Pretreatment optimization method for paint spraying

An optimization method and paint technology, applied in chemical instruments and methods, cleaning methods using liquids, surface pretreatment, etc., can solve the problems of unclean surface of parts, low work efficiency, high labor intensity, etc., to ensure cleanliness, improve Efficiency, ensure the effect of painting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

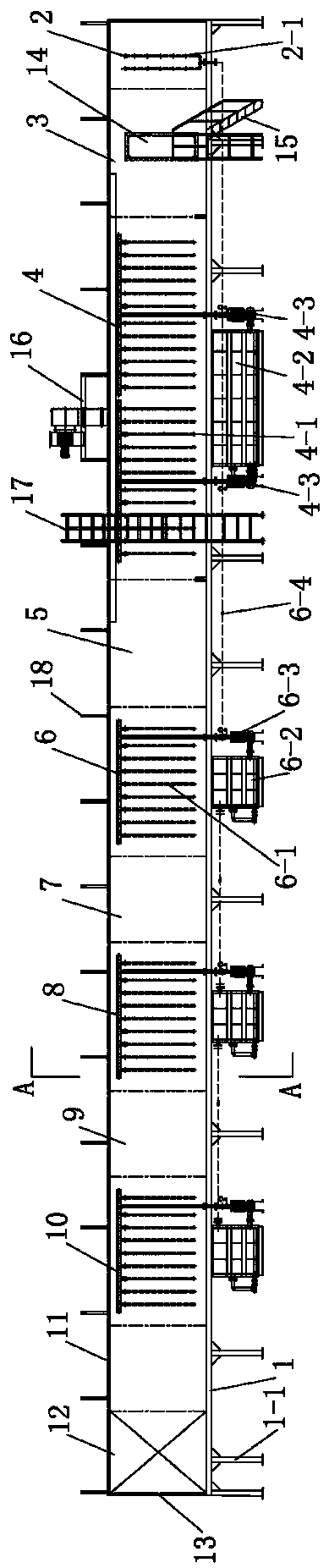

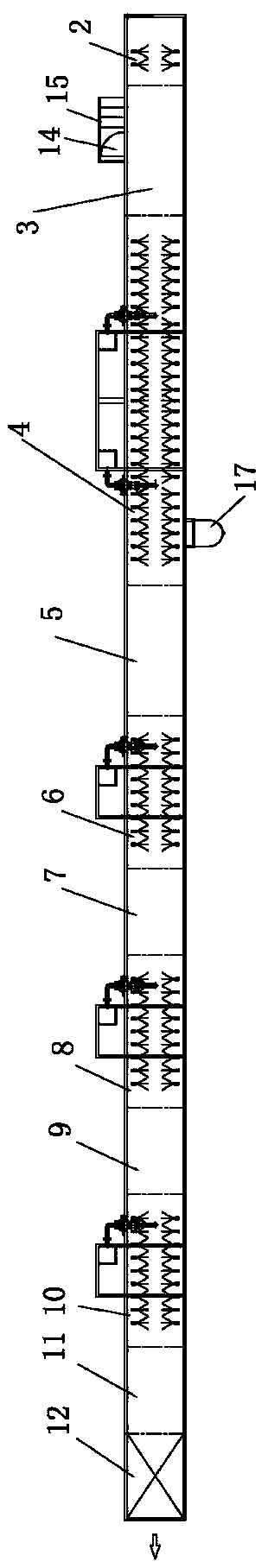

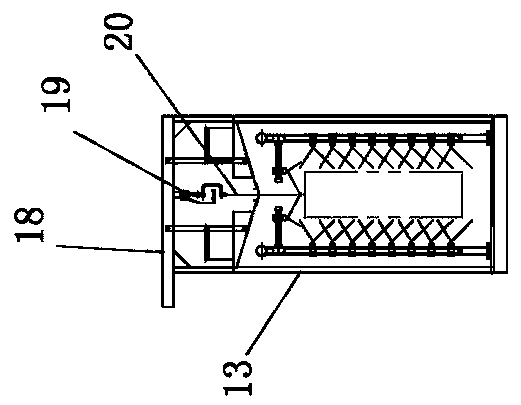

[0016] Below, further describe the present invention in conjunction with accompanying drawing.

[0017] Such as Figure 1-Figure 3 As shown, the integrated pre-processing combined equipment includes a support bottom frame 1, a support leg 1-1 is fixed on the bottom of the support bottom frame 1, a box body 13 is fixed along the length direction on the support bottom frame, and multiple A suspension chain fixed bracket 18, the suspension chain fixed bracket 28 is fixed with a suspension conveying chain 19, and the top of the casing is provided with the hook function part of the suspension chain and passes through the groove; one end of the casing is the entrance, and the other end of the casing is the exit (Such as figure 2 As shown by the arrow, here is the outlet); the box body 13 is sequentially provided with a front spray washing unit 2, a first drip section 3, a spray pickling unit 4, and a second drip unit from the inlet end to the outlet end. Section 5, rear first spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com