Wheel hub production method and production line based on drilling and sprue removal

A production method and de-gate technology, which is applied in the field of wheel hub production, can solve problems such as inconsistent secondary clamping and positioning benchmarks, reduced wheel hub processing accuracy, and inconsistent processing time, so as to shorten the de-gate time and improve material utilization. , The effect of small amount of material removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and described below with reference to the drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

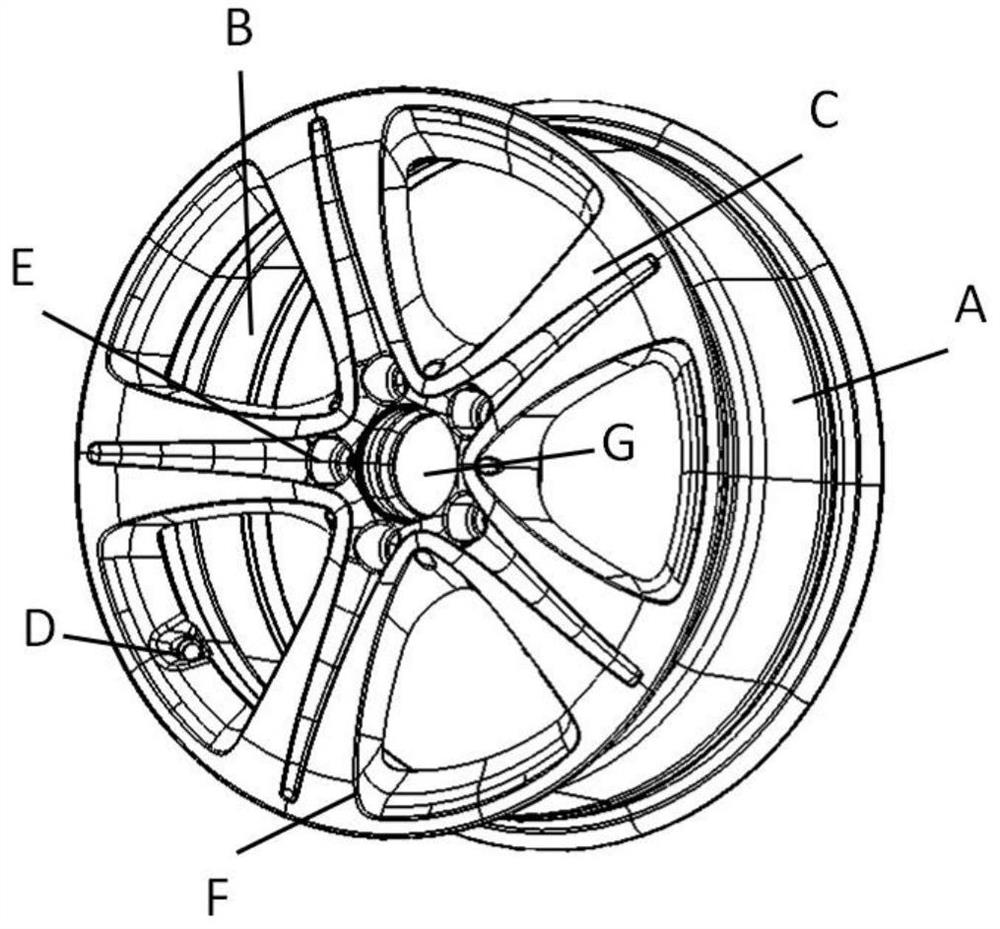

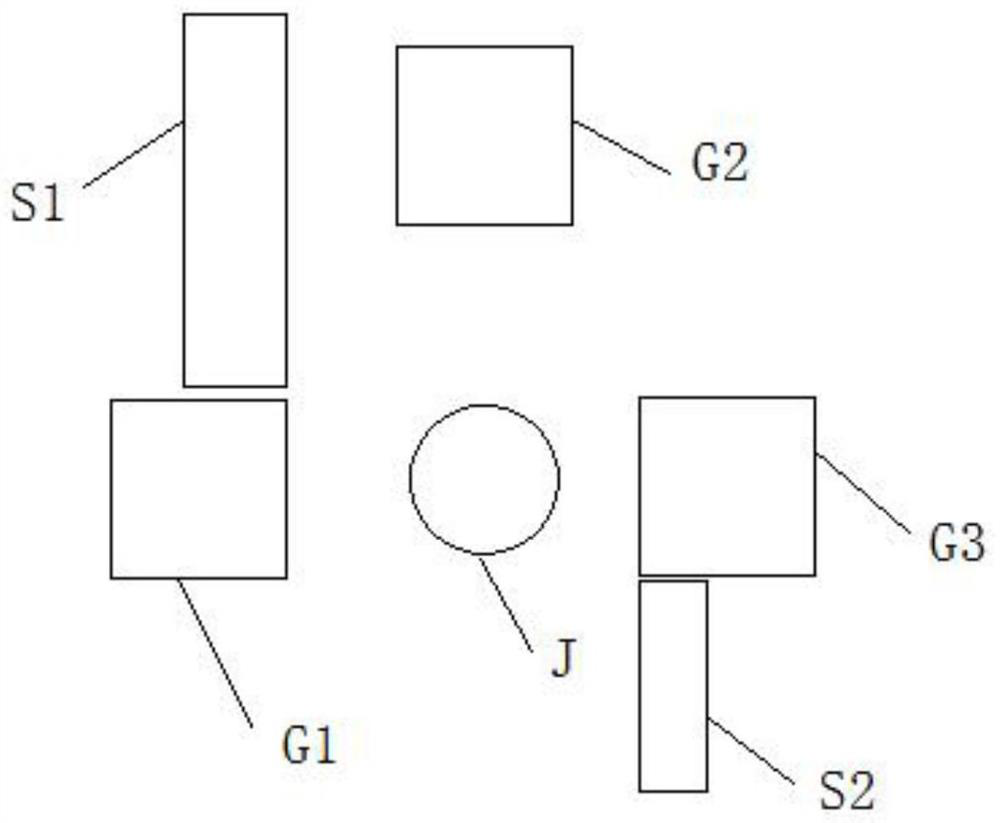

[0032] like figure 1 As shown, the processing elements of the hub to which the present invention is applicable include outer circular surface A, inner circular surface B, spoke surface C, valve hole D, bolt hole E, hub window chamfer F and hub casting gate area G. Among them, the outer circular surface and inner circular surface are processed by the first station machine tool G1, the spoke surface and gate are turned by the second station machine tool G2, and the valve hole D, bolt hole E and hub window chamfer F are processed by the third machine tool. The drilling and milling of the bit machine G3 is completed.

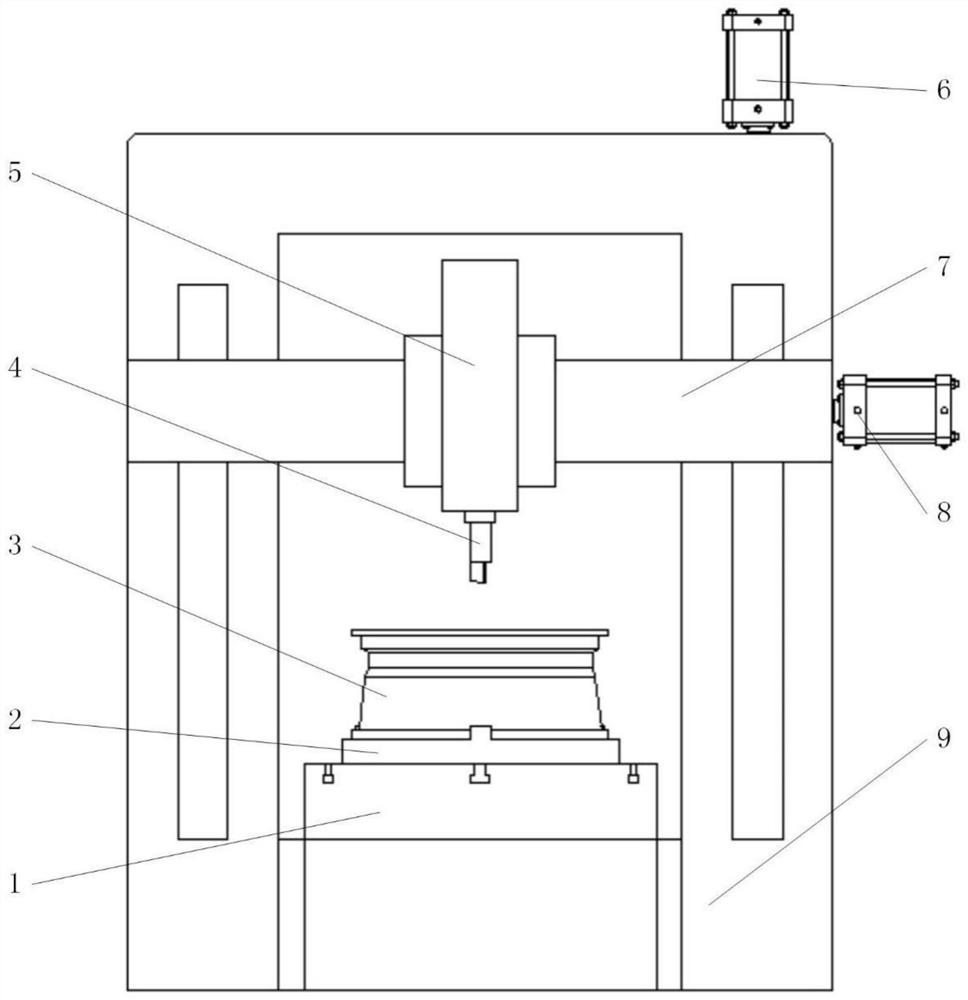

[0033] like figure 2 As shown, the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com