Electrochemical actuator structure optimization analysis method and system based on genetic algorithm

A genetic algorithm and analysis method technology, applied in the field of structural optimization analysis of electrochemical actuators, to achieve the effects of improving pretreatment efficiency, optimizing configuration, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

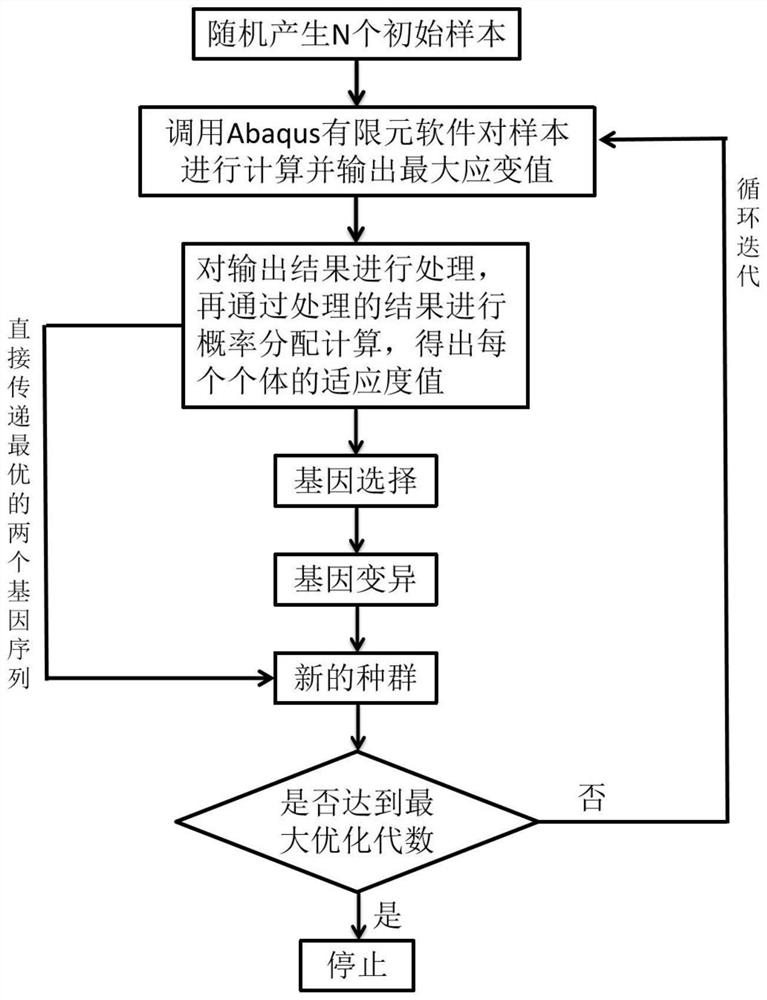

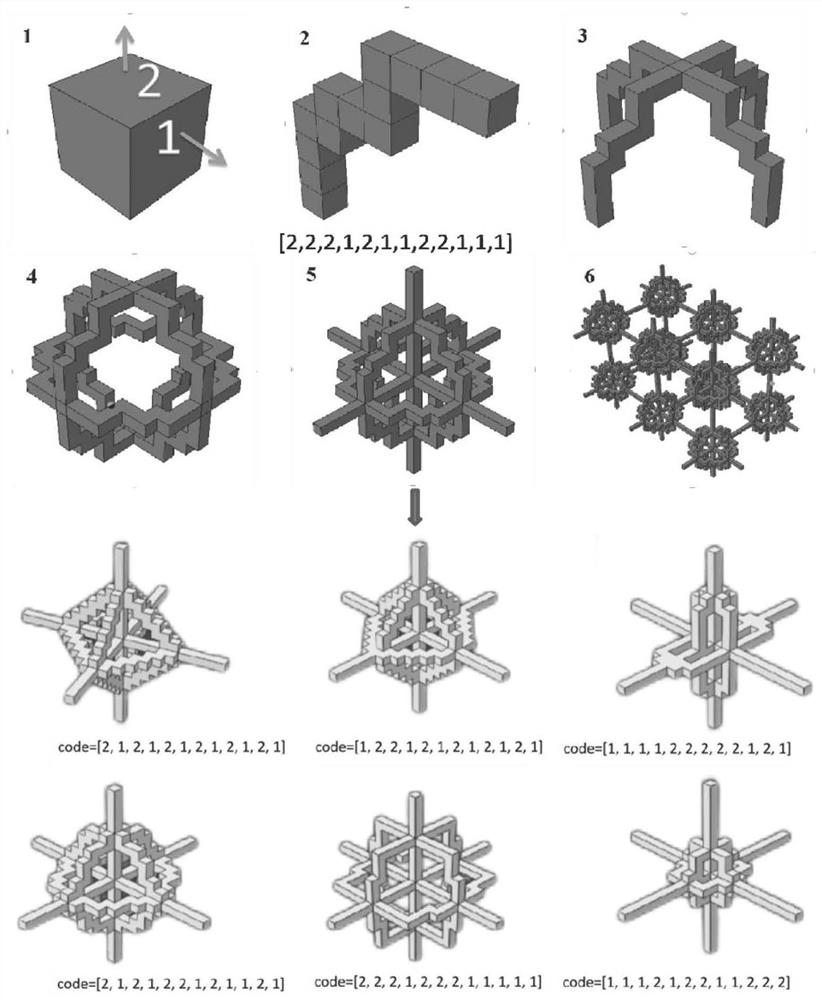

[0055] Such as figure 1 with figure 2 As shown, taking the graphene material as an example, in this embodiment, a method for analyzing the structural optimization of an electrochemical actuator based on a genetic algorithm includes the following steps:

[0056] a. Digital modeling, the process of mapping the genotype and phenotype of the model:

[0057] First, a cube is established based on the origin of the coordinate system, and then each face of the cube is numbered; since the structure is a symmetrical structure, the symmetrical part is constructed on a two-dimensional plane; on the basis of specifying the starting point and end point of the two-dimensional plane structure, use The numbered number represents the path, and after the two-dimensional structure is obtained, it is rotated and mirrored to generate a complete material structure, and the umat subroutine is used to define the constitutive relationship of the material; thus the genotype and phenotype of the model ...

Embodiment 2

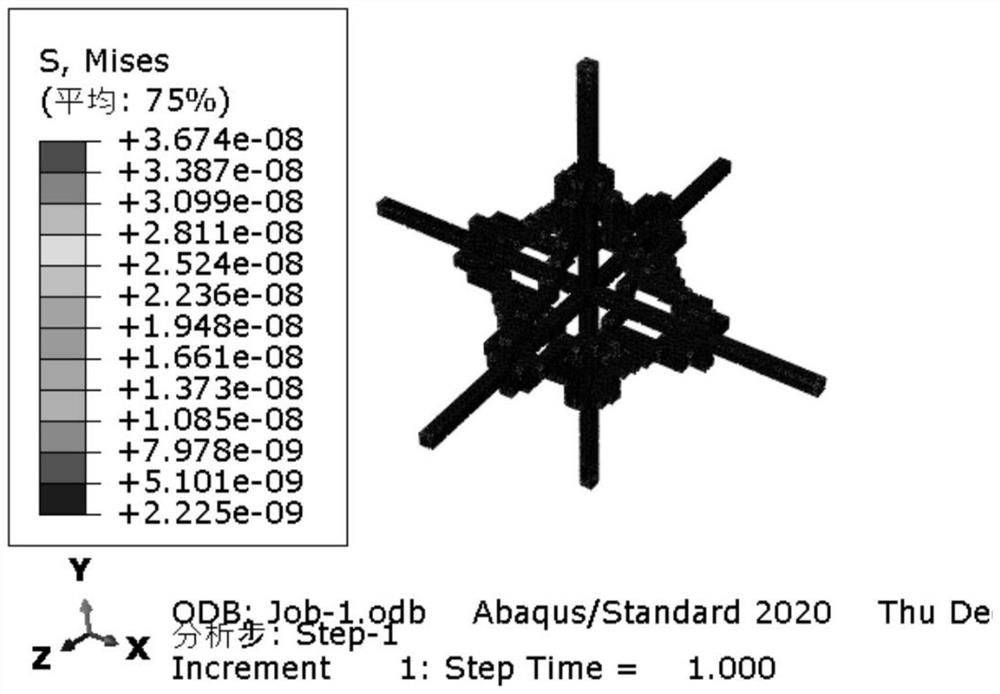

[0073] In the present embodiment, in the step a, the finite element pre-processing is carried out, the corresponding automatic pre-processing program code is written, and the constitutive relationship of the material is defined through the umat subroutine, so as to expand the function of the program; in order to simulate the material The phenomenon is actuated in the electrolyte, and the program code is written to realize the application of material surface stress, the interaction between components and the setting of boundary conditions based on the intrinsic stress model.

[0074] In this embodiment, in the step (3), the results obtained from the simulation are analyzed through post-processing, and the point sets in the model are extracted and calculated in the form of a python program file, and finally in the form of a txt file Output, the actuation effect data representing the structure as a result of postprocessing. The simulation results are shown in Table 1.

[0075] T...

Embodiment 3

[0089] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0090] In this embodiment, a genetic algorithm-based electrochemical actuator structure optimization analysis system includes a memory and a processor; wherein the memory is used to store computer programs; the processor is used to execute the above-mentioned embodiment A computer program for a genetic algorithm-based analysis method for structural optimization of electrochemical actuators.

[0091] The electrochemical actuator structure optimization analysis system based on genetic algorithm in this embodiment can realize automatic random modeling using finite element method, simulate various configurations of electrochemical actuators, and realize automatic structure extraction by applying surface stress Finally, combined with the genetic algorithm, the structure of the material is reversely optimized. Due to the parametric modeling and fully automatic extraction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com