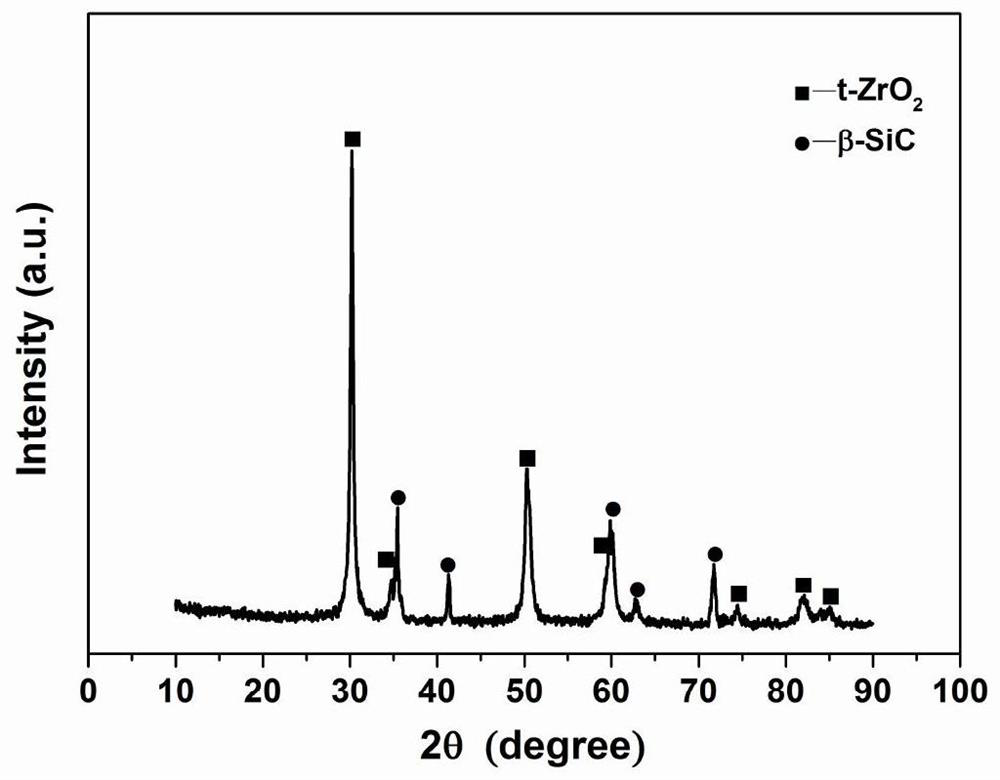

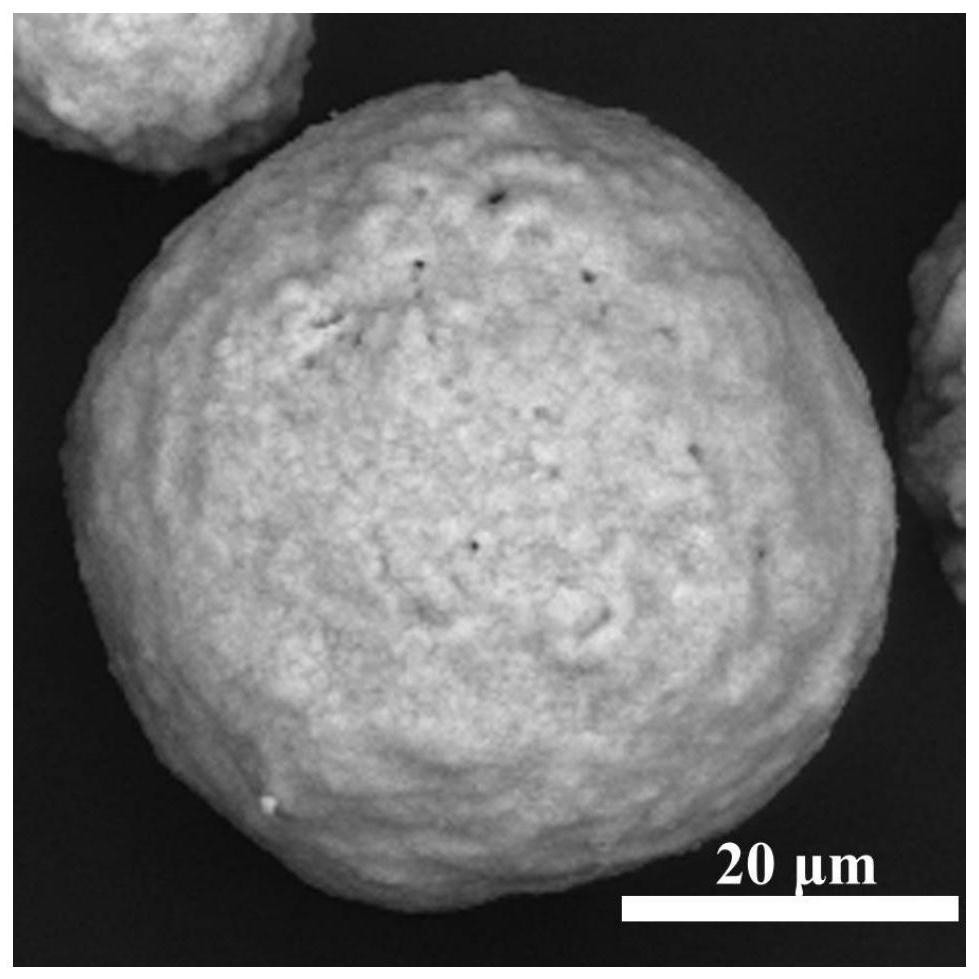

Micro-nano silicon carbide/calcium oxide stabilized zirconia spherical feed and preparation method thereof

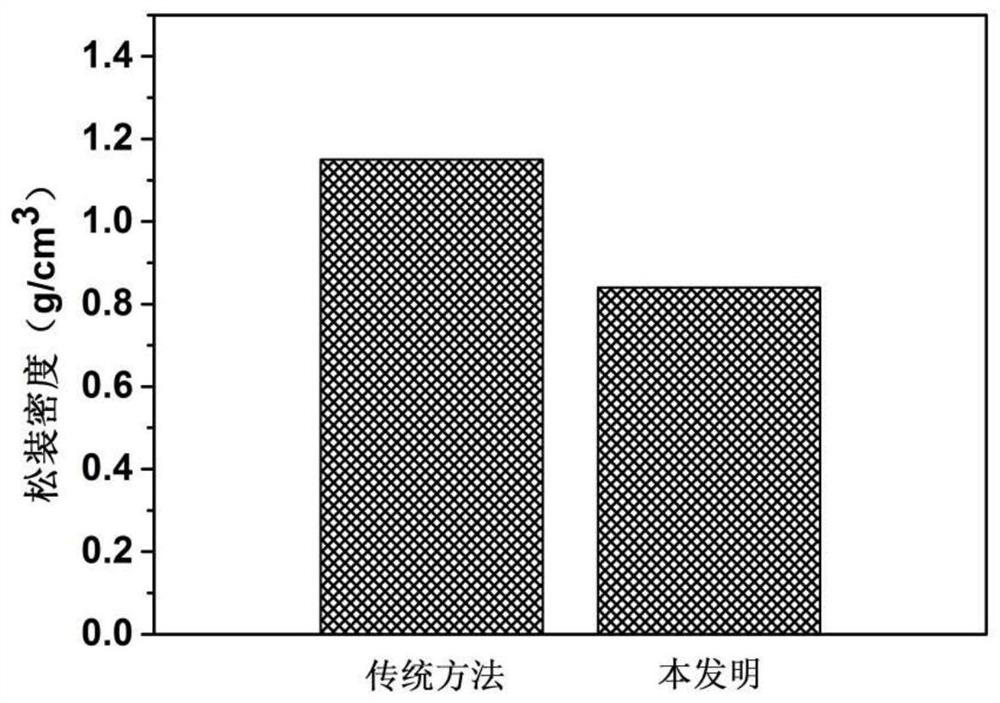

A technology for stabilizing zirconia and silicon carbide, which is used in the field of micro-nano powder, micro-nano silicon carbide/calcium oxide stabilized zirconia spherical feeding and preparation, which can solve the problem of incomplete coating melting, coarse feeding particle size and inconsistent composition. Uniformity and other problems, to achieve the effect of low bulk density, fine powder particle size and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1, configure ZrOCl according to a certain ratio 2 ·8H 2 O / Ca(NO 3 ) 2 4H 2 O mixed solution; the volume of mixed solution is 1000mL, ZrOCl 2 ·8H 2 O / Ca(NO 3 ) 2 4H 2 The mass fraction of O is 30wt.%, Zr 4+ Ca 2+ The molar concentration ratio is 92:8.

[0041] In step 2, excessive ammonia water is added dropwise to the mixed solution in step 1 and continuously stirred to form a white precipitate, and the concentration of ammonia water is 30%.

[0042] Step 3, dissolving a certain amount of polycarbosilane (PCS) in p-xylene solution, the volume of the configuration solution is 300mL, and the mass fraction of polycarbosilane (PCS) is 20wt.%.

[0043] Step 4, adding the solution configured in step 3 and a certain amount of PVA aqueous solution to the solution in step 2, wherein the concentration of the PVA aqueous solution is 5%, and its addition amount is 200mL.

[0044] In step 5, the mixture in step 4 is ball milled in a roller ball mill, the speed of th...

Embodiment 2

[0048] Step 1, configure ZrOCl according to a certain ratio 2 ·8H 2 O / Ca(NO 3 ) 2 4H 2 O mixed solution; the volume of mixed solution is 1000mL, ZrOCl 2 ·8H 2 O / Ca(NO 3 ) 2 4H 2 The mass fraction of O is 50wt.%, Zr 4+ Ca 2+ The molar concentration ratio is 97:3.

[0049] In step 2, excessive ammonia water is added dropwise to the mixed solution in step 1 and continuously stirred to form a white precipitate, and the concentration of ammonia water is 50%.

[0050] Step 3, dissolving a certain amount of polycarbosilane (PCS) in p-xylene solution, the volume of the configuration solution is 500mL, and the mass fraction of polycarbosilane (PCS) is 40wt.%.

[0051] Step 4, adding the solution configured in step 3 and a certain amount of PVA aqueous solution to the solution in step 2, wherein the concentration of the PVA aqueous solution is 10%, and the added amount is 300mL.

[0052] Step 5, the mixture in step 4 is ball milled in a roller ball mill, the speed of the rol...

Embodiment 3

[0056] Step 1, configure ZrOCl according to a certain ratio 2 ·8H 2 O / Ca(NO 3 ) 2 4H 2 O mixed solution; the volume of mixed solution is 1000mL, ZrOCl 2 ·8H 2 O / Ca(NO 3 ) 2 4H 2 The mass fraction of O is 35wt.%, Zr 4+ Ca 2+ The molar concentration ratio is 96:4.

[0057] In step 2, excessive ammonia water is added dropwise to the mixed solution in step 1 and continuously stirred to form a white precipitate, and the concentration of ammonia water is 42%.

[0058] In step 3, a certain amount of polycarbosilane (PCS) is dissolved in p-xylene solution, the volume of the solution is 350 mL, and the mass fraction of polycarbosilane (PCS) is 35 wt.%.

[0059] Step 4, adding the configured solution in step 3 and a certain amount of PVA aqueous solution to the solution in step 2, wherein the concentration of the PVA aqueous solution is 9%, and its addition amount is 240mL.

[0060] Step 5, the mixture in step 4 is ball milled in a roller ball mill, the speed of the roller b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com