Car body of track vehicle

A rail vehicle and car body technology, applied in the direction of railway car body, vehicle parts, railway car body parts, etc., can solve the problems of heavy weight and speed increase, and achieve the effect of light weight, low cost and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

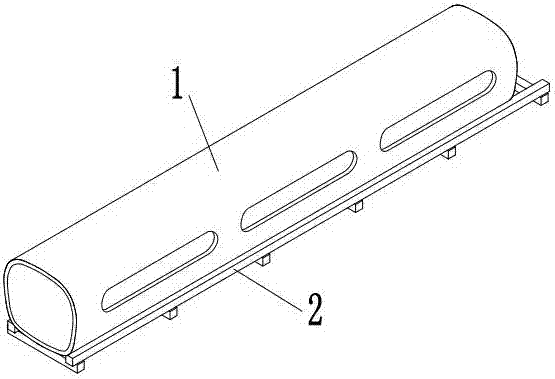

Image

Examples

Embodiment 1

[0027] A rail vehicle body, comprising a car body and an underframe, the car body is fixed on the underframe, and the car body has a second structural layer, a first structural layer and an outer protective layer sequentially from the inside to the outside, The second structural layer is formed by winding several layers of bamboo sheets impregnated with epoxy resin adhesive, and the first structural layer is formed by winding several layers of glass fibers impregnated with unsaturated polyester resin adhesive. The outer protective layer is made of epoxy resin. Its concrete preparation steps are as follows:

[0028] (1) Mandrel treatment: making a box mandrel, and coating the release agent on the mandrel surface;

[0029] (2) Preparation of the second structural layer: cut the original bamboo into thin bamboo slices with a length of 6m, a width of 25mm, and a thickness of 3mm, and bond them to a length of more than 150m. and the included angle are spirally wound on the mandre...

Embodiment 2

[0036]A rail vehicle body, comprising a car body and an underframe, the car body is fixed on the underframe, and the car body has a first structural layer, a second structural layer and an outer protective layer sequentially from the inside to the outside, The first structural layer is formed by winding several layers of basalt fiber impregnated with a flame-retardant epoxy resin adhesive, and the second structural layer is formed by winding several layers of wood and bonding with a flame-retardant epoxy resin adhesive The wood can be solidified, and the wood can be selected from planed veneer, laminated veneer lumber and other wood made of eucalyptus, poplar, birch, fir, sylvestris pine, masson pine, etc. The outer protective layer is Made of epoxy resin. Its concrete preparation steps are as follows:

[0037] (1) Mandrel treatment: making a box mandrel, and coating the release agent on the mandrel surface;

[0038] (2) Preparation of the first structural layer: After the b...

Embodiment 3

[0045] A rail vehicle body, comprising a box body and an underframe, the box body is fixed on the underframe, and the box body has a first structure layer, a second structure layer one, and a second structure layer in sequence from the inside to the outside Layer 2 and the outer protective layer, the first structural layer is formed by winding several layers of aramid fibers soaked in flame-retardant phenolic resin adhesive, and the second structural layer 1 is formed by winding several stalks of hemp plants layer and is bonded and solidified by a flame-retardant phenolic resin adhesive. The hemp plants can be selected from hemp, apocynum, ramie, jute, kenaf, etc. The second structural layer is made of a flame-retardant phenolic resin adhesive. The rattan can be wound and bonded in several layers, and the rattan can be selected from badan rattan, sand rattan and rattan rattan with uniform thickness, good flexibility and high strength. The outer protective layer is made of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com