Standard operation guidance system for intelligent manufacturing, processing and production, and operation method

A standard operation and guidance system technology, applied in manufacturing computing systems, using information identifiers to retrieve Web data, and other databases, can solve problems such as inaccuracy, complicated assembly steps, and missing parts, and achieve production step optimization , improve product quality, and prevent the effect of taking wrong materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

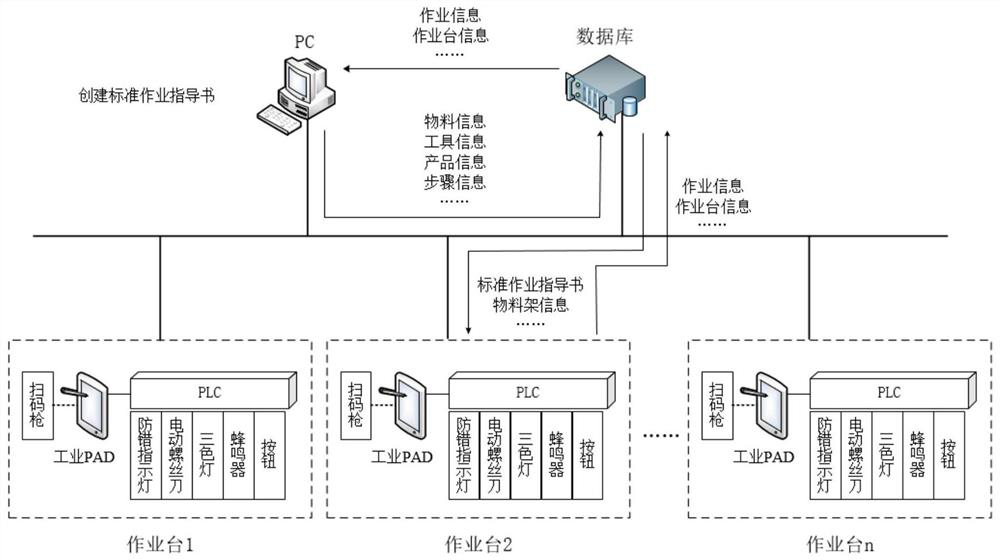

[0023] The system software of the present invention includes a Web terminal, an APP terminal and a workbench, and the Web terminal and the APP terminal communicate through the network. The workbench includes PLC, industrial PAD, code scanning gun, error-proof module, electric screwdriver, three-color lights, buzzer, buttons, etc. Among them, the code-scanning gun is connected to the industrial PAD through USB, and the error-proofing module, electric screwdriver, three The color lamp, buzzer, button and PLC are connected through wiring, and the PLC and industrial PAD are connected through the network, so that the real-time communication between the hardware device and the APP can be realized. The working diagram is as follows figure 1 .

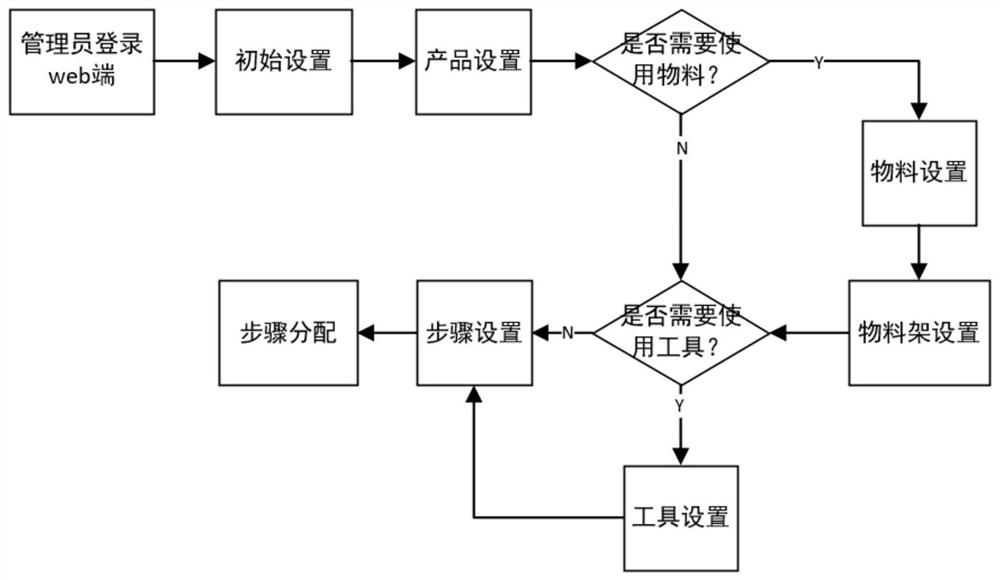

[0024] (1) The process for managers to configure product (P) work instructions on the web is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com