surface anti-slip treatment agent

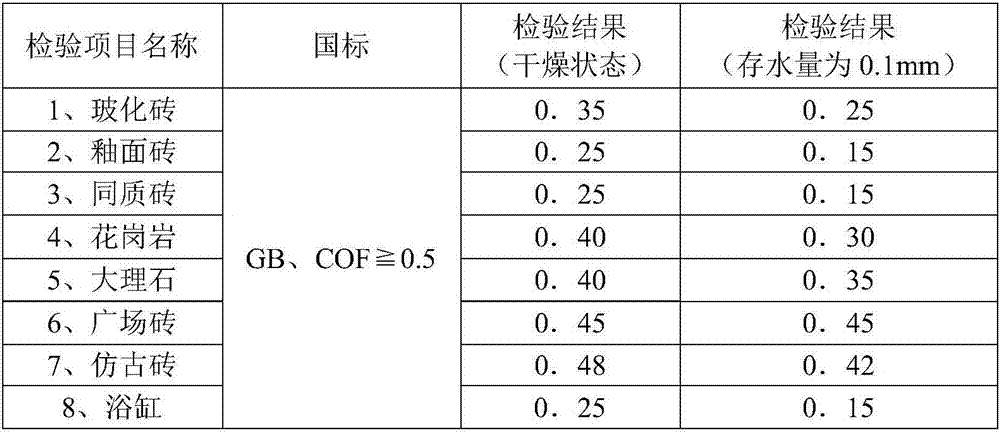

A technology of anti-slip treatment and surfactant, applied in the direction of polyester coatings, coatings, etc., can solve the problems of insufficient durable anti-slip effect, short effect duration, and damage to the original appearance of the ground, and achieve high anti-slip coefficient, fast response speed, and short construction period short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to compound ionic surfactant 14.7%wt; glycolic acid 8%wt; tartaric acid 17%wt; hydrophilic chain extender: 4%wt; salicylic acid 8%wt; succinic acid 7%wt; citric acid 12%wt and deionized water 29%wt taking materials for compounding, stirring at low speed for 20 minutes, adding 0.2%wt defoamer, stirring again at low speed for 15 minutes and adding 0.1%wt air-entraining agent to obtain surface anti-skid treatment agent.

Embodiment 2

[0033] According to compound ionic surfactant 15%wt; glycolic acid 8%wt; tartaric acid 24%wt; hydrophilic chain extender: 7%wt; salicylic acid 8%wt; succinic acid 10%wt; citric acid 15%wt and deionized water 12.5%wt taking materials for compounding, stirring at low speed for 20 minutes, adding 0.3%wt defoamer, stirring again at low speed for 15 minutes and adding 0.2%wt air-entraining agent to obtain surface anti-slip treatment agent.

Embodiment 3

[0035] According to compound ionic surfactant 12%wt; glycolic acid 7%wt; tartaric acid 20%wt; hydrophilic chain extender 5%wt; salicylic acid 7%wt; succinic acid 8%wt; citric acid 12%wt Take 28.6%wt of deionized water and compound, stir at low speed for 20 minutes, add 0.2%wt defoamer, stir again at low speed for 15 minutes, add 0.2%wt air-entraining agent to obtain surface anti-slip treatment agent.

[0036] The method of using the surface anti-slip treatment agent: after the surface anti-slip treatment agent obtained in Examples 1 and 3 is applied to the surface of the vitrified tile, after standing for 10 to 15 minutes, the surface anti-slip treatment agent on the surface of the vitrified tile is rinsed with clean water , rinse for 3 to 5 minutes. Get a non-slip finish. Scanning electron microscopy was carried out, and the results obtained were as follows figure 1 As shown, it can be seen from the figure that the surface anti-slip treatment agent provided by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com