Hybrid grid partitioning method of truck torsion bar type turnover mechanism finite element model

A flipping mechanism and mixed grid technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of single grid division method, prone to stress concentration in the main force-bearing area, affecting development efficiency and development quality and other problems, to save time and labor costs, convenient and effective grid processing, and improve the quality of product development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

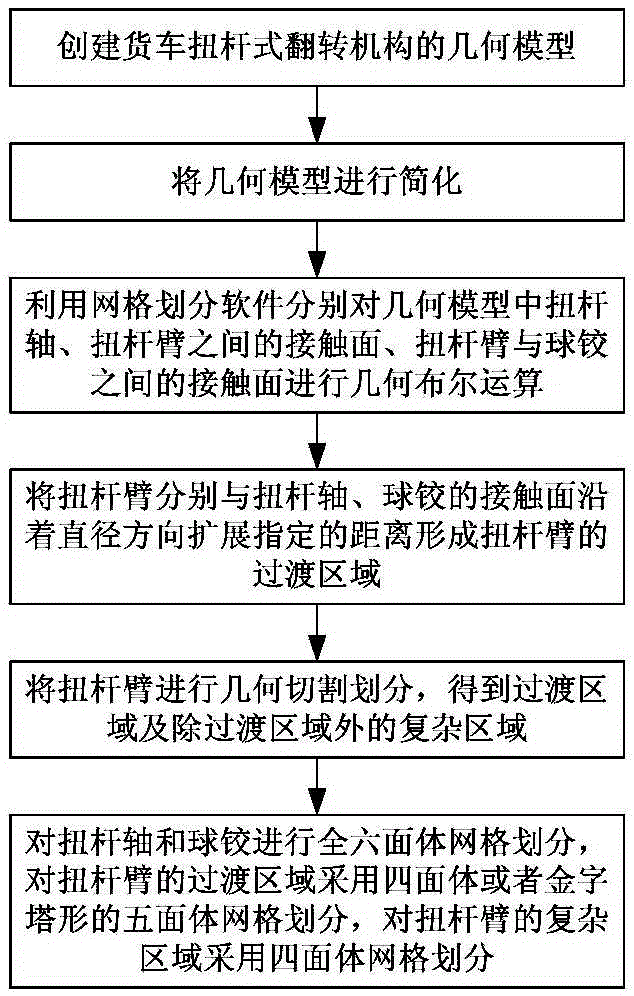

[0023] Such as figure 1 As shown, the steps of the mixed mesh division method for the finite element model of the torsion bar type turning mechanism of the truck in this embodiment include:

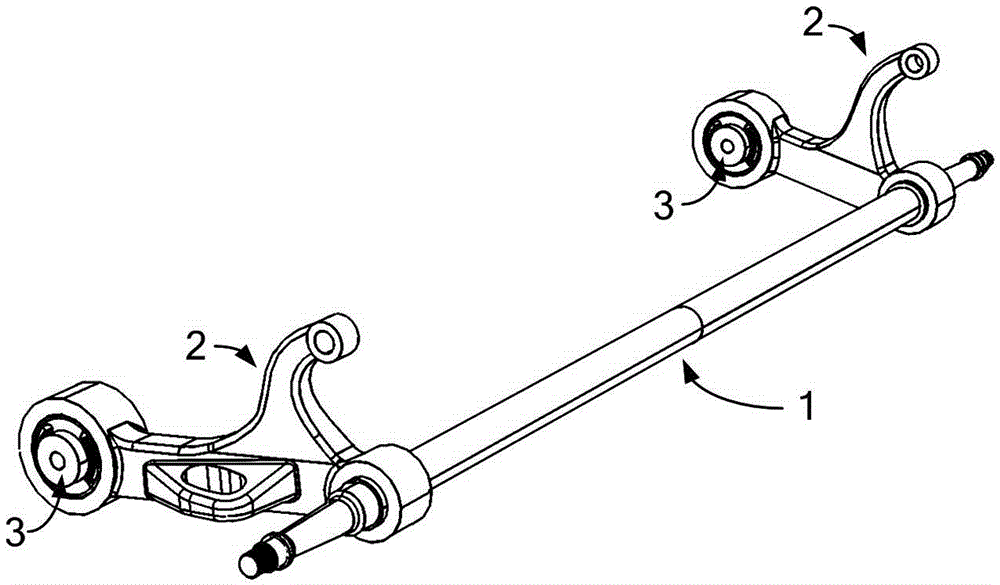

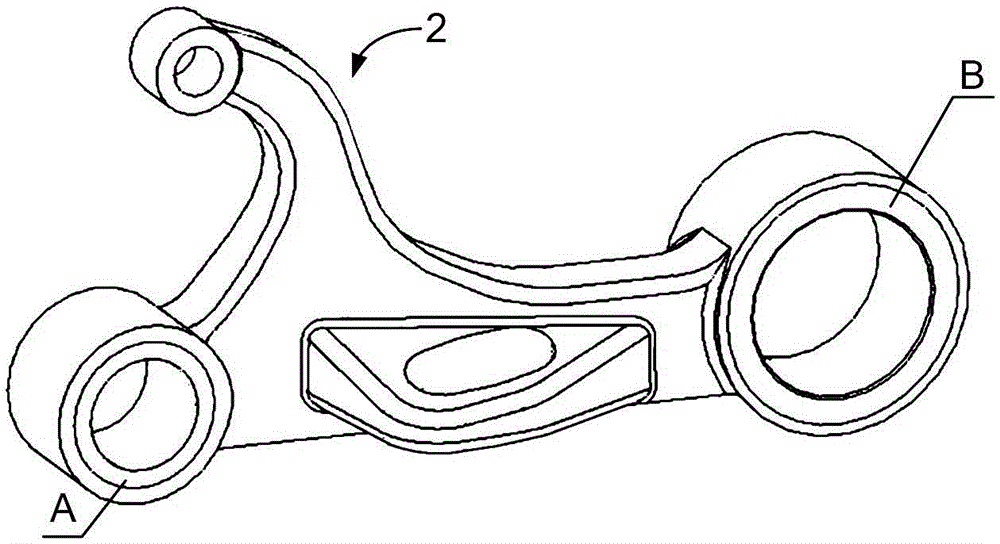

[0024] 1) Create the geometric model of the torsion bar turning mechanism of the truck, such as figure 2 As shown, the geometric model includes a torsion bar shaft 1 , a torsion bar arm 2 and a ball joint 3 . A torsion bar arm 2 is provided at each end of the torsion bar shaft 1 , and a ball joint 3 is provided on each torsion bar arm 2 .

[0025] 2) Use the mesh division software to perform geometric Boolean operations on the contact surface between the torsion bar axis 1 and the torsion bar arm 2, and the contact surface between the torsion bar arm 2 and the spherical hinge 3 in the geometric model, so that the torsion bar axis 1 , the contact surface between the torsion bar arm 2, and the contact surface between the torsion bar arm 2 and the spherical hinge 3 meet the requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com