Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Not easy to wear off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-slide fog seal material and its construction method

ActiveCN102815892AImprove skid resistanceAvoid the problem of insufficient skid resistanceIn situ pavingsKaolin clayRoad surface

The invention relates to an anti-slide fog seal material and its construction method. The anti-slide fog seal material is obtained by the following steps of: mixing 15-30 parts by weight of composite kaolin, 35-70 parts by weight of water and 1.2-2.0 parts by weight of an asphalt emulsifier, adjusting the pH value into a range required by the corresponding asphalt emulsifier with a pH value conditioning agent, then emulsifying 25-40 parts by weight of hot melt asphalt so as to obtain a stable mixed emulsion, and finally mixing the emulsion with 50-80 parts by weight of sand and conducting stirring. When the anti-slide fog seal material is sprayed on a road surface uniformly by a spraying vehicle, it can bond well with the road surface. Thus, the material not only seals original road surface micro-cracks and voids, plays a strong waterproof role, but also prolongs the road service life. And the sand in the anti-slide fog seal material can substantially improve the anti-slide performance of the road surface.

Owner:GAOYUAN HIGHWAY MAINTENANCE TECH HENAN PROV

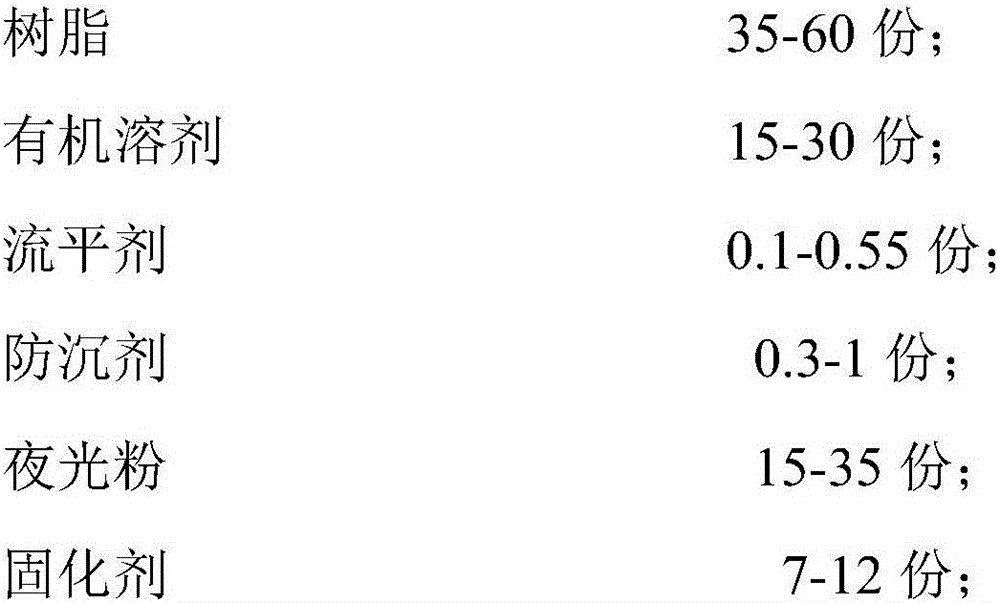

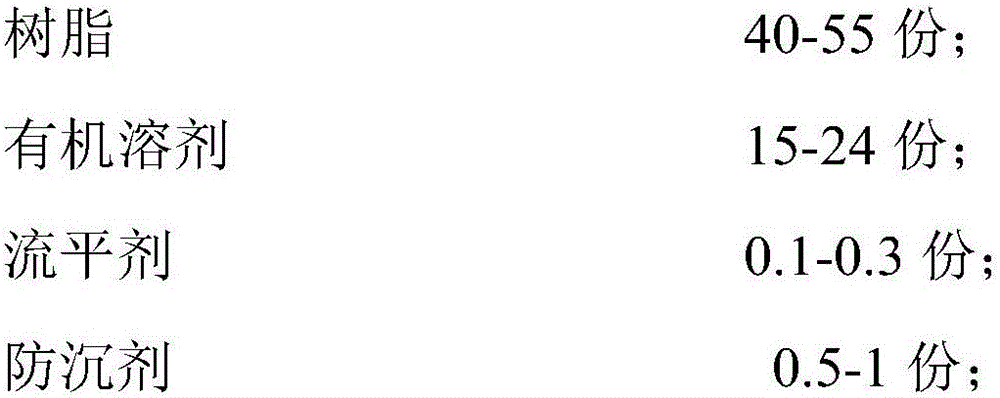

Noctilucent finish coat protective agent for permeable concrete pavements, and pavement containing noctilucent finish coat protective agent and construction method thereof

ActiveCN106046979AGood viewingGood water permeabilityIn situ pavingsLuminescent paintsRare-earth elementLight at night

The invention provides a noctilucent finish coat protective agent for permeable concrete pavements. The noctilucent finish coat protective agent contains the following components in parts by weight: 35-60 parts of resin, 15-30 parts of organic solvent, 0.1-0.55 part of leveling agent, 0.3-1 part of anti-settling agent, 15-35 parts of noctilucent powder and 7-12 parts of curing agent. The noctilucent powder is rare-earth-element-activated alkaline soil aluminate or alkaline soil silicate. The colored self-luminescent water-permeable concrete pavement has favorable ornamental value in the day time, can absorb and store light energies and emit light at night, has the effects of illumination indication and decoration, and has the advantages of favorable water permeability, favorable air permeability and high compressive strength.

Owner:上海砼仁环保技术发展有限公司

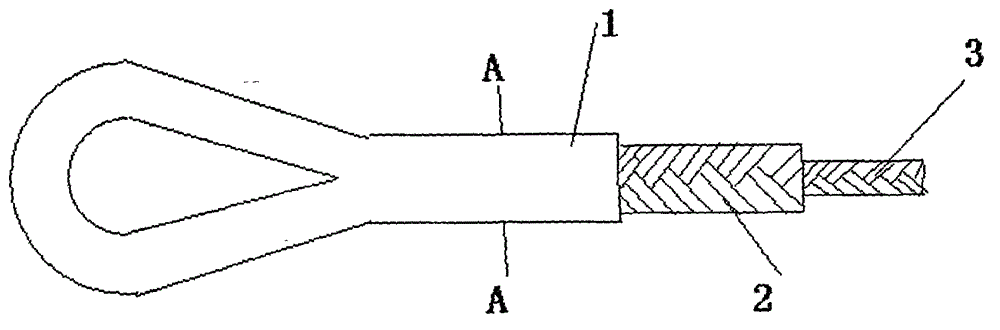

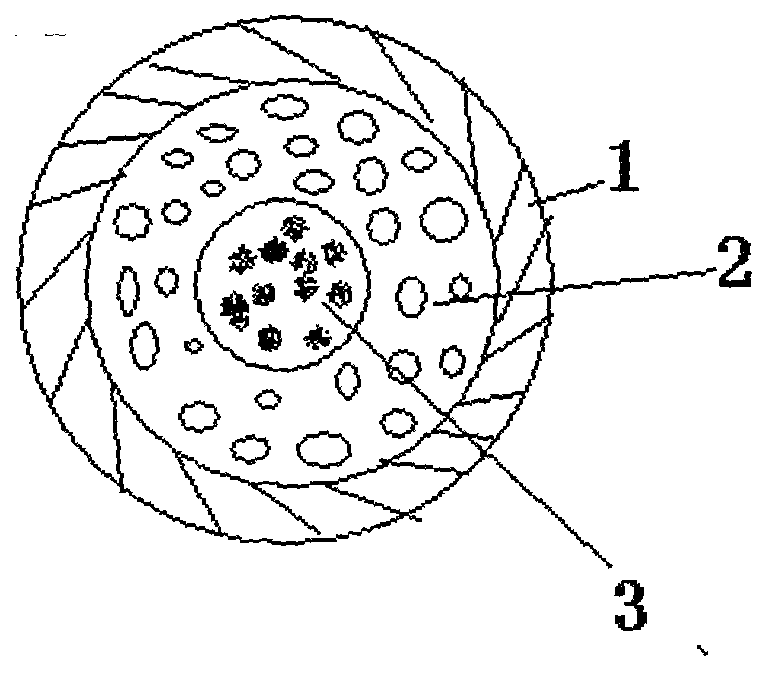

Coated mooring rope made of high-molecular-weight polyethylene fibers

The invention discloses a coated mooring rope made of high-molecular-weight polyethylene fibers, and belongs to the field of ropes for tugboats. An inner layer of the coated mooring rope comprises eight or twelve or sixteen strands of ropes made of high-molecular-weight polyethylene fiber materials, an outer layer of the coated mooring rope is an abrasion-resistant sheath consisting of thirty-two or forty-eight or sixty-four strands of ropes, and polyester adhesive and fluorescent dye are coated on the outer portion of the abrasion-resistant sheath. The specially spun high-strength polyethylene fibers are used for manufacturing the inner layer, the mooring rope has the strength more than four times higher than that of a common rope made of chemical fibers, and is light, the abrasion-resistant sheath and the polyester adhesive are coated on the outer layer to strengthen the abrasion resistance of the coated mooring rope, the mooring rope is not easy to wear or break when normally and continuously used by a boat, and is long in service life, and the fluorescent dye coated on the outer portion of the abrasion-resistant sheath is orange so that the coated mooring rope is easy to observe during usage.

Owner:陶香川

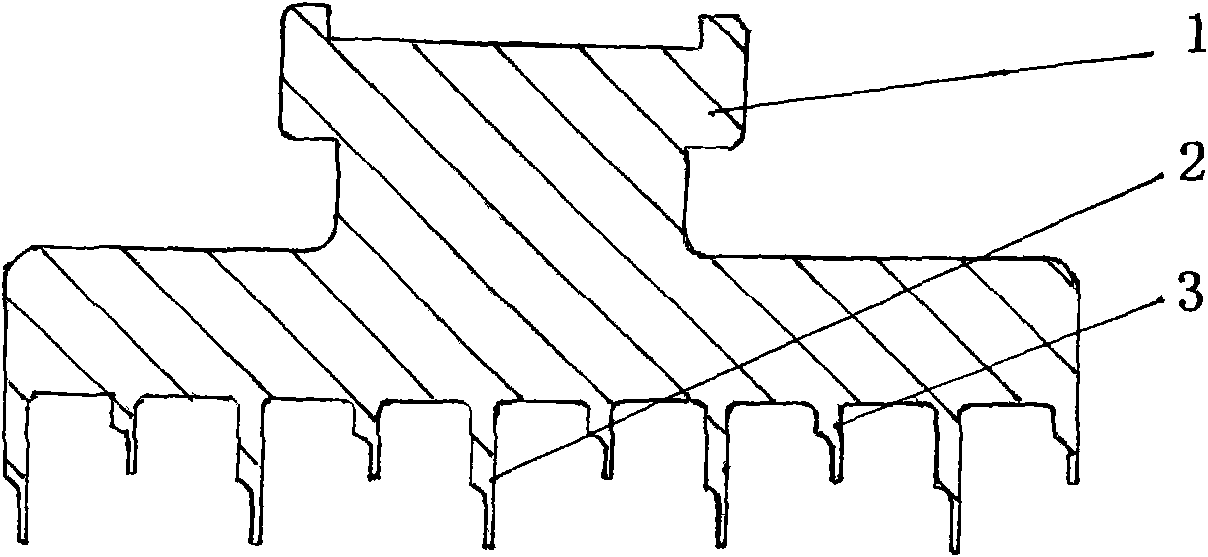

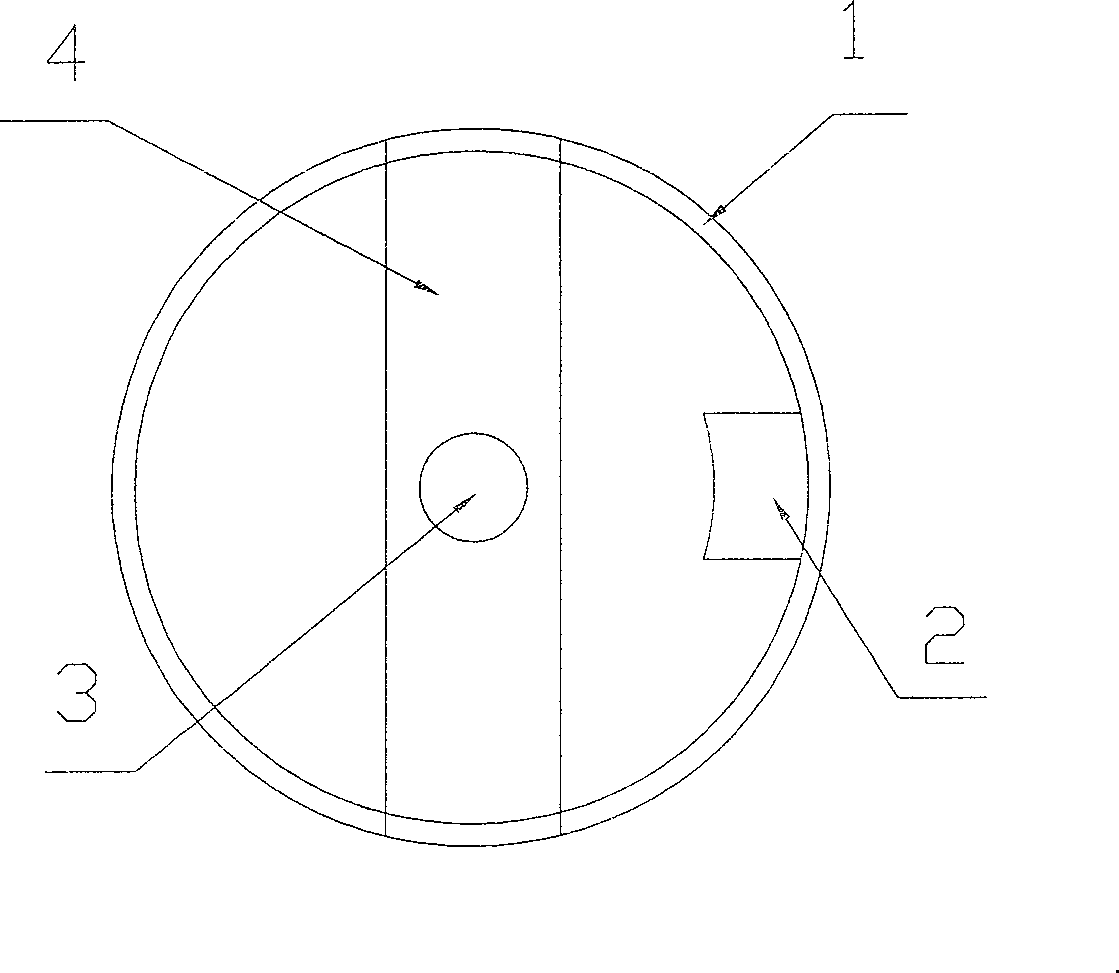

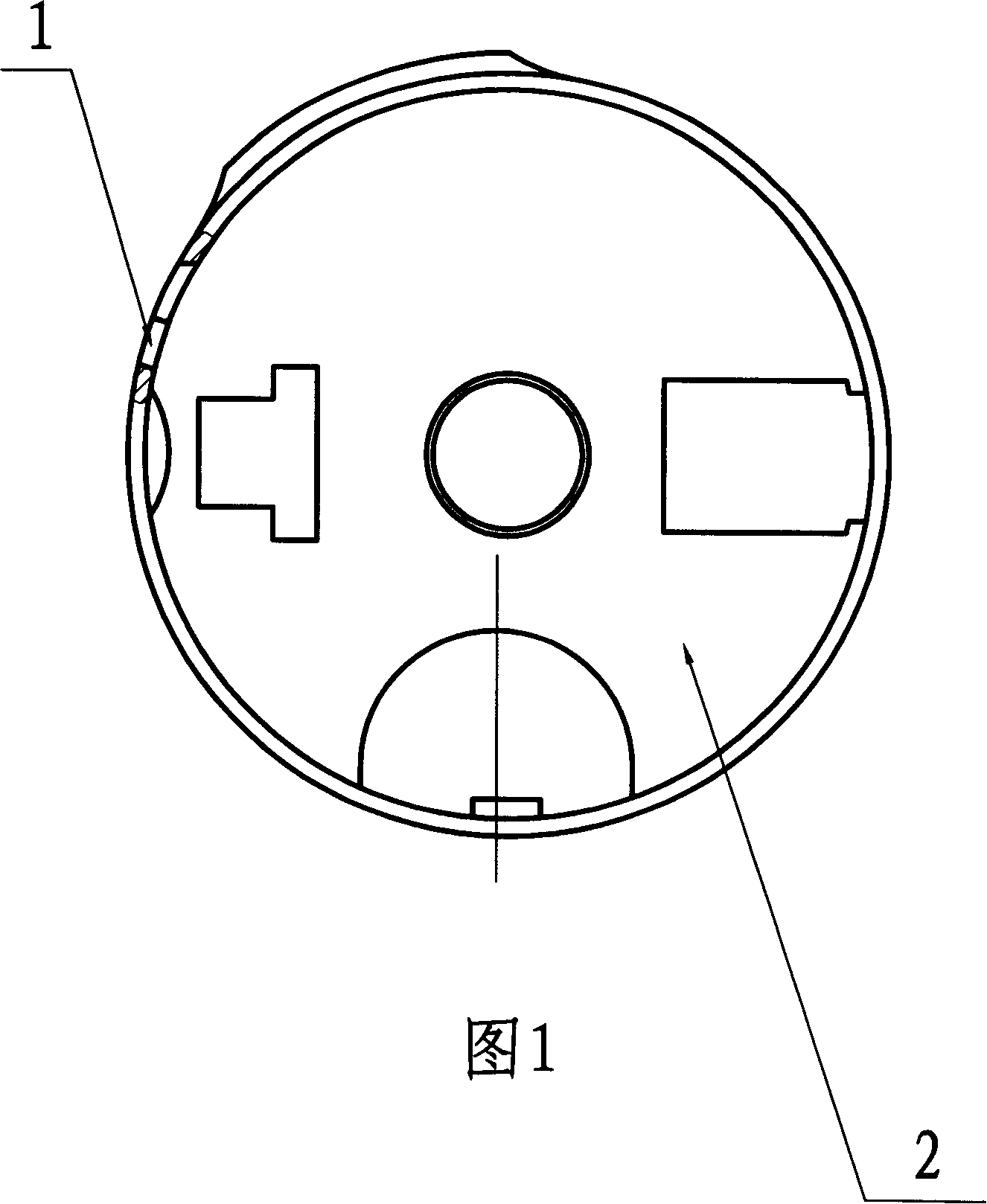

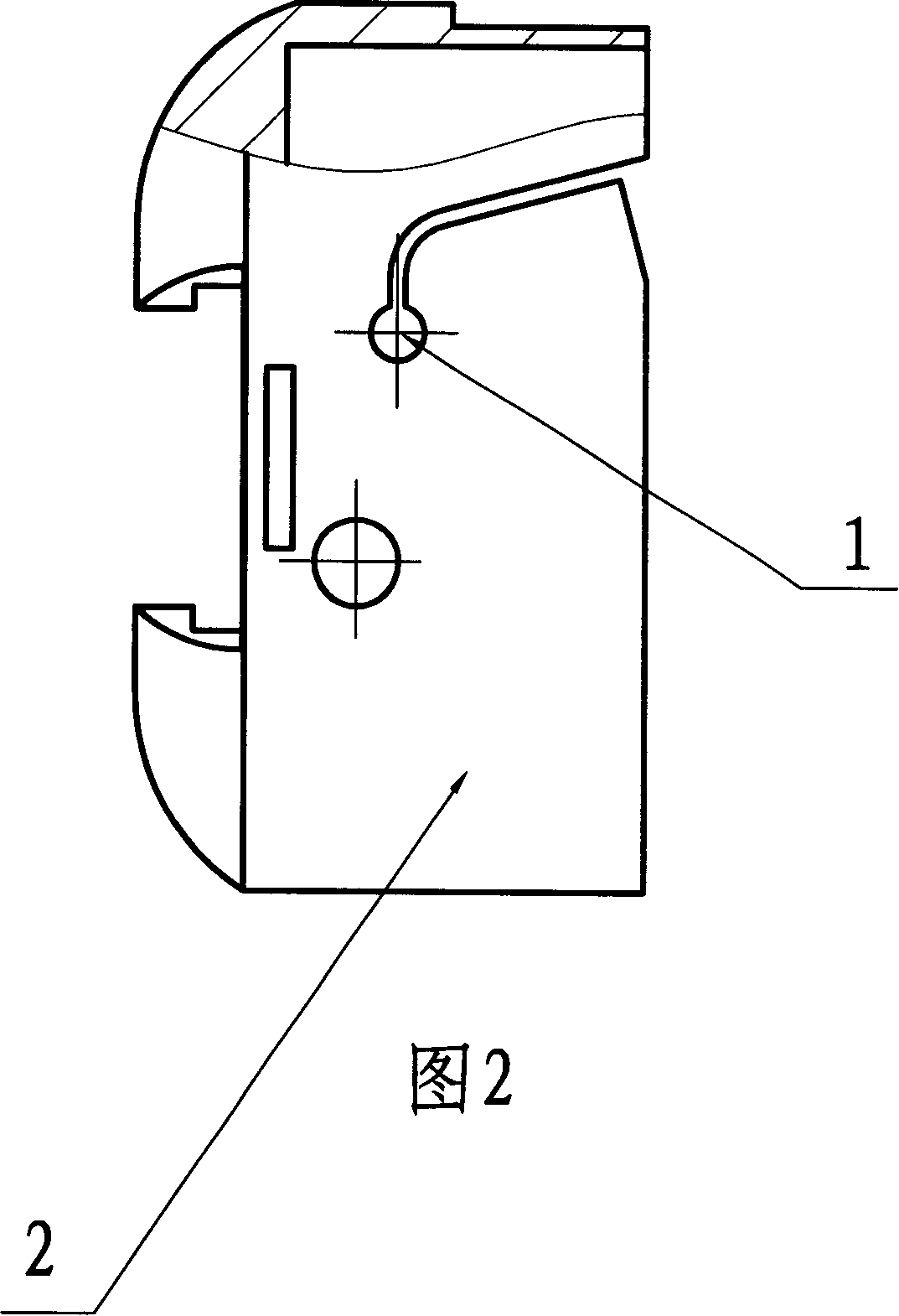

Preparation method for high-strength MC (monomer casting) nylon wheel

The invention relates to the field of engineering plastic, in particular to a preparation method for a high-strength MC (monomer casting) nylon wheel for elevator transmission. The preparation method comprises the steps as follows: heating, dehydrating, pouring, forming and processing in sequence to prepare the high-strength MC nylon wheel which overcomes the shortage of nylon wheels prepared by the existing preparation method, is better in flexibility and wear resistance, lighter in self weight and easy to mount, is prolonged in service life and is provided with a wheel groove for protecting a steel wire rope.

Owner:JIANGSU ADIN NEW MATERIALS

Automobile sealing strip rubber material with effects of restraining bacteria and removing abnormal smells and preparation method thereof

The invention discloses an automobile sealing strip rubber material with the effects of restraining bacteria and removing abnormal smells. The automobile sealing strip rubber material is prepared from, by weight, 100-120 parts of ethylene propylene diene monomer, 30-50 parts of white carbon black, 10-15 parts of shell powder, 2-4 parts of blumea oil, 2-4 parts of zinc oxide, 1.5-2.5 parts of sulphur S80, 1.5-2.5 parts of antiager MB, 0.3-0.5 part of accelerant TMTD, 0.03-0.05 part of tetradecyl dimethyl benzyl ammonium, 0.1-0.15 part of glycerol monolaurate, 3-5 parts of methyltrimethoxysilane, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 part of titanate coupling agent NDZ-401, 6-8 parts of nano-graphite powder and 20-30 parts of castor oil. The rubber material is good in anti-abrasion effect and durable in anti-friction performance, has the effects of restraining bacteria and removing abnormal smells, and has the advantages of being long in service life, good in sealing performance and good in sanitation when used as an automobile sealing strip material.

Owner:闻承岳

Telescopic brush type gland ring

InactiveCN101660430AGuaranteed safe operationHigh strengthLeakage preventionMachines/enginesAlloyElectrical and Electronics engineering

The invention relates to a telescopic brush type gland ring formed by a plurality of gland loops through head-to-tail connection. Each gland loop comprises a loop body, a high tooth sealing strip, a low tooth sealing strip and a telescopic sealing brush, wherein the sealing brush comprises a brush head and a T-shaped brush body; the brush head is formed by tightly arranged metal wire layers of which the outer ends are welded between two clamp plates; the brush head is fixedly arranged in a brush slot of the brush body; and the bottom of the brush body is arranged in a T-shaped slot of the loopbody by a sheet spring. The sealing brush mainly consists of tightly arranged fine alloy wires with good flexibility and high-temperature resistance, has good elasticity, and is matched with the sheet spring at the bottom of the brush body. When the sealing brush contacts and abrades with a rotor, the sealing brush can elastically retract. Due to the function of brush wire clearance, the uniformincoming flow changes the motion direction after entering the brush wire bundle, and is changed into transversal flow perpendicular to the main flowing direction, therefore generating self-sealing effect, and further reducing leakage. The invention has the advantages of good sealing performance, simple and reasonable structure and the like, and is especially suitable for replacement and update ofmovable seals of prior steam turbines.

Owner:江苏鑫信润科技股份有限公司

Printed mobile phone case and processing technology thereof

InactiveCN105196471ANot easy to wear offProduction process scienceTelephone set constructionsLithographic artistThin membrane

The invention relates to the technical field of plastic raw material integration and formation, in particular to a printed mobile phone case and a processing technology thereof. The processing technology comprises the steps that ink is overprinted on a processed sheet material, after all colors are superposed, patterns appear, then high pressure formation is conducted on the sheet material according to the stretching proportion of the sheet material, and then the sheet material is placed in an injection mold for injection molding. By means of the processing technology, a product is good in stereo effect, the patterns are vivid, plastic raw materials which are used for bearing the sheet material printing and are subjected to injection molding clamp the ink therein, a rigid shielding layer is formed on the surface, the hardness of the shielding layer reaches 3 H, various decorative patterns can be printed, the surface of a thin membrane can exhibit different textures, therefore a number of different surface textures can be imitated, the stereo-lithography height of three-dimensional patterns can reach 40 mm, the ink is silkscreened on an intermediate layer, the total membrane is arranged on resin, so that letters are not prone to being worn off, the product patterns are difficult to wear, scrape off or discolor, and the stability and durability are achieved.

Owner:洪江基

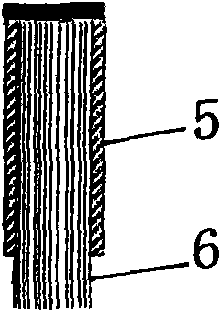

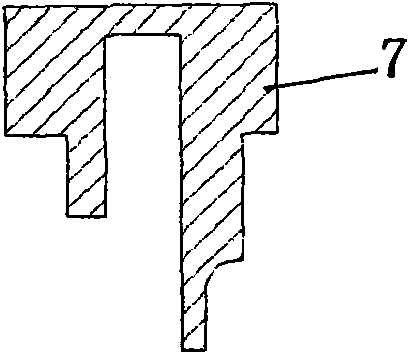

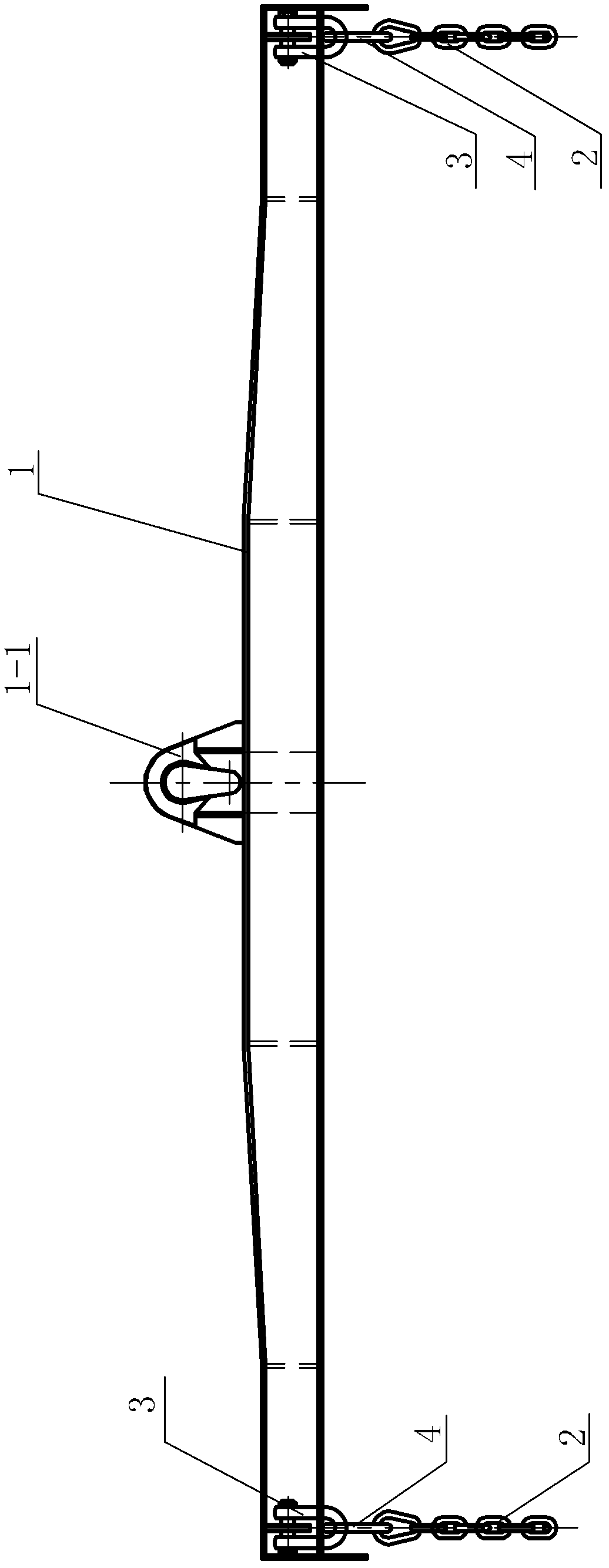

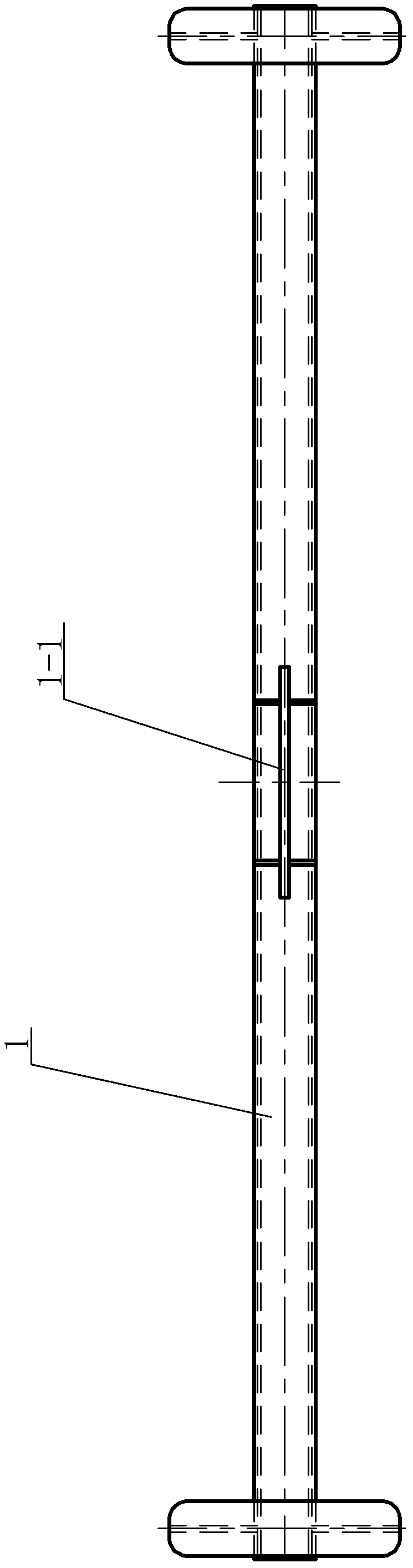

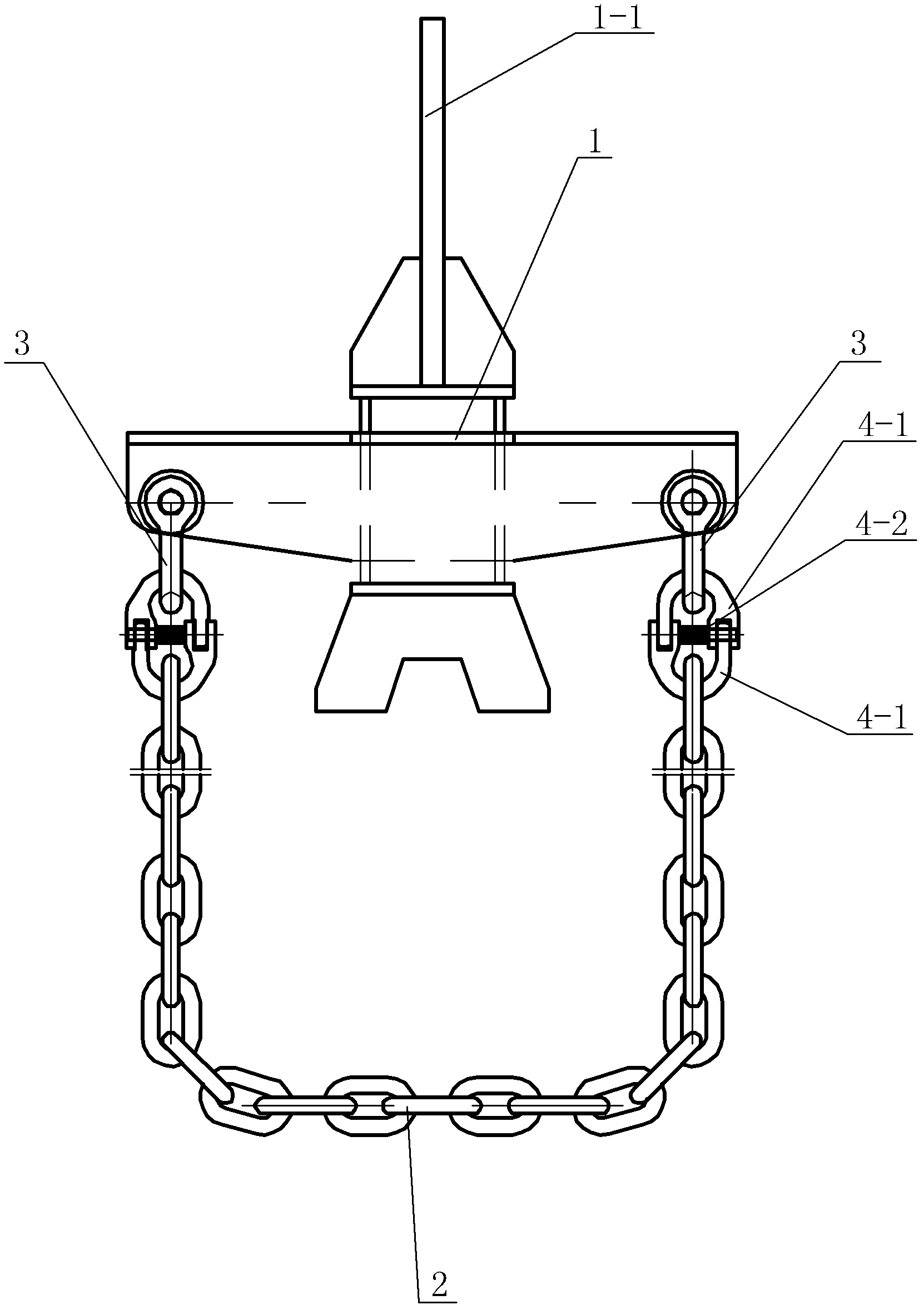

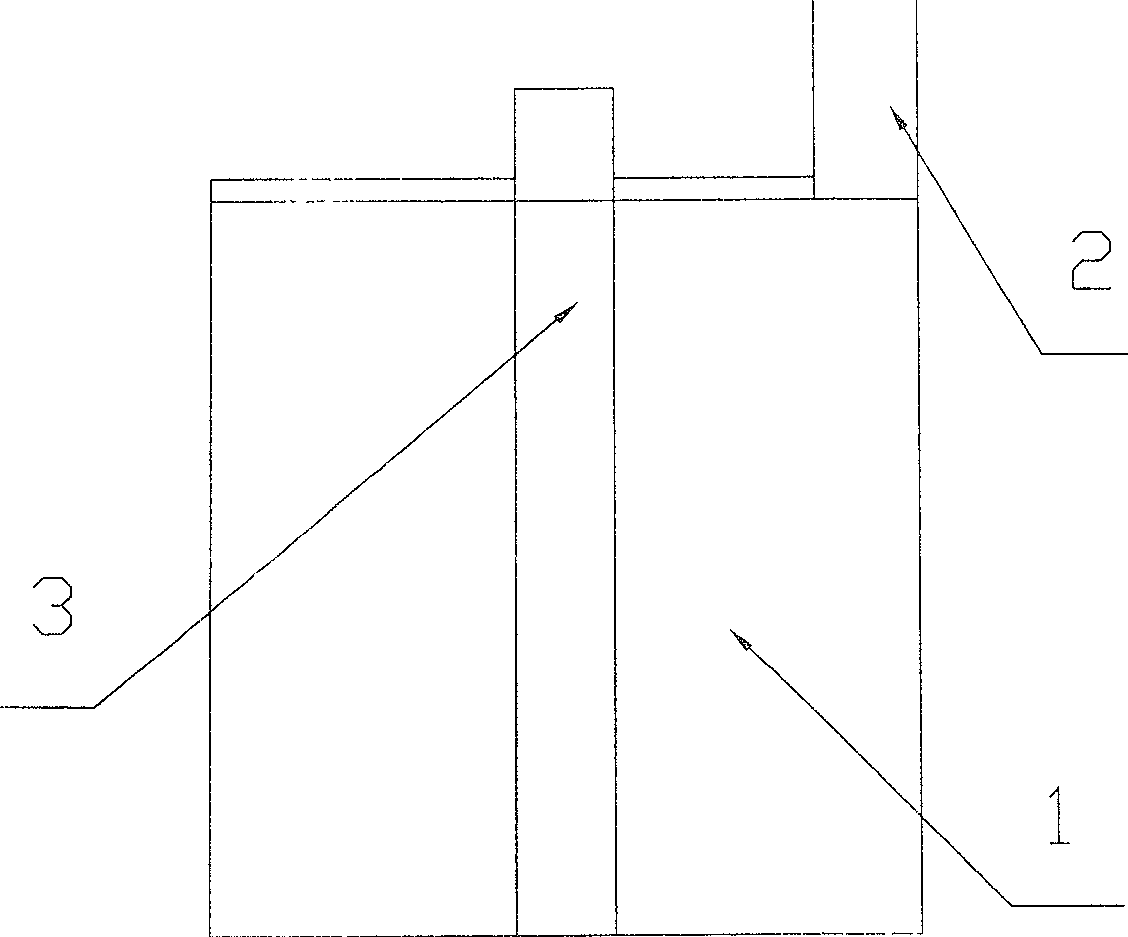

Sling for hoisting thread steel

InactiveCN102358561ANot easy to wearNot easy to wear offLoad-engaging elementsEngineeringFriction force

Relating to a sling, the invention specifically relates to a sling for hoisting thread steel. The invention aims to provide a solution to the problems that a small contact area between a sucker of a disk suspension and thread steel results in easy falling during hoisting, and great fraction force between a wire rope of a wire rope lockset and the thread steel leads to easy abrasion and even break of the wire rope and thereby causes production accidents. The sling of the invention comprises a beam 1, two chains 2, and four U-shaped rings 3. Specifically, lower surfaces at two ends of the beam 1 are respectively provided with two U-shaped rings 3 in parallel, two ends of each chain 2 are respectively connected to a U-shaped ring 3, and two ends of each chain 2 are located at one end of the beam 1. The sling provided in the invention is used for hoisting thread steel finished products.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Crush-resisting and high-temperature-resisting rubber material for transformer sealing rings and preparation method of crush-resisting and high-temperature-resisting rubber material

InactiveCN106496687AImprove wear resistanceImprove compatibility and lubricityRosinTriethylenetetramine

The invention discloses a crush-resisting and high-temperature-resisting rubber material for transformer sealing rings. The crush-resisting and high-temperature-resisting rubber material comprises, by weight, 70-90 parts of nitrile rubber, 20-40 parts of fluororubber, 60-80 parts of white carbon black, 2-4 parts of zinc oxide, 0.3-0.5 part of triethylenetetramine, 1.5-2.5 parts of sulphur S80, 1.5-2.5 parts of antiagers MB, 0.3-0.5 part of accelerant TMTD, 2-4 parts of methyl trimethoxy silane, 0.3-0.5 part of olein, 0.5-1 part of maleic rosin, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 part of titanate coupling agent NDZ-401, 6-8 parts of nano-graphite powder and 4-6 parts of castor oil. The crush-resisting and high-temperature-resisting rubber material has the advantages of good wear resistance, long-lasting antifriction performance, good crush and high temperature resistance performance, long service life, good sealing performance and applicability to transformer sealing ring materials.

Owner:岳承华

Anti-corrosion oil-resistant rubber material for bearing seal rings and preparation method thereof

The invention discloses an anti-corrosion oil-resistant rubber material for bearing seal rings, wherein the rubber material is prepared from the following raw materials in parts by weight: 70-90 parts of butadiene-acrylonitrile rubber, 20-40 parts of fluororubber, 40-60 parts of white carbon black, 20-30 parts of a talcum powder, 2-4 parts of zinc oxide, 0.5-1 part of maleic anhydride, 0.3-0.5 part of triethylenetetramine, 1.5-2.5 parts of sulfur S80, 1.5-2.5 parts of an anti-aging agent MB, 0.3-0.5 part of an accelerator TMTD, 2-4 parts of methyltrimethoxysilane, 0.5-1 part of oxidized petrolatum barium soap, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 part of a titanate coupling agent NDZ-401, 6-8 parts of a nano graphite powder, 4-6 parts of castor oil, and 0.5-1 part of vulcanized cotton seed oil. The rubber material has the advantages of good abrasion resistance, durable antifriction performance, good corrosion resistance, good oil resistance, long service life and good sealing property, and is suitable for bearing seal ring materials.

Owner:岳承华

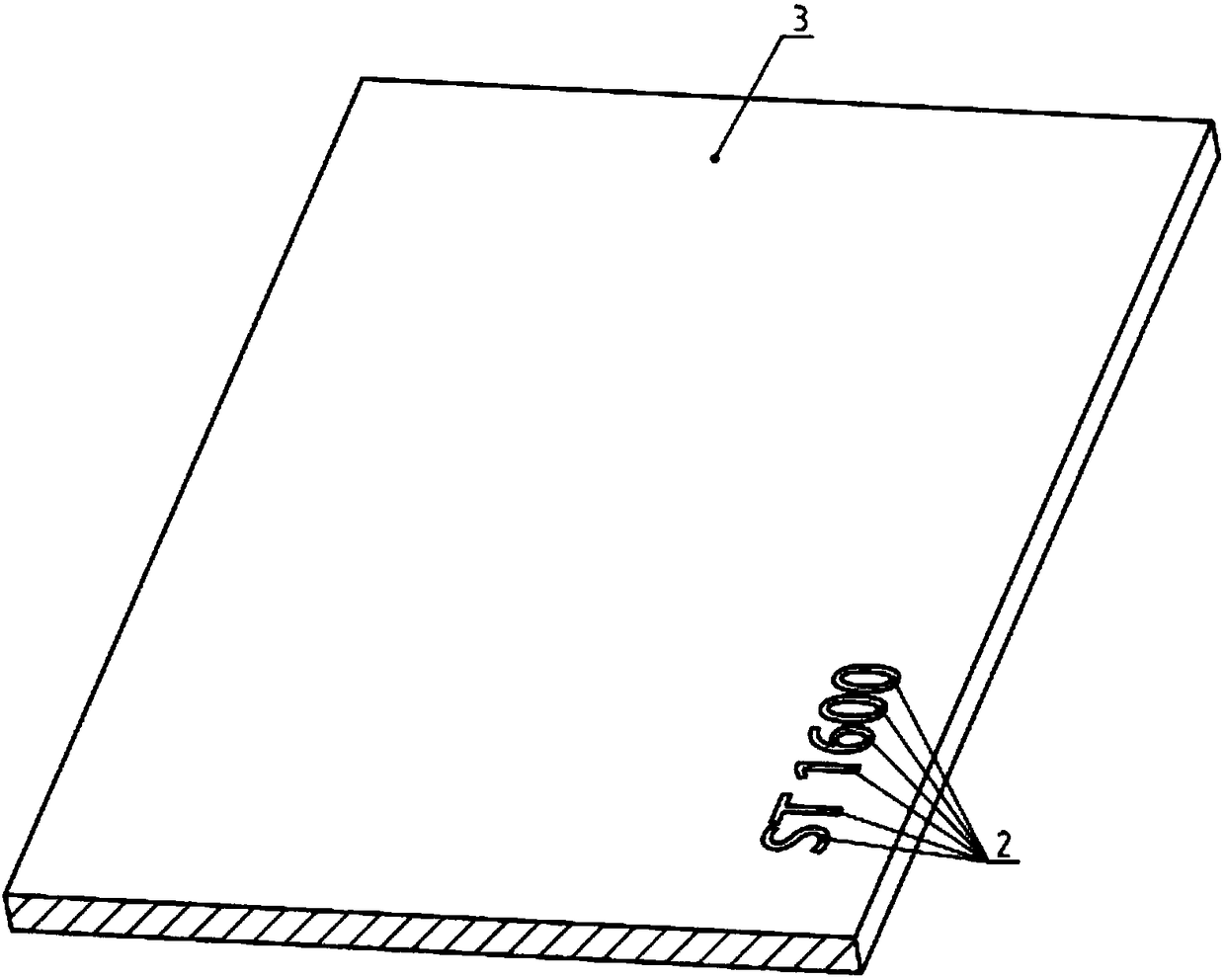

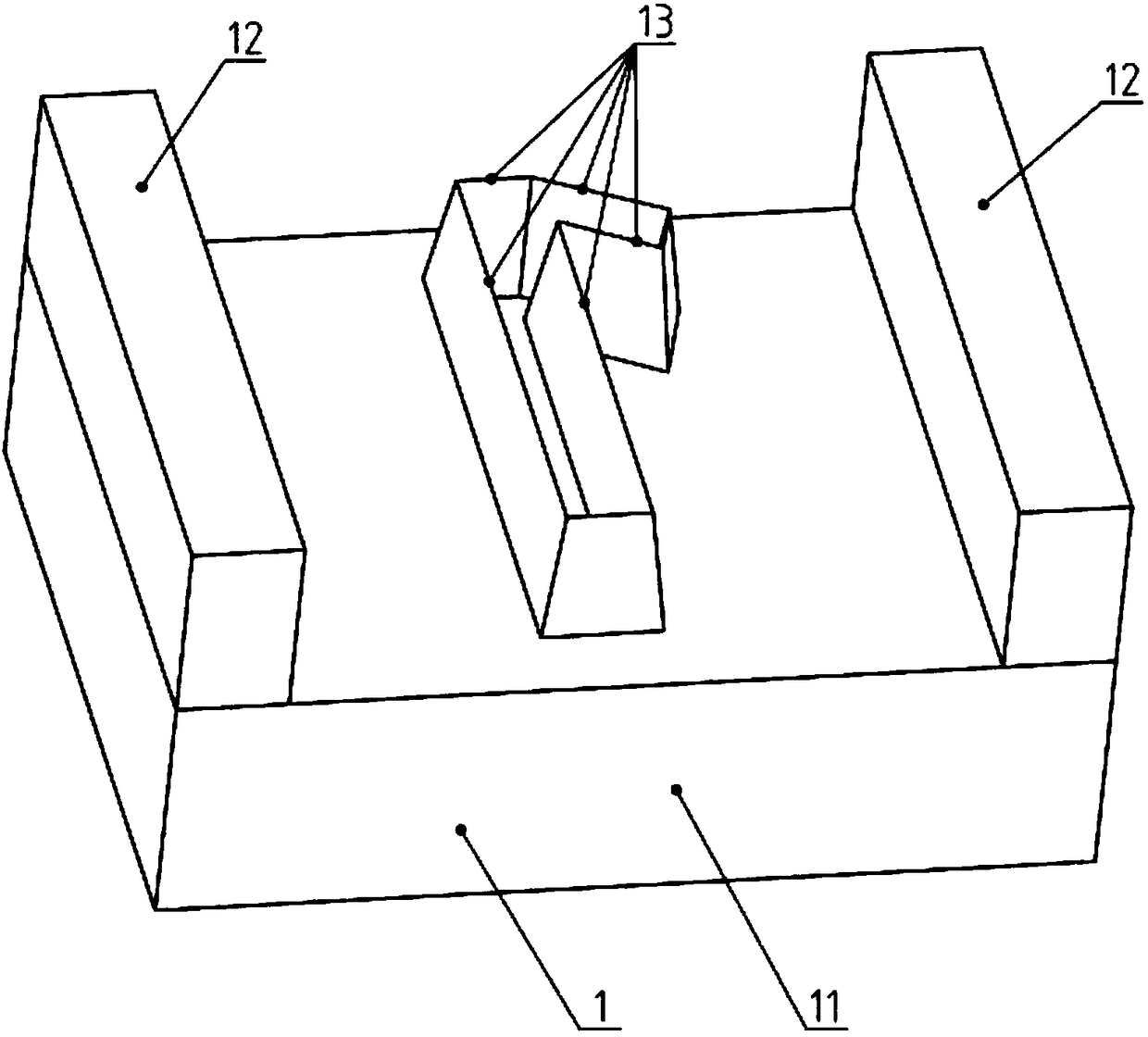

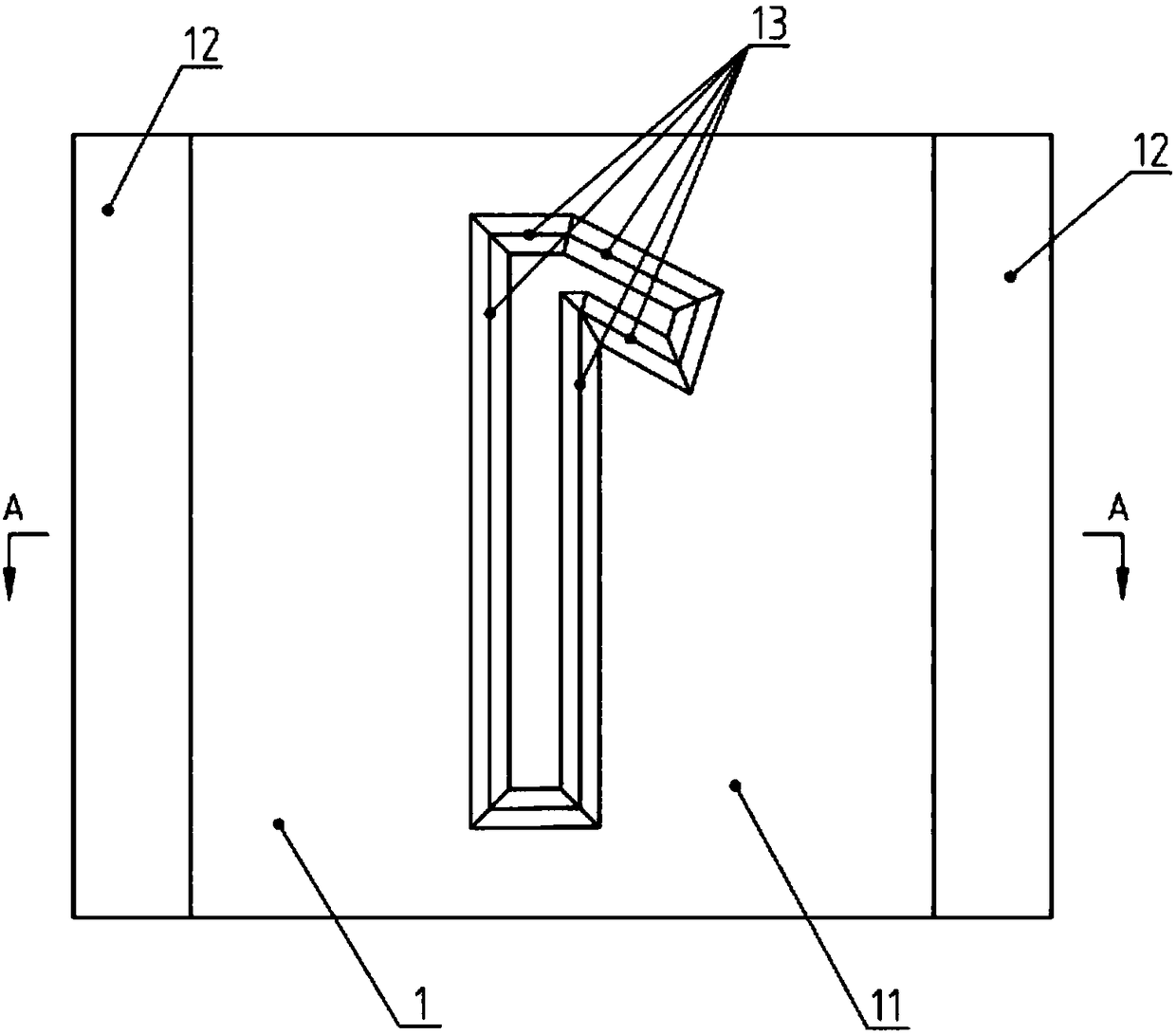

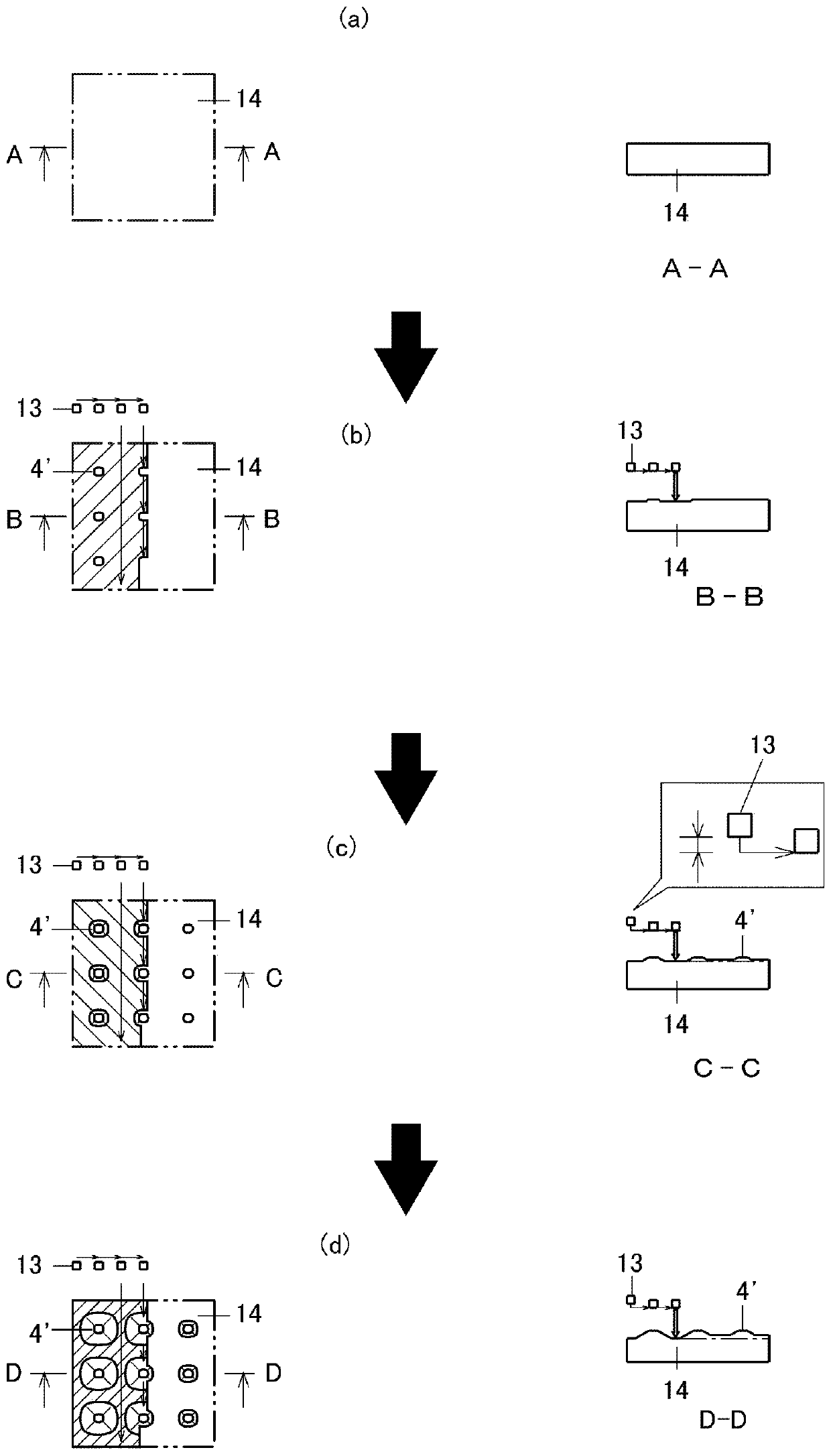

Sign blank processing equipment

InactiveCN108215256AQuality assuranceNot easy to wear offConveyorsBeltsRubber materialProcess equipment

The invention belongs to the technical field of rubber conveying belt manufacturing, and relates to a traceless sign rubber conveying belt, a manufacturing method and sign blank processing equipment.The traceless sign rubber conveying belt comprises a base band provided with a sign symbol, and an area where the sign symbol is located is rubber materials containing a coloring agent; the manufacturing method of the traceless sign rubber conveying belt comprises the steps that a base band blank provided with the sign blank is placed between two vulcanization plates, the base band blank is pressurized and heated for a certain time, and the base band blank and the vulcanization plates are fused into a whole; and the sign blank processing equipment comprises a plurality of stamping dies, a rack, an air cylinder, a pressing block and a cushion plate. The traceless sign symbol is generated on the surface of the conveying belt, the surface of the conveying belt is wholly abraded, sign information is kept all the time, the corresponding material and technical processes are selected by a user during connecting or repairing, the connecting or repairing quality is guaranteed, potential safetyhazards are eliminated, and accidents are avoided.

Owner:SHANGHAI SHUANGBAO MASCH CO LTD

Rubber material for antibacterial deodorant seal ring of drain pipe and preparation method thereof

The invention discloses a rubber material for an antibacterial deodorant seal ring of a drain pipe. The rubber material is made of raw material by following weight part: 80-100 of ethylene propylene terpolymer, 10-15 of chlorosulfonated polyethylene, 40-60 of white carbon black, 20-30 of bamboo charcoal powder, 0.5-1 of nano alumina, 2-4 of zinc oxide, 1.5-2.5 of sulfur S80, 1.5-2.5 of age resister MB, 0.3-0.5 of accelerator TMTD, 2-4 of methyltrimethoxy silane, 0.3-0.5 of tributyl citrate, 0.5-1 of tetrabutyl titanate, 0.15-0.25 of titanate coupling reagent NDZ-401, 6-8 of nano graphite powder, 4-6 of castor oil and 0.5-1 of peach gum. The rubber material is good in wear resisting effect and lasting in antifriction performance, has good antibacterial and deodorant performance and resistance to dirt and corrosion simultaneously, and is long in use life, good in airtightness, and suitably used as a seal ring material of the drain pipe.

Owner:岳承华

Waterproof anti-corrosion rubber material for automobile seal strips and preparation method thereof

The invention discloses a waterproof anti-corrosion rubber material for automobile seal strips, wherein the rubber material is prepared from the following raw materials in parts by weight: 100-120 parts of ethylene-propylene-diene monomer, 40-60 parts of white carbon black, 2-4 parts of zinc oxide, 1.5-2.5 parts of sulfur S80, 1.5-2.5 parts of an anti-aging agent MB, 0.3-0.5 part of an accelerator TMTD, 0.5-1 part of zinc naphthenate, 3-5 parts of trimethoxymethylsilane, 0.3-0.5 part of petroleum sodium sulfonate, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 part of a titanate coupling agent NDZ-401, 6-8 parts of a nano graphite powder, 1-2 parts of a polytetrafluoroethylene wax micro-powder, 15-25 parts of castor oil, and 3-5 parts of hydroxyl-fluoro silicone oil. The rubber material has the advantages of good abrasion resistance, lasting antifriction performance, and good waterproof and anti-corrosion properties, and has the advantages of long service life and good sealing performance when used as automobile seal strip materials.

Owner:闻承岳

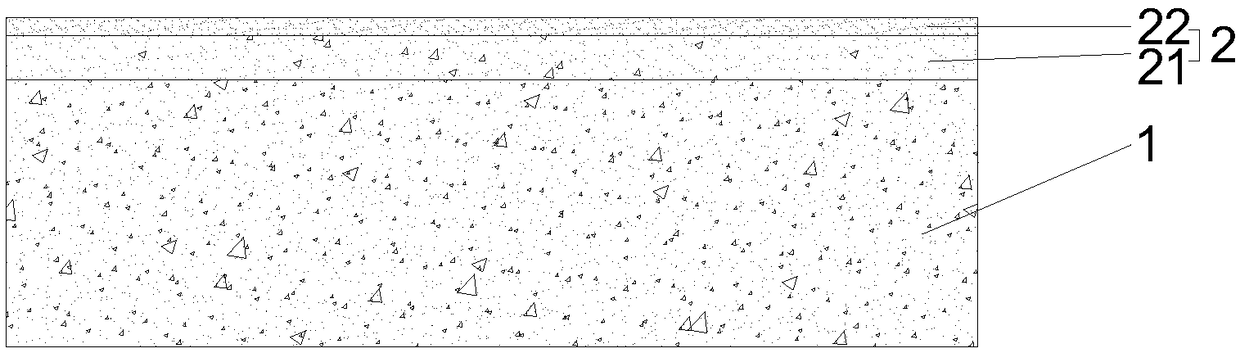

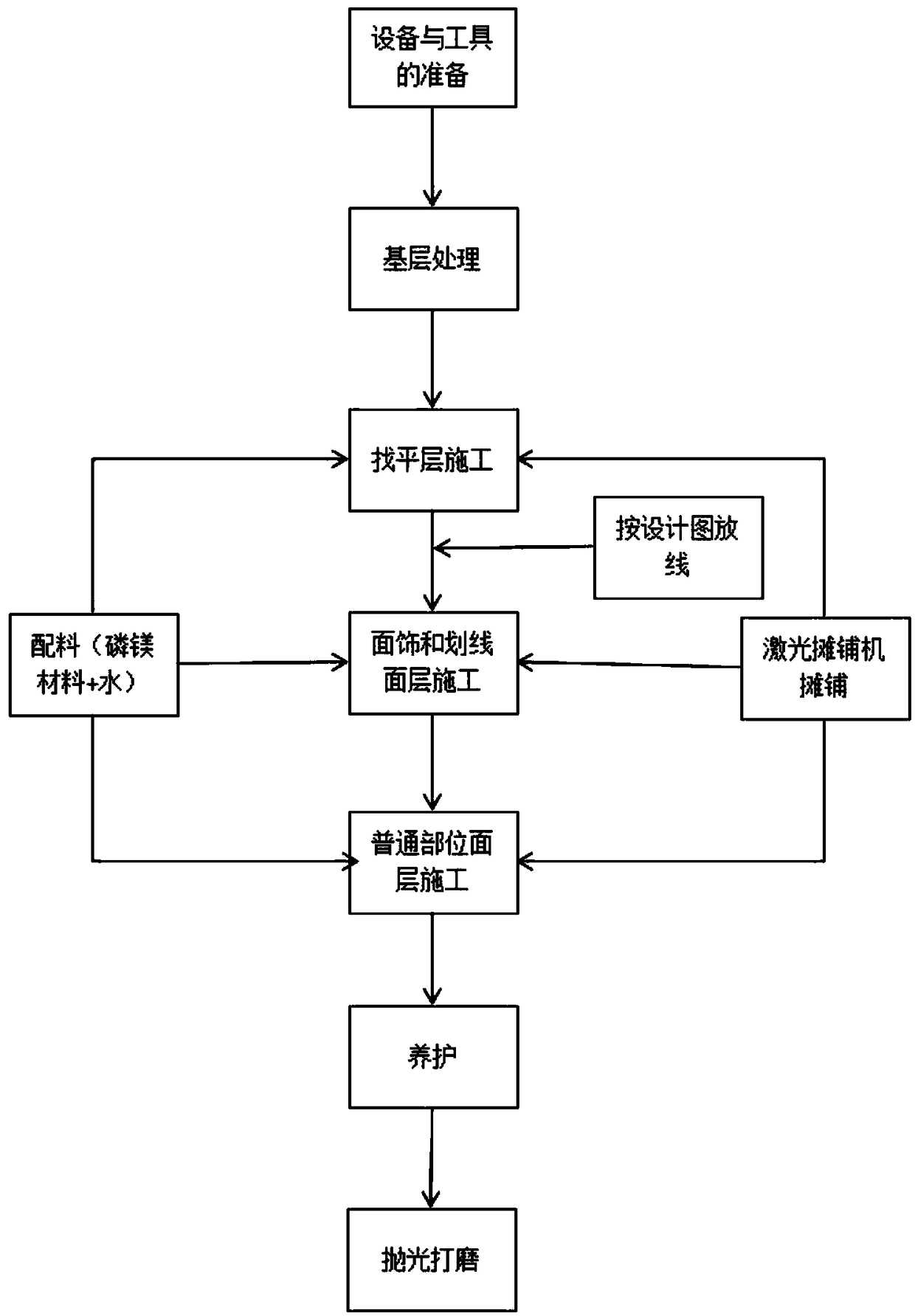

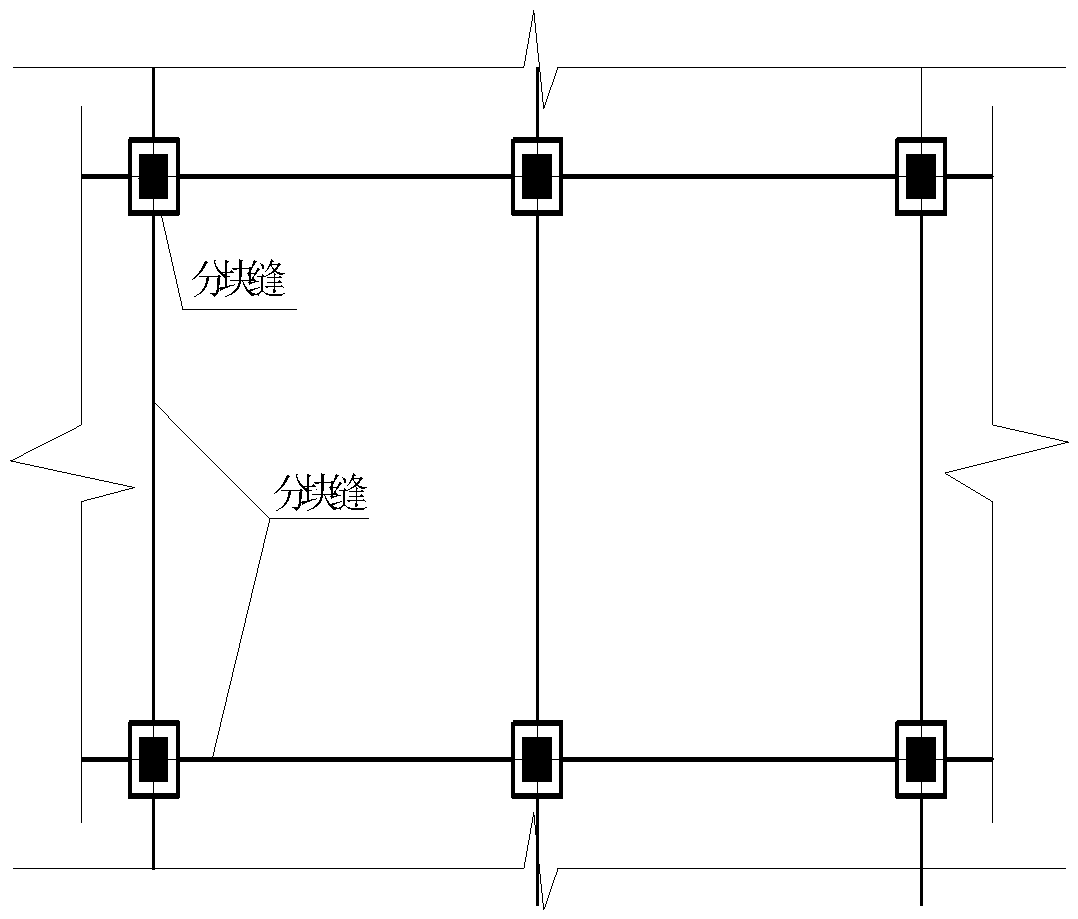

Ground surface course based on phosphorus and magnesium material and construction process thereof

ActiveCN108947464AShort construction periodQuality improvementFlooringMagnesium phosphateWear resistant

The invention relates to the technical field of terraces, in particular to a ground surface course based on a phosphorus and magnesium material and a construction process thereof. The ground surface course based on the phosphorus and magnesium material is formed by combining magnesium phosphate cement, an additive, an admixture, a pigment and an aggregate in a specific proportion. The ground surface course based on the phosphorus and magnesium material has high strength, wear resistance and bonding property and can be constructed anytime without construction joints. The content of volatile organic compounds (VOCs) is zero, and the ground surface course has very good fire resistance. The ground surface course is high in early strength, short in setting time, short in maintenance time, highin mechanical strength, unlike to crack, high in fracture resistance, wear-resistant and short in construction period and can be put into use immediately. By means of a paving process using a laser paver, a level ground is paved by the precision laser paver, the ground smoothness and levelness can be improved by over 3 times, and the compactness and strength can be improved by over 20%, and meanwhile, the work efficiency can be also improved and the labor is saved. The whole paved matrix is homogenous and compact.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

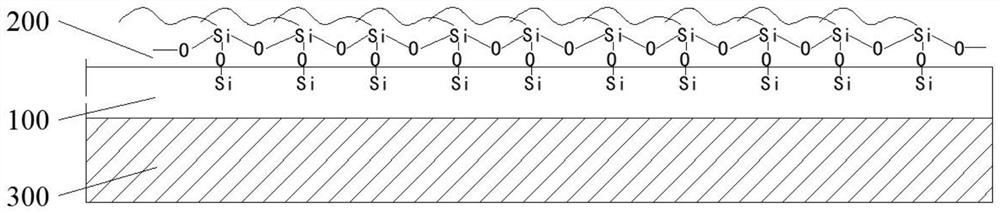

Metal surface easy-to-clean coating and easy-to-clean coating processing method

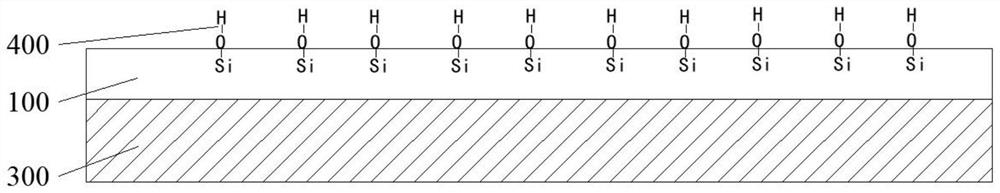

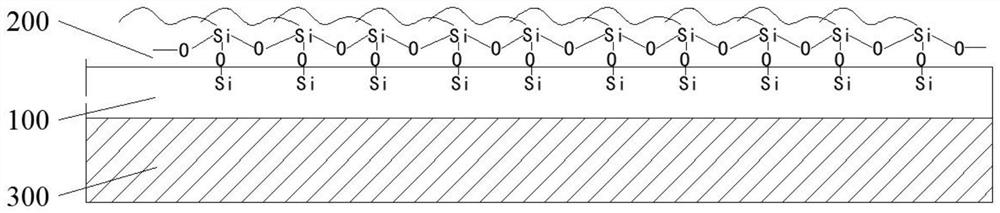

PendingCN113953166AAchieve technical advantageAchieve the desired effectPretreated surfacesCoatingsCoated surfacePerfluoropolyether

The invention provides a metal surface easy-to-clean coating and an easy-to-clean processing method, and relates to the technical field of paints. The metal surface easy-to-clean coating is formed on the surface of a metal base material and comprises a silicon dioxide glassy coating and a perfluoropolyether coating; the silicon dioxide glassy coating is arranged on the surface of the metal base material; and the perfluoropolyether coating is grafted on the surface of the silicon dioxide glassy coating. By means of the metal surface easy-to-clean coating, the technical problems that in the prior art, the coating on a stainless steel surface is poor in easy-to-clean effect and short in service life are solved, and the use requirement of a user for kitchen appliances is met.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

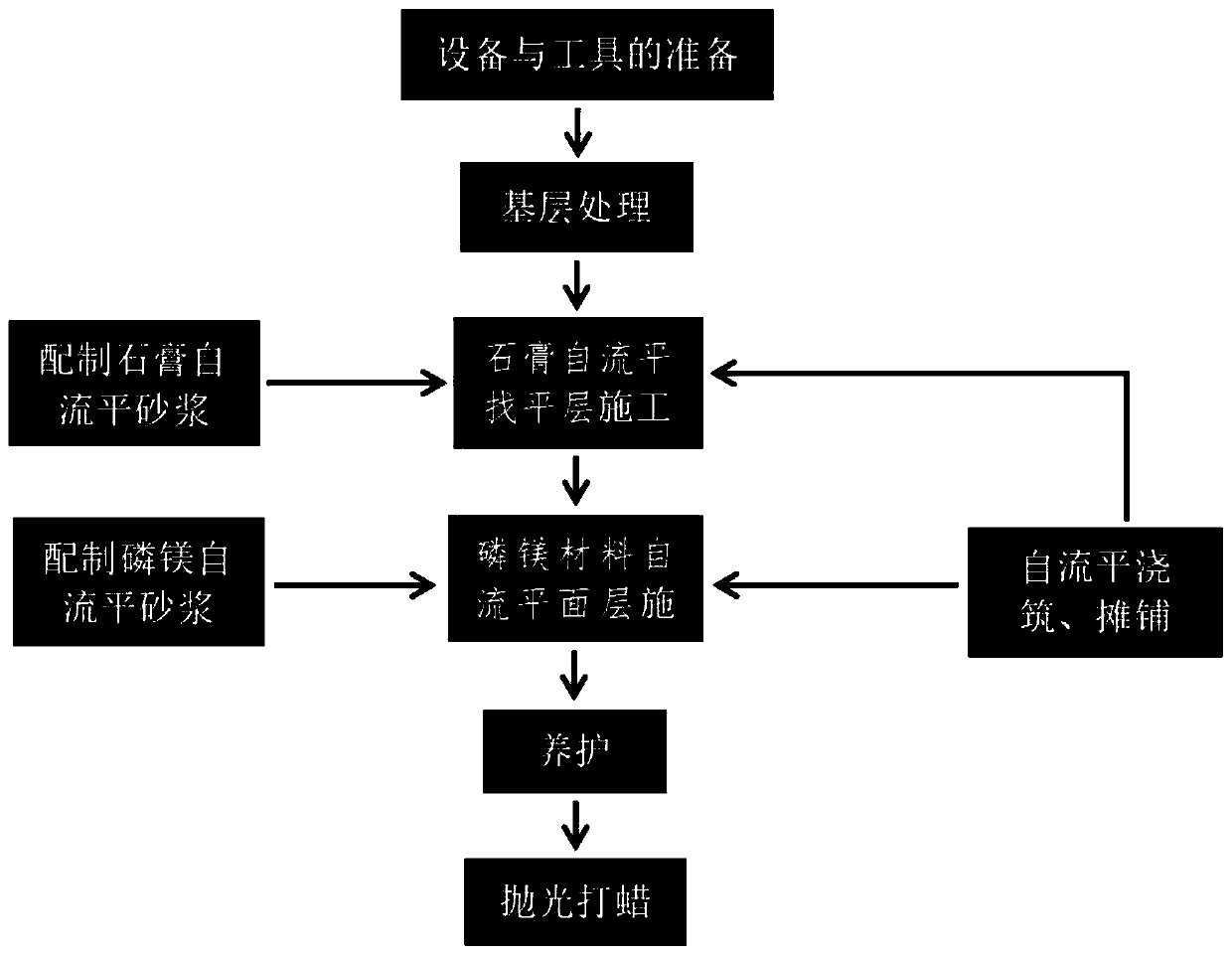

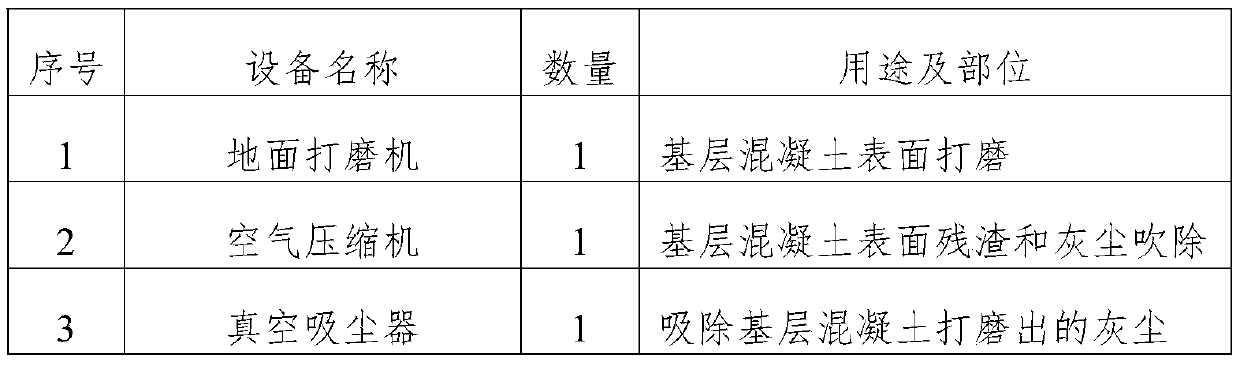

Indoor composite floor based on phosphorous magnesium materials and self-leveling gypsum, and construction method of indoor composite floor

ActiveCN110130615AImprove stabilityNot easy to wear offFlooringWear resistanceUltimate tensile strength

The invention discloses an indoor composite floor based on phosphorous magnesium materials and self-leveling gypsum. The indoor composite floor based on the phosphorous magnesium materials and the self-leveling gypsum comprises a concrete base layer and is sequentially provided with the concrete base layer, a gypsum self-leveling leveling layer and a phosphorous magnesium material self-leveling face layer from bottom to top, and the gypsum self-leveling leveling layer is located between the concrete base layer and the phosphorous magnesium material self-leveling face layer. A construction method of the indoor composite floor comprises the steps of preparation of equipment and tools, base layer treatment, construction of the gypsum self-leveling leveling layer, construction of the phosphorous magnesium material self-leveling face layer, curing, polishing and waxing, and the like. Aiming at solving the problems that organic self-leveling materials are high in construction cost and proneto peeling, and the self-leveling materials taking the gypsum as basic materials are poor in water resistance and abrasion resistance, the provided indoor composite floor has early strength and is short in coagulation time, short in curing time, high in mechanical strength, not prone to cracking, free of hollowing, high in breaking resistance, high in water resistance, high in abrasion resistance,good in flowing property and low in cost, the construction period is short, and the construction efficiency is high.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

High-temperature-resistant anti-aging rubber material used for hot-water valve seal ring and preparation method thereof

The invention discloses a high-temperature-resistant anti-aging rubber material used for a hot-water valve seal ring. The rubber material is composed of the following raw materials in parts by weight: 100 to 120 parts of EPDM rubber, 5 to 10 parts of bismaleimide resin, 1 to 2 parts of terpene resin, 60 to 80 parts of white carbon black, 2 to 4 parts of zinc oxide, 1.5 to 2.5 parts of sulfur S80, 1.5 to 2.5 parts of an anti-aging agent MB, 0.3 to 0.5 part of an accelerator TMTD, 2 to 4 parts of methyltrimethoxysilane, 0.3 to 0.5 part of rosin-polythylene oxide ester, 0.5 to 1 part of tetrabutyl titanate, 0.15 to 0.25 part of a titanate coupling agent NDZ-401, 6 to 8 parts of nanometer graphite powder, 4 to 6 parts of castor oil and 0.3 to 0.5 part of trinonylphenyl phosphite. The rubber material provided by the invention has the advantages of good wear-resistant effect, durable antifriction performance, good high-temperature-resistant and anti-aging performances, long service life, good sealing properties, and applicability to hot-water valve seal ring materials.

Owner:岳承华

Mosquito-repellent insect-proofing automobile sealing strip rubber material, and preparation method thereof

InactiveCN106496807ANot easy to wear offExcellent abrasion resistanceRubber materialMaterials science

The invention discloses a mosquito-repellent insect-proofing automobile sealing strip rubber material. The mosquito-repellent insect-proofing automobile sealing strip rubber material is prepared from, by weight, 100 to 120 parts of EPDM, 40 to 60 parts of white carbon black, 0.5 to 1 part of diethyltoluamide, 0.1 to 0.15 part of prallethrin, 1 to 2 parts of cashew nut shell oil, 2 to 4 parts of zinc oxide, 1.5 to 2.5 parts of sulphur S80, 1.5 to 2.5 parts of anti-aging agent MB, 0.3 to 0.5 part of accelerant TMTD, 0.1 to 0.15 part of tea saponin, 3 to 5 parts of methyltrimethoxysilane, 0.5 to 1 part of tetrabutyl titanate, 0.15 to 0.25 part of titanate coupling agent NDZ-401, 6 to 8 parts of nano-graphite powder, 20 to 30 parts of castor oil. The mosquito-repellent insect-proofing automobile sealing strip rubber material possesses excellent wear resistance, long-lasting antifriction performance, and excellent mosquito-repellent insect-proofing effect, and is long in service life and excellent in sealing performance as an automobile sealing strip material.

Owner:闻承岳

Flame-retarding antistatic rubber material used in bearing sealing ring and preparation method thereof

The invention discloses a flame-retarding antistatic rubber material used in a bearing sealing ring and a preparation method thereof. The rubber material is prepared from, by weight, 100-120 parts of nitrile butadiene rubber, 40-60 parts of white carbon black, 20-30 parts of electric-conductive mica powder, 2-4 parts of zinc oxide, 1.5-2.5 parts of sulfur S80, 1.5-2.5 parts of an anti-aging agent MB, 0.3-0.5 parts of an accelerant TMTD, 2-4 parts of methyltrimethoxysilane, 0.5-1 part of triethanolamine borate, 3-5 parts of triphenyl phosphite, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 parts of a titanate coupling agent NDZ-401, 6-8 parts of nano graphite powder, 4-6 parts of castor oil, and 0.5-1 part of oleamide. The rubber material has good wear resistance and durable friction reduction performance, has excellent anti-static and flame-retarding performance, is long in service life and has good sealability, and is suitable for being used for a bearing sealing ring.

Owner:岳承华

Impact-resisting and corrosion-resisting rubber material for water pump sealing rings and preparation method of impact-resisting and corrosion-resisting rubber material

The invention discloses an impact-resisting and corrosion-resisting rubber material for water pump sealing rings. The impact-resisting and corrosion-resisting rubber material comprises, by weight, 100-120 parts of ethylene-propylene-diene monomer rubber, 10-15 parts of butadiene styrene rubber, 3-5 parts of coumarone resin, 60-80 parts of white carbon black, 0.5-1 part of silicon carbide whisker, 2-4 parts of zinc oxide, 1.5-2.5 parts of sulphur S80, 1.5-2.5 parts of antiagers MB, 0.3-0.5 part of accelerant TMTD, 2-4 parts of methyl trimethoxy silane, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 part of titanate coupling agent NDZ-401, 6-8 parts of nano graphite powder, 4-6 parts of castor oil and 0.5-1 part of carnauba wax. The impact-resisting and corrosion-resisting rubber material has the advantages of good wear resistance effect, long-lasting antifriction performance, good impact and corrosion resistance performance, long service life, good sealing performance and adaptability to water pump sealing ring materials.

Owner:岳承华

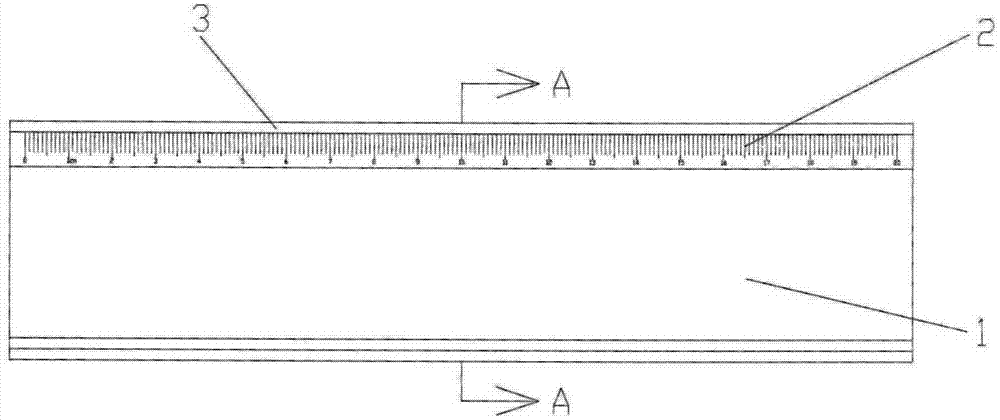

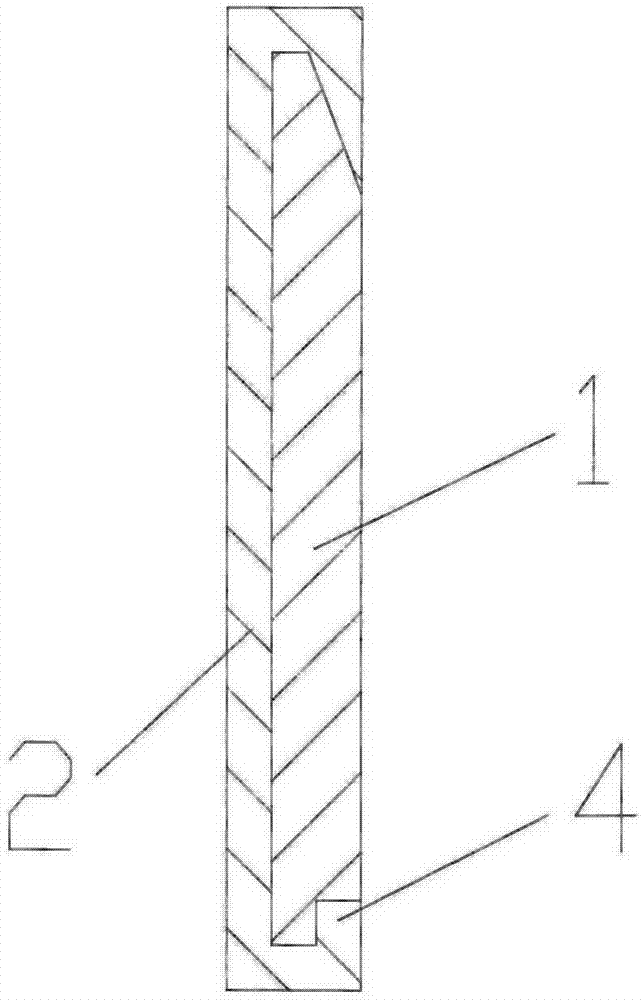

Plastic ruler with transparent protection sleeve

InactiveCN103112287AAvoid breakingNot easy to wear offStraightedgesRulers for direct readingEngineering management

Owner:徐子杰

High-durability mildewproof automobile sealing strip rubber material and preparation method thereof

The invention discloses a high-durability mildewproof automobile sealing strip rubber material. The material is prepared from, by weight, 100-120 parts of ethylene propylene diene monomer, 40-60 parts of white carbon black, 4-8 parts of hectorite, 0.5-1 part of cinnamon oil, 0.5-1 part of zanthoxylum oil, 2-4 parts of zinc oxide, 1.5-2.5 parts of sulphur S80, 1.5-2.5 parts of antiager MB, 0.3-0.5 part of accelerant TMTD, 3-5 parts of methyltrimethoxysilane, 0.5-1 part of caprylic capric triglyceride, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 part of titanate coupling agent NDZ-401, 6-8 parts of nanometer graphite powder, 20-30 parts of castor oil and 0.5-1 part of honey. The rubber material is good in wear-resisting effect, durable in antifriction performance, long lasting in anti-mold property, good in hygiene property and high in durability. When the rubber material is used as an automobile sealing strip material, the automobile sealing strip material has the advantages of being long in service life and good in sealing property.

Owner:闻承岳

Alkenyl succinic anhydride-modified highly flexible automobile sealing strip rubber material and preparation method thereof

InactiveCN106496804ANot easy to wear offExcellent abrasion resistanceRubber materialPolyvinyl butyral

The invention discloses an alkenyl succinic anhydride-modified highly flexible automobile sealing strip rubber material. The alkenyl succinic anhydride-modified highly flexible automobile sealing strip rubber material is prepared from 100-120 parts by weight of EPDM, 40-60 parts by weight of white carbon black, 3-5 parts by weight of gypsum whisker, 2-4 parts by weight of alkenyl succinic anhydride, 2-4 parts by weight of zinc oxide, 1.5-2.5 parts by weight of sulfur S80, 1.5-2.5 parts by weight of an antiager MB, 0.3-0.5 parts by weight of an accelerator TMTD, 3-5 parts by weight of methyl trimethoxysilane, 0.3-0.5 parts by weight of sodium stearyl lactate, 0.5-1 part by weight of polyvinyl butyral, 0.5-1 part by weight of tetrabutyl titanate, 0.15-0.25 parts by weight of a titanate coupling agent NDZ-401, 6-8 parts by weight of nano-graphite powder and 20-30 parts by weight of castor oil. The rubber material has good wear resistance, lasting anti-friction performances and excellent flexibility, and has the advantages of long service life and good sealing property in the automobile sealing strip.

Owner:闻承岳

Solid diffusion surface anti-corrosion treatment method for carbon steel clamping and pressing pipe fitting

ActiveCN111893430AImprove corrosion resistanceImprove wear resistanceSolid state diffusion coatingPipe fittingAluminium powder

The invention discloses a solid diffusion surface anti-corrosion treatment method for a carbon steel clamping and pressing pipe fitting. The surface anti-corrosion treatment method is a solid diffusion process and comprises the following steps of: wrapping a workpiece in an inert material, adding materials including but not limited to zinc powder, aluminum powder and nickel powder, and heating theresulting product in a closed container to 300-500 DEG C to make zinc, nickel, aluminum and other metals diffuse into the workpiece, so that a compact and uniform intermetallic compound coating of zinc, other alloys and iron is formed on the surface layer of a substrate. The coating can be polished, oiled, painted, sprayed with plastic, or treated with a sealing agent or an organic coating, and the corrosion resistance or decorative performance or the like of the coating can be further improved. The method is performed in the heat-insulating and sealed container, the heat efficiency is high,the energy-saving requirement is met, no waste water or smoke dust is generated in the whole process, and the process is environmentally friendly.

Owner:江苏领嘉科技有限公司

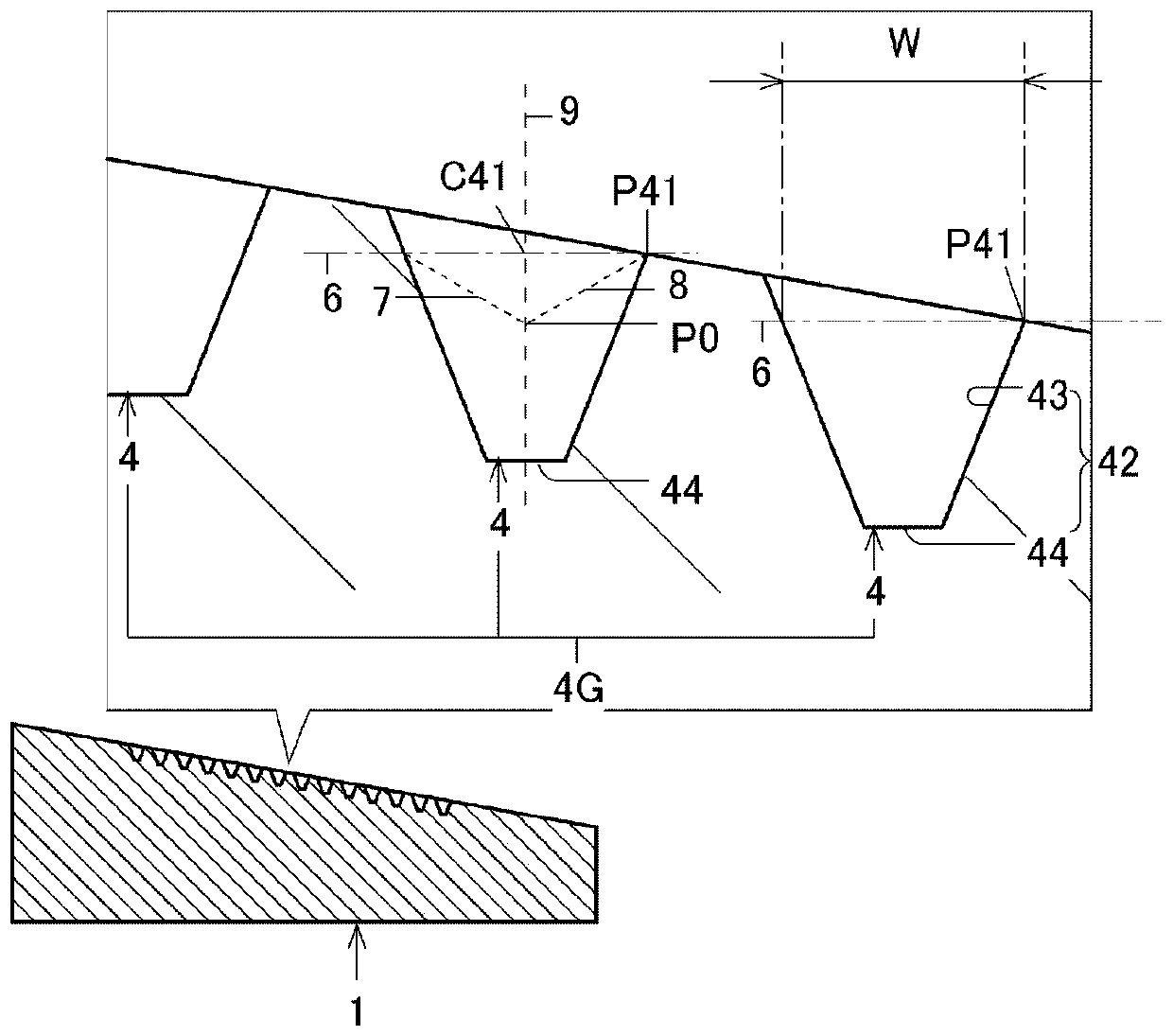

Sand bottom technique and mold thereof

The present invention relates to sewing machine producing technology, and is especially bobbin case sanding process and mold for smoothening the bottom and side wall of bobbin case to reduce damage to sewing thread. The technological scheme of the present invention includes the following steps: 1. fixing bobbin case on a seat and fixing one rotating head with sleeved abrasive paper onto a drilling machine; 2. inserting the rotating head into the bobbin case and rotating to polishing the bobbin case for 1-10 sec; and taking out the rotating head with abrasive paper.

Owner:ZHEJIANG HUAYA MACHINE PARTS

A solid-state diffusion surface anti-corrosion treatment method for carbon steel clamping pipe fittings

ActiveCN111893430BImprove corrosion resistanceImprove wear resistanceSolid state diffusion coatingPipe fittingAluminium powder

Owner:江苏领嘉科技有限公司

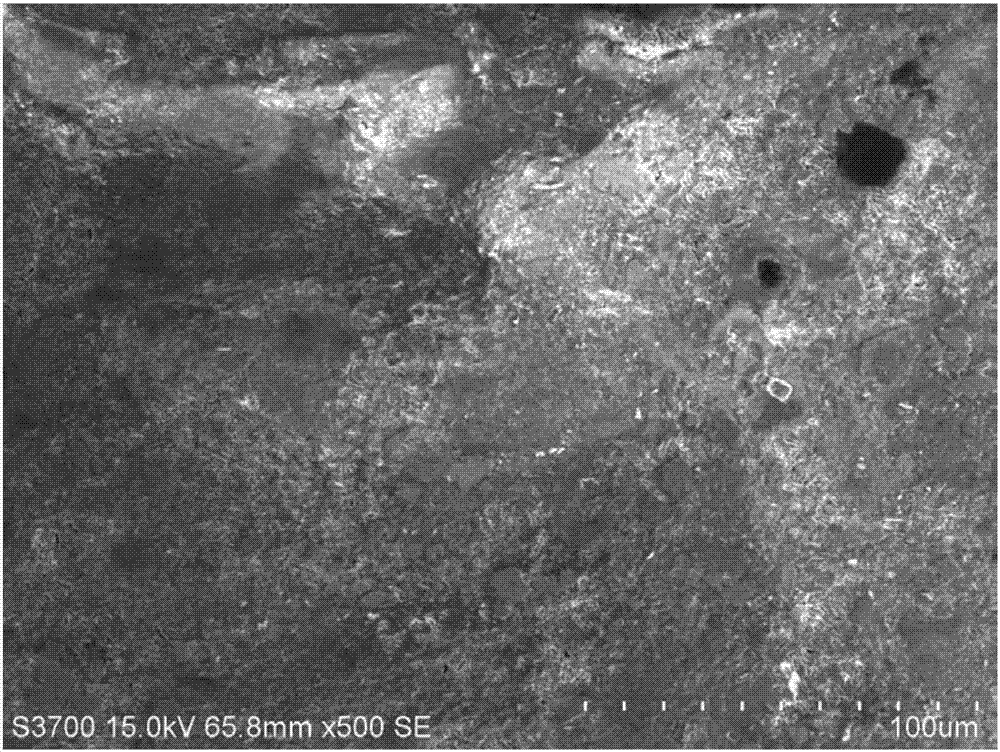

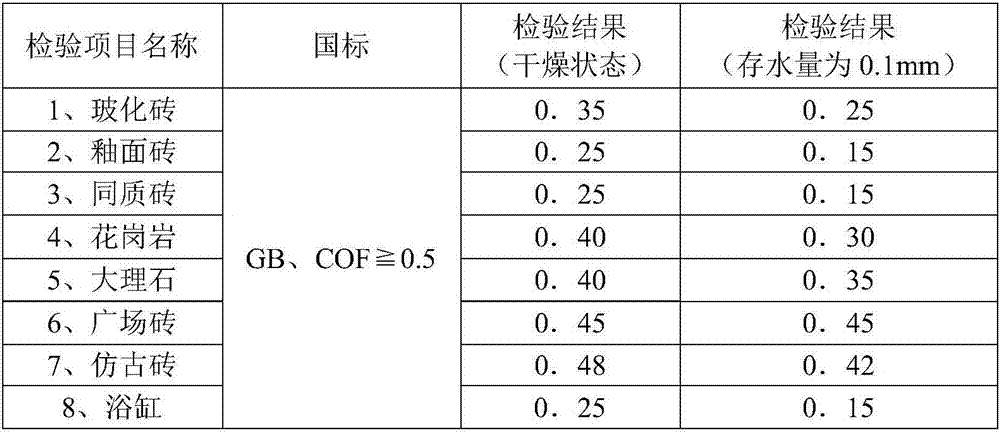

surface anti-slip treatment agent

ActiveCN105647360BSmall smellMicroscopic reaction speed is fastPolyester coatingsSalicylic acidSuccinic acid

The invention provides a surface antiskid treating agent which comprises 10-15 wt% of composite ionic surfactant, 6-8 wt% of hydroxyacetic acid, 16-24 wt% of tartaric acid, 4-7 wt% of hydrophilic chain extender, 5-8 wt% of salicylic acid, 5-10 wt% of succinic acid, 10-15 wt% of citric acid, 25-30 wt% of deionized water, 0.25-0.3 wt% of defoaming agent and 0.1-0.2 wt% of air entraining agent. Compared with the existing surface antiskid treating agent, the surface antiskid treating agent provided by the invention has the characteristics of low odor, high microreaction speed with various materials, high antiskid factor, small damage to the ceramic tile surface, and the like.

Owner:长沙友胜建材科技有限公司

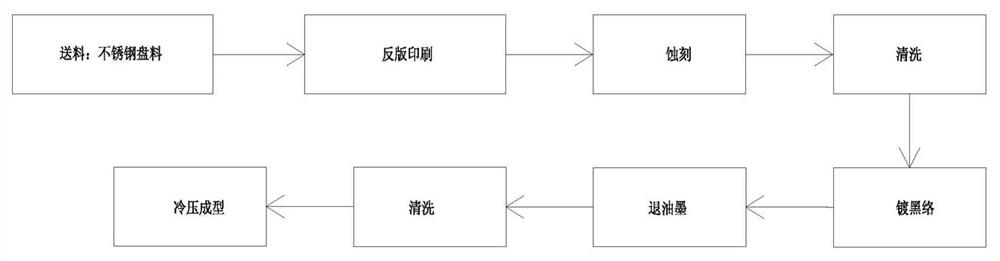

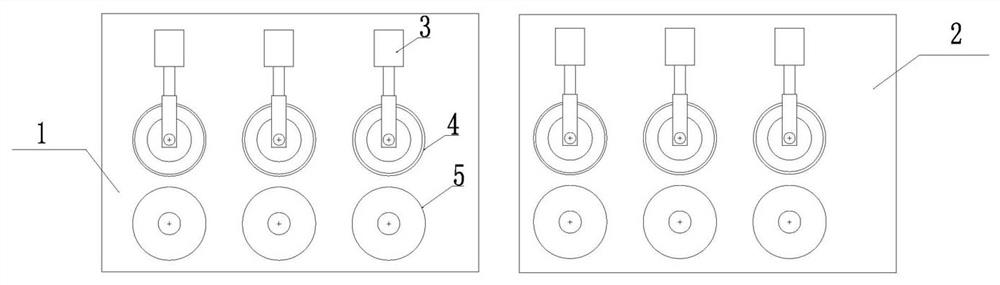

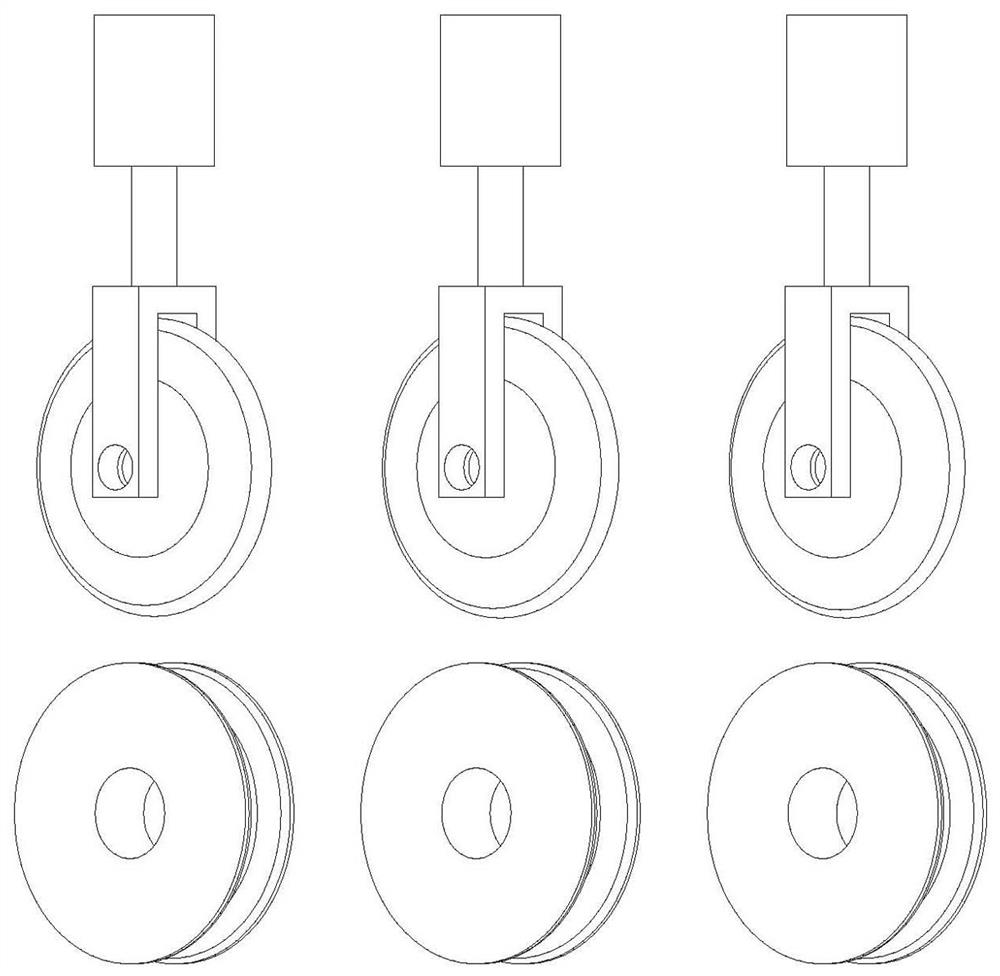

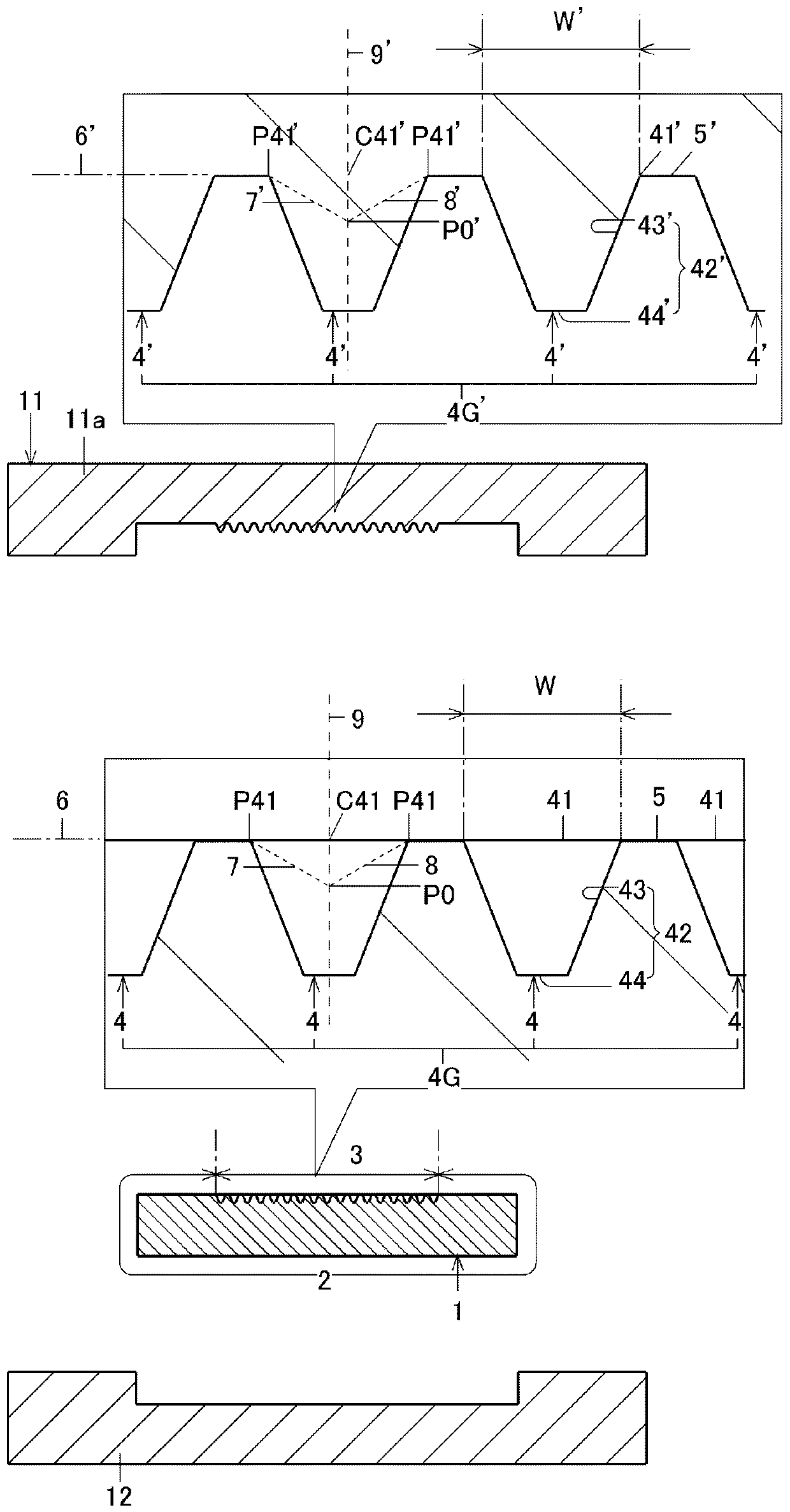

A processing technology of durable measuring tape based on stainless steel substrate

The invention relates to the field of tape measure production, in particular to a processing technology for a durable tape measure tape based on a stainless steel substrate that is not easy to rust, super wear-resistant, and can restore the forming radian after flattening, including selecting stainless steel coil materials, stainless steel coil materials Reverse printing is carried out by a reverse printing machine, and UV-resistant ink is printed on the stainless steel substrate, wherein the MiG lines and numbers on the stainless steel plate are not printed, and the printed stainless steel substrate is etched on the MiG lines and numbers. Carry out etching, etch out the groove, clean the groove with clean water after etching, coat a layer of black network in the etched groove, then use NaoH solution to remove the ink on the stainless steel substrate, and finally press it through cold pressing forming equipment Out of the radian of the tape, the tape of the present invention is not easy to rust, wear-resistant, and has a long service life; the tape formed by cold pressing has a more uniform deformation thickness, and the radian is more stable during use, and the radian can be restored after being flattened.

Owner:HENAN JIANGHUA MEASURE TOOLS CO LTD

Plastic molded product

PendingCN110612184AAvoid breakingNot easy to wear offDomestic articlesEngineeringMechanical engineering

Owner:YKK CORP

Technique of processing sewing machine shuttle putamen stay wire bore ram compression angle and mold thereof

Owner:ZHEJIANG HUAYA MACHINE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com