Load-supporting mirror shell structure of automobile mirror

A load-bearing structure and load-bearing technology, applied in vehicle parts, optical observation devices, transportation and packaging, etc., can solve the problems of high assembly requirements, high assembly difficulty, and high difficulty, so as to improve the strength and stiffness performance and optimize the production steps , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

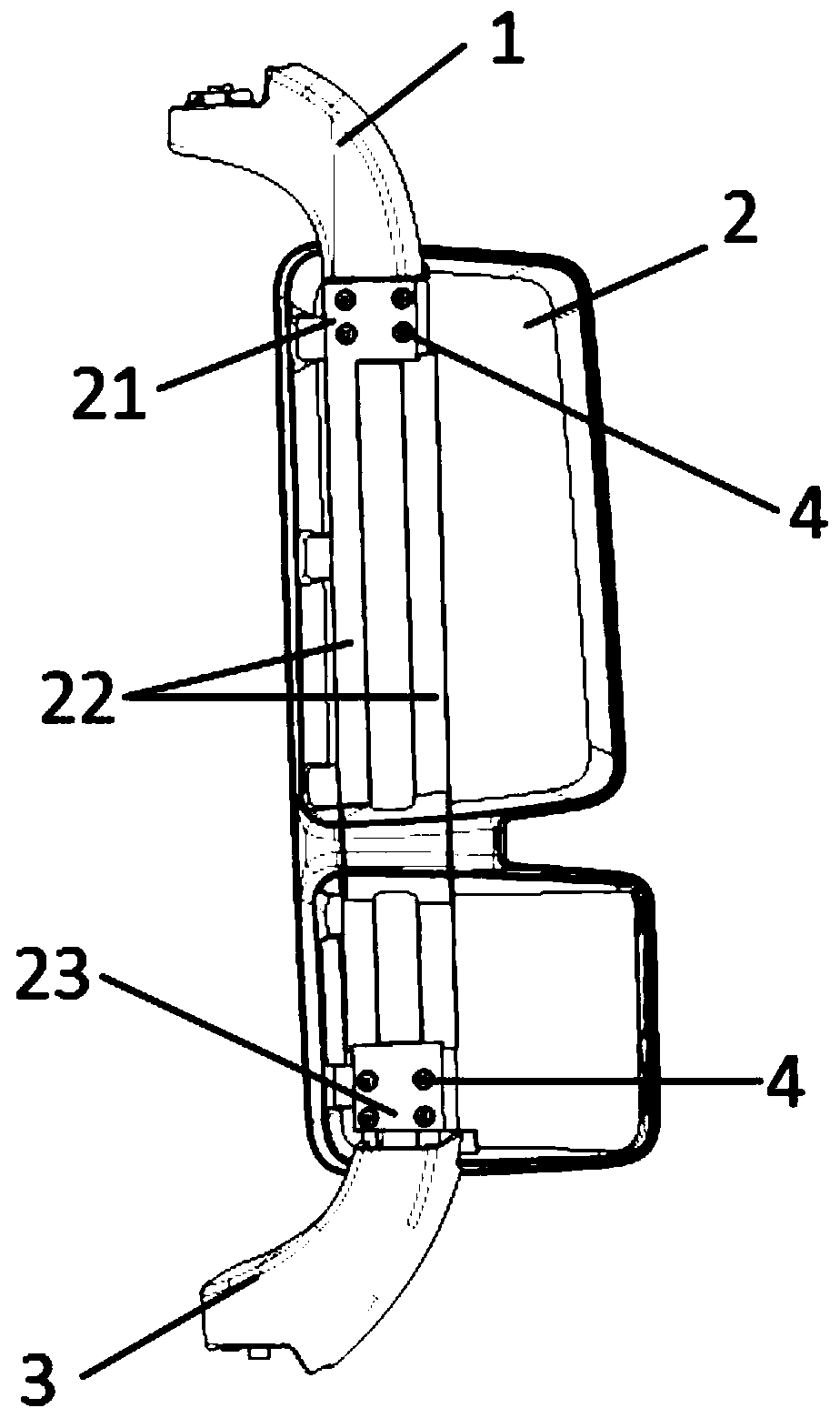

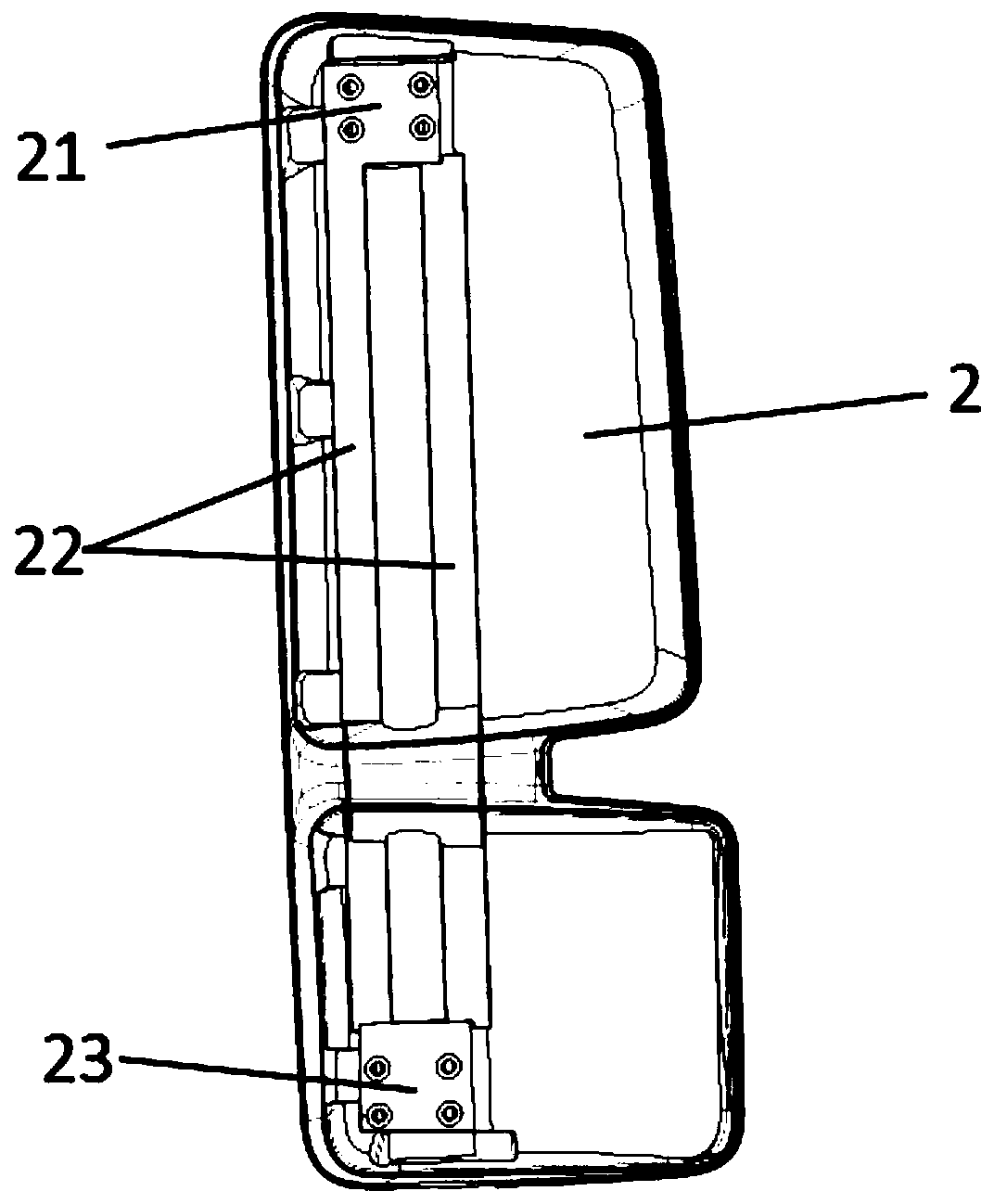

[0043] like Figure 1 to Figure 4 As shown, the automobile mirror-carrying type mirror housing structure, the mirror housing 2 is respectively connected with the upper and lower supports arranged on the car body by means of the upper mirror arm 1 and the lower mirror arm 3 .

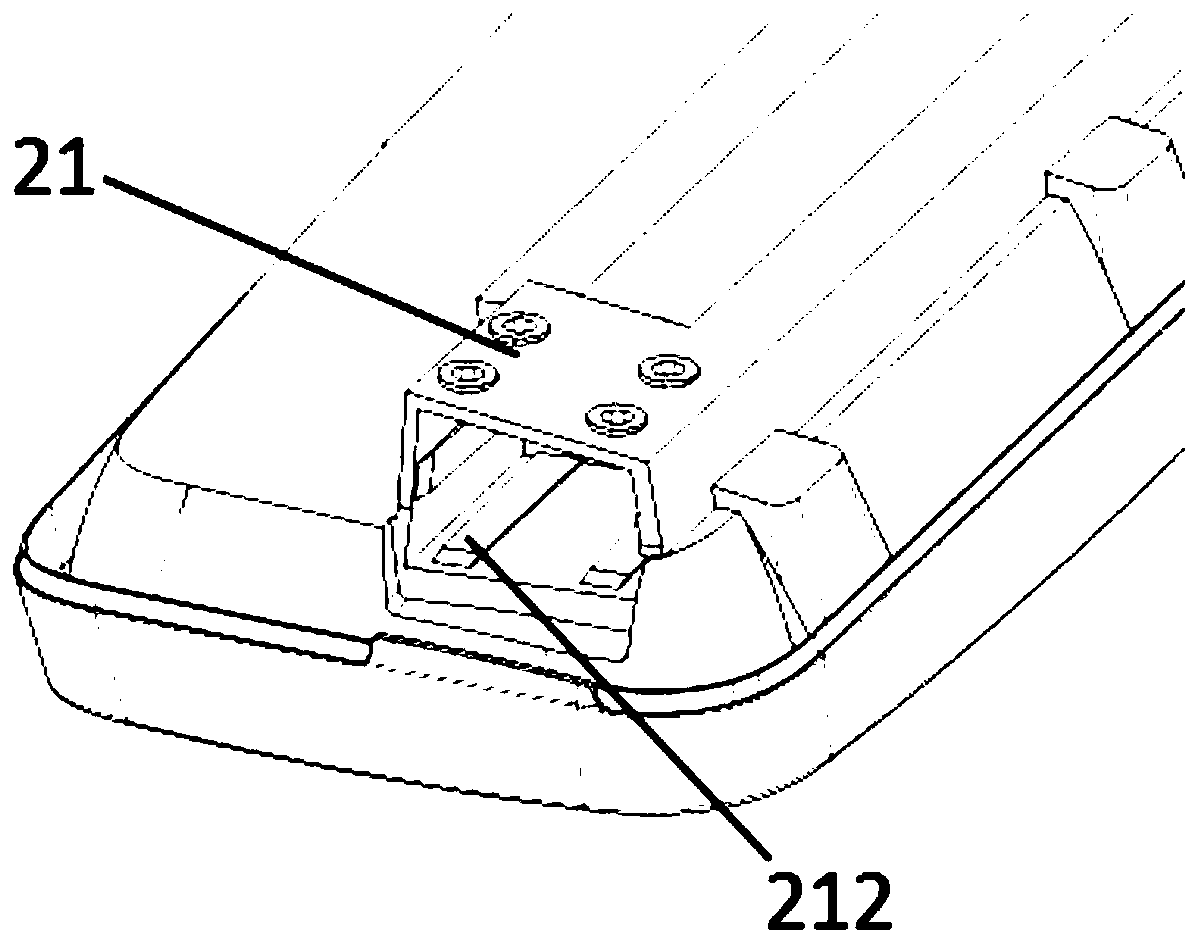

[0044] Wherein, the mirror case 2 and the upper mirror arm 1 and the lower mirror arm 3 are respectively fixed by the upper mirror arm connecting structure 21 and the lower mirror arm connecting structure 23;

[0045] Both the upper mirror arm connecting structure 21 and the lower mirror arm connecting structure 23 include jacks located at the upper and lower ends of the mirror housing 2;

[0046] One end of the upper mirror arm 1 and the lower mirror arm 3 connected to the mirror case 2 is a tubular joint matching with the corresponding socket;

[0047] All between each tubular joint and the matching socket are fastened by means of set screws 4;

[0048] Between the upper mirror arm connecting structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com