A hazardous waste recycling and processing production line

A technology for recycling and treating hazardous waste, applied in metallurgical wastewater treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as low production efficiency, unfavorable energy saving and emission reduction, and large energy consumption, and achieve structural Simplicity, reduction of time required for melting, effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

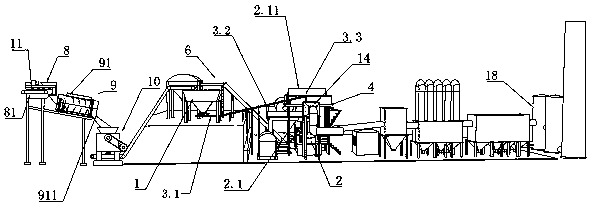

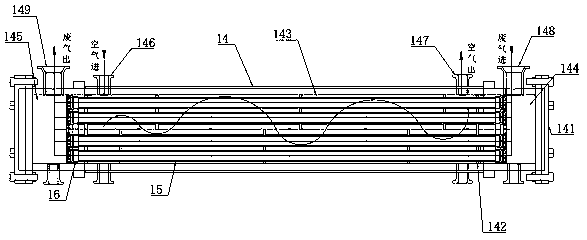

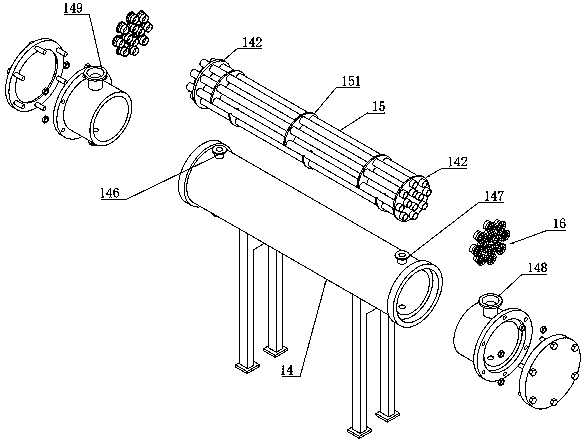

[0042] see Figure 1-13 Shown, a kind of hazardous waste recovery treatment production line of the present invention, this production line comprises:

[0043] A pretreatment device, the pretreatment device is used to sequentially dry and granulate the electroplating sludge, and store the pretreated electroplating sludge in the storage tower 1;

[0044] A smelting device, the smelting device includes a smelting furnace 2 arranged on the right side of the storage tower 1, the feed port of the smelting furnace 2 receives the electroplating sludge from the storage tower 1 through a transfer belt, and the electroplating sludge is roasted Mud is made into a melt, and the outer side of the melting furnace 2 is provided with a water jacket 2.1 for cooling the furnace body, and the water jacket 2.1 is connected to a water tank 2.11 through a pipeline, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com