Sling for hoisting thread steel

A threaded steel and spreader technology, applied in the field of spreaders, can solve the problems of small contact area between the suction cup and the threaded steel, easy wear of the wire rope, production accidents, etc., to reduce the probability of accidents, not easy to wear and tear, easy to operate and The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

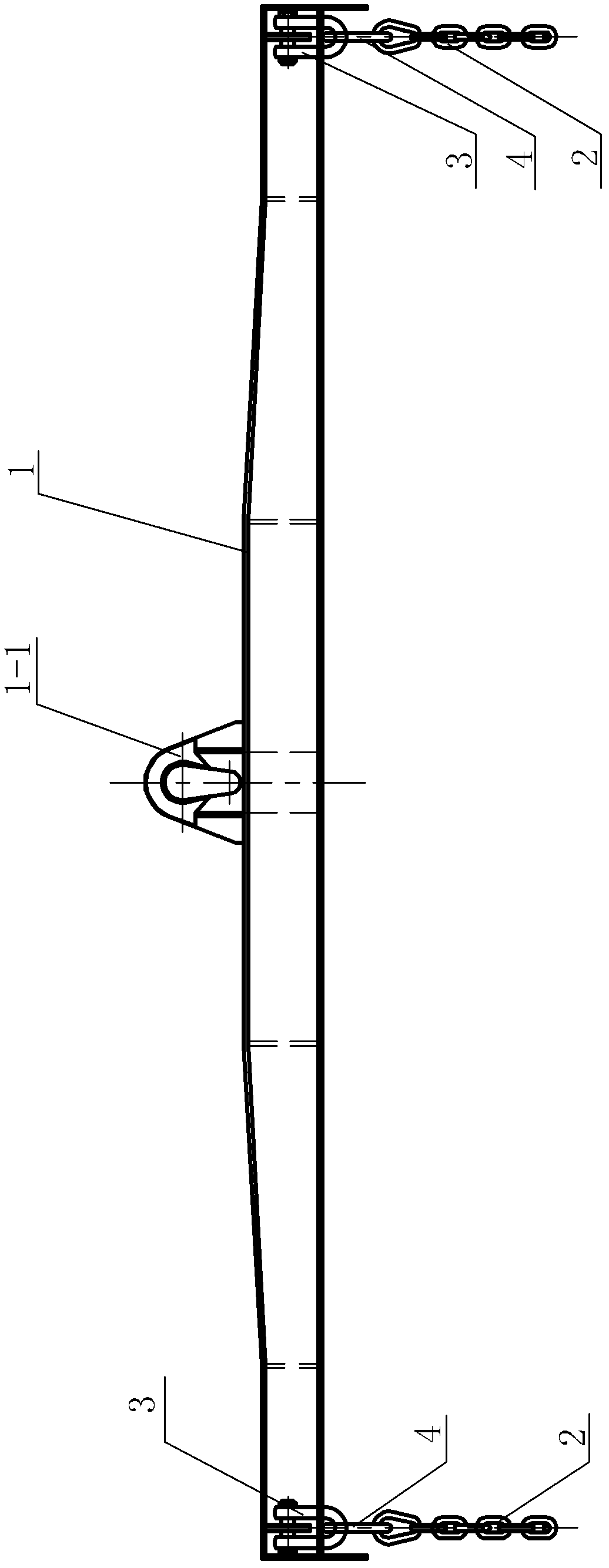

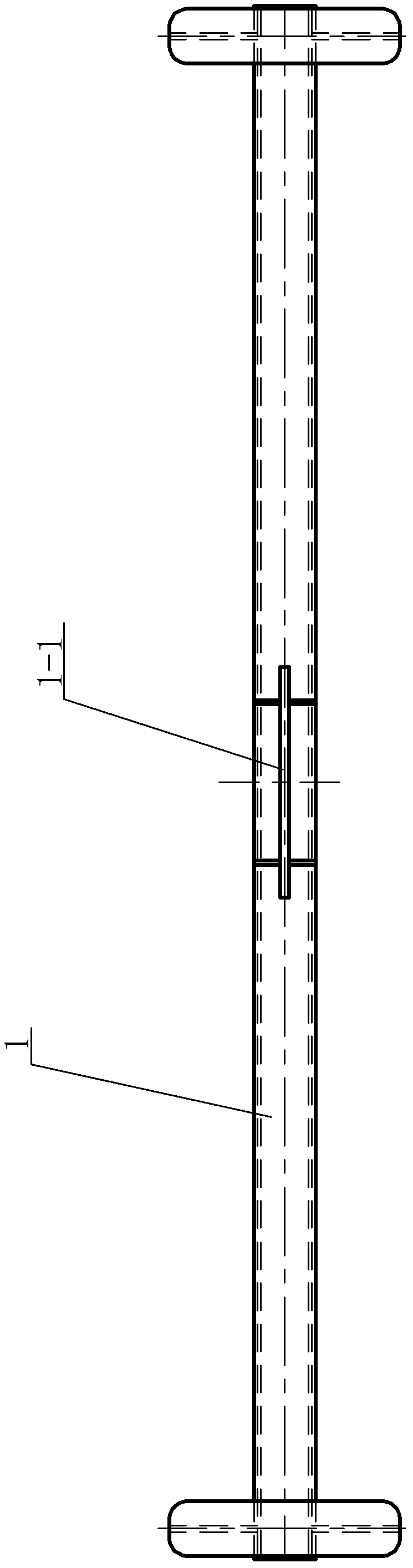

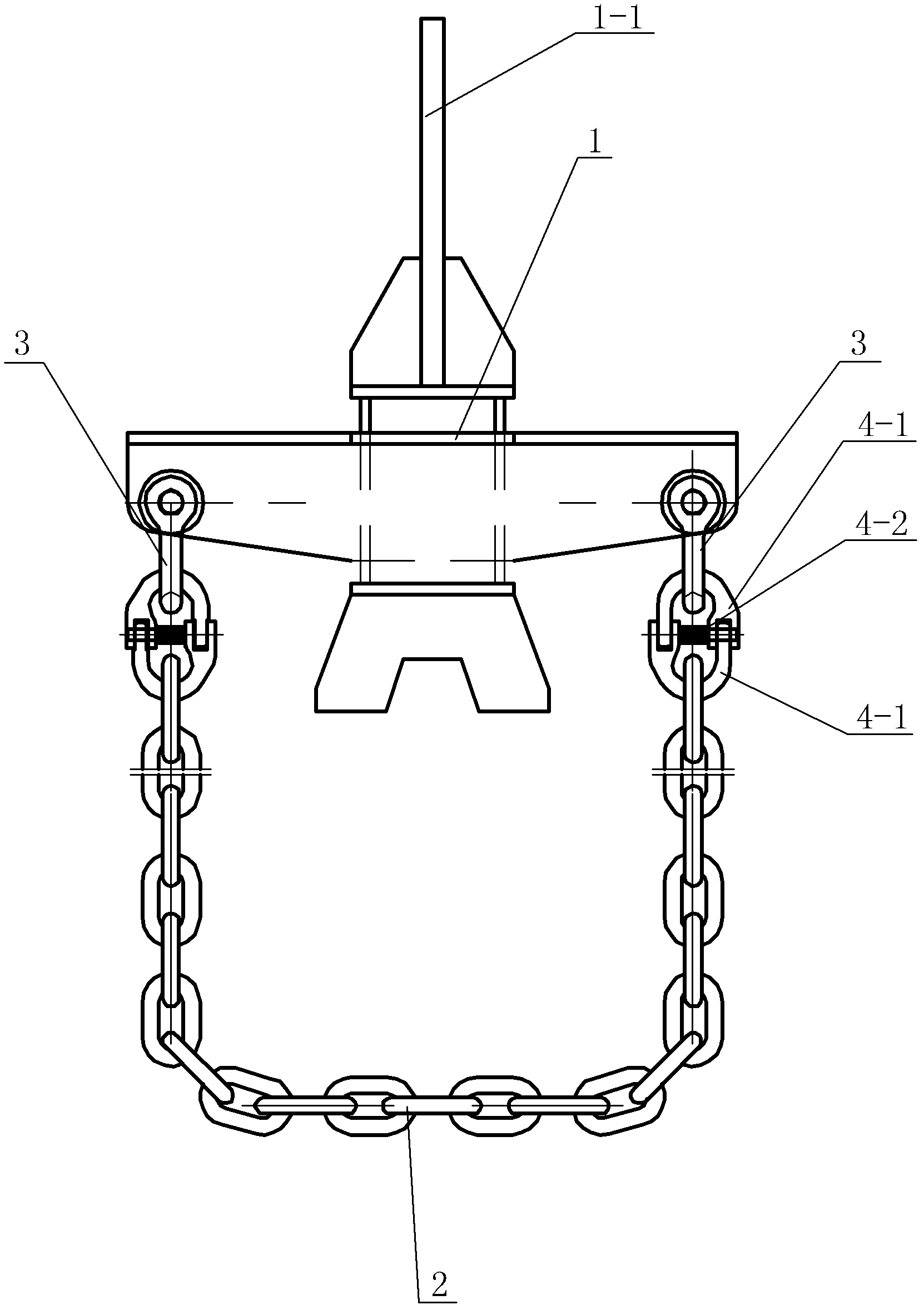

[0007] Specific implementation mode one: combine figure 1 , figure 2 with image 3 Describe this embodiment mode, the suspender of a kind of hoisting threaded steel described in this embodiment mode comprises beam 1, two chains 2 and four U-shaped rings 3, and the lower surface of described beam 1 two ends is respectively provided with two U-rings parallel to each other. The two ends of each chain 2 are respectively connected with a U-shaped ring 3 , and the two ends of each chain 2 are located at the same end of the beam 1 . In this embodiment, the chain 2 is used to hoist the finished threaded steel product. During the hoisting process, the friction between the chain 2 and the finished threaded steel product is small. chance of accidents.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination image 3 Describe this embodiment, the two locks of each lock chain 2 of the suspender described in this embodiment are respectively provided with a lock assembly 4, and each lock assembly 4 includes two U-shaped lock rings 4- 1 and the pin shaft 4-2, the open ends of the two U-shaped lock rings 4-1 are plugged together through the pin shaft 4-2, and the two U-shaped lock rings 4-1 form a closed oval lock. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 , figure 2 with image 3 To illustrate this embodiment, a hanger 1-1 is provided in the middle of the upper surface of the crossbeam 1 of a hanger for hoisting rebar in this embodiment. Other components and connections are the same as those in the first embodiment.

[0010] working principle

[0011] When the present invention is in use, the two ends of the finished threaded steel are suspended by a chain 2 respectively, the connecting hanger 1-1 on the crossbeam 1 is connected with the hook of the crane, and then the threaded steel is hoisted flatly to a designated position to complete the hoisting work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com