Nickel cobalt lithium manganese oxide positive electrode material and its preparation method and application

A positive electrode material, lithium nickel cobalt manganese technology, applied in the field of preparation of nickel cobalt lithium manganese oxide positive electrode material, can solve the problem of uneven ideal effect of doping elements, and achieve the effect of wide applicability, obvious effect and complete surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

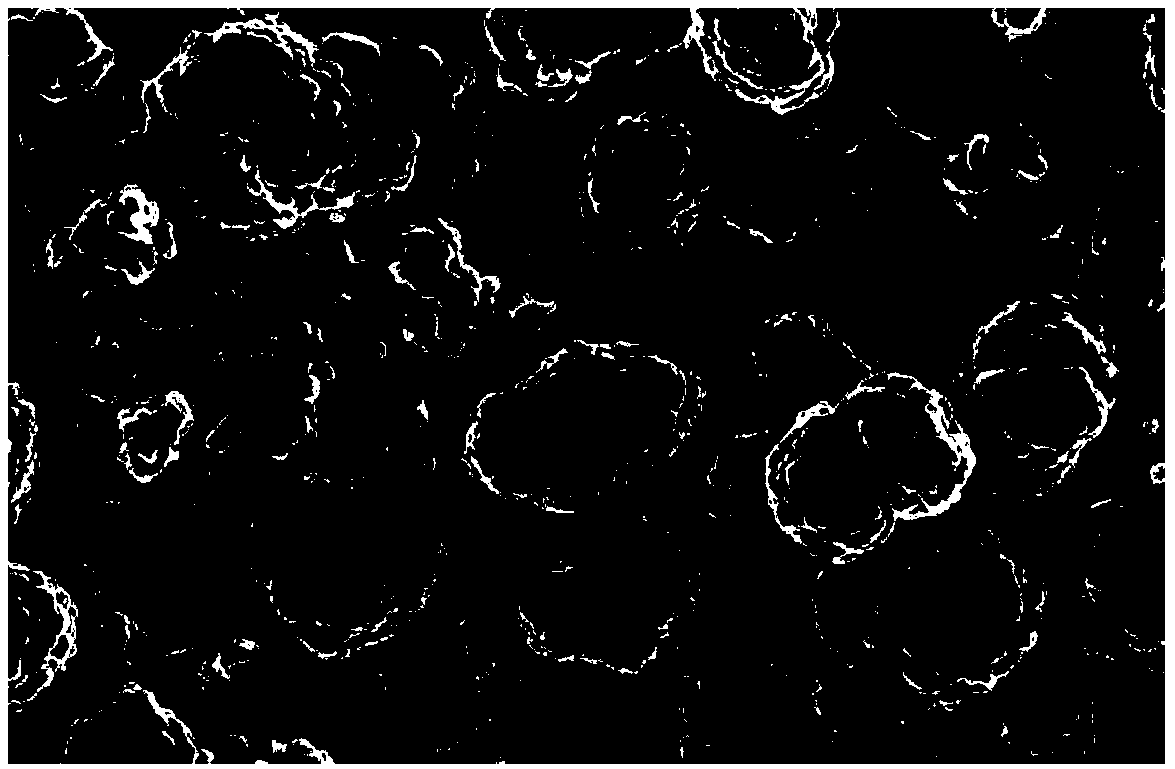

Image

Examples

preparation example Construction

[0041] The preferred method for preparing the doped / coated nickel-cobalt lithium manganese oxide positive electrode material in the present invention includes two methods of wet preparation and dry preparation. The semi-finished product of nickel-cobalt-lithium-manganese-manganese-oxide is used as the main body material, and the high-molecular acid polymer is mixed with the semi-finished product of nickel-cobalt-lithium manganese oxide, the compound of doped coating elements and the deionized water added as needed, and then sintered by wet mixing The positive electrode material is prepared by crushing, and the positive electrode material can also be prepared by dry mixing the high molecular acid polymer, the semi-finished product of nickel cobalt lithium manganese oxide, and the doped coating element compound, and then sintering and crushing.

[0042] The preferred wet preparation method of the present invention comprises the steps:

[0043] a) Ingredients, first add the semi-...

Embodiment 1

[0061] Embodiment 1 wet mixing does not doping process (as comparative example)

[0062] Choose 500L plow mixer. Open stirring (20rpm), add the nickel-cobalt-manganese semi-finished product (Li 1.02 Ni 0.33 co 0.33 mn 0.33 o 2 , granularity D 50 : 12.1 μm, active matter content 99.5%), then add 30kg deionized water under the stirring situation, further reduce the speed (3rpm) after stirring for 2h, and stir for 2h discharging to form a paste material with a certain forming degree for subsequent use.

[0063] Put the slurry into a ceramic bowl and put it into a muffle furnace to raise the temperature to 200°C at 5°C / min, keep it warm for 60min, and cool it out.

[0064]Adopt ventilated 24m roller kiln. Set the temperature in the heat preservation zone to 400°C, and under the condition of air (air flow rate 500m 3 / h) Put the material of Example 1 into a ceramic bowl for sintering, heat it for 8 hours, then cool and discharge the material, weigh the weight of the incomin...

Embodiment 2

[0065] Embodiment 2 wet mixing doping process (as comparative example)

[0066] Use 500LY mixer. Turn on stirring (30rpm), add 200kg of nickel cobalt lithium manganate (Li 1.04 Ni 0.4 co 0.3 mn 0.31 o 2 , granularity D 50 : 11 μm, effective matter content 99.5%), then add 100kg deionized water, 0.41kg aluminum hydroxide (industrial grade, particle size D 50 : 2.0 μm, purity 99.5%, content is 700ppm in terms of finished product aluminum content), 0.44kg lanthanum nitrate hexahydrate (industrial grade, purity 98.5% content is 700ppm in terms of finished product lanthanum content), after stirring 2h, further reduce speed (10rpm) Stir for 60 minutes and discharge to form a paste-like material with a certain degree of molding for later use.

[0067] Put the slurry into a ceramic bowl and put it into a muffle furnace to raise the temperature to 400°C at 10°C / min, keep it warm for 100min, and cool it out.

[0068] The difference from the sintering and crushing steps in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com