Plant straw pellet feed production equipment

A technology for pellet feed and production equipment, applied in feed, cutting equipment, food science and other directions, can solve the problems of incomplete straw crushing, affecting feed quality, lack of filtration and screening, etc., to optimize production steps, improve production quality, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

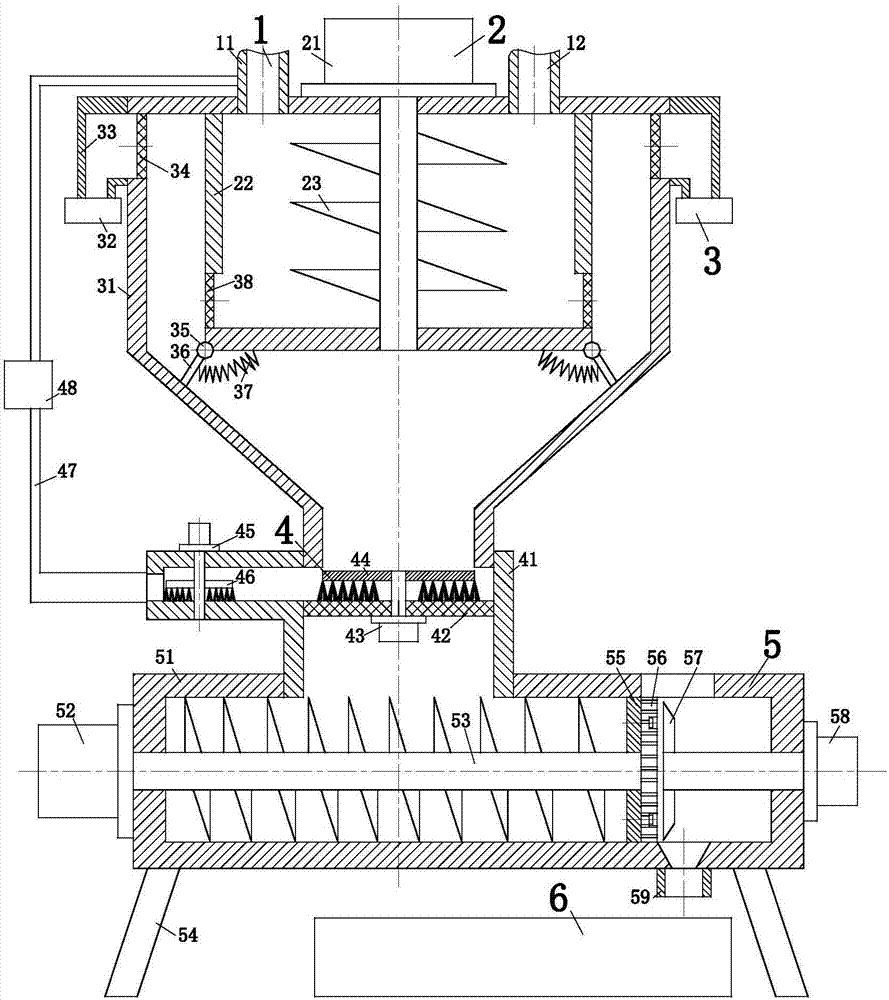

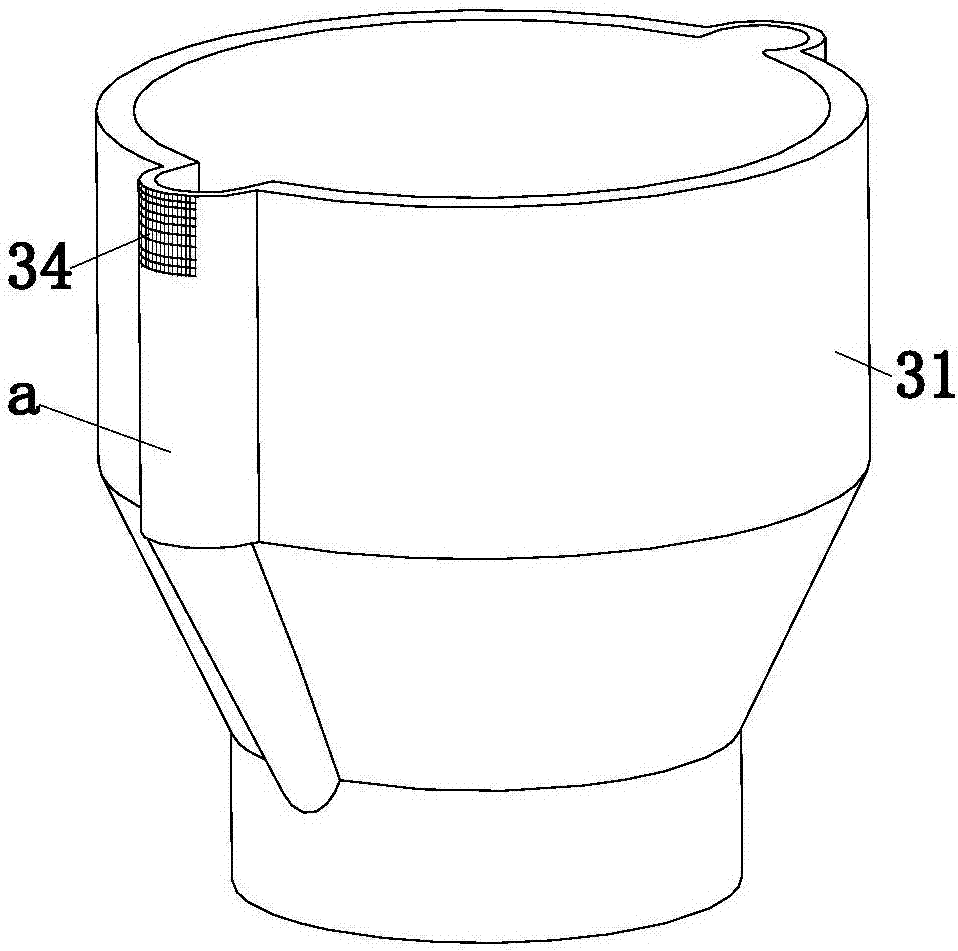

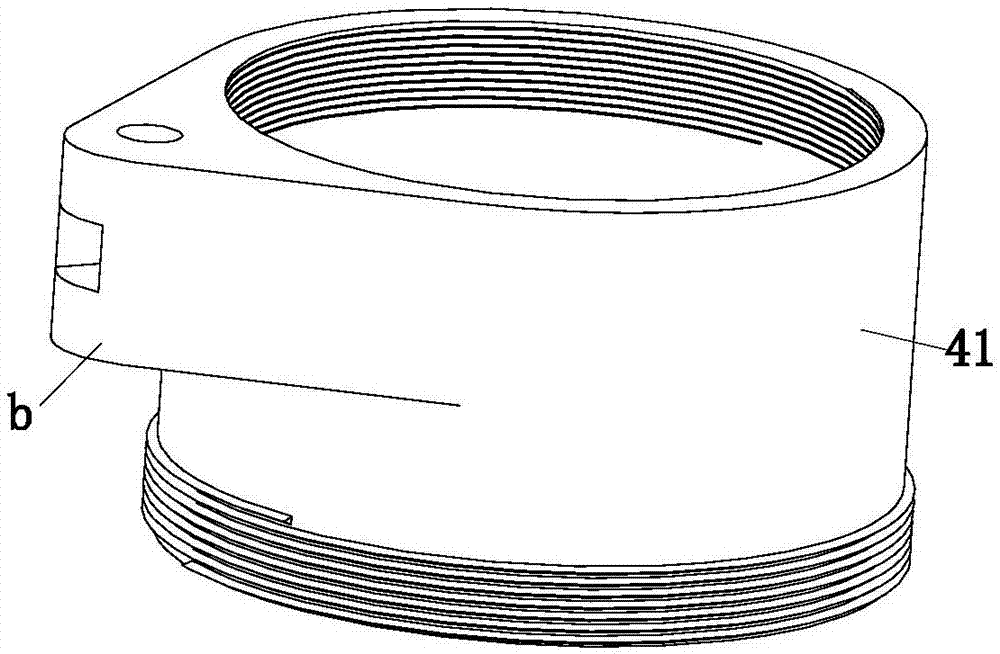

[0025] like Figure 1-5 As shown, a plant straw pellet feed production equipment described in the present invention is mainly suitable for processing straw-like plant feed pellets with relatively thick fibers, including a feeding system 1, a stirring and crushing system 2, a primary filtration system 3, a secondary Filtration system 4, forming system 5 and carrier 6. The feeding system 1 includes a straw feeding port 11 for conveying straw raw materials and an auxiliary material transferring port 12 for auxiliary material transfer. The straw feeding port 11 and the auxiliary material transferring port 12 are both It is connected with the stirring and crushing system 2; the stirring and crushing system 2 is used for crushing straw raw materials, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com