Coated mooring rope made of high-molecular-weight polyethylene fibers

A high-molecular polyethylene, coating technology, applied in the field of ropes for tugboats, can solve the problems of difficult identification and observation, non-wear resistance, heavy weight of cables, etc., to achieve easy observation, long service life, and not easy to wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

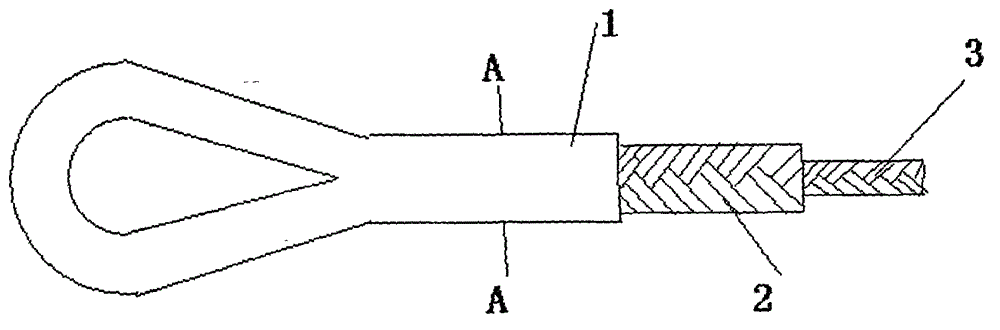

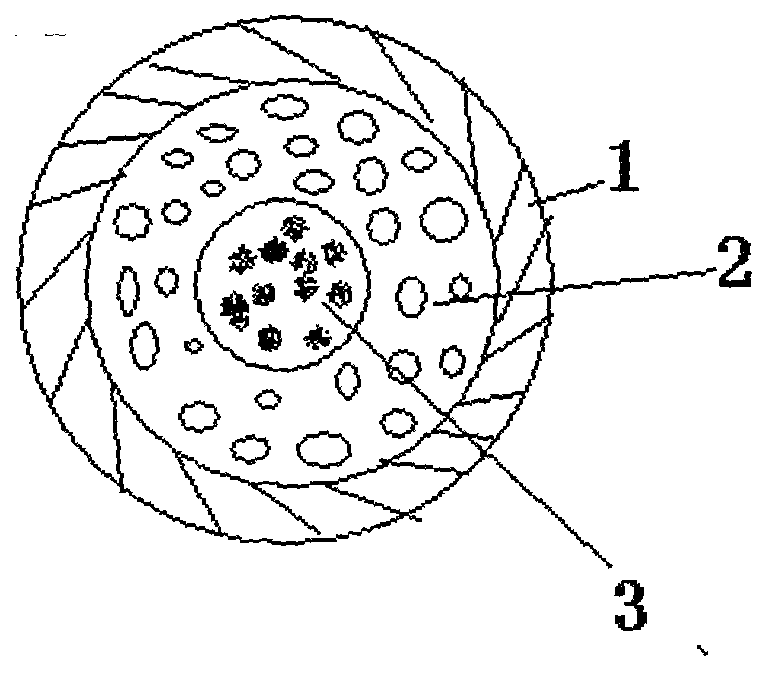

[0018] A high molecular polyethylene fiber coated cable, such as figure 1 and figure 2 As shown, the inner layer 3 of the coated cable is an eight-strand, twelve-strand or sixteen-strand rope made of high-molecular polyethylene fiber filament raw material, and the outer layer 2 is made of thirty-two strands, forty-eight strands or sixty-four strands of rope The wear-resistant sheath is composed of polyester glue and fluorescent dye 1 coated on the outside of the wear-resistant sheath. Thirty-two, forty-eight or sixty-four strands of rope are made of polyester filaments. The polyester glue is polyethylene terephthalate sebacate. The fluorescent dye is styrene pyridinium salt. The diameter of each rope in the inner layer of eight strands, twelve strands or sixteen strands is 2 to 30 mm. The diameter of each rope in the forty-eight or sixty-four ropes of the outer layer is 1 to 10 millimeters.

[0019] In the production process of the high molecular polyethylene fiber-coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com