Technique of processing sewing machine shuttle putamen stay wire bore ram compression angle and mold thereof

A sewing machine and bobbin case technology, which is applied in the field of sewing machinery, can solve the problems of pilling, uneven edges of the thread-pulling hole of the bobbin case, and thread breakage, etc., and achieves the effects of low cost, simple and easy operation, and reasonable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

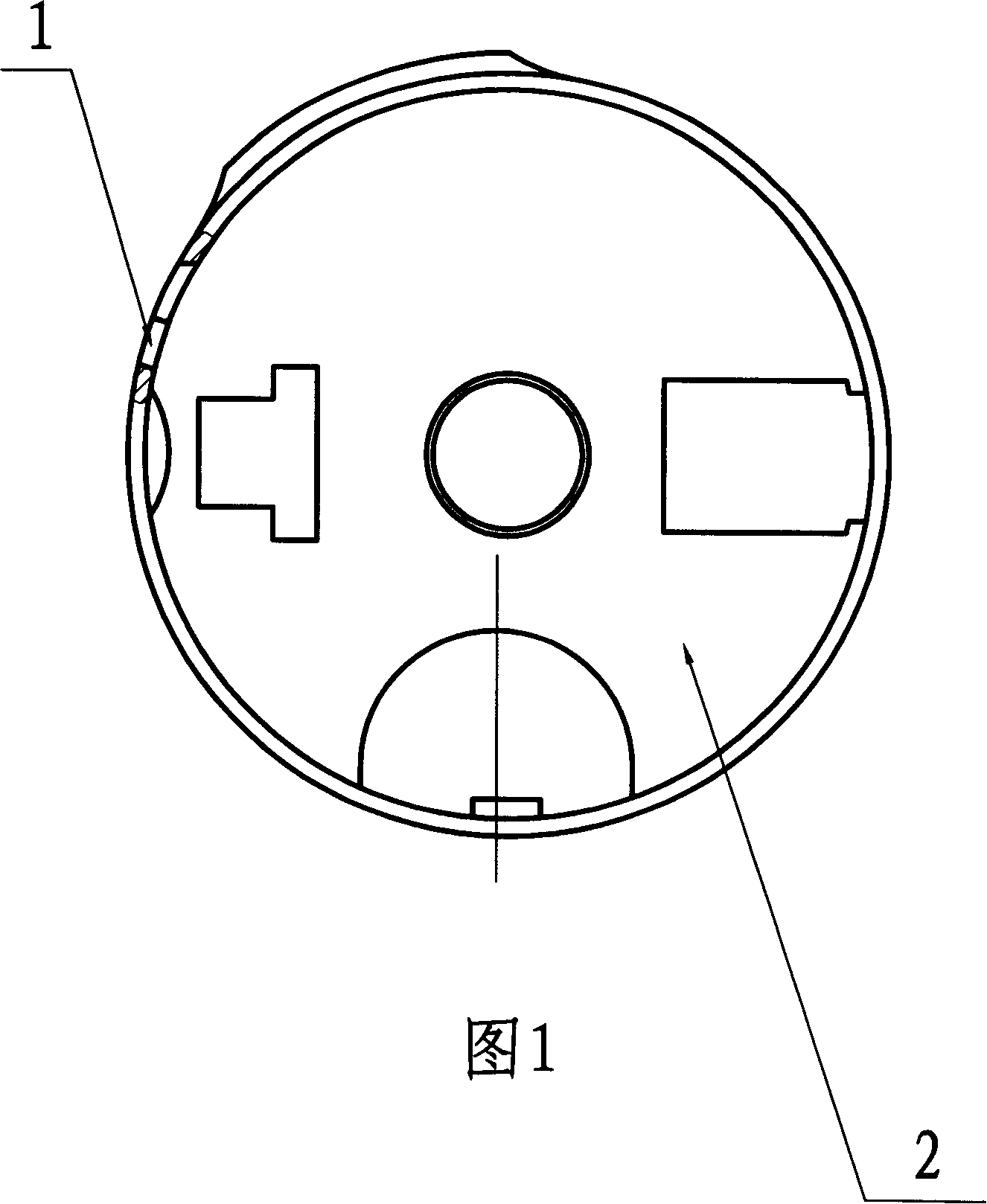

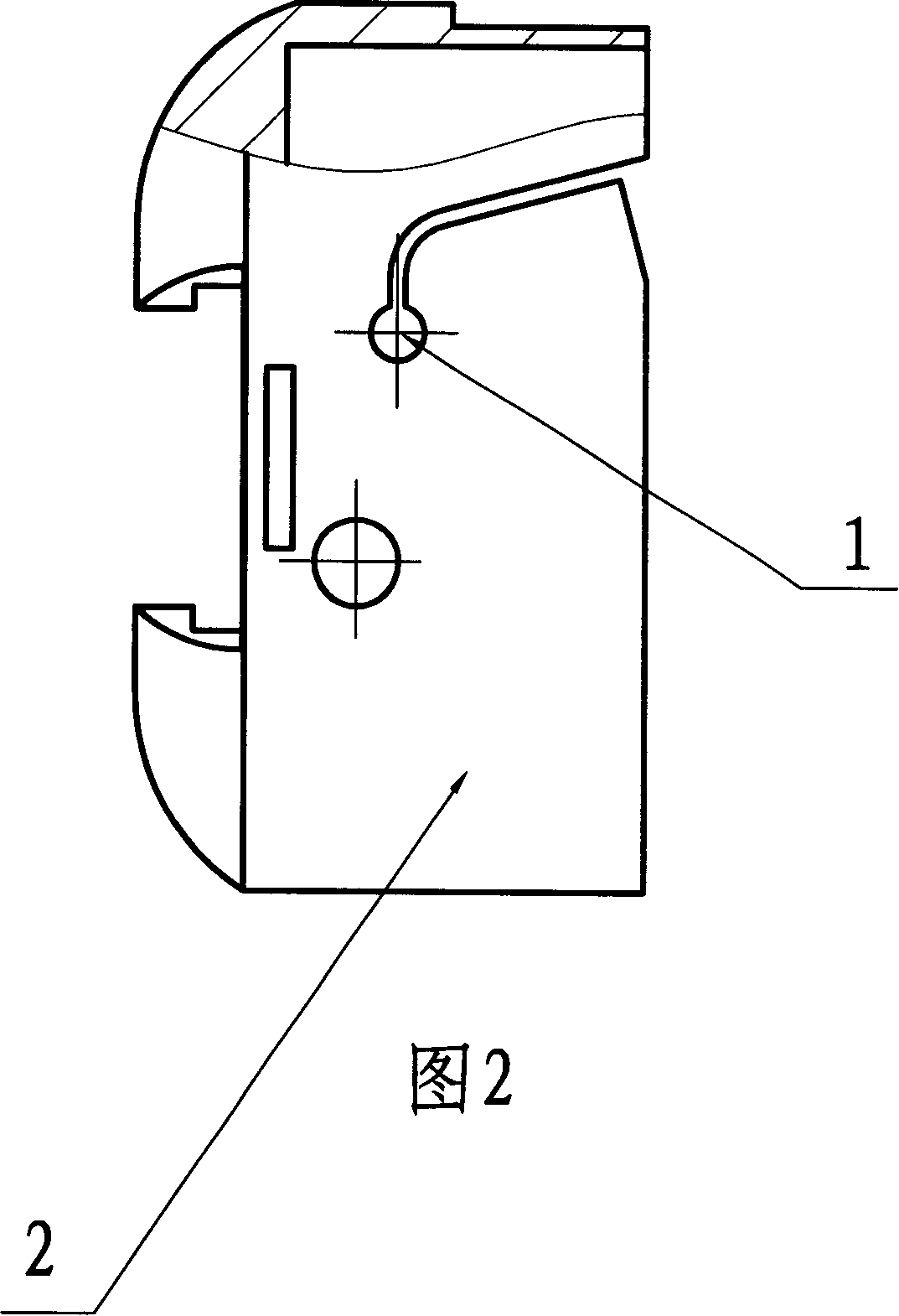

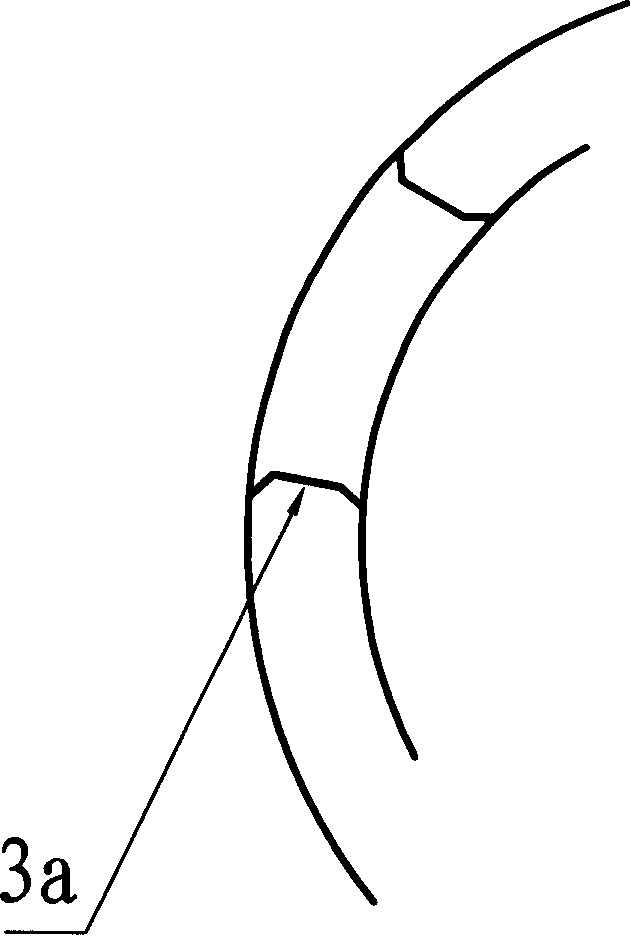

[0026] Such as figure 1 , figure 2 As shown, there is a backguy hole 1 on one side of the bobbin case 2, and the backguy hole 1 is only the processing object of the present invention; as image 3 As shown, the surface 3a of the wire hole made by the old technology is not smooth, which is easy to cause the wire to be broken; Figure 4 As shown, after punching the surface 3b of the cable hole in this technology, the surface of the cable hole is very smooth and achieves the expected purpose; as Figure 5 , Figure 6 As shown, an upper punch 6 is arranged radially at the lower end of the upper cylinder 5, and the upper cylinder and the upper punch are integrally made, and then processed to produce an arc transition 4, and the lower cylinder 7 is perpendicular to its axial direction. A lower punch 8 is provided, and the lower punch 8 is embedded and installed on the lower cylinder 7 . There is an arc transition 4 between the top of the lower punch 8 and the side wall of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com