Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Increased contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of light-colored polyisocyanate curing agent

ActiveCN103881050AIncreased contact areaUniform on a microscopic scalePolyurea/polyurethane coatingsAlcoholLiquid state

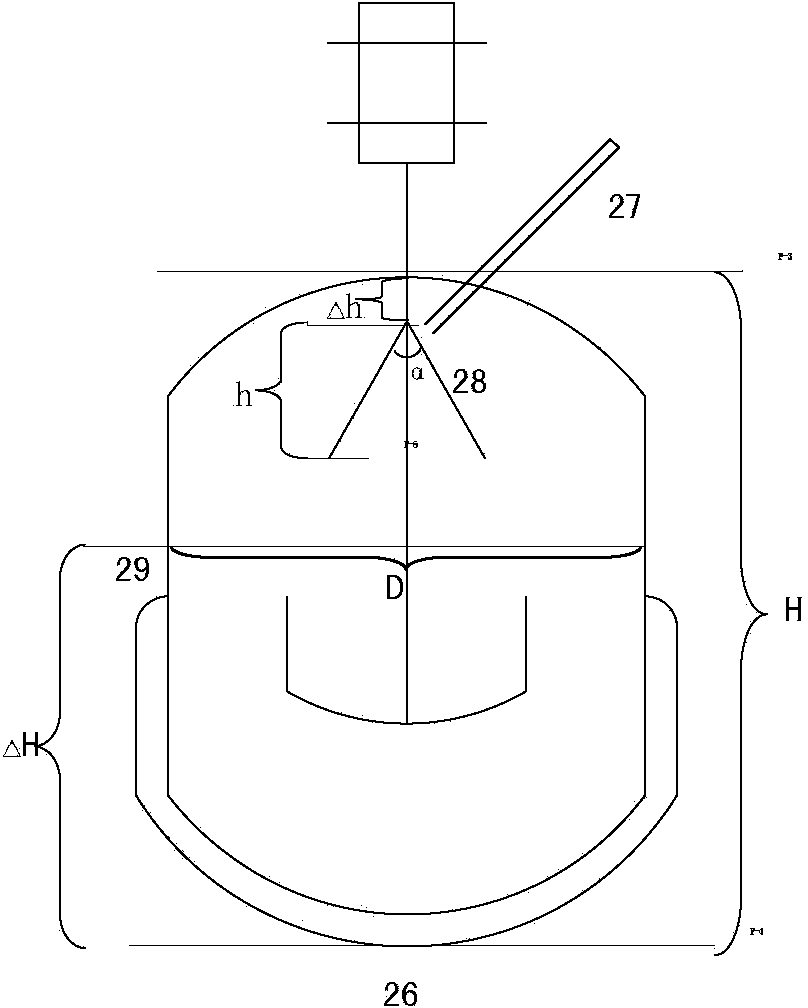

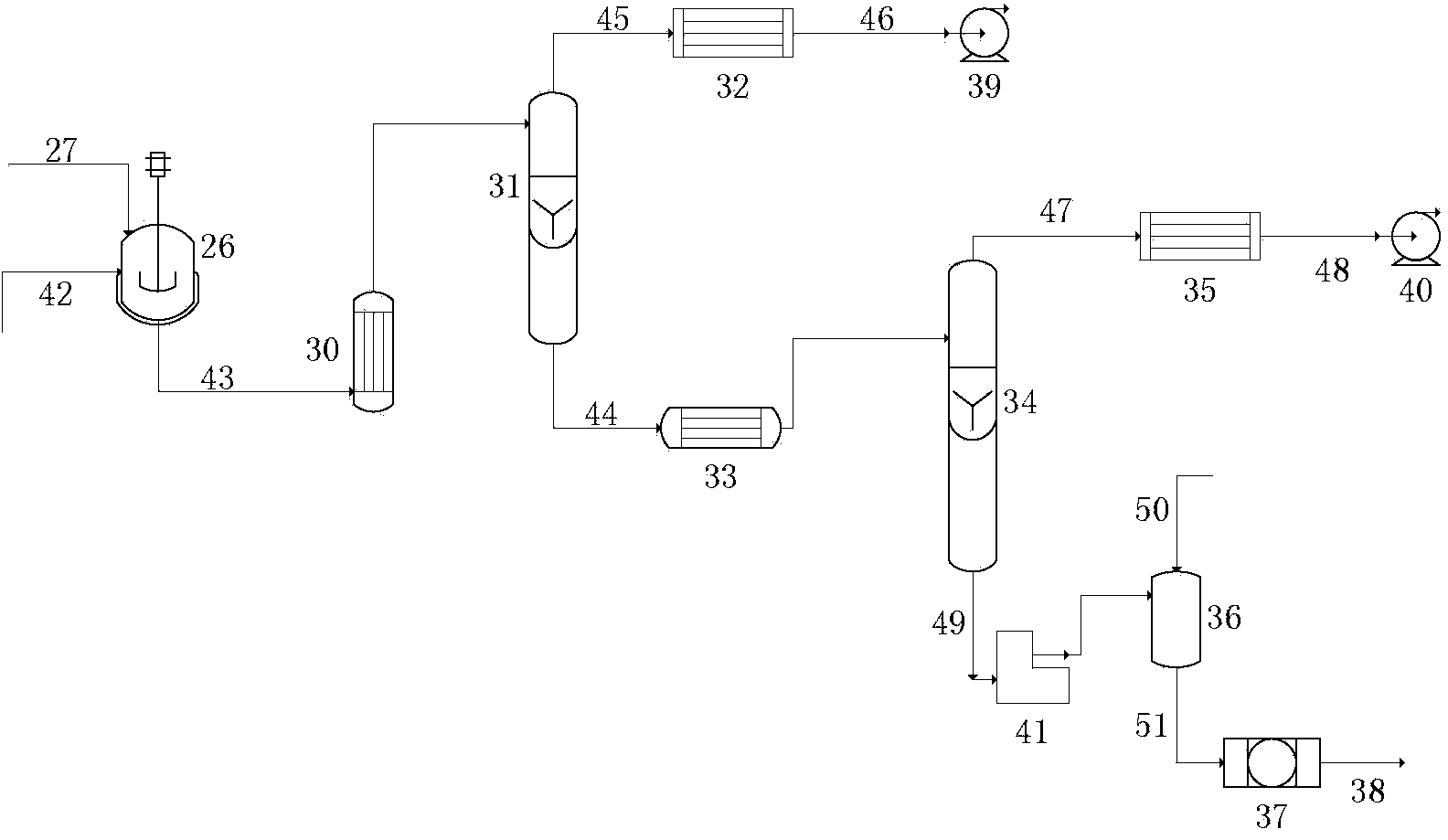

The invention relates to a preparation method of a light-colored polyisocyanate curing agent. The preparation method comprises the following steps: (a) purifying a raw material-trimethylolpropane to obtain trimethylolpropane with the carbonyl compound content lower than 0.1wt%; (b) reacting trimethylolpropane with the carbonyl compound content lower than 0.1wt% or a mixture of trimethylolpropane with the carbonyl compound content lower than 0.1wt% and micromolecular dihydric alcohol with excess diisocyanate in a reactor with a conical liquid distribution plate to obtain a liquid-state prepolymer reaction solution containing excess diisocyanate; and (c) removing monomers from the prepolymer reaction solution obtained in the step (b) by adopting a two-stage film evaporator, and diluting by a solvent to obtain the curing agent with the diisocyanate monomer content lower than 0.5wt%. The color number of the diisocyanate curing agent prepared based on the method can be lower than 20Hazen.

Owner:WANHUA CHEM GUANGDONG

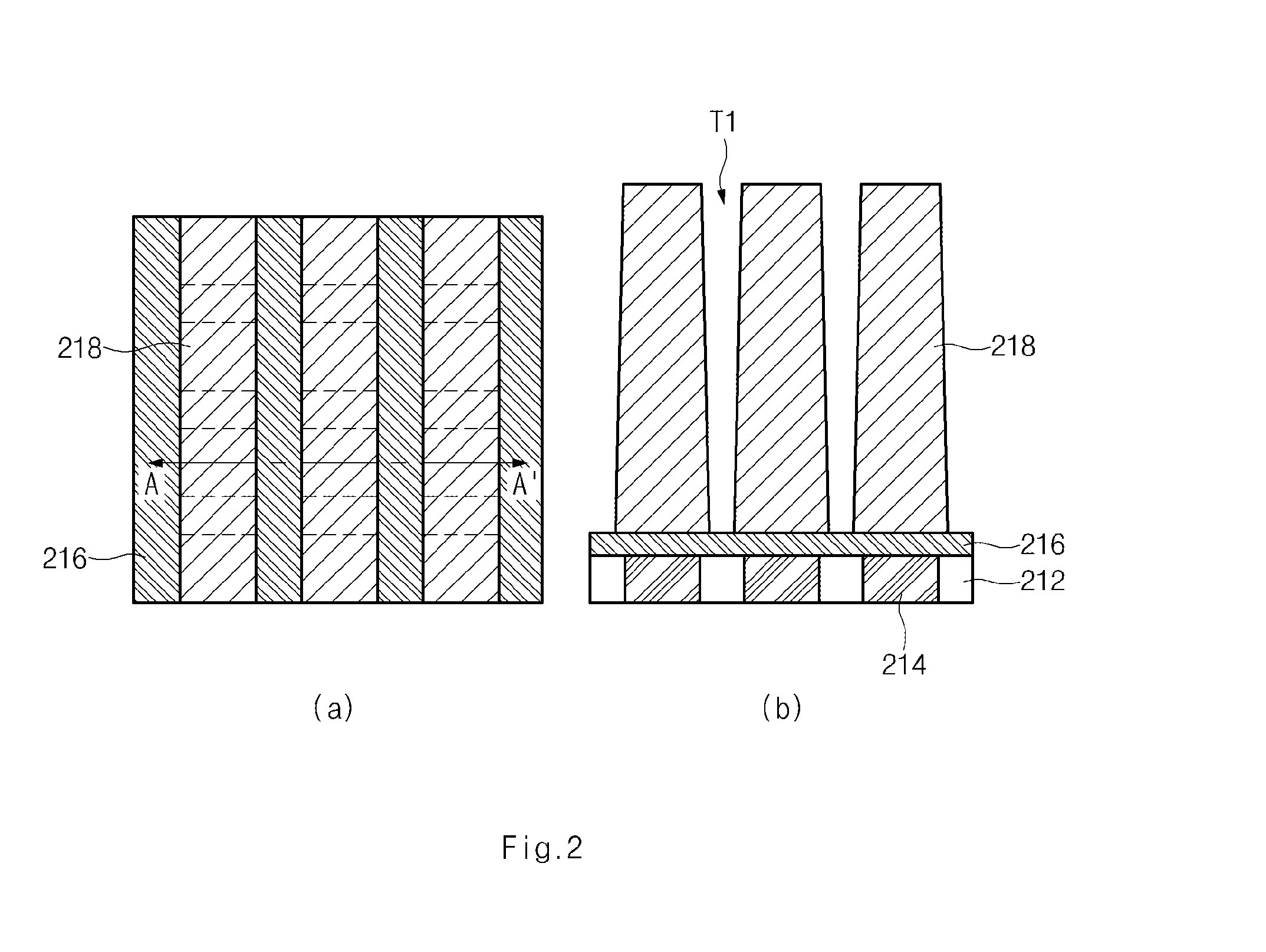

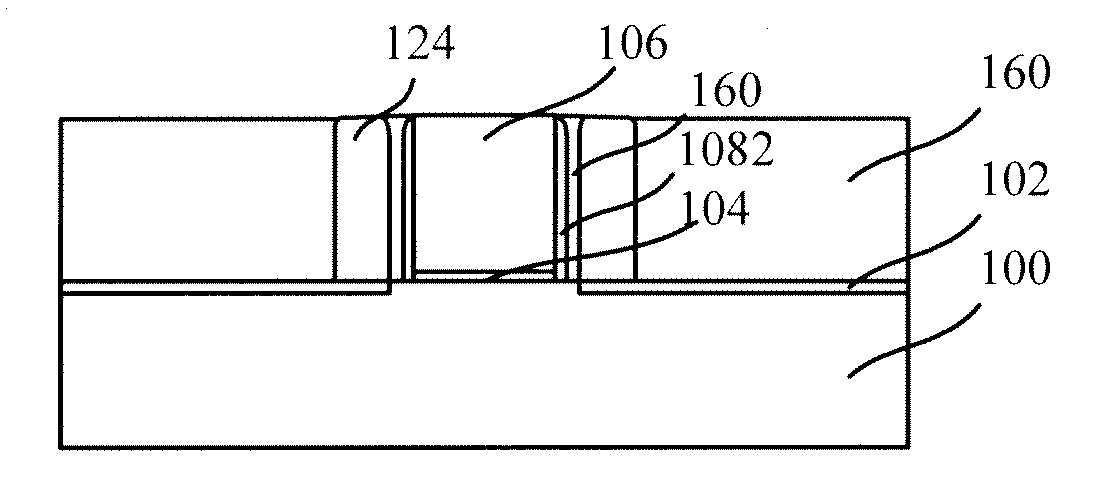

Semiconductor structures having improved contact resistance

ActiveUS20120132966A1Increase the areaReduce contact resistanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceSemiconductor structure

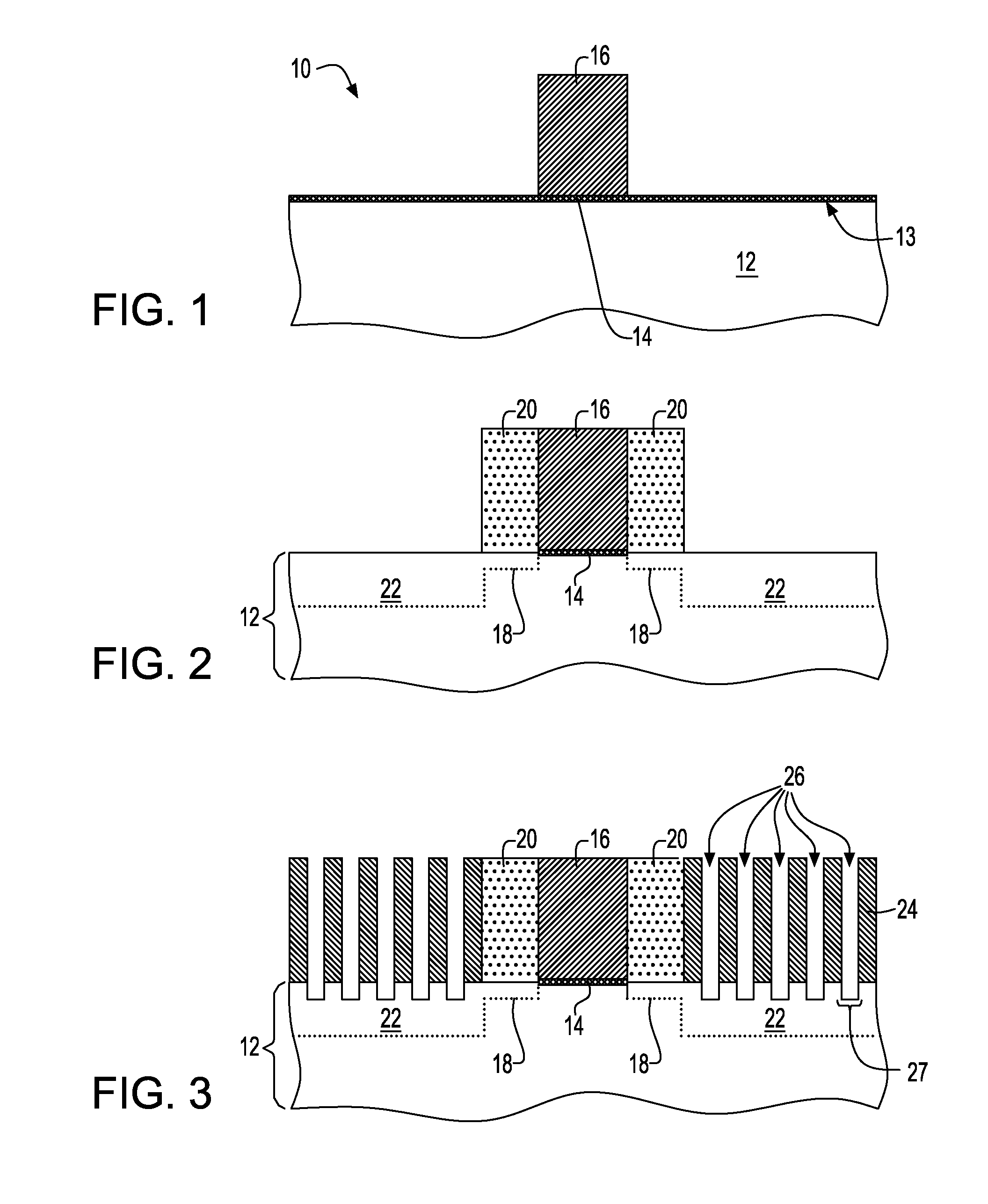

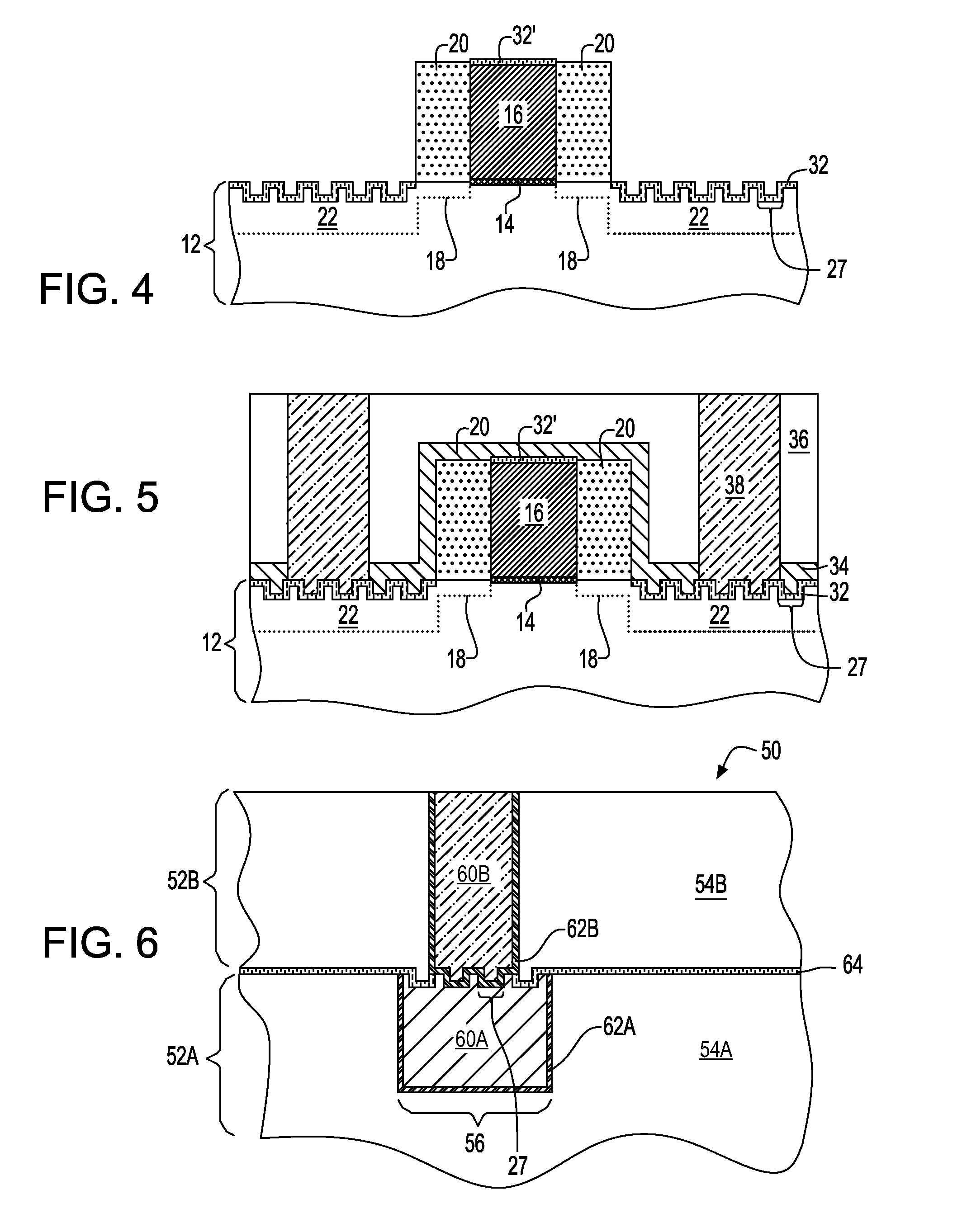

Self-assembled polymer technology is used to form at least one ordered nanosized pattern within material that is present in a conductive contact region of a semiconductor structure. The material having the ordered, nanosized pattern is a conductive material of an interconnect structure or semiconductor source and drain diffusion regions of a field effect transistor. The presence of the ordered, nanosized pattern material within the contact region increases the overall area (i.e., interface area) for subsequent contact formation which, in turn, reduces the contact resistance of the structure. The reduction in contact resistance in turn improves the flow of current through the structure. In addition to the above, the inventive methods and structures do not affect the junction capacitance of the structure since the junction area remains unchanged.

Owner:GLOBALFOUNDRIES US INC

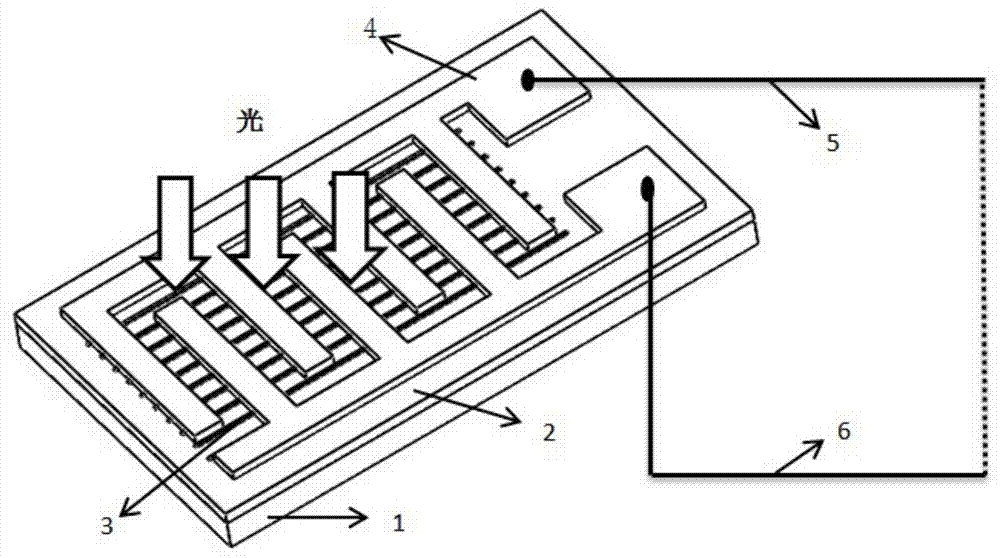

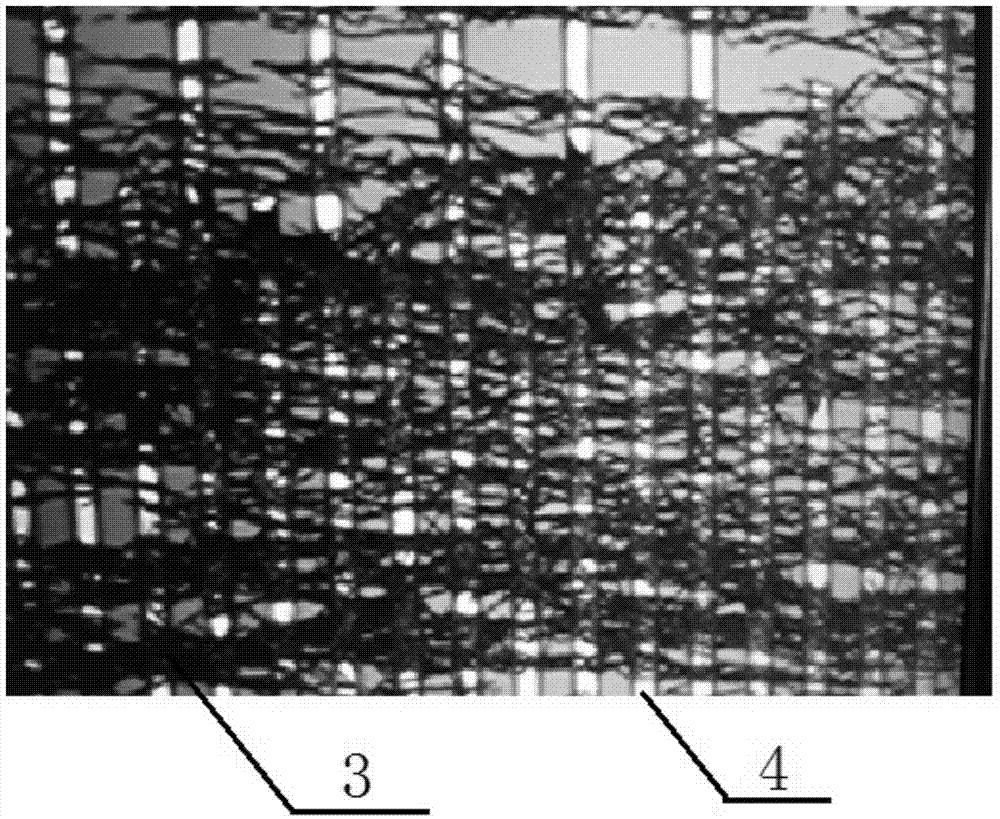

NiO nanowire ultraviolet light detector and preparation method and application thereof

InactiveCN104332513AIncreased contact areaHigh sensitivityFinal product manufactureNanotechnologyUltraviolet lightsEngineering

The invention provides a NiO nanowire ultraviolet light detector and a preparation method and application thereof. The detector comprises a substrate layer, a SiO2 thin film layer, a photosensitive layer, an interdigital electrode, a first lead wire and a second lead wire. The SiO2 thin film layer is attached to the substrate layer in a parallel manner; the photosensitive layer and the interdigital electrode are arranged on the SiO2 thin film layer in a parallel manner; the photosensitive layer is in contact connection with the interdigital electrode; the photosensitive layer is arranged on the upper layer or the lower layer of the interdigital electrode; the first lead wire and the second lead wire are connected with the two electrodes of the interdigital electrode respectively; and the photosensitive layer is an orderly-arranged NiO nanowire array parallel to the substrate layer. By adopting the large-area and orderly-arranged NiO nanowire array parallel to the substrate layer, the ultraviolet light detector is high in sensitivity and wide in measurement range, can realize ultraviolet light detection in continuous wave band or each wave band, is simple in preparation, low in cost, and easy to carry out industrial production, and has wide prospect in the actual application.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

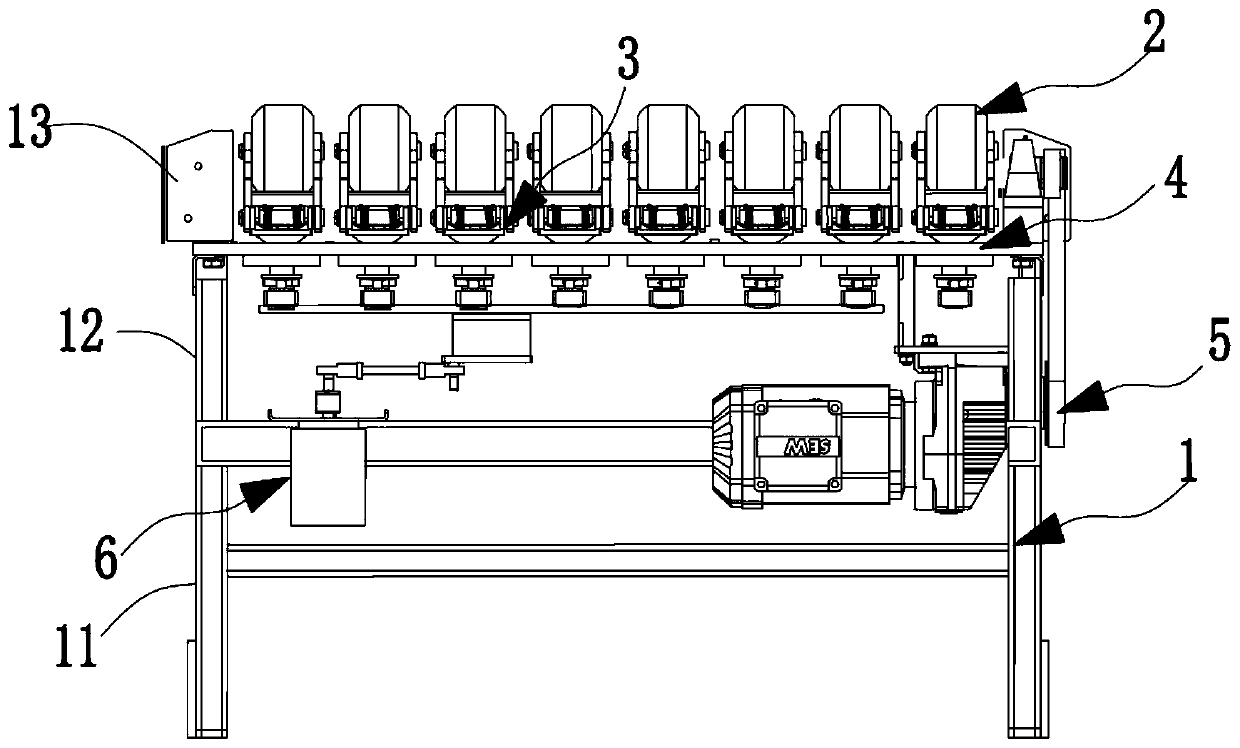

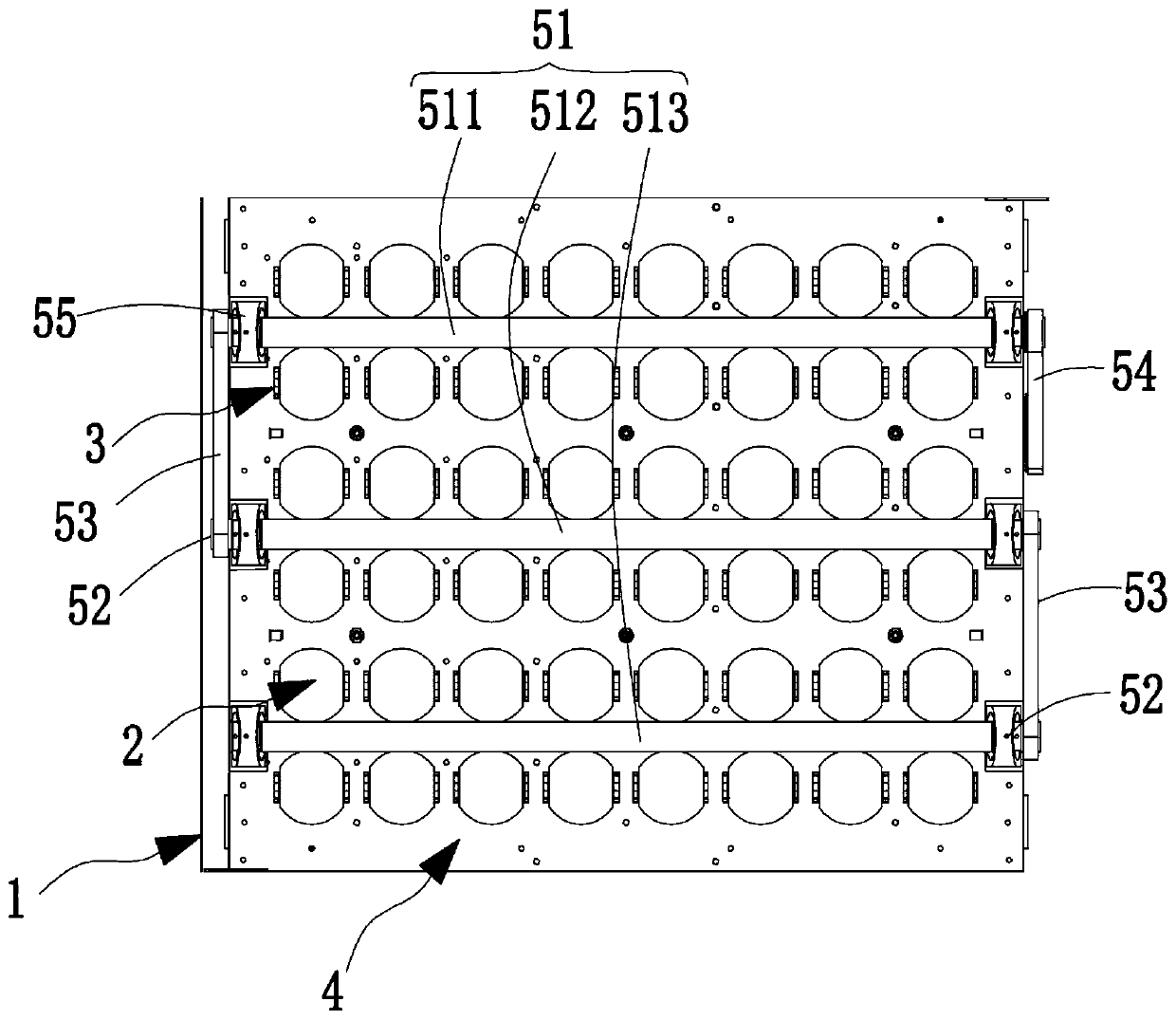

Wheel type conveying line

PendingCN110015540AEasy to assembleGuaranteed reliabilityConveyor partsRoller-waysSelf adaptiveFriction force

The invention discloses a wheel type conveying line which comprises a rack. Multiple rows of eccentric rotating wheels are arranged on the rack in an equal height manner. The axes of all the eccentricrotating wheels are parallel to one another and are parallel to the horizontal plane. Each eccentric rotating wheel is arranged on an installing frame located on the rack in the manner of rotating around the axis of the eccentric rotating wheel. The eccentric rotating wheels on each row are attached to a driving roller, the driving roller makes contact with the lower semicircle of each eccentricrotating wheel, the driving roller is affected by upward elastic force, and thus the eccentric rotating wheels are attached to the driving roller in a self-adapting manner, or the driving roller makescontact with the upper semicircle of each eccentric rotating wheel, the eccentric rotating wheels are affected by the upward elastic force, and the eccentric rotating wheels are attached to the driving roller in a self-adapting manner. The driving roller rotates under the driving of a first power source, and the eccentric rotating wheels are driven to rotate through friction force. According to the wheel type conveying line, the design of the scheme is elaborate, the eccentric rotating wheels or the driving roller are affected by the upward elastic force, thus the eccentric rotating wheels always keep being attached to the driving roller, after abrasion is caused or when the installing position precision is poor, self-adaptive adjusting is achieved, rotating between the eccentric rotatingwheels and the driving roller is effectively ensured, and the conveying stability is improved.

Owner:SUZHOU GP LOGISTICS SYST

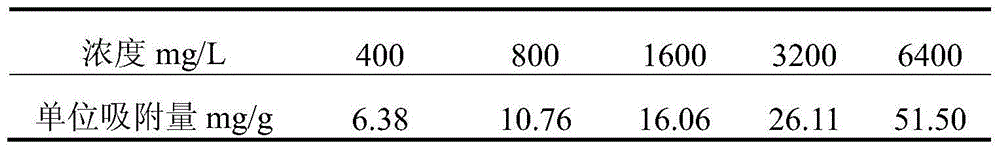

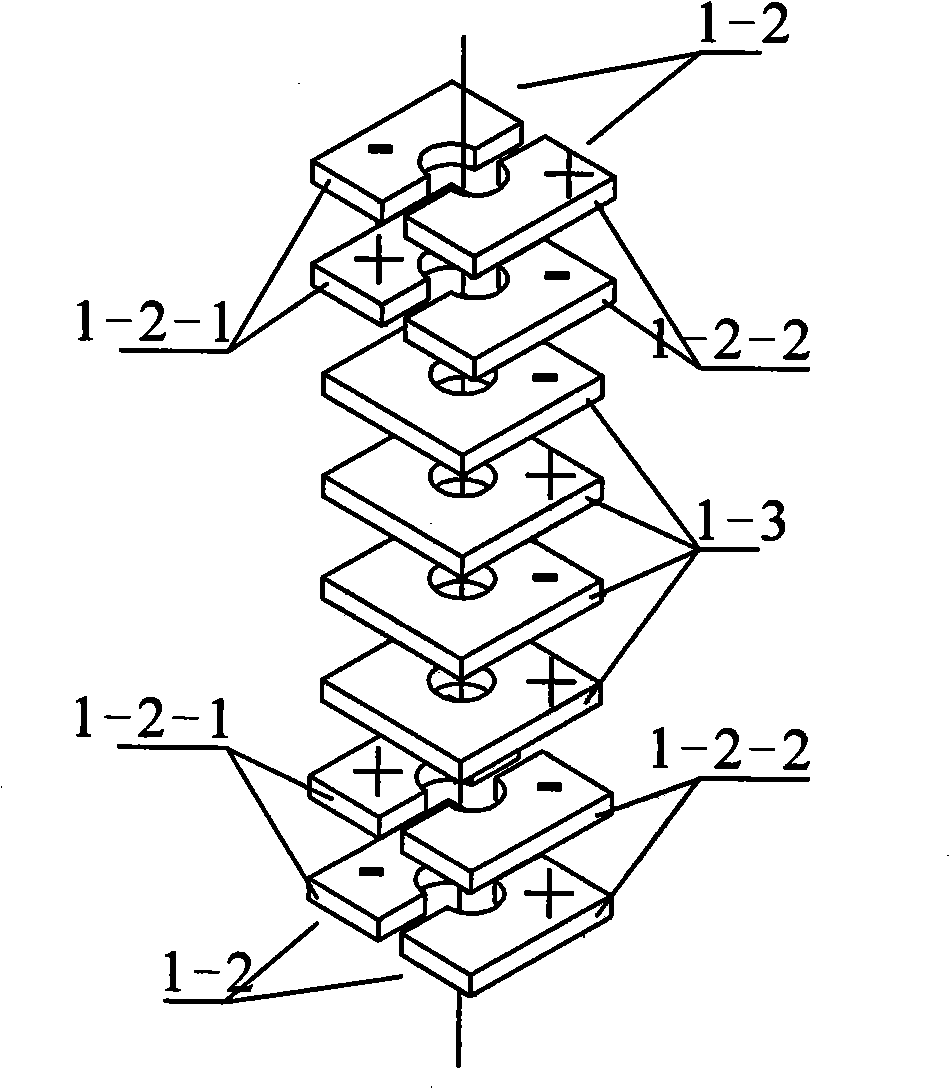

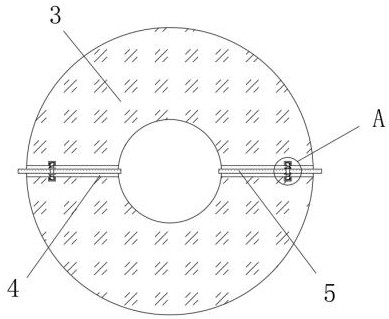

Method for preparing electro-adsorption component by virtue of self-assembly technology

ActiveCN103979650AIncreased contact areaEasy to penetrate throughDispersed particle separationElectricityPolyelectrolyte

The invention relates to a method for preparing an electro-adsorption component by virtue of a self-assembly technology. The preparation mechanism of the electro-adsorption component is shown in the figure, wherein the electro-adsorption component comprises an electrode substrate (1), an adsorption material (2) and long chain polymer ions (3) assembled on the surface of the adsorption material. By using the abundant functional groups of the adsorption material, a layer of very thin long chain polyelectrolyte film with homogeneous charge is uniformly assembled on the surface of a solid through a non-covalent function, two electrode plates respectively provided with a positive charge polyelectrolyte film and a negative charge polyelectrolyte film are respectively connected with the positive pole and negative pole of a power supply, when the electro-adsorption component is used in electric adsorption desalting experiments, the positive charge film and the negative charge film formed by polymer ions can permeate ions with opposite charge and repel the homogenous charge, so that the ion adsorption efficiency is greatly accelerated, and the electro-adsorption component shows strong desalting capacity. The electro-adsorption component has the advantages of very thin surface assembly layer, low cost, short technological process and the like, and has good industrial application prospect.

Owner:BEIJING UNIV OF CHEM TECH

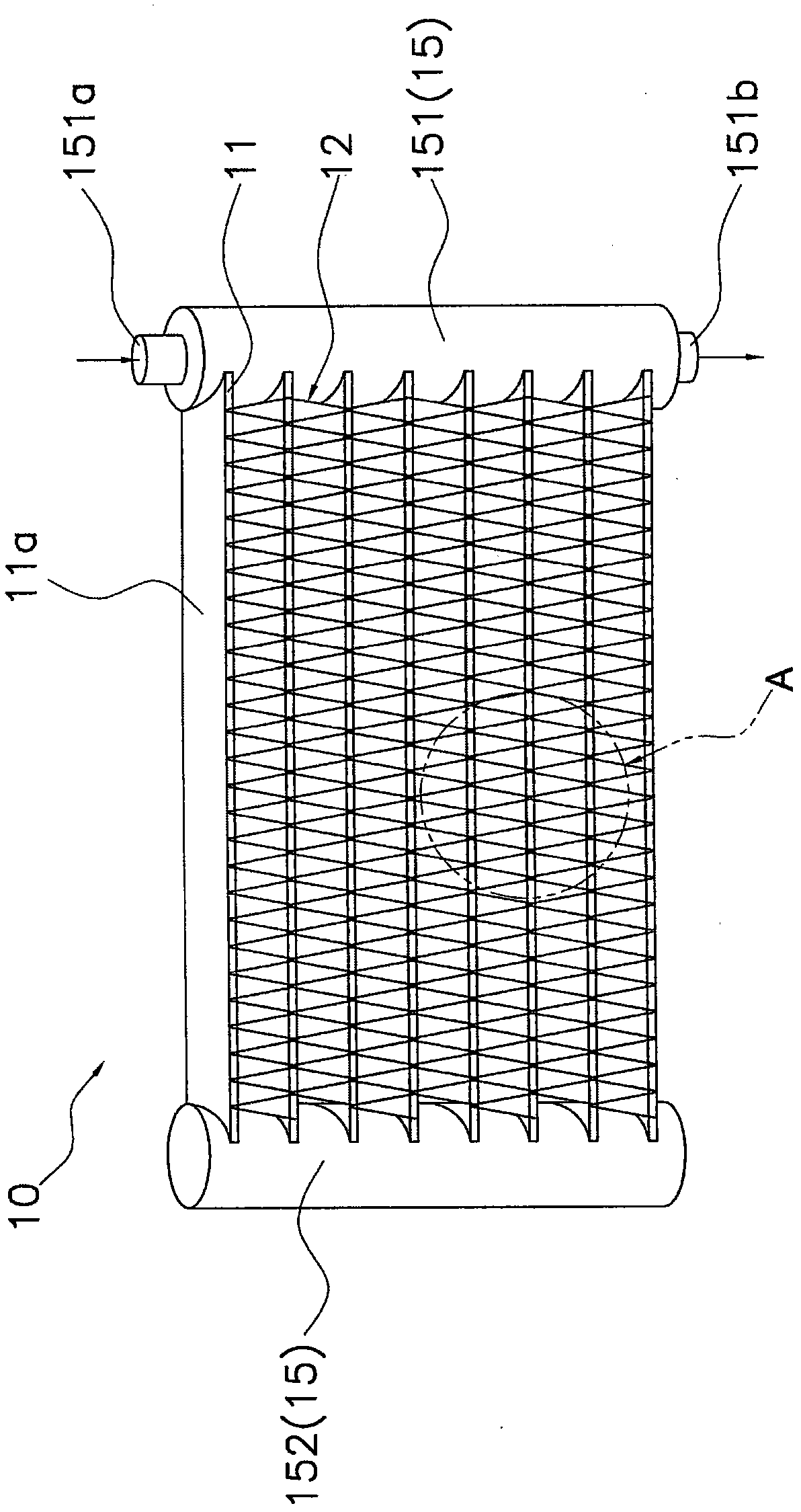

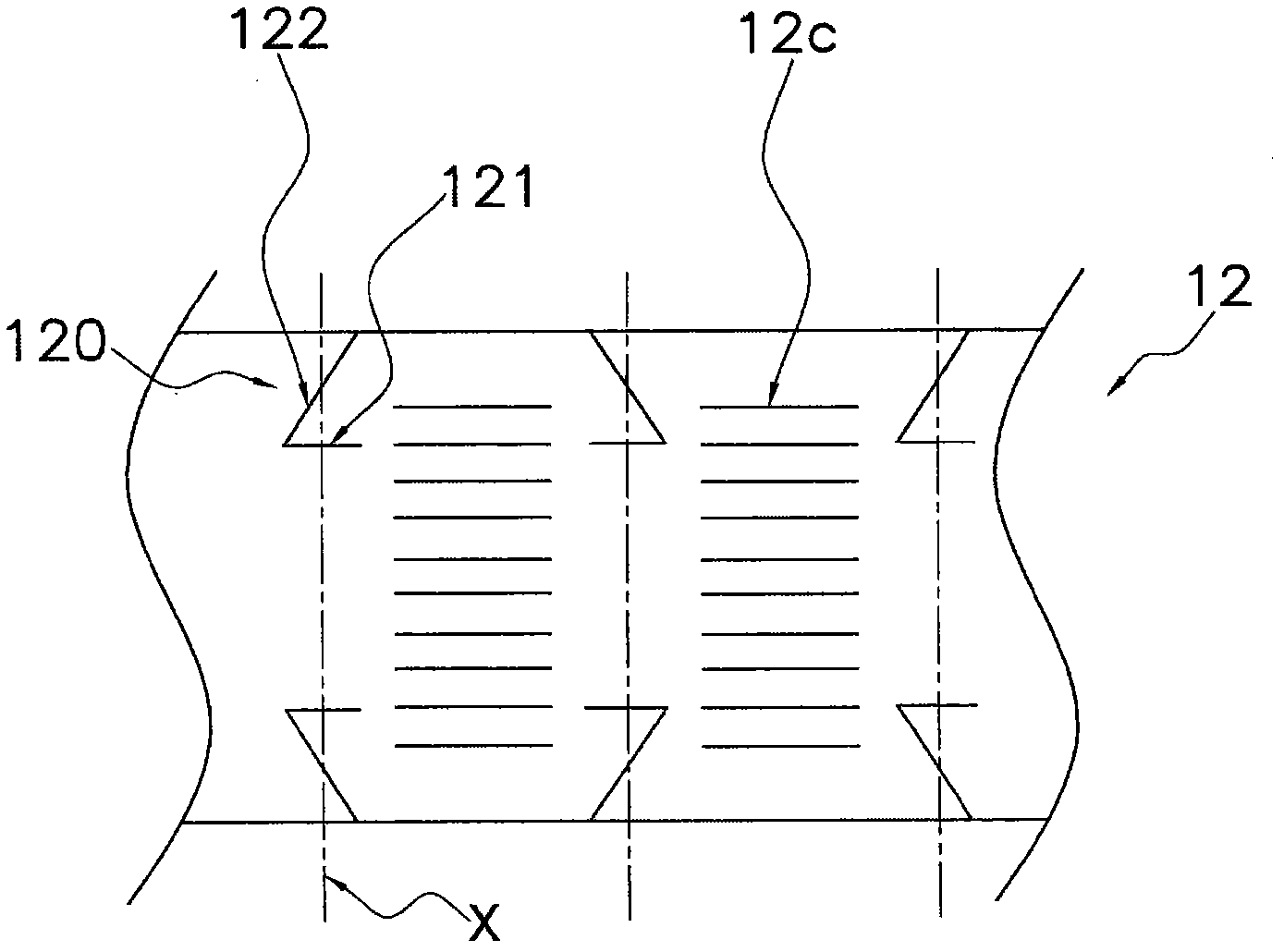

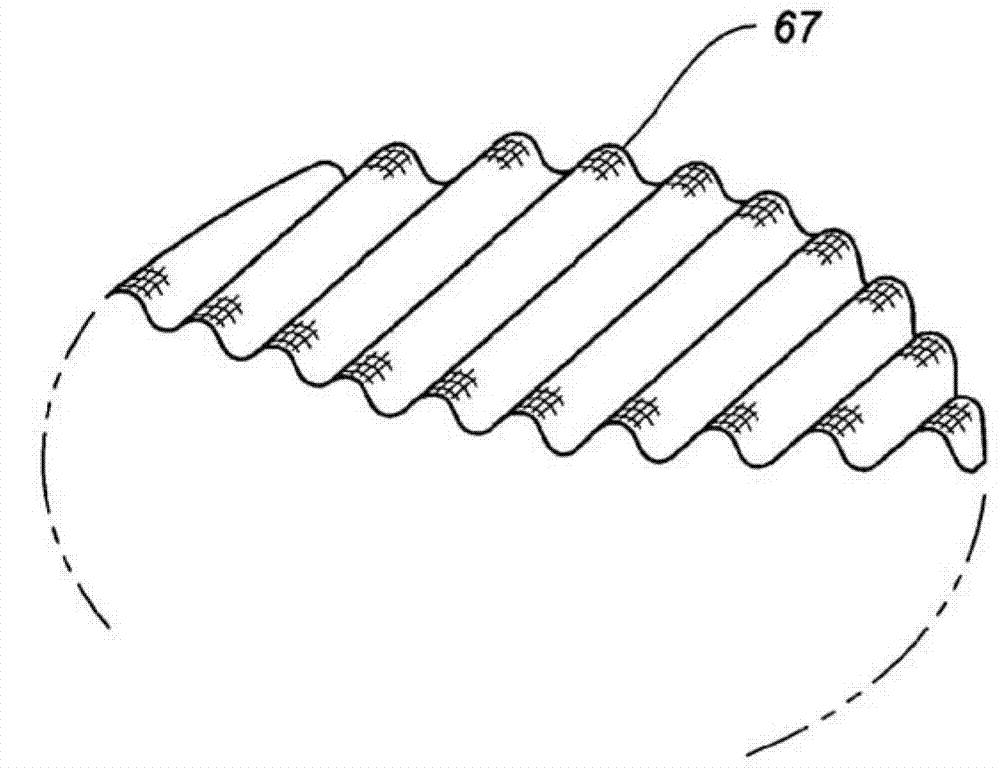

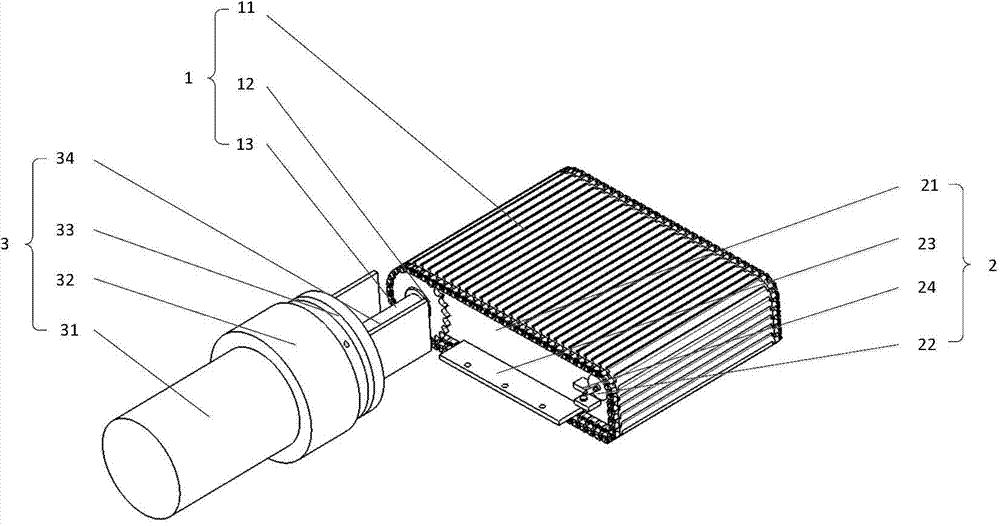

Heat exchanger

ActiveCN102047064AIncreased contact areaEasy accessStationary conduit assembliesIce removalEngineeringHeat exchanger

A heat exchanger from which condensation water is more smoothly discharged. In a heat exchanger (10), first cut lines (121) and second cut lines (122) are formed in a blank material for corrugated fins (12) before the blank material is bent in corrugations. The first cut lines (121) each cross an imaginary center line (X) of a bent section of the corrugations, and the second cut lines (122) each extend from the vicinity of an end of the first cut line (121) and cross the imaginary center line (X). When the blank plate is bent, acute-angled triangle portions sandwiched between the first cut lines (121) and the second cut lines (122) are raised to form cut-and-raised sections (12b). The distance between the top and root of each cut-and-raised section (12b) is greater than that of conventional products to increase the amount of contact between cut-and-raised sections (12b) adjacent to each other in the top-bottom direction. This allows condensation water to more easily flow through the cut-and-raised sections (12b), improving water discharge ability of the heat exchanger.

Owner:DAIKIN IND LTD

Water lubricated rubber stern bearing and design method thereof

ActiveCN103821826AImprove compressive stress distributionImprove contact performanceBearing componentsEngineeringHardness

The invention discloses a design method for a water lubricated rubber stern bearing. According to the method, axial hardness division is performed on a traditional slat-type water lubricated rubber stern bearing, a rubber bearing bush of the traditional slat-type water lubricated rubber stern bearing is divided into a plurality of regions from the stern end to the front end, the hardnesses of rubber from the stern end to the front end are sequentially increased, and the length of a region close to the front end is the longest, so as to enable the water lubricated rubber stern bearing to adapt to actual load and improve the contact pressure performance of the bearing. The invention further provides the water lubricated rubber stern bearing. According to the method, the whole long stern bearing is divided into the regions with different hardnesses based on a pressure distribution feature of the water lubricated rubber stern bearing, so that the pressure distribution of the water lubricated rubber stern bearing is remarkably improved, the contact regions are effectively extended in the circumferential direction, and the contact performance of the stern bearing is well improved as a whole.

Owner:HUAZHONG UNIV OF SCI & TECH +1

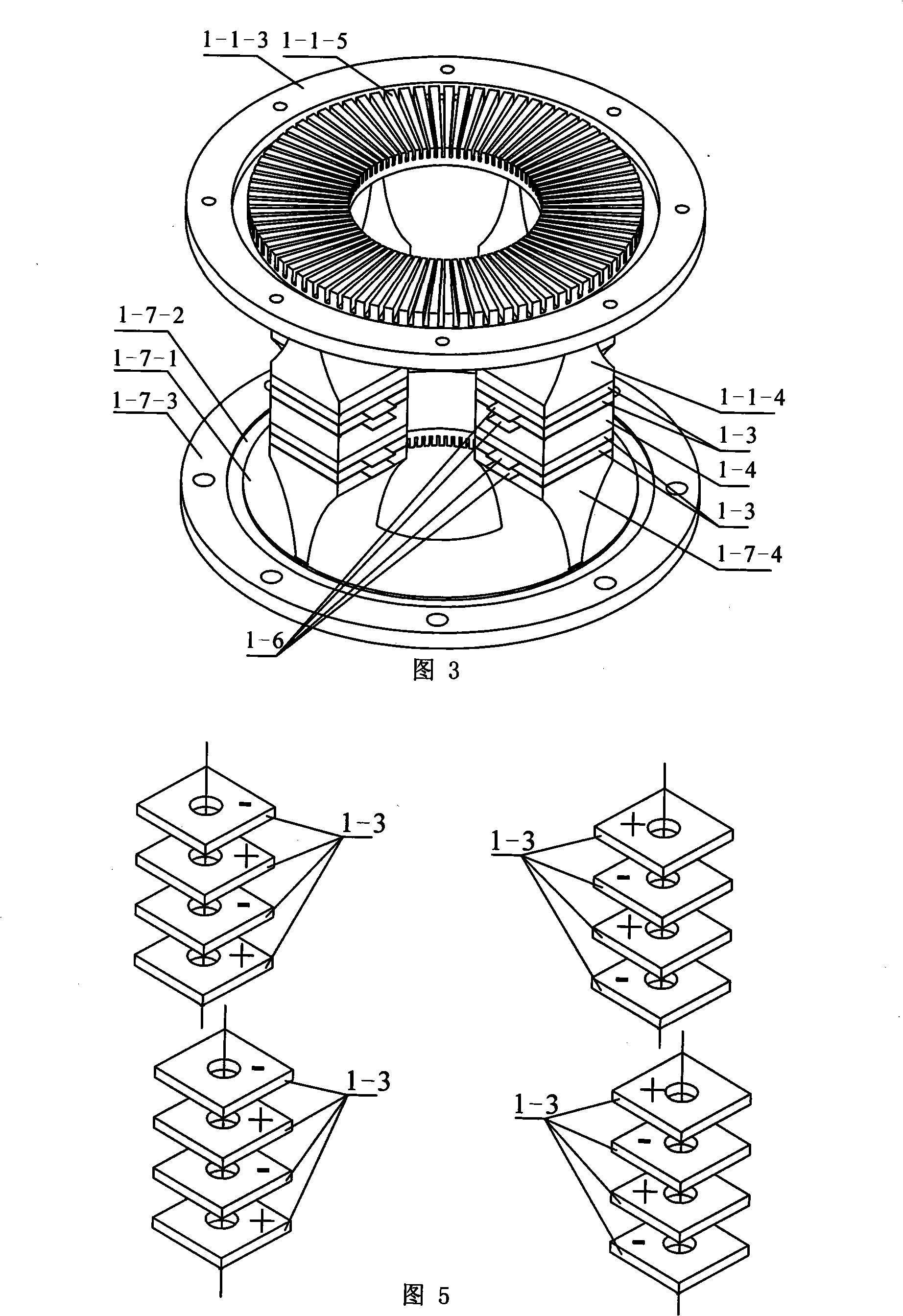

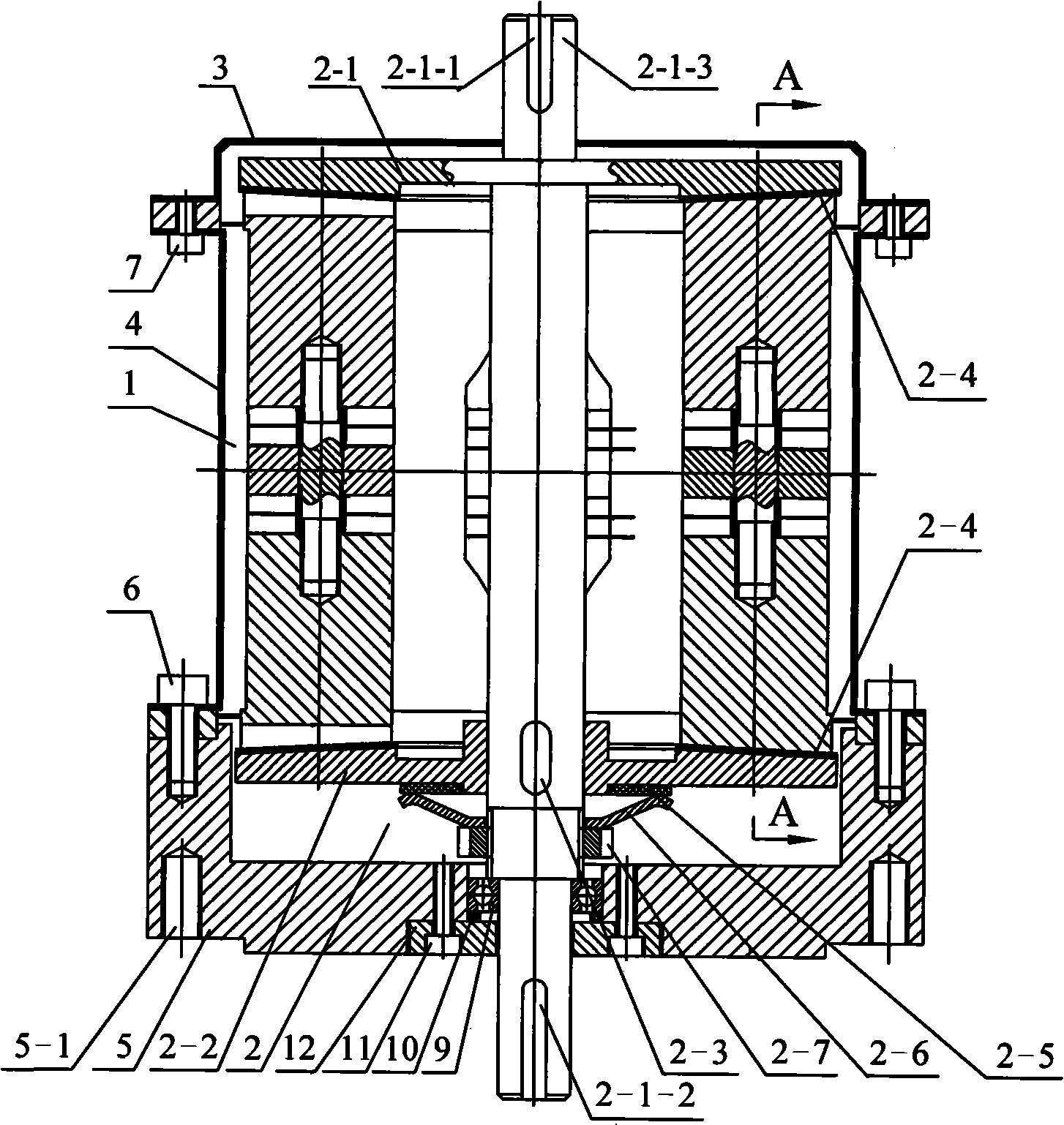

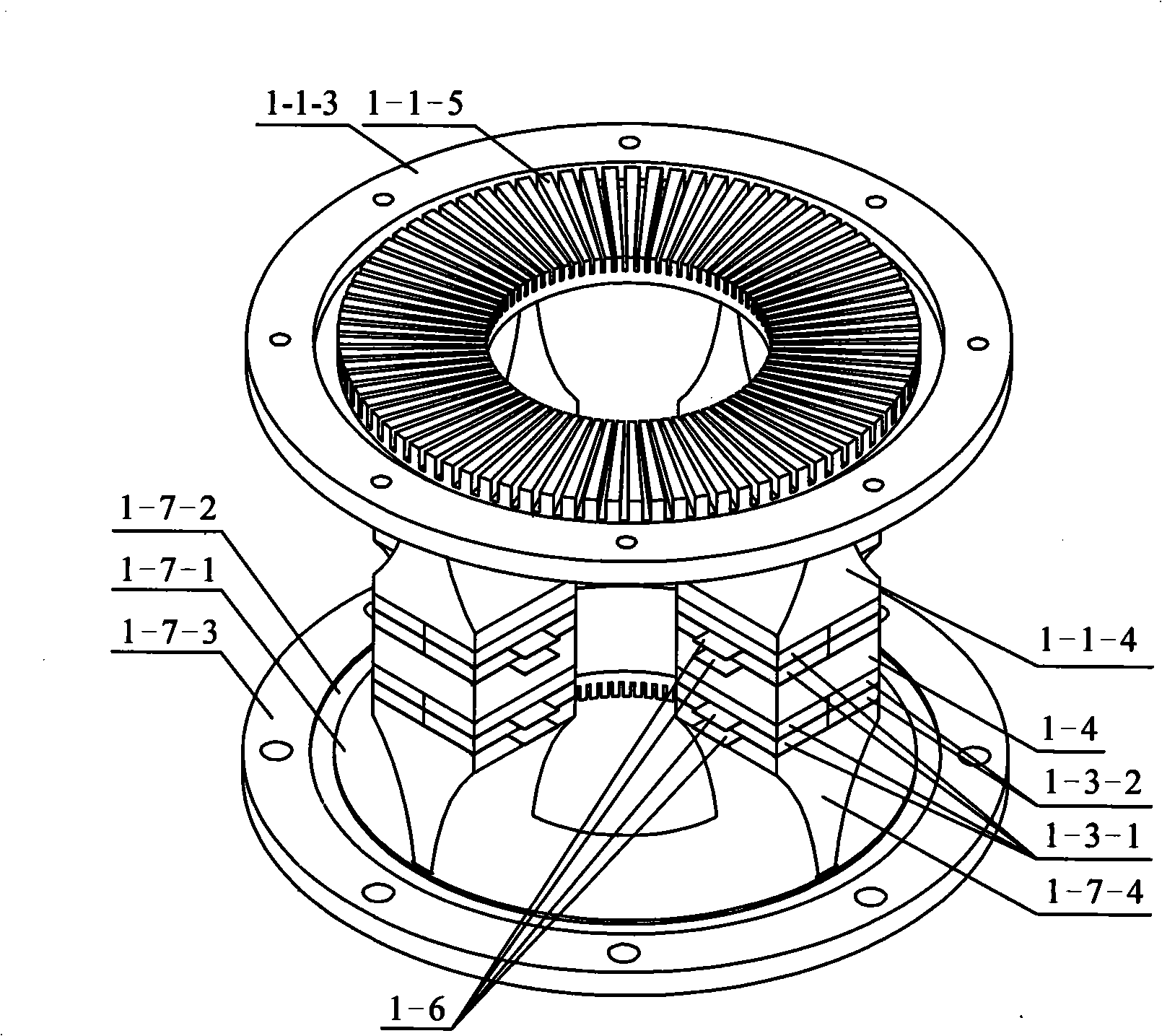

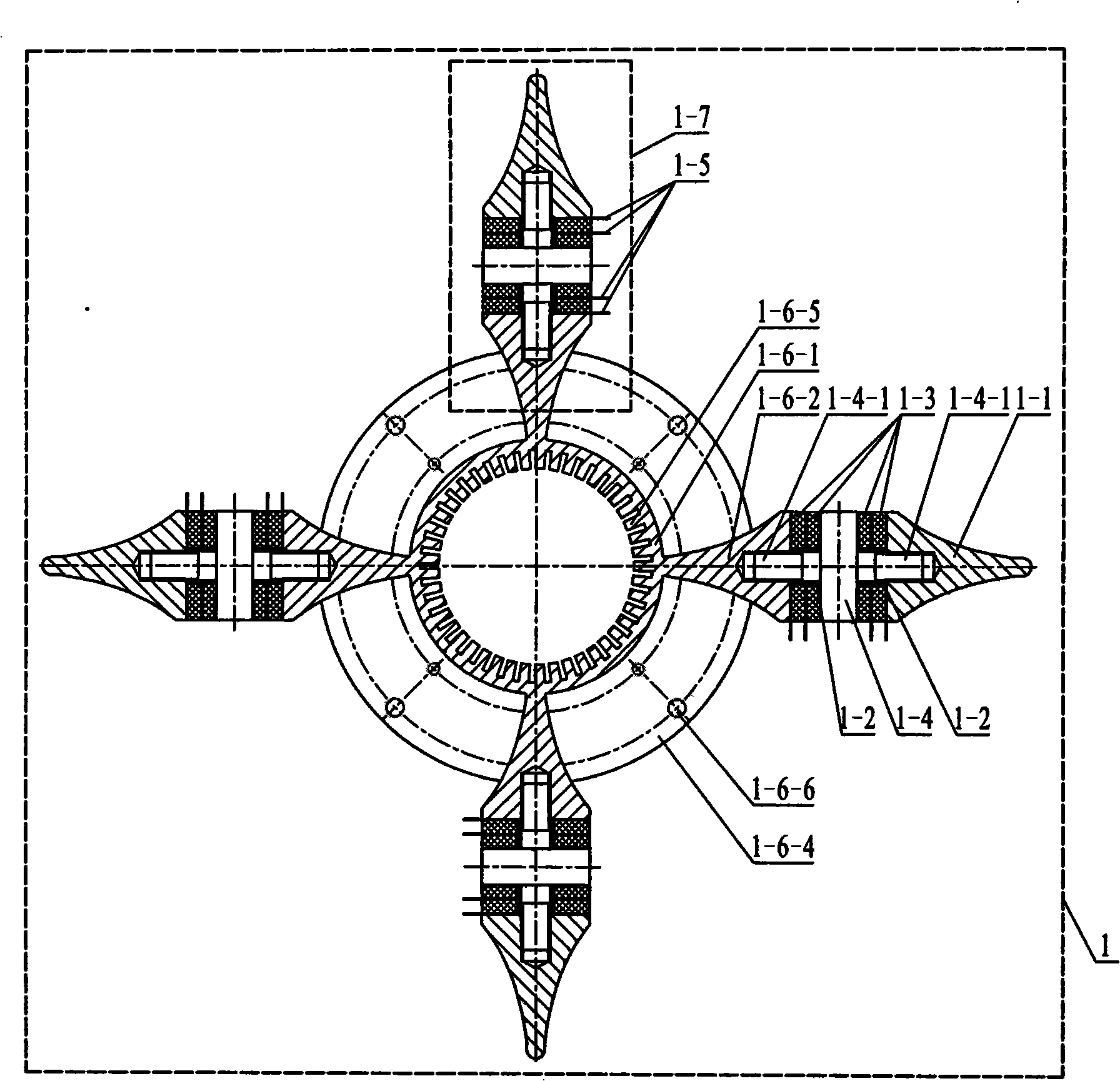

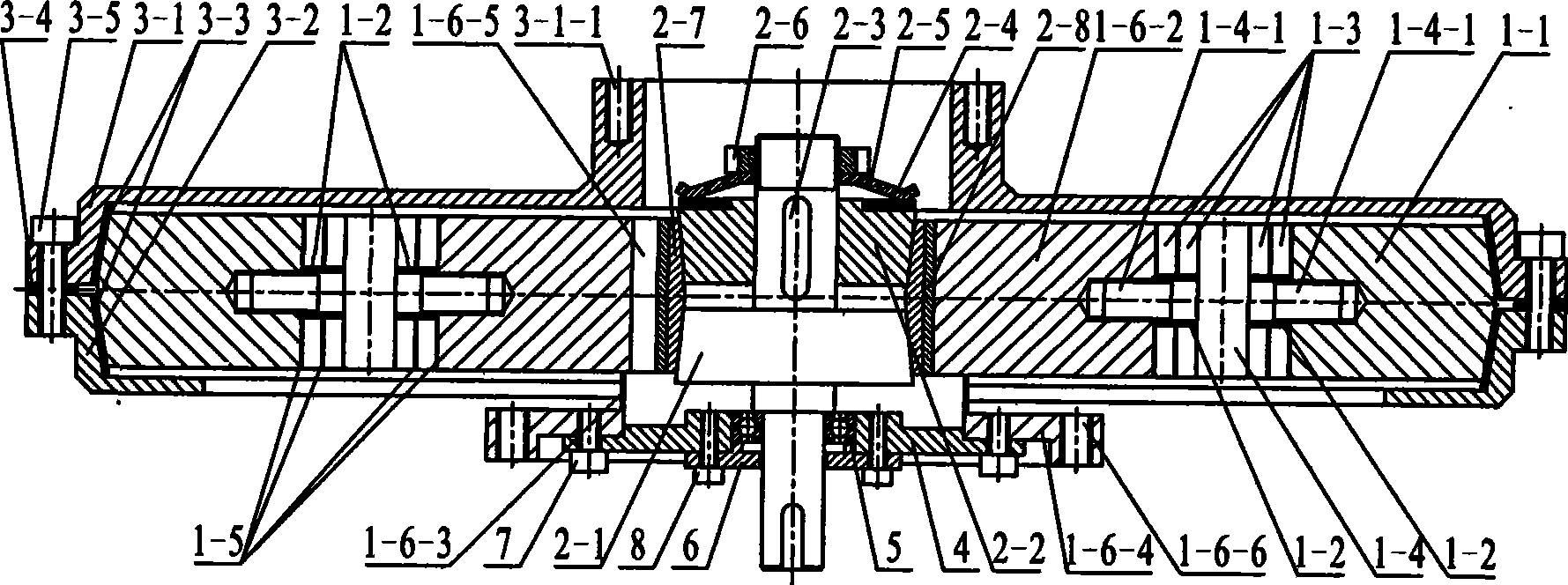

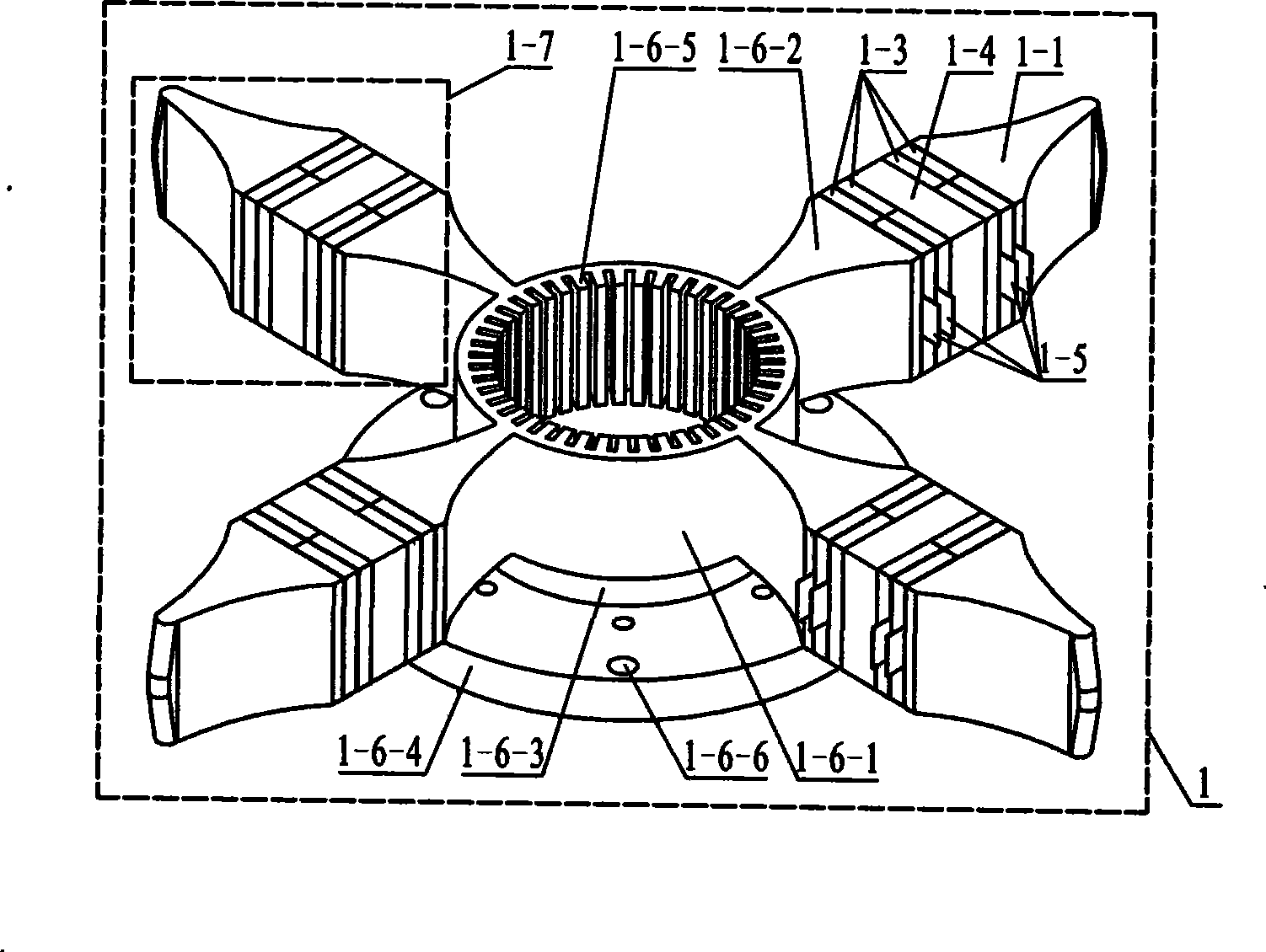

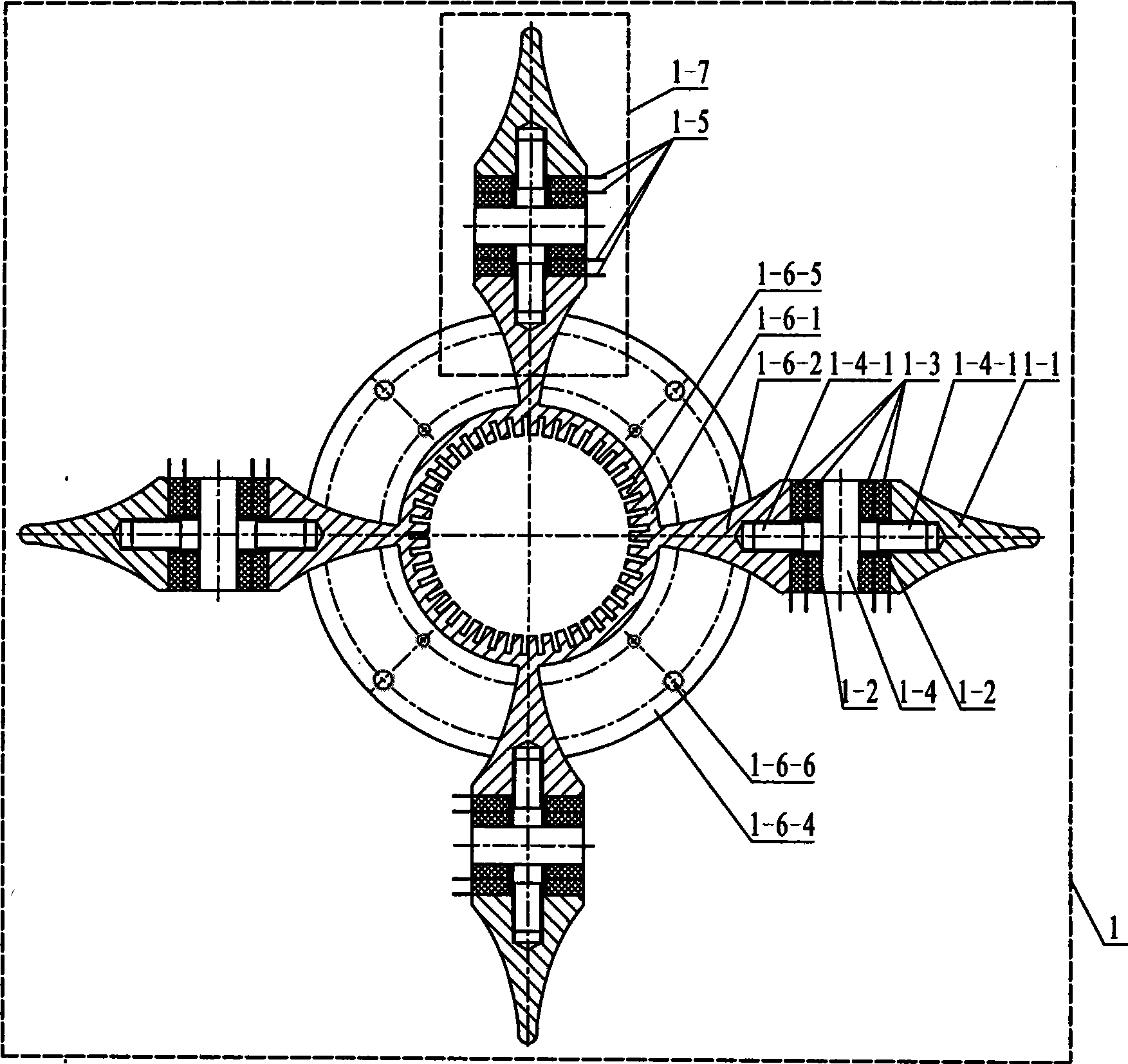

Vertical bending layer energy converter round disk stator and ultrasonic electromotor using this stator

InactiveCN101262184AMake the most of vibrational energyImprove vibration trajectoryPiezoelectric/electrostriction/magnetostriction machinesCircular discEngineering

The invention discloses a longitudinal bending sandwiched energy converter-typed round disc stator and an ultrasonic motor to which the stator is applied, which relates to the ultrasonic motor field. The invention solves the problems in the existing ultrasonic motor, of complex processing, difficult assembly, and lower mechanical output capacity and controllability of the ultrasonic motor. The longitudinal bending sandwiched converter of the stator is fixed between a round disc at the upper end and a round disc at the lower end, both the front end cover and the back end cover of the longitudinal bending sandwiched energy converter are a quadrangular with a rectangle cross section narrowing down gradually, the small end faces of the front end cover and the back end cover are fixedly connected with the upper round disc and the lower round disc; each piezoelectric ceramic piece is polarized along the thickness direction and four pairs of piezoelectric ceramic pieces are respectively fixed between the front end cover, the back end cover and the flange. Rotors in the ultrasonic motor take the shape of a round disc and are embedded respectively from the top and the bottom of the stator component, a wearable cushion is fixed at the end face, contacting the round disc, of the rotor and the stator is fixed to a base through the flange on the energy converter. The longitudinal bending sandwiched energy converter-typed round disc stator and the ultrasonic motor of the invention has the advantages of simple structure, flexible design, high electromechanical coupling efficiency, output with large torque, stable performance and easy control.

Owner:HARBIN INST OF TECH

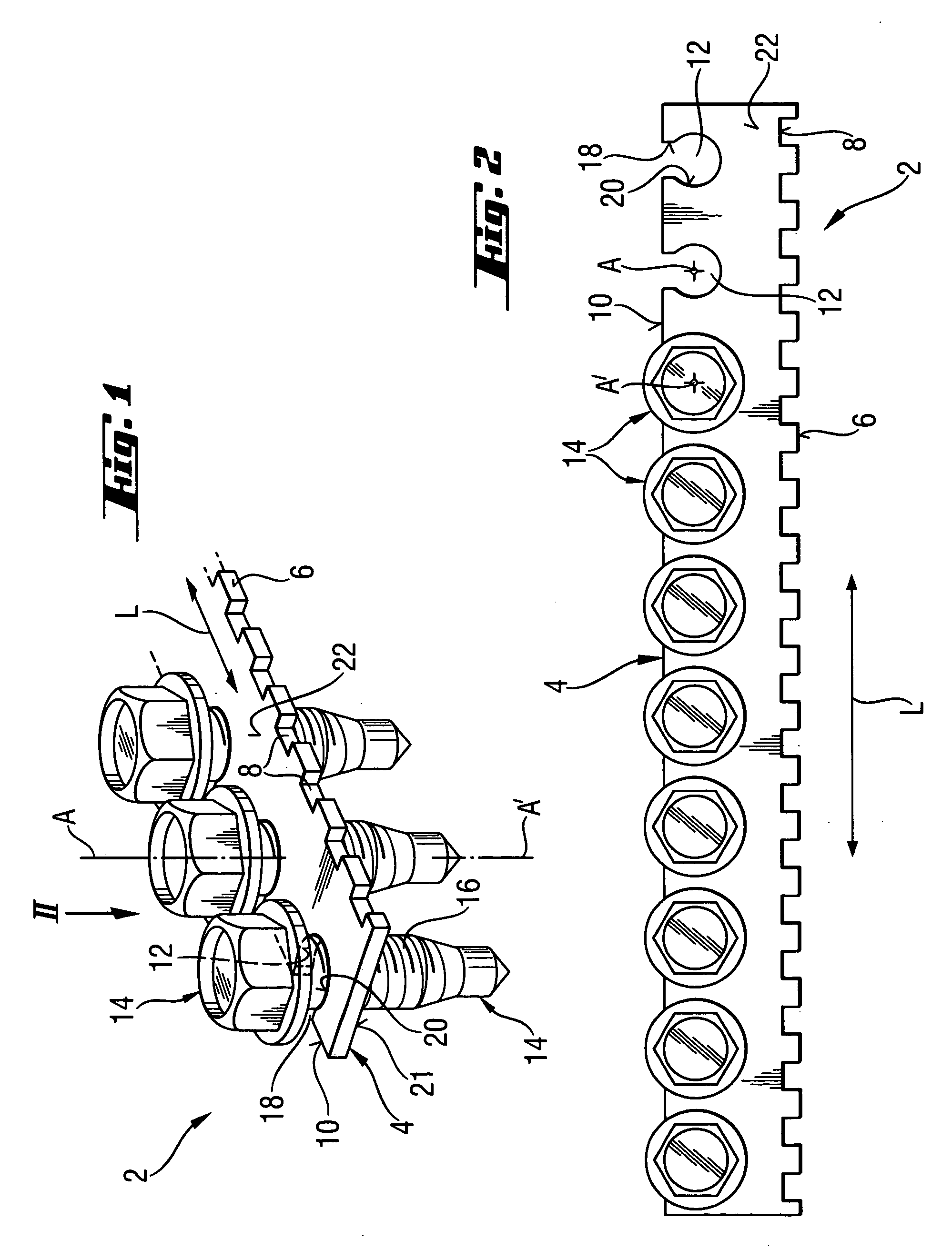

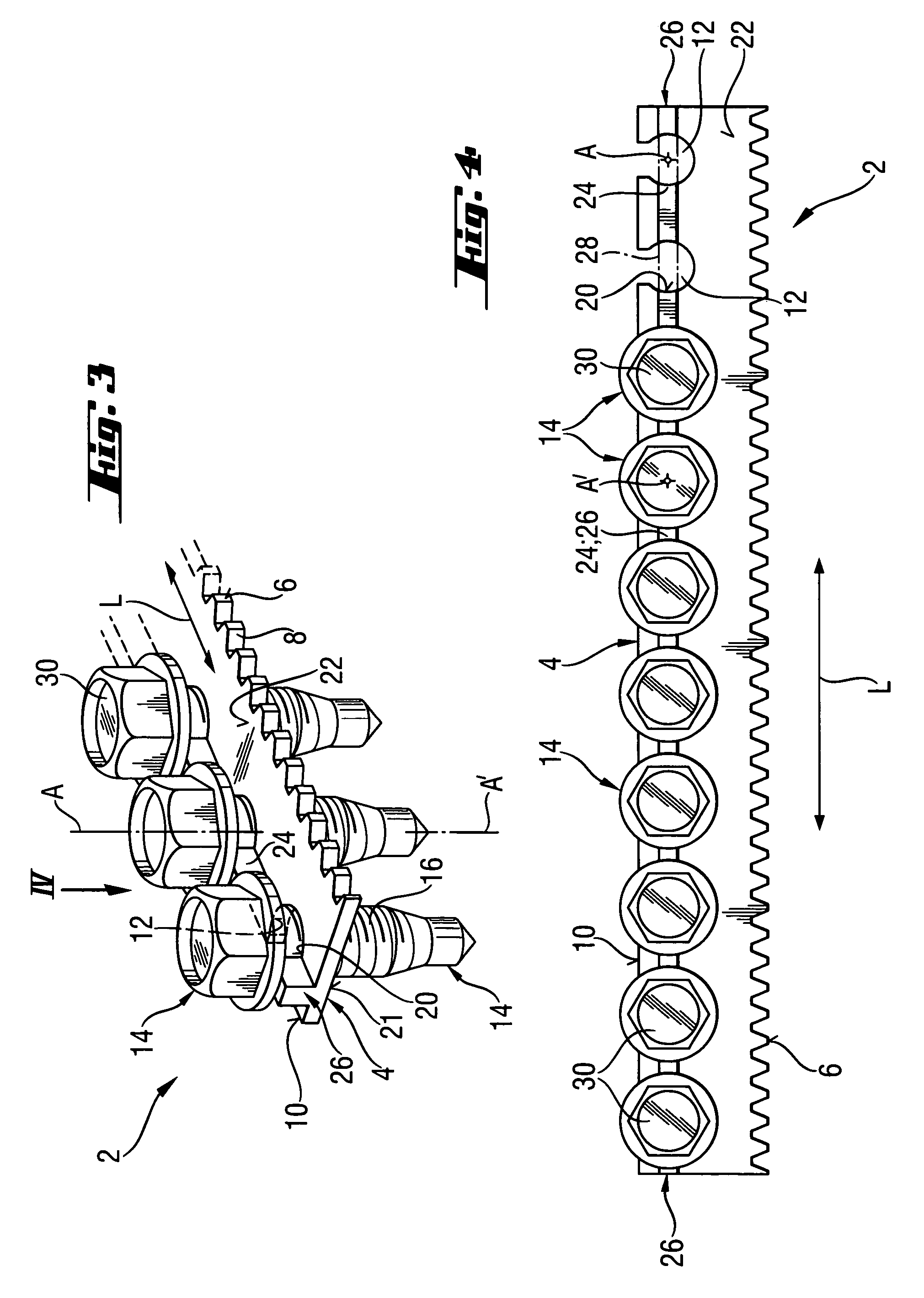

Magazine strip

A magazine strip (2) for fastening elements (14) includes a strip-shaped support strap (4), a plurality of uniformly spaced from each other, transporting recesses (8) for a stepwise displacement of the magazine strip (2) in a magazine receptacle and opening toward a first one (6) of opposite longitudinal edges of the strap, and a plurality of substantially cylindrical receptacles (12) for retaining fastening elements (14) and limited by a lower surface (21) and an upper surface (22) of the support strap (4) and opening toward a second one (10) of the opposite longitudinal edges of the support strap (4).

Owner:HILTI AG

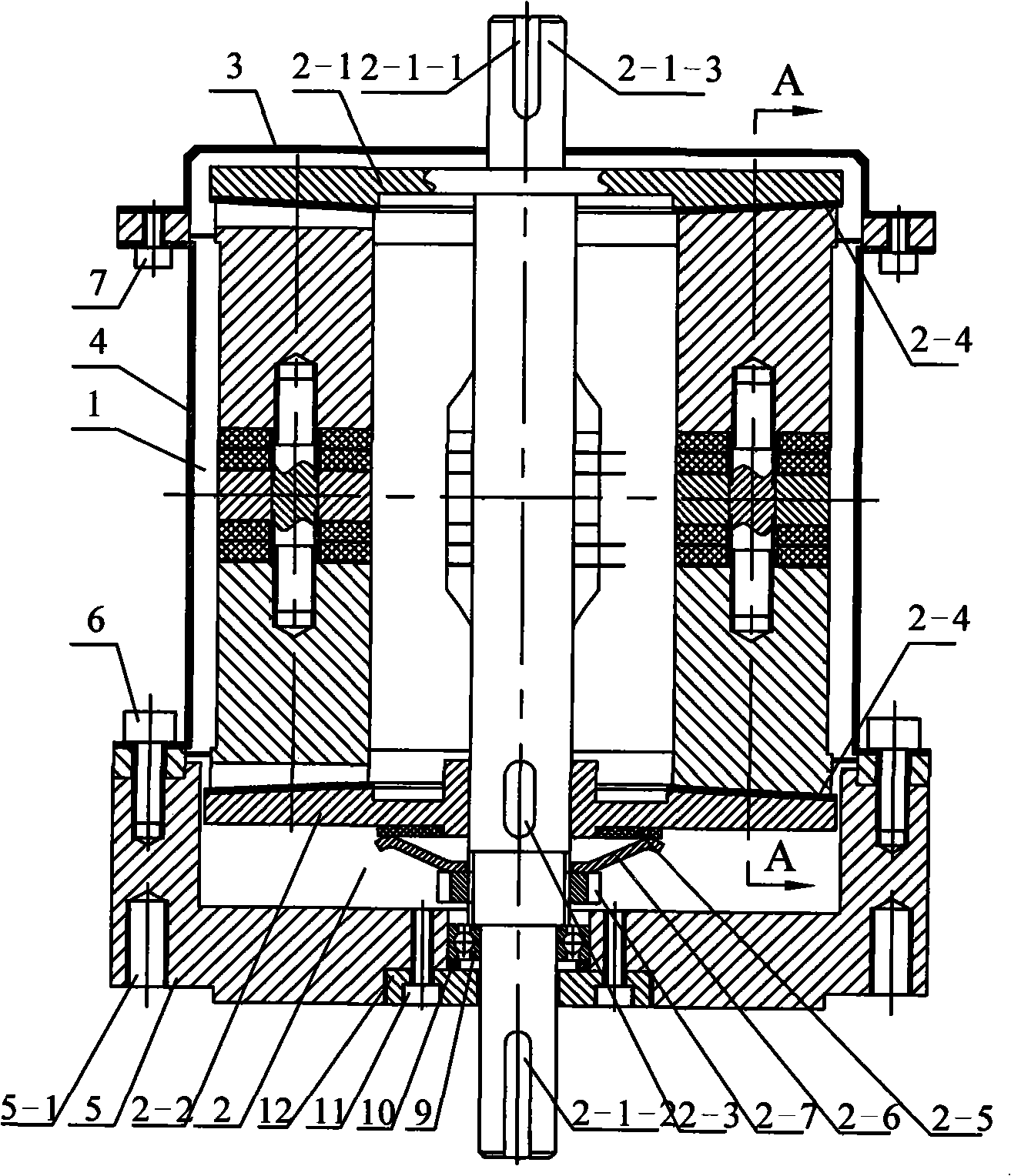

Vertical vibration layer energy converter round disk stator and ultrasonic electromotor using this stator

InactiveCN101262183AIncrease output torqueReduce the influence of output characteristicsPiezoelectric/electrostriction/magnetostriction machinesElastomerVertical vibration

The invention discloses a longitudinal vibration sandwiched energy converter-typed round disc stator and an ultrasonic motor to which the stator is applied, and relates to the ultrasonic motor field. The invention solves the problem in the existing ultrasonic motor that mechanical output capacity is restrained due to the adoption of elastic metal body stuck on piezoelectric ceramic pieces for excitation. Even longitudinal vibration sandwiched energy converters of the stator are symmetrically arrayed and fixed between a round disc at the upper end and a round disc at the lower end; both the front end cover and the back end cover of the sandwiched energy converter are a quadrangular with a rectangle cross section and narrowing down gradually, the small end faces of the front end cover and the back end cover are fixedly connected with the upper round disc and the lower round disc; a flange is arranged at the section where the energy converter vibrates longitudinally and two pairs of piezoelectric ceramic pieces are respectively fixed between the front end cover and the back end cover and the flange. A rotor with a shaft and a rotor without a shaft in the ultrasonic motor both take the shape of a round disc and are embedded respectively from the top and the bottom of a stator cylinder, a wearable cushion is fixed at the end face, contacting the round disc, of the rotor and the stator is fixed to a base through the flange on the energy converter. The longitudinal vibration sandwiched energy converter-typed round disc stator and the ultrasonic motor of the invention are applicable to the manufacturing field of the ultrasonic motor.

Owner:HARBIN INST OF TECH

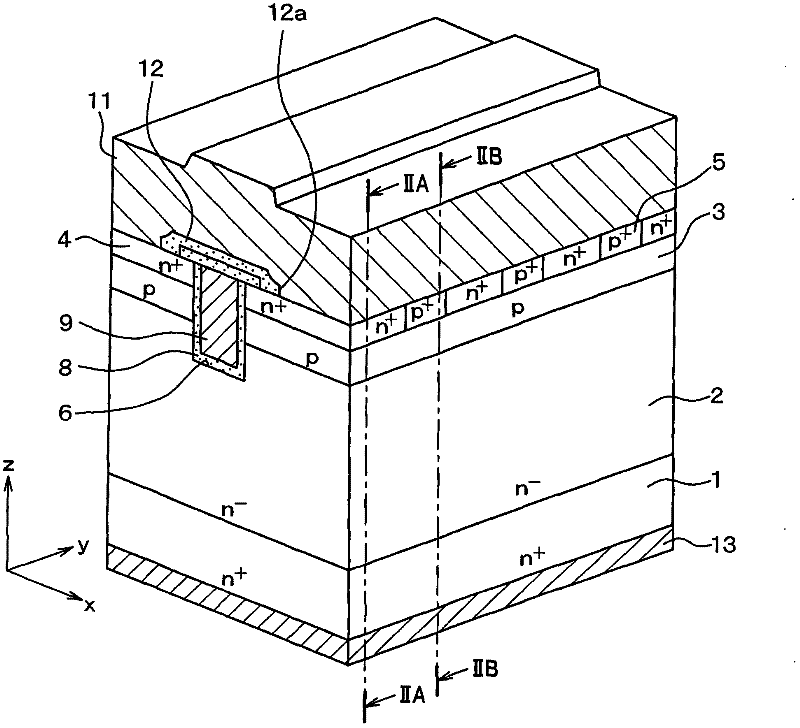

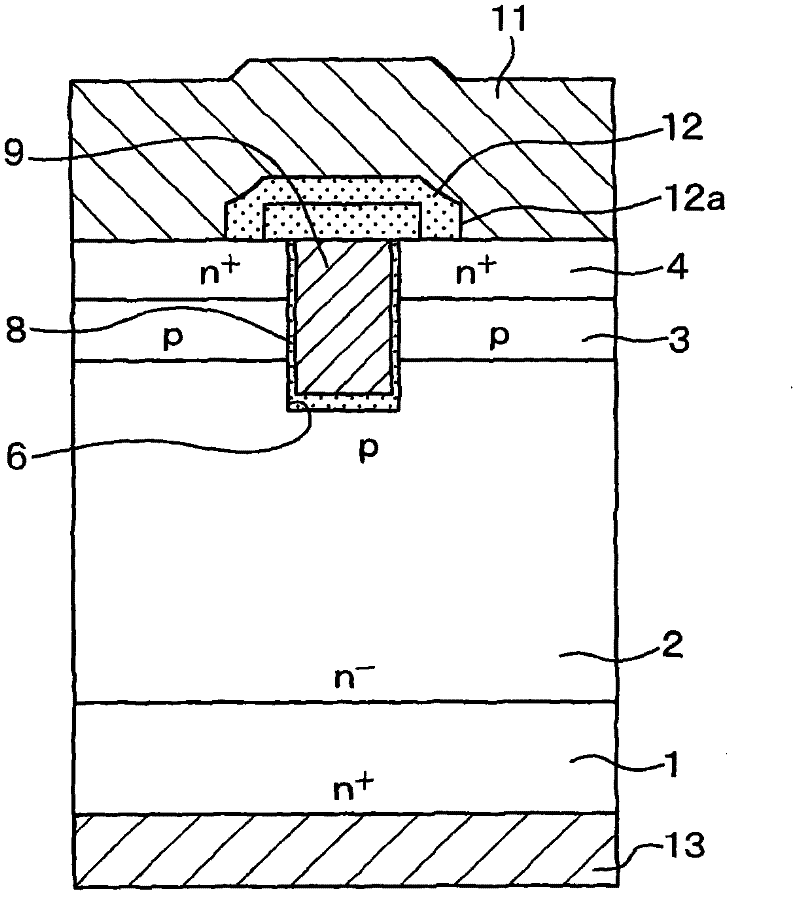

Sic semiconductor device

A SiC semiconductor device includes a reverse type MOSFET having: a substrate 1; a drift layer 2 and a base region 3 on the substrate; a base contact layer 5 and a source region 4 on the base region; multiple trenches 6 having a longitudinal direction in a first direction penetrating the source region and the base region; a gate electrode 9 in each trench via a gate insulation film 8; an interlayer insulation film 12 covering the gate electrode and having a contact hole 12a, through which the source region and the base contact layer are exposed; a source electrode 11 coupling with the source region and the base region through the contact hole 12a; a drain electrode 13 on the substrate. The source region and the base contact layer extend along with a second direction perpendicular to the first direction, and are alternately arranged along with the first direction. The contact hole has a longitudinal direction in the first direction.

Owner:DENSO CORP +1

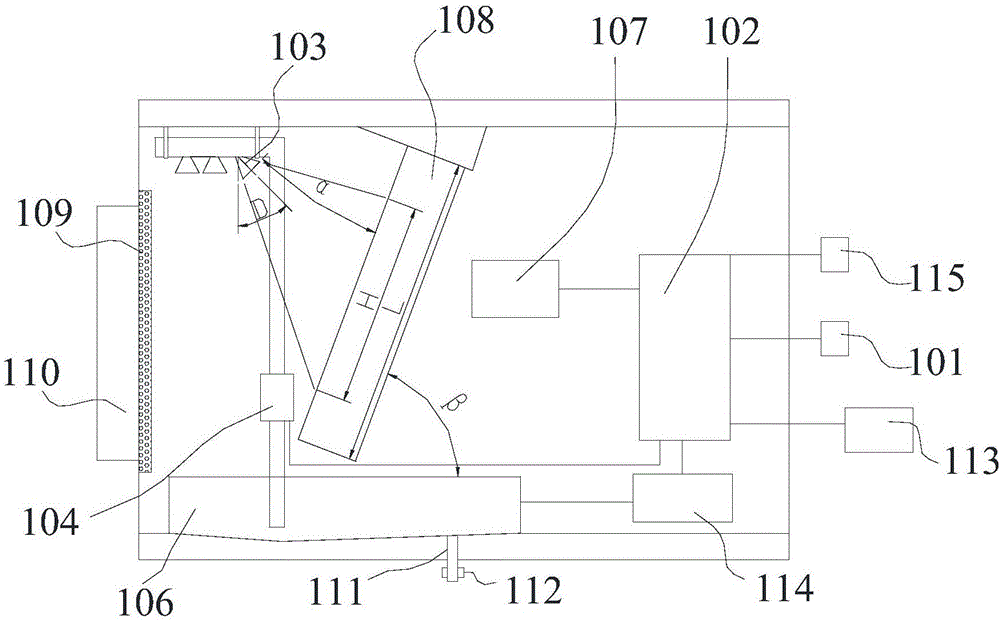

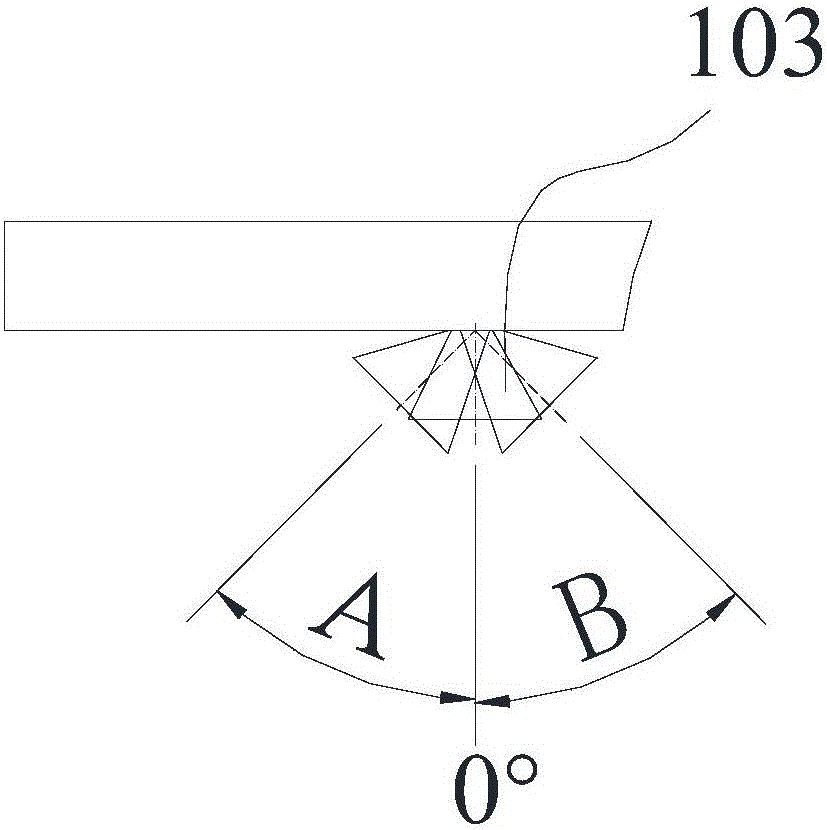

Air conditioner system and air conditioner control method

ActiveCN106839212AIncreased contact areaChange of spray areaMechanical apparatusSpace heating and ventilation safety systemsEngineeringWater spray

The invention discloses an air conditioner system, and belongs to the field of air conditioners. The air conditioner system comprises a temperature sensor used for measuring the temperature of the indoor environment, a spray header for spraying water, a draught fan used for blowing out water sprayed by the spray header, and a controller used for opening the draught fan and the spray header and determining the angle of the spray header when the difference between the temperature of the indoor environment measured by the temperature sensor and the set temperature is smaller than the threshold. According to the technical scheme, the temperature sensor is used for measuring the temperature of the indoor environment; the spray header is used for spraying water; the draught fan is used for blowing out water sprayed by the spray header; and the controller is used for opening the draught fan and the spray header and determining the angle theta of the spray header when the difference between the temperature of the indoor environment measured by the temperature sensor and the set temperature is smaller than the threshold. The controller controls the angle of the spray header to change a spraying zone and achieve the purpose of spraying different zones. The contact area of air and water is increased, and the humidification amount is increased. The invention further provides an air conditioner control method.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Magazine strip

A magazine strip (2) for fastening elements (14) includes a strip-shaped support strap (4), a plurality of uniformly spaced from each other, transporting recesses (8) for a stepwise displacement of the magazine strip (2) in a magazine receptacle and opening toward a first one (6) of opposite longitudinal edges of the strap, and a plurality of substantially cylindrical receptacles (12) for retaining fastening elements (14) and limited by a lower surface (21) and an upper surface (22) of the support strap (4) and opening toward a second one (10) of the opposite longitudinal edges of the support strap (4).

Owner:HILTI AG

Sandwich type round plate stator and ultrasonic motor using the same

InactiveCN101388621ASolve efficiency problemsAddress mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamElastomer

The invention relates to a sandwich disk stator and an ultrasonic motor which uses the stator, which relate to the technical field of piezoelectric ultrasonic motors. The sandwich disk stator and the ultrasonic motor solve the problem in an existing ultrasonic motor that since a mode that a metallic elastomer is pasted with a piezoelectric ceramic slice is adopted to actuate, the mechanical output ability is restricted. Driving elements with even number in the sandwich disk stator are fixed on the upper end surface of a disk, two pairs of piezoelectric ceramic pieces are fixed between each pair of cantilever beams, and a plurality of comb-shaped driving gears are evenly distributed on the lower end surface of the disk. The ultrasonic motor which uses the stator comprises two stators, a rotor component is composed of a rotor and a wear resistance bush ring, wherein the end surface of the wear resistance bush ring is provided with same taper with the upper end surface of the driving gears, two stators are respectively installed on and under the rotor, the pre-tightening between the stator component and the rotor component can be realized through two stator flanges, and the rotor component is connected with bearing blocks of the two stators through output shafts and bearings on two ends of the rotor in a rotary mode. The sandwich disk stator and the ultrasonic motor have simple structure, can realize big force moment output, and have stable performance.

Owner:HARBIN INST OF TECH

Semiconductor device and method for manufacturing the same

ActiveUS20130127013A1Increase capacitanceIncreased contact areaSolid-state devicesSemiconductor/solid-state device manufacturingNODALEngineering

In a semiconductor device, a support wall is formed between storage nodes to more effectively prevent leaning of a capacitor, and the storage nodes are formed using a damascene process, which may increase a contact area between each storage node and a storage node contact.

Owner:SK HYNIX INC

Device for applying surface finishes, in particular finishing or paint, to a textile item in thread pattern

ActiveCN102828366APromote absorptionAvoid formingTextile treatment carriersLiquid/gas/vapor textile treatmentYarnSurface finish

The device (1) has a driving roller (4) for covering a peripheral part of a textile material (3), where the textile material (3) forms an inlet gusset (6) with the driving roller (4). A surface agent feeding device (7) feeds into the gusset (6), and a supporting roller (10) for supporting the textile material (3) is arranged in a region of the gusset (6) on a side of the driving roller (4), where the side faces away from the textile material.

Owner:KARL MAYER STOLL R&D GMBH

Bending layer energy converter round disk stator and ultrasonic electromotor using this stator

InactiveCN101262185ASolve efficiency problemsAddress mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesElastomerCircular disc

The invention discloses a flexural vibration sandwiched energy converter-typed round disc stator and an ultrasonic motor to which the stator is applied, and relates to the ultrasonic motor field. The invention solves the problem in the existing ultrasonic motor, that mechanical output capacity is restrained due to the adoption of elastic metal body stuck on piezoelectric ceramic pieces for excitation. Even flexural vibration sandwiched energy converters of the stator are symmetrically arrayed and fixed between a round disc at the upper end and a round disc at the lower end; both the front end cover and the back end cover of the sandwiched energy converter are a quadrangular with a rectangle cross section narrowing down gradually, the small end faces of the front end cover and the back end cover are fixedly connected with the upper round disc and the lower round disc; two pairs of piezoelectric ceramic pieces are respectively and fixed between the front end cover, the back end cover and the flange. A rotor with a shaft and a rotor without a shaft in the ultrasonic motor both take the shape of a round disc and are embedded respectively from the top and the bottom of a stator cylinder, a wearable cushion is fixed at the end face, contacting the round disc, of the rotor and the stator is fixed to a base through the flange on the energy converter. The flexural vibration sandwiched energy converter-typed round disc stator and the ultrasonic motor of the invention are applicable to the manufacturing field of the ultrasonic motors.

Owner:HARBIN INST OF TECH

Longitudinal-shaking sandwich energy converter type cylinder type birotor ultrasonic motor

InactiveCN101304223AStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesTransducerLongitudinal vibration

The invention discloses a longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor, which relates to the technical field of an ultrasonic motor and aims at solving the problems that the mechanical output capacity is restricted and a single stator can only realize single moving output existing in present ultrasonic motor. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention comprises a stator component, a medial rotor component, an outer rotor component, a bearing base, a bearing and a bearing pretension cover. The inner surface of a cylinder is manufactured with continuous comb-shaped driving gears; a medial rotor with a shaft and a medial rotor without the shaft are cone-shaped, the thin ends of the medial rotor with the shaft and the medial rotor without the shaft are respectively inserted from the lower part of a stator cylinder and the upper part of the stator cylinder; an outer rotor with the shaft and an outer rotor without the shaft are respectively arranged on the upper part of the stator component and the lower part of the stator component; the lateral surfaces that the outer rotor with the shaft and the outer rotor without the shaft are contacted with the back end cover of the stator are respectively fixed with wear-resistance lining rings; the medial rotor with the shaft is rotatablely connected with the bearing base by the bearing. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention can be applied to the ultrasonic motor manufacturing field.

Owner:HARBIN INST OF TECH

Diverting and converging system based on multi-directional sorting wheels

The invention discloses a diverting and converging system based on multi-directional sorting wheels. The diverting and converging system comprises a main conveying line, wherein the main conveying line is connected with a friction driving type sorting wheel conveying line in a matched mode, the output end of the sorting wheel conveying line is connected with a first branch conveying line and a second branch conveying line which are parallel, and in a converging state, axes of the sorting wheels in the sorting wheel conveying line are parallel to driving rollers in the sorting wheel conveying line, wherein the driving rollers drive the sorting wheels to rotate through friction; and in a diverting state, the axes of the sorting wheels in the sorting wheel conveying line keep included angleswith the driving rollers, and the conveying direction of the sorting wheel conveying line can be switched between facing the first branch conveying line and facing the second branch conveying line. According to the scheme, the characteristic that the sorting wheels of the sorting wheel conveying line can freely turn is fully utilized, so that diverting or converging operation is realized, objectsare not damaged in the diverting process, the movement of the objects is not hindered in the converging process, and the combination of the high safety and the high efficiency are effectively realized.

Owner:SUZHOU GP LOGISTICS SYST

Contact hole, semiconductor device and method for forming the same

ActiveUS20110281413A1Reduce the possibilityReduce gap sizeSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceElectrical conductor

The invention provides a method for forming a contact hole, comprising: forming a gate, a sidewall spacer, a sacrificial sidewall spacer, a source region and a drain region on a substrate, wherein the sidewall spacer is formed around the gate, the sacrificial sidewall spacer is formed over the sidewall spacer, and the source region and the drain region are formed within the substrate and on respective sides of the gate; forming an interlayer dielectric layer, with the gate, the sidewall spacer and the sacrificial sidewall spacer being exposed; removing the sacrificial sidewall spacer to form a contact space, a material that the sacrificial sidewall spacer is made of being different from any of materials that the gate, the sidewall spacer and the interlayer dielectric layer are made of; forming a conducting layer to fill the contact space; and cutting off the conducting layer, to form at least two conductors connected to the source region and the drain region respectively. The invention also provides a contact hole, the contact hole a gate and a sidewall spacer being formed on a substrate and within an interlayer dielectric layer, wherein the sides of the contact hole meet the sidewall spacer. The invention also provides a semiconductor device and a method for forming the same. With the technical solutions provided by the invention, the number of masks used can be reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Absorber

InactiveCN103370119AIncreased surface areaImprove absorption efficiencyGas treatmentUsing liquid separation agentFlue gasMechanical engineering

An absorber is provided which utilizes a solvent froth to absorb a selected component, such as CO2 for example, from a flowing gas stream, such as flue gas from a fossil fuel power plant, for example. In one embodiment, a flooded tube gas absorber utilizes a bulkhead plate extending across a reaction chamber. The plate carries a plurality of vertical absorption tubes, each carrying a plurality of spaced apart screens. The incoming gas stream flows downwardly and at equal velocities through the tubes. Solvent is injected downwardly into the tubes. The screen array forms a froth and rapidly and repeatedly bursts the froth bubbles, forming a rapidly changing absorption surface. A second embodiment uses full diameter screens without a bulkhead plate. An option is to use ridge shaped screens to achieve solvent pulsing, increasing efficiency. Both vertical and horizontal reaction chambers are disclosed.

Owner:WESTEC ENVIRONMENTAL SOLUTIONS

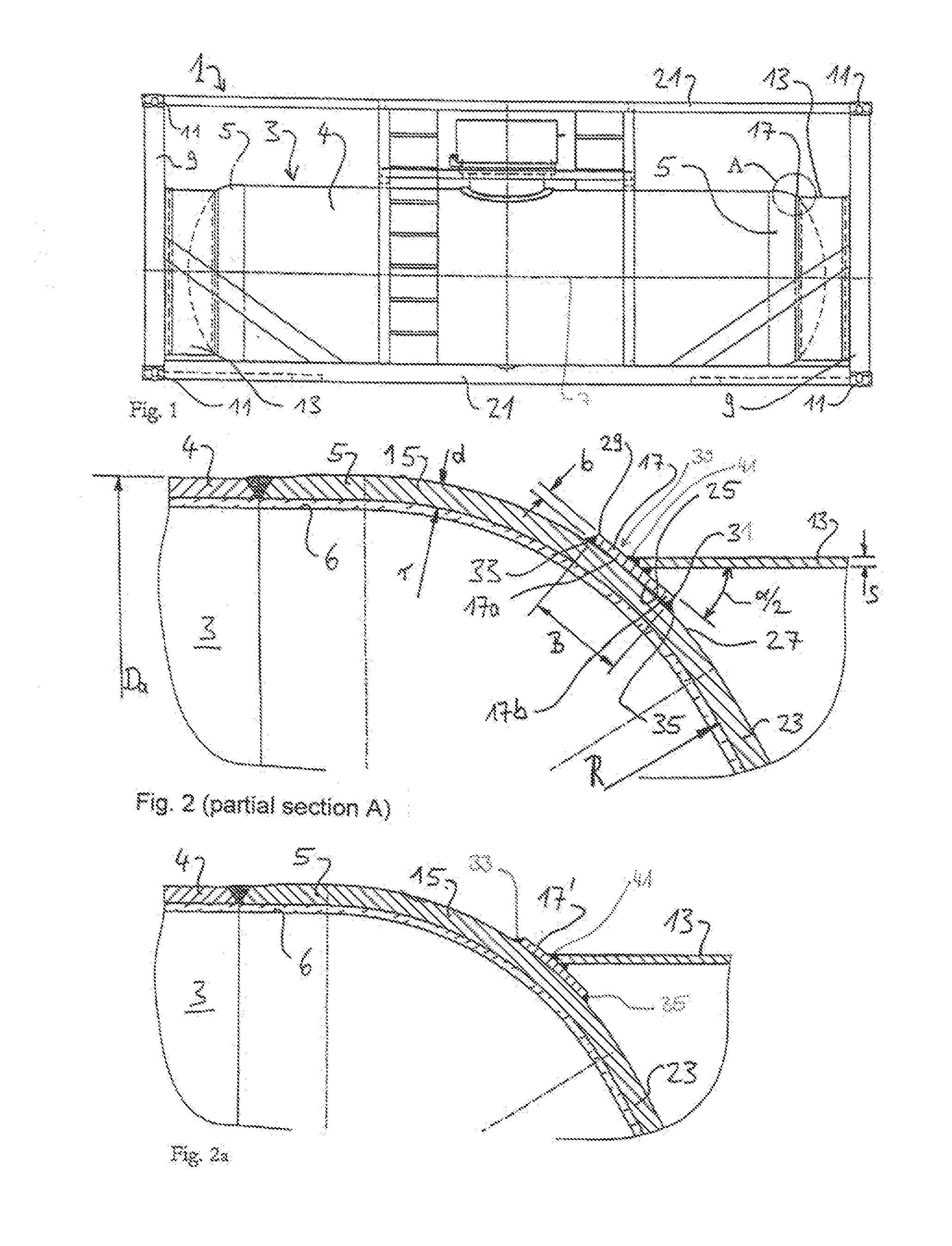

Tank container

InactiveUS20150260340A1Dimensionally stableLoad minimizationVessel geometry/arrangement/sizeVessel wallsRing deviceEngineering

The invention relates to a tank container (1) including a cylindrical vessel (3), the ends of which are closed by domed bottoms (5), and provided with an inner lining (6), in particular lead lining, and being connected at the bottoms (5) in each case by way of an annular device (13) to an end frame device (9). The annular device (13) is provided in a rim region (15) of the bottom (5). Between the annular device (13) and the bottom, in the rim region (15), a frustoconical annular support element (17, 17′) extends concentrically to the annular device (13). It engages flush by way of a broad side (25) with the outside (27) of the rim region (15) and is fixed on its inner and outer edge (29, 31) by way of welding seams (33, 35) to the rim region (15), such that loads acting between the vessel (3) and the annular device (13) are transmitted by way of the broad side (25) between the vessel (3) and the annular support element (17, 17′).

Owner:WEW WESTERWAELDER EISENWERK

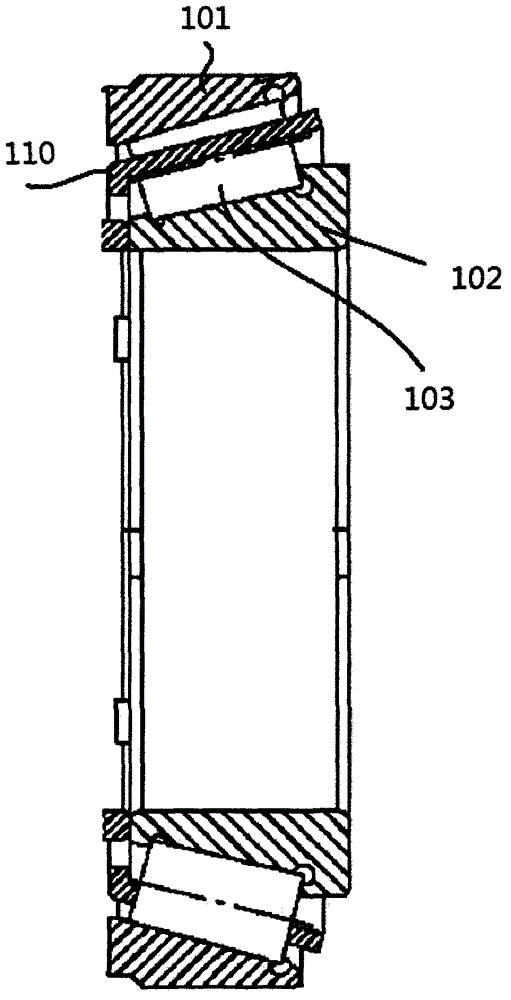

Roller bearing for supporting main shaft of wind driven generator

ActiveCN102748382AAvoid the problems of obvious stress concentration and high heat generationImprove enduranceRoller bearingsWind drivenHigh intensity

The invention discloses a roller bearing for supporting a main shaft of a wind driven generator. The roller bearing for supporting a main shaft of a wind driven generator is prepared from a high-strength alloy steel material, has a single-row tapered roller bearing structure, and comprises an outer ring, an inner ring, a tapered roller, an upper groove which is used for receiving the tapered roller and is located at the outer ring, a lower groove which is used for receiving the tapered roller and is located at the inner ring, a keeper which is used for keeping the tapered roller, an upper lubricant groove which is located at the outer ring and provides lubricant to the tapered roller, and a lower lubricant groove which is located at the inner ring and provides lubricant to the tapered roller, wherein four corners of the tapered roller have arc shapes; the upper groove which is used for receiving the tapered roller and is located at the outer ring and the lower groove which is used for receiving the tapered roller and is located at the inner ring compose a tapered roller receiving groove; and four corners of the tapered roller receiving groove have arc shapes.

Owner:JIANGSU JINYUAN FORGE

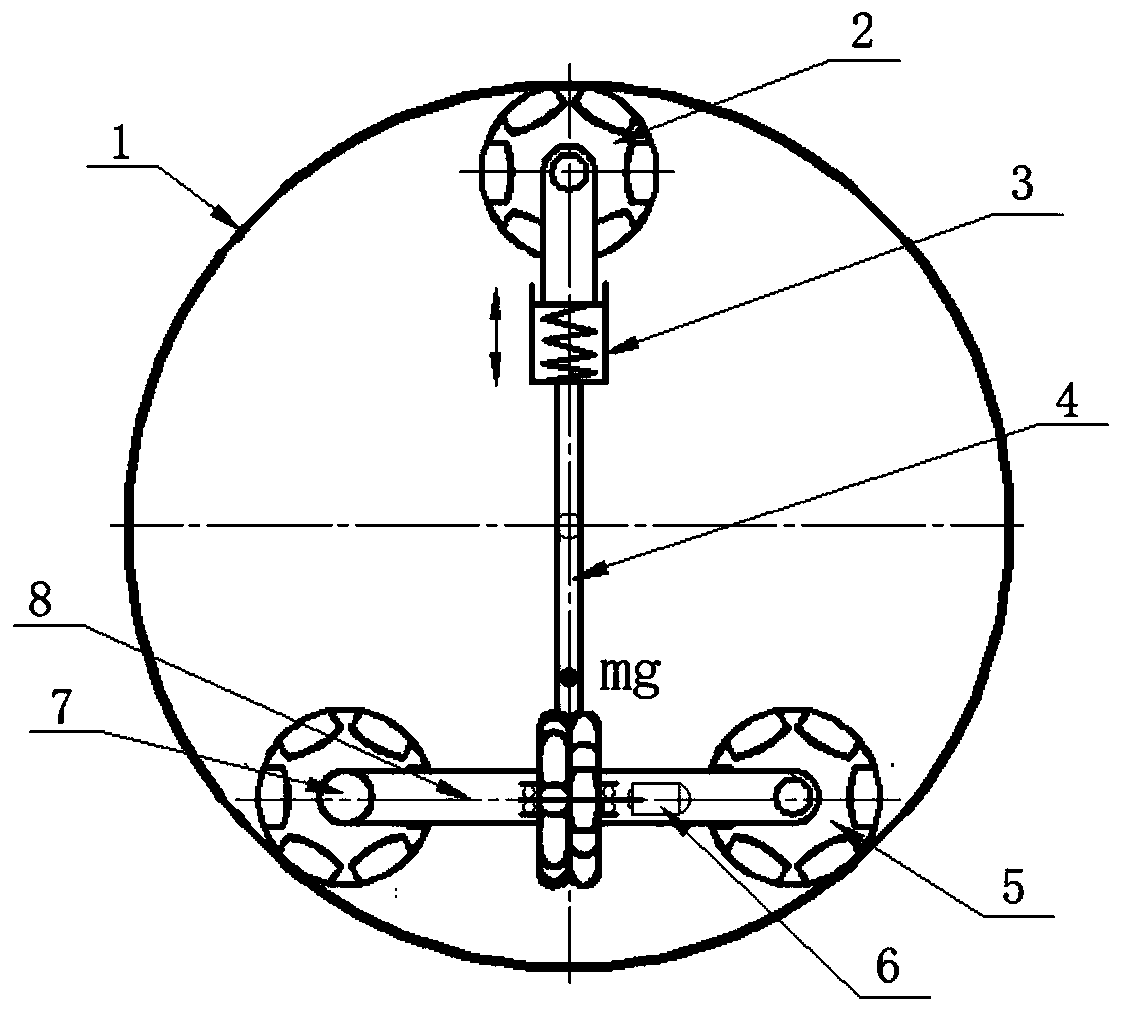

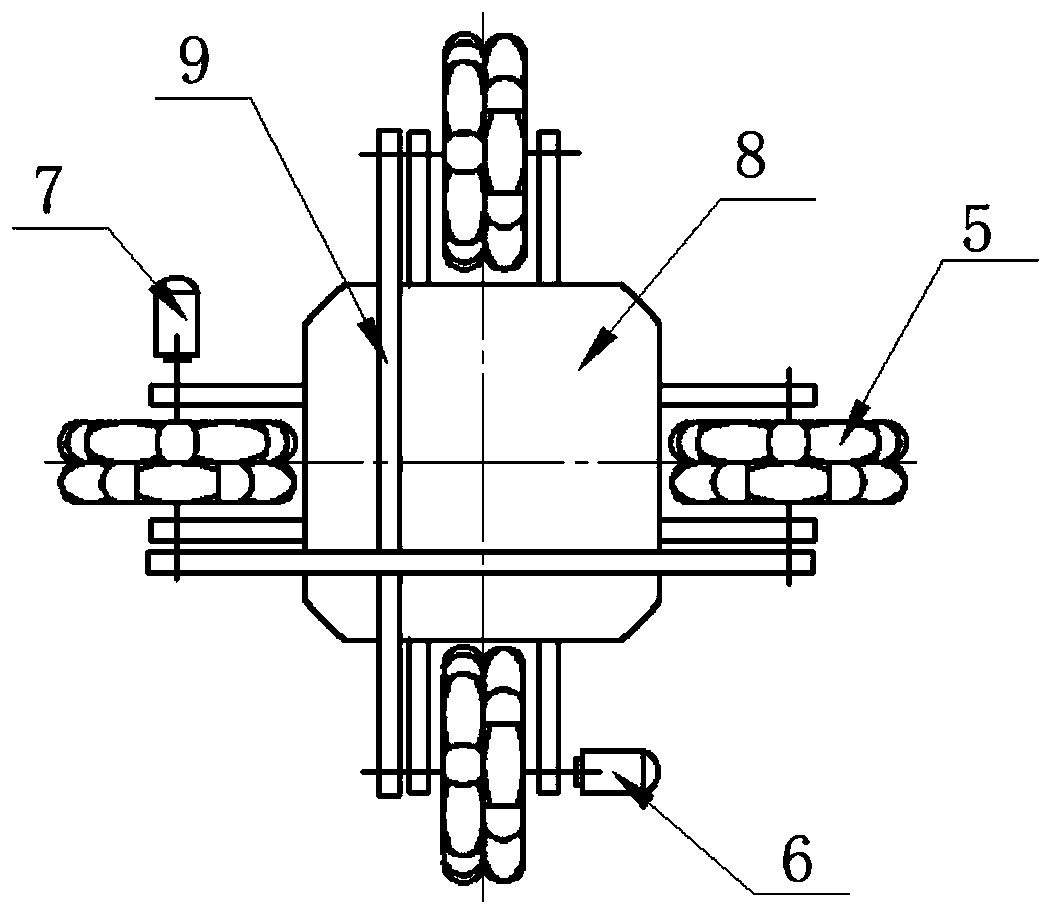

Double-power four-wheel-drive five-omnidirectional-wheel heavy-load spherical robot

PendingCN111332378AIncreased contact areaDistribute pressureWheelsVehiclesElectric machineryOmni directional

The invention relates to a four-wheel-drive spherical robot with five omnidirectional wheels. The robot mainly comprises a spherical shell, a rack, a walking drive, a steering drive, a spring, a support, four driving omnidirectional wheels, a chassis and the like. Eccentric mass of parts in the spherical shell and pre-pressure of the spring jointly act on the inner surface of the spherical shell,the provided friction force enables the eccentric mass to deviate from the sphere center, and therefore eccentric torque is generated to enable the spherical shell to roll. The four omnidirectional wheels are supported below the chassis in pairs in an orthogonal mode, large bearing capacity can be provided, the front omnidirectional wheel and the rear omnidirectional wheel are driven by one walking motor, the left omnidirectional wheel and the right omnidirectional wheel are driven by one steering motor, and the supporting omnidirectional wheel located at the top can prevent the chassis from overturning.

Owner:BEIJING JIAOTONG UNIV

Longitudinal-shaking sandwich energy converter type cylinder shape dual rotor ultrasonic motor

InactiveCN101388623AStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesTransducerEngineering

The invention relates to a bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor which relates to the technical field of piezoelectric ultrasonic motors. The ultrasonic motor solves the problem in an existing ultrasonic motor that the mechanical output ability is restricted and a single stator only can realize single movement output. The bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor of the invention comprises a stator component, an inside rotor component, an outside rotor component, a bearing block, a bearing and a bearing pre-tightening end cap, wherein continuous comb-shaped driving gears are manufactured on the inner surface of a cylinder, an inside rotor with a shaft and an inside rotor without the shaft are truncated cone-shaped, thin ends of the inside rotor with the shaft and the inside rotor without the shaft are respectively inserted on and under the cylinder, an outside rotor with the shaft and an outside rotor without the shaft are respectively installed on and under the stator component, wear resistance bush rings are respectively fixed on the side surfaces of the outside rotor with the shaft and the outside rotor without the shaft, which are contacted with a stator rear end cap, and the inside rotor with the shaft is connected with the bearing block in a rotary mode through the bearing. The bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor can be applied in the manufacture field of ultrasonic motors.

Owner:HARBIN INST OF TECH

Keyboard module and key

InactiveCN106328412AImprove stabilityIncreased contact areaElectric switchesComputingSymmetric structureKey pressing

The invention relates to a keyboard module, which comprises a first key and a second key, wherein the first key comprises a first key cap and a first scissor connection element, wherein the first scissor connection element comprises a first outer frame and a first inner frame; the second key comprises a second key cap and a second scissor connection element; the second scissor connection element comprises a second outer frame and a second inner frame; the first outer frame, the first inner frame and the second inner frame all are of a symmetric structure; and the second outer frame is of an asymmetric structure.

Owner:PRIMAX ELECTRONICS LTD

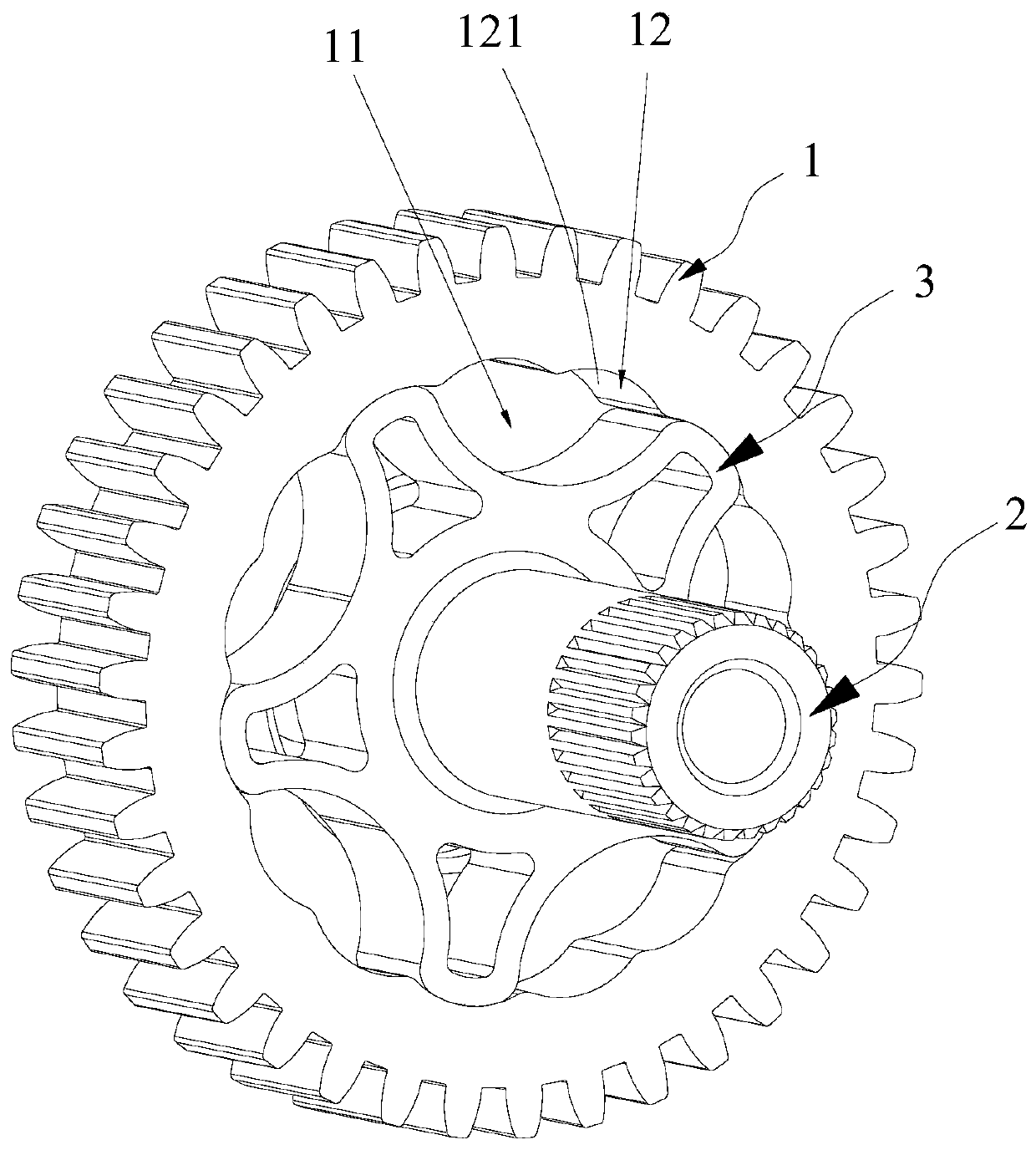

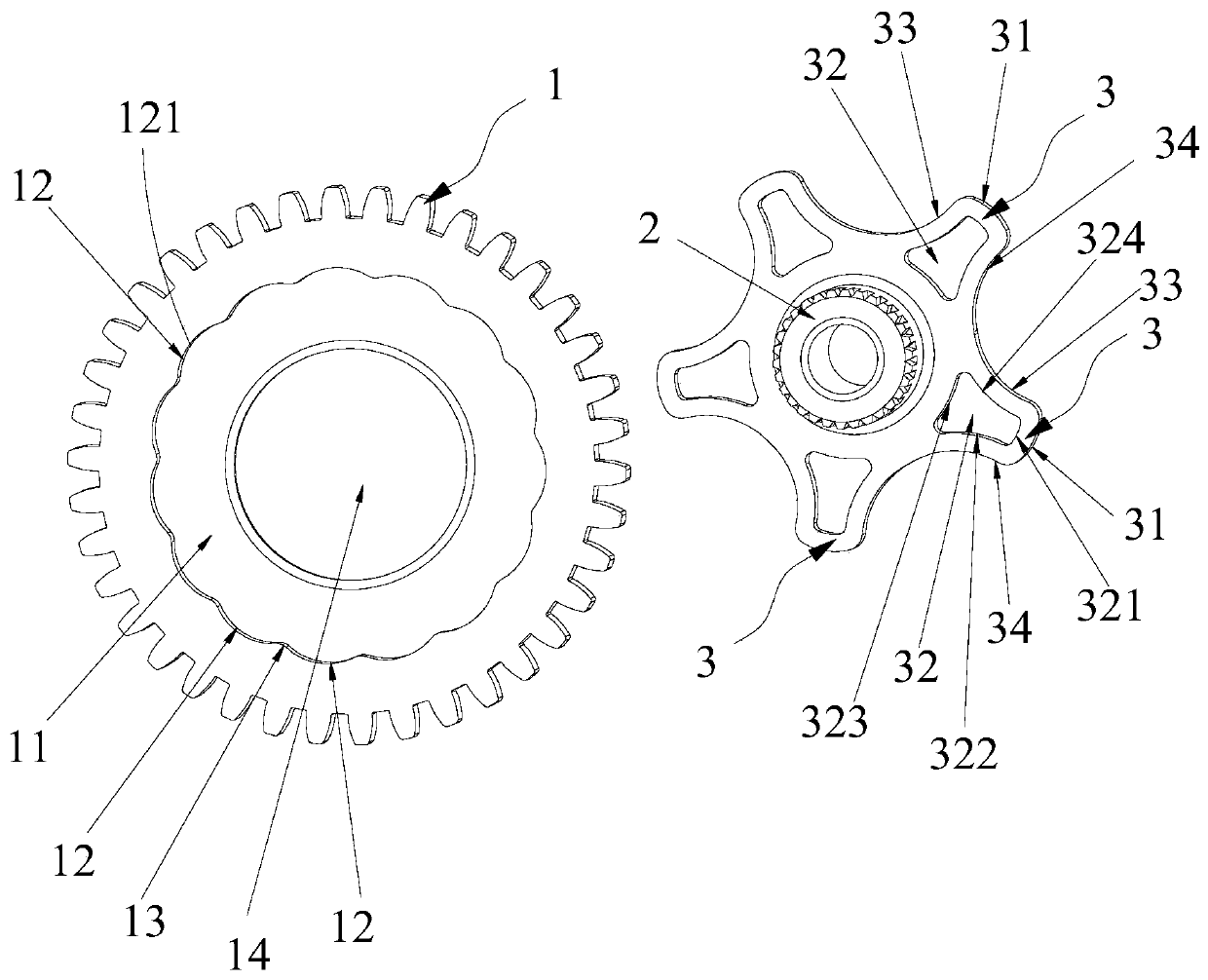

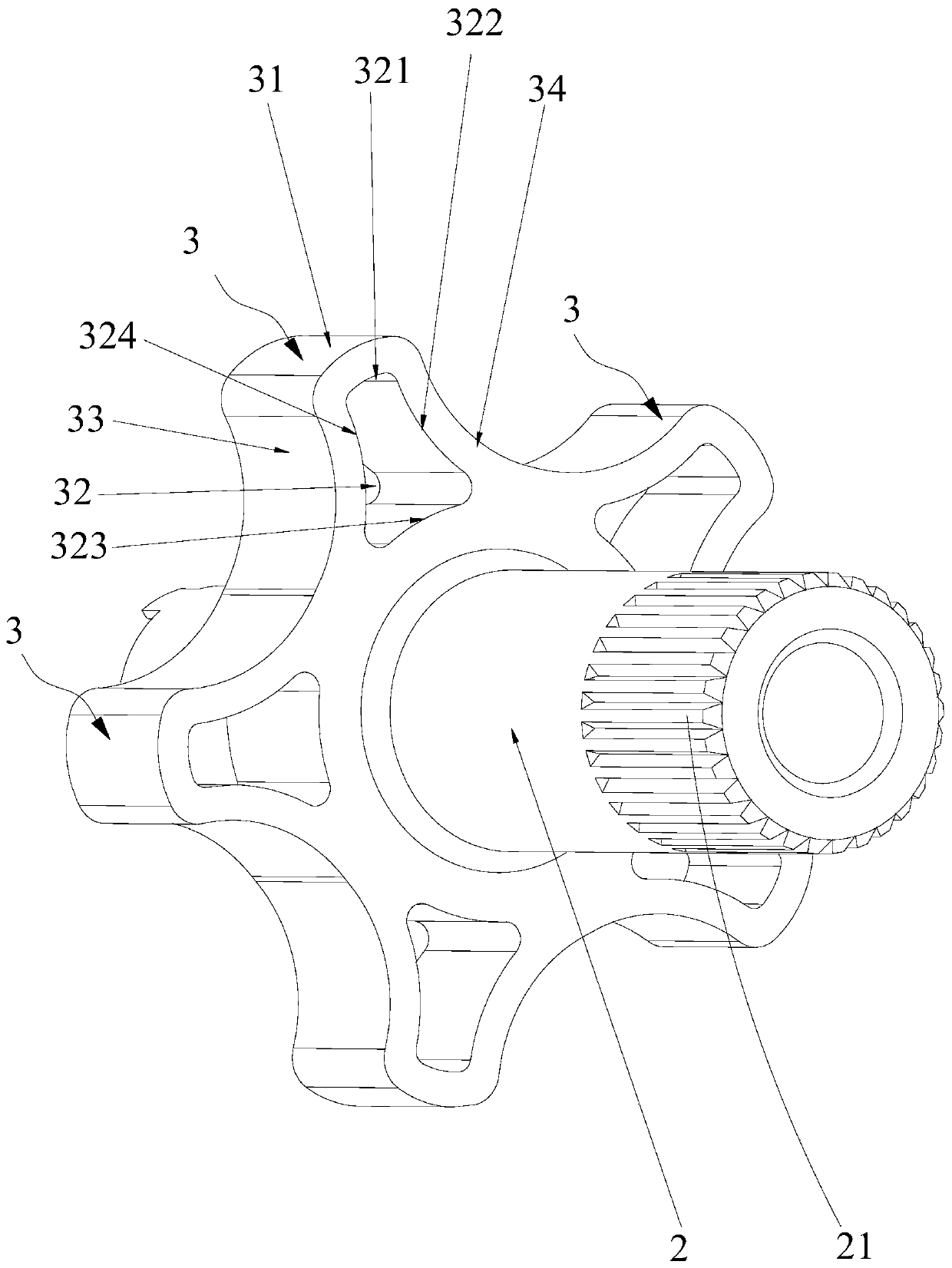

Clutch, steering engine and robot

ActiveCN111015643AIncreased contact areaImprove stabilityProgramme-controlled manipulatorGear wheelEngineering

The invention discloses a clutch. The clutch comprises an output gear, a rotating shaft and at least one clutch tooth arranged on the rotating shaft, wherein the output gear is provided with a containing groove; the inner side wall, positioned in the containing groove, of the output gear is provided with a plurality of inner tooth grooves matched with the clutch teeth; the ends, away from the rotating shaft, of the clutch teeth are provided with first contact arc faces; the inner tooth grooves are provided with second contact arc faces making contact with the first contact arc faces; the clutch teeth are provided with deformation holes; and the first contact arc faces are arranged at the positions where the clutch teeth make contact with the output gear, that is, the tops of the clutch teeth are of a cylindrical structure, compared with an involute type gear, the contact area of the clutch teeth is larger, and vibration in the transmission process can be effectively reduced. Meanwhile,the second contact arc faces are arranged in the inner tooth grooves of the output gear and make contact with the first contact arc faces of the clutch teeth, and therefore when clutch slipping happens, due to the fact that the first contact arc faces and the second contact arc faces are gentle, tooth jumping is easily achieved to achieve safe clutch.

Owner:UBTECH ROBOTICS CORP LTD

Bevel gear machining device for machining

InactiveCN111790952AImprove deburring effectImprove work efficiencyGear-cutting machinesGear teethElectric machineStructural engineering

The invention belongs to the technical field of machining, particularly discloses a bevel gear machining device for machining, and puts forward the following scheme now to solve the problems of poor deburring effect and low efficiency for inner walls of tooth grooves in bevel gears in the prior art. The device comprises a fixing frame; a horizontally-placed positioning piece is rotationally connected at the bottom of one end of the fixing frame; one end of the positioning piece is rotationally connected with a rotating motor; a horizontally-rotating transmission piece is arranged in the position, located above the positioning piece, of the fixing frame; and a driving motor is fixed to the middle of the top of the transmission piece. According to the device, a bevel gear and the transmission piece are rotated synchronously in a stepping manner, a striking piece extends into the corresponding tooth groove and vibrates and strikes the inner wall of the tooth groove along with a vibratingsheet, deburring operation is performed on the tooth groove of the inner wall of the bevel gear, after the transmission piece and the bevel gear are rotated by one circle, the transmission piece is paused, the bevel gear is rotated by the distance of one tooth groove gap, and deburring operation is performed on the tooth grooves in various positions of the bevel gear.

Owner:宣城知明灯机械设计有限公司

Crawler follower mechanism for thin steel material quenching and leveling process

InactiveCN104120243AIncrease stiffnessIncreased contact areaFurnace typesHeat treatment furnacesRolling-element bearingFuel tank

The invention discloses a crawler follower mechanism for a thin steel material quenching and leveling process. The crawler follower mechanism comprises chain-plate crawler units, an oil tank assembly and a motor transmission system, wherein the chain-plate crawler units are arranged surrounding tank bodies, each chain-plate crawler unit comprises chain wheels, a chain wheel shaft and a closed-ring crawler which is formed through connecting a plurality of chain-plate assemblies in series, and thus, the closed-ring crawlers cyclically revolve around the face of an oil tank under the drive of the chain wheels; each chain-plate assembly comprises a chain plate, chain plate pin shafts, rollers, embedded shafts and rolling bearings; the motor transmission system is connected with the chain wheel shafts and is used for transferring motor power, so that the closed-ring crawlers are driven to cyclically revolve, and meanwhile, relative-sliding-free follow-up with a quenched thin material is realized. Through the crawler follower mechanism, the phenomena that folds appear after the thin material is quenched, the thin material is stuck due to the fact that the rolling bearings are burnt out due to too high temperature of the thin material, and the like can be effectively avoided; meanwhile, the surface quality of the quenched thin material is remarkably improved, and the leveling efficiency of the quenched thin material is remarkably increased.

Owner:WUHAN UNIV OF SCI & TECH

Anticorrosive inner coating film for inner layer of steel drum

InactiveCN113943517AAct as a physical shieldReduce corrosion rateAnti-corrosive paintsEpoxy resin coatingsActive agentFirming agent

The invention belongs to the technical field of anticorrosive coatings, and relates to an anticorrosive inner coating film for an inner layer of a steel drum. The anticorrosive inner coating film mainly comprises the following components in percentage by weight: 60-70% of modified epoxy resin emulsion; 1-5% of a coalescing agent; 3-15% of anticorrosive pigment and filler; 2-8% of a surfactant; 4-10% of a coupling agent; 10-15% of a curing agent; 0.1-2% of a defoaming agent; 0.1-2% of a leveling agent; 0.1%-0.6% of a corrosion inhibitor; and 10-50% of water. The modified epoxy resin emulsion is adopted, so that a formed coating plays a role in physically shielding various corrosive media; the corrosion inhibitor is added, so that the corrosion rate of steel is greatly reduced; and a pigment and filler are modified to form the anticorrosive pigment and filler, the dispersity of the pigment and filler in epoxy resin is improved, and a phase interface between the pigment and filler and the resin is eliminated, so that the shielding property and the corrosion resistance of a colored paint film are improved on the premise of ensuring high hardness and high adhesive force of the paint.

Owner:荆州市先隆包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com