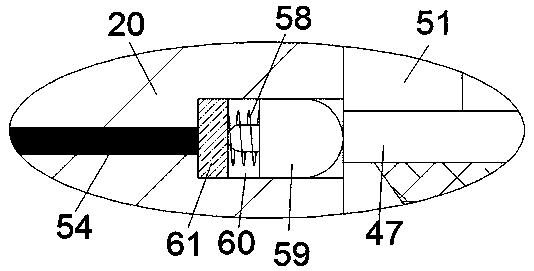

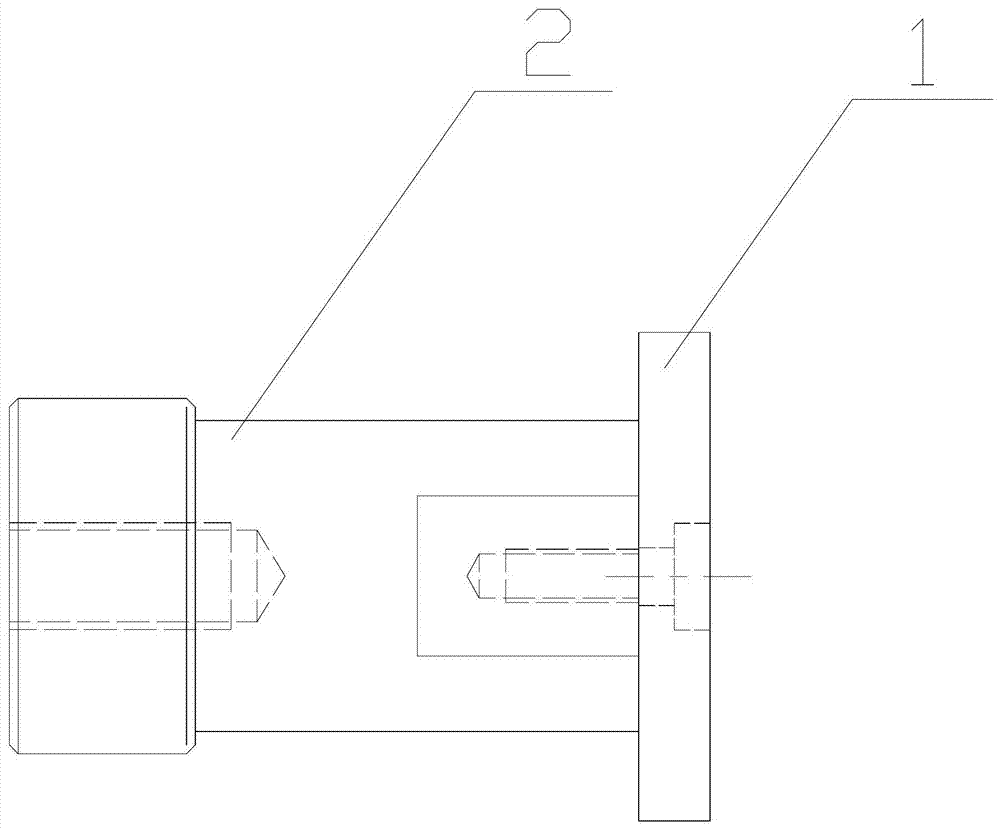

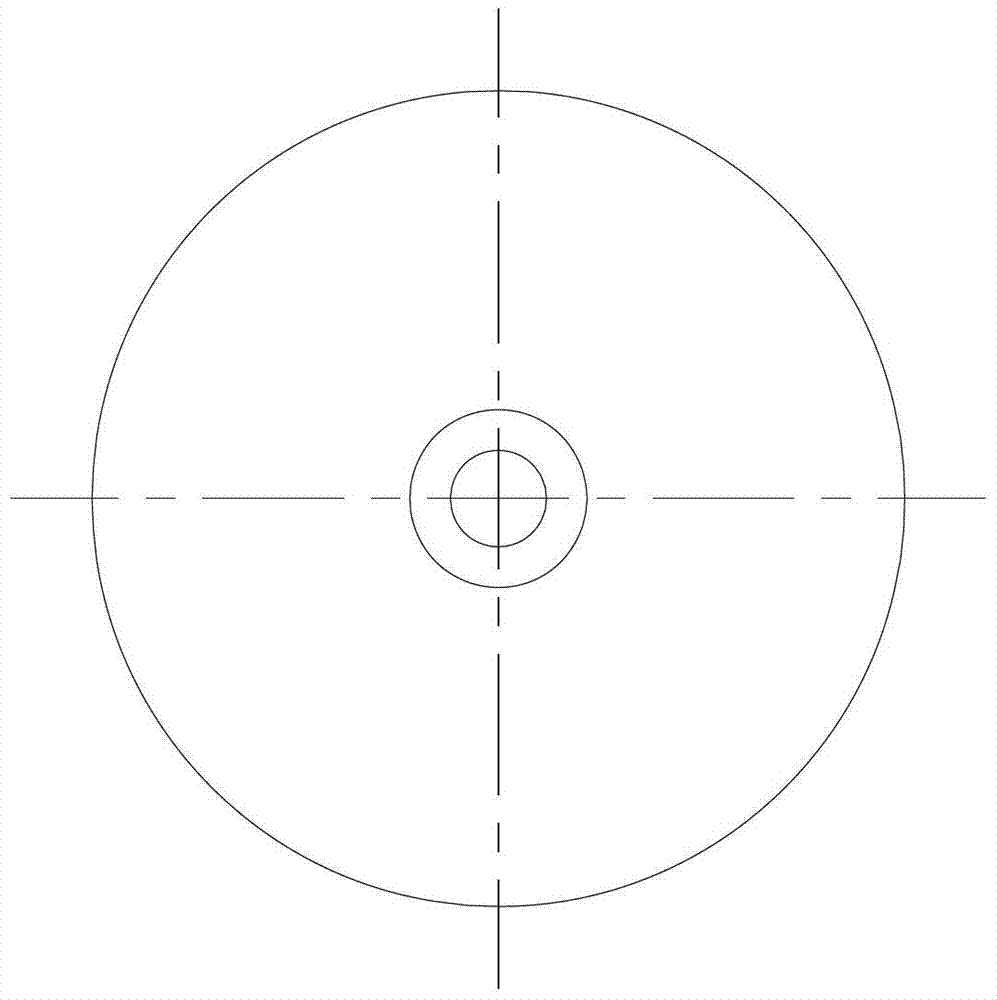

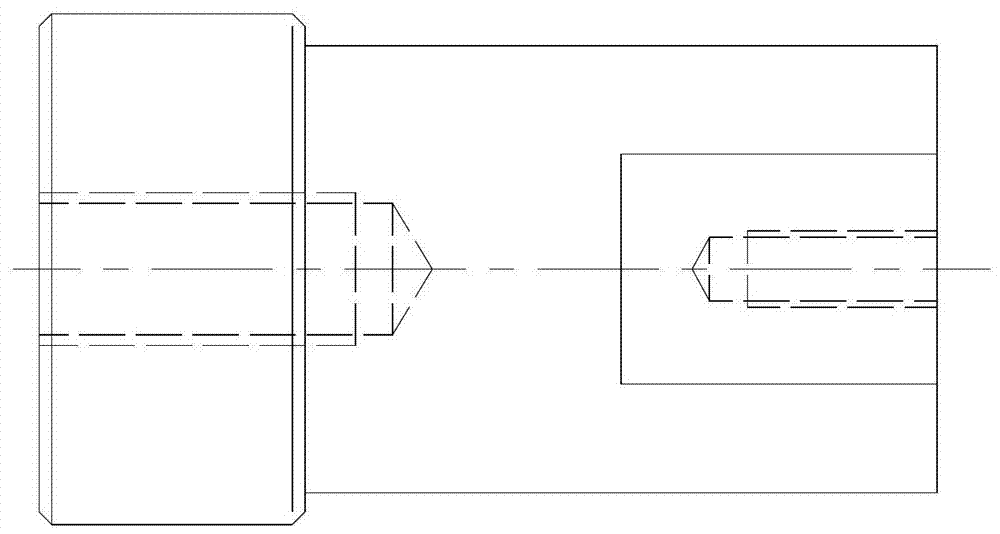

A concentric boring positioning mechanism

ActiveCN102896361BReasonable designSimple structurePositioning apparatusBoring/drilling componentsEngineeringScrew thread

A concentric boring positioning mechanism of the present invention comprises: an upper disc and a center rod; the upper disc is a solid disc with a diameter of 55 mm and a thickness of 8 mm, and a countersink hole with a diameter of 6.5 mm in the center; the center rod The length is 71mm, the diameter of the top is 40mm, the upper and lower ends of the top are provided with chamfers, and the top surface has M12 threaded holes; the diameter of the bottom end of the central rod is 35mm, and the bottom surface has M6 threaded holes, which can be used for bolts Secure with the upper disc. Through the above method, a concentric boring positioning mechanism of the present invention has a reasonable design and a simple structure, and the one-step processing of concentric circular holes can be realized through the tooling, the production steps can be optimized, and the production efficiency can be improved.

Owner:SUZHOU ERIC MECHANICS & ELECTRONICS CO LTD

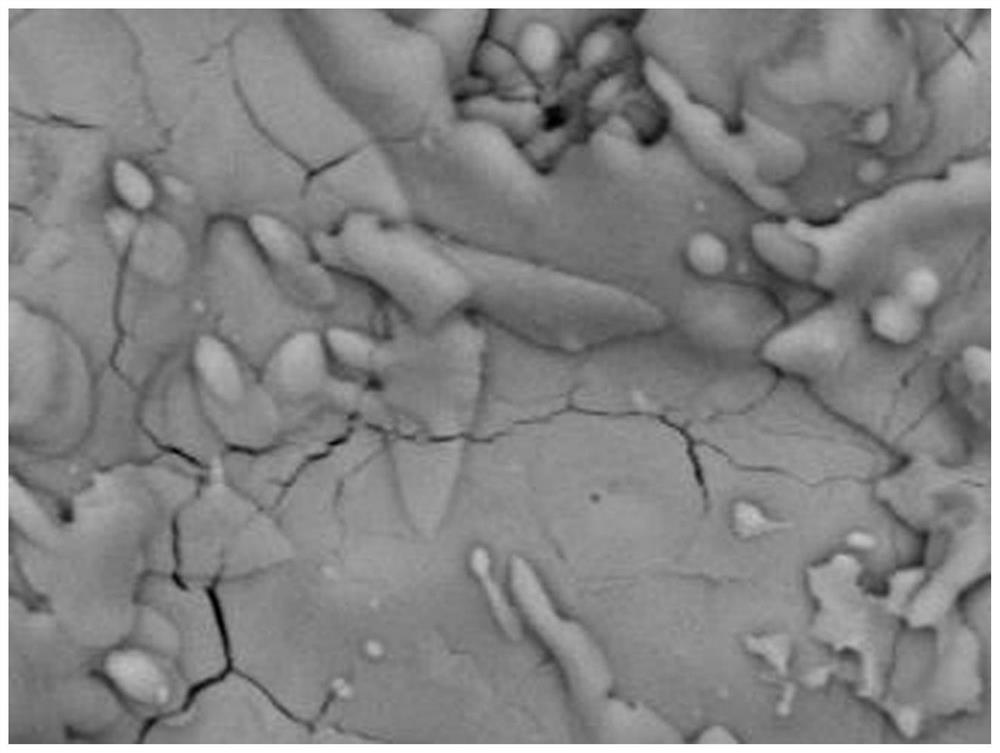

N-SiC/Al2O3 nano-composite anti-corrosion coating and preparation method thereof

PendingCN113957379AUniform compositionIncrease meltingMolten spray coatingNanotechnologyXylyleneMetallic materials

The invention discloses an N-SiC / Al2O3 nano-composite anti-corrosion coating and a preparation method thereof. The preparation method comprises the following steps that an aqueous solution of Al (NO3) 3.9 H2O is prepared according to a set proportion; urea in the set proportion is added into the aqueous solution and fully stirred to be dissolved; ammonia water is dropwise added into a mixed solution and continuously stirred until white precipitate is generated; polycarbosilane is dissolved in a xylene solution; the prepared solution and a PVA aqueous solution are added into the solution in the previous step; the mixture is placed on a roller ball mill for ball milling; dried spherical spraying feeding mixed powder of Al (OH) 3, the polycarbosilane and the urea is obtained; and the wear-resistant and compact N-SiC / Al2O3 nano-composite coating is prepared by a one-step method. The N-SiC / Al2O3 nano-composite anti-corrosion coating and the preparation method thereof has the strength and toughness of a metal material and the advantages of high temperature resistance, corrosion resistance and wear resistance of a ceramic material, and the service life of metal parts is greatly prolonged.

Owner:XIAN THERMAL POWER RES INST CO LTD

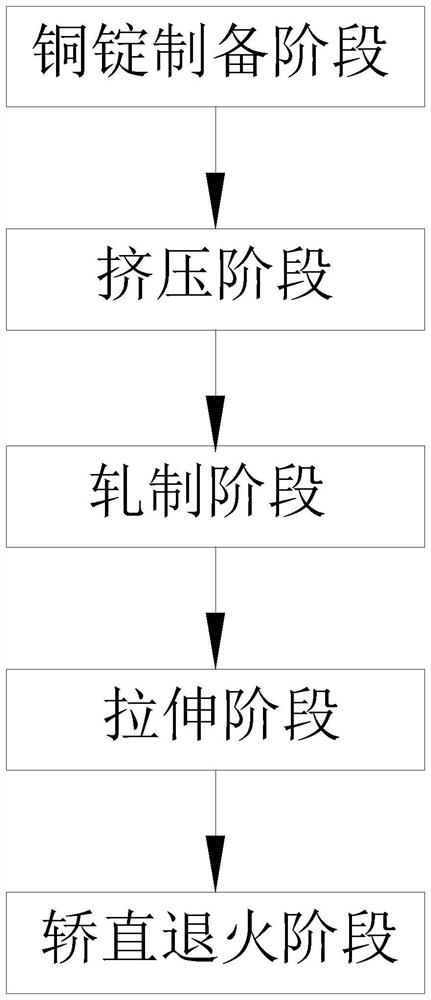

Preparation method of iron blue copper pipe

PendingCN114850238AOptimize product production stepsIncrease productivityIncreasing energy efficiencyMetal rolling arrangementsNon-ferrous metalPipe

The invention belongs to the technical field of non-ferrous metal processing, and particularly relates to a preparation method of an iron blue copper pipe, which comprises a copper ingot preparation stage, an extrusion stage, a rolling stage, a stretching stage and a straightening annealing stage, and solves the blank of the production of the existing iron blue copper pipe from raw materials to finished iron blue copper pipe products. The copper pipe is prepared after the copper ingot preparation stage, the extrusion stage, the rolling stage, the stretching stage and the straightening annealing stage, on the premise that the quality of the copper pipe is guaranteed, the product production steps are optimized, and the production efficiency is improved.

Owner:上海海亮铜业有限公司 +1

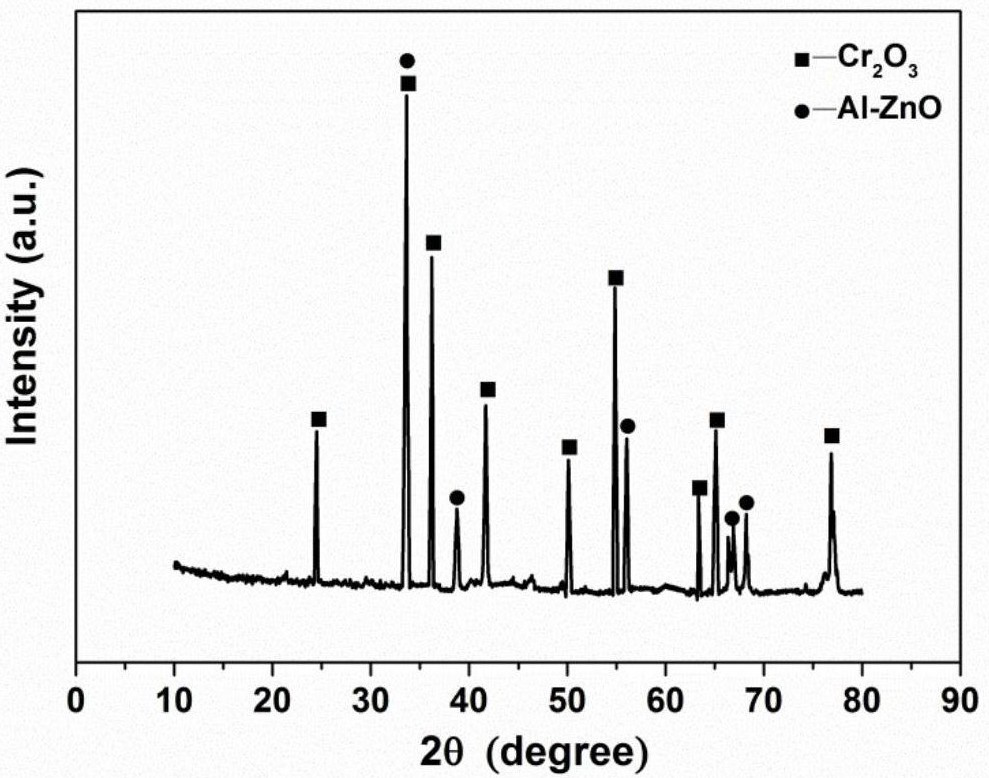

Chromium oxide-aluminum doped zinc oxide anti-corrosion composite coating and preparation method thereof

PendingCN113981360AUniform compositionHigh densityMolten spray coatingChromium trioxideAluminiumPolyvinyl alcohol

The invention discloses a chromium oxide-aluminum doped zinc oxide anti-corrosion composite coating and a preparation method thereof. The preparation method comprises the following steps of: 1, preparing a mixed solution according to a set proportion; 2, dropwise adding excessive ammonia water into the mixed solution step by step, and continuously stirring until a mixed white precipitate is generated; 3, adding a PVA (Polyvinyl Alcohol) aqueous solution into the obtained white precipitate; 4, putting the mixture on a roller type ball mill for ball milling; 5, granulating the ball-milled slurry on a spray granulator, and removing moisture to obtain spherical mixed powder; 6, calcining the obtained spherical mixed powder in a vacuum high-temperature environment, and decomposing to obtain spherical feed of Cr2O3 and AZO; and 7, putting the prepared spherical feed in a powder feeder, and preparing a Cr2O3 / AZO anti-corrosion composite coating on a metal plate in an atmosphere plasma spraying mode. The conductivity of the ZnO material is improved in an Al doping manner, so that the corrosion resistance of the coating is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

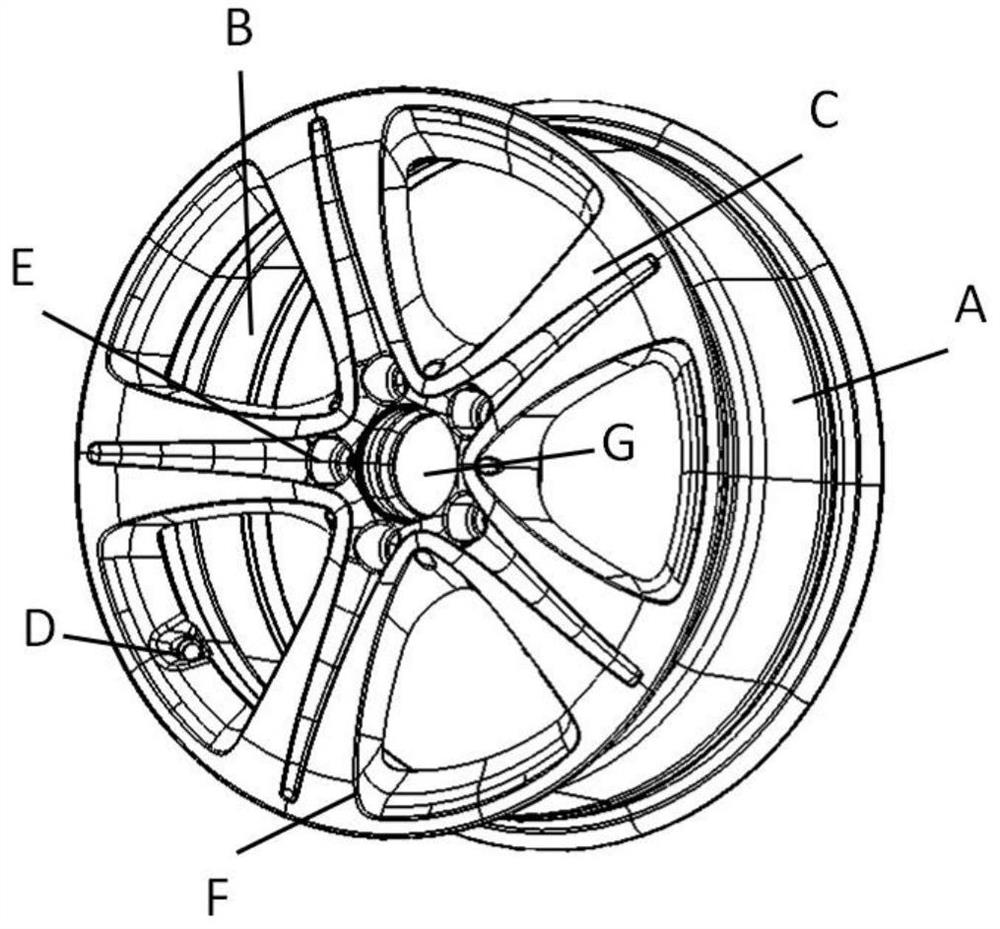

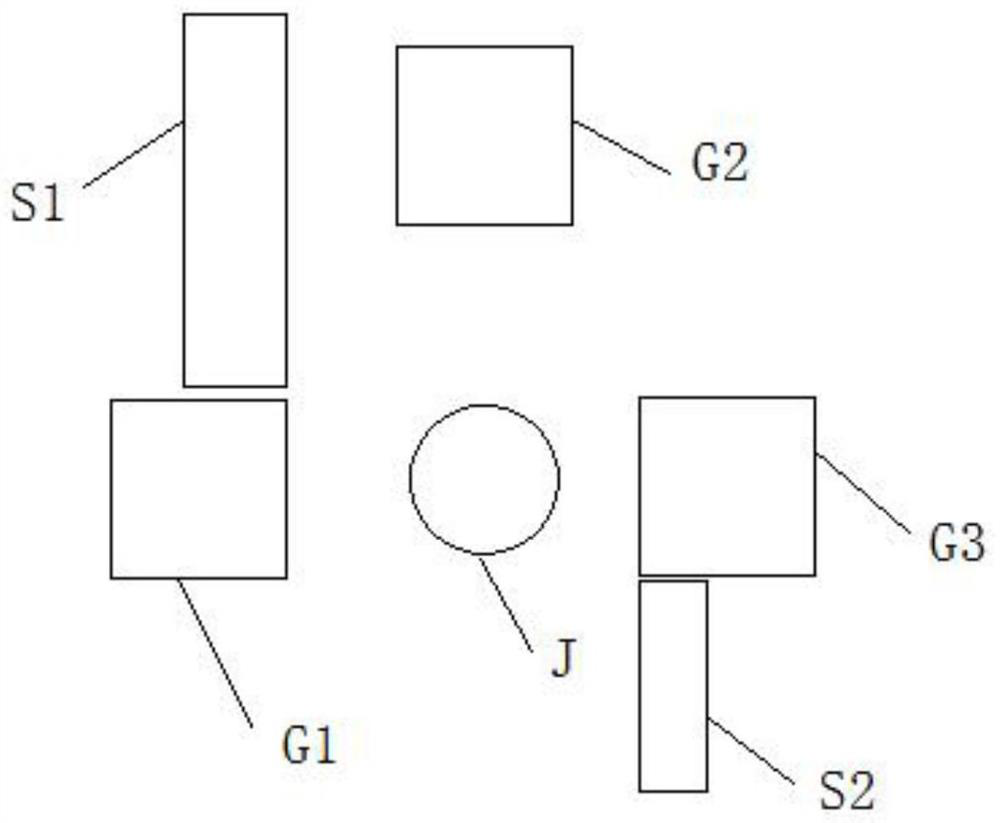

Wheel hub production method and production line based on drilling and sprue removal

The invention discloses a wheel hub production method and a production line based on drilling and de-sprueing with a car, which comprises a mechanical arm, a conveying roller table, a machine tool and a de-sprue turning tool. The feeding roller table grabs the hub to the first station; S2, the lathe at the first station turns the inner and outer surfaces of the hub; S3, the robotic arm grabs the hub to the second station; S4, the second station S5, the lathe at the second station replaces the gateless turning tool to remove the blank gate; S6, the robotic arm grabs the hub on the second station to the third station; S7, The drilling and milling machine at the third station processes the bolt holes, valve holes and window chamfers of the hub; S8, the robotic arm grabs the hub on the third station to the blanking roller table. The wheel hub de-sprue method, the de-sprue turning tool and the process optimization method of the hub production line related to the invention can effectively shorten the hub de-sprue time and improve the production efficiency.

Owner:YANSHAN UNIV

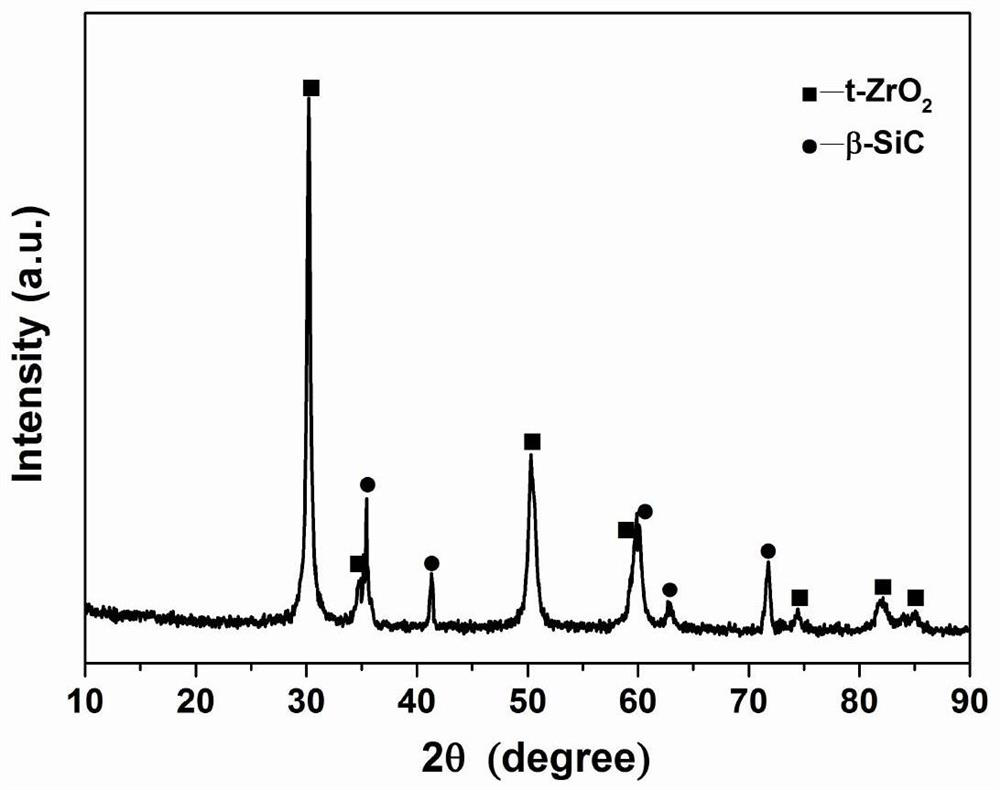

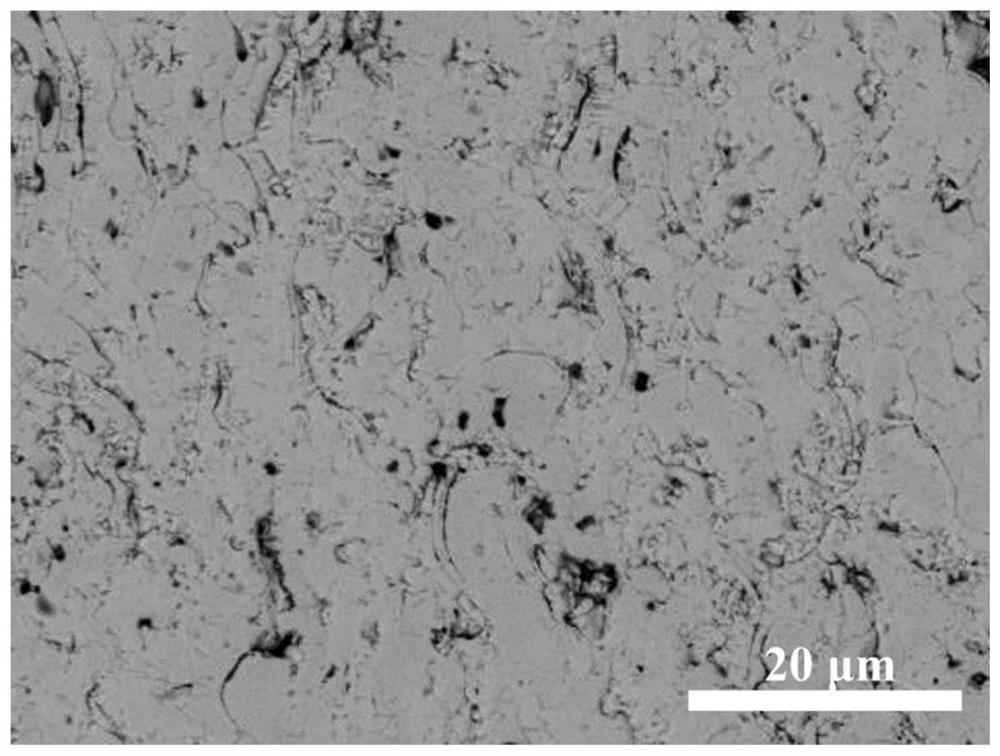

A silicon carbide-calcium oxide stabilized zirconia composite thermal barrier coating and its preparation method

ActiveCN113233907BHigh densityUniform coating compositionMolten spray coatingEfficient propulsion technologiesThermal sprayingSilanes

Owner:XIAN THERMAL POWER RES INST CO LTD

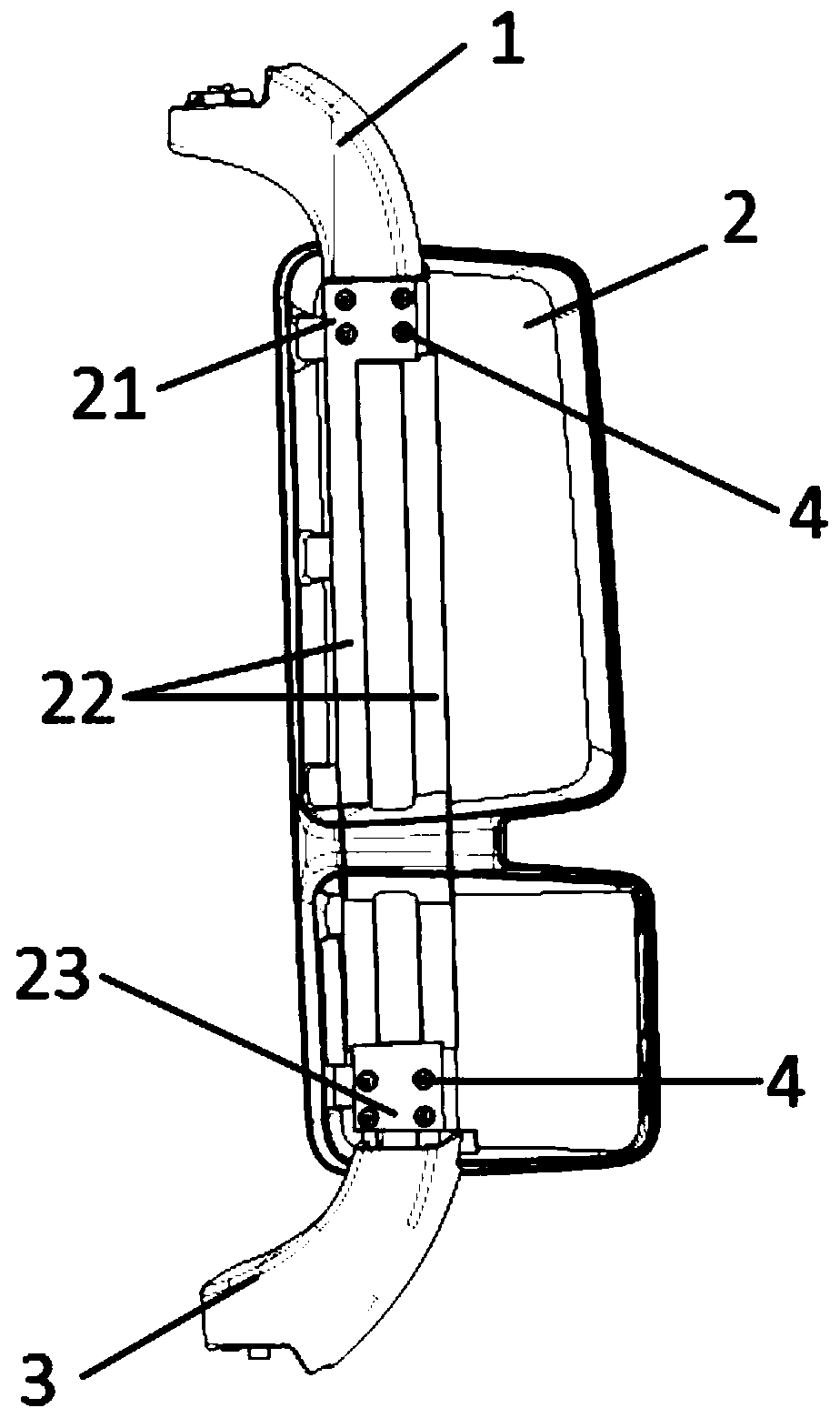

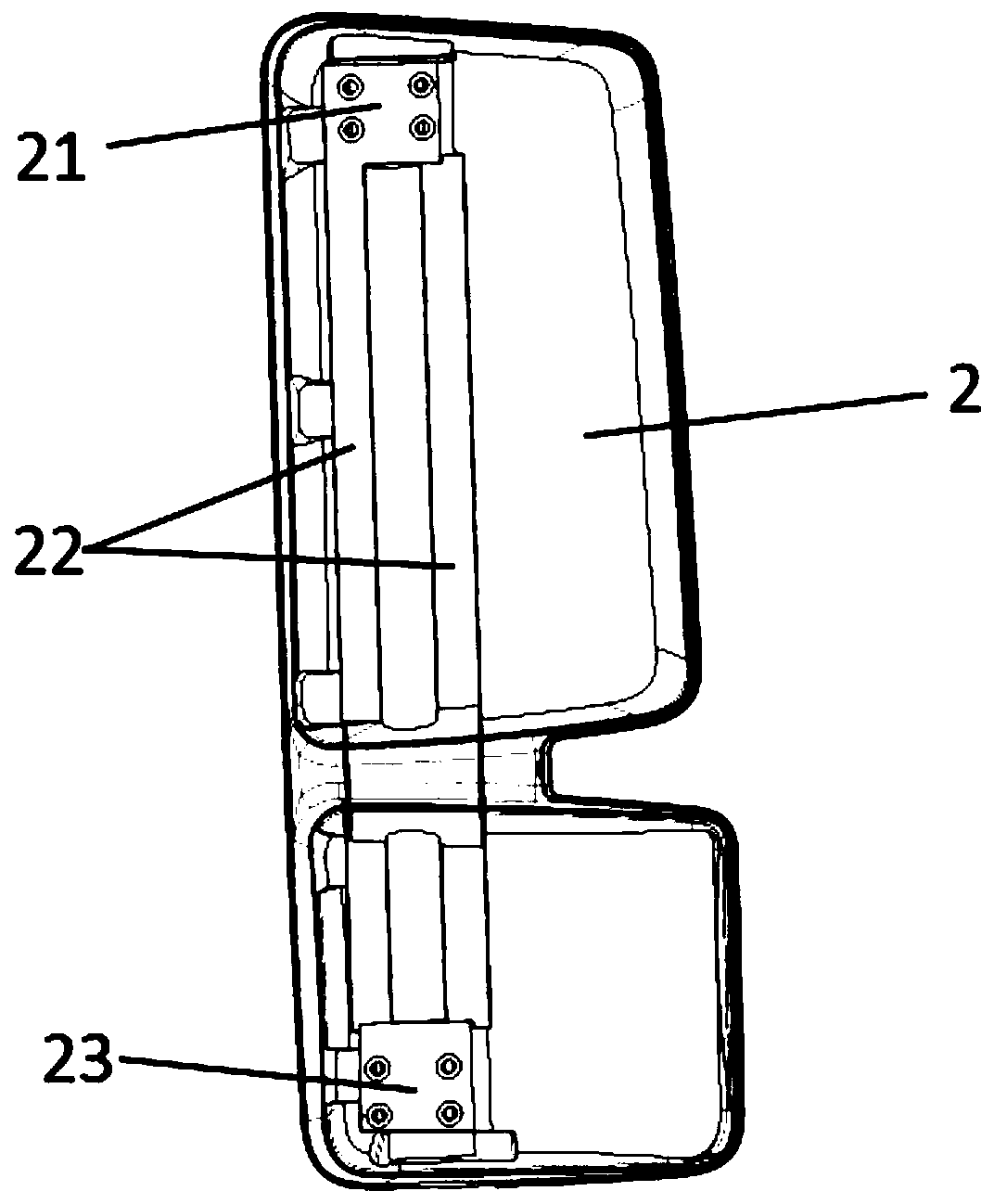

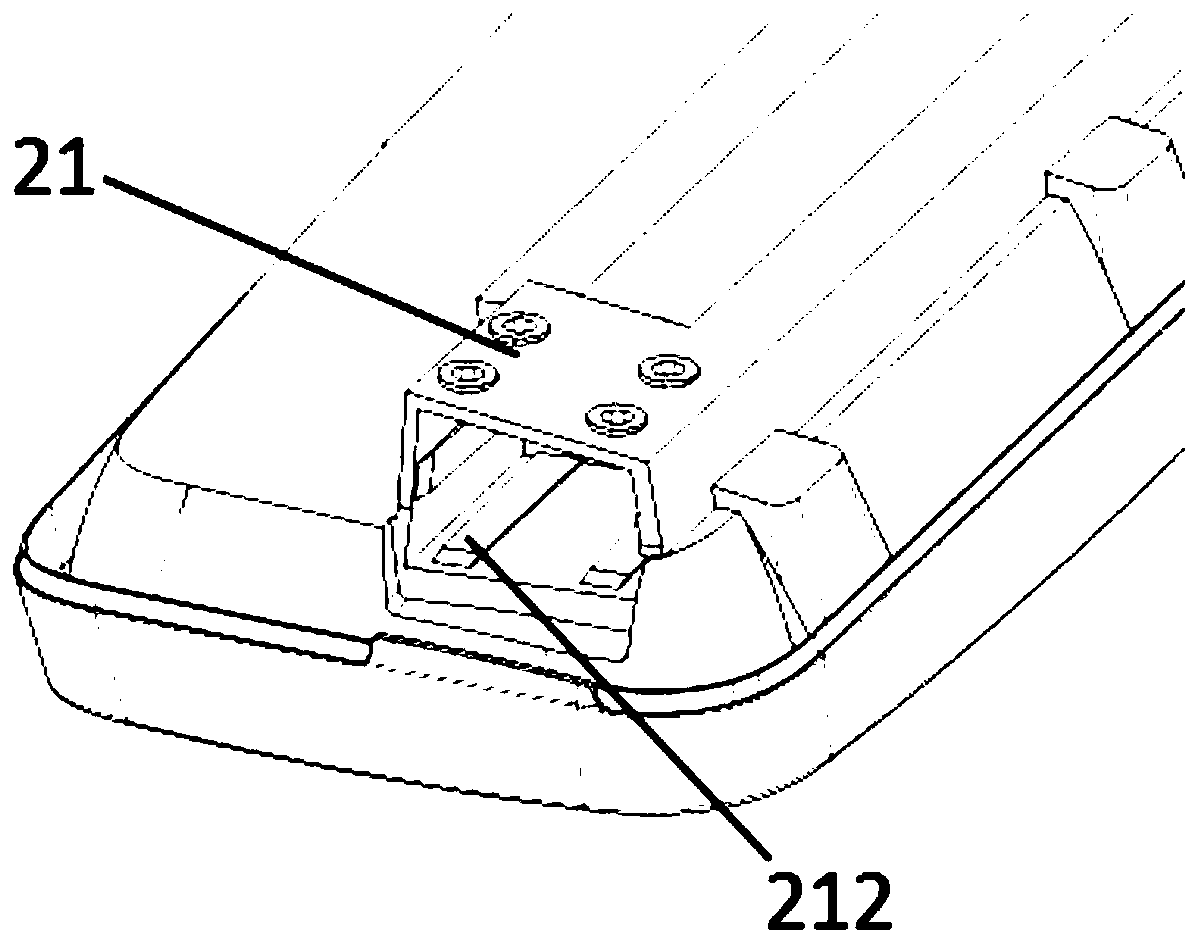

Load-supporting mirror shell structure of automobile mirror

PendingCN110435545AReduced stabilityOptimize production stepsOptical viewingSet screwRear-view mirror

The invention discloses a load-supporting mirror shell structure of an automobile mirror. A mirror shell, an upper mirror arm and a lower mirror arm are fixed by an upper mirror arm connection structure and a lower mirror arm connection structure, the upper mirror arm connection structure and the lower mirror arm connection structure include inserting holes formed in the upper end and the lower end of the mirror shell correspondingly, the ends, connected with the mirror shell, of the upper mirror arm and the lower mirror arm are tubular joints matched with the corresponding inserting holes, each tubular joint is fastened with a matched inserting hole through a set screw, a mirror shell bearing structure is arranged between the upper mirror arm connection structure and the lower mirror armconnection structure, the mirror shell bearing structure includes a main reinforcing rib extending in the length direction of the mirror shell, and the main reinforcing rib is arranged between the upper mirror arm connecting structure and the lower mirror arm connecting structure and is connected with the upper mirror arm connecting structure and the lower mirror arm connecting structure. According to the load-supporting mirror shell structure of the automobile mirror, the production steps are optimized, the working efficiency is improved, the strength and stiffness properties of products canbe improved by decreasing the number of connecting parts, and meanwhile, the shaking risk and the stability of rearview mirror use are also lowered.

Owner:SHANGHAI MEKRA LANG VEHICLE MIRROR

4-amino-3-fluorophenol and preparation method thereof

InactiveCN105646245ALow costLow priceOrganic compound preparationSulfonic acid preparationSubstitution reaction4-Nitrophenol

The invention discloses a 4-amino-3-fluorophenol and a preparation method thereof. 4-nitrophenol is taken as a raw material and has a sulfonation reaction firstly after catalytic hydrogenation, then a product has a fluoro-substitution reaction, fluorine has substitution at the 3 site, then a desulfonation reaction is performed, and a target product is obtained through extraction. According to the preparation method, 4-nitrophenol with lower cost is used as the raw material, so that the cost of the production raw material is reduced, aftertreatment steps are simple, and the method is suitable for large-scale industrial production.

Owner:叶芳

Garment pattern automatic shrinkage system and method

ActiveCN104699896BOptimize production stepsRealize automated productionSpecial data processing applicationsShrinkage rateSemi automatic

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

A micro-nano silicon carbide/calcium oxide stabilized zirconia spherical feeding material and its preparation method

A micro-nano silicon carbide / calcium oxide stabilized zirconia spherical feeding material and a preparation method of the present invention, comprising: step 1, configuring ZrOCl 2 ·8H 2 O / Ca(NO 3 ) 2 4H 2 O mixed solution; step 2, add excess ammonia water dropwise to the mixed solution and continue stirring to generate a white precipitate, forming solution A; step 3, dissolving polycarbosilane in p-xylene solution to form solution B; step 4, dissolving the solution B and PVA aqueous solution are added to solution A to obtain a mixture; step 5, the mixture in step 4 is ball-milled in a roller ball mill to obtain a ball-milled slurry; step 6, the ball-milled slurry is carried out on a spray granulator Granulate, get dry Zr(OH) after dehydration 4 , Ca(OH) 2 and the spherical mixed powder of polycarbosilane; step 7, the spherical powder obtained after granulation is placed in a corundum crucible, and placed in a vacuum sintering furnace for calcination at high temperature, so that Zr(OH) 4 , Ca(OH) 2 And polycarbosilane (PCS) undergoes pyrolysis to form a uniform SiC / CSZ spherical feed.

Owner:XIAN THERMAL POWER RES INST CO LTD

Production technology for aluminum plate

The invention discloses a production technology for an aluminum plate. The technology comprises the following steps that 1, an aluminum material is heated to 700 DEG C so as to be molten; 2, a formingdie and an inner core veneer are heated and preheated respectively; 3, the molten aluminum material is injected into the mold, the injection amount is one third of the formed aluminum plate piece, then, the inner core veneer piece is placed into the forming die, then, the molten aluminum material is injected again, and the aluminum material wraps the inner core veneer; 4, the filled forming die is placed into pressure maintaining forming equipment to be subjected to pressure maintaining forming, and a formed sandwiched aluminum board blank is formed; 5, the formed sandwiched aluminum board blank is taken out from the forming die, then, degreasing treatment, washing treatment, alkali erosion treatment, anodic oxidation treatment, second-time washing treatment, hole sealing treatment and polishing treatment are performed in sequence, and then the sandwiched aluminum plate is obtained; 6, the sandwiched aluminum plate is packaged, and production of the sandwiched aluminum plate is completed.

Owner:广东湘珠建材科技有限公司

A plant straw pellet feed production equipment

ActiveCN107411149BOptimize production stepsIncrease productivitySievingGas current separationFiltrationFilter system

The invention relates to the field of feed production equipment and particularly relates to plant straw pellet feed production equipment which comprises a feeding system, a stirring and crushing system, a primary filtration system, a secondary filtration system, a forming system and a supporting body, wherein the feeding system comprises a straw conveying port for conveying straw raw materials and an auxiliary material conveying port for conveying auxiliary materials, and the straw conveying port and the auxiliary material conveying port are connected with the stirring and crushing system; the stirring and crushing system is used for crushing the straw raw materials; the primary filtration system is connected with the stirring and crushing system; the secondary filtration system is connected with the primary filtration system; the forming system is connected with the secondary filtration system; and the supporting body is positioned below the forming system. By virtue of integrated treatment of crushing, mixing, filtration and pellet forming, the production steps of the plant straw pellet feed are greatly optimized, and the production efficiency is improved.

Owner:共青城市正邦生物科技有限公司

A hazardous waste recycling and processing production line

ActiveCN110804699BReduce consumptionIncrease contact areaCombination devicesSludge treatment by de-watering/drying/thickeningWater useSlag

The invention discloses a hazardous waste recycling and processing production line, aiming to provide a hazardous waste recycling and processing production line with reasonable process layout, improved production efficiency, energy saving and emission reduction. The main points of the technical solution include: a melting device, which includes The smelting furnace installed on the right side of the storage tower, the feeding port of the smelting furnace receives the electroplating sludge from the storage tower through the conveyor belt, and makes the electroplating sludge into a melt by roasting, and the outside of the smelting furnace is provided with a cooling The furnace body is water-jacketed, and the water jacket is connected to a water tank through a pipeline, and the water tank is arranged on a mounting frame erected on the outside of the smelting furnace; and the upper end of the collection pool is provided with a slag outlet for discharging the upper layer of the melt; a slag removal device, the slag removal device is arranged on one side of the collection pool for collecting the waste slag discharged from the slag outlet; the present invention Applicable to the technical field of environmental protection production line.

Owner:宁波双能环保科技有限公司

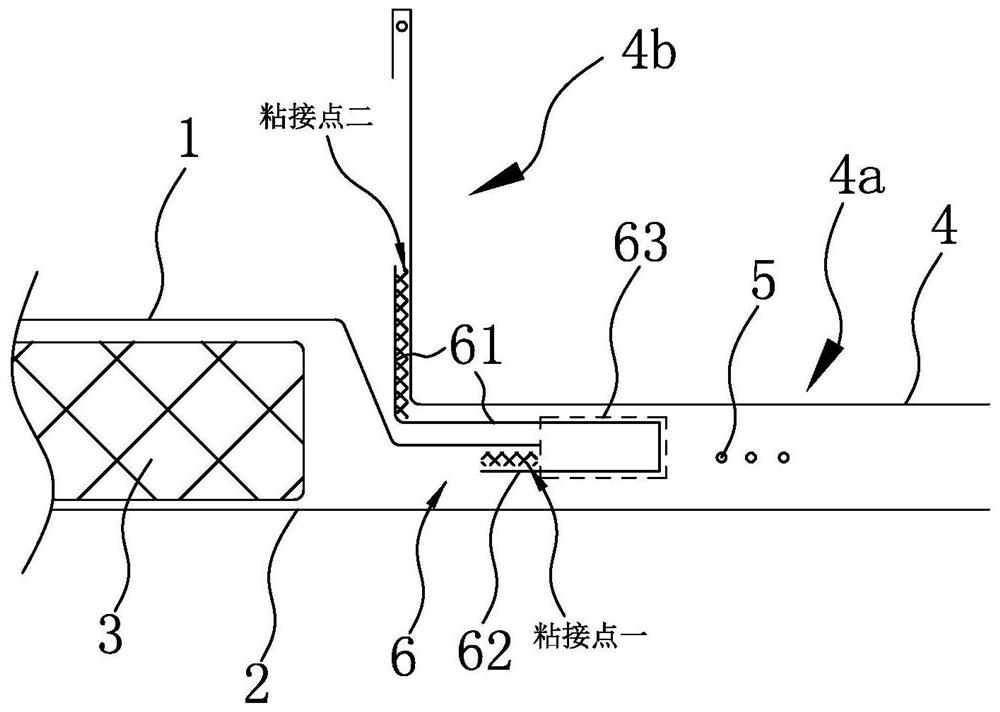

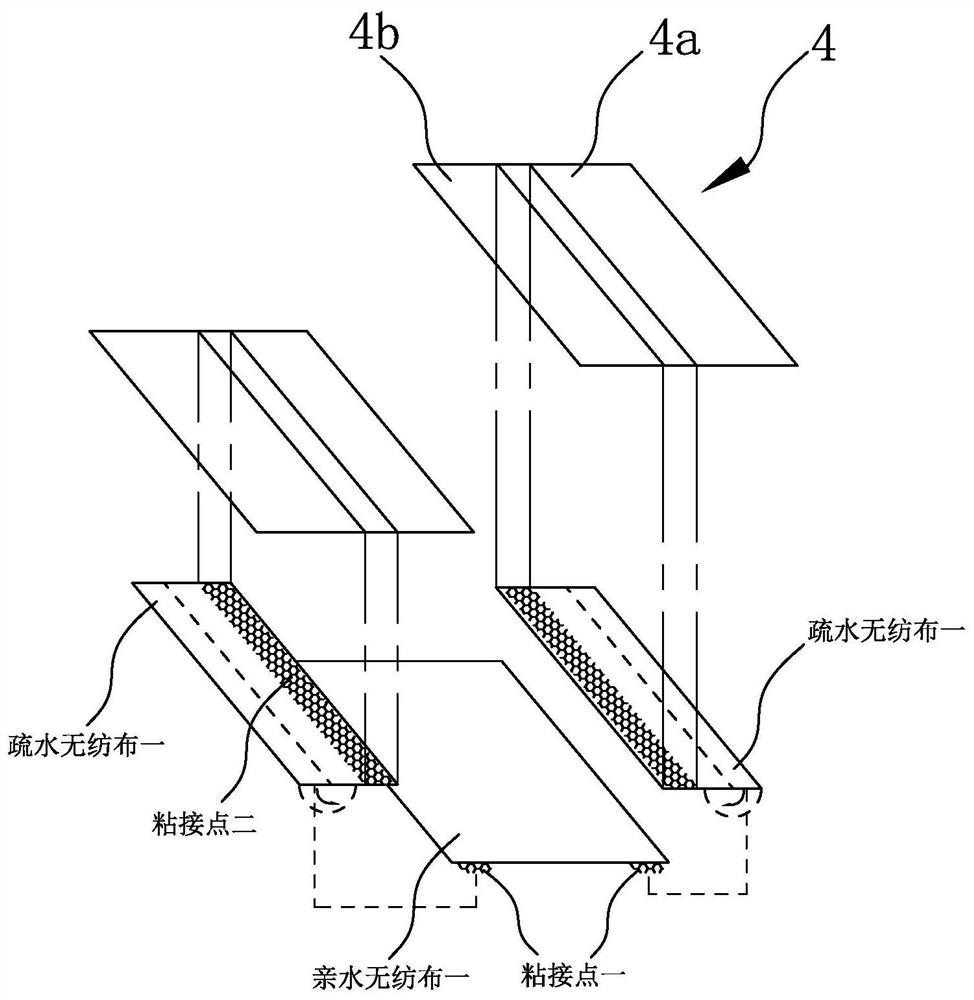

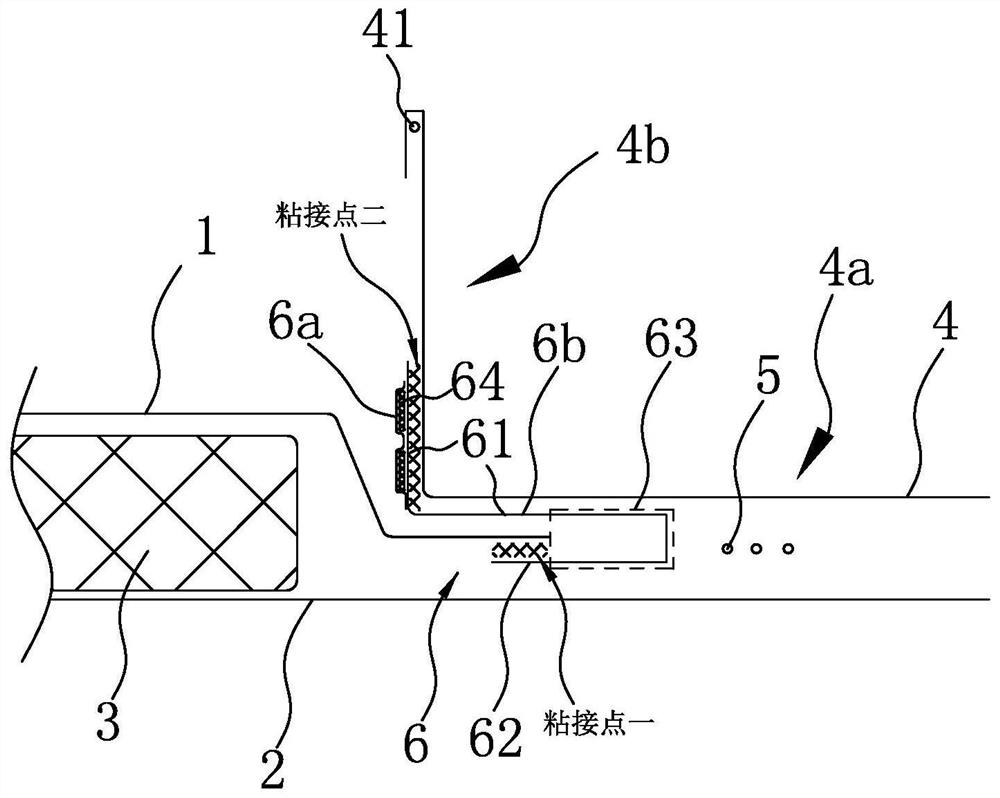

Application process of absorption article capable of preventing side leakage

ActiveCN113476213AReduce horizontal sizeAvoid side leakageAbsorbent padsBaby linensPolymer scienceEngineering

The invention relates to the technical field of hygienic product production, in particular to an application process of an absorption article capable of preventing side leakage. The application process comprises the following steps: 1, preparing a liquid-permeable surface layer; and step 1 comprises the following steps: a, taking a continuously conveyed first hydrophilic non-woven fabric, and applying glue to the end parts of two transverse sides of the lower surface of the first hydrophilic non-woven fabric to form first bonding points; b, conveying two pieces of first hydrophobic non-woven fabric above the two transverse sides of the first hydrophilic non-woven fabric in the same direction, and folding the part, located outside the first hydrophilic non-woven fabric, of the first hydrophobic non-woven fabric downwards and inwards through a folding mechanism so that the part makes contact with and adheres to the first bonding points; and c, applying glue to the end part, close to the unfolded ends, of the upper surfaces of the two pieces of first hydrophobic non-woven fabric, so as to form second bonding points. The problem that according to an existing absorption article, leakage occurs from the two sides, close to the front end and the rear end, of a leakage-proof partition edge, and consequently side leakage is caused is solved, and the production technology and related equipment are adjusted.

Owner:FUJIAN HENGAN HLDG CO LTD +2

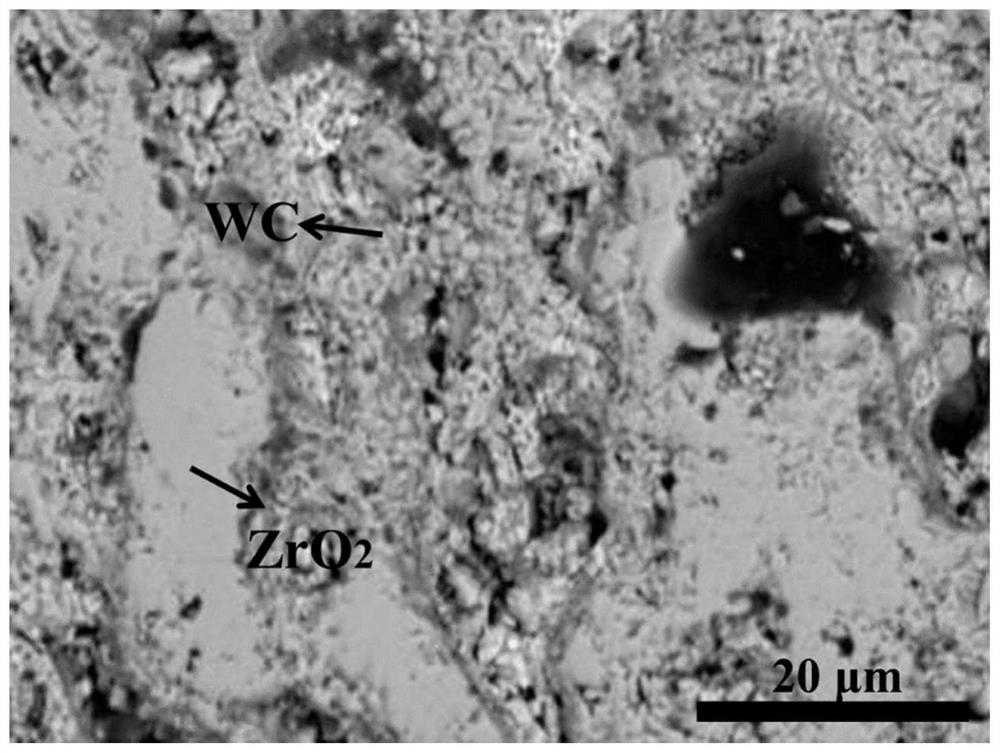

Tungsten carbide-yttria-stabilized zirconia composite thermal barrier coating and preparation method thereof

ActiveCN113430481AUniform compositionHigh densityMolten spray coatingSlurryYttria-stabilized zirconia

The invention relates to a tungsten carbide-yttria-stabilized zirconia composite thermal barrier coating and a preparation method thereof. The preparation method comprises the following steps that step 1, a ZrOCl2.8H2O / Y (NO3)3.6H2O mixed solution is prepared; step 2, excessive ammonia water is added into a mixed solution A, and continuously stirring is carried out until white precipitate is generated; step 3, a PVA aqueous solution is added to form a mixed solution B; 4, nanoscale WC particles are added, and a mixture is formed; 5, the mixture in the step 4 is placed on a roller type ball mill for ball milling, and slurry obtained after ball milling is obtained; step 6, the slurry subjected to ball milling in the step 5 is granulated on a spray granulator, and dried Zr(OH)4, Y(OH)3 and WC spherical spray feed mixed powder is obtained after moisture is removed; and 7, the spherical spray feed mixed powder is placed in a powder feeder, thermal spraying is conducted on the surface of a metal substrate in a vacuum plasma spraying mode, Zr(OH)4 and Y(OH)3 are subjected to high-temperature decomposition under the high-temperature flame condition, Y<3+> is dissolved in ZrO2 crystal lattices, and the WC-YSZ composite thermal barrier coating with high abrasion resistance and high compactness is formed by the ZrO2 crystal lattices and WC.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com