Layered super-hydrophilic Ti-Cu-MOFs as well as preparation method and application thereof

A ti-cu-mofs, super-hydrophilic technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of affecting the separation and purification performance of MOFs, preparation methods and reaction conditions affecting the morphology, crystal structure and pores of MOFs efficiency and other issues, to achieve the effects of saving pretreatment time and cost, controllable morphology and structure, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing layered superhydrophilic Ti-Cu-MOFs, comprising the following steps:

[0026] mixing the copper source, the rigid aromatic amine ligand, the stabilizer and water, and performing the first solvothermal reaction to obtain the intermediate;

[0027] The intermediate is mixed with a titanium source and an organic solvent for a second solvothermal reaction to obtain layered superhydrophilic Ti-Cu-MOFs.

[0028] The invention mixes the copper source, the rigid aromatic amine ligand, the stabilizer and water, and performs the first solvothermal reaction to obtain the intermediate. In the present invention, the copper source is preferably a copper salt, more preferably at least one of copper acetate and copper nitrate; the rigid aromatic amine ligand preferably includes 4,4'-diamino-terphenyl and tri( At least one of 4-aminophenyl)amine; said stabilizer preferably includes at least one of sulfamic acid and p-aminobenzoic acid. In ...

Embodiment 1~9

[0042] (1) Add copper source, rigid aromatic amine ligand, stabilizer and 30mL pure water into a polytetrafluoroethylene thick-walled pressure-resistant bottle, seal it with a polytetrafluoroethylene screw plug, and ultrasonically disperse for 30 minutes;

[0043] (2) Transfer the polytetrafluoroethylene thick-walled pressure-resistant bottle described in step (1) to a microwave reactor, set the reaction temperature to 180° C., and perform solvothermal reaction at this temperature for 24 hours;

[0044] (3) After the solvothermal reaction in step (2) is completed, naturally cool to room temperature, collect the filter residue by vacuum filtration, rinse the filter residue with water, methanol, and acetone in sequence, and dry it in vacuum at 60°C for 12 hours;

[0045] (4) Add the product obtained in step (3) into a polytetrafluoroethylene thick-walled pressure-resistant bottle, then add 15mL N,N-dimethylformamide and titanium source in sequence, seal it with a polytetrafluoroe...

Embodiment 1

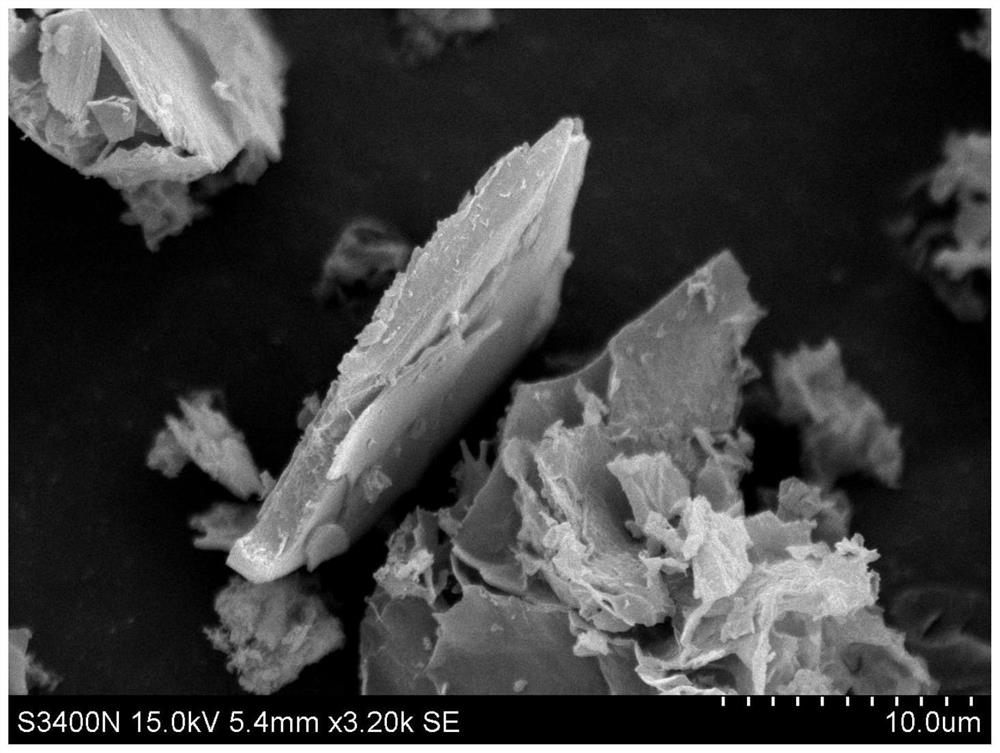

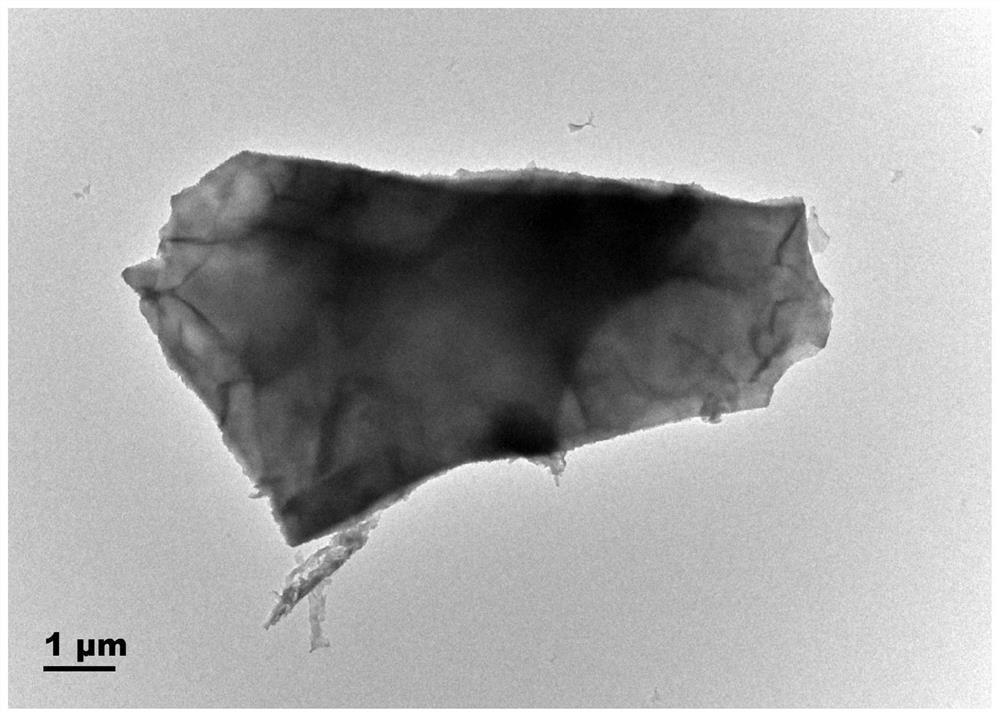

[0052] The transmission electron micrographs and scanning electron micrographs of the layered superhydrophilic Ti-Cu-MOFs prepared in Example 1 are as follows: figure 1 with figure 2 shown. Depend on figure 1 It can be seen that the layered superhydrophilic Ti-Cu-MOFs prepared by the present invention have regular morphology and present an obvious lamellar structure, which is characterized by figure 2 The scanning electron microscopy characterization results were further confirmed.

[0053] The layered superhydrophilic Ti-Cu-MOFs prepared in Examples 2-9 are similar in appearance to the layered superhydrophilic Ti-Cu-MOFs prepared in Example 1, and the surface is rich in hydroxyl groups. The layered superhydrophilic Ti-Cu-MOFs prepared in Examples 2-9 have a high adsorption capacity for phospholipid co-extraction in clinical biological samples, and thus can achieve efficient separation and purification of complex matrices in clinical biological samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ion source temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com