Device and process for recovering butanol from low-concentration organic wastewater

An organic waste water, low-concentration technology, applied in the preparation of organic compounds, organic chemistry, separation/purification of hydroxyl compounds, etc., can solve the problems of complex process, many operating points, high energy consumption, and achieve simple process flow and recovery efficiency. High and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

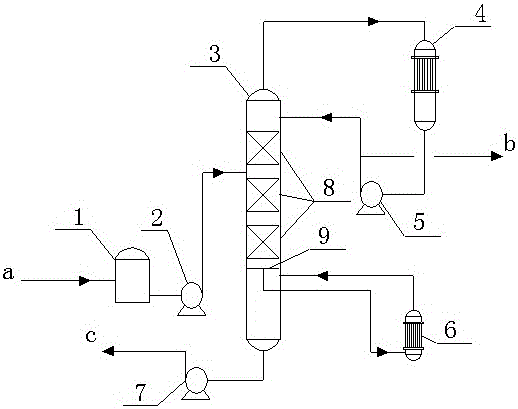

[0037] Refer to attached figure 1 , a device for recovering butanol from low-concentration organic wastewater described in this embodiment includes a wastewater storage tank (1), a feed pump (2), a rectification tower (3), a cooling separator (4), a tower Top reflux pump (5), tower bottom pump (7), boiler (6); rectification column (3) includes tower top reflux section, packing section (8), liquid collection tank (9) and tower bottom liquid collection section ;

[0038] The wastewater storage tank (1) is connected to the inlet of the feed pump (2), and the outlet of the feed pump (2) is connected to the packing section (8) of the rectification tower (3), and the top of the rectification tower (3) The outlet is connected to the upper inlet of the cooling separator (4) through a pipeline, and the bottom of the cooling separator (4) is connected to the inlet of the top reflux pump (5) through a pipeline. to the upper part of the rectification tower (3), and the other road is con...

Embodiment 2

[0040] Refer to attached figure 1 , a kind of technology that reclaims butanol from low-concentration organic waste water described in the present embodiment, comprises the steps:

[0041] The organic waste water (a) with a butanol concentration of 0.1% from the production unit enters the waste water storage tank (1), and under the delivery of the feed pump (2), the waste water flows from the packing section (8) of the rectification tower (3) ) enters the rectifying tower (3); the gas phase rising in the rectifying tower (3) enters the cooling separator (4) from the top of the tower, forms a liquid phase in the cooling separator (4), and returns to the top of the tower (5) The liquid phase in the cooling separator (4) flows back into the rectification tower (3) from the upper part of the rectification tower (3) under the action of cooling; the reflux liquid phase and the organic waste water entering the rectification tower (3) move downward and concentrate in the The liquid c...

Embodiment 3

[0043] Refer to attached figure 1 , a kind of technology that reclaims butanol from low-concentration organic waste water described in the present embodiment, comprises the steps:

[0044] The organic waste water (a) containing 1% butanol from the production unit enters the waste water storage tank (1); under the delivery of the feed pump (2), the waste water flows from the packing section (8) of the rectification tower (3) ) into the rectifying tower (3); the gaseous phase rising in the rectifying tower (3) enters the cooling separator (4) from the top of the tower, forms a liquid phase in the cooling separator (4), and returns to the top reflux pump (5) The liquid phase in the cooling separator (4) flows back into the rectification tower (3) from the upper part of the rectification tower (3) under the effect of cooling; the reflux liquid phase and the organic waste water entering the rectification tower (3) move downward and concentrate The liquid collection tank (9), enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com