Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Novel technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

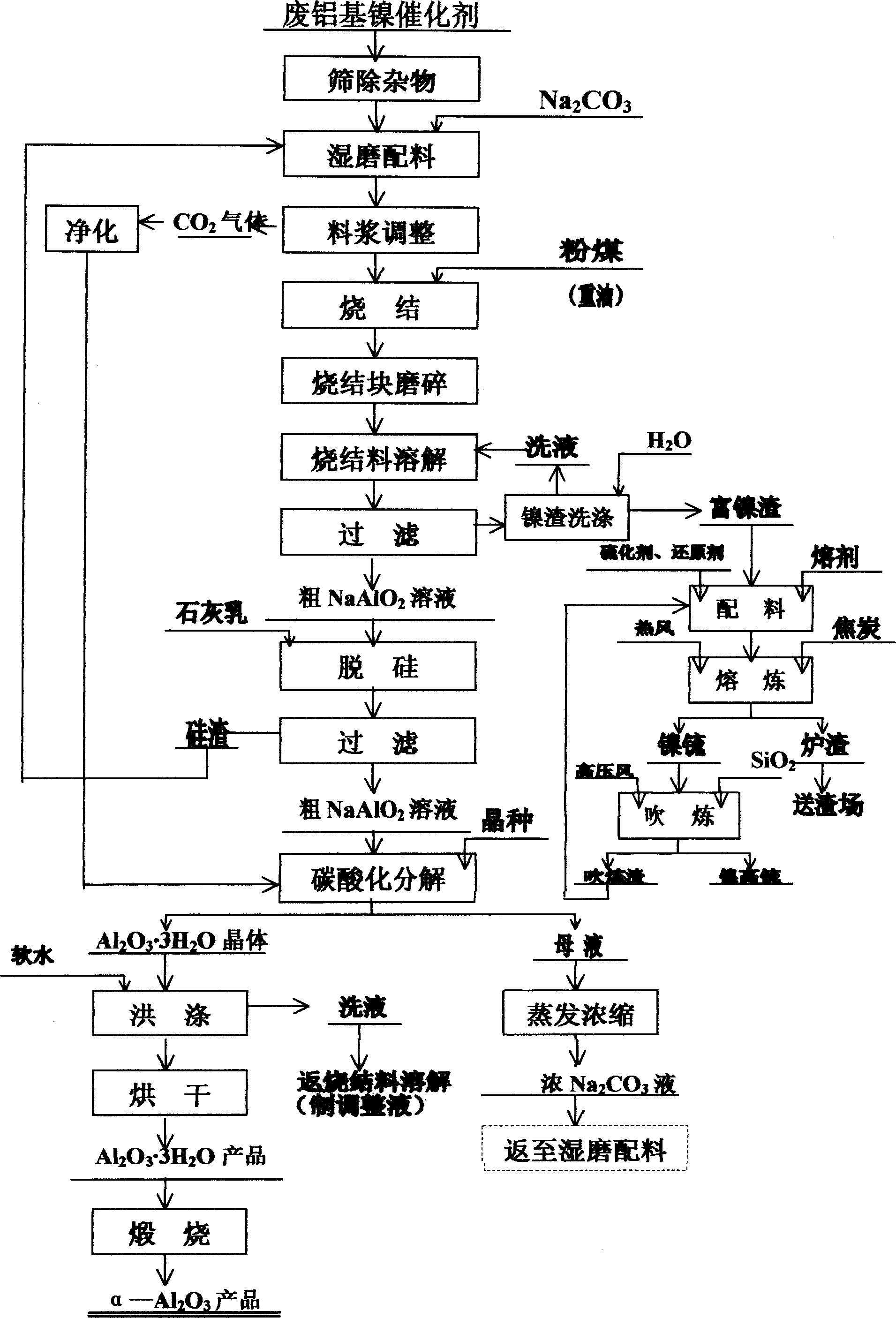

Method for recovering nickel and aluminum from waste aluminum based nickel-containing catalyst

InactiveCN1544666AEfficient separationEfficient recyclingProcess efficiency improvementDecompositionSodium aluminate

The invention is a method of recovering nickelic and aluminum from waste aluminum-based nickel catalyst, it has the characters of novel technique, reasonable flow, simple and convenient method and easy operation, and convenient scaled production, and benefits environmental protection. It includes the steps: sodium carbonate sintering and state-changing--boiling water dissolving sodium aluminate and separating aluminum--- making reducing-matte-making melting on nickel residues to obtain nickel matte Ni3S2-FeS-Ni-Fe alloy or copper-nickel matte Cu2S-Ni3S2-FeS alloy---blowing to obtain high-grade nickel matte Ni3S2 or high-grade copper-nickel matte Cu2S-Ni3S2-Cu-Ni alloy---desiliconizing crude NaAlO2 solution---making carbonated decomposition to obtain aluminum hydrate Al2O3íñ3H2O---calcining to obtain anhydrous aluminum oxide alpha-Al2O3. It is suitable to recover nickel and aluminum from the waste residue generated by extracting molybdenum and vanadium from waste aluminum-based nickelic catalysts and disabled catalysts containing nickel, aluminum, molybdenum and vanadium.

Owner:SHENYANG JIAHE METALLURGICAL FURNACE CHARGE

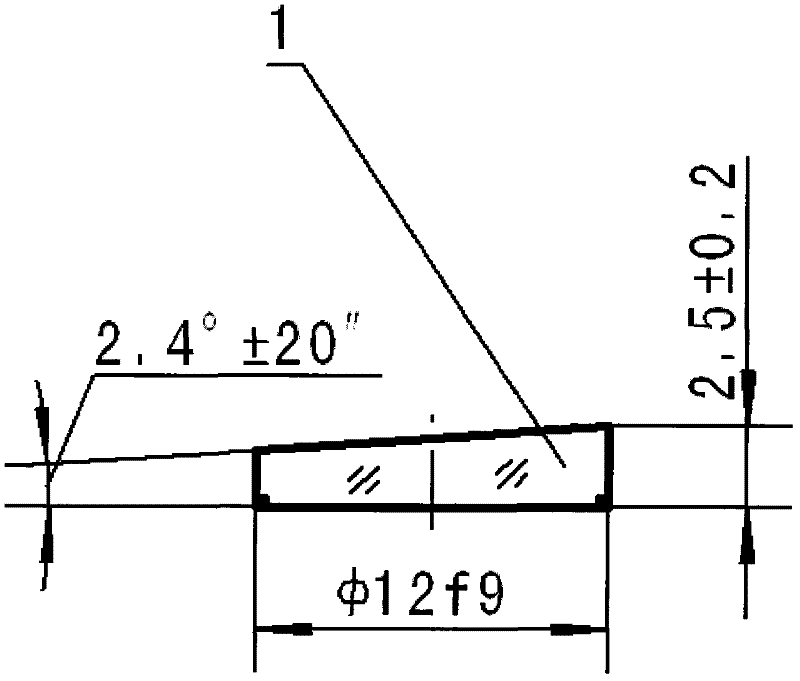

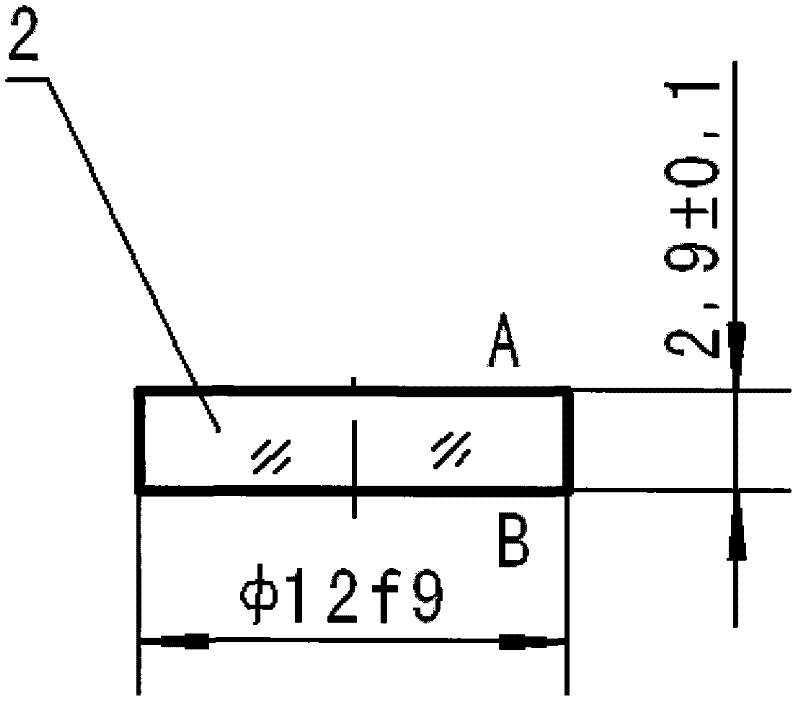

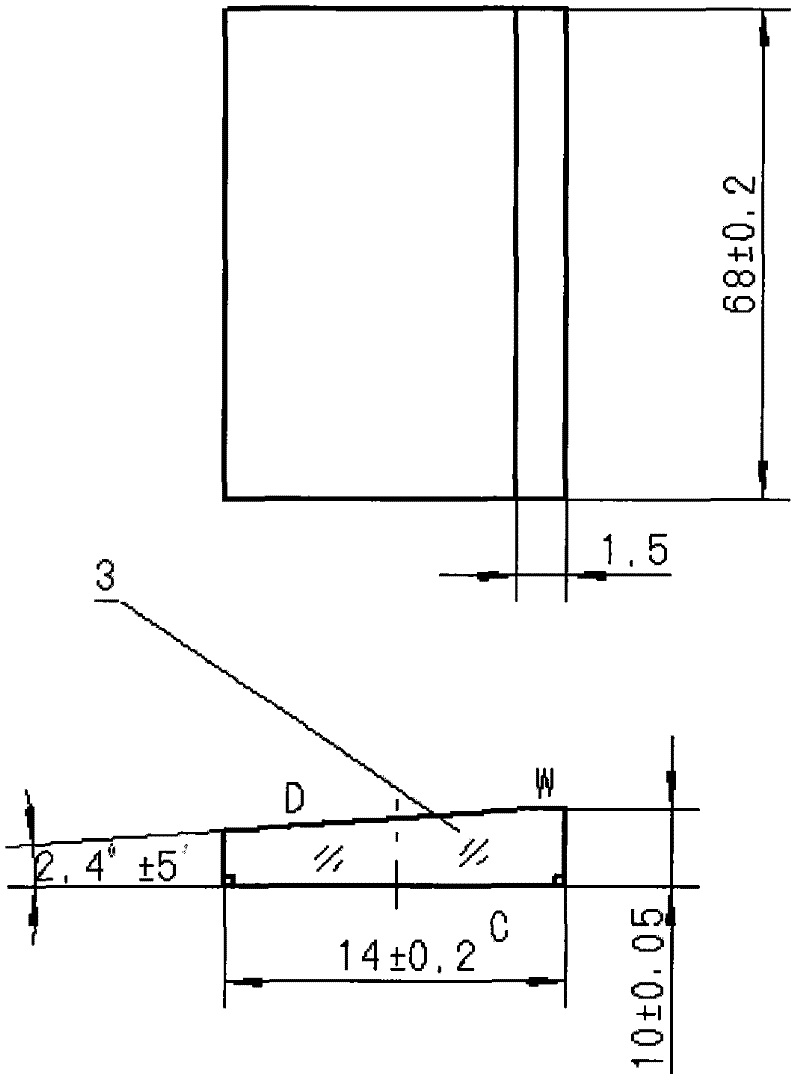

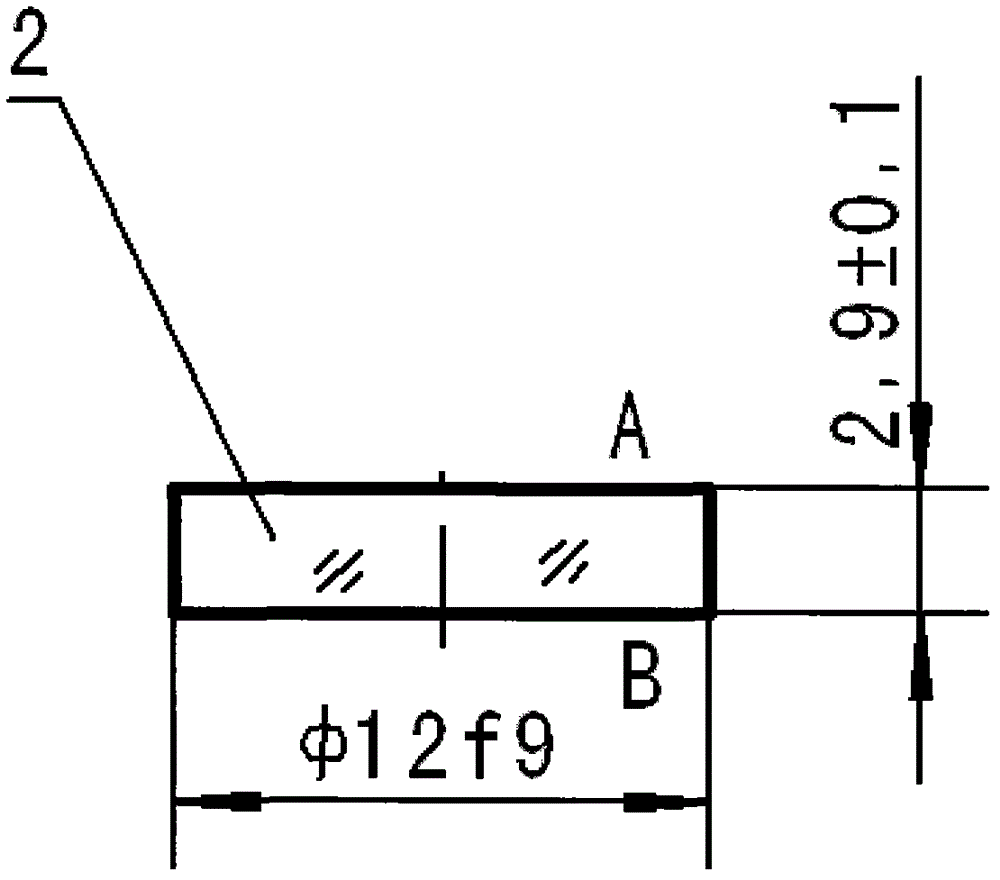

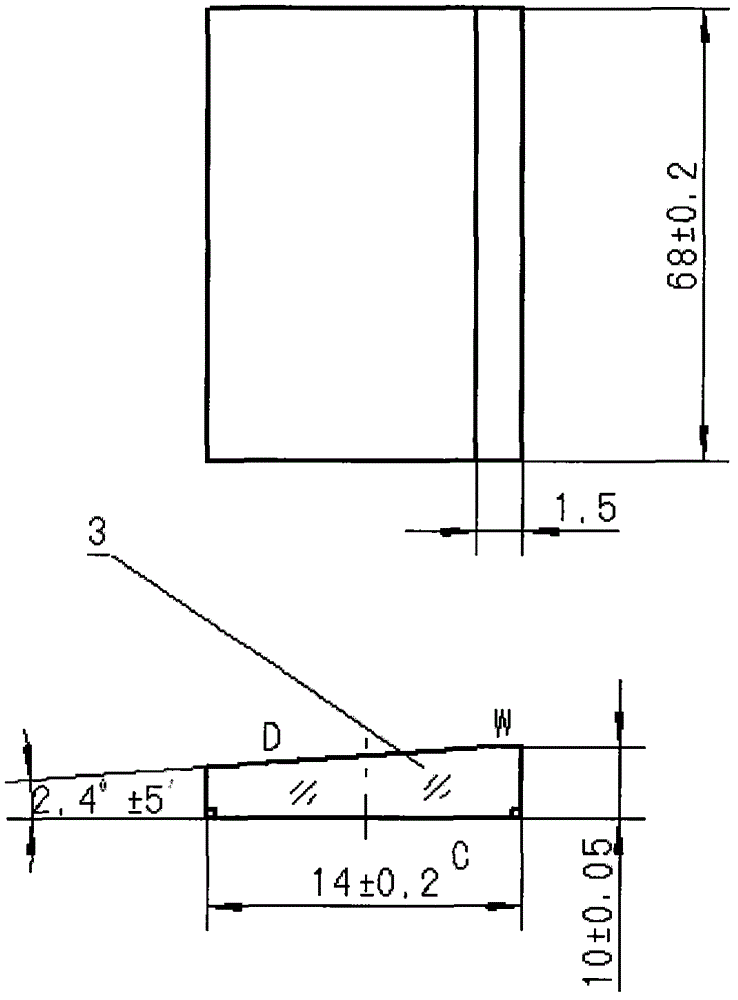

Manufacturing method of wedge-shaped lens

ActiveCN102229082ANovel technologyUnique process methodOptical surface grinding machinesOptical processingEngineering

The invention discloses a manufacturing method of a wedge-shaped lens, belonging to the technical field of optical cold processing. The manufacturing method comprises the specific steps of: manufacturing a wedge-shaped lens blank and a high-precision glass clamp by adopting a conventional optical processing technology so as to ensure that a first guide through face of the wedge-shaped lens as well as the surface shape and the surface defects of the wedge-shaped glass clamp meet formulated requirements; optically cementing the first light through face of the wedge-shaped lens onto the inclined surface of the wedge-shaped glass clamp which is already optically cemented onto a parallel planer optical cementing base plate, carrying out fine grinding and polishing on a second light through face of the wedge-shaped lens, and obtaining the wedge-shaped lens with second-level precision by controlling the thickness, the parallel difference and the surface shape precision of the second light through face and the parallel planer optical cementing base plate. The manufacturing method for machining the wedge-shaped lens, disclosed by the invention, not only has a simple process, strong operability and a greatly-prolonged manufacturing period, but also is easy to ensure the single-batch finished product ratio of wedge-shaped lens parts with small sizes, large angles and second-level precision and overcomes the difficulties of unstable quality, low efficiency and low finished product ratio in the conventional processing method.

Owner:CHINA NORTH IND NO 205 RES INST

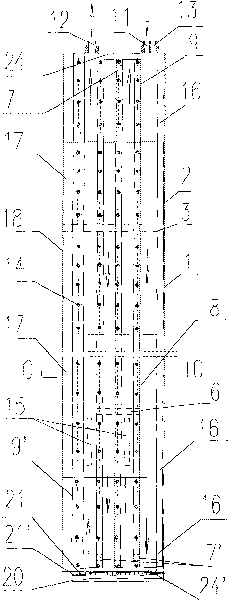

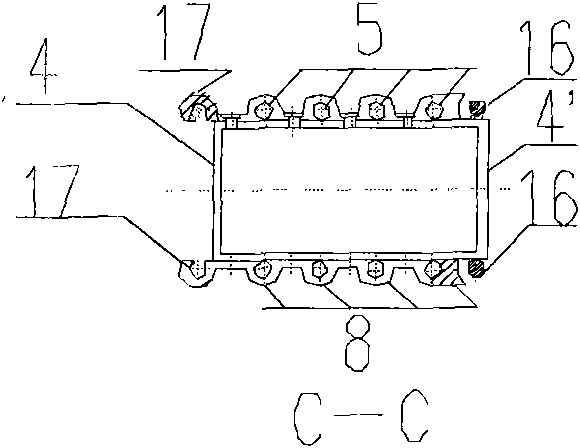

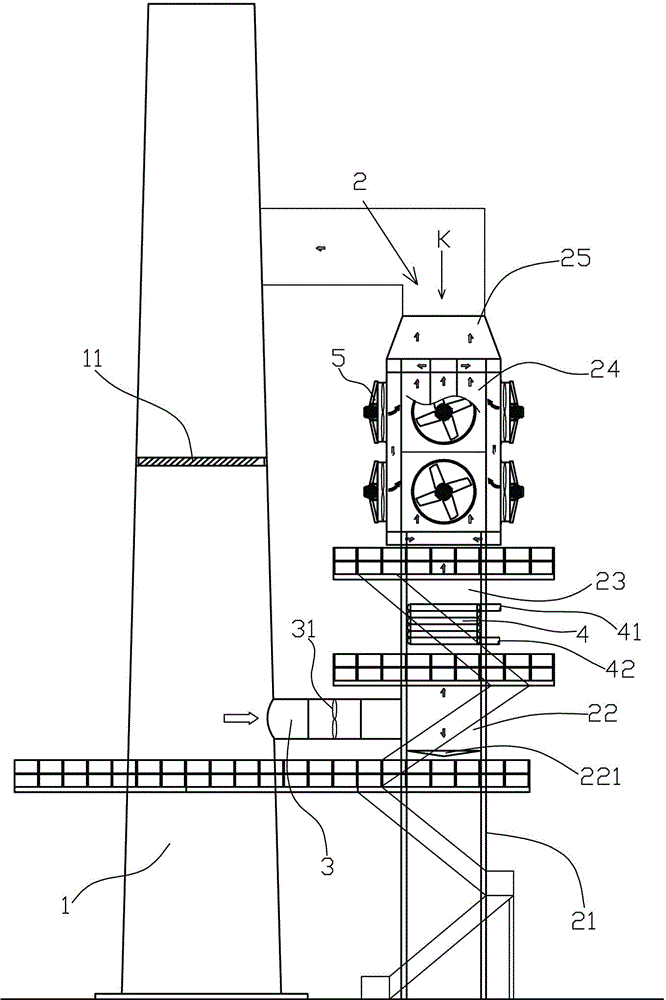

Automatic wall-forming device and method of static pressure continuous concrete wall

ActiveCN101718099AEasy constructionPrevent leakageArtificial islandsUnderwater structuresSlurry wallReinforced concrete

The invention belongs to the technical field of buildings, relating to an automatic wall-forming device and method of static pressure continuous concrete wall used for anti-seepage, water interception and retaining occasions such as deep foundation pit, tunnel and riverbank; the existing full hydraulic static pile machine is used as a host machine; two automatic wall-forming device combinations mutually associated and respectively independently moved having wave-shaped sections can be clamped simultaneously; the surface shape of the wave-shaped plate and the rectangle inside casing are used as references, and the two short outer edges thereof are respectively provided with connectors having specific guiding limit function; the automatic wall-forming device provided with a double-open type valve at the end part thereof is internally pre-hung with a steel reinforcement cage; concrete is filled sequentially, and the wall-forming device is pressed into a preset thickness of soil layer one by one; one of the wall-forming device combination is lifted, and simultaneously a high frequency vibrator installed in a wave-shaped body is started; a reinforced concrete unit wall sections are formed by vibrating and lifting the wall-forming device; and the device and method has novel technology, good environmental protection effect, reliable quality, high bearing capacity, board applicability and short construction period.

Owner:QINGDAO JINGLI ENG

Preparation process of large titanium alloy air inlet for missiles

InactiveCN108465780ASolve technical bottlenecksSolve the deformationFoundry mouldsFoundry coresMicrometerMold filling

The invention relates to a preparation process of a large titanium alloy air inlet for missiles. The preparation process cannot be realized by adopting the production of conventional equipment of graphite type titanium alloy castings and a traditional titanium alloy casting technique. The graphite coating scheme of the preparation process is adopted, and the advantages of titanium alloy investmentcasting are combined, so that the mold filling integrity of missile castings is effectively guaranteed, the surface roughness of the missile titanium alloy castings can reach 6.3 micrometers, and thefeasible titanium alloy casting technique of the missile castings is realized. By adopting the laser welding scheme of the preparation process, the feasibility of an air inlet opening casting technique is realized, and internal cracks of an air inlet mold cavity are effectively avoided.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Method for utilizing waste hydro-treatment catalyst

ActiveCN103769173APhysical properties (lower than surfaceLow pore volumeOrganic compound preparationCarbonyl compound preparationPartial oxidationAcrolein

The invention discloses a method for utilizing waste hydro-treatment catalyst. The method utilizes waste hydro-treatment catalysts which have been used in partial oxidation of propane to prepare acrolein and hydro-treatment, recycles the Mo, Co, Ni, and alumina carriers in waste hydro-treatment catalysts, also fully recycles Ni and V which are deposited on the waste hydro-treatment catalysts, thus solves the pollution problem caused by waste catalysts, saves the resources, increases the economic profit, and is easy to carry out in technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

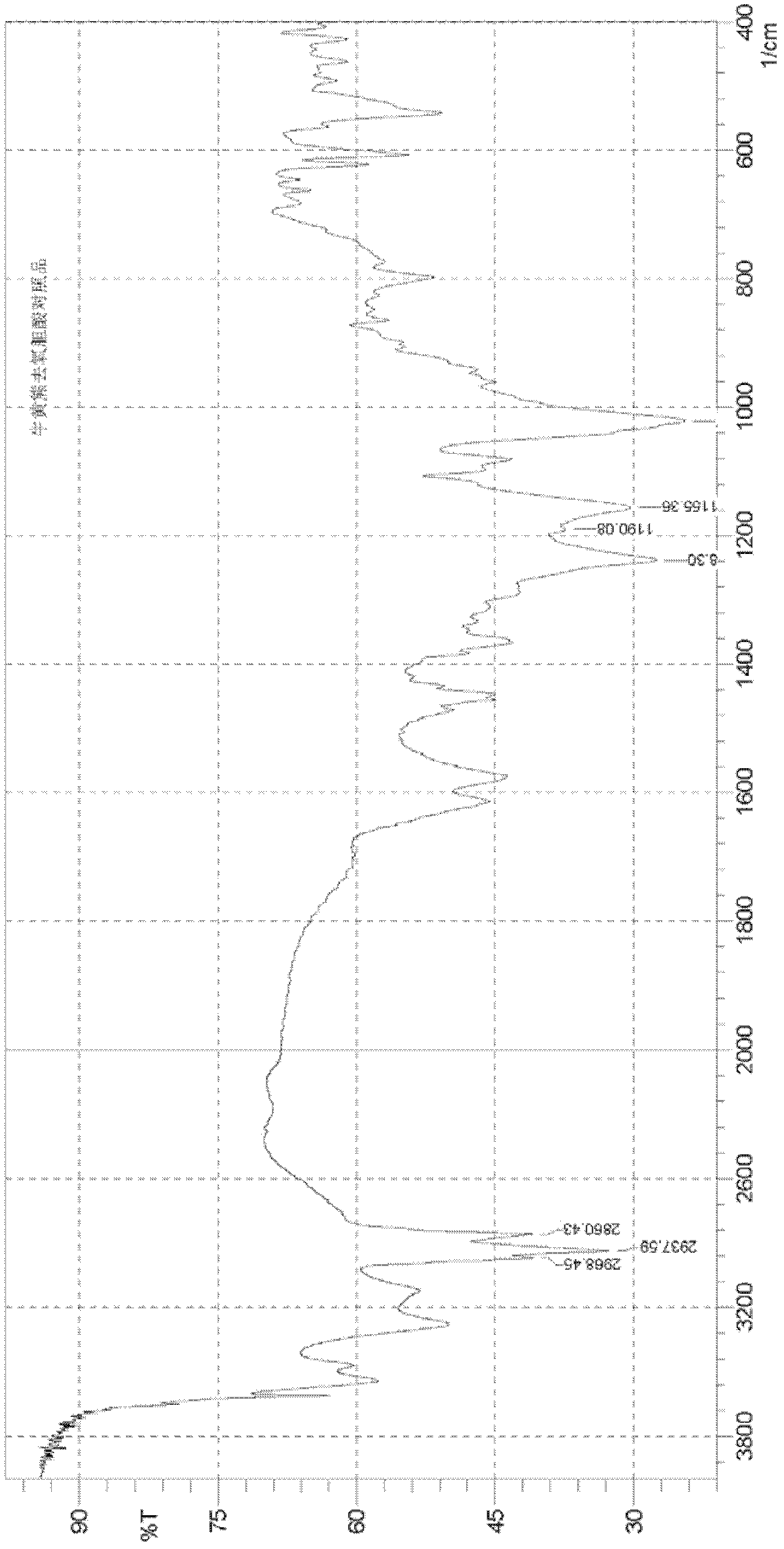

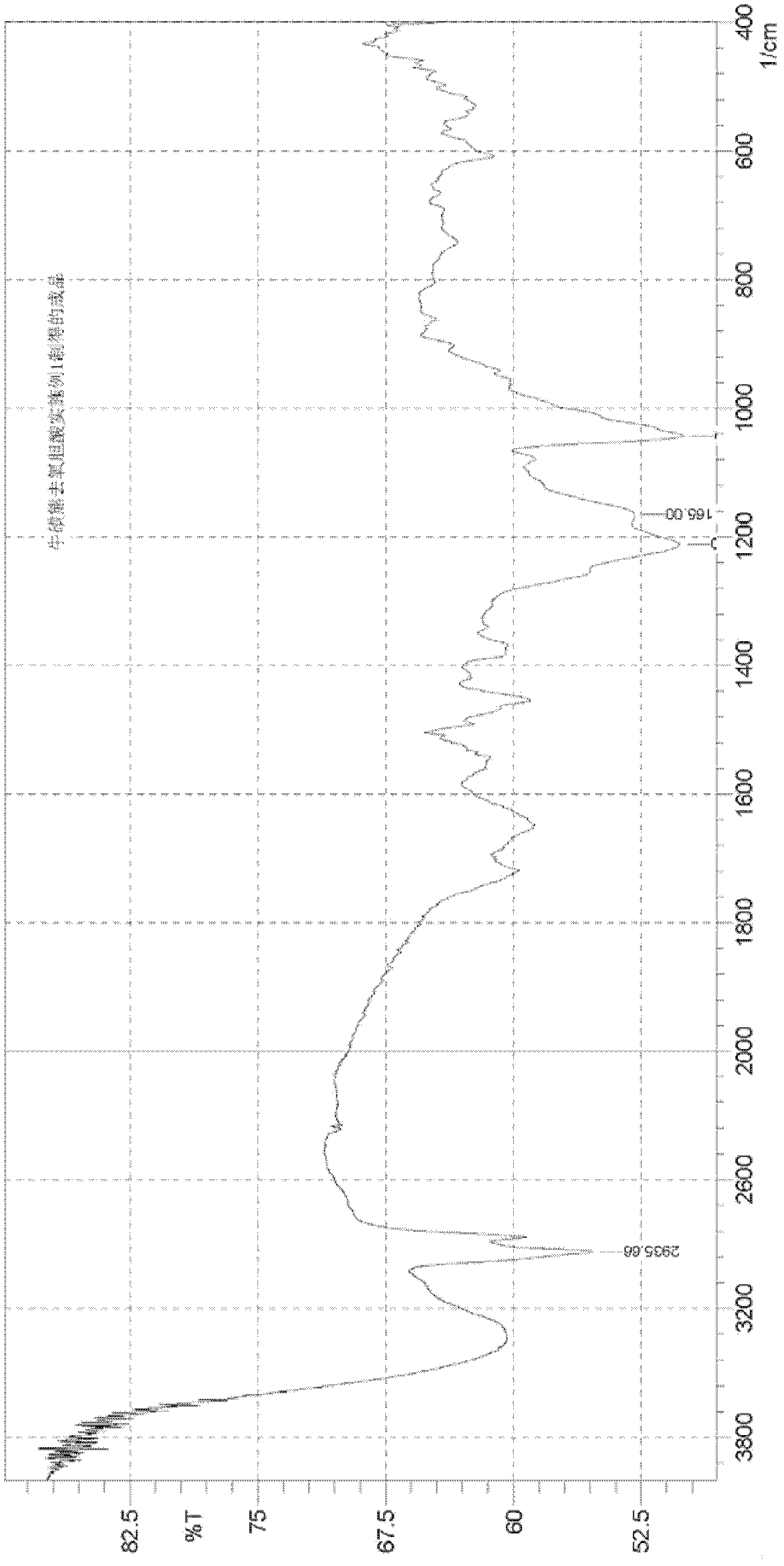

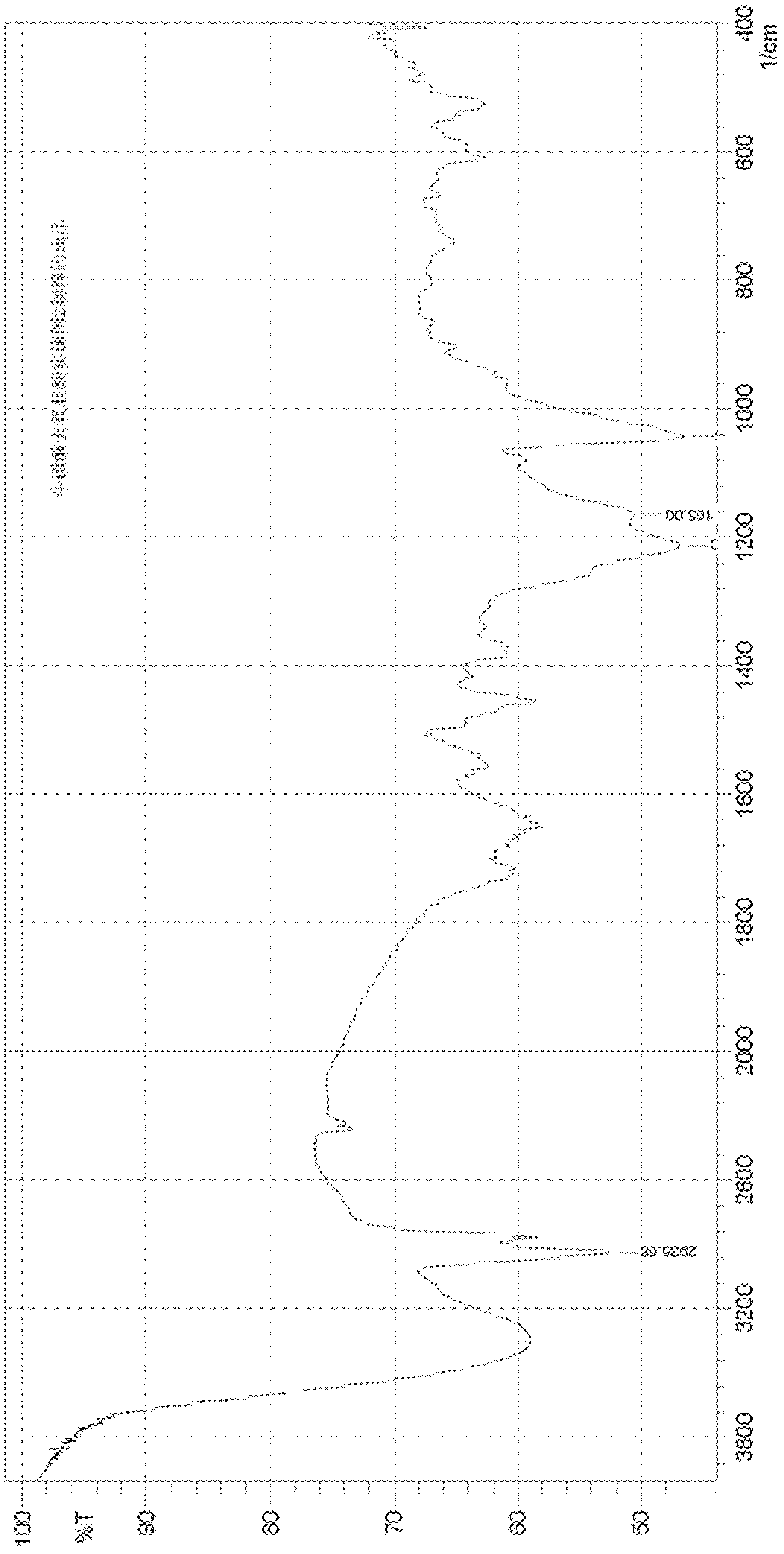

Preparation method of tauro ursodesoxy cholic acid

The invention discloses a preparation method of tauro ursodesoxy cholic acid. The method comprises the following steps: firstly, dissolving ursodesoxycholic acid in organic solvent, reducing the temperature of the ursodesoxycholic acid to 0 to 10 DEG C, adding amine compounds into the ursodesoxycholic acid, and stirring the ursodesoxycholic acid; secondly, adding condensing agent and 4-dimethylamino pyridine after stirring in the first step, and performing stirring reaction at room temperature, obtaining reaction liquid A; thirdly, adding the reaction liquid A obtained in the second step into sodium taurocholate salt water solution, and dropwise adding triethylamine at room temperature while stirring so as to ensure that the triethylamine is reacted with the reaction liquid A; and fourthly, adding methylene dichloride to perform extraction and liquid separation after the reaction in the third step, then washing a water layer through methylene dichloride, adjusting the pH value after washing, performing concentration after stirring, and then obtaining the tauro ursodesoxy cholic acid. The preparation method has the advantages that the tauro ursodesoxy cholic acid is prepared through a novel technical process, the reaction speed is high, the product quality is high, and raw material is cheap.

Owner:山东天绿制药有限公司 +1

Technological process of fish oil low-temperature the smell of fish removing

InactiveCN101253952AThe inner structure is not destroyedSolve the problem of destroying the inner structure of fish oilEdible oils/fatsFood preparationHazardous substanceFish oil

The invention provides a method for removing a fishy smell from fish oil at a low temperature, belongs to the animal oil finery processing technology field, and aims to solve the problem that the prior method for removing the fishy smell from the fish oil at a high temperature can destroy the inner structure of the fish oil. The method for removing the fishy smell from the fish oil at a low temperature comprises the steps of mixing ethyl ester fish oil, glycerin and lipase in a hermetically sealed reaction vessel; subjecting the mixture to enzyme catalyzed interesterification; adding a fragrant fishy smell removing agent, the weight of which accounts for 0.1%-0.2% of that of ethyl ester; stirring for reaction for 24-33hr with pressure of 100-11300Pa in the vessel at the temperature of 60-80 DEG C; terminating the reaction; nitrogen filled packing after inspection; and refining to get the fish oil free of fishy smell. The method with significant effect of removing the fishy smell does not produce trans-fatty acid and polymerized hazardous substances, such as ketone and aldehyde, is applicable to manufacturing triglyceride fish oil by removing the fishy smell from the ethyl ester fish oil, and processing and refining other fish oil by removing the fishy smell.

Owner:河北康睿达脂质有限公司

Preparation method of sodium carboxymethyl starch with superhigh viscosity

The preparation method of ultra-high viscosity sodium carboxymethyl starch belongs to the modified starch technology; the method steps are: starch and ethanol solution are made into starch milk in a reactor, and the starch milk is processed by using NaOH twice put into the reactor. Alkalinization, then put the cross-linking agent into the reactor for cross-linking reaction, put chloroacetic acid into the reactor twice to react for 2-3h, after the reaction, neutralize the pH=7 with HCl, centrifuge and wash with ethanol solution , centrifugal separation, and drying to obtain the product; the method is novel and reasonable, and the obtained sodium carboxymethyl starch has high viscosity, good transparency, strong stability and wide application range.

Owner:吴也平 +1

Waste hydrogenation catalyst utilization method

ActiveCN106944137AIncrease profitImprove pore structureOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsHeteropoly acidFurfural

The present invention discloses a waste hydrogenation catalyst utilization method, which comprises: grinding a waste hydrogenation catalyst, soaking with ammonia water, adding alumina, a binder and an acid solution to the remaining solid, and carrying out mixing kneading molding; carrying out reducing treatment with hydrogen gas in a high pressure reaction kettle; adding a polyol and / or furfural solution to the high pressure reaction kettle, and carrying out a hydrogenation reaction; and drying the material obtained after the reaction until the surface is liquid-free, sequentially contacting an organic acid, ammonium or ammonia, and loading a heteropoly acid to produce the catalyst for ethylene preparation through ethanol dehydration. According to the present invention, with the method, the hydrogenation activity metal component and the carrier component in the waste hydrogenation catalyst are utilized, and the hydrogenation activity of the waste hydrogenation catalyst is completely utilized, such that the utilization rate of the waste catalyst is improved, the pollution problem of the waste catalyst is solved, and the obtained catalyst for ethylene preparation through ethanol dehydration has the excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

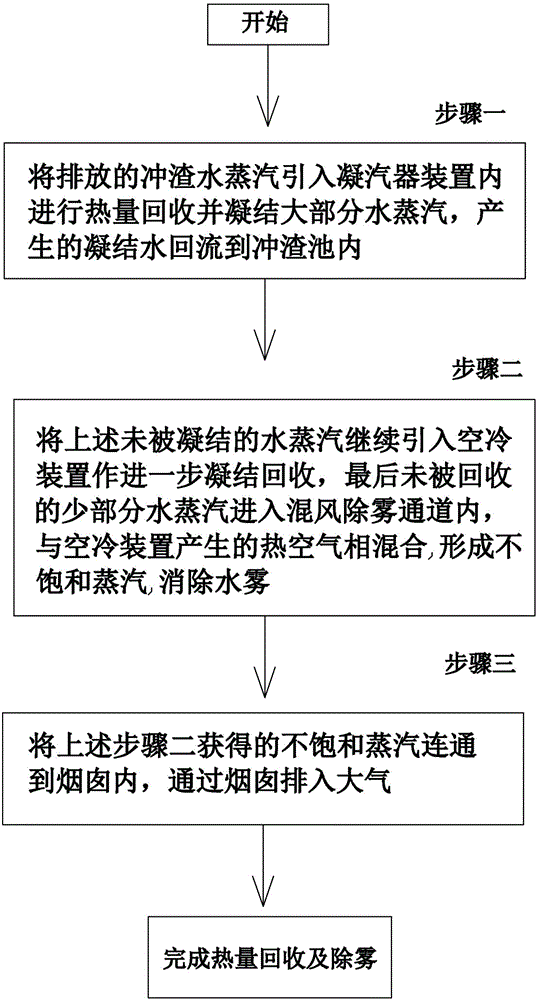

Process for recycling waste heat of slag flushing water vapor and dispersing fog and equipment adopted in same

ActiveCN104087691AAchieve modularityReduce investmentSteam/vapor condensersSteam condensationWater vapor

The invention discloses a process for recycling waste heat of slag flushing water vapor and dispersing fog and equipment adopted in the same. The process comprises the following steps: (1), introducing slag flushing water vapor into a waste heat-recycling and fog-dispersing tower, condensing part of the water vapor by virtue of a water vapor condenser, and recycling latent heat of water vapor; (2), continuously introducing the uncondensed vapor into an air cooling device, condensing and recycling condensed water, conveying the rest of un-recycled vapor into an air-mixing and fog-dispersing channel, and mixing the reset of un-recycled vapor with hot air produced by the air cooling device to form unsaturated vapor, so that water fog is dispersed; (3), exhausting the obtained unsaturated vapor into atmosphere. The process adopted in the invention is novel and unique, and outstanding in effect; the adopted equipment is compact in structure, small in floor area, modularized in design, beneficial to installation, maintenance and cost decrease; meanwhile, in a practical production process, heat of most of water vapor can be recycled, and water fog pollution can be eliminated, so that not only can good economic benefits be generated, but also requirement of protecting the environment is achieved.

Owner:福建立宜信科技股份有限公司

Preparation method of catalyst for oxidative hydrogenation of propane

ActiveCN103769136APhysical properties (lower than surfaceLow pore volumeHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidResource utilization

The invention discloses a preparation method of a catalyst for oxidative hydrogenation of propane. The method comprises the following steps: grinding waste residual oil desulfurization catalysts into powder, adding a strong inorganic acid into the powder, filtering, adding an organic acid into the filtrate, then adding pseudo-boehmite, stirring the solution and heating at the same time until the solution is totally evaporated so as to obtain a solid substance, and then subjecting the solid substance to processes of drying, burning, and forming so as to obtain the catalyst for oxidative hydrogenation of propane. The preparation method fully utilizes the waste residual oil hydro-desulfurization catalysts, improves the resource utilization rate, and greatly reduces the cost; furthermore, the obtained catalyst has a large specific surface area, the active metal is highly dispersed on the catalyst surface, thus the utilization rate of active metal is improved, so the catalytic activity and selectivity of the catalyst are both improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing high-purity auramine O

ActiveCN103146219AHigh puritySolve the problem of high-purity auramine ODiarylmethane dyesOrganic solventDistillation

The invention discloses a process for preparing high-purity auramine O. The process is characterized in that the process concretely comprises the following steps: 1, adding a crude auramine O raw material to an organic solvent at 20-40DEG C, uniformly stirring, and maintaining the temperature for 2-8h, wherein the weight of the organic solvent is 5-10 times the mass of auramine O; 2, carrying out reduced pressure suction filtration of the obtained mixture, pressing the obtained filter cake to dryness, carrying out reduced pressure distillation of the obtained mother solution, and recovering the organic solvent which can be recycled; 3, adding a solid obtained after the reduced distillation concentration of the mother solution to an another organic solvent, and stirring for 1-2h, wherein the weight of the another organic solvent is 1-3 times the weight of the solid; and 4, carrying out reduced pressure suction filtration of a mixture obtained in step 3, washing the obtained filter cake with the another organic solvent 1-3 times, carrying out suction drying of the filter cake, and drying to obtain the high-purity auramine O, wherein the weight of the another organic solvent is 0.5-1 times the weight of the solid. The process successfully solves the high purity auramine O preparation problem.

Owner:SHANGHAI JINGCHUN BIOCHEM TECH CO LTD

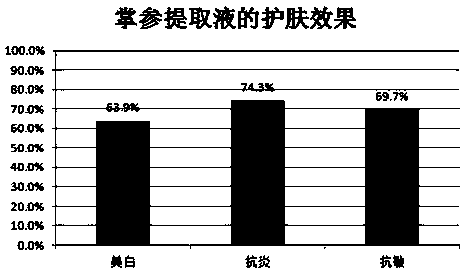

Method for extracting gymnadenia conopsea and related gymnadenia conopsea extract

PendingCN109939057ANovel technologyIngenious designCosmetic preparationsToilet preparationsGymnadenia conopseaNeutral protease

The invention discloses a gymnadenia conopsea extraction method, which comprises the following steps of:(1) soaking roots of the gymnadenia conopsea in water, fully soaking the roots, until the rootsof the gymnadenia conopsea are sampled and observed without white cores;(2) carrying out wet superfine grinding on the roots of the gymnadenia conopsea to obtain dispersion slurry;(3) adding additional water into the dispersion slurry to obtain diluted dispersion liquid, heating to make the temperature rise, then adding neutral protease, and carrying out circulation homogenization extraction through a homogenizing pump to obtain extract liquid;(4) carrying out heat preservation and enzyme inactivation;(5) carrying out crude filtration to obtain crude filtrate; and (6) carrying out fine filtration to obtain refined filtrate. By means of the method, the related extract of gymnadenia conopsea is also provided. The method for extracting the gymnadenia conopsea is unique and novel, the extracted gymnadenia conopsea extract has safety and unique application value in the aspects of skin care, wound repair, wrinkle resistance, sun protection, oxidation resistance, allergy resistance, skin moisture retention and the like, has good application prospect in the field of cosmetics, and is ingenious in process design, simple and convenient to operate and low in cost.

Owner:SHANGHAI HOPE TEC BIOTECH

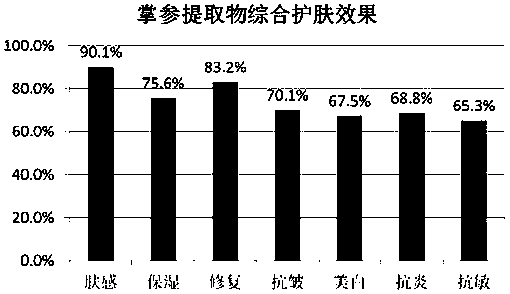

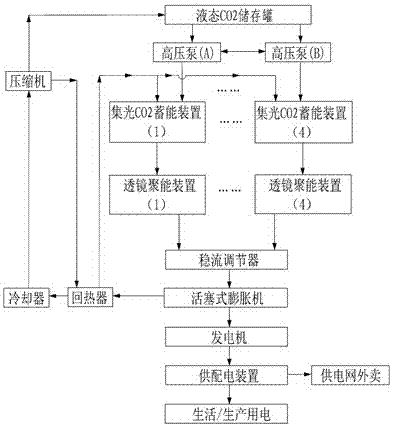

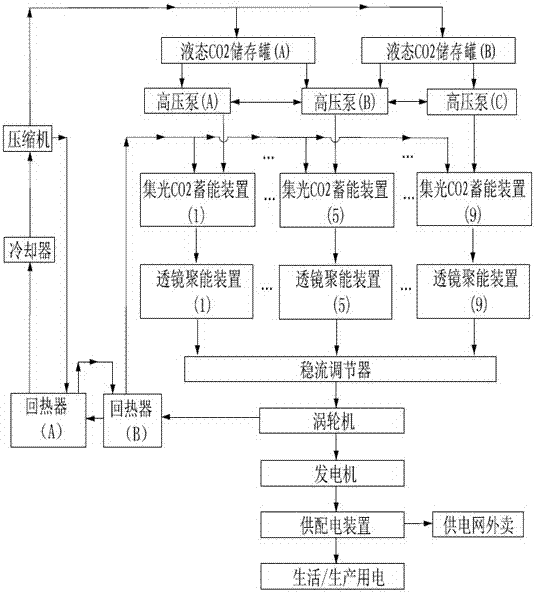

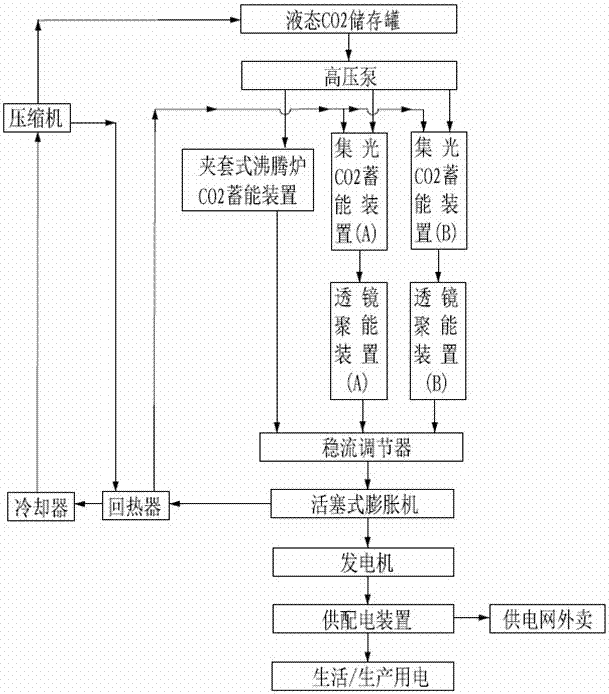

Carbon dioxide circular power generation method adapting to countries with solar energy as energy

ActiveCN106988972AMeet the requirements of unfavorable economic environment conditionsReduce self-consumption powerSolar heating energyFrom solar energyEcological environmentCo2 storage

The invention discloses a carbon dioxide circular power generation method adapting to countries with solar energy as energy. CO2 is used as a working medium; a solar CO2 energy storage device is adopted to convert the solar energy to a high-pressure heat-state supercritical CO2 fluid with high energy storage density; a flow stabilizing adjuster adjusts the high-pressure heat-state supercritical CO2 fluid as an equal-pressure heat-state supercritical CO2 fluid for acting a turbine / piston expander to drive a generator to generate electricity; the solar CO2 energy storage device includes a light collection CO2 energy storage device and a lens energy collecting device; and the method mainly comprises the steps of: (1) CO2 storage and conveying; (2) CO2 energy storage; (3) tempering and power generation of the supercritical CO2 fluid; and (4) CO2 circulation and regeneration utilization. The method has such advantages as convenience to use the solar energy as the energy under complex topography conditions in vast countries with different longitude and latitude conditions, small floor area, no influence on ecological environments of the countries, stable operation, low self energy consumption, low investment and low operating cost.

Owner:长沙紫宸科技开发有限公司

Ion pair chromatographic-grade reagent sodium 1-octanesulfonate purifying process

InactiveCN103145591AHigh speedReduce the binding forceOrganic chemistryOrganic compound preparationPurification methodsIon pairs

The invention provides an ion pair chromatographic-grade reagent sodium 1-octanesulfonate purifying process. The process is characterized in that the process concretely comprises the following steps: adding a raw material sodium 1-octanesulfonate to acetone, carrying out ultrasonic irradiation vibration, cooling to room temperature, carrying out primary reduced pressure suction filtration of the above obtained mixture, adding the obtained filter cake soild to an ethanol-water mixed solution, carrying out heating refluxing stirring, filtering while hot, naturally cooling the obtained filtrate, freezing at a low temperature to precipitate crystals, carrying out secondary reduced pressure suction filtration, collecting crystals, and drying to obtain an ion pair chromatographic-grade reagent sodium 1-octanesulfonate. The purifying process successfully solves the chromatographic-grade reagent sodium 1-octanesulfonate preparation problem, and has the advantages of novelty, simple operation, fastness, high efficiency, recycle of an organic solvent, economy, environmental protection, and suitableness for the industrialized production.

Owner:上海晶纯实业有限公司

Waste hydrotreating catalyst utilization method

ActiveCN106944114APhysical properties (lower than surfaceLow pore volumePhysical/chemical process catalystsCatalystsHeteropoly acidFurfural

The present invention discloses a waste hydrotreating catalyst utilization method, wherein the waste hydrotreating catalyst is prepared into a catalyst for ethylene preparation through ethanol dehydration. The waste hydrotreating catalyst utilization method comprises: preparing a catalyst precursor A from a waste hydrotreating catalyst, and reducing the catalyst precursor A by using hydrogen gas in a high pressure reaction kettle; adding a polyol and / or a furfural solution to the high pressure reaction kettle, and carrying out a hydrogenation reaction; and drying the material obtained after the reaction until the surface is liquid-free, sequentially contacting an organic acid, ammonium or ammonia, and loading a heteropoly acid to produce the catalyst for ethylene preparation through ethanol dehydration. According to the present invention, with the method, the active metal and the alumina carrier in the waste hydrotreating catalyst are utilized, the metal impurities such as Ni, Fe and the like deposited on the waste hydrotreating catalyst are completely utilized, the pollution problem of the waste catalyst is solved, and the obtained catalyst for ethylene preparation through ethanol dehydration has the excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

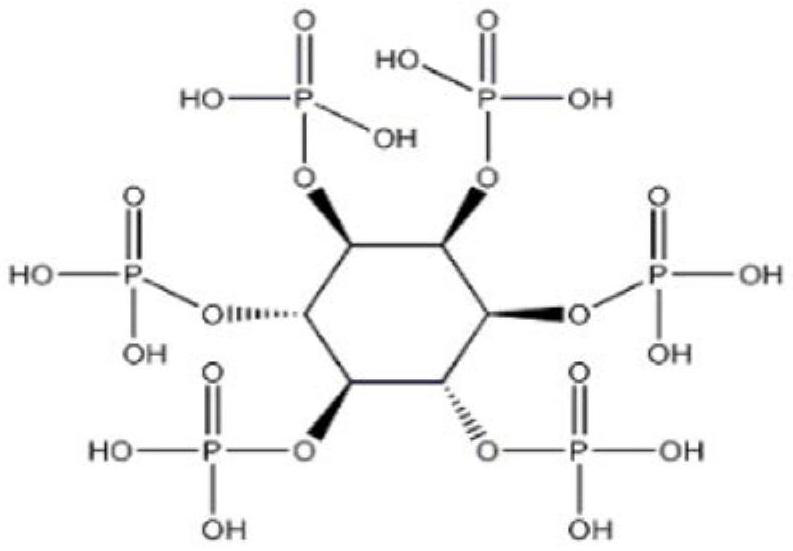

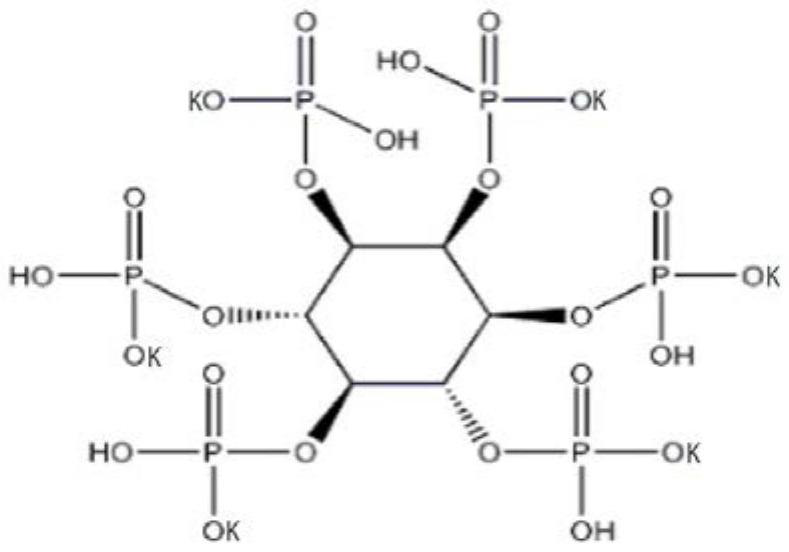

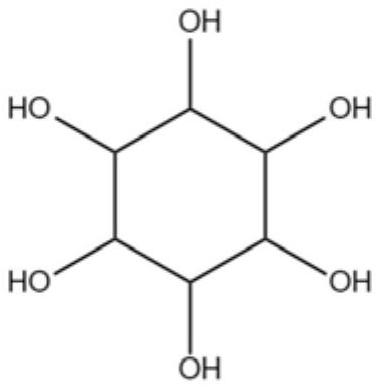

Method for producing inositol and co-producing monopotassium phosphate by adopting corn steep liquor as well as inositol and monopotassium phosphate produced by the method

ActiveCN114031058AHigh purityIncrease added valueOrganic compound preparationHydroxy compound preparationHydrolysatePhosphate

The invention discloses a method for producing inositol and co-producing potassium dihydrogen phosphate by using corn steep liquor, which comprises the following steps: (1) selectively adsorbing phytic acid in the corn steep liquor by using anion exchange resin, and desorbing the anion exchange resin by using a potassium chloride solution to obtain a desorption solution containing potassium phytate; (2) hydrolyzing the desorption solution to obtain hydrolysate; and (3) separating the hydrolysate through electrodialysis to obtain a salt phase and an inositol phase, purifying inositol in the inositol phase to obtain an inositol finished product, and crystallizing monopotassium phosphate in the salt phase to obtain a monopotassium phosphate finished product. The method for producing the inositol and co-producing the monopotassium phosphate by adopting the corn steep liquor is unique and novel, high-purity inositol can be produced, the added value of the byproduct monopotassium phosphate is high, and the method is suitable for large-scale popularization and application.

Owner:ZHUCHENG HAOTIAN PHARMA

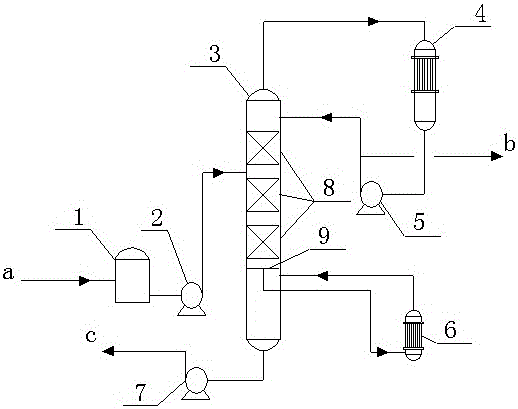

Device and process for recovering butanol from low-concentration organic wastewater

InactiveCN106008158AAvoid influenceNovel technologyOrganic compound preparationHydroxy compound separation/purificationWastewaterButanol

The invention discloses a device and process for recovering butanol from low-concentration organic wastewater. The device comprises a wastewater storage tank, a feed pump, a rectification tower, a cooling separator, a top reflux pump, a tower bottom pump, and a boiling device, wherein the rectification tower comprises a stuffing section and a sump. During the process of operation, the butanol is continuously enriched in the cooling separator at the top of the tower. When the concentration is qualified, a butanol product is sent out by the top reflux pump, the wastewater is continuously enriched to the lower part of the rectification tower and is used as wastewater to be discharged out of the tower bottom pump. The device and process provided by the invention have the advantages of simple process flow, low operating pressure, low energy consumption and high recovery efficiency, and are particularly suitable for the treatment of butanol-containing low-concentration organic wastewater, and simultaneously the high-concentration butanol product is recovered, accordingly, the pollution of the butanol-containing organic wastewater to the environment is avoided, and the recovered butanol product creates economic benefits.

Owner:XINJIANG TIANYE GRP

Poplar softening treatment method

InactiveCN107511903ASoft materialImprove toughnessWood treatment detailsWood impregnation detailsWater vaporCleansing Agents

The invention discloses a poplar softening treatment method, and relates to the technical field of poplar processing. The poplar softening treatment method comprises the steps that pre-softening treatment is conducted, specifically, firstly poplar is cut to be wood chips with the thickness being 3-5 cm, then the poplar is placed into a washing bath, water is added to immerse the poplar, a cleaning agent is stirred to be completely dissolved in the water, soaking is conducted for 3-5 min, then scrubbing with clear water is conducted for 2-3 times, the poplar is taken out and dried, placed on a tension bracket to be stretched, straightened and leveled, and the pre-treated poplar is obtained; a softening agent is prepared; softening is conducted, specifically, the pre-treated poplar is placed into a softening tank, firstly water is pumped into the softening tank, so that three-quarter of water is contained in the softening tank, then the softening agent is pumped into the softening tank, so that the mass proportion of the softening agent and the water is 1:50, water vapor is pumped in the softening tank so that the temperature of the interior of the softening tank can be maintained to be 30-35 DEG C, the pressure intensity can be maintained to be 5-10 MPa, and continuous soaking is conducted for 3-4 days; washing is conducted; and drying is conducted. According to the softening and drying technology, the poplar texture is relatively soft, the toughness is high, certain brittleness is achieved, and the poplar is suitable for serving as materials to make pencils.

Owner:安徽杰可森木业科技有限公司

Nickel cobalt lithium manganese oxide positive electrode material and its preparation method and application

ActiveCN107359335BImprove structural stabilityImprove securityCell electrodesSecondary cellsManganateManganese

The invention relates to a Ni-Co lithium manganate positive electrode material and a preparation method and application thereof. The lithium ion battery positive electrode material is formed by sintering raw materials containing a Li-Ni-Co-Mn half-finished product and a macromolecule acid polymer, wherein the content of free lithium ions is lower than 0.025wt%, the chemical formula of the Li-Ni-Co-Mn half-finished product is Li<x>NiCoMn<c>O2, 0.95<=x<=1.08, 0.32<=a<=0.58, 0.05<=b<=0.34, 0.2<=c<=0.46, and (a+b+c) is equal to 1.0-1.05. The preparation method comprises the following steps of mixing raw materials containing the Li-Ni-Co-Mn half-finished product, the macromolecule acid polymer and a doped element compound added according to demand according to a stoichiometric ratio, and performing sintering and smashing to obtain the lithium ion battery positive electrode material. The preparation method is simple in process, the prepared material is good in uniformity, complete in crystal structure and low in free lithium content, the electrochemical performance of a lithium battery is favorably improved, and the commercial application of the lithium ion battery is expanded.

Owner:湖南金富力新能源股份有限公司

Method for recovering nickel and aluminum from waste aluminum based nickel-containing catalyst

InactiveCN1257292CEfficient separationEfficient recyclingProcess efficiency improvementDecompositionSodium aluminate

The invention is a method of recovering nickelic and aluminum from waste aluminum-based nickel catalyst, it has the characters of novel technique, reasonable flow, simple and convenient method and easy operation, and convenient scaled production, and benefits environmental protection. It includes the steps: sodium carbonate sintering and state-changing--boiling water dissolving sodium aluminate and separating aluminum--- making reducing-matte-making melting on nickel residues to obtain nickel matte Ni3S2-FeS-Ni-Fe alloy or copper-nickel matte Cu2S-Ni3S2-FeS alloy---blowing to obtain high-grade nickel matte Ni3S2 or high-grade copper-nickel matte Cu2S-Ni3S2-Cu-Ni alloy---desiliconizing crude NaAlO2 solution---making carbonated decomposition to obtain aluminum hydrate Al2O3íñ3H2O---calcining to obtain anhydrous aluminum oxide alpha-Al2O3. It is suitable to recover nickel and aluminum from the waste residue generated by extracting molybdenum and vanadium from waste aluminum-based nickelic catalysts and disabled catalysts containing nickel, aluminum, molybdenum and vanadium.

Owner:SHENYANG JIAHE METALLURGICAL FURNACE CHARGE

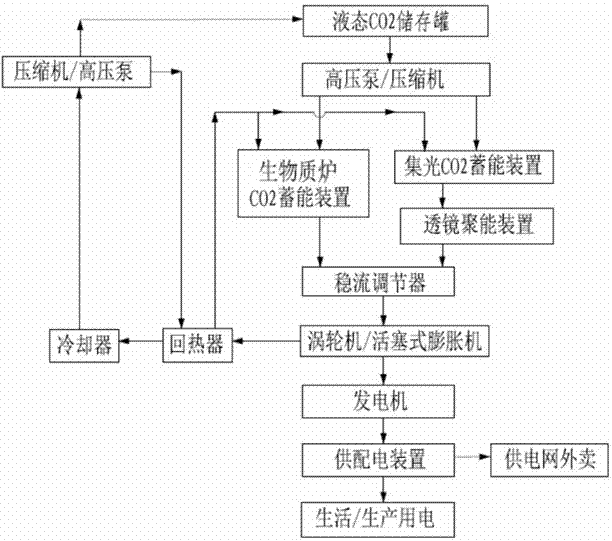

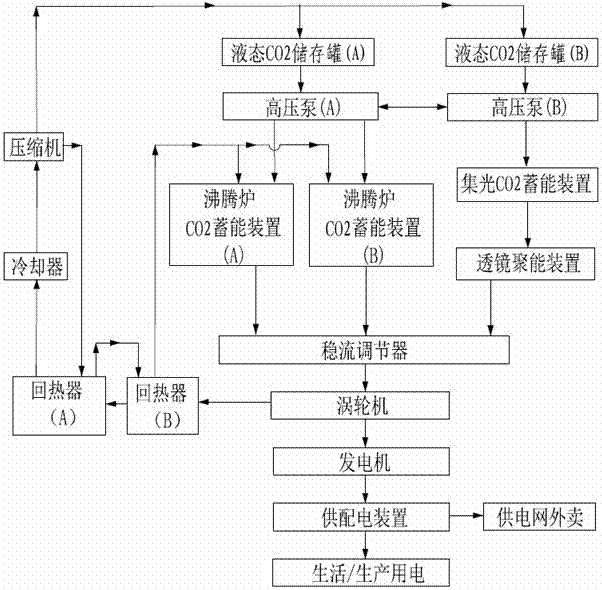

Method suitable for rural carbon dioxide cycle power generation

ActiveCN106884690AEfficient acquisitionMeet supercritical CO

<sub>2</sub>

High temperature energy conditions required for cycle power generationIncreasing energy efficiencySteam engine plantsHigh energyVolumetric Mass Density

Provided is a method suitable for rural carbon dioxide cycle power generation. According to the method, CO2 is used as a working medium, biomass energy and solar energy can be converted into high-energy-storage-density high-pressure thermal supercritical CO2 fluid through biomass furnace CO2 energy storage devices and solar energy CO2 energy storage devices, and the fluid is regulated into equipressure thermal supercritical CO2 fluid through a steady flow regulator and supplied to a turbine / piston expander so that the turbine / piston expander can do work to drive an electric generator to generate electricity; and each solar energy CO2 energy storage device comprises a light collecting CO2 energy storage device and a lens energy gathering device. The method mainly comprises the following steps of (1), storage and conveying of CO2, (2), CO2 energy storage, (3), supercritical CO2 fluid hardening and tempering and electricity generation and (4), CO2 circulating and backheating utilization. The method has the beneficial effects that a lot of renewable biomass resources and solar energy in villages can be used as energy, operation is stable, self-energy consumption is low, the investment is low and the operation cost is low.

Owner:长沙紫宸科技开发有限公司

Manufacturing method of wedge-shaped lens

ActiveCN102229082BNovel technologyUnique process methodOptical surface grinding machinesLensEngineering

The invention discloses a manufacturing method of a wedge-shaped lens, belonging to the technical field of optical cold processing. The manufacturing method comprises the specific steps of: manufacturing a wedge-shaped lens blank and a high-precision glass clamp by adopting a conventional optical processing technology so as to ensure that a first guide through face of the wedge-shaped lens as well as the surface shape and the surface defects of the wedge-shaped glass clamp meet formulated requirements; optically cementing the first light through face of the wedge-shaped lens onto the inclined surface of the wedge-shaped glass clamp which is already optically cemented onto a parallel planer optical cementing base plate, carrying out fine grinding and polishing on a second light through face of the wedge-shaped lens, and obtaining the wedge-shaped lens with second-level precision by controlling the thickness, the parallel difference and the surface shape precision of the second light through face and the parallel planer optical cementing base plate. The manufacturing method for machining the wedge-shaped lens, disclosed by the invention, not only has a simple process, strong operability and a greatly-prolonged manufacturing period, but also is easy to ensure the single-batch finished product ratio of wedge-shaped lens parts with small sizes, large angles and second-level precision and overcomes the difficulties of unstable quality, low efficiency and low finished product ratio in the conventional processing method.

Owner:CHINA NORTH IND NO 205 RES INST

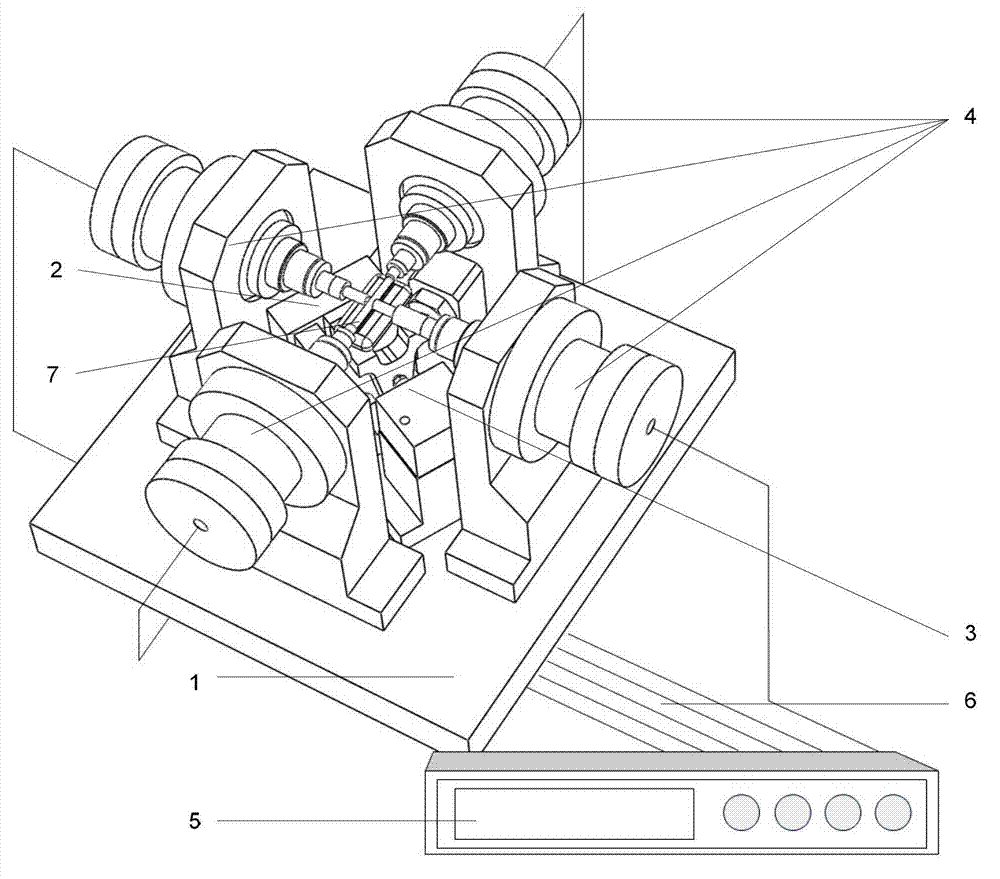

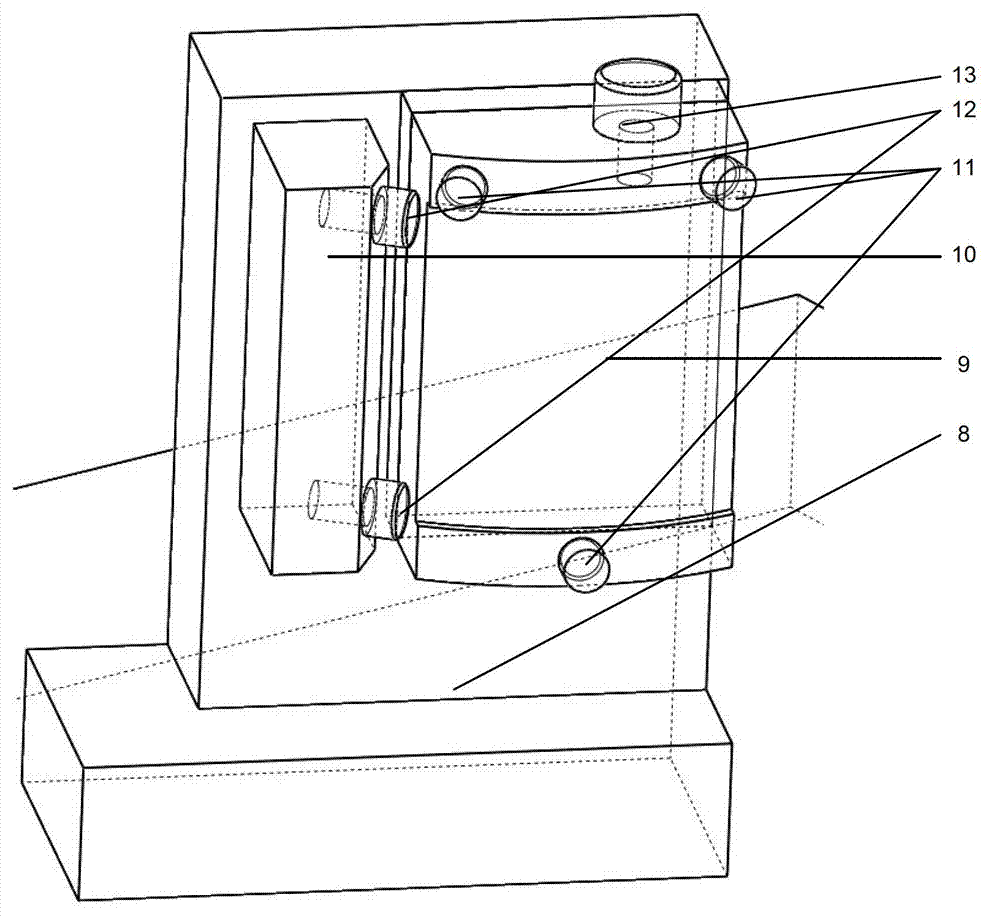

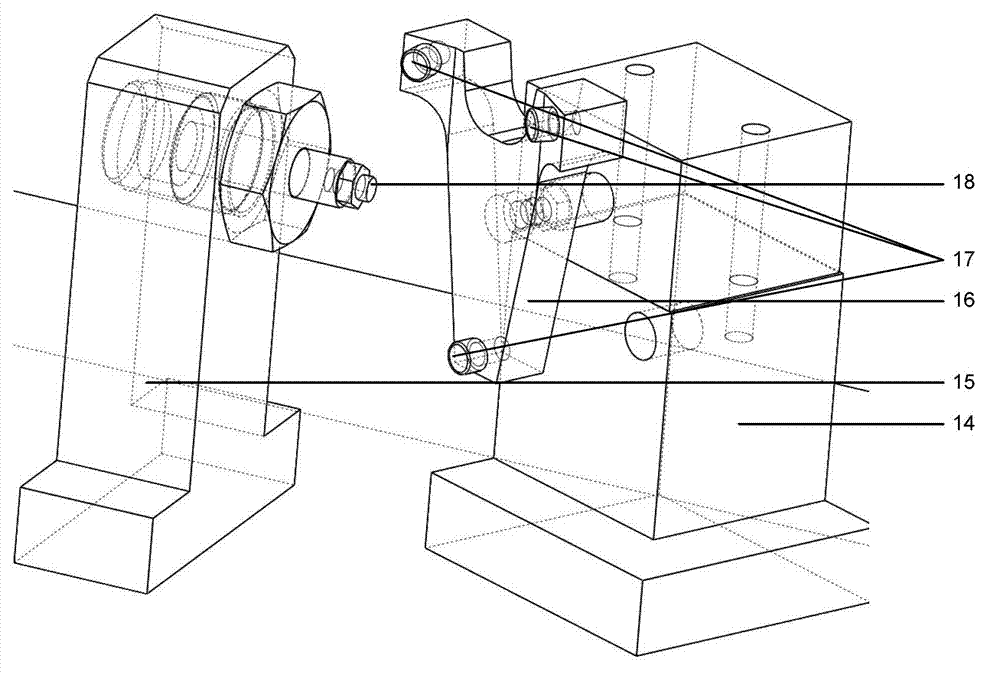

Precision machining technological equipment and machining method for blade of aviation engine

ActiveCN102975061BAvoid pouringAvoid meltingPositioning apparatusMetal-working holdersAviationHydraulic cylinder

The invention discloses precision machining technological equipment for a blade of an aviation engine. The precision machining technological equipment comprises a positioning device, a clamping device and an auxiliary supporting device, wherein the positioning device, the clamping device and the auxiliary supporting device are fixed on a foundation table top, the positioning device is used for positioning of a curved surface of a blade body, the clamping device is used for clamping the blade body, the auxiliary supporting device is fixed outside the positioning device and the clamping device, a working head of the auxiliary supporting device directly contacts a tenon portion of the blade, and a master controller controls each hydraulic cylinder on a tool through a control loop. According to the precision machining technological equipment, the blade body provided with a thin wall and the curved surface is directly positioned and clamped for machining the tenon, and therefore continuous mechanical operation and machining can be achieved in production of the blade, and working efficiency and machining quality can be improved.

Owner:TSINGHUA UNIV +1

Method for removing solid impurities of catalytic slurry oil through low-temperature coalescence

ActiveCN112480959AEasy to removeNo risk of contaminationTreatment with plural serial refining stagesPtru catalystSlag

The invention discloses a method for removing solid impurities of catalytic slurry oil by low-temperature coalescence, which comprises the steps of heating, dehydrating, adding a liquid assistant, mixing, heating a solid assistant, mixing, and carrying out solid-liquid separation, thereby obtaining the purified catalytic slurry oil with low ash content in which solid impurities are removed. According to the invention, through the combined action of the liquid auxiliary agent and the solid auxiliary agent, tiny catalyst solid particles are aggregated into large particles, so that impurities areeasy to remove; the solid impurities in the catalytic slurry oil are separated out in a solid form, the process technology is novel, the operation is easy, and continuous separation can be achieved;the separated solid slag is in a loose solid state in appearance, is convenient to mix and burn with fire coal, and is environment-friendly; no concentrated solution or other liquid hazardous waste isgenerated, and no environmental pollution risk is caused; and the method has the advantages of mild process conditions, simple equipment, easy operation, continuous production, thorough solid-liquidseparation and high finished product yield, and the yield of the purified catalytic slurry oil obtained after separation reaches 99% or above.

Owner:MAOMING YINGPENG ELECTROMECHANICAL EQUIP

Traditional Chinese medicine extraction method

InactiveCN108670983AHigh extraction rateNovel technologyPlant ingredientsMedicinal herbsReflux extraction

The invention discloses a traditional Chinese medicine extraction method. The method comprises the following steps: (1) pre-treating medicinal materials; (2) putting the medicinal materials into an extraction tank and adding water; (3) adding alcohol; (4) extracting by adopting a reflux extraction method; (5) performing oil-water separation on extract liquid; (6) concentrating; (7) drying. The method provided by the invention is novel in technology; through the implementation of the method, the extraction rate of active ingredients in the medicine materials can be improved; and the method plays an important role in improving the production efficiency in the continuous production of an enterprise.

Owner:JIANGXI DESHANG PHARMA

A kind of utilization method of waste hydrogenation catalyst

ActiveCN106944138BRealize comprehensive utilizationHydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsHeteropoly acidFurfural

The present invention discloses a waste hydrogenation catalyst utilization method, which comprises: pre-treating a waste hydrogenation catalyst; in a high pressure reaction kettle, reducing with hydrogen gas; adding a polyol and / or a furfural solution to the high pressure reaction kettle, and carrying out a hydrogenation reaction; and drying the material obtained after the reaction until the surface is liquid-free, sequentially contacting an organic acid, ammonium or ammonia, and loading a heteropoly acid to produce the catalyst for ethylene preparation through ethanol dehydration. According to the present invention, with the method, the hydrogenation activity metal component and the carrier component in the waste hydrogenation catalyst are utilized, the hydrogenation activity of the waste hydrogenation catalyst is completely utilized, the pollution problem of the waste catalyst is solved, and the obtained catalyst for ethylene preparation through ethanol dehydration has the excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

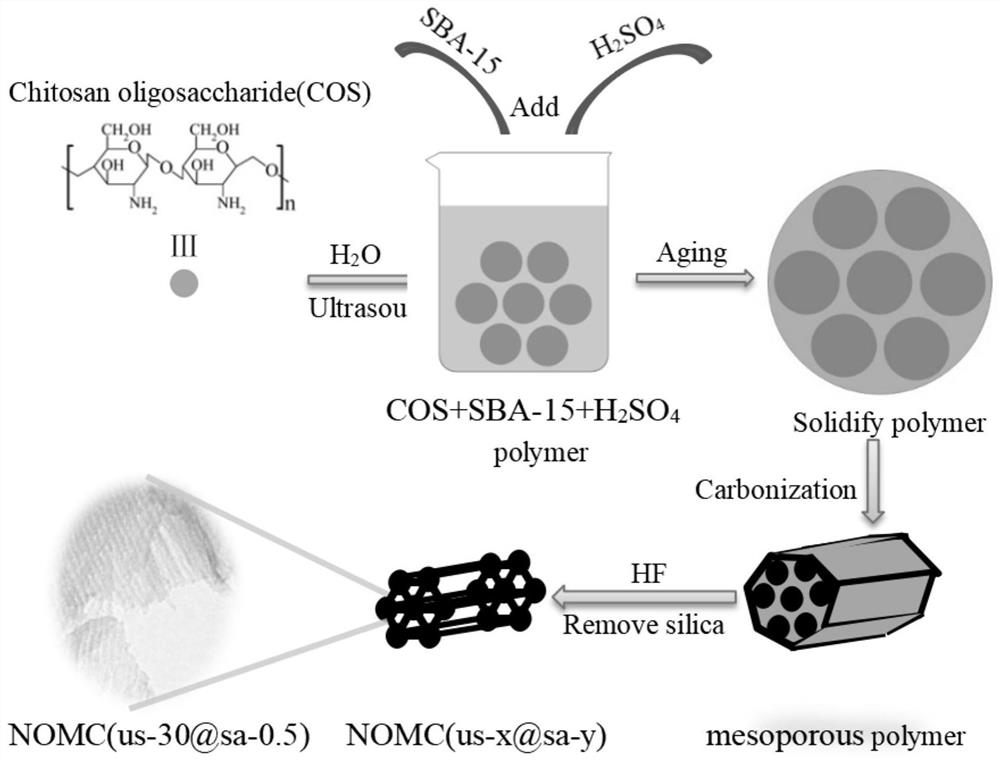

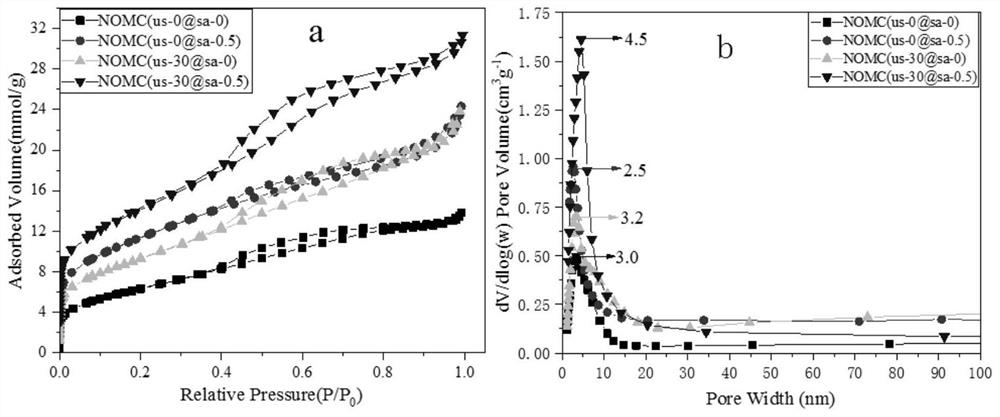

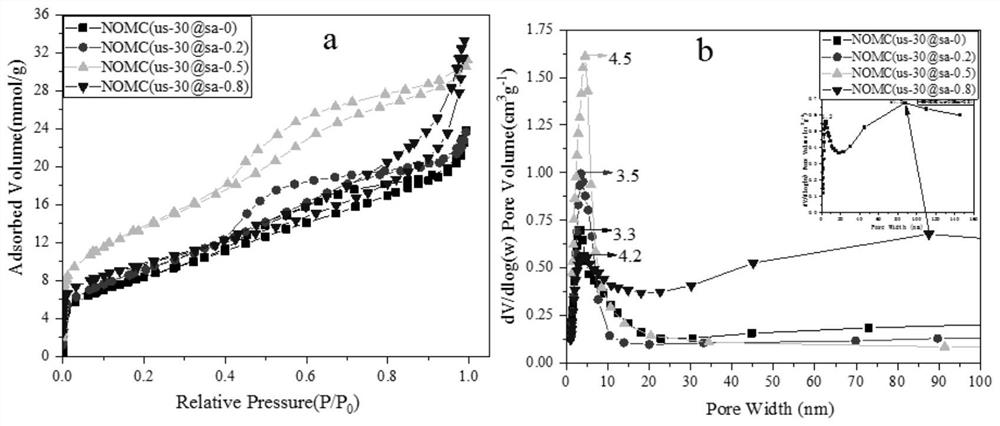

Preparation method of chitosan oligosaccharide-based in-situ N-doped ordered mesoporous carbon with uniform and adjustable pore diameter

ActiveCN113460990ASolve technical problems that are toxic, harmful and unfriendly to the environmentSolve process problemsCarbon preparation/purificationEngineeringMesoporous silica

The invention discloses a preparation method of chitosan oligosaccharide-based in-situ N-doped ordered mesoporous carbon with uniform and adjustable pore diameter. Chitosan oligosaccharide is used as a carbon and nitrogen source, SBA-15 ordered mesoporous silica is used as a template, and the preparation of the in-situ N-doped ordered mesoporous carbon and the adjustment of the pore diameter are realized by controlling the ultrasonic time and the concentration of added sulfuric acid. The method has the characteristics that the process is simple, the raw materials are easy to obtain, and the pore size of the ordered mesoporous carbon is controllable and adjustable, and the prepared ordered mesoporous carbon is uniform in pore size and good in dispersity and wettability.

Owner:GUIZHOU UNIV

Process for preparing high-purity auramine O

ActiveCN103146219BHigh puritySolve the problem of high-purity auramine ODiarylmethane dyesOrganic solventDistillation

The invention discloses a process for preparing high-purity auramine O. The process is characterized in that the process concretely comprises the following steps: 1, adding a crude auramine O raw material to an organic solvent at 20-40DEG C, uniformly stirring, and maintaining the temperature for 2-8h, wherein the weight of the organic solvent is 5-10 times the mass of auramine O; 2, carrying out reduced pressure suction filtration of the obtained mixture, pressing the obtained filter cake to dryness, carrying out reduced pressure distillation of the obtained mother solution, and recovering the organic solvent which can be recycled; 3, adding a solid obtained after the reduced distillation concentration of the mother solution to an another organic solvent, and stirring for 1-2h, wherein the weight of the another organic solvent is 1-3 times the weight of the solid; and 4, carrying out reduced pressure suction filtration of a mixture obtained in step 3, washing the obtained filter cake with the another organic solvent 1-3 times, carrying out suction drying of the filter cake, and drying to obtain the high-purity auramine O, wherein the weight of the another organic solvent is 0.5-1 times the weight of the solid. The process successfully solves the high purity auramine O preparation problem.

Owner:SHANGHAI JINGCHUN BIOCHEM TECH CO LTD

Comprehensive utilization method of sea salt bittern

InactiveCN100410175CReduce cost inputNovel technologyCalcium/strontium/barium chloridesCalcium/strontium/barium sulfatesPotassiumEvaporation

The present invention relates to a comprehensive utilization method of bittern. Said method uses bittern as raw material and adopts the following steps: making the bittern undergo the processes of mixing reaction with calcium liquor, synthesis reaction with lime cream, evaporation concentration crystallization, four-step evaporation, aerifying chlorine, filtering and removing impurity and solid-liquid separation, etc, so as to make the bittern into several products of hemi-hydrate calcium sulfate, magnesium hydroxide, industrial salt, potassium chloride, industrial bromine and dehydrate calcium chloride.

Owner:杨秀文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com