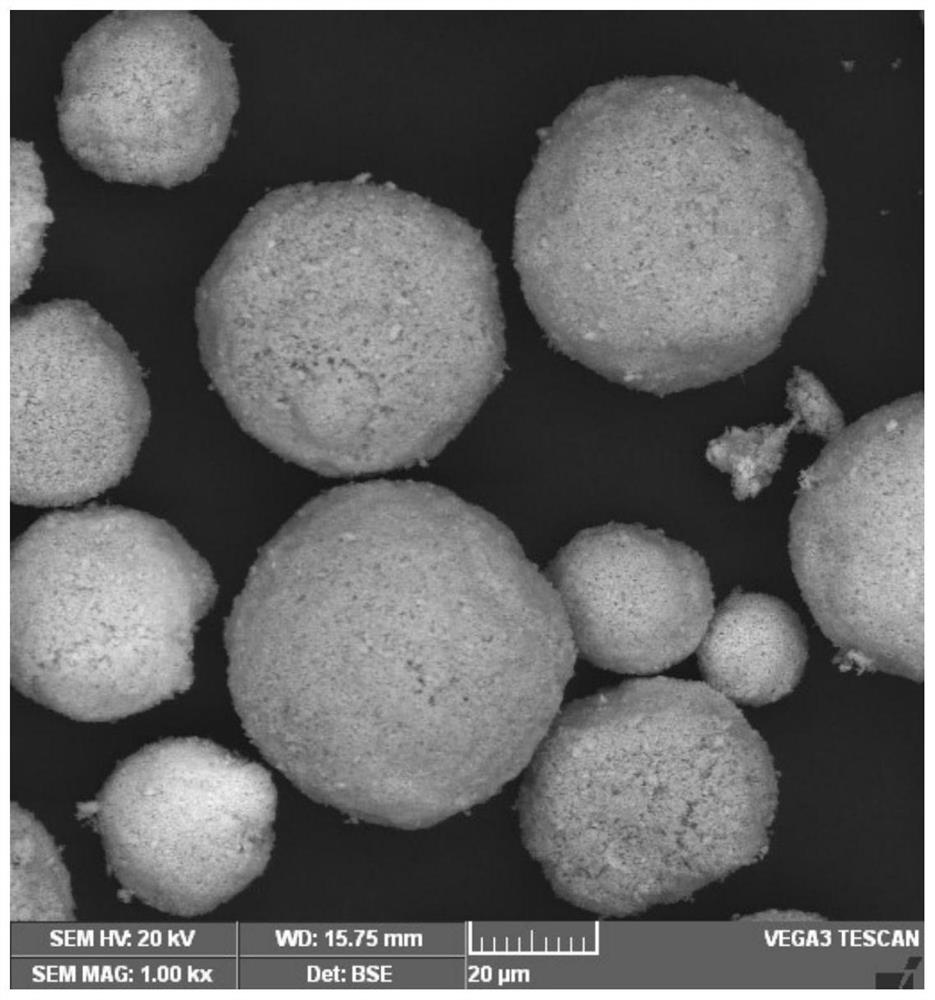

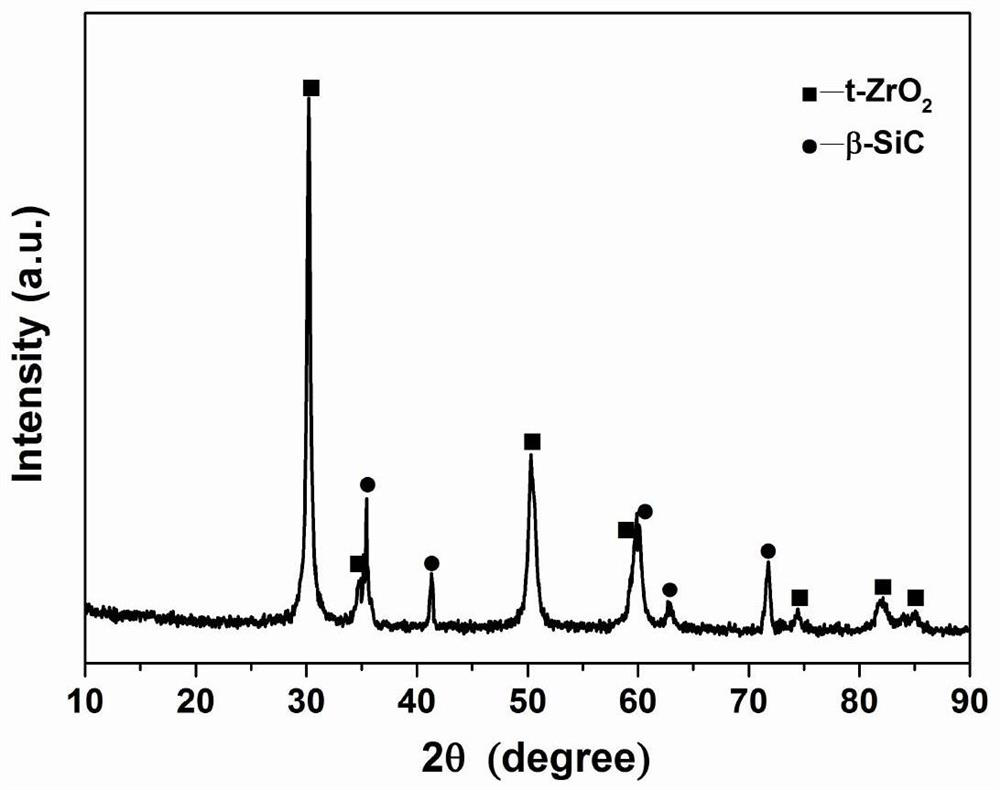

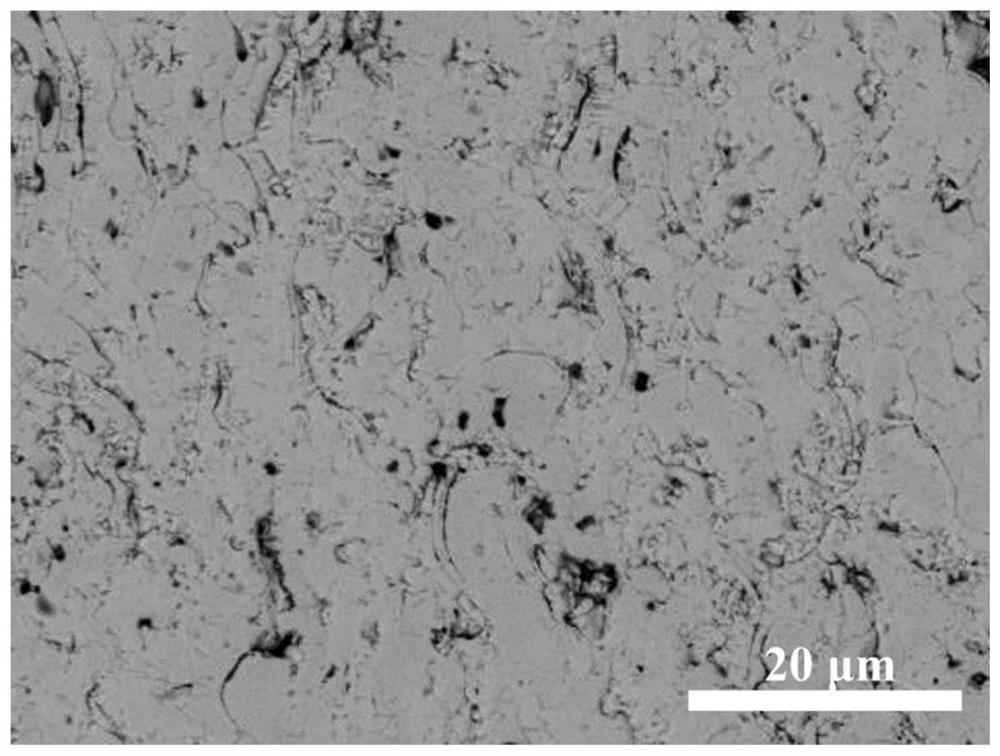

A silicon carbide-calcium oxide stabilized zirconia composite thermal barrier coating and its preparation method

A technology for stabilizing zirconia and thermal barrier coatings, applied in coatings, metal material coating processes, sustainable transportation, etc., can solve problems such as incomplete melting, poor wear resistance, and uneven composition of thermal barrier coatings. Achieve the effect of saving energy, improving wear resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 4, the solution configured in the step 3 and a certain amount of PVA aqueous solution are added to the solution in the step 2. PVA water

Embodiment 2

[0051] Step 4, the solution configured in the step 3 and a certain amount of PVA aqueous solution are added to the solution in the step 2. PVA water

Embodiment 3

[0059] Step 4, the solution configured in the step 3 and a certain amount of PVA aqueous solution are added to the solution in the step 2. PVA water

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com