Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Improve pretreatment efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for coarse grain rice noodles

ActiveCN103271292AConserve waterReduce manufacturing costFood preparationEnergy consumptionWater content

The invention discloses a preparation method for coarse grain rice noodles. The preparation method comprises the following steps of (1) mixing raw materials of rice and coarse grains according 55-75% by weight of the rice and 25-45% by weight of the coarse grains; (2) adding water to adjust water content in powder so as to make the powder accounts for 35-45% of a total weight of rice pulp, adding a quality improver with an amount of 0.3% of the total weight of the rice pulp, stirring and mixing uniformly to form powder base, performing early steam by passing through steam to make the gelatinization degree of the powder base reach 70-80%; (3) putting the powder base into a rice machine to extrude noodles, re-steaming for 8-12 minutes, cutting the re-steamed rice noodles into sections; and (4) sending the cut rice noodles into a drying oven, drying the rice noodles, controlling the water content within 11-13 wt%, and cooling the dried rice noodles to obtain the coarse grain rice noodles. The preparation method can increase preparation efficiency of the rice noodles and at the same time, reduces water consumption and energy consumption in the preparation process.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

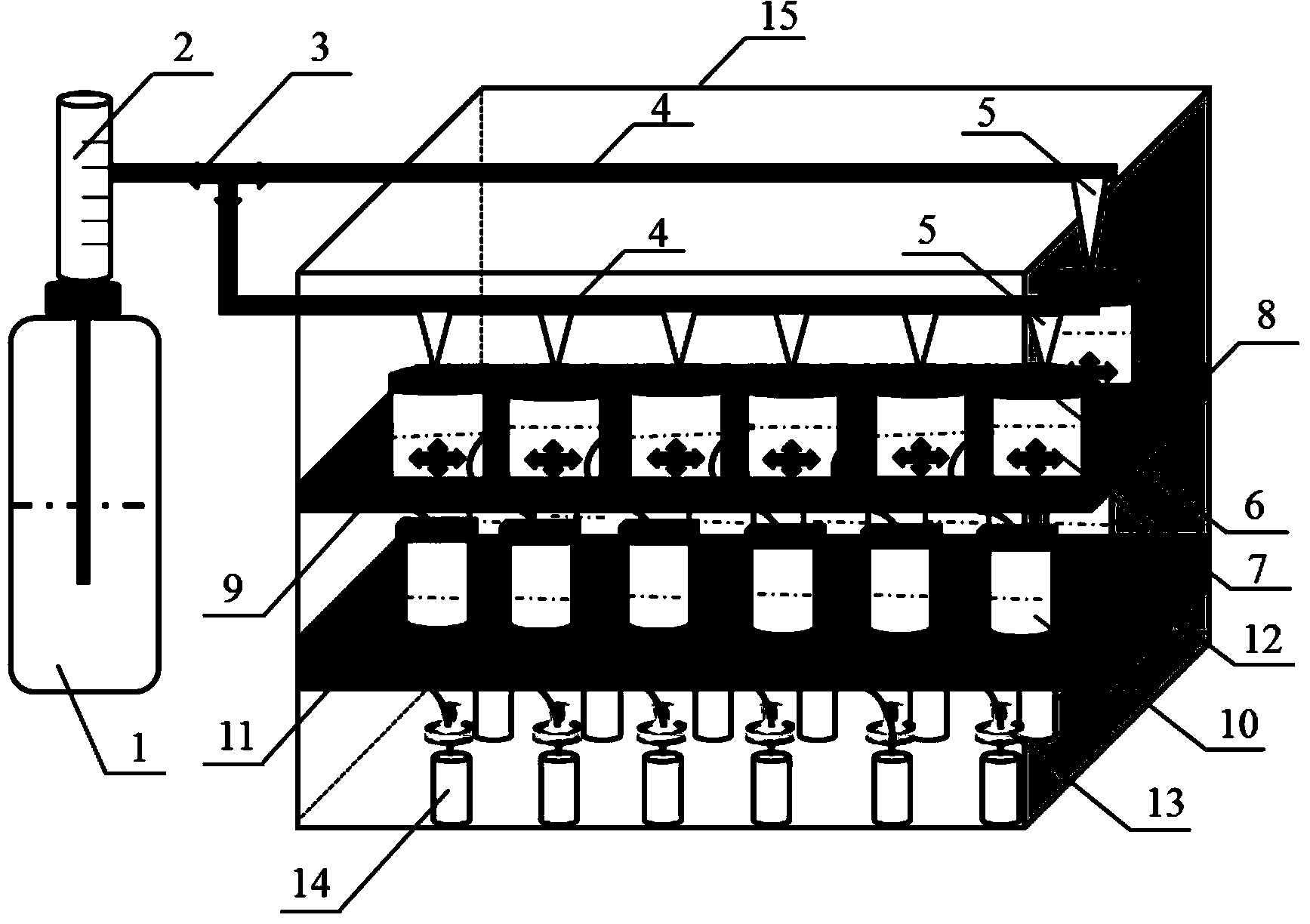

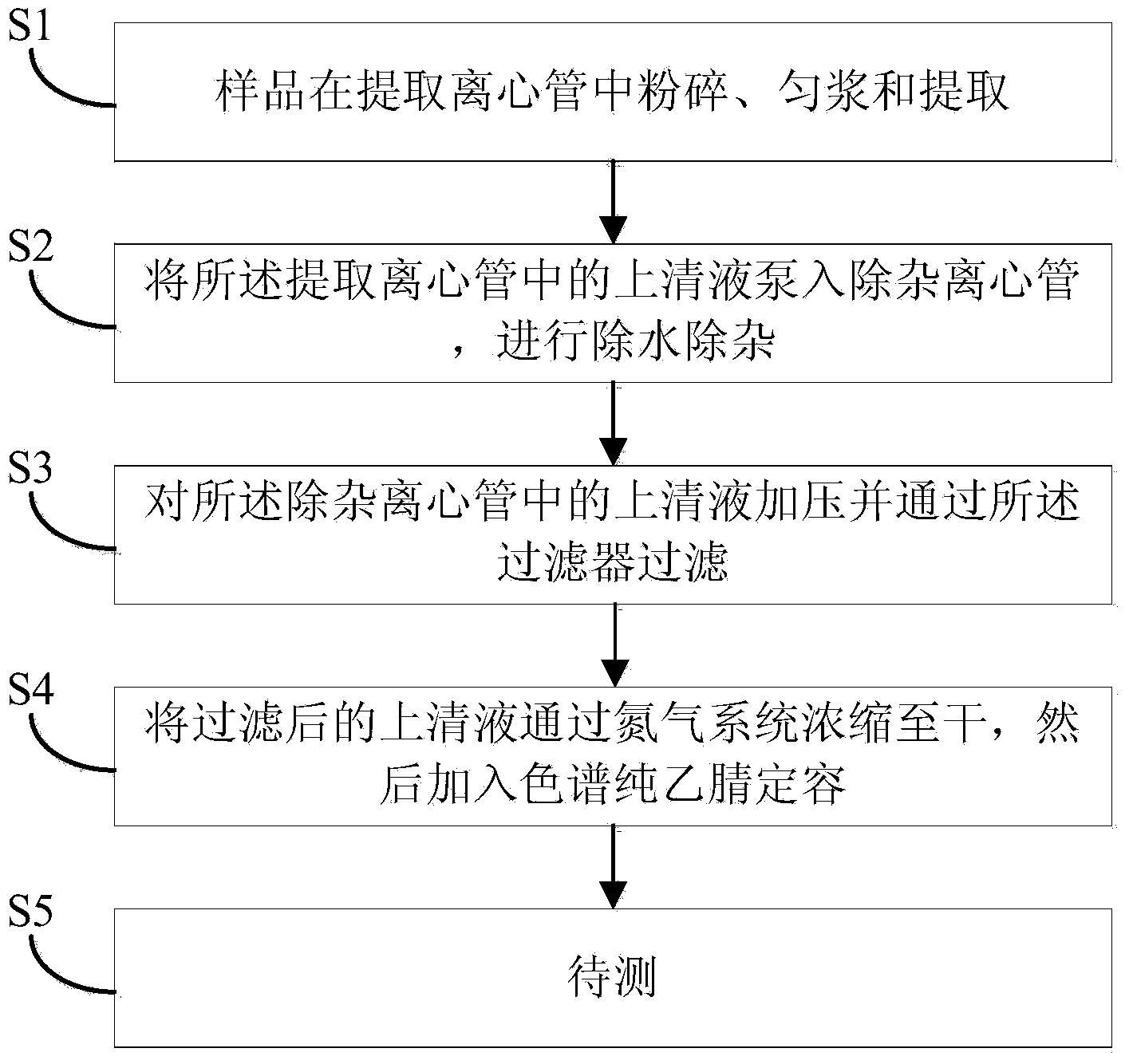

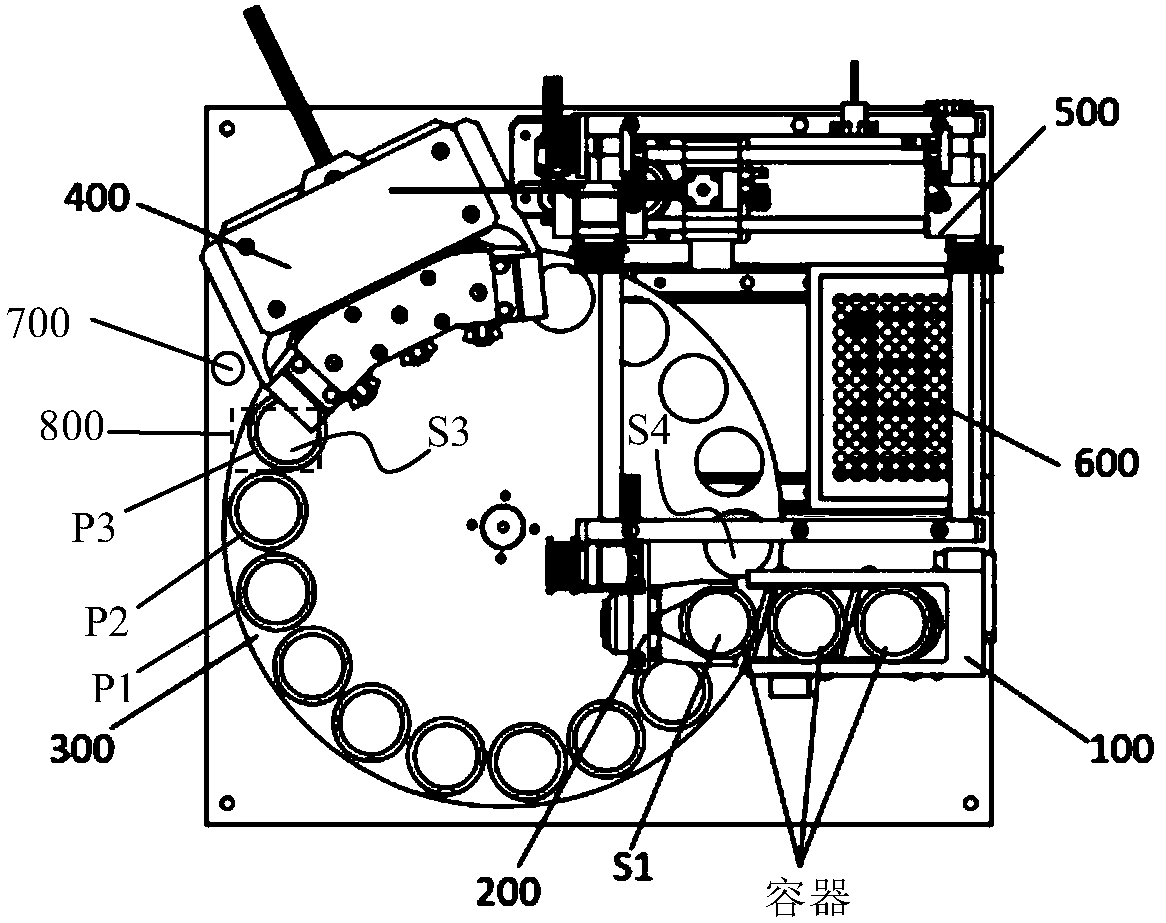

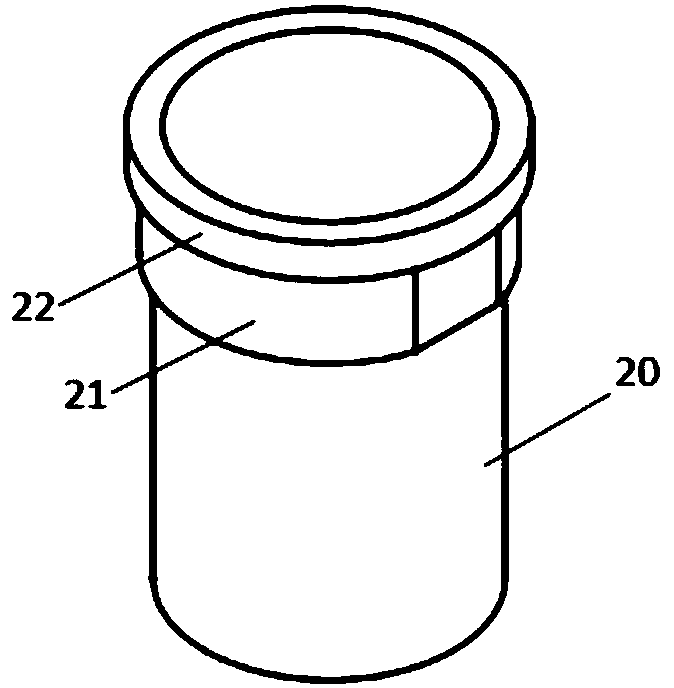

Full-automatic QuEChERS preprocessing all-in-one machine and preprocessing method

ActiveCN103822999AFree from contagiousFree from toxicityComponent separationPulp and paper industrySolid phase extraction

The invention relates to a full-automatic QuEChERS preprocessing all-in-one machine and a preprocessing method. The preprocessing all-in-one machine comprises a reagent container, wherein the reagent container is connected with a container distributor; the container distributor extends out to form liquid discharge pipes; the liquid discharge pipes are connected with a plurality of extracting centrifugal pipes; each extracting centrifugal pipe is connected with an impurity-removing centrifugal pipe through a first guide pipe; the preprocessing all-in-one machine further comprises pulverizers and an inner sucking pump; the pulverizers pulverize samples in the extracting centrifugal pipes; the inner sucking pump pumps a supernatant liquor in the centrifugal pipes into the impurity-removing centrifugal pipes; the impurity removing centrifugal pipes are connected with filters through second guide pipes; the supernatant liquor in the impurity removing centrifugal pipes is pressurized by a pressure pump and enters sample introduction containers through the filters. The preprocessing all-in-one machine combines the process of sample pulverization, liquid adding, extraction, centrifugal separation and solid phase extraction into one, saves time, simplifies operation and steps, reduces errors, and is efficient and high in safety.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

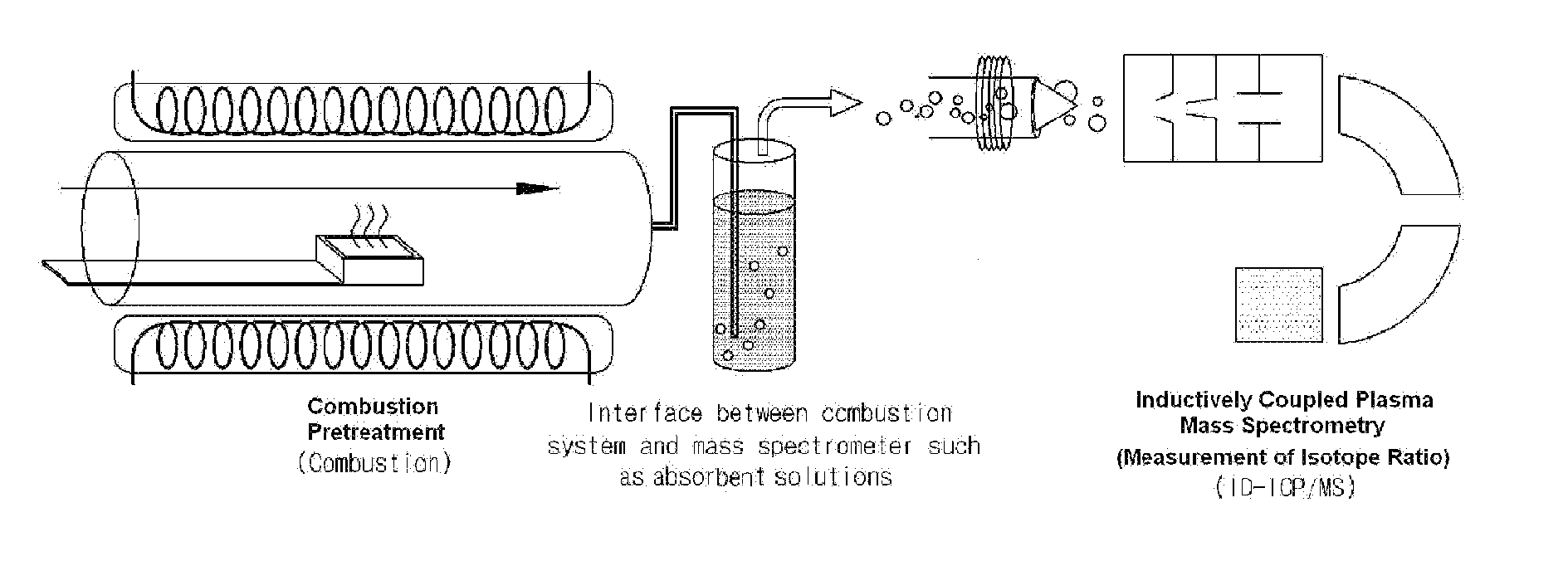

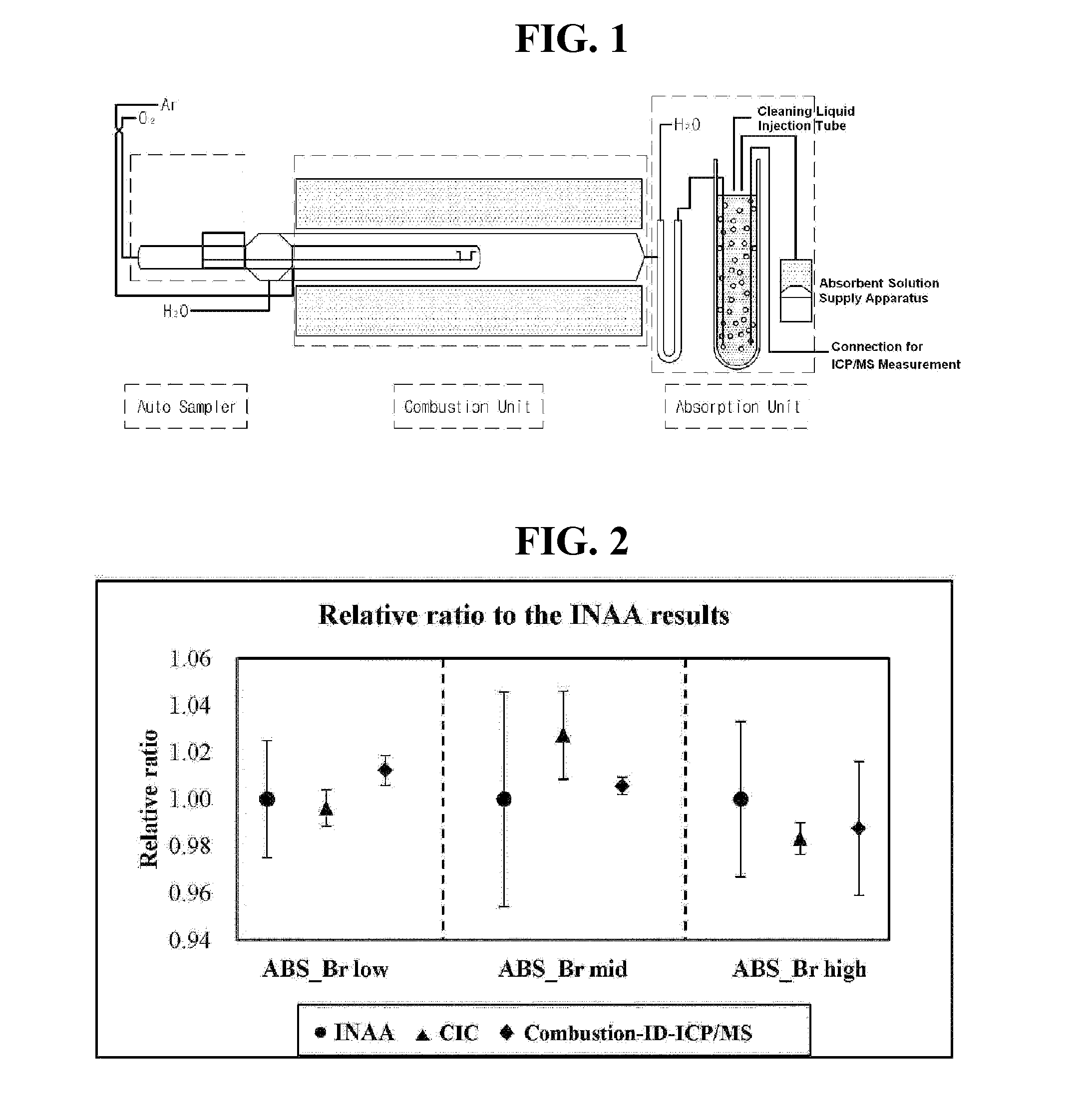

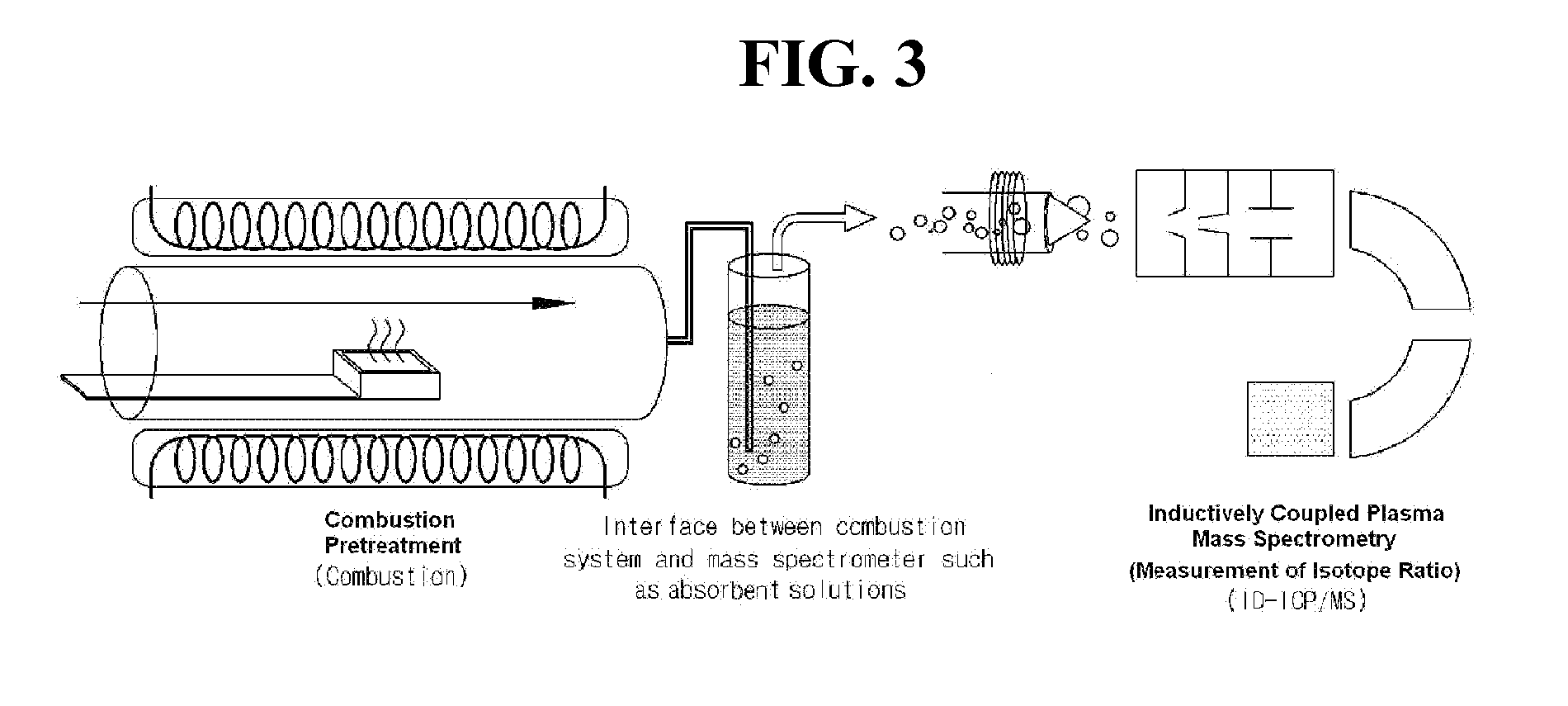

Combustion pretreatment-isotope dilution mass spectrometry

ActiveUS20150348768A1Reduce uncertaintyImprove analytical performanceSamples introduction/extractionMaterial analysis by electric/magnetic meansElement analysisPhysical chemistry

Provided is a combustion pretreatment-isotope dilution mass spectrometry measuring concentration of a target element for detection contained in a target sample for detection by using an isotope dilution mass spectrometry, including: pretreating the target sample for detection by combustion during an isotope dilution mass spectrometry, to thereby stabilize an isotope and further improve analysis ability, and therefore, the present invention is expected to be utilized as an element analysis method surpassing accuracy of the existing mass spectrometry method.

Owner:KOREA RES INST OF STANDARDS & SCI

Measurement method of cation exchange capacity in soil

ActiveCN104330522AIncrease concentrationOptimizationMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationCation-exchange capacityAlcohol

The invention discloses a measurement method of cation exchange capacity in soil. The method comprises the five steps of preparing a soil sample, carrying out exchange elution with an EDTA-ammonium acetate mixed solution and 95% alcohol, distilling by a full-automatic distiller, measuring by an instrument, and calculating. According to the method, optimization and improvement are carried out on soil sample extraction and leaching conditions, the full-automatic FOSSKjeltec8400 distiller is selected, relevant test conditions are optimized and screened, and concentration and volume conditions of absorption liquid are improved and optimized, so that the cation exchange capacity in the soil can be accurately measured. The method has the advantages of being simple and convenient as well as rapid and accurate in operation and good in repeatability.

Owner:SICHUAN BRANCH OF CHINA TOBACCO

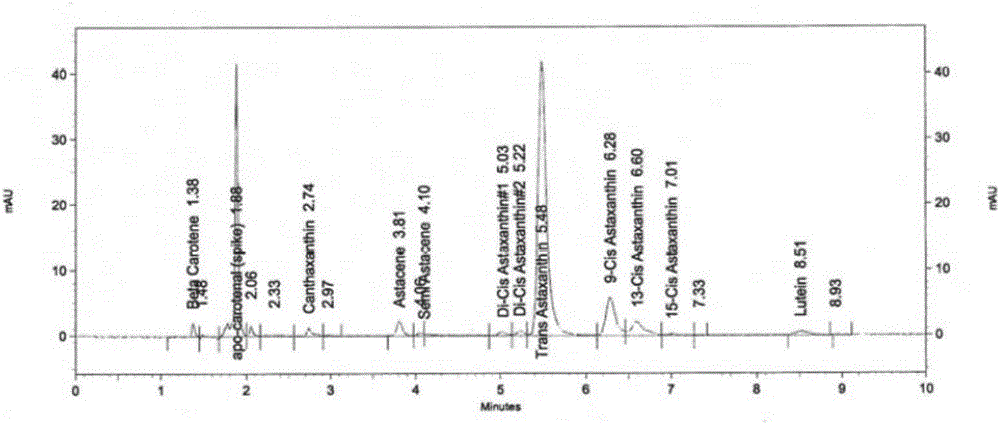

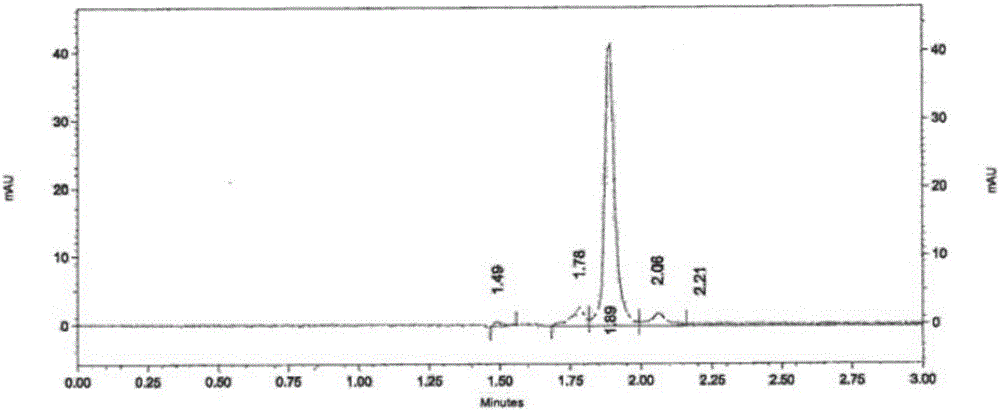

Separation and detection method for astaxanthin in haematococcus pluvialis extract

InactiveCN106501395AGood miscibilityImprove pretreatment efficiencyComponent separationHaematococcus pluvialis extractAstaxanthin

The invention relates to a separation and detection method for astaxanthin in a haematococcus pluvialis extract. The separation and detection method comprises the following steps of 1 extraction of carotenoid in the haematococcus pluvialis extract; 2 enzymolysis of the carotenoid; 3 astaxanthin separation and detection through a normal-phase high performance liquid analysis method, wherein the liquid-phase on-device conditions comprise the detection wavelength is 474 nm, a chromatographic column is Luna 3micro Silica(2), the chromatographic column temperature ranges from 20 DEG C to 25 DEG C, the flow speed is 1-1.2 ml / min, a flow phase is prepared from n-hexane and acetone according to the volume ratio of 75%:25%-90%:10%, and isocratic elution is conducted. According to the separation and detection method, the pretreatment efficiency is high, the intersolubility between the extracting reagent acetone and the astaxanthin is good, the enzymolysis time is shorter than the saponification time, and the efficiency is high; the high performance liquid chromatography on-device conditions are good; isocratic elution is achieved, a base line is easier to stabilize, the peak shape is good, the separation degree is high, and more isomers can be separated out; the peak flowing time is short, and the method is not prone to be influenced by outside light and heat and more suitable for large-scale detection.

Owner:QINGDAO SAMUELS INDAL & COMML

Zinc-nickel alloy electroplating process

The invention discloses a zinc-nickel alloy electroplating process. The zinc-nickel alloy electroplating process comprises the following steps: performing oil and rust removal, carrying out ultrasonic cleaning, electroplating, conducting hydrogen removal, performing hydrophobic treatment, washing with water and blow-drying. According to the process, the steps of oil removal and rust removal are integrated, so that the procedures are simplified, the cost is reduced, and the efficiency is improved; the step of ultrasonic cleaning is added, so that the whole pretreatment efficiency is high, and environmental protection and zero contamination are realized; in the electroplating process, the pH value of an electroplating solution is about 5, namely, weak acidity, electric current density of 50 mA / cm<2> is adopted, and silicon carbide particles with the particle diameters of 1-10 microns are added into the electroplating solution, so that the wearing resistance of a cladding subjected to electroplating is greatly enhanced, and the reduction is smaller than 0.02 micron under the condition that the friction speed is 15000 r / min.

Owner:太仓市金鹿电镀有限公司

Nickel-magnesium alloy electroplating technique

The invention discloses a nickel-magnesium alloy electroplating technique which comprises the following steps: deoiling and derusting, ultrasonic cleaning, electroplating, dehydrogenation, water repelling treatment, alcohol washing, water washing and blow-drying. The technique integrates the deoiling and derusting steps, thereby saving the procedure, lowering the cost and enhancing the efficiency. The ultrasonic cleaning step is added, so that the overall pretreatment is efficient, environment-friendly and pollution-free. In the electroplating process, the pH value of the electroplating solution is 5 or so which is weakly acidic, and the current density is 50 mA / cm<2>. The silicon carbide particles with the particle size of 1-10 mu m are added into the electroplating solution, so that the wear resistance of the final electroplating coating is greatly enhanced, and the reduction quantity is less than 0.02 mu m when the friction rotation speed is 15000 r / min.

Owner:太仓市金鹿电镀有限公司

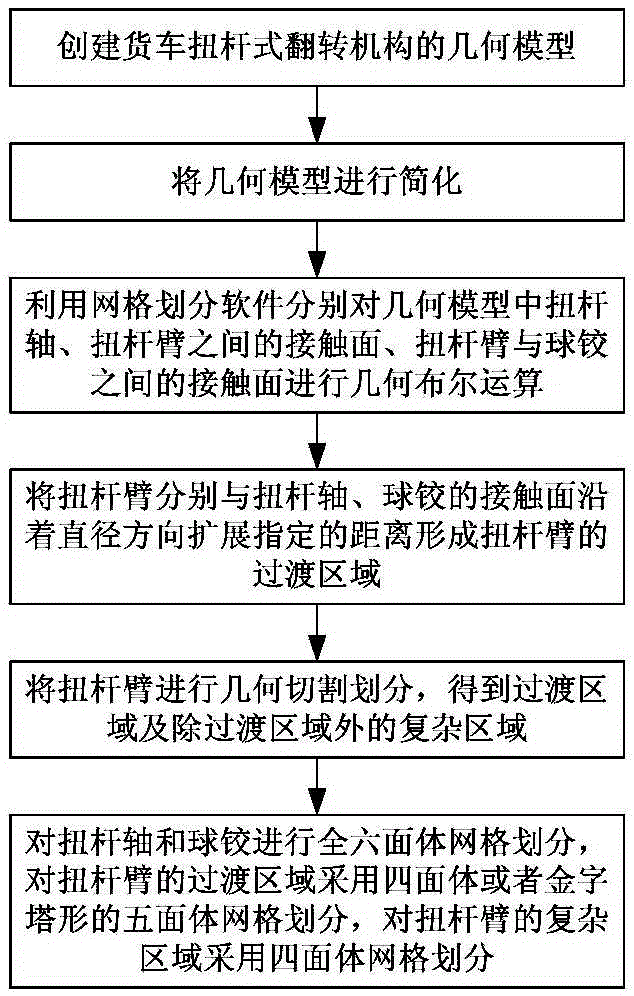

Hybrid grid partitioning method of truck torsion bar type turnover mechanism finite element model

InactiveCN106649903AQuick divisionDoes not affect calculation accuracySpecial data processing applicationsElement modelEngineering

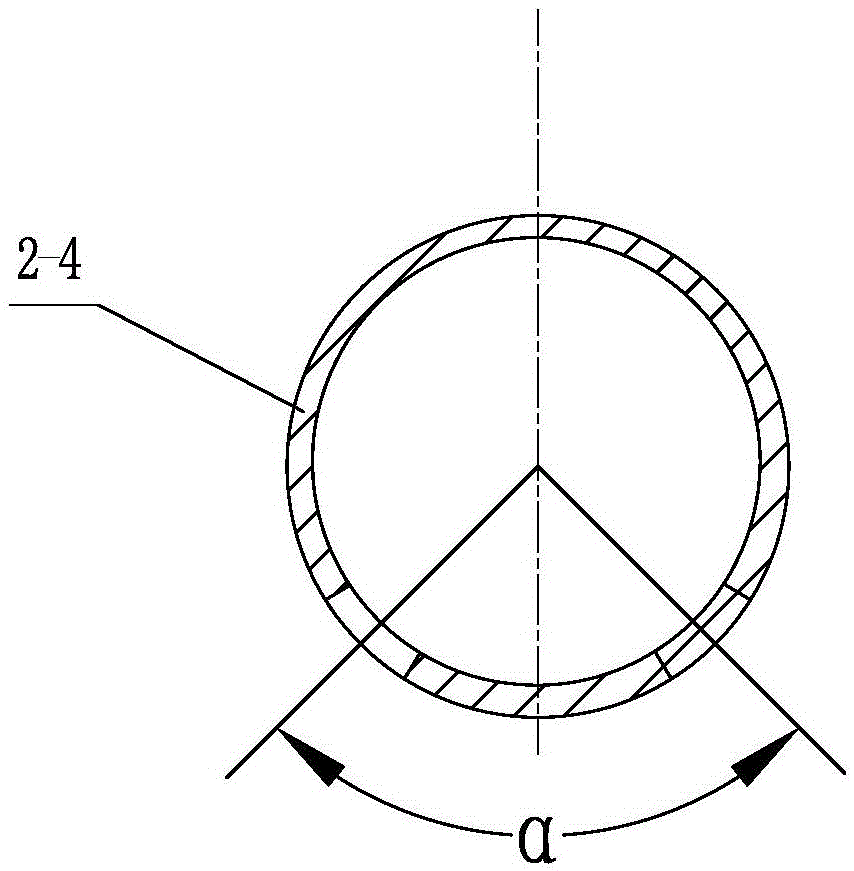

The invention discloses a hybrid grid partitioning method of a truck torsion bar type turnover mechanism finite element model. The method comprises the steps that a geometric model of a truck torsion bar type turnover mechanism is constructed; grid partitioning software is utilized for carrying out geometric Boolean operation on the contact face between a torsion bar arm, a torsion bar shaft and a spherical hinge in the geometric model, so that the contact face between the torsion bar arm, the torsion bar shaft and the spherical hinge achieves node merging; the contact face of the torsion bar arm is expanded to form a transition area, and geometric cutting partitioning is carried out to obtain a transition area and a complex area; the torsion bar shaft and the spherical hinge are subjected to full hexahedron grid partitioning, pentahedron grid portioning is adopted for the transition area of the torsion bar arm, tetrahedral grid portioning is adopted for the complex area of the torsion bar arm, and hybrid grid portioning of the torsion bar type turnover mechanism is completed. The truck torsion bar type turnover mechanism can be subjected to fast finite element grid portioning, calculation precision is not influenced, meanwhile, pretreatment efficiency can be improved, the product development quality can be improved, time can be saved, and the human cost can be reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Copper-manganese alloy electroplating technique

The invention discloses a copper-manganese alloy electroplating technique which comprises the following steps: deoiling and derusting, ultrasonic cleaning, electroplating, dehydrogenation, water repelling treatment, alcohol washing, water washing and blow-drying. The technique integrates the deoiling and derusting steps, thereby saving the procedure, lowering the cost and enhancing the efficiency; and the weakly alkaline conditions can produce less pollution to the environment. The ultrasonic cleaning step is added, so that the overall pretreatment is efficient, environment-friendly and pollution-free. In the electroplating process, an acidic system is adopted, and thus, can produce less pollution to the environment. By adding ascorbic acid, hydroquinone and other additives, the electroplating is performed under the conditions of proper current density and electroplating temperature, so the copper / manganese codeposition effect is good, and the finally obtained copper-manganese alloy electroplating coating has the advantages of uniform color, fine crystals, high film thickness (up to 10 mu m) and favorable wear resistance. After being rubbed 100 times by W40 sand paper in a single direction, the coating can not peel. The alloy coating has favorable electric conductivity, and can effectively prevent chromium in the stainless steel from outward transfer and dispersion.

Owner:太仓市金鹿电镀有限公司

Vomitoxin and derivative aptamer affinity column and preparation method and application thereof

ActiveCN109833648ASimple and fast operationLow priceOther chemical processesPreparing sample for investigationDeoxynivalenol-3-glucosideN-Hydroxysuccinimide

The invention provides vomitoxin and a derivative aptamer affinity column and a preparation method and application thereof. The affinity column is prepared by the following steps: using N-hydroxysuccinimide modified agarose as a carrier, then carrying out covalent coupling on the carrier and a nucleic acid aptamer capable of high-affinity and high-specificity recognition of deoxynivalenol, deoxynivalenol-3-glucoside, 3-acetyl deoxynivalenol and 15-acetyl deoxynivalenol in a sample, and finally filling an affinity column with the coupled aptamer composite carrier. The affinity column is mainlyused for purification and decontamination of vomitoxin and its derivative in food, feeds, milk, food crops, traditional Chinese medicines and other various samples, which is beneficial to high performance liquid chromatography and rapid detection of toxins in the sample in later period. By one-time loading of the column, four types of toxins can be purified and enriched, the number of reuse can reach 15 times, recovery rate is 80% and above, the cost is reduced, and the sample pre-treatment efficiency of the sample is enhanced.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Nickel-cobalt alloy electroplating technique

The invention discloses a nickel-cobalt alloy electroplating technique which comprises the following steps: deoiling and derusting, ultrasonic cleaning, electroplating, dehydrogenation, water repelling treatment, water washing and blow-drying. The technique integrates the deoiling and derusting steps, thereby saving the procedure, lowering the cost and enhancing the efficiency. The ultrasonic cleaning step is added, so that the overall pretreatment is efficient, environment-friendly and pollution-free. In the electroplating process, the pH value of the electroplating solution is 3 or so which is weakly acidic, and the current density is 110 A / dm<2>, so the wear resistance of the electroplating coating is greatly enhanced in the specific electroplating solution; under the condition that the friction rotation speed is 15000 r / min, the reduction quantity is less than 0.02 mu m, and the coating hardness is increased; and when the pulse period is 24ms, the maximum coating hardness is 609HV which is 1.5 times of the conventional nickel-cobalt coating, the surface is smooth, and the average grain size is 14nm or so.

Owner:太仓市金鹿电镀有限公司

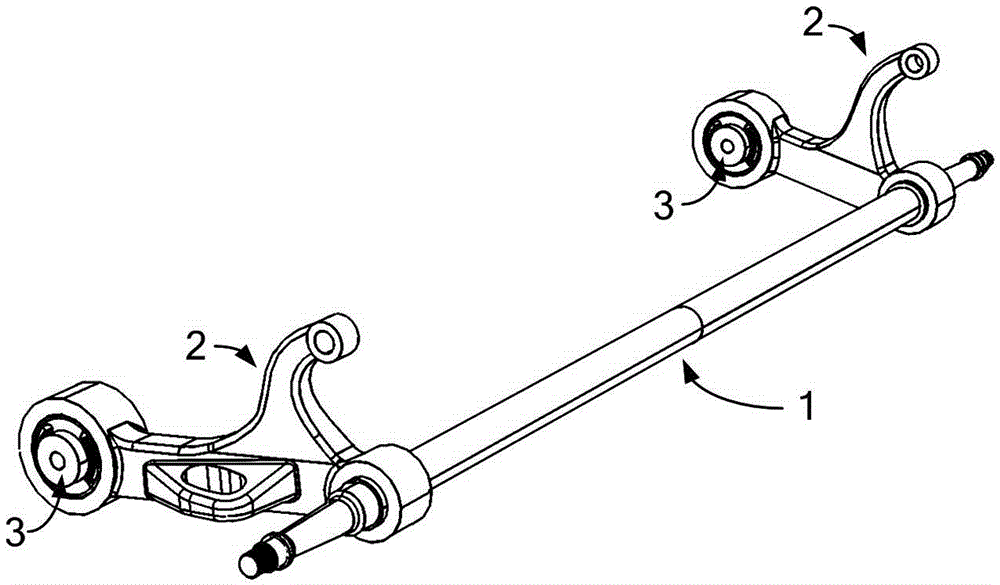

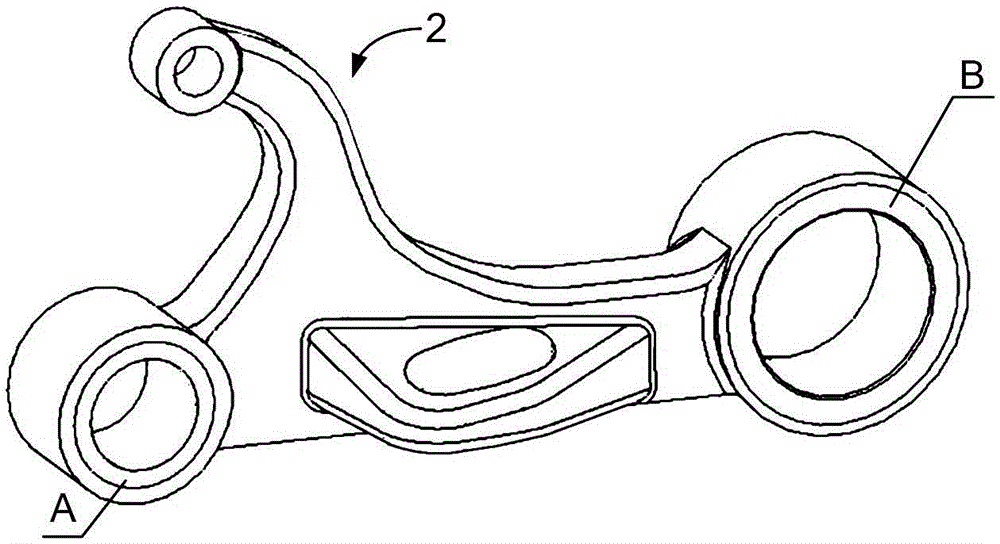

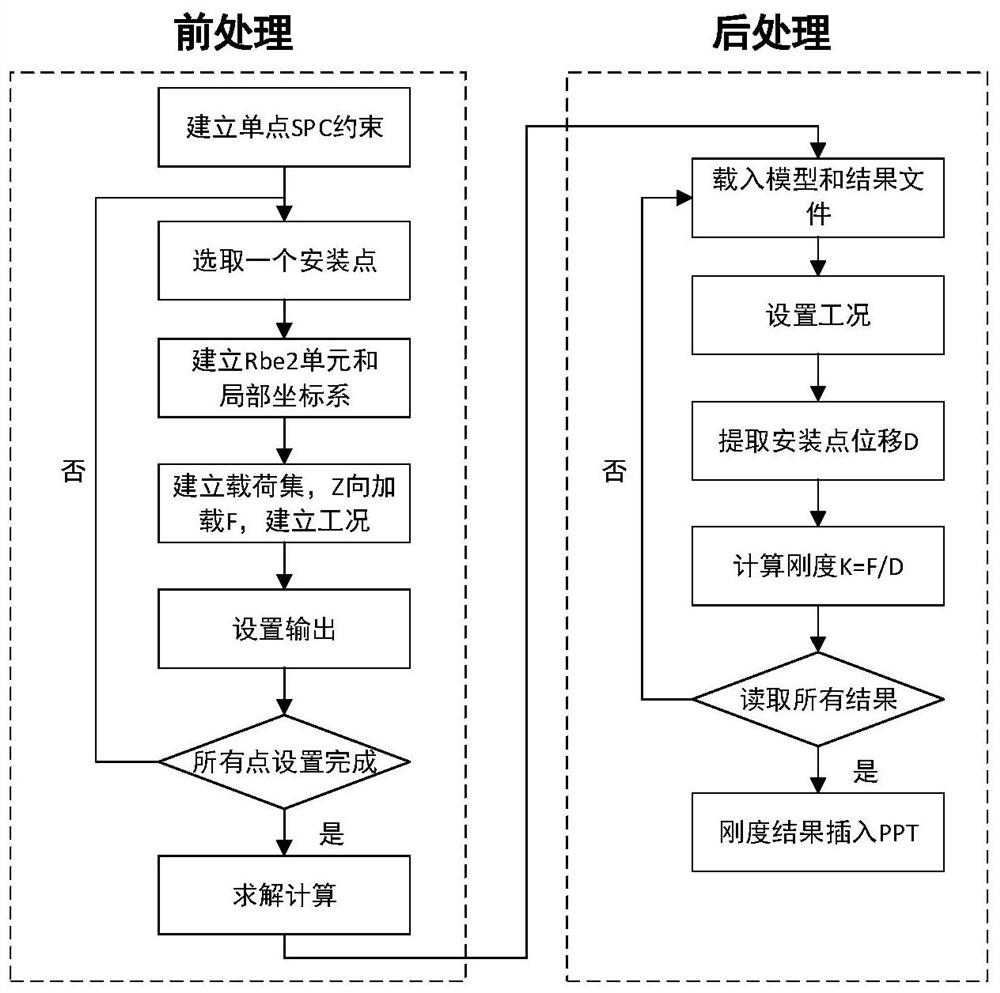

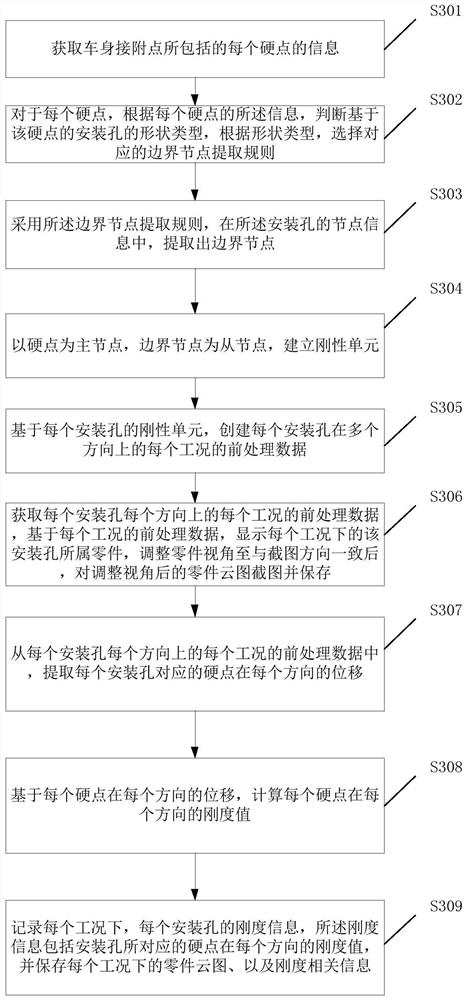

Vehicle body attachment point rigidity result extraction method and electronic equipment

PendingCN111814376AImprove pretreatment efficiencyImprove processing efficiencyGeometric CADDesign optimisation/simulationStructural engineeringInformation searching

The invention discloses a vehicle body attachment point rigidity result extraction method, electronic equipment and a storage medium. The method comprises the steps: searching a boundary node of an installation hole based on each hard point according to the information of each hard point, and constructing a rigid unit related to the installation hole based on the boundary node of the installationhole; creating preprocessing data of each mounting hole under each working condition in multiple directions; acquiring pretreatment data of each working condition in each direction of each mounting hole, displaying a part cloud picture of the part to which the mounting hole belongs under each working condition based on the pretreatment data of each working condition, and performing screenshot on the part cloud picture and storing; and based on the pre-processing data of each working condition in each direction of each mounting hole, rigidity information of each mounting hole under each workingcondition is calculated and stored. According to the method, the workload of engineers is reduced, all attachment points are selected in a framing mode at a time through the pretreatment part, namely, pretreatment and aftertreatment parts of all attachment points are achieved, and automatic adjustment and screenshot of the cloud picture view angle of each part are achieved.

Owner:EVERGRANDE NEW ENERGY AUTOMOTIVE INVESTMENT HLDG GRP CO LTD

Copper electroplating process

The invention discloses a copper electroplating process. The copper electroplating process comprises the steps of deoiling and derusting, ultrasonic cleaning, electroplating, hydrogen removal, hydrophobic treatment, alcohol washing, water washing and blow-drying. As the two procedures of deoiling and derusting are integrated, the procedures are simplified, the cost is lowered, the efficiency is improved, and the weakly basic condition causes less environmental pollution; as the ultrasonic cleaning procedure is added, the integral pretreatment efficiency is high, and the environment-friendly and pollution-free purposes are achieved; in the electroplating process, as a cyanide-free alkali system is adopted, environmental pollution is small; hydroxyethyl acrylate, hydroxypropyl distarch phosphate, EDTA, hydroquinone and other additives are added, electroplating is performed under the conditions of appropriate current density and electroplating temperature, finally, a fully-bright, uniform, compact and no-microcrack copper coating with a relatively good binding force can be obtained, and the coating can be 10 [mu]m in thickness, excellent in wearing resistance and free of scales when rubbing for 100 times on W40 sand paper.

Owner:太仓市金鹿电镀有限公司

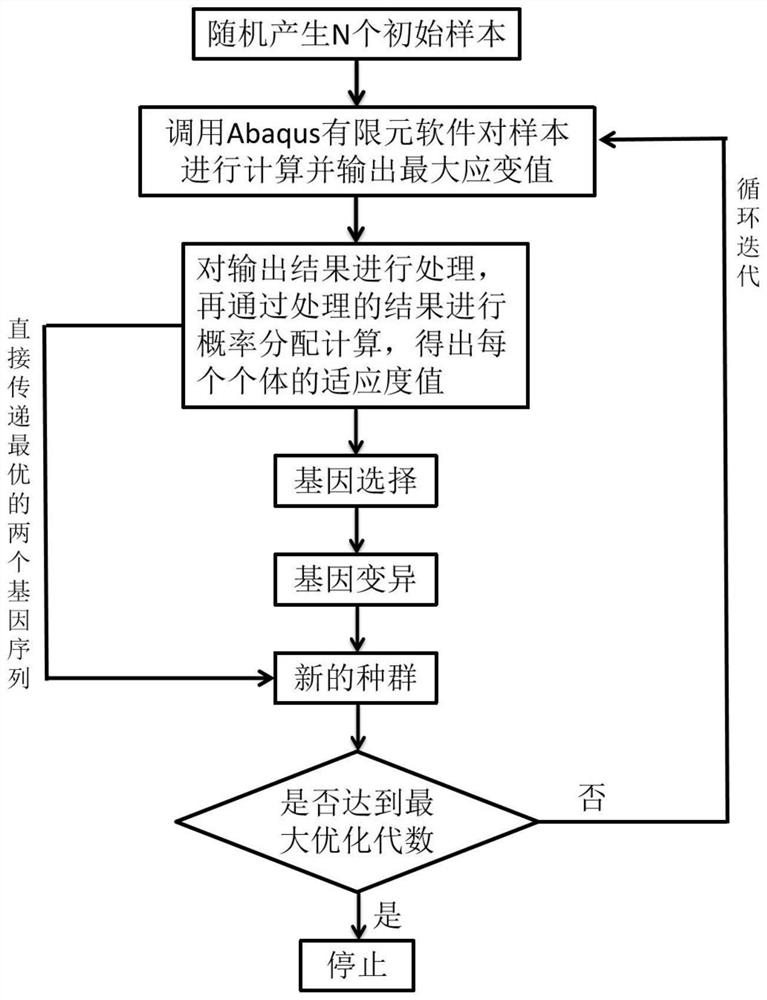

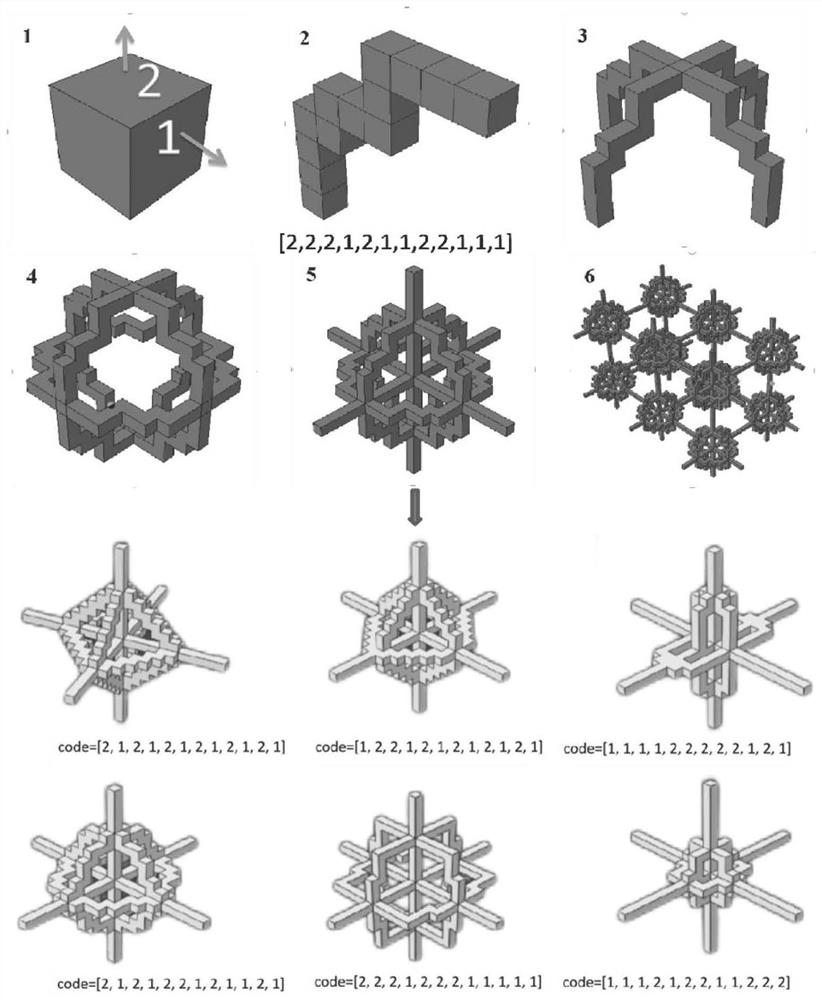

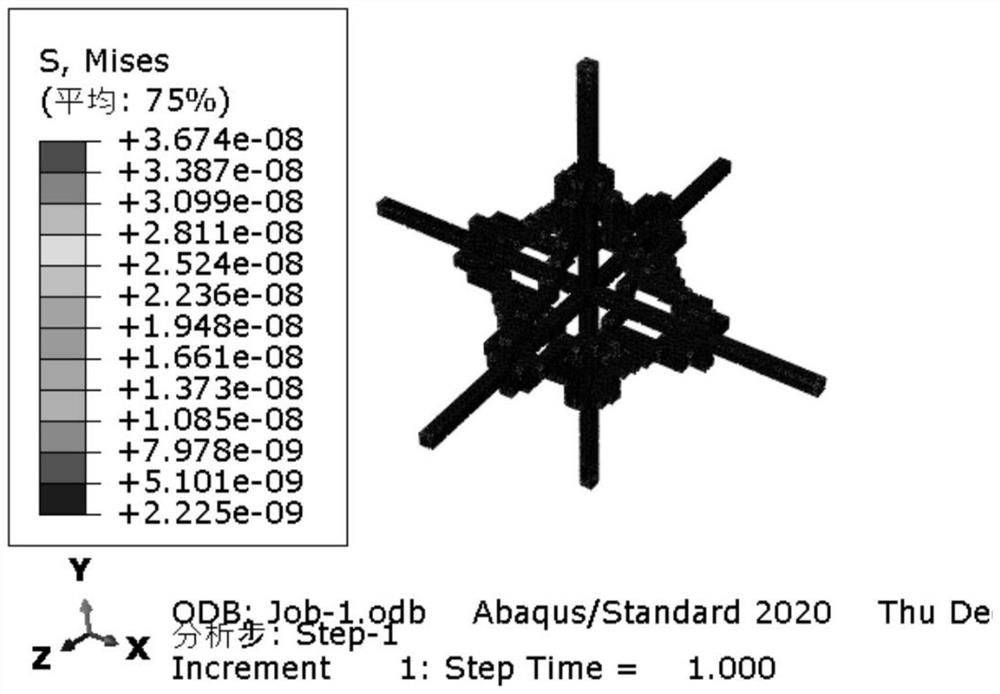

Electrochemical actuator structure optimization analysis method and system based on genetic algorithm

PendingCN114492119AImprove pretreatment efficiencySave materialDesign optimisation/simulationSpecial data processing applicationsGenetics algorithmsMacroscopic scale

The invention discloses an electrochemical actuator structure optimization analysis method and system based on a genetic algorithm, which are suitable for finite element method numerical simulation calculation of an electrochemical actuation reaction process of a material in an electrolyte and achieve the purpose of optimizing the actuation performance of the material in combination with the genetic algorithm. According to the method, on the basis of an intrinsic stress model, a finite element method is combined, automatic random modeling is achieved through a program, the macroscopic strain of the material under different structures is effectively calculated, and under the condition of combining a genetic algorithm, the structure of the material is optimized so as to increase the macroscopic strain of the material, and the actuating performance of the material is effectively improved. According to the method, automatic random modeling can be realized by utilizing a finite element method, various electrochemical actuators with different configurations can be simulated, macroscopic strain of the structure is automatically extracted by applying surface stress, finally, the structure of the material is reversely optimized in combination with a genetic algorithm, required computing resources and computing time are fewer, the efficiency is higher, and the method is suitable for large-scale popularization and application. And the cost is lower.

Owner:SHANGHAI UNIV

Zinc-magnesium alloy electroplating technology

The invention discloses a zinc-magnesium alloy electroplating technology. The technology includes the following steps of oil and dust removing, ultrasonic cleaning, electroplating, hydrogen removing, hydrophobic treatment, washing and drying. According to the technology, the process of removing oil and the process of removing dust are combined into one, so that the processes are omitted, cost is reduced and efficiency is improved. In the electroplating process, additives such as SDMBA-Cl, polyethylene glycol and lauryl sodium sulfate are added in electroplating liquid, so that the deposition effect in the electroplating process is good, the self-corrosion current of an ultimate electroplated layer in a 3.5% sodium chloride solution is lowered, and the corrosion resistance is enhanced. Finally, the zinc-magnesium alloy electroplating technology is good in deposition effect, high in pretreatment efficiency and environmentally friendly.

Owner:太仓市金鹿电镀有限公司

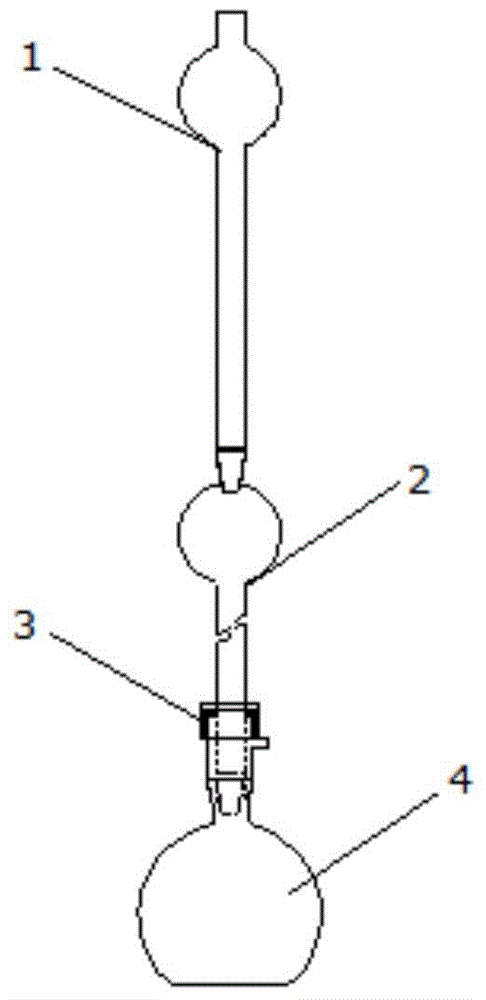

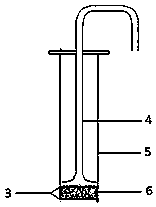

Combined air exhaust-type dioxin pretreatment device

InactiveCN106289925ARapid Purification and SeparationImprove pretreatment efficiencyPreparing sample for investigationEngineering

Owner:BAOSHAN IRON & STEEL CO LTD

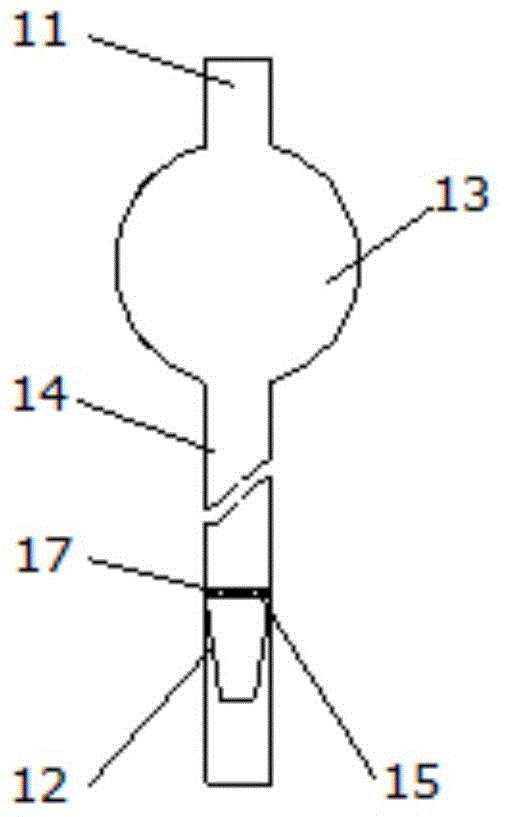

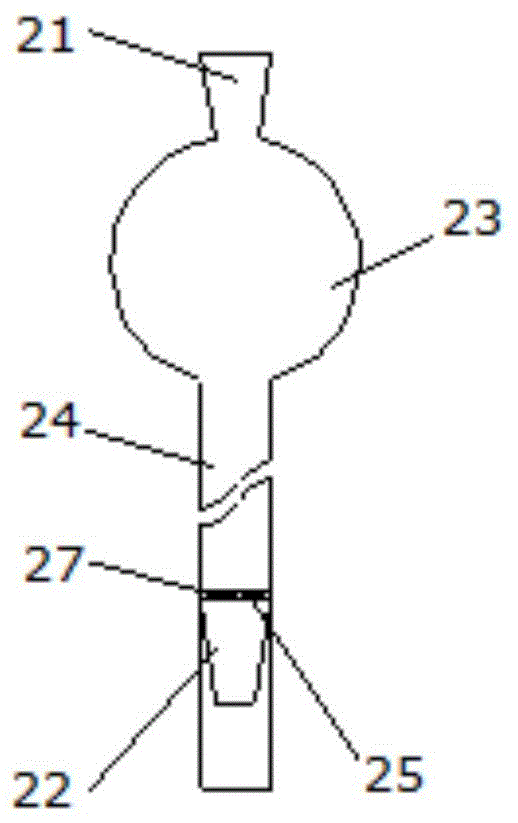

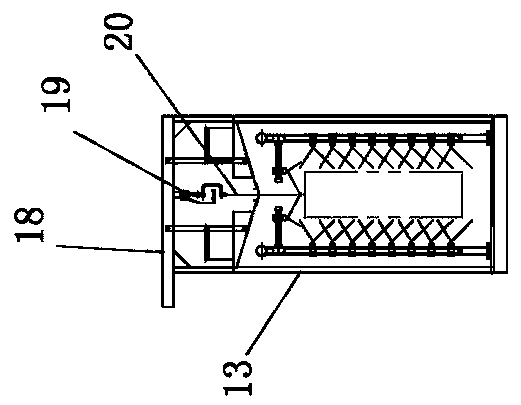

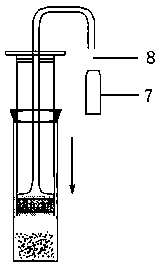

Oscillation device for sample pretreatment, oscillation method and pretreatment device

ActiveCN108627384AImprove pretreatment efficiencyPreparing sample for investigationComputer scienceAutomation

The invention discloses an oscillation device for sample pretreatment. The oscillation device comprises a support, a shaking part and a grabbing assembly, wherein the support is provided with at leastone stand column; the grabbing assembly is separately connected with the support and the shaking part, can move up and down along the support, and grabs single containers containing samples and sample extracts when moving upwards; the shaking part is used for oscillating the grabbed containers. The oscillation device is high in degree of automation, and can realize one-button type treatment of agreat batch of samples so as to greatly improve the pretreatment efficiency.

Owner:广纳达康(广州)生物科技有限公司

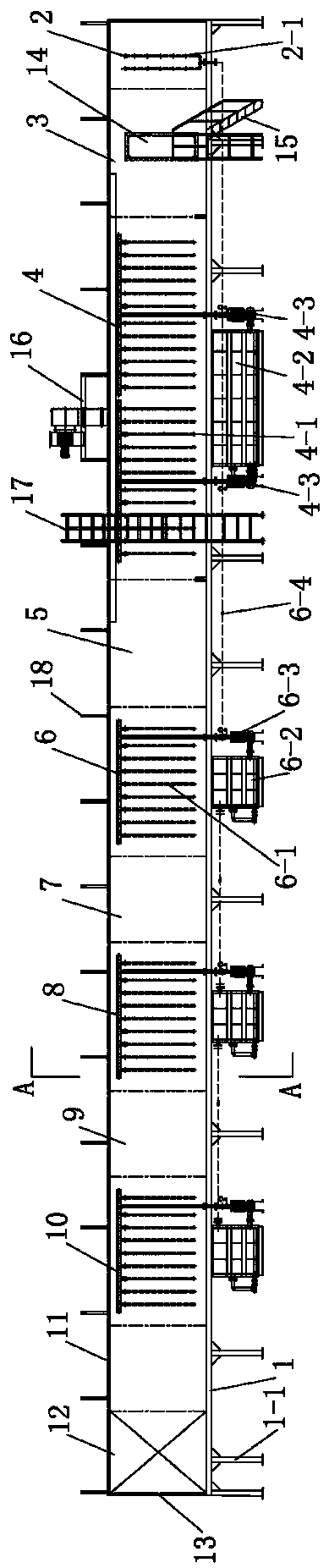

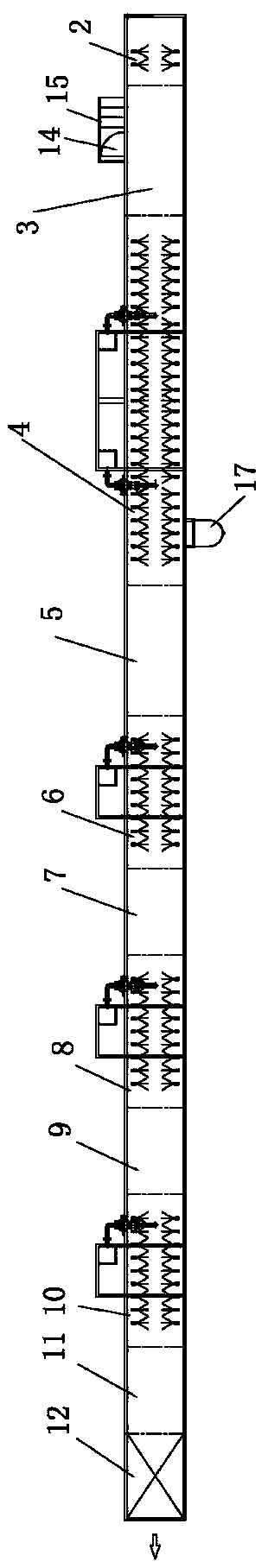

Pretreatment optimization method for paint spraying

PendingCN110538781AImprove efficiencyGuaranteed cleanlinessPretreated surfacesCoatingsProcess engineeringCompressed air

The invention provides a pretreatment optimization method for paint spraying. The method is realized on the basis of integrated pretreatment combined equipment, and specifically comprises the following steps that (1) the front end of the inlet of the pretreatment combined equipment is hung on a hook function part of a suspension chain by a hanger, and then a part is hung on the hanger; and (2) thepretreatment combined equipment is started, a pretreatment combination chain is started, then under drive from the suspension conveying chain of the integrated pretreatment combined equipment, the part sequentially passes through a front spraying type water washing unit, a first dripping section, a spraying type pickling unit, a second dripping section, a rear first spraying type washing unit, athird dripping section, a rear second spraying type water washing unit, a fourth dripping section, a rear third spraying type water washing unit, a fourth dripping section and a compressed air automatic drying unit, and the pretreatment process is completed. The method is realized on the basis of the pretreatment combined equipment, manual wiping is replaced by the arrangement of the dripping sections, so that the pretreatment efficiency is improved, and through three-time water washing after pickling, surface cleanliness of the part is guaranteed.

Owner:湖北世亮汽车零部件有限公司

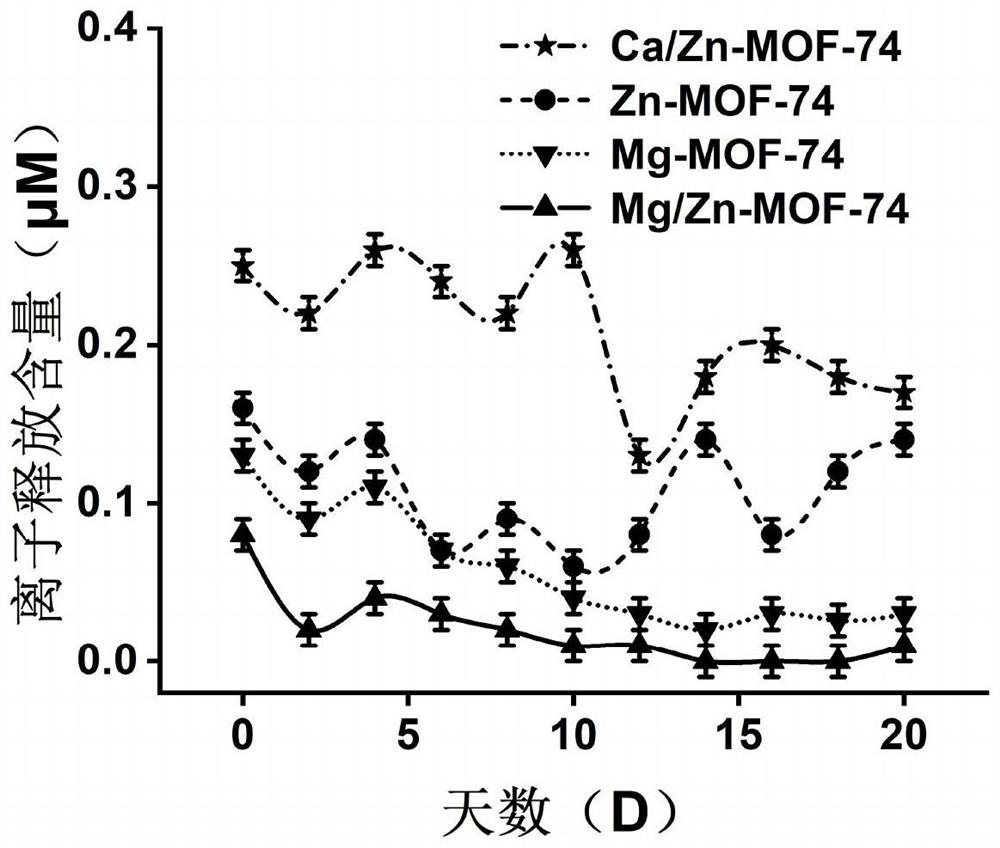

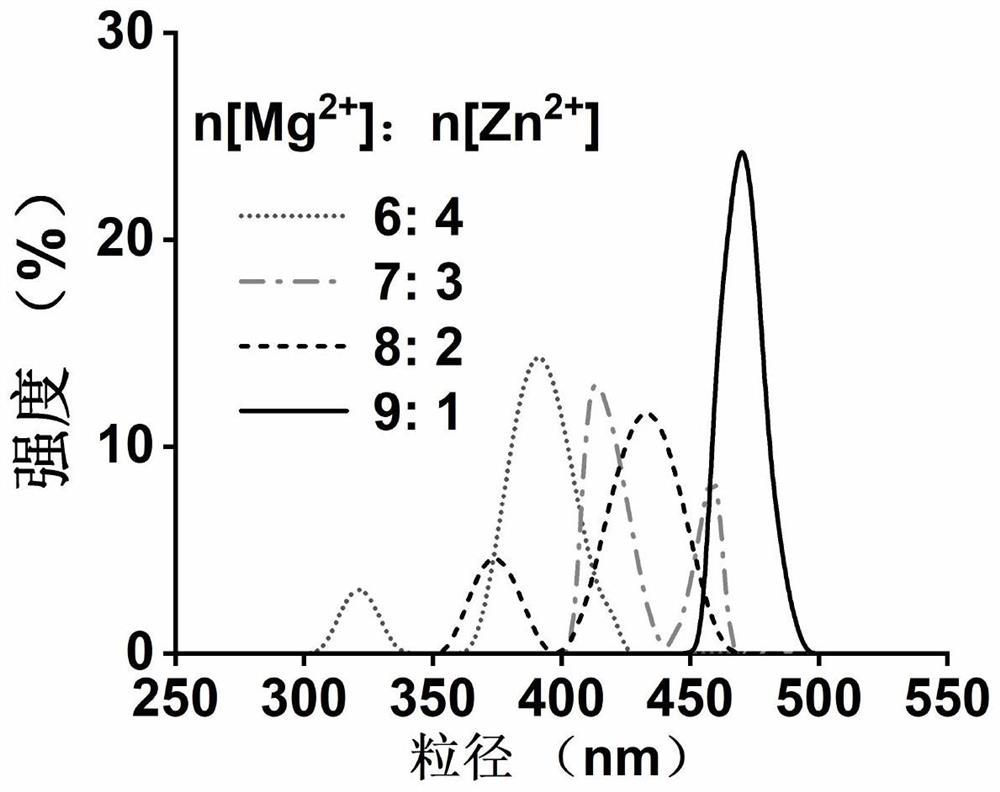

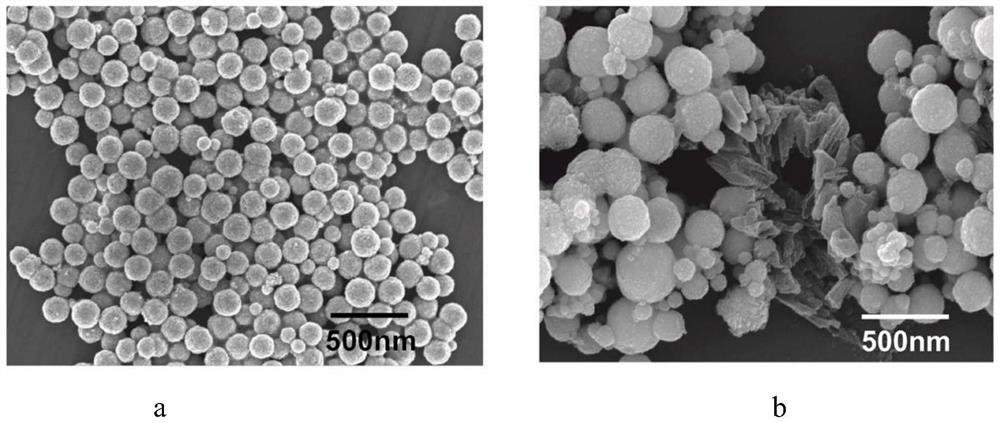

Mg/Zn-MOF-74-coated Fe3O4 magnetic composite material and application thereof in aflatoxin enrichment

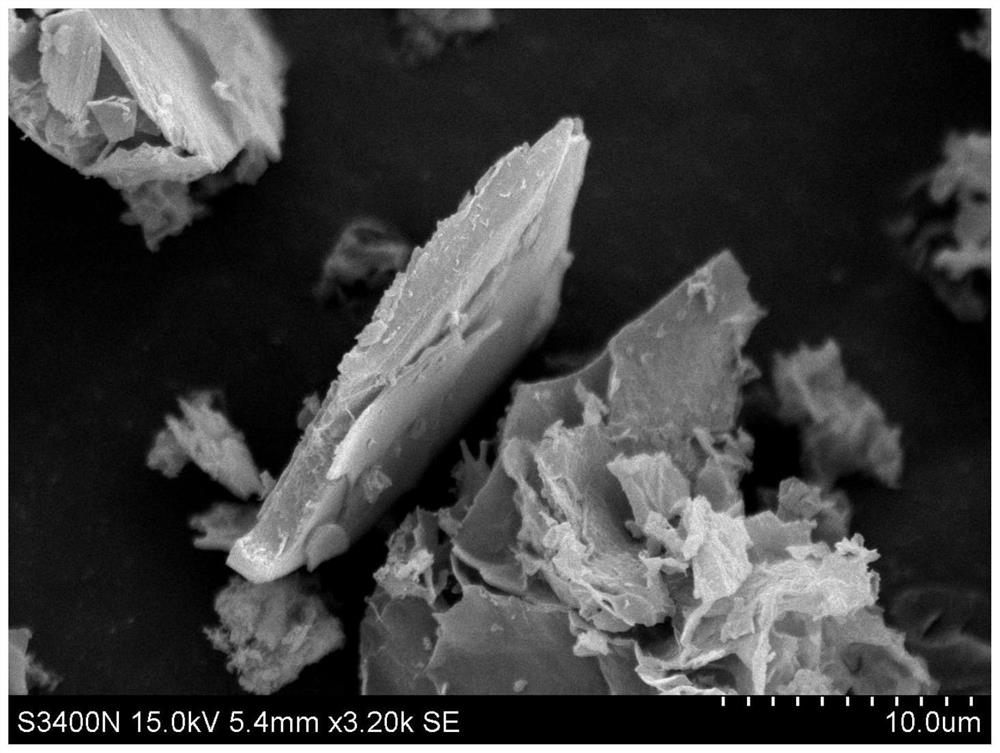

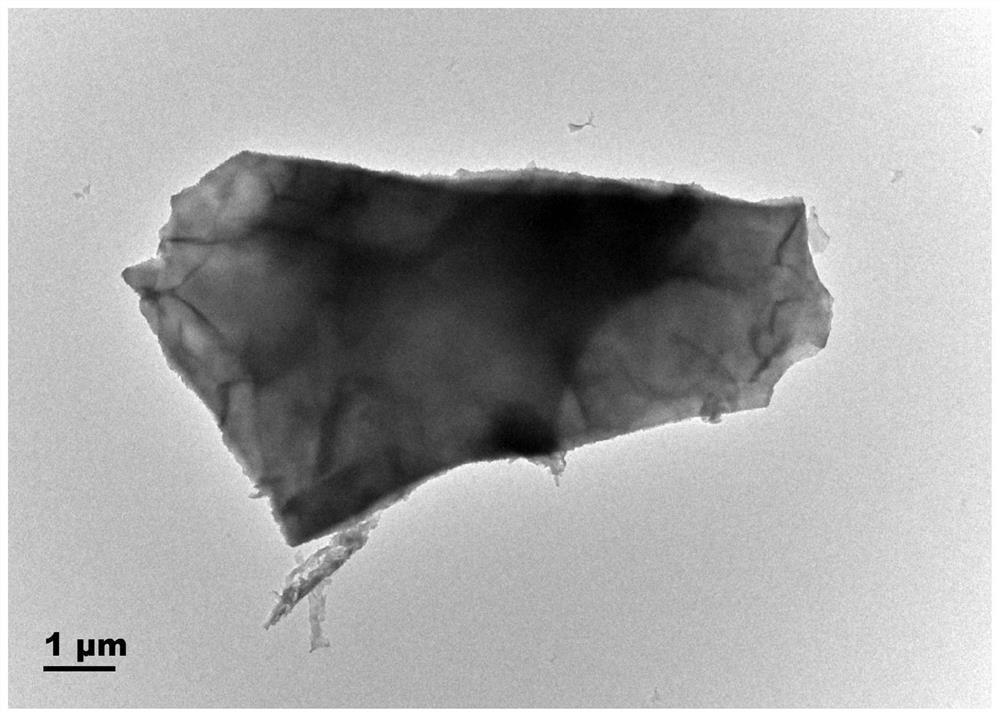

ActiveCN114836045ABoth structural adaptabilitySuperparamagneticSolid sorbent liquid separationInorganic material magnetismMetal frameworkMagnetite Nanoparticles

The invention discloses an Mg / Zn-MOF-74 (at) Fe3O4 magnetic composite material and an application of the Mg / Zn-MOF-74 (at) Fe3O4 magnetic composite material in enrichment of aflatoxin. According to the preparation method, the Fe3O4 magnetic nanoparticles with uniform particle size and relatively strong magnetic responsiveness are successfully prepared by adopting a hydrothermal method. Then synthesizing a hollow-structure organic framework material Mg / Zn-MOF-74 mixed with Mg / Zn metal by utilizing an ion exchange method, compounding amino on the surface of Fe3O4 with the Mg / Zn metal of the metal framework material by utilizing a layer-by-layer assembly method, and rapidly synthesizing Mg / Zn-MOF-74-coated Fe3O4 under the microwave-assisted action. Zn < 2 + > in the material and beta-dicarbonyl in an aflatoxin B1 structure can generate a stable chemical bonding effect, so that when the material is applied to magnetic solid-phase extraction, efficient adsorption of aflatoxin B1 in food can be realized, and the maximum adsorption capacity can reach 8.921 mg / g. Compared with the traditional pretreatment method, the prepared Mg / Zn-MOF-74-coated Fe3O4 has the advantages of high separation speed, high extraction efficiency, environment friendliness, low price and the like.

Owner:HUAZHONG AGRI UNIV

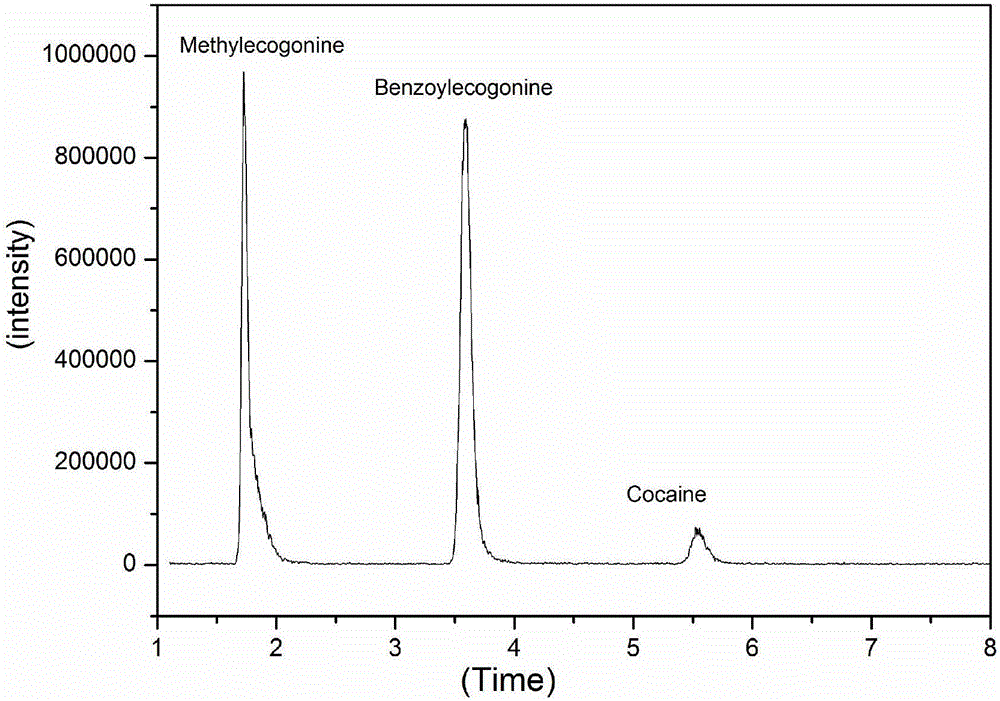

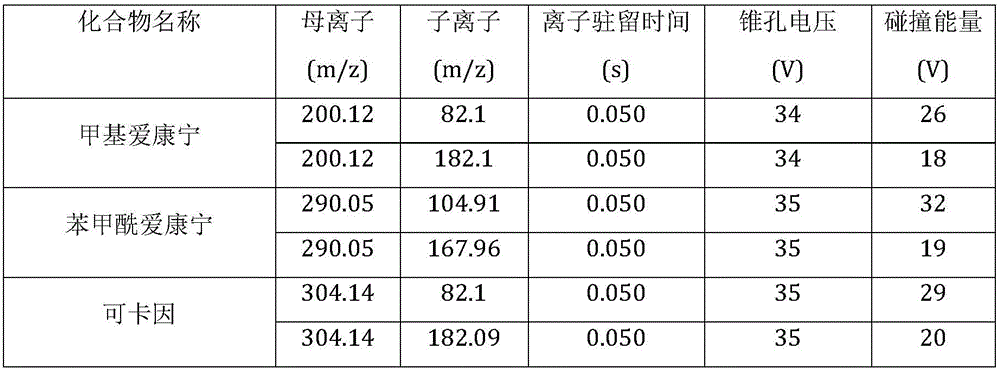

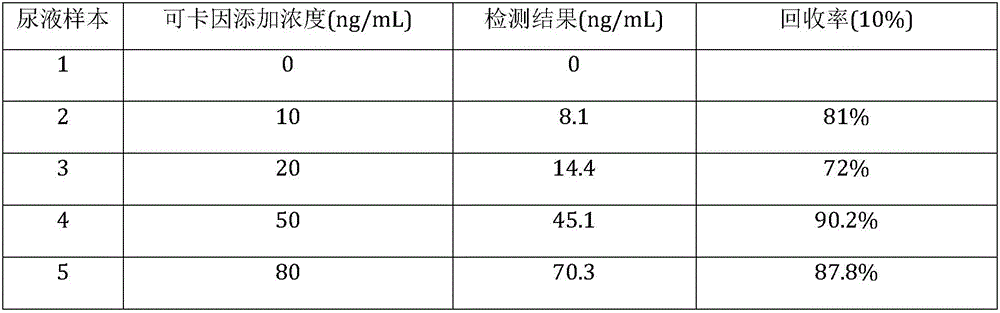

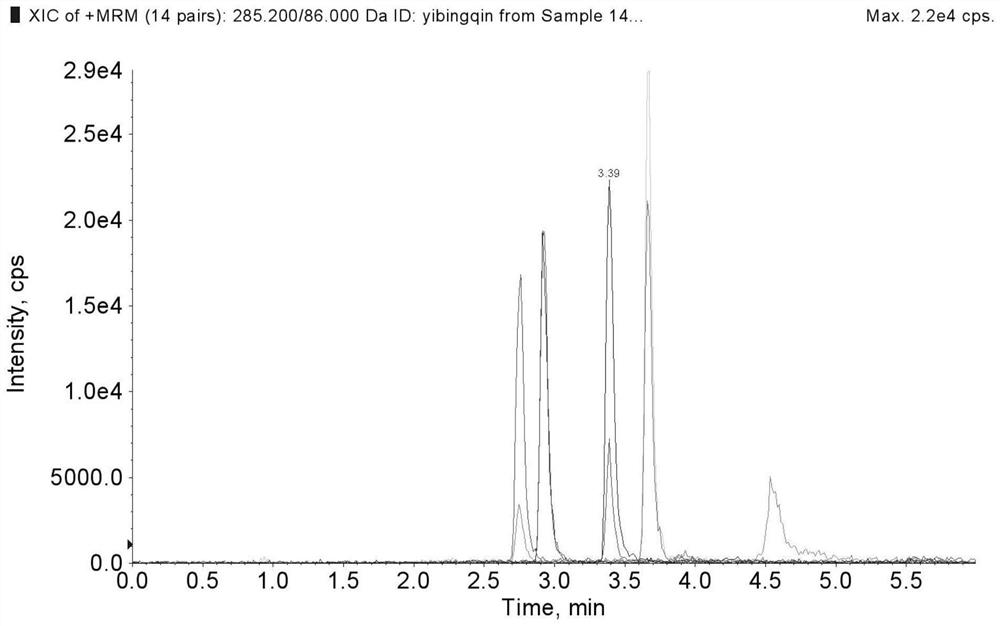

Method for enriching and detecting cocaine and metabolin thereof in urine through magnetic dispersed extraction materials

The invention discloses a method for enriching and detecting cocaine and metabolin thereof in urine through magnetic dispersed extraction materials. The method comprises the following steps: mixing polyvinylpyrrolidone modified magnetic-particles with PSA magnetic beads, then enriching cocaine and metabolin thereof in urine through the mixture, and detecting and analyzing the contents of the cocaine and the metabolin thereof through an LS-MS method after elution. The method can rapidly separate and enrich cocaine, can effectively combine with, magnetically enrich and separate from cocaine through functional magnetic-particles, can obviously improve the pretreatment efficiency because pretreated samples are not damaged and polluted and high in concentrations, reduces the influence of human factors, improves the detection accuracy to a great extent, and provides a more reliable guarantee for the accurate inspection of micro cocaine.

Owner:SHANGHAI CRIMINAL SCI TECH RES INST

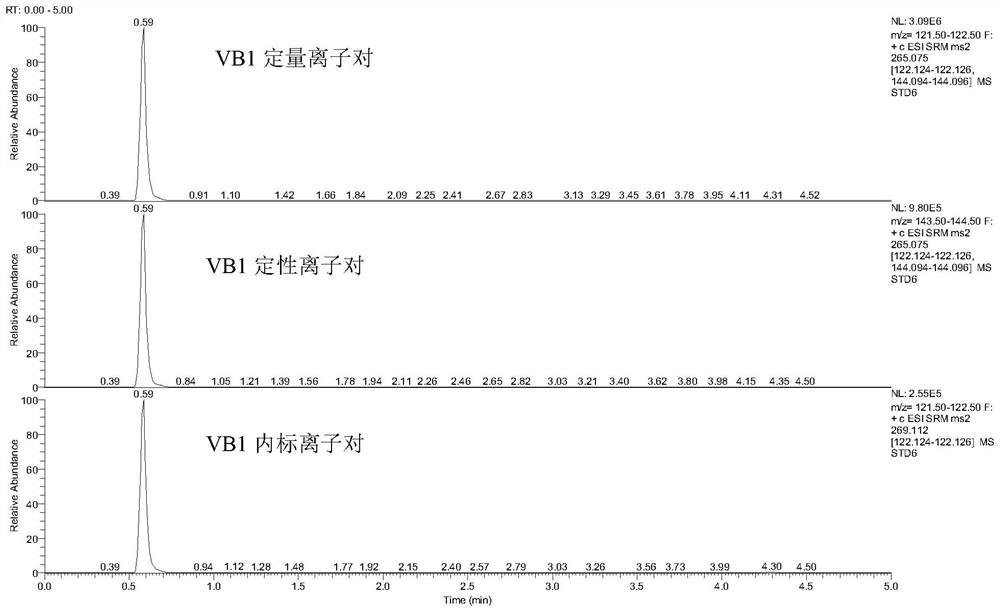

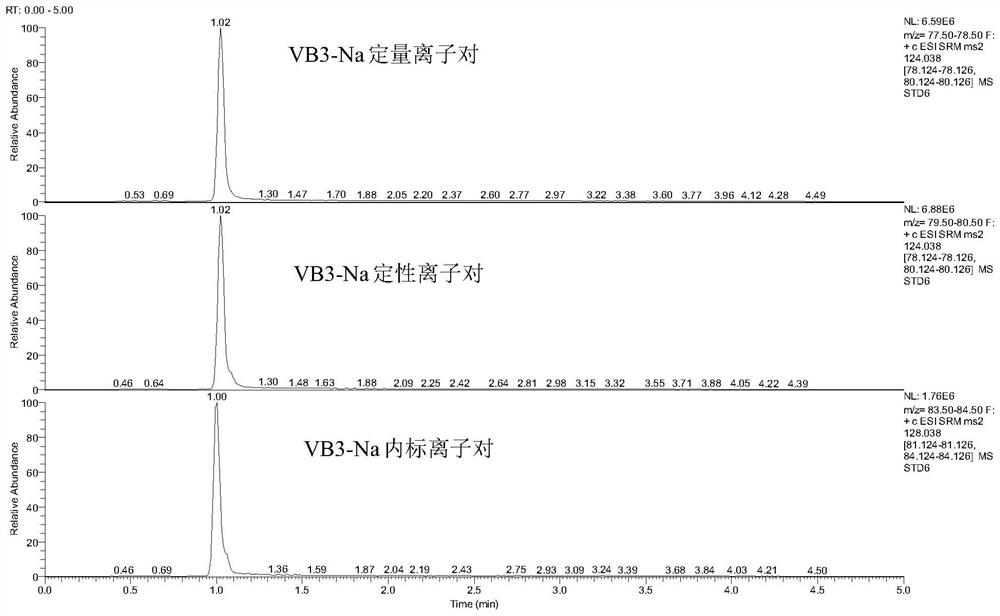

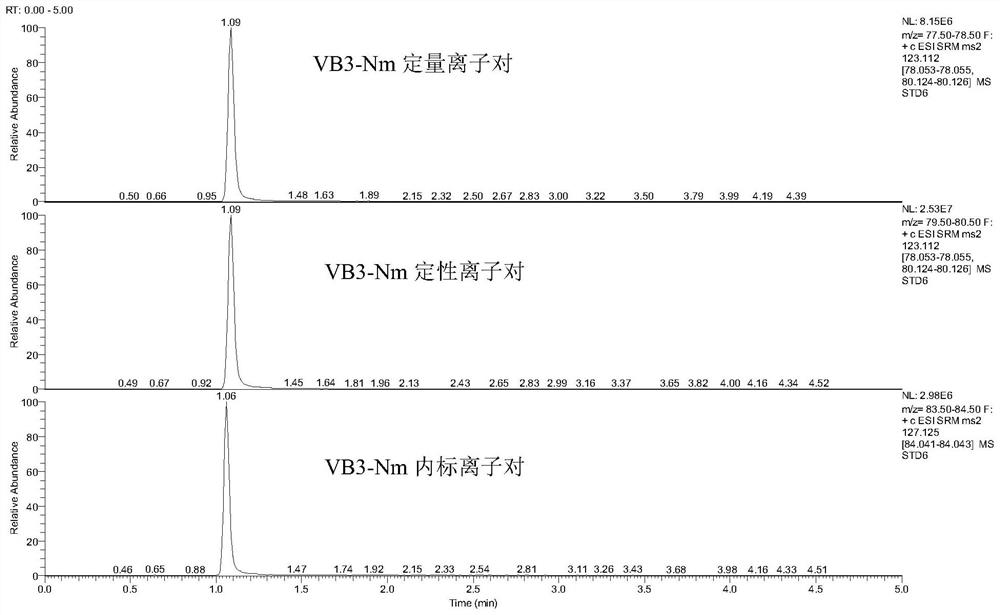

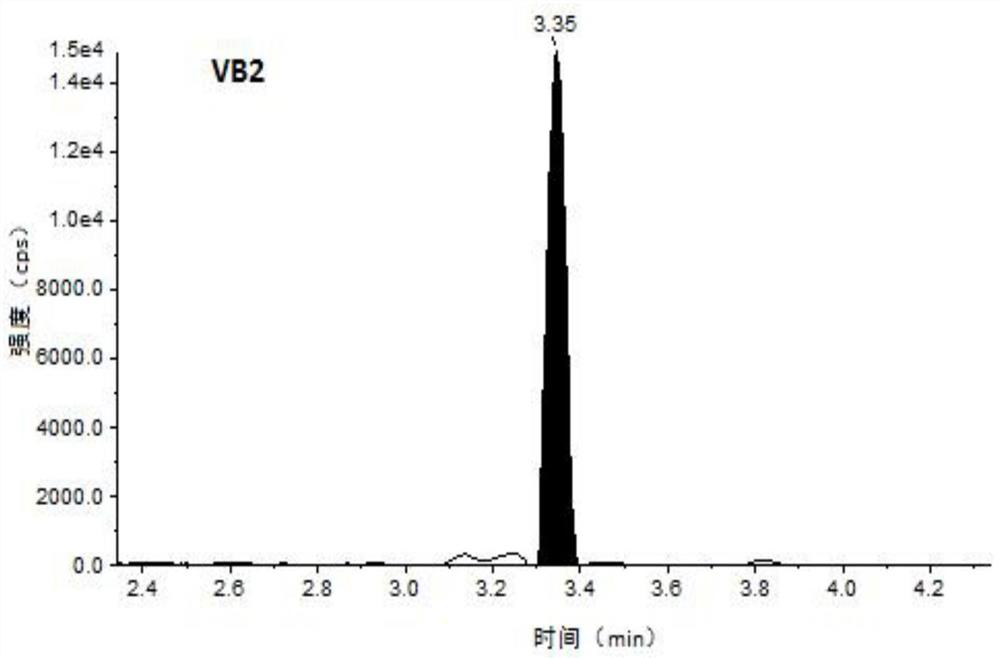

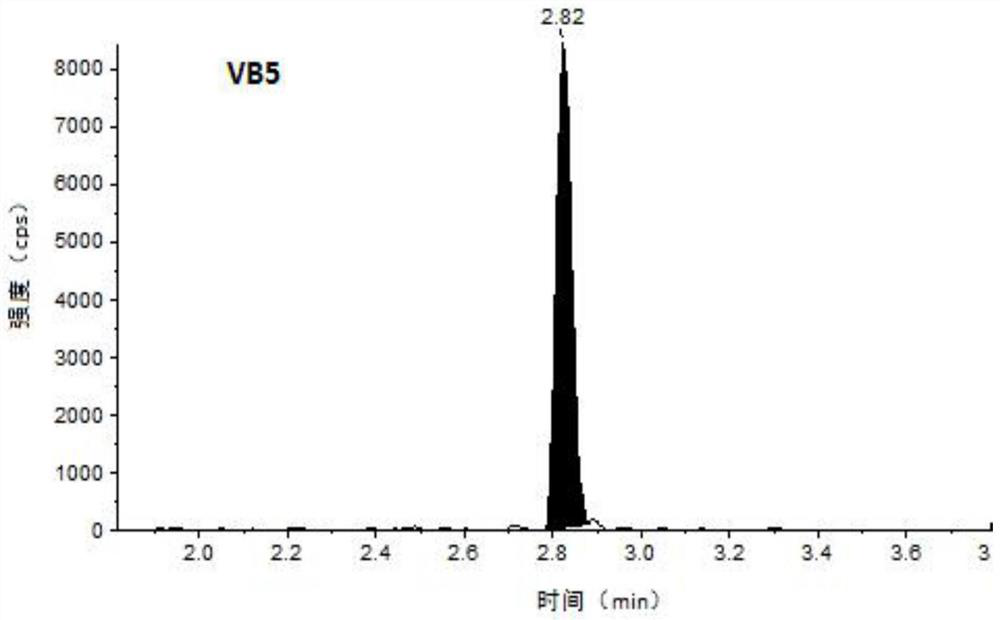

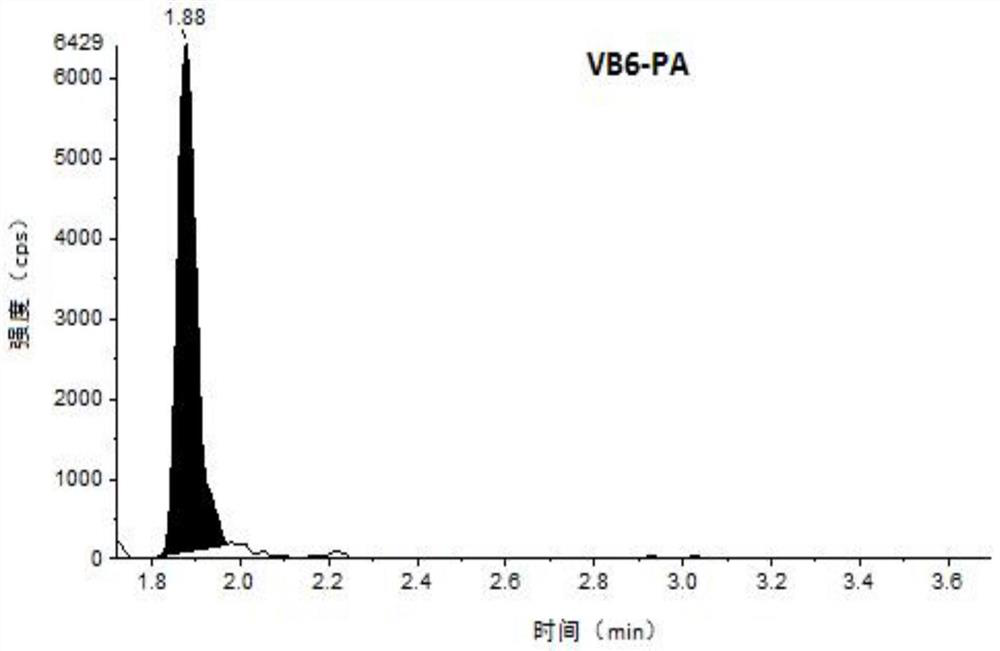

Method for simultaneously detecting multiple water-soluble vitamins in serum based on liquid chromatography-tandem mass spectrometry

PendingCN114441673AImprove pretreatment efficiencyReduce lossesComponent separationAgainst vector-borne diseasesTandem mass spectrometryUltrafiltration

The invention provides a method for simultaneously detecting various water-soluble vitamins in serum based on liquid chromatography-tandem mass spectrometry, which comprises the following steps: adding a proper amount of internal standard solution into a serum sample, then adding an extracting agent I, carrying out vortex oscillation to uniformly mix the sample, standing, then adding an extracting agent II into the sample, carrying out vortex oscillation, and carrying out gradient elution. And transferring all the samples into an ultrafiltration tube, carrying out high-speed centrifugation, taking out the ultrafiltration tube, transferring the centrifuged extracting solution at the lower layer into a sample feeding plate, adding an extracting agent III, carrying out vortex oscillation, uniformly mixing, and loading the sample onto a liquid chromatography-tandem mass spectrometer for detection. The method can rapidly and accurately detect 11 water-soluble vitamins in serum at the same time, pretreatment is simple and easy to operate, time and labor are saved, high efficiency and accuracy are achieved, 11 water-soluble vitamins are detected through one-time testing and one-needle sample injection, the efficiency and accuracy of medical examination are greatly improved, convenience is brought to doctors and patients, and the method is worthy of popularization and application. And an effective and feasible basis is provided for monitoring the content of the water-soluble vitamins in a human body.

Owner:上海睿质科技有限公司

Method for detecting various water-soluble vitamins

PendingCN114280178AImprove pretreatment efficiencyShorten detection timeComponent separationBlood specimenPhysical chemistry

The invention provides a method for detecting various water-soluble vitamins B2, B5, B6, B9 and MMA (methyl methacrylate), which comprises the following steps: (1) taking a blood sample, and directly diluting with a buffer solution to obtain a sample to be loaded; (2) carrying out anion exchange solid-phase extraction column extraction on the to-be-loaded sample to obtain a required eluent; (3) blow-drying and redissolving the eluent at 40 DEG C to obtain a sample to be detected; and (4) performing LC-MS / MS analysis on the to-be-detected sample, and detecting to obtain the content of the water-soluble vitamins. According to the method, various water-soluble vitamins can be detected at the same time, precipitation and blow-drying are not needed before solid-phase extraction, sample loading can be carried out only after simple dilution, compared with complex methods such as precipitation and blow-drying, the detection efficiency is improved, the pretreatment time is saved, sample loss caused by protein precipitation is avoided, and the requirement for accurate and rapid clinical detection is met.

Owner:CENT HOSPITAL XUHUI DISTRICT SHANGHAI CITY

Layered super-hydrophilic Ti-Cu-MOFs as well as preparation method and application thereof

ActiveCN114479108AImprove adsorption capacityImprove pretreatment efficiencyOther chemical processesMetabolitePhospholipid

The invention provides layered super-hydrophilic Ti-Cu-MOFs as well as a preparation method and application thereof, and relates to the technical field of composite materials. According to the invention, copper ions and titanium ions are taken as bimetallic centers and are subjected to a coordination reaction with rigid aromatic amine ligands, so that layered super-hydrophilic Ti-Cu-MOFs with a lamellar structure are efficiently synthesized. Compared with the prior art, the preparation method is simple, the morphology and the structure are controllable, the surface of the prepared layered super-hydrophilic Ti-Cu-MOFs has rich hydroxyl groups, and the prepared layered super-hydrophilic Ti-Cu-MOFs has high adsorption capacity on phospholipid co-extracts in clinical biological samples; the method can be used for analyzing phenothiazine drugs and metabolites thereof in biological samples and realizing one-step separation and purification, so that the pretreatment efficiency of clinical biological samples is greatly improved, and the analysis time is shortened.

Owner:ZHEJIANG SHUREN UNIV

A kind of assay method of cation exchange capacity in tobacco planting soil

ActiveCN104330522BIncrease concentrationOptimizationChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorCation-exchange capacityAlcohol

The invention discloses a measurement method of cation exchange capacity in soil. The method comprises the five steps of preparing a soil sample, carrying out exchange elution with an EDTA-ammonium acetate mixed solution and 95% alcohol, distilling by a full-automatic distiller, measuring by an instrument, and calculating. According to the method, optimization and improvement are carried out on soil sample extraction and leaching conditions, the full-automatic FOSSKjeltec8400 distiller is selected, relevant test conditions are optimized and screened, and concentration and volume conditions of absorption liquid are improved and optimized, so that the cation exchange capacity in the soil can be accurately measured. The method has the advantages of being simple and convenient as well as rapid and accurate in operation and good in repeatability.

Owner:SICHUAN BRANCH OF CHINA TOBACCO

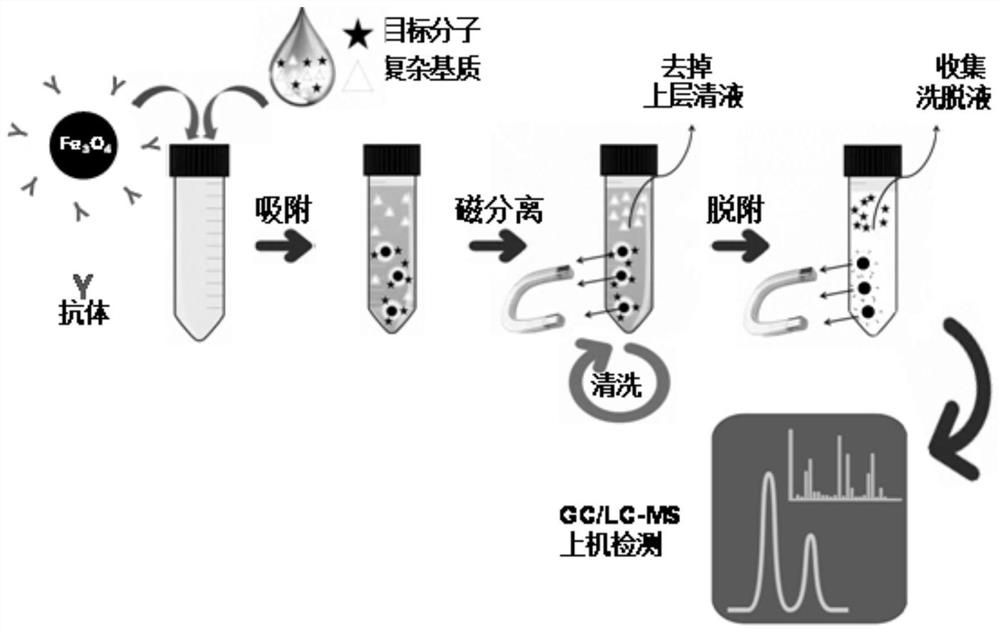

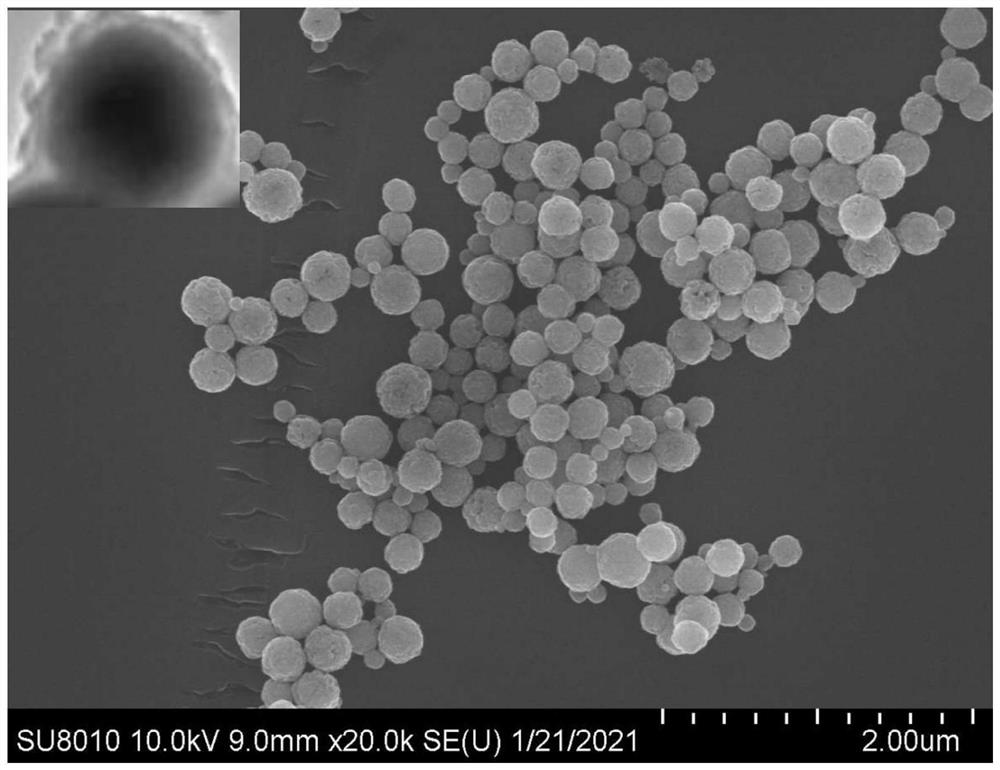

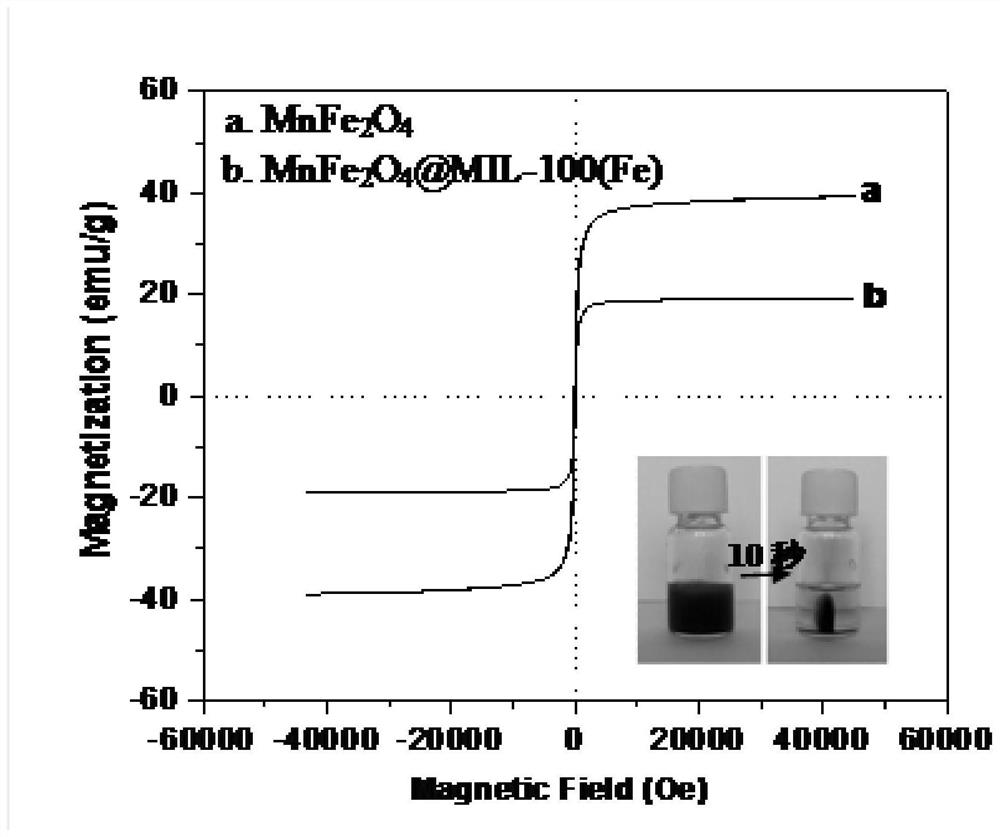

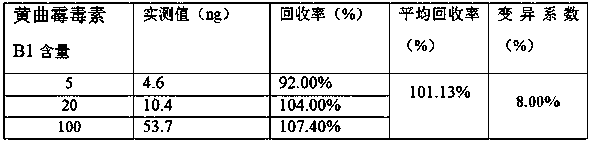

Preparation method and application of wide-spectrum specific antibody modified magnetic metal organic framework material

PendingCN113663646AImprove throughputThe pre-processing process is simpleOther chemical processesTransportation and packagingPesticide residueMetal-organic framework

The invention discloses a preparation method and application of a wide-spectrum specific antibody modified magnetic metal organic framework material. The preparation method comprises the steps: preparing nanoscale magnetic MnFe2O4 nanoparticles, adding the magnetic MnFe2O4 nanoparticles and trimesic acid into N, N-dimethylformamide, evenly stirring, synthesizing a magnetic metal organic framework material MnFe2O4@MIL-100 (Fe) through a hydrothermal method, activating the MnFe2O4@MIL-100 (Fe) by using 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS), adding a wide-spectrum specific antibody, and carrying out incubation to obtain the wide-spectrum specific antibody modified magnetic metal organic framework material. According to the invention, when the wide-spectrum specific antibody modified magnetic metal organic framework material is used for sample pretreatment, effective enrichment and concentration of various organophosphorus pesticide residues can be realized on the basis of material magnetism and immune performance, and the sample pretreatment process is greatly simplified, so that ultra-sensitive detection of small-molecule hazardous substances in agricultural product samples is realized.

Owner:CHINA JILIANG UNIV

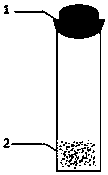

Universal immunoaffinity column for mycotoxin detection

The invention provides a universal immunoaffinity column for detecting mycotoxin, which comprises a column tube, a sieve plate, a filler and a mycotoxin antibody, the bottom of the column tube is provided with a liquid outlet, the mycotoxin antibody is independently subpackaged in a storage tube, the mycotoxin antibody is coupled with biotin, and the filler is coupled with streptavidin. The fillerused by the immunoaffinity column is coupled with streptavidin, the filler only needs to be in affinity binding with an antibody modified by biotin to modify the antibody to the surface of the filler, and the filler is filled into a column tube to perform pretreatment on a sample. The column capacity of the prepared immunoaffinity column can reach 5000 ng; meanwhile, the recovery rate of actual sample detection is high, and the coefficient of variation is small, so that the immunoaffinity column has a good pretreatment effect and relatively high stability on samples, can simultaneously carryout high-flux adsorption on various targets, and has a wide application prospect in the field of food safety detection.

Owner:MEIZHENG BIO TECH CO LTD

Alternariol aptamer affinity column and its preparation method and application

Provided are an alternariol aptamer affinity column and a preparation method and an application therefor. The affinity column uses agarose modified with N-hydroxysuccinimide as a carrier, and then covalently couples to the carrier a nucleic acid aptamer capable of recognising alternariol with high affinity and high specificity, the coupled product being used as a filler for packing the affinity column.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

A continuous processing technology for fabric degreasing, presetting and whitening

ActiveCN105908419BReduce turnover timesSave human effortSucessive textile treatmentsHeating/cooling textile fabricsProcess engineeringEnergy conservation

The invention discloses a continuous fabric oil removing, pre-forming and whitening process which comprises the following steps: treating gray cloth according to continuous processes of removing oil, washing with water, whitening and pre-forming. By adoption of the continuous fabric oil removing, pre-forming and whitening process disclosed by the invention, continuous production can be achieved, a good washing effect can be achieved, and the energy and the water can be saved.

Owner:GUANGDONG DERUN TEXTILE CO LTD

Pretreatment method for simultaneous determination of free-state and binding-state sterols in tobaccos

InactiveCN109738553AMeet pre-processing needsExperiment operation is simpleComponent separationWater bathsPretreatment method

The invention relates to an efficient pretreatment method for simultaneous determination of free-state and binding-state sterols in tobaccos. 2.0 mol / L of a hydrochloric acid-ethanol solution is usedto finish hydrolysis in a 60 DEG C constant-temperature ultrasonic water bath for 1 hour; 4 mol / L of a potassium hydroxide-ethanol solution is used to finish saponification in the 60 DEG C constant-temperature ultrasonic water bath for 40 minutes; isooctane and a saturated potassium chloride solution is oscillated for 5 minutes, and standing is performed for 10 minutes to finish extraction of total sterol; and drying is finished through anhydrous sodium sulfate between sieve plates, filtering of a sample is finished by the sieve plates, then the total sterol is exported from a sample exportingtube in the isooctane, and liquid chromatography-tandem mass spectrometry can be directly adopted for detection, thereby finishing the determination of the sterols in the tobaccos. The hydrolysis, saponification, extraction, drying and filtering operations of the pretreatment of the sterols in the tobaccos are finished in a pretreatment device; and the to-be-analyzed sample can be obtained without sample transfer in the whole sample pretreatment process, so that the experiment operation is greatly simplified and the pretreatment efficiency is improved.

Owner:CHINA TOBACCO YUNNAN IND

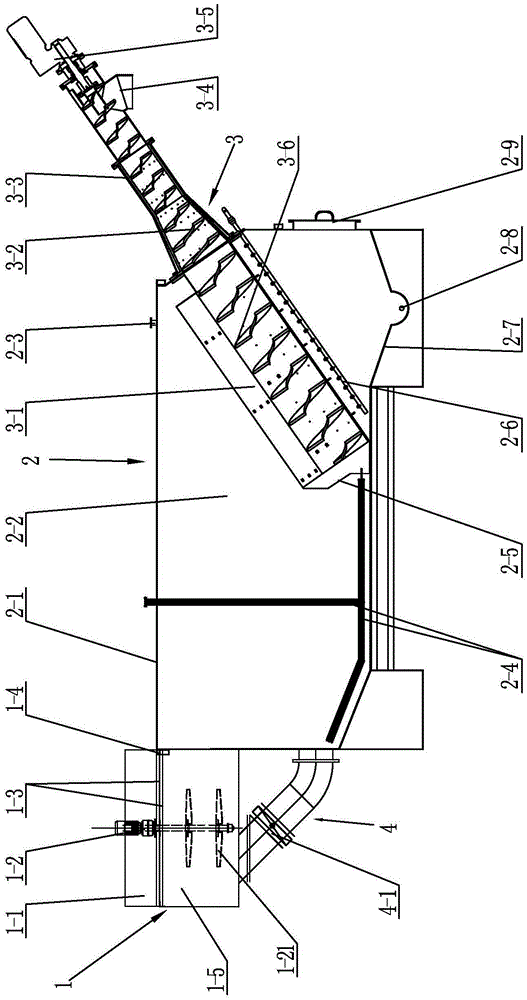

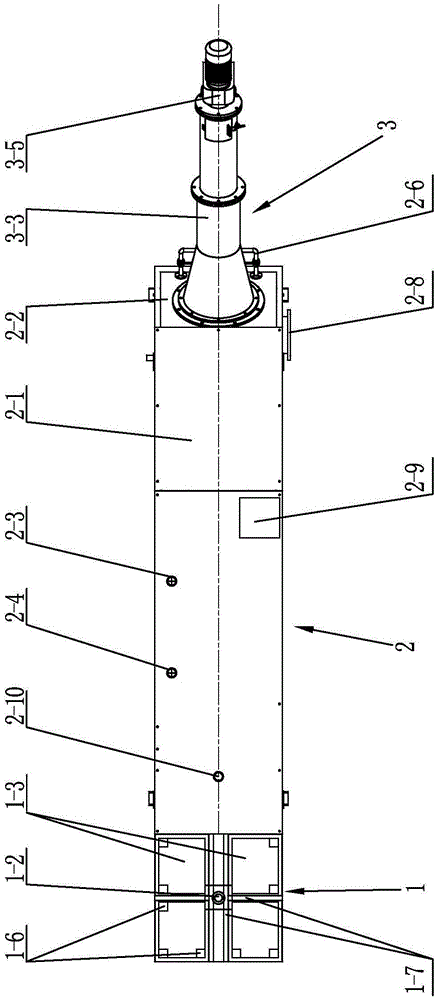

Waste grease receiving, sampling and pretreating device

ActiveCN105606431AEasy to replaceWell mixedWithdrawing sample devicesPreparing sample for investigationGratingEngineering

The invention relates to a waste grease receiving, sampling and pretreating device which comprises a sampling tank, a pretreating mechanism, a deslagging screw mechanism and a connecting pipe connected between the sampling tank and the pretreating mechanism. The sampling tank comprises a tank body, at least two layers of grating plates and a stirrer, the grating plates with open pores are detachably installed on the upper portion of the tank body, the tank body is provided with a feed port and at least three sampling holes, and the stirrer is installed on a supporting frame arranged on the upper portion of the tank body; the pretreating mechanism comprises a receiving bin with a top cover and multiple sets of steam pipes arranged on the middle-lower portion of the receiving bin, and a liquid collecting tank is arranged in the receiving bin; the deslagging screw mechanism is upwards and obliquely arranged on the middle-rear portion of the receiving bin, the lower portion of a shaft-free deslagging screw is provided with the liquid collecting tank, and the upper portion of the liquid collecting tank is provided with at least one set of washing water pipes. According to the waste grease receiving, sampling and pretreating device, the structure is compact and reasonable, not only can the fed material sampling function be achieved, but also the solid-liquid separation capacity can be improved, and the problem that the blocking and maintaining frequency of follow-up equipment is high due to existence of impurities can be effectively solved.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com