Vehicle body attachment point rigidity result extraction method and electronic equipment

An extraction method and attachment point technology, which is applied to the extraction method of body attachment point stiffness results and the field of electronic equipment, can solve problems such as manual selection of rigid units, screenshots of parts lacking mounting holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

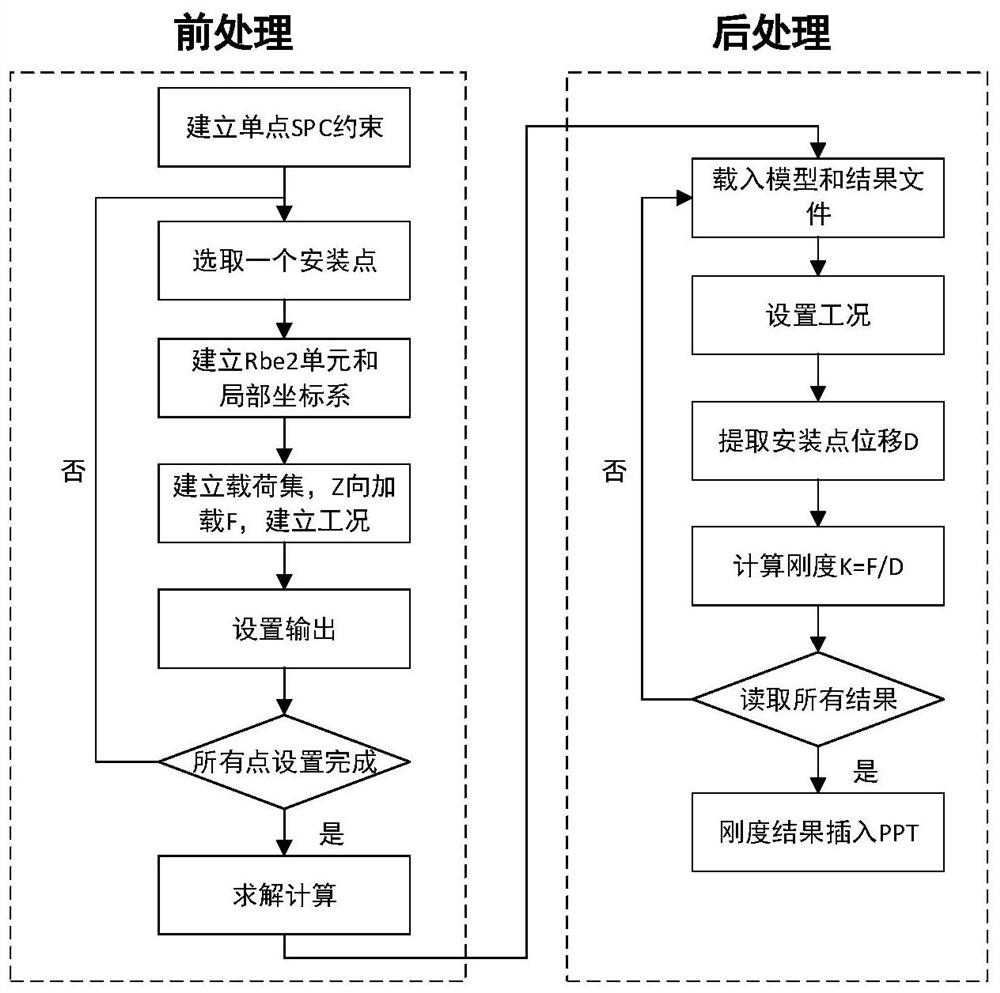

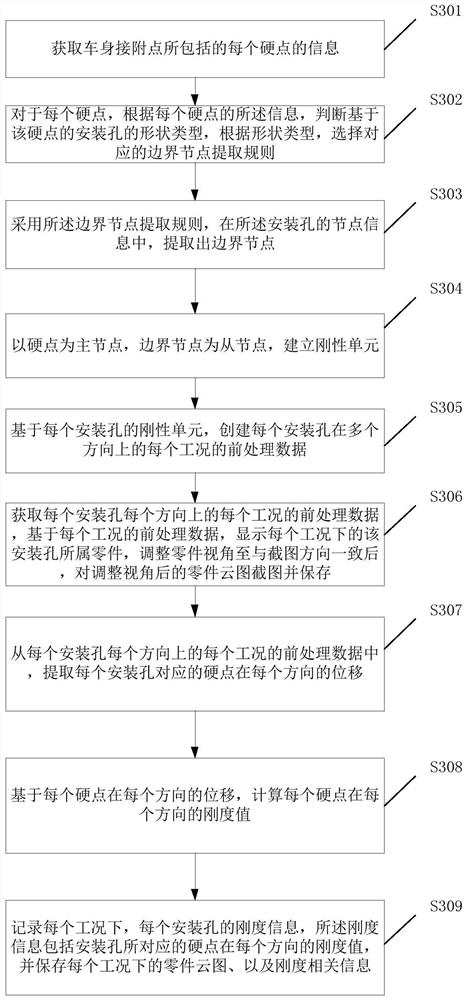

[0070] Such as image 3 Shown is a working flow chart of a method for extracting the stiffness result of the attachment point of the vehicle body according to one embodiment of the present application, including:

[0071] Step S301, obtaining the information of each hard point included in the body attachment point;

[0072] Step S302, for each hard point, according to the information of each hard point, determine the shape type of the installation hole based on the hard point, and select the corresponding boundary node extraction rule according to the shape type;

[0073] Step S303, using the boundary node extraction rule to extract boundary nodes from the node information of the installation hole;

[0074] Step S304, using the hard point as the master node and the boundary node as the slave node to establish a rigid unit;

[0075] Step S305, based on the rigid unit of each mounting hole, create pre-processing data of each working condition of each mounting hole in multiple ...

Embodiment 3

[0111] Such as Figure 7 Shown is a working flow chart of a method for extracting the stiffness result of the attachment point of the vehicle body according to one embodiment of the present application, including:

[0112] Step S701, open Hypermesh, import the body model, including the hard point geometry file of the attachment point, and run the pre-processing module;

[0113] Step S702, select all hard points of attachment points that need to be calculated;

[0114] Step S703, respectively setting the load size in the X, Y, and Z directions;

[0115] Step S704, establishing a rigid unit of the Washer layer with mounting holes;

[0116] Step S705, setting up X, Y, Z loads and loading conditions;

[0117] Step S706, submitting to the solver for calculation;

[0118] Step S707, running the post-processing module;

[0119] Step S708, calculating the stiffness of each working condition, and saving Excel;

[0120] Step S709, only displaying the part where the mounting hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com