A micro-nano silicon carbide/calcium oxide stabilized zirconia spherical feeding material and its preparation method

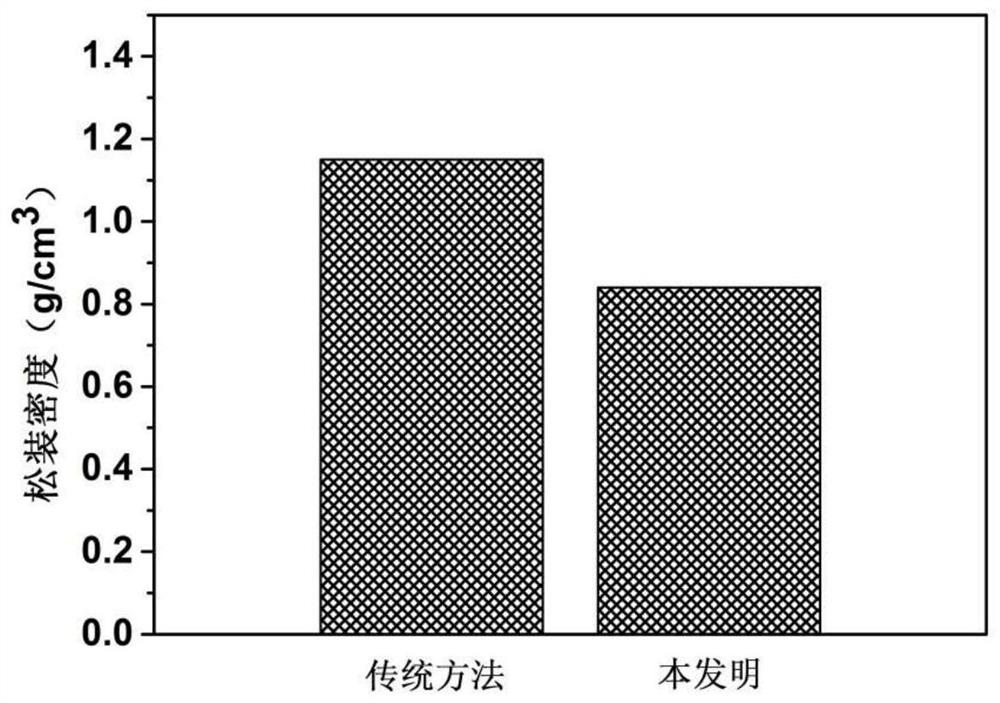

A technology for stabilizing zirconia and silicon carbide. It is applied in the field of micro-nano silicon carbide/calcium oxide stabilized zirconia spherical feeding and preparation, and in the field of micro-nano powder. Uniformity and other problems, to achieve the effect of low bulk density, fine powder particle size and uniform composition

Active Publication Date: 2022-05-31

XIAN THERMAL POWER RES INST CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

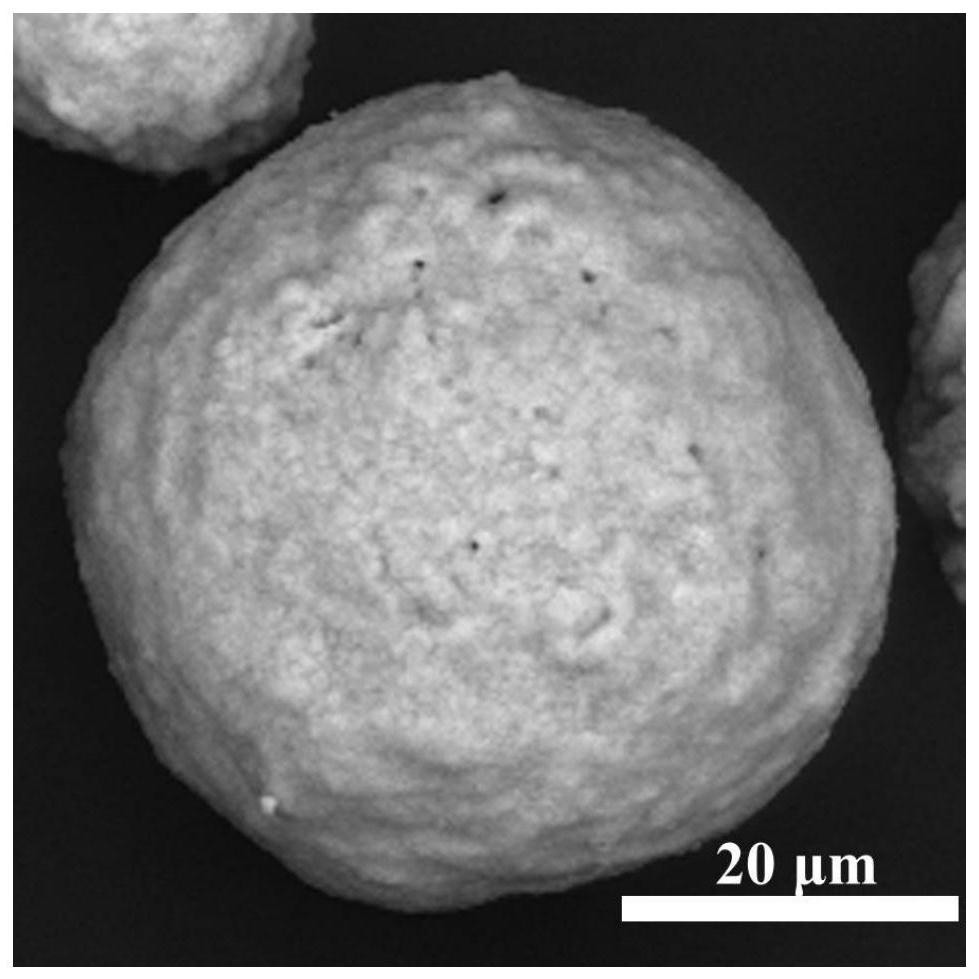

[0005] The purpose of the present invention is to provide a micro-nano silicon carbide / calcium oxide stabilized zirconia spherical feeding material and its preparation method, which solves the problems of coarse particle size, uneven composition, incomplete melting and poor density of the traditional feeding material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Login to View More

Abstract

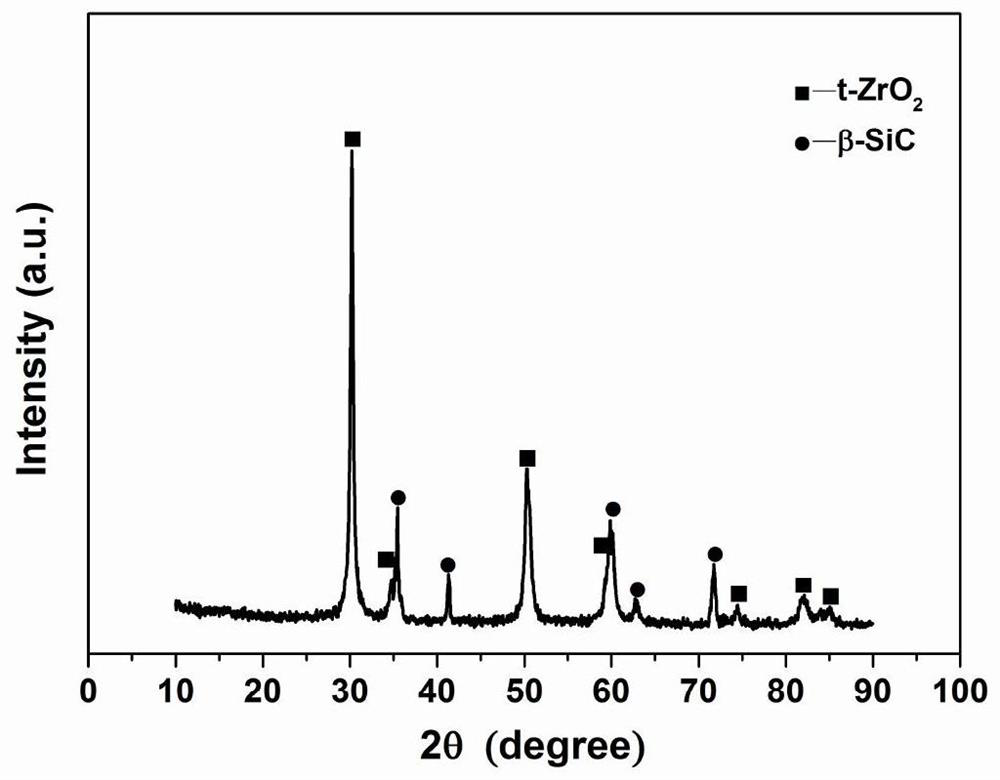

A micro-nano silicon carbide / calcium oxide stabilized zirconia spherical feeding material and a preparation method of the present invention, comprising: step 1, configuring ZrOCl 2 ·8H 2 O / Ca(NO 3 ) 2 4H 2 O mixed solution; step 2, add excess ammonia water dropwise to the mixed solution and continue stirring to generate a white precipitate, forming solution A; step 3, dissolving polycarbosilane in p-xylene solution to form solution B; step 4, dissolving the solution B and PVA aqueous solution are added to solution A to obtain a mixture; step 5, the mixture in step 4 is ball-milled in a roller ball mill to obtain a ball-milled slurry; step 6, the ball-milled slurry is carried out on a spray granulator Granulate, get dry Zr(OH) after dehydration 4 , Ca(OH) 2 and the spherical mixed powder of polycarbosilane; step 7, the spherical powder obtained after granulation is placed in a corundum crucible, and placed in a vacuum sintering furnace for calcination at high temperature, so that Zr(OH) 4 , Ca(OH) 2 And polycarbosilane (PCS) undergoes pyrolysis to form a uniform SiC / CSZ spherical feed.

Description

A kind of micro-nano silicon carbide / calcium oxide stabilized zirconia spherical feed and preparation method technical field The invention belongs to the micro-nano powder of high temperature protection technical field, be specifically related to a kind of micro-nano silicon carbide / oxidation Calcium-stabilized zirconia spherical feed and preparation method. Background technique Thermal barrier coating, as a special material, is coated on the surface of the hot end component, and has a good thermal insulation effect. It is used to reduce the influence of steam turbine or engine blades by high temperature environment, and reduce the impact of substrate wear, high temperature oxidation and other factors on the substrate. The destruction of the body can greatly extend the service life of the blade and increase the working temperature of the machine. Calcium oxide stabilized zirconia (ZrO 2 ) coating is currently the most promising thermal barrier material. Due to t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/48C04B35/571C04B35/626C04B35/66

CPCC04B35/48C04B35/571C04B35/62605C04B35/62695C04B35/66C04B2235/5436C04B2235/5454C04B2235/5445

Inventor 杨哲一崔锦文王弘喆崔雄华张磊曹海涛

Owner XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com